Our HISTORY

Arnost Polak - 1946

to INMALO www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk Product INDEX Mantovanibenne MBI SGR Grapples ................................ SH EAGLE II Shears ...................... SH EAGLE III Shears ...................... CR Cracker .................................... CC Combi Cutter RP-IT Rotating Pulveriser ............... RP Rotating Pulveriser ................... MCP-IT Fixed Pulveriser ................. MCP Fixed Pulveriser ..................... MS Demolition Multi-System ......... MS140 Multi-System ..................... GI-DA Magnets HMG/HMG-T Magnets .................. Montabert Hydraulic Breakers ......................... Rock.Zone Dust Suppression (Jets) ................ Motofog Dust Suppression (Jets) ................ Rotofog Demolition Pack MB Dust Control Dust Suppression (Cannons) ........ Steelwrist Fully Automatic Quick Couplers .... Engineering Manufacturing / Servicing Repairs & Line Boring .................... PAGE 3 4-5 6-7 8 9 10 11 12 13 14 15 16-17 18-19 20-21 22 23 24-25 26 27 2 1975 - John Polak joins his fathers business developing a product range for the Demolition market 2011 - Charles Polak joins the family business 2022 - Today, Inmalo are a well known and respected supplier of attachments and dust suppression equipment to the Demolition and Recycling Industry 5 6

Welcome

With the War over, the need to clear and rebuild our major Cities provides the inspiration to start a business supplying tracks and later demolition equipment. ‘Inmalo, International Marketers (London) Ltd’ is born. Lt. Col.

Inmalo - International Marketers (London) Ltd, retired Secretary

and

Squadron 1946 - Demolition, clearance and rebuilding start 1947 - Increase in sales of tracked propelled heavy plant and machinery 1954 - Business meeting at home 1962 - Inmalo supply replacement tracks from a new purpose built warehouse in Chertsey 1 2 3 4

Arnost Polak, founder of

of The Free Czechoslovakian Air Force Association,

a veteran of 311

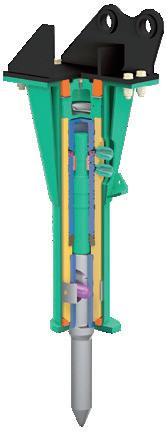

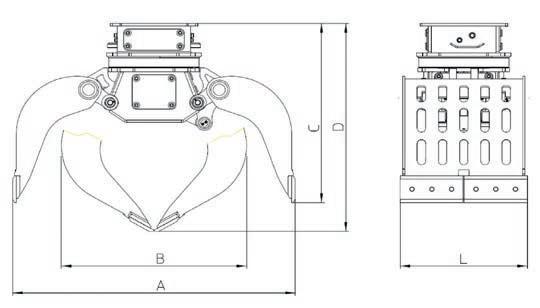

Our grapple has been designed to be extremely sturdy and allows the user to perform demolition tasks and heavy materials handling. In addition, it incorporates some important safety features like the load blocking valve and the cylinder hydraulic brake.

The reinforced body structure allows the use of the SGR for heavy-duty tasks such as the demolition of brick buildings or the handling of rock blocks.

• The powerful cylinders, with integrated hydraulic braking system, guarantee strong clamping force. The SGR1000 model and above have 2 cylinders.

• The continuous hydraulic rotation enables accurate tool positioning in every working environment. In addition, the robust components and the double motor, on bigger models, ensure durability and rotating power.

• The load-block valve, that prevents grapple opening without operator command, maximizes the safety standards of the SGR.

• The double bevelled blades are interchangeable and can be turned four times before replacement ensuring high precision clamping.

• The new hydraulic system improves performances and durability

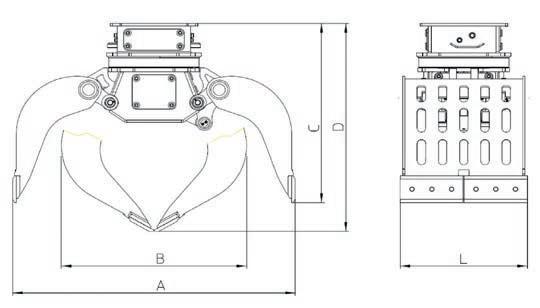

DEMOLITION & SORTING GRAPPLES SGR BT.SGR.03 MODEL GR150 GR300 SGR450 SGR600 SGR850 SGR1000 SGR1100 SGR1200 SGR1500 SGR1900 SGR2500 SGR2700 Excavator weight t 1-2.5 3-6 7-10 10-12 12-15 14-18 16-20 18-25 21-27 25-35 35-40 35-45 Tool weight ** kg 140 320 565 750 860 1330 1400 1480 1570 2260 2520 2570 Capacity l 48 100 200 300 400 500 600 700 800 900 1000 1100 A mm 920 1200 1500 1650 1700 2000 2000 2000 2100 2230 2240 2240 B mm 610 700 1030 1090 1100 1300 1300 1300 1430 1400 1420 1455 C mm 775 900 1100 1130 1140 1340 1340 1340 1370 1490 1500 1500 D mm 850 1010 1240 1310 1340 1550 1550 1550 1600 1745 1770 1770 L mm 350 500 600 600 800 750 900 1000 1100 1200 1300 1350 Hydraulic working pressure bar 180-200 200-250 200-250 250-300 300-320 300-350 300-350 300-350 300-350 300-350 300-350 300-350 Oil flow l/min 20-40 20-30 20-30 20-30 20-30 50-60 50-60 50-60 50-60 70-80 70-80 70-80 TECHNICAL DATA We are constantly improving our products and therefore we reserve the right to change the design and technical specifications without prior notice. * Available soon ** Tool weight does include Mantovanibenne top bracket. www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk 3

• Forged Reversed Cylinders

The extremely powerful SH cylinder are reversed to improve rod protection and enable the “naked design” to save weight. The cylinder rod is forged to maximize robustness and functionality.

• Auto Lube System

Shears above 7 tons are equipped with the patented Manto-Autolube system, an automatic greasing pump that ensures the correct lubrication of the important moving parts.

The MBI Eagle II Shears are powerful, robust and economical scrap shears. They have been proven over many years in the Demolition and Scrap Recycling industries. With a high power to weight ratio and innovative design the Eagle Shears work

• Jaw Design

The SH jaws are designed to work in combination and maximize cutting performances. The fixed jaw tilts the materials while the mobile jaw delivers the full cutting power on a reduced surface.

• Blades design

All the *blades can be turned three times before replacement and are specifically shaped to improve cutting performances. The piercing tip and the frontal blade improve perforation capabilities. * Excluding piercing tip

•

Rotating Group

The sturdy rotation grants precise tool positioning while the anticavitation valve increases operational safety.

• Speed-Valve

The speed valve reduces opening and closing time boosting productivity.

•

Double Cutting Guide

Jaw alignment is vital to ensure the maximum cutting power. Two different adjustable guides allow the operator to check and fine-tune the alignment over time with a simple operation. In addition, the adjustment kit on the central pin facilitates pin removal and maintenance.

www.inmalo.co.uk tel: 01962 760055 email:

.co.uk 4

sales@inmalo

MODEL HYDRAULIC ROTATION 360° SH25R SH50R SH100R SH130R SH180R SH310R SH410R SH550R SH700R SH900R SH1500R SH2000R EXCAVATOR WEIGHT WITH SH BUCKET PLACE t 5-7 7-10 11-13 13-17 18-25 30-40 45-55 55-65 75-85 90-110 110-170 170-200 EXCAVATOR WEIGHT WITH SH STICK PLACE t 2-4 4-6 7-10 8-12 14-18 20-28 28-39 39-45 45-60 60-80 80-110 110-150 TOOL WEIGHT * kg 380 650 1100 1220 2100 3300 4700 5750 7700 10100 14500 21000 HYDRAULIC WORKING PRESSURE bar 200-250 250-300 250-300 250-300 320-350 320-350 320-350 320-350 320-350 320-350 320-350 320-350 OIL FLOW l/min 60-100 80-100 90-110 90-110 150-200 200-250 250-300 275-375 500-600 600-700 700-1000 700-1000 MAX HYDRAULIC MOTOR OIL PRESSURE bar 190-200 90-100 190-200 90-100 130-150 100-115 100-115 100-115 140-150 170-190 170-200 170-200 MAX MOTOR OIL FLOW l/min 10-15 15-20 10-15 30-40 30-40 30-40 30-40 30-40 50-60 55-65 140-150 140-150 SPEEDVALVE AUTOMATIC GREASING SYSTEM TECHNICAL DATA We are constantly improving our products and therefore we reserve the right to change the design and technical specifications without prior notice. * Tool weight does include Mantovanibenne top bracket. Not available Available A B C MODEL HYDRAULIC ROTATION 360° SH25R SH50R SH100R SH130R SH180R SH310R SH410R SH550R SH700R SH900R SH1500R SH2000R A mm 195 290 375 375 445 565 670 760 830 940 1100 1200 B mm 200 290 395 395 525 630 720 780 840 950 1100 1200 C mm 1350 1900 2000 2100 2700 3300 3700 3950 4300 4600 5200 6000 DIMENSIONS www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk 5

The new range of MBI Eagle III shears is designed to be a market leader for power and reliability and will run alongside the existing and well proven Eagle II range.

The new shears are able to out-compete the biggest names in the market with new, larger cylinders offering 2530% more power than existing shears, as well as redesigned cylinders that can work at 380 bar pressure instead of the industry standard of 350 bar – these shears are designed to be industry leaders for the most demanding projects.

Oversized cylinder and Increased working pressure

ease in power oved piercing tip protects the beak and reduces

Compact frame improves centre of gravity

• Improved profits and reduced down-time

•

30% More Cutting Force

The Eagle III line has been designed to increase the cutting force on all models, the new design of the jaws allows up to 9% larger opening to maximize work when scrapping.

• Compact Frame

The new design features a a unique weightperformance-ratio and of the excavator thanks to the center of gravity being moved to the rear.

•

New Oversized Cylinders

The extremely powerful SH cylinder are reversed to improve rod protection and enable the “naked design” to save weight. The cylinder rod is forged to maximize robustness and functionality.

•

New Cutting System

A single integrated guide puck allows the upper jaw to use 100% of the cutting capacity even at difficult angles, such as when cutting tanks and reduces the deflection of the upper jaw. This results in increased productivity.

• New Upper Jaw Design Jaw is made from a single element without welding. New piercing tip offers greater protection and reduced costs. The blade seats are milled from the solid to increase resistence.

•

New Armoured Plates

The most heavily used part are armored with interchangeable Hardox® 500 steel plates installed on the jaw profiles to avoid frequent maintenance that could affect the operational readiness of the shear.

www.inmalo.co.uk tel: 01962 760055

sales@inmalo

6

email:

.co.uk

TECHNICAL DATA We are constantly improving our products and therefore we reserve the right to change the design and technical specifications without prior notice. * Tool weight does include Mantovanibenne top bracket. www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk 7 MODEL HYDRAULIC ROTATION 360° SH250R SH320R SH490R SH600R SH800R SH1500R SH2200R A mm 530 620 730 780 900 1100 COMING SOON B mm 570 640 760 800 890 1100 COMING SOON C mm 2700 2975 3450 3710 3980 4800 COMING SOON DIMENSIONS A B C TECHNICAL SPECIFICATION MODEL SH250R SH320R SH490R SH600R SH800R SH1500R SH2200R Weight (with bracket) 2,600kg 3,300kg 5,150kg 6,360kg 8,700kg 15,000kg 22,000kg Jaw Opening 530mm 620mm 730mm 780mm 900mm 1,100mm 1,250mm Jaw Depth 570mm 640mm 760mm 800mm 890mm 1,100mm 1,290mm Length 2,700mm 2,975mm 3,450mm 3,710mm 3,980mm 4,800mm 5,550mm Excavator Weight Dipper Mount 24-29t 30-40t 45-55t 55-65t 75-85t 120-170t 170-300t Excavator Weight Boom Mount 17-19t 20-28t 28-39t 39-45t 45-60t 80-110t 110-160t Oil Flow O/C (L/min) 200-250 250-300 300-350 500-600 600-700 800-1,000 800-1,000 Presure O/C (Bar) 320-380 320-380 320-380 320-380 320-380 320-380 320-350

Designed to face the toughest demolition operations, the CR best features are power and durability, enabling fast, precise and safe demolitions. This tool has been engineered for primary demolition of reinforced concrete, also on high-reach applications.

• The continuous hydraulic rotation enables precise positioning during in height demolitions and the double-row slew bearing ensures longevity and increased safety.

• The powerful cylinders deliver an enormous force with a very wide jaw opening.

• Special teeth profiles, studied to remain sharp despite wear, maximizing penetration.

• The twin-pin system enables larger opening and higher power, even at maximum opening.

• The interchangeable rebar cutting blades can be turned 4 times before replacement.

The patented Speed-Valve improves productivity and protects the hydraulic system from

BT.CR.08 BT.CR4.00 BT.CRR.12 MODEL CR2 CR4 CR5 CR5R CR15R CR20R CR26R CR40R CR60R CR80R CR100R CR120R ROTATION Mechanical Rotation 360° Hydraulic Rotation EXCAVATOR WEIGHT t 03-05 03-06 06-10 07-11 16-20 21-26 27-35 45-55 60-70 75-95 100-120 120-140 TOOL WEIGHT * kg 240 320 530 630 1600 2100 2800 4720 6250 8250 11000 12000 OPENING (MAX/MIN) mm 360/0 440/0 450/0 450/0 800/0 1050/0 1100/0 1350/0 1580/0 1800/0 2050/0 2310/320 HEIGHT mm 1070 1070 1290 1315 1800 2030 2200 2800 3020 3400 3200 3300 HYDRAULIC WORKING PRESSURE bar 180-220 250 200-250 200-250 280-320 280-320 280-320 280-320 320-350 320-350 320-350 320-350 OIL FLOW l/min 30-50 65 50-90 50-90 130-150 180-220 220-250 250-300 320-350 500-600 600-800 600-800 TECHNICAL DATA We are constantly improving our products and therefore we reserve the right to change the design and technical specifications without prior notice. * Tool weight does include Mantovanibenne top bracket.

pressure

www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk 8

•

peaks.

The ultimate tool for demolition operations involving highly-reinforced concrete buildings or metal structures. The CC series incorporates characteristics of scrap shears and concrete crushers to ensure the delivery of unbeatable performance even in the toughest situations.

The union of powerful cylinders and a twin pin system give an enormous breaking and cutting force with a wide jaw opening.

• The unique design of jaws incorporates shaped shear blades, which, together with the cutting guide, gives to the CC an incredible cutting power.

• The continuous hydraulic rotation enables precise positioning during in height demolitions and the double-row thrust bearing ensures high robustness and increases safety.

•

Speed-Valve

The

and

• Interchangeable teeth

blades make maintenance operations easy and quick to keep the tool at full efficiency.

* Tool weight does include Mantovanibenne top bracket. We are constantly improving our products and therefore we reserve the right to change the design and technical specifications without prior notice. BT.CCR.03 TECHNICAL DATA MODEL CC25R CC35R CC65R CC90R ROTATION 360° Hydraulic EXCAVATOR WEIGHT t 25-30 30-40 60-70 75-95 TOOL WEIGHT * kg 2500 3500 6650 9600 OPENING (MAX/MIN) mm 1000/0 1100/0 1525/0 1750/0 HEIGHT mm 1960 2270 3000 3360 HYDRAULIC WORKING PRESSURE bar 320-350 320-350 320-350 320-350 OIL FLOW l/min 180-220 280-300 500-600 600-700 www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk 9

speed valve reduces opening and closing time boosting productivity.

The reinforced RP-IT structure is designed to last forever and facilitates the crushed material falling through the jaw.

• The continuous hydraulic rotation enables precise positioning during in height demolitions and ground operations, while its robust components grant high durability.

Due to its high versatility and efficacy, the RP-IT has become a benchmark in the demolition industry. It is suitable for both primary and secondary demolition, also on high reach applications. The interchangeable wear parts simplify maintenance and ensure a perfect fit with different jobs. Split Top Jaw Plates - As the front plate always wears far quicker than the rear, you can replace only this part saving you time and money on maintenance costs. • Speed-Valve The speed valve reduces opening and

closing time boosting productivity.

BT.RP-IT.10 MODEL RP10-IT RP16-IT RP20-IT RP30-IT RP40-IT RP50-IT RP80-IT ROTATION 360° Hydraulic EXCAVATOR WEIGHT t 10-15 16-20 21-26 27-35 35-50 50-65 70-95 TOOL WEIGHT * kg 1100 1690 2000 2850 4100 5200 8200 OPENING mm 580 700 750 900 1000 1100 1250 HEIGHT MAX. mm 1710 2150 2130 2400 2780 3000 3600 HYDRAULIC WORKING PRESSURE bar 300-350 300-350 300-350 300-350 300-350 300-350 300-350 OIL FLOW l/min 100-180 130-150 180-200 200-220 220-280 335-375 500-600 TECHNICAL DATA We are constantly improving our products and therefore we reserve the right to change the design and technical specifications without prior notice. * Tool weight does include Mantovanibenne top bracket. • The interchangeable parts, like teeth plates and blades, ensure quick and easy maintenance. RP10-IT RP16-IT RP20-IT RP30-IT RP40-IT RP50-IT RP80-IT www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk 10

The essential features for demolition jobs in a single tool. The RP is suitable for primary and secondary demolition, and it is available for 7 to 35 tons excavators

The reinforced RP structure is designed to last forever and facilitates the crushed material falling through the jaw.

• The continuous hydraulic rotation enables accurate tool positioning in every working environment. In addition, the double-row thrust bearing ensures high robustness and increases safety.

• The re-bar cutting blades are interchangeable and can be turned four times before replacement.

• Speed-Valve The speed valve reduces opening and closing time boosting productivity. BT.RP.08 MODEL RP07 RP16 RP18 RP25 ROTATION 360° Hydraulic EXCAVATOR WEIGHT t 7-10 16-20 21-26 27-35 TOOL WEIGHT* kg 660 1720 2000 2750 OPENING mm 500 700 760 930 HEIGHT MAX. mm 1560 2020 2136 2440 HYDRAULIC WORKING PRESSURE bar 220-280 300-350 300-350 300-350 OIL FLOW l/min 90-120 180-200 180-200 200-220 TECHNICAL DATA We are constantly improving our products and therefore we reserve the right to change the design and technical specifications without prior notice. * Tool weight does include Mantovanibenne top bracket. www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk 11

A fixed head pulverizer is the ideal tool for secondary demolition on the ground. Its interchangeable plates have become a landmark in the industry and are designed to grant high productivity and easy maintenance. Its principal job is to crush concrete in order to separate the metal reinforcement bars.

• The reinforced MCP-IT structure is designed to last forever and makes the tool extremely functional to operate on the ground. In addition, it facilitates the crushed material to fall away increasing efficiency

• The interchangeable parts, like teeth plates and blades, ensure quick and easy maintenance.

• The Speed-Valve reduces opening and closing time boosting productivity.

• Split Top Jaw Plates - As the front plate always wears far quicker than the rear, you can replace only this part saving you time and money on maintenance costs.

BT.MCP-IT.04 MODEL MCP600-IT MCP800-IT MCP910-IT MCP1000-IT MCP1300-IT EXCAVATOR WEIGHT t 11-18 18-27 28-38 39-50 60-90 TOOL WEIGHT * kg 1050 2200 3100 4200 8000 OPENING mm 620 830 1000 1150 1300 HEIGHT MAX. mm 1600 2070 2400 2700 3250 CRP PLATE PP PLATE HYDRAULIC WORKING PRESSURE bar 280-320 280-320 280-320 280-320 320-350 OIL FLOW l/min 100-180 180-220 220-280 280-320 500-600 TECHNICAL DATA We are constantly improving our products and therefore we reserve the right to change the design and technical specifications without prior notice. * Tool weight does include Mantovanibenne top bracket. FIXED PULVERIZER MCP-IT www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk 12 NEW 2 PART PLATE DESIGN

The MCP design enhances simplicity and performances. It is engineered for secondary demolition on the ground and is available for a wide range of construction machines weighting from 2 to 38 ton.

• The reinforced MCP structure is designed to last forever and makes the tool extremely functional to operate on the ground. In addition, it facilitates the crushed material drop off increasing efficiency

• *The Speed-Valve reduces opening and closing time boosting productivity.

• The interchangeable parts, like teeth plates and blades, ensure quick and easy maintenance.

ER MCP *Not available for MCP300 and MCP480 models. BT.MCPmini.06 BT.MCP.06 TECHNICAL DATA We are constantly improving our products and therefore we reserve the right to change the design and technical specifications without prior notice. * Tool weight does include Mantovanibenne top bracket. MODEL MCP300 MCP480 MCP800 MCP910 EXCAVATOR WEIGHT t 2-4 5-10 18-27 28-38 TOOL WEIGHT * kg 150 490 2050 2850 OPENING mm 300 480 850 1000 HEIGHT mm 770 1225 2070 2400 HYDRAULIC WORKING PRESSURE bar 200-250 220-280 280-320 280-320 OIL FLOW l/min 30-60 80-100 180-220 220-280 www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk 13

The transformer machine of the MBI family. It is not a single tool to perform different jobs, it is an attachment that transforms itself into specific tools according to the task to accomplish. Specific jaw sets, make the MS a proper crusher, pulverizer, shear, combi cutter or tank cutter.

MS LINE

A perfect tool for different specific jobs. All in one.

• Many different JAW KITS are available for the MS line, literally transforming it into the perfect tool for a wide array of specific jobs.

• Thanks to the powerful cylinders, the MS delivers an incredible force. In addition, pistons are reversed to be protected from debris and the rod is forged to increase durability.

• The continuous hydraulic rotation enables accurate tool positioning in every working environment. In addition, the doublerow thrust bearing ensures high robustness and increases safety.

• The speed valve reduces opening and closing time boosting productivity.

DEMOLITION MULTISYSTEM MS TECHNICAL DATA BT.MS.11 MS09R MS15R MS22R MS28R MS40R MS60R EXCAVATOR WEIGHT WITH MS BUCKET PLACE t 10-15 16-20 21-27 28-40 40-50 60-70 EXCAVATOR WEIGHT WITH MS STICK PLACE t 7-10 10-15 12-18 15-24 24-30 30-50 HYDRAULIC WORKING PRESSURE bar 300-320 320-350 320-350 320-350 320-350 320-350 OIL FLOW l/min 90-120 130-150 180-220 220-250 250-300 280-320 MS + CRUSHER JAWS SET CR TOOL WEIGHT* kg 950 1650 2210 2900 4550 6500 OPENING mm 650 750 890 970 1200 1540 MS + PULVERIZER JAWS SET CP TOOL WEIGHT* kg 1700 2250 3100 4650 7000 OPENING mm 650 780 885 950 1250 MS + COMBI CUTTER JAWS SET CC TOOL WEIGHT* kg 980 1700 2235 3000 4700 6600 OPENING mm 585 700 830 875 1075 1385 MS + SHEAR JAWS SET SH TOOL WEIGHT* kg 950 1700 2200 2900 4550 6600 OPENING mm 275 330 460 550 620 875 MS + PLATE SHEAR JAWS SET PSH TOOL WEIGHT* kg 2070 4300 6000 OPENING mm 290 370 400 We are constantly improving our products and therefore we reserve the right to change the design and technical specifications without prior notice. * Tool weight does include Mantovanibenne top bracket. Not available www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk 14

The MS140 is a unique tool: it’s the biggest Multisystem on the market, fitting excavators from 120 to 160 tons. Three different jaw kits are available to be applied to the main machine body, transforming the tool in a concrete crusher or in a metal-cutting shear as well. By using the special crusher kit, the MS140 is able to release even more power

A double guide on each side keeps the jaws in perfect

• The sturdy rotation allows accurate positioning of the attachment in any working environment and in complete safety.

• The patented Speed Valve allows faster cycle times (opening/ closing), improving productivity. It also protects the hydraulic circuit

• The Crusher Jaws kit has a 2500 mm opening and is equipped

• The Special Crusher Jaws kit has been specially designed to increase breaking forces by 25%. No rebar cutting blades are

• The Shear Jaws Kit is designed for top - performances in metal structure demolition and scrap processing.

www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk 15

BT.MS140.00 TECHNICAL DATA We are constantly improving our products and therefore we reserve the right to change the design and technical specifications without prior notice. * Tool weight does include Mantovanibenne top bracket. MODEL MS140 EXCAVATOR WEIGHT t 120-160 TOOL WEIGHT * kg 14000 OPENING CRUSHER JAWS mm 2500 OPENING SPECIAL CRUSHER JAWS mm 2300 OPENING SHEAR JAWS mm 1150 CRUSHER JAWS SPECIAL CRUSHER JAWS SHEAR JAWS F = 356 T F = 445 T F = 417 T

The GIDA HMG series of scrap magnet directly connect to the excavators breaker circuit. The HMG magnet has an overflow relief valve and can handle 35 bar of back pressure so there will be no oil spills on site. Collecting the smaller pieces of scrap from site can add a large amount of profit to a company every year!

The HMG-T models work on the same principles as the standard HMG series. They come fitted with a dedicated head bracket and replaceable teeth. Allowing you to rake through loose material on-site to unearth buried scrap material.

HYDRAULIC SCRAP MAGNETS GI-DA www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk 16 MODEL HMG 85 HMG 95 HMG 105 HMG 115 HMG 125 EXCAVATOR WEIGHT t 10-18 14-25 19-28 20-35 26-38 TOOL WEIGHT kg 780 960 1100 1200 1600 DIAMETER SIZE mm 850 950 1050 1130 1250 KILOWATT kw 3,5 4,5 5,5 6 7 VOLTS V 220 220 220 220 220 OIL FLOW (min/max) l/min 38-200 50-200 70-200 80-200 100-200 HYDRAULIC WORKING PRESSURE bar 180 180 180 180 180 LIFTING FORCE - PLATE kg 3,500 3,500 7,000 11,000 12,000 LIFTING FORCE - SCRAP kg 250 350 450 650 900

HMG

HMG-T MODEL HMG-T 85 HMG-T 95 HMG-T 105 HMG-T 115 HMG-T 125 EXCAVATOR WEIGHT t 10-14 14-22 19-28 20-30 26-38 TOOL WEIGHT kg 950 1130 1400 1550 1950 DIAMETER SIZE mm 850 950 1050 1130 1250 KILOWATT kw 3,5 4,5 5,5 6 7 VOLTS V 220 220 220 220 220 OIL FLOW (min/max) l/min 38 / 200 50-200 70-200 80-200 100-200 HYDRAULIC WORKING PRESSURE bar 180 180 180 180 180 FORCE - PLATE kg 3,500 3,500 7,000 11,000 12,000 FORCE - SCRAP kg 250 350 450 650 900 • Robust cover pinned rather than bolted • 1 sec release rate • Safety features stop unnecessary oil spills from site • Can be fitted with any automatic quick coupler system - Steelwrist, OilQuick, Lenhoff etc. • Internal hydraulically generated power unit • Plumbs directly in to breaker circuit • High flow range • One way safety valve • High back pressure (up to 35 bar) • Overflow relief valve dumps back to tank We are constantly improving our products and therefore we reserve the right to change the design and technical specifications without prior notice.

The EBL series of scrap magnet has an in-built rechargeable battery, so you don’t need to connect it to a hydraulic circuit or generator on an excavator. It is the perfect unit for a small yard where you don’t have a specific machine to run the magnet.

You can carry the EBL magnet on a forklift, orange peel grapple or chains. Simply operate it with a remote control when required and re-charge it overnight.

• Internal rechargeable batteries provide the power

• Charge it overnight when not in use

• Options for hanging choice

• Mount on a forklift, orange peel grab or chains

• Operate it from a remote control in the cab

www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk 17 GI-DA ELECTRIC BATTERY SCRAP MAGNETS MODEL EBL 80 EBL 100 EXCAVATOR WEIGHT t 5-7 8-10 TOOL WEIGHT kg 550 950 DIAMETER SIZE mm 770 1000 CHARGING TIME hr/s 10 12 FORCE - PLATE kg 3,500 3,500 FORCE - SCRAP kg 250 350 We are constantly improving our products and therefore we reserve the right to change the design and technical specifications without prior notice.

EBL ELECTROMAGNET

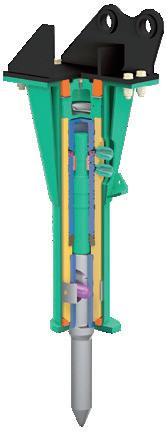

Whether for demolition, construction or quarrying industries, the Montabert range of breakers is unique in optimising performance with patented features such as automatic speed/power change, energy recovery and overflow protection.

With four ranges available, Montabert’s range of breakers are designed for all types of carriers, from 0.7 to 80 tons. With the SD Compact Range, XL, Heavy and the Variable Range, you have the best available choice to match your carrier and project challenges.

They are equipped with the latest patented technology to ensure optimal operation regardless of variations in working materials Montabert breakers provide the best lifespan and efficiency for any type of material. They are also highly tolerant to back pressure. It isn’t easy to find a carrier on which Montabert breakers cannot be mounted.

Take a look at how the Montabert ranges suit you carriers from the specifications tables below.

We are constantly improving our products and therefore we reserve the right to change the design and technical specifications without prior notice. www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk 18 HYDRAULIC HAMMER RANGE MONTABERT

MODEL - SD COMPACT RANGE SD6 SD8 SD12 SD16 SD22 SD28 SD36 SD42 501NG 900 CARRIER WEIGHT RANGE (MIN-MAX) t 0.7-1.2 1-1.7 1.2-2.2 1.5-3.7 2.2-5.3 3-7.5 4-10 5-12 8-18 15-25 BREAKER OPERATING WEIGHT kg 78 112 133 194 286 318 396 456 730 1228 OIL FLOW RANGE (MIN-MAX) l/min 12-23 15-30 17-35 25-50 30-65 40-75 55-100 70-120 80-140 100-150 FREQUENCY bpm 1,150 1,600 1,700 1,500 1,310 1,420 1,550 1,450 870 800 OPERATING PRESURE bar 110 120 120 120 120 120 125 125 125 125 TOOL DIAMETER mm 37 45 47 55 65 72 76 84 106 118 BACK PRESURE(MAX) bar 35 35 35 35 35 35 35 35 35 35 MODEL - XL RANGE XL1000 XL1300 XL1700 XL1900 XL2600 CARRIER WEIGHT RANGE (MIN-MAX) t 11-17 15-22 18-28 21-31 28-38 BREAKER OPERATING WEIGHT kg 980 1,285 1,660 1,900 2,670 OIL FLOW RANGE (MIN-MAX) l/min 70-120 90-140 100-150 120-180 150-240 FREQUENCY bpm 750 600 520 540 550 OPERATING PRESURE bar 170 170 180 180 180 TOOL DIAMETER mm 106 124 137 142 156 WORKING FREQUENCY 1 1 1 2 (manual) 2 (manual OPTIONS AUTOMATED GREASING • • • • •

www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk We are constantly improving our products and therefore we reserve the right to change the design and technical specifications without prior notice. 19 Heavy Range MODEL - HEAVY RANGE V1800 EVO V2500 EVO V3500 V4500 V6000 V7000 CARRIER WEIGHT RANGE (MIN-MAX) t 20-35 27-40 35-60 45-80 58-85 75-120 BREAKER OPERATING WEIGHT kg 1,884 2,571 3,261 4,668 6,909 7,754 OIL FLOW RANGE (MIN-MAX) l/min 140-220 175-250 250-320 280-380 400-500 450-550 FREQUENCY bpm 310-800 350-800 550-850 500-750 400-500 450-550 OPERATING PRESURE bar 165 155 175 185 160 170 TOOL DIAMETER mm 140 160 175 190 214 214 WORKING FREQUENCY 2 (auto) 2 (auto) 2 (auto) 2 (auto) STANDARD AUTOMATED GREASING • • • • • • MODEL - VARIABLE RANGE V32 V45 V55 V65 CARRIER WEIGHT RANGE (MIN-MAX) t 18-30 27-40 35-50 45-90 BREAKER OPERATING WEIGHT kg 1,450 2,547 3,430 5,589 OIL FLOW RANGE (MIN-MAX) l/min 120-170 180-265 240-320 380-420 FREQUENCY bpm 400-1,050 510-1,160 440-1,045 380-950 OPERATING PRESURE bar 135 165 165 165 TOOL DIAMETER mm 140 160 175 190 WORKING FREQUENCY 15 (auto) 15 (auto) 15 (auto) 15 (auto) STANDARD AUTOMATED GREASING • • • •

ROCKCRUSHER

With over 35 years’ experience in the crushing industry, Hartl became technology leader in the market. Robust German engineering gives these attachments the highest level of performance and product durability.

The Rockcrusher enables material to be crushed and recycled directly on site as an attachment on an excavator. Disposal or transportation costs to stationary crushing plants are avoided, making demolition more sustainable.

The attachment comes in 4 sizes RC7R, RC9R, RC11R, RC13R, depending on your project requirements and excavator size. Rockcrusher produces reusable crushed backfill material with a consistent aggregate size for

The crushing process uses a Quattro movement with hydraulic jaw plates removing the need for further processing. A reverse function also enables any jammed material to be ejected safely. The cube-shaped end product will solidify the soil with less risk of unwanted bumps or sinkholes making it ideal for on-site land stabilisation and reinstatement work.

• Quarrying

We are constantly improving our products and therefore we reserve the right to change the design and technical specifications without prior notice. www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk 20

- HYDRAULIC CONCRETE

TECHNICAL DATA RC 7 R (HBC 650) RC 9 R (HBC 750) RC 11 R (HBC 950) RC 13 R (HBC 1250) CARRIER WEIGHT RANGE (MIN-MAX) t ≥ 12 ≥ 20 ≥ 25 ≥ 35 INLET OPENING mm 650 x 500 750 x 500 950 x 525 1250 x 570 SURFACE SIZE JAW PLATES m² 0,9 1,2 1,7 2,4 GAP ADJUSTMENT MIN-MAX mm 10 – 100 12 – 100 12 – 100 12 – 100 OIL FLOW l/min >100 145 200 290 OIL PRESSURE bar 220 220 220 220 kg 2000 3000 4100 6100 mm 1940 2210 2350 2570 mm 1100 1210 1450 1820 HEIGHT mm 1300 1370 1390 1550 • Recycling • Infrastructure / Road construction • Natural stone processing

www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk We are constantly improving our products and therefore we reserve the right to change the design and technical specifications without prior notice. 21

& RENTAL

The NEW MFX20

The most portable model in the range with an amazing 20m throw. Can be moun ted on an IBC water tank or on wheels. Draws its own water.

MOTOFOG, dust control units launched by INMALO in the UK in 2013. A truly innovative and effective dust suppression unit with a diesel engine (no generator required), just plug in the water and you’re good to go.

The 5 models have a range from 15 to 55m throw. They are light and simple to move/transport. For clients looking for dust suppression hire, we always have a number of units available.

• Powerful units offering from 15m - 55m throw

• All Motofog models can draw water from a tank

• Robust design with long warranty

• Easy to move around site by hand, forklift or chains

• The new MFX20 can be mounted on an IBC or on wheels

• Optional remote control

• In stock in the UK

Motofog DUST SUPPRESSION RANGE TECHNICAL DATA MODEL MFJ10 MFX20 MF20SD MF40SD MF60D THROW 15M 20M 25M 35M 55M OSCILLATION N/A 0-270˚ 0-270˚ 0-270˚ 0-90˚ POWER Petrol Engine or 110v Electric Petrol Engine On-board Diesel Engine On-board Diesel Engine On-board Diesel Engine WARRANTY 12 MONTHS 12 MONTHS 12 MONTHS 12 MONTHS 12 MONTHS WATER SUPPLY 3/8” to 3/4” Hose (6-13 Lpm) 3/4” to 1” Hose (20 Lpm) 3/4” to 1” Hose (10-20 Lpm) 1” to 2.5” Fire Hose (30-40 Lpm) 2.5” Fire Hose (50-100

www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk

Lpm)

We are constantly improving our products and therefore we reserve the right to change the design and technical specifications without prior notice. 22

SALES

MF60D 55m Throw MF40SD 35m Throw MF20SD 25m Throw MFJ10 15m Throw MFX20 20m Throw

A Control Unit and pump feeds the nozzles on the arm by means of a flexible pipe. The nozzles spray a nebulised water jet, wetting the structures to be demolished.

The Control Unit is activted by an auxiliary push button inside the cabin. The unit is provided with an inlet electric valve and a stainless steel filter cartridge.

Safety devices on board prevent against dry running of the pump. The unit is also provided with BOA fuses. A free hanging hose provides the main water supply.

Rotofog / DemoPack

and EXCAVATOR MOUNTED

STATIONARY

SOLUTIONS

TECHNICAL DATA MODEL 10 20 40 WATER PUMP kW 2 4 5,5 OPERATING VOLTAGE Vac 50Hz (60 Hz) 230V 50 Hz 2+T 16 A 400V 50 Hz 4+T 16 A THROW m 10-15 20-25 30-35 OSCILLATION ˚ 0-360˚ 0-360˚ 0-360˚ NOZZLES 1 1 1 WATER PRESURE bar 25-60 25-60 25-60 WATER CONSUMPTION l/1’ 2-13 24 42 OPERATING HEIGHT m 3 standard 3-7 3-7 WEIGHT kg 110 150 170 www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk RFA 10, 20 and 40 range are low energy / water consumption autonomous dust suppression and humidifier units with a nebulized jet suitable for indoor and outdoor environments. RFA is equipped with a 360° turning head.

range from 3m to 6m. The rotation angle of the spraying head, working and waiting timings can be easily set from the control panel on board. TECHNICAL DATA MODEL DEMOLITION PACK CONTROL UNIT DIMENSIONS mm 600 X 400 X 350 OPERATING VOLTAGE kW 1.25 POWER W /DC 1250W (24 V DC) WATER CONSUMPTION l /min 10 NOZZLE SUPPLY WATER INLET “ 1/2 3/4 Rotofog RFA 10, 20, 40 Demolition Pack Direct Dust Suppression We are constantly improving our products and therefore we reserve the right to change the design and technical specifications without prior notice. 23

Masts

MB Spay Cannon provides the most extensive range of models and configuration options available on the market. From demolition, recycling, soil remediation, bulk material handling or quarrying, the MB range has a solution to suit the environment you work in, whether inside or outside.

With the largest choice of Spray Cannons in the world for suppressing odour and dust our range extends from SC5 (5m throw) up to the SC150 (150m throw).

MB-Dust THE LARGEST FAN DUST SUPPRESSION RANGE www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk

TECHNICAL DATA MODEL SC5 SC15 SC25 SC35 SC40 SC50 SC60 SC75 SC90 SC100 SC130 SC150 THROW (windstill conditions) 10M 15M 25M 35M 40M 50M 60M 75M 90M 100M 130M 150M OSCILLATION None None None 0-180˚ 0-320˚ 0-320˚ 0-320˚ 0-320˚ 0-320˚ 0-320˚ 0-320˚ 0-320˚ TILT 0-60˚ N/A -15-60˚ -15-60˚ -15-60˚ -15-60˚ -15-60˚ -15-60˚ -15-60˚ -15-60˚ 0-60˚ 0-60˚ POWER Electric 110/230V Electric 110/230V Electric 110/230V Electric 110/230V Electric 400V Electric 400V Electric 400V Electric 400V Electric 400V Electric 400V Electric 400V Electric 400V MAX WATER USAGE (Litres per minute) 3 Lpm 3 Lpm 5 Lpm 16 Lpm 16 Lpm 58 Lpm 75 Lpm 75 Lpm 75 Lpm 150 Lpm 250 Lpm 250 Lpm WATER SUPPLY 3/8” Hose 3/8” Hose 1/2” Hose 3/4” Hose 3/4” Hose 1” Hose 1” Hose 2.5” Hose 2.5” Hose 2.5” Hose 2.5” Hose 2.5” Hose WEIGHT 2kg 18kg 100kg 230kg 240kg 500kg 615kg 650kg 700kg 750kg 1,100kg 1,200kg OPTIONS UP/DOWN ELECTRIC • • • • • • • • • WHEEL SET • • • • • • • • • • W - WALL MOUNT • • • SS - SELF SUPORTING • • • • • • • • • • SS - TELESCOPIC • • • • TRAILER • • • • • • • • • REMOTE CONTROL • • • • • • • • • SC40 40m Throw SC15 15m Throw SC40SS-M 40m Throw SC75 75m Throw Main Varriable Options Shown - Others available, please ask for details We are constantly improving our products and therefore we reserve the right to change the design and technical specifications without prior notice. 24 SALES & RENTAL

www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk SC60 60m Throw SC25SS 25m Throw SC50SS 50m Throw SC90 90m Throw SC150 150m Throw SC100 100m Throw SC90SS Heavy 90m Throw SC5 10m Throw SC15 15m Throw SC40SS MAST 40m Throw 25

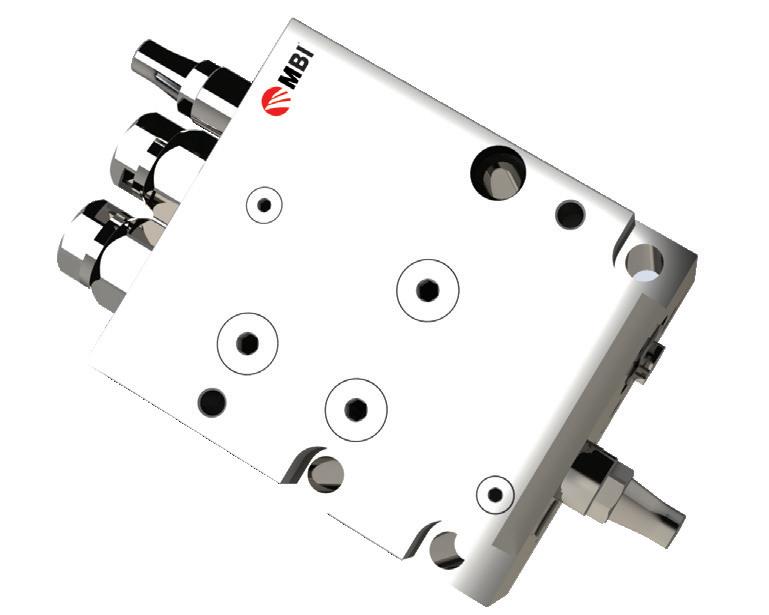

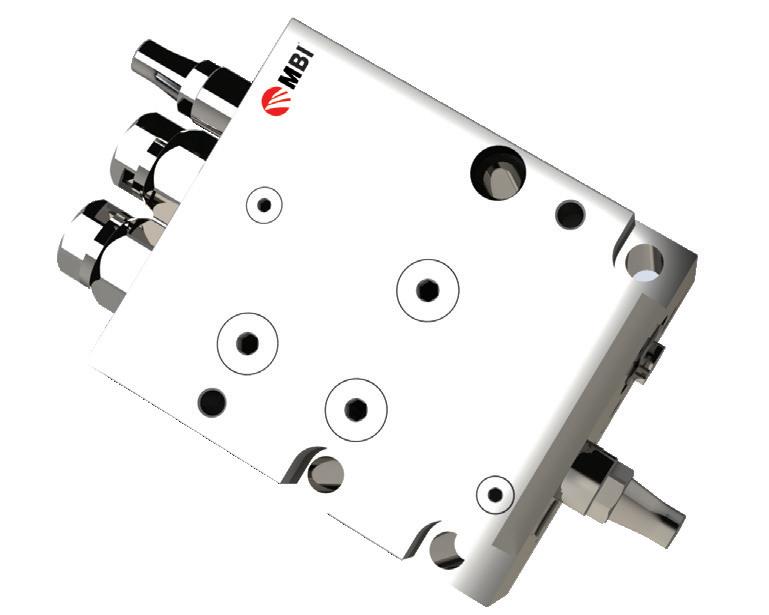

The SQ fully automatic quick coupler system allows the safe and efficient selection of a wide variety of hydraulic attachments in seconds without the need for the operator to leave the cab. The SQ range are available for small to large excavators alike, all models have the same technology.

Steelwrist have patented the “Front Pin Lock” system, and it is the safest and most advanced fully automatic hydraulic quick coupler on the market.

Front Pin Lock means that the attachment cannot fall off the coupler even if the rear wedge isn’t connected properly.

Benefits of Steelwrist SQ System

Up to 50% time saving on jobs Use the right tool for the right job

Fully Automatic Quick Couplers Quick COUPLERS TECHNICAL DATA We are constantly improving our products and therefore we reserve the right to change the design and technical specifications without prior notice. MODEL SQ 60 SQ 70/55 SQ 80 SQ 90 EXCAVATOR SIZE Tonnes 12-20 15-33 25-43 40-70 PIN DIAMETER mm 60-80 70-90 80-110 100-130 SQ70/55 SQ80 SQ RANGE - WELD ON ADAPTOR SQ RANGE - ADAPTOR PLATE WITH MANIFOLD HIGHFLOW HYDRAULICS STEELWRIST AUTOCONNECTION STEELWRIST www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk 26

Front Pin Lock + Visual indication = Safest system on market No damage to loose hydraulic hoses • Reduce oil spills on site SQ

Inmalo provide a bespoke engineering and design service for the manufacture of non-standard attachment tools and couplings as well as mobile line boring.

ENGINEERING SOLUTIONS

Our facilities in Hampshire and Sussex enable us to carry out testing, development and fabrication of complex engineering projects for specialist tools and couplings.

REPAIR & SERVICING

We offer a comprehensive repair service for all demolition plant including hydraulic attachments and dust suppression equipment. We carry an extensive range of spare parts for all the manufacturers we represent, allowing us to provide a fast and reliable response time to support our clients throughout the UK.

LINE BORING

Our mobile line boring service is available for equipment of all types across all industries.

Our engineers will come to your site and where feasible do the repair “in situ”. We can bore and weld between 42mm and 400mm and up to 3 metres long.

Bespoke Engineering Solutions Mobile Line Boring On-site Fitting Attachment Installation Flow & Presure Testing Spare Parts Eqipment Refurbishment Welding Repairs www.inmalo.co.uk tel: 01962 760055 email: sales@inmalo.co.uk

SERVICES Engineering

/ LINE

27

MANUFACTURING

BORING

Winchester Andover Newbury Basingstoke Sutton Scotney INMALO International Marketers (London) Ltd The Workshops, Lower Norton Farm Norton, Sutton Scotney, Winchester Hampshire SO21 3NE. tel: 01962 760055 fax: 01962 761956 email: sales@inmalo.co.uk www.inmalo.co.uk SALES & RENTAL brochure V3.0 - 08/2022