Editor

Becky Schultz

becky.schultz@khl.com

Managing Editor

Chad Elmore

chad.elmore@khl.com

Power Briefing Editor

Art Aiello

art.aiello@khl.com

Editorial Contributors

Jack Roberts, Chris Sleight

MEDIA PRODUCTION

Client Delivery & Success Manager

Charlotte Kemp

charlotte.kemp@khl.com

Client Delivery & Success Team

Alex Thomson | alex.thomson@khl.com

Ben Fisher | ben.fisher@khl.com

Olivia Radcliffe | olivia.radcliffe@khl.com

Group Design Manager Jeff Gilbert

Group Designer Jade Hudson

Events Manager Steve Webb

Events Design Manager Gary Brinklow

Creative Designer Kate Brown

Subscriptions circulation@khl.com

Data Manager Anna Philo

Data Executive Vicki Rummery

Audience Development & Marketing Executives

Helen Hughes, Laura Walker

SALES

VICE PRESIDENT SALES, POWER DIVISON

PLUS USA Tony Radke

+1 602 721 6049

tony.radke@khl.com

CHINA Cathy Yao

+86 (0)10 6553 6676

cathy.yao@khl.com

ITALIAN TERRITORY SALES MANAGER

Giuseppe Di Leva

+44 (0) 7593 586 562

giuseppe.dileva@khl.com

JAPAN Michihiro Kawahara

+81 (0)3 32123671

kawahara@rayden.jp

MAINLAND EUROPE Gabriele Dinsel

+49 711 3406 73 50

gabriele.dinsel@khl.com

SCANDINAVIA/UK Greg Roberts

+44 (0)1892 786238

greg.roberts@khl.com

USA

Thomas Kavooras

+1 312 929 3478

thomas.kavooras@khl.com

GLOBAL VICE PRESIDENT SALES

Alister Williams

+1 312 860 6775

alister.williams@khl.com

CHIEF EXECUTIVE OFFICER

James King

CHIEF FINANCIAL OFFICER

Paul Baker

CHIEF OPERATING OFFICER

Trevor Pease

KHL GROUP AMERICAS LLC

14269 N 87th Street, Suite 205, Scottsdale, AZ 85260, USA

americas@khl.com

hose of us of a certain age may recall from our childhoods Kermit the Frog lamenting from his lily pad that “It’s not easy being green.” Today, that could easily be revised to “It’s not easy going green.”

There are a multitude of options of varying complexity and cost available to deliver more ecofriendly machines. Yet, I’ll throw back to another memorable phrase which dates to the 1960s: “Keep It Simple, Stupid”, or more often referred to as the KISS principle. In essence, the concept is that designs and/or systems should be as simple as possible in order to guarantee the greatest levels of user acceptance.

When it comes to powering machines, the “simple” solution to going green is to improve the performance of existing internal combustion engines, thus reducing fuel burn and emissions output. This could be as minor a step as changing out fluids and filters to eke out incremental improvements, or as involved as extensive changes in materials and components to deliver quantifiable results. Regardless of the approach, the core engine technology remains the same, making it easier in the eyes of the end user to accept.

Approval of “drop-in” fuels such as HVO, renewable diesel, biodiesel, propane and others is another relatively simple solution that can significantly lower emissions output – if approved by the manufacturer and if supplies are readily available and at the right price.

Pairing ICEs with today’s advanced hydraulic systems – some of which may be offered in packaged subsystems for easier integration – presents a further means to maintain the familiar power source while delivering gains in overall machine efficiency.

Of course, the tricky bit is figuring out which solutions are right for your applications and your customers. In this case, the simplest way to find the right mix is to take advantage of the experts in their fields by collaborating with power systems and component suppliers.

Power Progress is offering the chance to do just that on October 6th, in Louisville, Ky., with the introduction of an industry exclusive networking forum. This one-of-kind event lets you pre-schedule one-on-one meetings with those experts to discuss these and other power system and component-related challenges.

And better yet, it’s followed by a party as we toast our 90th anniversary and look to the future of Power Progress! Learn more about the Power Progress Networking Forum at www.powerprogresssummit.com

Becky Schultz becky.schultz

@khl.com

As part of the 90th anniversary celebration of Power Progress (formerly Diesel Progress), the team at Power Progress, Power Progress International and KHL Group will be kicking off an industry-first event with the Power Progress Networking Forum, taking place Oct. 6th, in Louisville, Ky., the day prior to the opening of AEM’s Utility Expo.

The Power Progress Networking Forum will connect buyers and suppliers in the engine and powertrain industry in a one-day event

FAIRBANKS

held at the Galt House Hotel in the city’s downtown area. Inaugural suppliers slated to participate include:

Rehlko – Formerly Kohler Energy, it is building upon the 100-plus year history of Kohler as it moves into a new era as a standalone company with a new majority owner and new name. The company plans to continue to grow its existing portfolio and brands, while exploring new

opportunities in new markets and power systems.

Volvo Penta – With a history dating back to 1907, the Swedish manufacturer became part of the Volvo Group in 1935. While it has an extensive history of supplying engines to the industrial and marine sectors, it continues to broaden its portfolio, most recently with subsystems for battery energy storage systems (BESS).

Zenith Power Products – This vertically integrated company in Tomahawk, Wis., provides natural gas,

LP and gasoline industrial and power generation engines ranging from 1.6 L to 11.8 L. It caters to industries needing reliable and customizable engine solutions, including construction, ag, irrigation, power generation and other industrial applications. Details on additional suppliers will be shared at www.powerprogress.com as they become available. PP Find out more about the Power Progress Networking Forum by visiting KHLForums. com/PowerProgressForum or PowerProgressSummit.com.

MORSE DEFENSE has appointed Steve Pykett as Chief Executive Officer. He brings more than 25 years of experience in the aerospace and defense industry, and most recently served as president of Investment Castings at Precision Castparts Corp. There, he reportedly drove significant growth across a global operation spanning more than 30 international sites and over 7,000 employees.

GKN Aerospace and Rolls-Royce.

“I’m honored to lead this next chapter of innovation and growth alongside incredible employees whose expertise, pride, and dedication are the foundation of our mission to ensure freedom of the seas,” said Pykett.

Johan Inden has been named CEO of NIMBUS GROUP AB, with the appointment taking effect September 1. Inden succeeds Jan-Erik Lindström, who plans to retire.

Prior to PCC, Steve served in senior leadership and engineering roles at L3Harris Technologies,

Inden has more than 15 years of experience from senior leadership roles in the marine and boating industry. He will be leaving his position as president of the

Marine Business Unit at Volvo Penta, where since 2018 he has led the company’s global marine operations.

Previously, Inden was responsible for product development, procurement and strategy at Volvo Penta.

“Following Jan-Erik Lindström’s successful efforts in developing Nimbus Group, we now welcome Johan Inden, a highly experienced leader with a solid background in the marine industry,”

said Mats Engblom, Chairman of the Board of Nimbus Group AB. “His visionary leadership in developing companies and people, together with a strong focus on entrepreneurship, will be highly valuable in making Nimbus Group a stronger and larger player in the global boating industry.”

The group produces boats under several brands. Its largest markets are the Nordic region, Europe and U.S.

CREATING POWER SOLUTIONS

Hatz is widening its footprint in the liquidcooled industrial engine market with the new F-series. Reliable and compact diesel engines with power outputs from 10 to 24.6hp and torque from 35 to 56 ft lbs.

With their extremely robust design, the F-Series Open Power Units are ideal for any applications requiring reliable power in a compact package.

The global nature of supply chains means tariffs also present challenges for U.S.-based producers. By

Chris Sleight

April’s tariff announcements have thrown long-established trading relationships into a tailspin, as companies seek to understand the impacts and do all they can to mitigate them. While the intention is to discourage imports into the United States and give a leg up to domestic manufacturers, the reality is that supply chains for manufactured goods are global, so U.S.based producers will be facing increased input costs and will be working hard to minimize them.

The foreign content of goods will always vary from product to product and manufacturer to manufacturer, so it is not possible to make a blanket statement about

CHRIS SLEIGHT is the managing director of Off-Highway Research, a market research and forecasting business specializing in analysis of the global construction and agricultural equipment markets. Formed in 1981 as part of The Economist Intelligence Unit (EIU), it is now the largest consultancy of its kind in the world, with offices in Chile, China, Germany, Japan, India, the U.K. and the U.S. OHR is part of the KHL Group. www.offhighwayresearch.com

SOURCE: CNH Industrial & Power Progress.

how much the tariffs will increase costs for U.S. producers. However, this is something that can be modeled.

An interesting example was given by CNH Industrial in the company's first quarter investor relations presentation, where it gave an outline example of its U.S.-made equipment. Although these would certainly be regarded as American machines, the company revealed that about 30% of the components used are sourced from suppliers outside the U.S.

Taking the figures that CNH supplied and applying the announced tariffs reveals that the cost of producing this equipment could go up 10% if the company can’t do anything to mitigate the tariffs (sourcing from less heavily taxed countries, or from within the U.S.).

(See table – the percentage component content by

country is provided by CNH, while the assumptions about tariff levels and their cost impact is from Power Progress.)

That simple exercise highlights the priority areas. In this case, the combination of volume and content sourced from China and the European Union would have the biggest impact on input prices.

But life is never that simple. Although there is no tariff on U.S.-sourced components, the suppliers of those items will almost certainly be sourcing the materials they need from around the world. At the most reductive, it absolutely will not be the case that every atom of an “American” component will have been extracted from within U.S. borders and spent its life within the supply chain inside those borders. At some

point, constituent parts of components come into the country (and perhaps cross the border many times) at which point the importer will have to pay a tariff.

As a thought exercise, assume U.S. components have the same content by origin as the finished machine (70% U.S., 30% from other countries, including EU and China), then over time the tariffs will push the cost of those components up by the same 12%. That would translate to adding a further 8% to the cost of the finished goods.

The reality of global supply chains leads on to the unintended and unfortunate outcomes in terms of the policy objective. If for example an American-made component had more than 8% Chinese content, the 145% tariff on those parts when imported would translate to a 20% increase in the cost of the component. It would therefore be compelling to source exactly the same component (with exactly the same amount of Chinese content) from Mexico and take just a 10% tariff hit.

To learn more, Power Progress readers can access the free Off-Highway Research white paper “The Impact of US Tariffs on the Construction Equipment Industry” at www. offhighwayresearch.com PP

Aggressive diesel

exhaust emission regulations

are being rolled back. Maybe that’s not such a bad thing.

By Jack Roberts

The reelection of Donald Trump as President of the United States last Fall was a gut punch to climate change activists all over the world.

We’re only five months into the second Trump administration, but the President and the (justever-so-barely) Republican majority in Congress have already begun rolling back diesel exhaust emissions regulations spearheaded by the California Air Resources Board (CARB) and backed by the U.S. Environmental Protection Agency (EPA).

Say what you will about CARB, it clearly knows when it’s beat. On May 7, the agency announced that it was abandoning its controversial and unpopular Advanced Clean Fleets Rules in the face of the proactive Republican moves to roll back environment regulations – led by

the state of Nebraska, of all places.

Given all this, I was curious what the general mood would be heading into the Advanced Clean Transportation Expo (ACT Expo) in Anaheim, Calif., in late April.

ACT Expo has emerged as one of the most important truck/transportation shows in the world over the past decade or so. It’s a show that has an unwavering focus on helping the trucking industry transition away from fossil fuels to a net-zero emissions future.

So, I was naturally curious walking into the Anaheim Convention Center as the show kicked off.

Would attendance be down? What would be the mood among exhibitors and attendees? What would be the focus of the show?

JACK ROBERTS is a Tuscaloosa, Ala.-based independent journalist and licensed commercial driver with more than 20 years’ experience covering the North American and global trucking industries.

As it happened, the show was packed. The mood was decidedly upbeat.

ACT Expo attendees were greeted by this CNG-powered Freightliner as they walked into the Anaheim Convention Center.

OEMs and suppliers had plenty of new, clean and green trucking tech to show off. And there was plenty of new technology still to talk about as well – natural gas as a truck fuel and a sense that the real-world deployment of autonomous trucks is coming soon.

There was a general consensus among industry insiders I talked to that the current emissions rollback was merely a bump in the road on the journey toward a cleaner trucking industry.

It’s important to note that the policy makers at CARB are true believers when it comes to combatting climate change, which is why the agency has been pushing a very aggressive agenda

that would have completely phased out diesel-powered trucks by 2036. The problem was that CARB also seemed to be suffering from what some industry insiders called “combustion bias.”

As I’ve noted in the past, CARB and EPA (to a lesser extent) appeared to be ignoring excellent transitional fuels – like renewable diesel fuel and renewable natural gas – in favor of new technologies like battery-electric and hydrogen fuel cell-powered trucks.

But there are currently substantial problems with those technologies. Acquisition costs are prohibitive. Infrastructure is virtually nonexistent. And while these powertrains work well in some applications (drayage, urban delivery, short and regional haul),

they are nowhere near ready to being a viable option for long-haul fleets.

As I often say, the trucking industry should have been at this point in the war on climate change 20 years ago. So, I get the sense of urgency on the part of environmental regulators.

Yet, it has to be said,

Despite a concerted effort by the Trump administration to roll back diesel exhaust emissions regulations, the mood at ACT 2025 was upbeat – and even hopeful.

the policies CARB was ramrodding down the throat of the trucking industry were an incoherent, unworkable mess.

And turning a deaf ear to the legitimate concerns of the trucking industry while ignoring perfectly viable interim clean fuels like renewable diesel and

ACT EXPO

renewable natural gas was a serious strategic miscalculation on the part of CARB that turned potential allies into intractable adversaries.

Now, thanks to last Fall’s election, there’s been a reset. And there’s a very real hope out there that this pause will eventually lead to more reasonable and workable climate initiatives that the trucking industry can not only live with but even embrace.

It will be interesting to see if CARB and other environmental regulators learn anything from this setback.

If nothing else, the coming four years will give OEMs and tech developers

While Hyundai highlighted hydrogen fuel cell capabilities at ACT Expo, cost and lack of hydrogen infrastructure continue to challenge the technology’s adoption.

more time to develop their zero-emissions solutions. It will also grant more time to get workable electric and hydrogen infrastructure installed and up and running. My hope is we will also see more movement toward solutions that provide cleaner and reliable fuel solutions that will allow long-haul fleets to continue to profitably move freight while cleaning up the air we breathe. PP

We simplify the selection of components to meet your unique application needs.

Select from preconfigured, highly compatible components that integrate seamlessly into your system architecture.

1. Power Distribution Unit

2. LIOS battery system

3. Charging management

4. Drive sets

5. Mobile, variable-speed air coolers 6. Software 7. Controllers We support your

www.powerprogress.com/events/all-events-diary

August 20 to 21 IVT EXPO

Donald E. Stephens Convention Center Rosemont, Ill.

https://ivtexpo-usa.com/

August 26 to 28 FARM PROGRESS SHOW

Decatur, Ill.

www.farmprogressshow.com

September 16 to 18

SAE INTL.’S COMVEC

Schaumburg, Ill.

https://comvec.sae.org

October 6 POWER PROGRESS NETWORKING FORUM

The Galt House Louisville, Ky.

www.powerprogresssummit.com

October 6 to 9 THE BATTERY SHOW

Huntington Place Detroit, Mich.

www.thebatteryshow.com

October 7 to 9 THE UTILITY EXPO

Kentucky Exposition Center Louisville, Ky.

www.theutilityexpo.com

October 21 to 24 EQUIP EXPO

Kentucky Exposition Center Louisville, Ky.

www.equipexposition.com

November 9 to 15

AGRITECHNICA

Messegelände Hanover, Germany www.agritechnica.com

December 3 to 5

INTERNATIONAL WORKBOAT SHOW

Morial Convention Center New Orleans, La. www.workboatshow.com

January 6-9

CES

Las Vegas Convention Center Las Vegas, Nev.

www.ces.tech

January 19 to 22

WORLD OF CONCRETE

Las Vegas Convention Center Las Vegas, Nev.

www.worldofconcrete.com

FEBRUARY

February 10 to 12

WORLD AG EXPO

International Agri-Center Tulare, Calif.

www.worldagexpo.com

February 11 to 14

NATIONAL FARM MACHINERY SHOW

Kentucky Exposition Center Louisville, Ky.

https://farmmachineryshow.org

March 3 to 7

CONEXPO-CON/AGG

Las Vegas Convention Center Las Vegas, Nev.

www.conexpoconagg.com

Indicates shows in which POWER PROGRESS will participate

When the editorial staff compiled the 90th anniversary edition of Power Progress (see the May issue), we spent many hours paging through back issues of this title as well as its companion publication, Global Sourcing Guide (also introduced in 1935). It’s easy to say, “things were sure different back then.” When a mine decided to get its energy from diesel gen-sets, it often replaced a building full of external combustion units (steam). When a farmer bragged about his diesel crawler tractor, that machine likely shared the barn with a team of trusted draft horses. However, after

Linnavuori, Finland sales.agcopower@AGCOcorp.com www.agcopower.com

POWER RANGE

DIESEL: 74 to 476 hp

AGCO Power introduced its new U.S. EPA Tier 4 Final and EU Stage V CORE80 engine at the Bauma trade fair in Germany. The CORE80 is the third in the current CORE engine family and complements the 5 L CORE50 and 7.5 L CORE75. It is rated 338 hp (252 kW). The CORE80 is the first AGCO Power engine to offer over-the-air (OTA) connectivity to its

collecting, writing, editing and trimming to fit a year’s worth of internal combustion engine specialist news in 14 pages for this issue, it was nice to see where things have not changed. Consider that discussions about fuel were common in the early years of the engine industry as well as within this publication. So it is today. Consider, too, that engines back then were a way to increase productivity and profitability. With power-hungry artificial intelligence and battery charging spreading globally, engines are again (still) being employed to provide reliable power PP

engine control unit, enabling remote diagnostics, monitoring and simpler updates.

ARROW ENGINE CO. Tulsa, Okla. www.arrowengine.com

POWER RANGE

DIESEL: 15 to 156 hp

GASEOUS FUEL: 5 to 200 hp

Vanguard Commercial Power Wauwatosa, Wis. www.vanguardpower.com

POWER RANGE

GASOLINE: 4.9 to 40 hp

GASEOUS FUEL: 6.5 to 37 hp

Highlights from the past year include the introduction of the Vanguard 300 single-cylinder engine and the continued development of battery systems. The company said its broadened portfolio demonstrated its commitment to offering comprehensive power solutions that meet the diverse needs of the commercial equipment

The Vanguard 300 has 307 cc and 10.0 gross hp, which it said was ideal for a range of applications, including pressure washers, generators and hydraulic power packs and concrete trowels. The company said the Vanguard

300 engine was selected to power the Z Turf Equipment

Z-Spray lean-to-steer stand-on spreader sprayer. Vanguard power has been used in Z Turf machines since 2020.

The Vanguard 300 gets an improved mechanical compression release and choke engineered for cold-weather starts down to 0°F. The carburetor ensures consistent starting and smooth operation across a wide spectrum of load requirements, said the company. The integrated cyclonic air filtration system extends air filter replacement intervals to 600 hours, while the TransportGuard system prevents the mixing of fuel and oil during transport.

Irving, Texas www.cat.com/industrialengines

POWER RANGE

DIESEL: 11 to 8,180 hp

GASEOUS: 95 to 5,500 hp

Caterpillar’s inline six-cylinder Cat C13D engine platform will be available in eight power ratings from 456 to 690 hp (340 to 515 kW) with up to 3,200 Nm of peak torque.

The 13 L C13D platform, which goes into production in 2026, is designed for use in a wide range of offhighway equipment. Engine mounted aftertreatment and cooling packs will be available from the factory. The C13D will meet the emissions standards of highly regulated markets, such as EU Stage V, U.S. EPA Tier 4 Final, China Nonroad Stage IV, Korea Stage V, and Japan 2014, with models available for less regulated markets.

The engine is designed to perform at altitudes of up to 12,000 ft. and in ambient temperatures as high as 140°F (60°C) and as low as minus 40°F (minus 40°C) with aids. Service intervals have been extended to 1,000 hours for oil and fuel filters.

By modularizing and eliminating components, the company said the

engine’s architecture

adjustments anticipated for future emission standards without moving customer connection points.

The Caterpillar C13D engine platform enables the use of renewable liquid fuels such as 100% HVO, up to B20 for models with aftertreatment and B100 for models without aftertreatment. Its core architecture is designed to support future development for a range of alternative fuels such as natural gas and hydrogen.

In late 2024 Caterpillar began work on a hydrogen-hybrid project by leveraging the C13D engine platform. The threeyear program is expected to develop a system for off-highway applications and demonstrate how state-of-the-art control systems and electric-hybrid components can help hydrogen-fueled engines match the power density and transient performance of diesel engines.

At Bauma 2025, the company showed a simulated test cell environment with an engine that has been run on 100% hydrogen. Caterpillar has developed multiple engines with hydrogen over the past three decades, and said it will continue to apply lessons learned through the hydrogen-hybrid project.

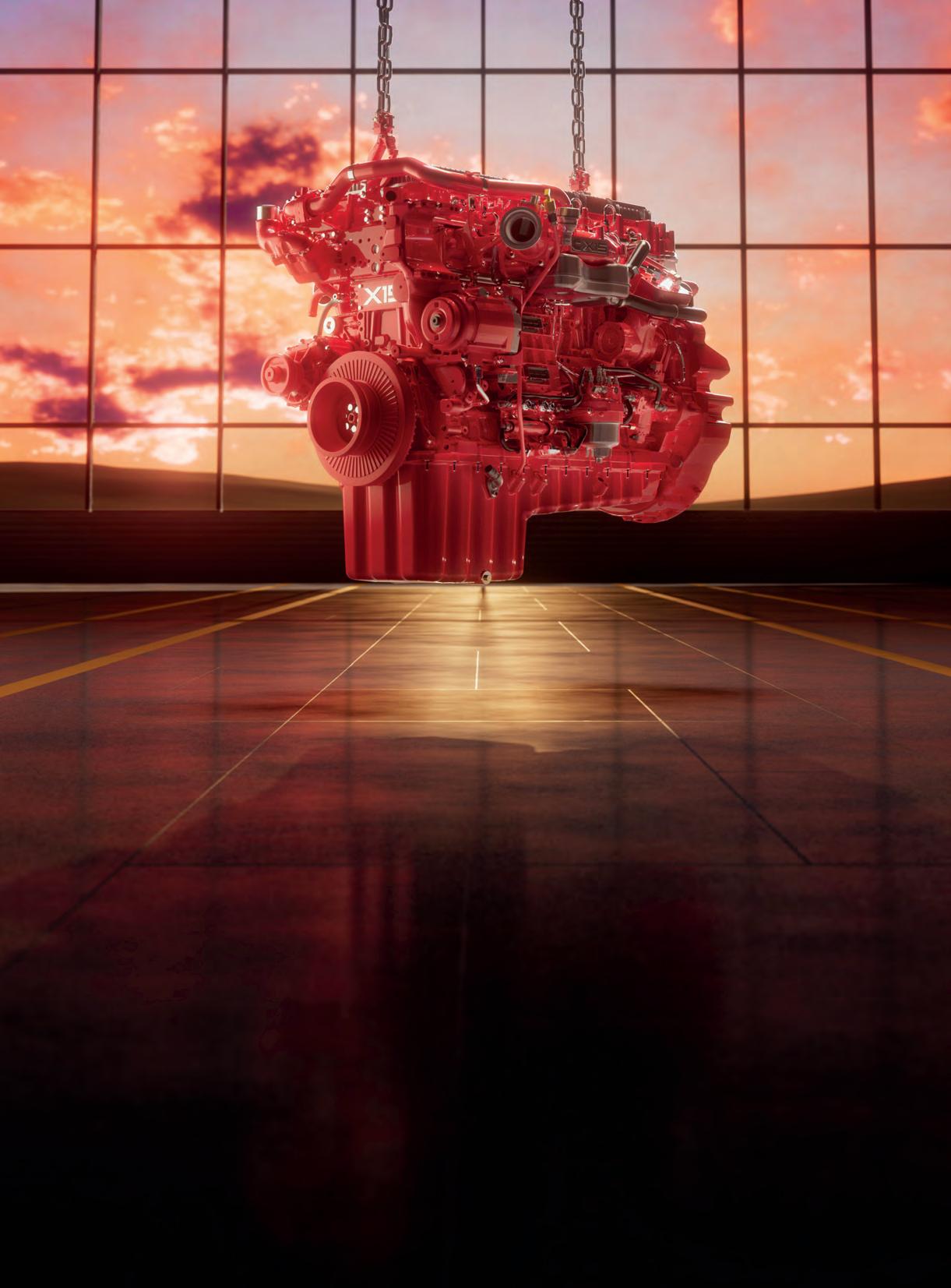

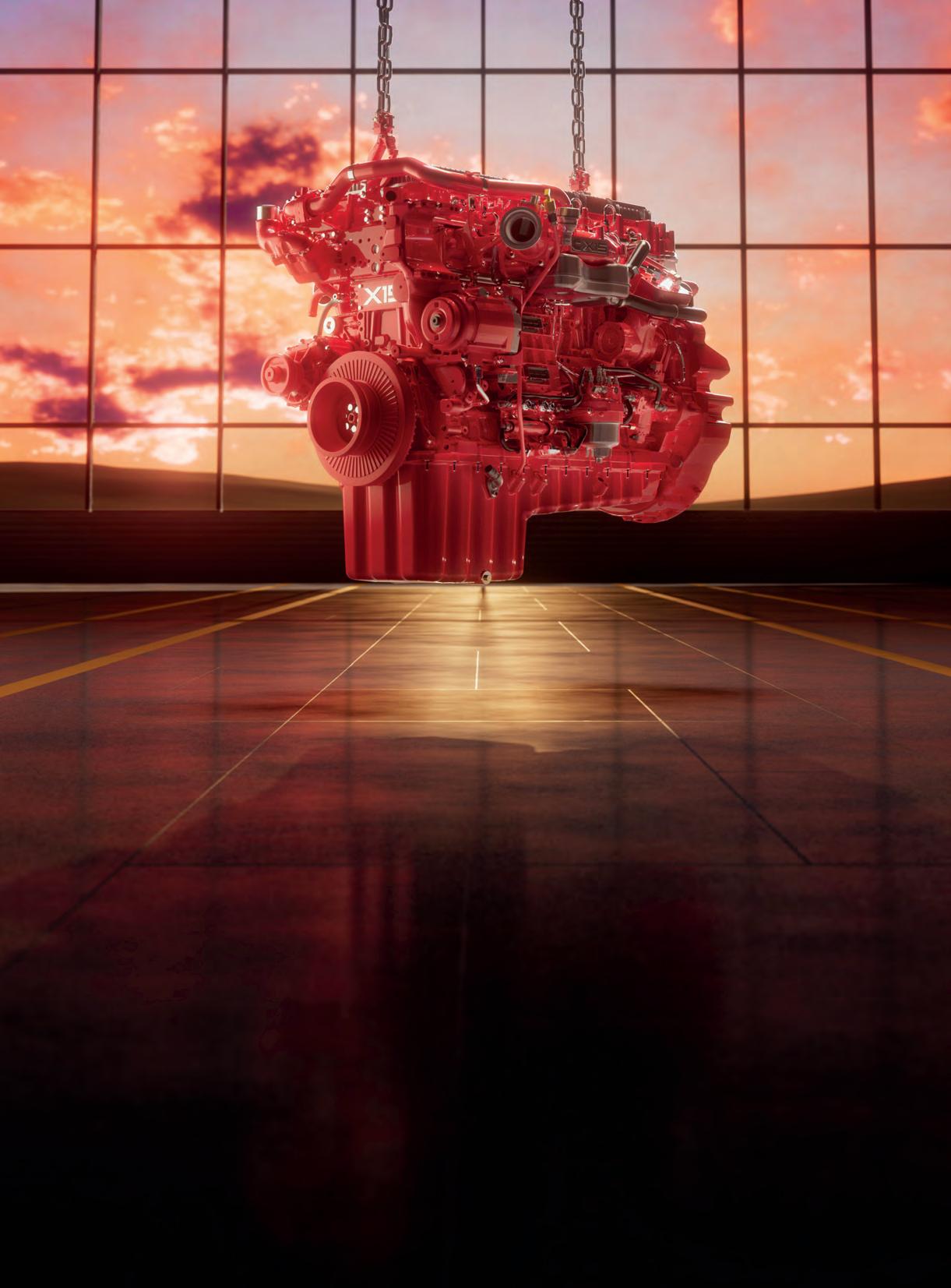

Columbus, Ind. www.cummins.com

POWER RANGE

DIESEL: 49 to 5,100 hp

GASEOUS FUEL: 67 to 2,600 hp

Cummins Inc. selected NTEA Work Truck Week in Indianapolis in March to show new engines, including the X10 diesel, B6.7 Octane and B7.2 diesel. The X10 is a

heavy-duty, mid-bore engine rated up to 450 hp. It is built off the proven L9 and X12 platforms.

With the B6.7 Octane, the company showed its first move into the gasoline engine market. The company said it provides power, durability and diesellike performance while adding the convenience of gasoline. It is rated 300 hp and has 660 lb.-ft. of torque.

Cummins said B6.7 Octane uses 87 octane gasoline and requires less maintenance with a simple, passive threeway catalyst and no need for DEF (diesel exhaust fluid). The company said the engine has been validated via 2 million real-world test miles across various applications and duty cycles.

Cummins also announced an update to its B-Series engine platform, unveiling the new B7.2 diesel engine.

“Our B engine is a legend known around the world. We are proud to unveil the newest version, the B7.2 diesel engine….,” said Vice President and President – Engine Business Brett Merritt. “The B7.2 brings the latest technology and advancements to one of our most proven platforms. Combined with the rest of our medium-duty lineup, our customers will have the right engine choices to fit their business needs, with the power and dependability they have come to expect from Cummins.”

The B7.2 diesel is the latest member of the B series HELM platform, and will serve a variety of medium-duty and vocational applications. The new engine will feature a slightly higher displacement, increasing to 7.2 L, and is designed to be a global platform which allows customers to ensure their vehicles are ready for what is to come, without sacrificing performance or durability.

A higher displacement also allows for a wider range of torque offerings, said the company. n application news, Cummins and Colorado-based Liberty

>

Our systems come factory tested, ready for plug and play installations, straight o the truck. And you get the benefit of Cummins’ extensive power generation expertise as well as world-class global aftermarket support.

• Integrated package for best-in-class power density and performance with LiFePO4 technology

• Grid-Forming & Grid-Following capable for maximum fl exibility

• CE, IEC, AS Compliance and certifi cations meeting global standards

• Robust IP55 containerized scalable design

Energy Inc. said the natural gas, variable speed, large displacement engine in Liberty’s digiPrime hydraulic fracturing platform will be deployed this year. The companies entered into a strategic partnership in June 2024 to develop the technology for the well completion and service market.

The Cummins HSK78G natural gas engine was launched in 2019 as part of a fixed speed gen-set for power generation. The recent for the digiPrime platform leveraged the HSK78G and improved the 78 L natural gas sparkignited engine’s response time and load acceptance during operation. The digiPrime pump, anchored by a 3,000 hp natural gas engine, is a direct drive solution that Cummins said translates into reduced fuel costs and is one of the lowest emissions solutions in the oil & gas market.

Daegu, South Korea daedong-kioti.com

DIESEL: 24 to 140 hp

Daedong’s latest innovation is the Power Pack solution, which it said was designed to make engine usage more convenient and efficient. By integrating essential components such as the engine, radiator, air cleaner, fuel filter, cooling fan and mounting devices into a single unit, the company said users can easily utilize engines for various applications. With the Daedong Power Pack, the company said users can expect fuel efficiency and outstanding performance,

3.8 L Daedong Power Pack.

ensuring a dependable partnership for all their needs.

Available in a range of power options from 19 kW (engine model 3L123) to 105 kW (engine 4J383TA) that meet U.S. EPA Tier 4 Final and EU Stage V emissions regulations, the Power Pack lineup is designed to offer versatility and adaptability in a compact size.

Daedong diesel engines support the use of conventional diesel as well as 100% HVO fuels.

Redford, Mich.

demanddetroit.com

POWER RANGE

DIESEL: 200 to 600 hp

In December, Detroit Diesel’s parent company, Daimler Truck North America LLC (DTNA), said it would invest in its Detroit Manufacturing Plant located in Wayne County, about 15 miles west of downtown Detroit. The plant has been a cornerstone of DTNA’s operations since 1938, and today produces engines, transmissions and axles for the Freightliner, Western Star and Thomas Built Buses vehicle platforms.

The company’s plans include reinvesting in the internal combustion engine (ICE) platform and the enhancement of its research and development (R&D) facilities.

It plans to modernize the existing plant to maintain its current production capacity and innovation of ICE components and support the growing demand for cleaner, more fuel-efficient engines and components. DTNA anticipates an investment of up to $285

million for the project. In addition to the over 2,000 existing jobs at the facility, more than 400 new jobs are expected to be created at the site.

The investment was in partnership with the local community, Michigan legislature, and the Michigan Economic Development Corp. (MEDC).

Norcross, Ga.

www.deutz.com info@deutz.com

POWER RANGE

DIESEL: 25 to 831 hp

GASOLINE: 48 to 72 hp

GASEOUS FUEL: 34 to 295 hp

Under the banner “We ensure the world keeps moving,” Deutz used its Bauma 2025 stand to showcase its system solutions including engines powered by a variety of fuels as well as hybrids and fully electric drives.

In the engine category, the company’s TCD 3.9/4.0 diesel was developed to offer customers in the off-highway segment a “powerful and reliable solution that can cope with the most challenging conditions.” It has a power range of 75 to 129.4 kW, and the company said options make it modular and suitable for a wide range of applications. The engine is made at the Deutz factory in Cologne-Porz, Germany.

The Deutz New Technology segment has developed a hydrogen-powered series production engine. The company said the TCG 7.8 H2 is the first hydrogen combustion engine to be EU Stage V certified.

Late in 2024, Deutz acquired 50% of HJS Emission Technology, a German exhaust aftertreatment specialist with experience in the development of systems for exhaust gas aftertreatment, particularly with diesel engines. The purchase is part of a consolidation plan for the production of internal combustion engines at Deutz, which

will now see it supplied with emissions control technology from within its own group.

Blackwood, N.J.

www.edi-dist.com

POWER RANGE

DIESEL: 25 to 250 hp

GASEOUS FUEL: 25 to 250 hp

Beloit, Wis.

www.FairbanksMorseDefense.com

POWER RANGE

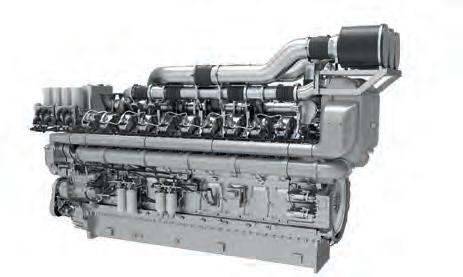

DIESEL: 764 to 19,200 hp

GASEOUS FUEL: 1,566 to 3,628 hp

Fairbanks Morse Defense (FMD) was awarded a contract by General Dynamics NASSCO to build and deliver the main propulsion diesel engines for the Military Sealift Command’s future USNS Dolores Huerta, the 10th vessel in the John Lewis-class of fleet replenishment oilers. The ships can carry 162,000 barrels of oil, providing fuel to the U.S. Navy’s carrier strike groups.

The vessel will be powered by two V12 48/60 CR main propulsion engines and two 7 L 32/44 CR service diesel engines, all manufactured at FMD’s Wisconsin facility. Each engine will use a common rail fuel injection system. Engine delivery for the USNS Dolores Huerta is

New Holland, Pa. fptindustrial.com

fpt-na@fptindustrial.com

POWER RANGE

DIESEL: 31 to 600 hp

FPT Industrial introduced the R24 generator drive engine during PowerGen 2025. The 2.4 L engine platform is available in naturally aspirated or turbocharged models, covering power outputs from 16 kWe to 32 kWe. The company has integrated the engine, radiator and air filter into a compact package for prime and standby power applications.

Stauffer Diesel, an engine distributor in Ephrata, Pa., is expanding its offering of FPT Industrial marine engines into the northeastern United States, including the NEF and Cursor series. The NEF series, used in commercial and pleasure vessels, is available in 4.5 and 6.7 L in mechanical and electronic versions. The Cursor series offers 9 and 16 L engines for commercial applications.

The company also signed ADR Power Systems, Tampa, Fla., to provide marine engine distribution throughout Florida, Georgia, North Carolina, South Carolina and Virginia.

Waukesha, Wis. www.hatzamericas.com

POWER RANGE

DIESEL: 2 to 74 hp

Hatz said the new F-Series engine is suitable for stationary applications, compact machines and vehicles. The variable speed engines are also available in fan-to-flywheel and open power unit (OPU) configurations. The engine has a maintenance interval of 250 hours and the ability to operate in -4°F without additional starting aids.

With displacements of 0.95 L, 1.1 L, 1.3 L and 1.75 L, the company said the F-Series engines are a solution for a wide variety of drive systems.

A total of 11 different engine models are available in the F-Series globally (including versions that meet EPA Tier 4 Final and EU Stage V regulations), giving customers the optimum power output from 10 to 24.6 hp and torque from 48 to 76 Nm for different applications. The engines meet the requirements of EU Stage V and EPA Tier 4 final without exhaust aftertreatment.

New engine ratings:

■ 3F45E VS – 24.8 hp / 2,500 rpm, EPA Tier 4 Final

■ 3F35E VS – 24.8 hp / 3,000 rpm, EPA Tier 4 Final

■ 4F45E CS – 24.8 hp / 1,800 rpm, EPA Tier 4 Final

■ 3F45E VS – 21.4 hp / 1,800 rpm, EPA Tier 4 Final

■ 3F35E CS – 14.7 hp / 1,800 rpm, EPA Tier 4 Final

Hatz said its performance-tracking telematics will provide customers with structured information about equipment and can help improve profitability, uptime and efficiency. The system features the real-time transfer of engine operating status, over-the-air updates and potential remote diagnostics. Remote diagnostics and over-the-air updates are available only on the Hatz E1 and H50 engines.

Seongnam, South Korea enginesales@hd.com www.hd-hyundaiengine.com

POWER RANGE

DIESEL: 36 to 1,334 hp

GASEOUS FUEL: 54 to 697 hp FPT Industrial’s R24 engine. PHOTO: FPT

HD Hyundai Infracore (HDI) is set to unveil its new power generation engine, the DX15, this summer. Based on a 15.1 L, V-type and eight-cylinder configuration, the DX15 will have a power output range of 457 to 662 kWm and comply with unregulated, EPA Tier 2 and Tier 3 emission standards, making it suitable for a wide range of global markets.

Despite its compact design, the company said the DX15 will offer high performance and exceptional power density (43.8 kW/L at 60 Hz). It is also compatible with eco-friendly fuels such as HVO and GTL (gas-to-liquid) and can operate for up to 500 hours without oil replenishment.

Earlier in March, a marine engine based on the same DX15 platform was launched, delivering 551 to 870 hp of power while meeting IMO Tier 2, Tier 3, and EPA Tier 3 regulations.

HD Hyundai Infracore also launched its new DM03HP engine for power generation. This 3.4 L inline fourcylinder diesel engine complies with EU Stage V emission regulations and delivers 92 to 113 kWm, which the company said makes it a very compact engine for the 100 kVA mobile generator class.

The DM03HP is based on the proven DM03 engine platform, with optimized development leading to approximately a 25% increase in output. It supports ecofriendly fuels such as HVO and GTL, offering environmental sustainability and operational flexibility. The engine has an extended oil change interval of up to 1,000 hours.

Additionally, the DM02HP, which meets the EU Stage V emission standard and is also scheduled for release this summer, maintains the displacement of the existing DM02 engine while delivering enhanced performance.

Honda introduced two new engine design concepts at World of Concrete in 2025, including this iGX430 singlecylinder gasoline engine.

said the new iGX models will offer a standardized method for communication across ECUs. The iGX400 and iGX430 engines will have a control panel with an LED indicator that informs the user about potential problems with diagnostic trouble codes.

(American Honda Motor Co.) Alpharetta, Ga. engines.honda.com

GASOLINE: 1 to 24.8 hp

Honda showcased two new gasoline engines during January’s 2025 World of Concrete trade show in Las Vegas. Unveiled as design concepts, the Honda iGX400 and the Honda iGX430 are horizontal-shaft, single-cylinder engines equipped with smart fuel injection technology and an integrated electronic self-tuning regulator (STR) governor that delivers drive-by-wire remote control capability to manage engine operation.

“We have been committed to the engine business for a long time, especially with our GX lineup, which came about in 1983, and we’ve slowly evolved our products over time,” said Tyler Ricketts, assistant manager, Honda Engines, and application engineering, American Honda Motor Co. Inc. “The GX has been a really good product, and our customers are very happy with that line. Based on feedback from our customers and through our own research, a gap was revealed in our current lineup. We found that there was demand for an intermediate power range and combined with the growing need to include advanced technology, we developed the iGX400 and iGX430.”

Through the adoption of a J1939 CANbus, the company

The new iGX engines will have a higher power output and torque in a design comparable to the compact footprints of other Honda engines. While development continues, the target power output for the iGX430 is around 9.5 kW, with the iGX400 slightly less. The design compatibility minimizes changing time, making it easy for the OEM or an end-user to install the new models when older engines reach the end of their service lives. The design also allows manufacturers flexibility with current tooling and frames, said the company.

Fuel injection technology improves operating efficiencies, eliminates the engine choke, reduces fuel-associated carburetor issues, and provides easier, smoother starting after extended storage. The proven Honda Self-Tuning Regulator (STR) governor, available on a single-cylinder engine for the first time in the new models, minimizes engine rpm droop by electronically regulating the throttle opening.

The design concept behind the iGX400 and iGX430 engines is expected to offer commercial customers versatile power and greater adaptability. Potential applications for the new engines include power screeds, hydraulic power units, concrete saws, ride-on concrete trowels, vibratory rollers, generators and pressure washers.

“One of the reasons why drive-by-wire is such a benefit in this size of engine is because it allows manufacturers to place the engine in an optimal location,” said Ricketts. “Both for manufacturing and for the finished product, engineers can move the engine somewhere that fits the design but where the controls might not be as accessible.

“Hydraulic power packs, for example, are often put on large pieces of equipment, such as a truck or trailer, and by having the drive-by-wire functionality, we can put the controls inside the cab of the truck or somewhere on the trailer such as part of a control station. With this technology, we can control everything, not just the throttle. We can set up the computer for multiple ways of controlling the engine.”

Honda first gave its compact gasoline engines an integrated ECU when it introduced the iGX general purpose engine in 2005. In 2019, the company integrated ECU architecture and fuel injection technology into new models with the iGX700 and iGX800. The new iGX design concept brings the technology to smaller single-cylinder engine models.

“These concept engines make the statement that we’re here to stay,” said Ricketts. “We’re putting resources into the engine business — and we never stopped. A lot of customers rely on our engines for their livelihoods. Our GX engines mean a lot to us, and we are continually evolving, not only for regulations but to bring technology into the engine business that benefits our customers.”

Jenbach, Austria

www.innio.com

POWER RANGE

JENBACHER (GASEOUS):

335 to 14,215 hp

WAUKESHA (GASEOUS):

335 to 5,000 hp

Innio Group is expanding its production capacity with about 4,000 sq.m. of space at a new site in the town of Hall in Tirol, Austria. The facility will manufacture cylinder liners, valvetrain components and general parts for Jenbacher engines. The company said operations are set to begin in the fourth quarter 2025 with completion scheduled for 2026. An additional expansion is planned for 2029. Innio said a key driver behind the

expansion is artificial intelligence, which presents new challenges to global energy systems. Public power grids are often unable to meet the massive power demands needed to operate AI data centers, said the company, and that fact underscores the importance of scalable, decentralized power plants for independent energy supply.

Plymouth, Mich.

www.isuzuengines.com

POWER RANGE

DIESEL: 11.8 to 512 hp

In 2025, Isuzu Motors is marking 50 years of powering the U.S. market with diesel engines that have been the heart of off-road industrial equipment across countless industries.

Isuzu said its engines are designed with reliability and efficiency at their core. Whether it is the compact three-cylinder 3C-Series, the versatile 4L- and 4J-Series, or the heavy-duty 6U- and 6W-Series, each engine is built with advanced fuel systems, robust construction and compact packaging.

The company’s latest 4J-Series power unit features packaging improvements including a shallow oil pan and lowermounted air cleaner for a reduced overall footprint – height, length, and width – comparable to its 4L-series power units, but with more horsepower. A new radiator package allows for enclosure flexibility, which the company said makes

it easier to integrate into existing designs. The company also offers pre-validated gen-set power units that are 100% tested on specific models and over 90% validated on optional configurations. New in 2025, available in the 4LE2T (40.2 hp @ 1,800 rpm) and 4LE2X (66 hp @ 1,800 rpm), the company said the units save engineering time, reduce startup costs and ensure reliable operation under constant-speed rpm demands.

Along with its Isuzu REDTech Tough Series and Tough Series Pro control panels, the company has introduced a new, lower-cost Tough Series controller designed for broad engine and machine compatibility. The plug-and-play solution supports 12V and 24V systems and includes pre-validated base engine controller software. With remote monitoring capabilities, telematics readiness, and expandable I/O, the company said it offers performance and flexibility for current and future needs

JCB POWER SYSTEMS LTD. Derbyshire, England www.jcb.com

DIESEL: 74 to 285 hp

As part of its net zero program, JCB has pioneered the development of hydrogen internal combustion engines for use in construction and agricultural machines. JCB’s engineers designed an engine especially for hydrogen, taking advantage of the properties of the zero CO2 fuel. >

JCB’s hydrogen engines have surpassed 22,500 hours in

SMALL INDUSTRIAL ENGINES 5 kW-66 kW

LARGE INDUSTRIAL ENGINES 600 kW-2000 kW

GAS ENGINES 450 kW-2000 kW

The result, said the company, is an engine that can deliver the same power, torque and performance as the existing diesel engine, but without the carbon or air quality emissions.

The company said its team has made significant strides in perfecting hydrogen combustion engine technology, with the engines having now surpassed 22,500 hours in test cells, and machines having achieved over 30,000 hours of testing and 25,000 km on the road. Moreover, in a first of its kind, JCB’s hydrogen engine has achieved Stage V type approval certification in the EU and UK. JCB worked closely with the Department for Transport to secure an amendment to UK road transport legislation to permit hydrogen-powered machines to drive on UK roads.

Waterloo, Iowa www.deere.com/en/engines-anddrivetrain

POWER RANGE

DIESEL: 48 to 908 hp

John Deere Power Systems (JDPS) said it is embracing a new era in power by investing across a broad spectrum of technologies to meet the evolving needs of its customers and contribute to a more sustainable and efficient future. Recognizing that multiple powertrain technologies will coexist, JDPS is optimizing its traditional internal combustion engines while actively exploring the potential of electrification and renewable fuels. Recognizing the role of internal combustion engines in powering large, heavy-duty equipment, JDPS is focused on delivering adaptable

and reliable power solutions through its engine lineup. The clean-sheet-designed JD4, JD14 and JD18 engines were engineered to power the off-highway industry into the future.

The latest addition is the JD4 engine rated 173 hp (129 kW) and 516 lb.-ft. (700 Nm) of maximum torque. It has a more dependable DEF delivery system, extended fluid service intervals up to 750 hours, and hydraulic lash adjusters. The engine has a 20% to 25% smaller package size and a more than 110 lb weight reduction compared to the John Deere 4.5L PWS or PWL single turbo base engine.

JDPS has also enhanced its current offerings, such as the JD9 engine, which builds on the existing PSS 9.0 L engine. The JD9 expands the company’s 9.0 L lineup by stretching the maximum power output up to 460 hp (343 kW) and peak torque up to 1,389 lb.-ft. (1883 Nm).

The engines are compatible with renewable diesel fuel and biodiesel blends. These engines also come standard with John Deere Connected Support, offering remote diagnostics to maximize uptime without subscription fees.

John Deere said it is monitoring renewable fuels and assessing geographic considerations in addition to customer power needs. By analyzing regional application differences and how they impact the adoption of renewable fuels and hybrid- and battery-electric solutions, JDPS said it is tailoring its offerings to better serve its global customers. Current John Deere engines can utilize 100% renewable

diesel and various blends of biodiesel. Earlier this year, JDPS also added to its marine engine lineup. The JD14 marine engine for various workboat and pleasure craft applications is a 13.6 L, six-cylinder engine with an anticipated power range from 400 up to 803 hp (298 up to 599 kW). The JD18 marine engine is designed for customers in commercial fishing, passenger vessel and tugboat markets with its 18 L displacement and anticipated power levels from 550 up to 803 hp (410 up to 599 kW). The JD14 and JD18 marine engines will be IMO Tier 2, EPA Tier 3, and EU RCD II certified.

Menomonee Falls, Wis. https://k5power.com

POWER RANGE

GASEOUS FUEL: 35 to 44 hp

K5 Power distributes engines made by Cooper Corp. Pvt. Ltd. Based in India, Cooper manufactures millions of cylinder liners a year for a long list of engine makers and it also manufactures and sells air- and water-cooled engines. Vertically integrated with foundry and machine work completed onsite, Cooper builds its engines in a dedicated facility. K5 will lead with Cooper’s 1.2 L twocylinder engine, a water-cooled, natural gas, turbocharged version rated 35 hp at 1,800 rpm. The company also said it has had “significant interest” in Cooper’s single- and twin-cylinder air-cooled engines for industrial applications. The 1.2 L engine is used in Cooper’s 22 kVA standby natural gas generator, about which K5 Power said the first shipments were expected to hit the market in Houston, Texas, this summer.

Grand Rapids, Mich.

kawasakienginesusa.com

POWER RANGE

Magnolia, Texas

www.kirloskaramericas.com

POWER RANGE

DIESEL (Tier 4 Final, stationary): 15.7 to 23.5 hp

DIESEL (Tier 3 emergency stationary): 48.7 to 156 hp

Kirloskar Americas Corp. is a 100% owned subsidiary of Kirloskar Oil Engines. It was established in 2015 to cater to the United States, Canada and Latin American regions.

The current Kirloskar product line in North America includes:

EPA Tier 4 Final:

■ 2R550 rated 15.7 hp @ 1800 rpmsuitable for 10 kWe gen-set

■ 3R550 rated 23.5 hp @ 1800 rpmsuitable for 15 kWe gen-set

EPA Tier 3 emergency stationary generator set applications:

■ 4R810NA1 rated 48.7 hp @ 1800 rpm suitable for 30 kWe

■ 4R810TA2 rated 65 hp @ 1800 rpm suitable for 40 kWe

■ 4R810TA1 rated 95 hp @ 1800 rpm suitable for 60kWe

■ 4K1080TA1 rated 156 hp @ 1800 rpm suitable for 100kWe

Non-regulated / India CPCB-4+ range: 15 to 1760 hp

Looking toward the future, Kirloskar Americas said its U.S. EPA Tier 4 Final and CARB certified variable speed engines are planned for release in 2026 and will be in the range of 25 to 75 hp. The engines will be 1.65 L and 2.2 L capacities in naturally aspirated and turbocharged-aftercooled versions with an aftertreatment comprised of an EGR and DOC.

Lincolnshire, Ill.

www.kubotaengine.com

kea g.contactus@kubota.com

DIESEL: 6 to 210 hp

GASOLINE: 33 to 87 hp

GASEOUS FUEL: 30 to 94 hp

In March, the Performance Review Institute (PRI) Registrar recognized Kubota Engine America Corp. for having met the requirements of the ISO 9001:2015 international standard and its dedication to continuous improvement of its management system.

“This is a significant milestone that underscores Kubota’s commitment to quality and excellence in our operations,” said Yoshiharu Yamaguchi, KEA president. “This certification demonstrates our adherence to internationally recognized standards, ensuring that we consistently meet customer expectations and regulatory requirements. By implementing robust quality management systems, we are dedicated to continuous improvement and delivering superior products and services to our customers.”

In other news, Kubota Engine America added MarIndustrial Inc. and DAC Industrial Engines Inc. as distributors of its engines, generators and parts in eastern Canada. With its headquarters in Montreal, Quebec, and additional locations in Mississauga, Ontario, and Moncton, New Brunswick, Kubota said MarIndustrial is well positioned to serve the needs of the region.

As part of the MarIndustrial corporate group, DAC Industrial Engines Inc. will

Liebherr D9612 engine.

serve as a distributor for the Atlantic Canada provinces. Based in Dartmouth, Nova Scotia, DAC specializes in the overhaul and service of industrial diesel engines with factory-trained technicians and well-stocked facilities.

Bulle, Switzerland

www.liebherr.com/engines

POWER RANGE

DIESEL: 188 to 5,753 hp

At Bauma 2025, Liebherr showed a new D9612 engine rated 950 kW that it said is suited for applications in agriculture, industry and construction. The company also showed an ammonia engine concept for dual-fuel internal combustion engines. The company said green ammonia serves as a hydrogen carrier, offering the benefits of reduced transportation and storage costs.

LISTER PETTER

Gloucestershire, England www.listerpetter.com

POWER RANGE

DIESEL: 7 to 1,287 hp

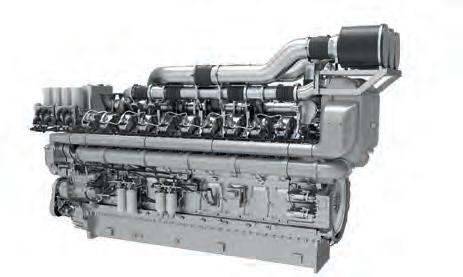

Augsburg, Germany www.man-es.com

POWER RANGE

DIESEL: 671 to 110,554 hp

GASEOUS: 4,104 to 110,554 hp

DUAL FUEL: 625 to 110,554 hp

India’s Hindustan Shipyard Ltd. awarded MAN Energy Solutions a contract for the >

supply of the main propulsion packages for five newbuild Fleet Support Ships (FSS) for the Indian Navy. The order consists of ten 20V32/44CR marine engines and main reduction gearboxes, shaft generators and bow thrusters. The FSS is a new class of replenishment vessels for the Indian Navy.

With a power ouput of 12 MW per engine, the company said the V20 32/44CR will be the largest MAN fourstroke marine engine delivered to the Indian Navy during a relationship that spans more than 50 years.

In addition, MAN Energy Solutions reported that since its debut in 2014, the two-stroke MAN B&W dual-fuel MEGI marine engine is closing in on 1,000 orders, with the strongest interest coming from the container segment with more than 400 engines ordered, followed by gas and liquid tanker vessels (225-plus) and car and truck carriers (175-plus).

MAN Engines

Munich, Germany www.man-engines.com info@man-engines.com

POWER RANGE

DIESEL: 110 to 2,200 hp

GASEOUS FUEL: 67 to 986 hp

MAN Engines, a business unit of MAN Truck & Bus, showed its proven 24 L MAN D2862 for construction

machinery and mining vehicles at Bauma 2025. The V12 engine has been used in a variety of applications on the water, in the field and on rails.

“We not only offer our customers the robust and reliable MAN engines with excellent power density,” said Hubert Gossner, head of Off-Road/Power of the MAN Engines business unit. “Rather, our experienced integration specialists adapt these engines to the requirements of the respective application. In this way, they create added value and a unique selling point for our customers.”

For construction machinery, MAN Engines focuses on power ranges between 394 and 1,094 hp (294 and 816 kW), with a displacement of 9 to 30 L.

At EnergyDecentral 2024 in Hanover, Germany, MAN showed the E3268, a V8 gas engine. The company said an update to the cylinder head increased the robustness of the engine. The engine series also includes the V12 E3262.

Itasca, Ill. www.mtea-us.com

DIESEL (industrial): 6.2 to 88.5 hp, 898 to 2,923 hp

DIESEL (marine): 429 to 2,809 hp

GASEOUS: 603 to 2,682 hp

Mitsubishi introduced a 16-cylinder natural gas engine (G16NB) which provides an electrical efficiency of 44.3%, which it said is the highest for a 2,000 kW-class engine. This efficiency was achieved via new approaches such as

steel pistons for increased maximum cylinder pressure and optimum control of ignition timing for each cylinder. This new engine expands the power range of its natural gas lineup (450 kW to 1,500 kW), making it ideal for applications such as cogeneration systems, and a bridge power solution for data centers and microgrids.

Mitsubishi also continued to offer its small industrial diesel engine lineup of 5 kW to 66 kW. For this year, it is introducing three new engines to the L3E family: 15.0 kW (20.1 hp) at 2,900 rpm, 17.0 kW (22.8 hp) at 3,000 rpm and 18.4 kW (27.4 hp) at 3,000 rpm. All three engines meet U.S. EPA Tier 4 Final and are suitable for variable speed off-highway applications.

Mitsubishi Marine Engine Div. also launched to the U.S. market two new ratings as part of the S12R engine family: S12R-Y3MPTAW-5 rated 1,350 hp @ 1,800 rpm and S12R-Y3MPTAW-7 rated 1,350 hp @ 1,600 rpm. The product release is an effort by Mitsubishi to help operators looking for options to help them extend the life of their vessels.

For the Canadian marine market, Mitsubishi Marine Engines offers an IMO III-compliant lineup ranging from 434 hp to 2,528 hp, with heavyduty, medium-duty, and light-duty ratings available. The lineup is fully mechanical and incorporates a selective catalytic reduction (SCR) system to meet IMO III emissions standards and it’s currently available through its network of authorized Canadian distributors.

Beginning in early 2025, a collaboration established Ancora Chile as Mitsubishi’s authorized dealer in Chile, offering the complete range of Mitsubishi marine engines.

This partnership was said to reinforce Mitsubishi’s and Ancora Chile’s commitment to customer satisfaction, providing top-tier solutions to keep vessels operating at peak performance. Mitsubishi said the collaboration is part of a long-term investment in the region.

Seattle, Wash.

www.northern-lights.com info@northern-lights.com

POWER RANGE

DIESEL: 174 to 425 hp

Lugger marine propulsion diesel engines are available in two series: the L4105 four-cylinder and the L6105 six cylinder. The L4105 has a horsepower rating of 174 to 300 and the L6105 has a rating of 255 to 425 hp.

The Lugger engine uses individual cylinder heads, a forged crankshaft and replaceable wet liners. Both engines can be spec’ed to meet requirements in continuous duty, medium duty, high output and pleasure craft applications.

Kearney, Neb.

www.OriginEngines.com info@OriginEngines.com

POWER RANGE

GASEOUS FUEL: 35 to 750 hp

GASOLINE: 35 to 174 hp

Origin Engines has announced the addition of certified prime power ratings to its full range of power generation engines. These new EPA-certified ratings enhance the company’s established lineup, which already includes emergency and standby power ratings ranging from 20 kWe to 525 kWe. This expansion reflects Origin’s commitment to meeting evolving customer needs and regulatory standards in both continuous and backup power applications.

The company’s engine portfolio includes displacements of 3.6 L, 4.3 L, 5.7 L, 6.2 L, 8.0 L, 9.1 L, 10.3 L, 15.9 L, 19.9 L and 23.9 L. The engines are available in naturally aspirated and turbocharged variants, and can operate on a variety of fuels including gasoline, liquid propane (LP), natural gas and wellhead gas. Origin said they are highly versatile for different power environments and fuel availability.

All of the company’s engines are engineered and manufactured in the United States, which it said not only ensures a high-quality design tailored for demanding industrial applications, but also offers a significant advantage in today’s tariff climate.

Origin Engines said its engines are trusted across a wide range of sectors, such as prime and standby power generation, oil and gas production equipment, agricultural irrigation pumps, forestry equipment and industrial power units.

With its latest certification milestone, Origin Engines said it has continued to position itself as a reliable and flexible power solutions provider for industries requiring rugged, emissions-compliant performance.

Origin Engines offers engineering and manufacturing capabilities as part of its partnerships with OEMs, and said it offers reliability and consistency when it comes to engine design, manufacturing capacity and production lifespan.

Peterborough, England www.perkins.com

POWER RANGE

DIESEL: 12 to 2,582 hp

With expected availability in 2026, the 13 L Perkins 2600 Series engine platform is designed for off-road applications. The engine platform is offered in eight power ratings from 340 to 515 kW (456 to 690 hp)

offering up to 3,200 Nm of peak torque. Perkins also introduced a 106 kW variant of the 904 Series platform. With a 6% power uplift from the previous model and a 3% increase in torque, the Perkins 904J-E36TA has been fitted with a new 12 plate oil cooler to improve the durability and reliability while highefficiency fuel filters improve altitude capability. The engine meets EU Stage V, U.S. EPA Tier 4 Final and Japan 2014 emissions standards.

Wood Dale, Ill. www.psiengines.com

POWER RANGE

DIESEL: 33 to 4291 hp

GASOLINE: 34 to 295 hp

GASEOUS FUEL: 34 to 1609 hp

Power Solutions International (PSI) has entered into multiple agreements with South Korea-based HD Hyundai Infracore (HDI) to develop its compact diesel engines for spark-ignited LPG and gasoline, as well as market its diesel engine range in North America. The company said HDI’s products, which include 1.8 L, 2.4 L, 3.4 L, 5.0 : and 7.5 L engines, complement its existing line of products >

Isuzu REDTech™ is the driving force behind reliable, eco-friendly, durable and technologically advanced engines that power the offroad industrial agricultural, construction, medical and rental markets. Our engines provide clean, quiet and fuel-efficient performance.

3C SERIES

.99–1.6L 11.8–23.2HP 8.8–17.3kW

4L SERIES

6H SERIES

4J SERIES

6U SERIES

4H SERIES

6W SERIES

389–512HP

290–382kW

Engineered for seamless integration, our Power Units include air intake and exhaust gas aftertreatment systems, along with engine control modules. Paired with our Diagnostic Service Tool and training programs, Isuzu ensures efficient troubleshooting and enduring performance through our Distributor Network and genuine parts.

STANDARD | CUSTOMIZED | PRE-VALIDATED

Learn more about our full range of Isuzu Diesel Engines, Power Units, genuine parts, diagnostic tools, training & support, dedicated service network and our industry-leading warranty at IsuzuEngines.com

Learn more about our full range of Isuzu Diesel Engines, Power Units, genuine parts, diagnostic tools, training & support, dedicated service network and our industry-leading warranty at IsuzuEngines.com

for the industrial and power generation end markets, and provide customers with alternatives for U.S. EPA Tier 4 Final and EU Stage V diesel engine needs. PSI said it will support the engines through its existing parts and service networks, supplemented by HDI distributors.

In 2025, PSI will release its recently developed GM LS-based 6.0 L engine for industrial markets to operate on LPG and natural gas, which will complement its previously released gasoline product. This engine offering is mainly targeted at stationary applications such as oil and gas, wind machines and irrigation applications.

In addition, this past year PSI introduced its new 110 L diesel engine for large-scale power generation applications. The engine has an emergency standby power rating of 4,250 kWe/4,550 kWm and an EPA Tier 2 emissions certificate.

PSI recently launched a new online aftermarket parts platform, replacing the first-generation online store. The company said the new website offers a modern, user-friendly interface with pictures of parts, an on-line shopping cart feature, the ability to one-click repeating stock orders and more.

PSI will merge the updated interactive parts catalog later this year with the store,

which it said will provide exploded views of engines and parts, driven by engine serial number.

www.engines.rehlko.com

POWER RANGE

DIESEL: 4.5 to 141 hp

GASEOUS: 9.5 to 25 hp

GASOLINE: 4.5 to 38 hp

During Bauma 2025 in Munich, Germany, Rehlko showed the new highpower version of the KDI 1903TCR, a next-generation diesel engine that it said was designed to “redefine performance in compact applications.” Rehlko said the new model offers a 50 kW (67 hp) output and 250 Nm (184 lb.-ft.) of torque in a compact footprint.

The engine’s design reportedly ensures maximum installation flexibility, which Rehlko said makes it ideal for a wide range of equipment in construction, agriculture and material handling applications.

The new KDI 1903TCR engine has a sophisticated aftertreatment system, featuring a diesel particulate filter (DPF) that provides efficient automatic regeneration, even at low engine speeds. The engine is engineered for operation on HVO fuel, allowing a lifecycle emissions reduction of up to 90% over standard diesel fuel without sacrificing performance or maintenance intervals. Rehlko said it has focused on serviceability by providing one-side service access and oil change intervals at 500 hours. Further customization is available, Rehlko said, with options for flywheels, oil pans and other components.

The Rehlko name, created by stirring up the letters in “Kohler,” was introduced in September 2024 to represent the newly independent business that was created from Kohler Power Systems and Kohler Engines and includes the brands

Clarke Energy, Curtis Instruments and Heila Technologies. Also shown during the German trade fair was the company’s new look. Rehlko Light Gray has replaced Kohler’s traditional bronze.

Friedrichshafen, Germany www.mtu-solutions.com

POWER RANGE

DIESEL: 50 to 13,410 hp

GASEOUS: 174 to 3,486 hp

Following record investments in 2024, Rolls-Royce Power Systems said it will continue to invest in the development of new products and the expansion of production capacities. This includes the development of a new MTU engine platform, which the company said will be ready for series production in the medium term. It said it will have more than 20% more power when compared to a current model of the same size. Substantial investments have been made in a new building for the assembly of gen-sets in Mankato, Minn., and in the expansion of the engine plant in Aiken, S.C. The investment is expected to help it meet the needs for energy supply for data centers. Other major investments are being channeled into the expansion of production capacity in Friedrichshafen, Germany.

San Antonio, Texas www.scaniausa.com

POWER RANGE

DIESEL (industrial): 275 to 770 hp

DIESEL (marine): 350 to 1,050 hp

DIESEL (prime power generation): 260 to 500 kVA

The North American debut of Scania’s Next Generation inline engine platform took place at World of Concrete in January, where the company displayed its new 13 L DC13 engine. The 13 L engine has a power range from 275 hp (202 kW) to 612 hp (450 kW) and reportedly delivers up to 11% more power and 21% more torque than the company’s current engines. The new platform also includes an 11 L engine with a power range from 275 hp (202 kW) to 500 hp (368 kW).

Torque for the DC13 is close to 2,215 lb.-ft. (3,003 Nm). While the engine displayed on the company’s stand in the Las Vegas Convention Center was designed for industrial applications, a power generation engine will also be available.

“Our mindset throughout the development of the new platform,” said Henrik Nilsson, Scania’s director of Product Management, Power Solutions, “has been to ease the transition for our customers while positively impacting fuel efficiency and product performance.”

While maintaining Scania’s modular design philosophy, some of the features of the new engine line include more precise cooling and a more rigid engine

block and single cylinder head. The new engines also get a diesel particulate filter (DPF).

“This is our most fuel-efficient engine ever, with more torque, more power and up to 50% longer base engine lifespan. A game-changer for power solutions,” said Jorg Franzke, President, Scania USA. The enhanced gas exchange system, reduced internal friction, and increased turbocharger efficiency all have a positive impact on the fuel efficiency.

For the 13 L engine, this means up to 7% improvement in fuel consumption compared to the current generation at the same power output. That translates to 4 L [about 1 gal.] of diesel saved per engine hour at full load.

World of Concrete was the North American introduction of the U.S. EPA Tier 4 final version of the company’s Next Generation engines, which were first shown at the 2022 Bauma trade show in Munich, Germany. Prior to that event, the engine was proven in Scania’s trucks for several years. For North America, series production of the New Generation engines begins in Sweden this year.

“There were global challenges that made us think about this Next Generation engine line, such as reducing CO2 emissions and driving the shift towards sustainable transport and sustainable power solutions,” said Andres Tomas Kohring, sales Top of Formmanager, Scania USA. “These new engines are our way of helping customers improve their emissions. With a 7% reduction in fuel consumption compared to our previous engines, that’s a way of being more sustainable. The new platform is also HVO capable.

“We wanted to make the transition to our next generation engines as easy as possible for the OEMs, so this engine will fit in the same footprint as our previous platform. This engine platform was designed with consideration for both current and future emissions regulations.”

The new 11 L and 13 L engines are dual certified for EU Stage V and U.S. EPA Tier 4 Final and will meet Korean Tier 5 and China Stage IV. There are also versions for lesser and unregulated

emission countries.

“One benefit to us making engines for on-highway and off-highway is that we can use the components and experience from all of the applications to build the products that the customer needs,” said Kohring. “We found that the compression release brake that we have for the trucks today is a really good fit for wheeled industrial applications. Now we have this engine brake as an option for industrial engines and we can help our customers improve their braking performance.”

For marine applications, Scania showed its new 13 L DI13 marine engine developed for propulsion and auxiliary use at the international maritime industry trade fair SMM in Hamburg, Germany, in September 2024.

Based on the new generation platform, the company said the new engine is fit for a wide range of applications, including downsizing from higher-size alternatives. The engine complies with current IMO Tier III emission standards and is compatible with biodiesel blends and HVO fuels. The new marine propulsion engine has a power range of 350 to 1,050 hp (257 to 772 kW) for IMO II and IMO Tier III, and 350 to 950 hp for US EPA Tier 3.

Chesapeake, Va. www.volvopenta.com/en-us/

DIESEL (off-highway): 143 to 796 hp

DIESEL (power gen): 217 to 975 hp

DIESEL (commercial marine): 12.2 to 1,350 hp

As the energy transition evolves, Volvo Penta said high-efficiency combustion engines will remain crucial for offhighway and power generation applications. The company is committed to the industry’s path to net zero, supporting renewable fuels such as HVO while advancing hydrogen dual-fuel technology as well as the use of batteries in a wide range of applications. >

Mobile versions of the company’s battery electric storage system (BESS) shown at Bauma in Germany can be used to charge electric or electrified machines on a work site. These can be recharged when needed at a remote location and returned to support machine charging. Larger permanent installations using multiple units can be used as backup power for critical infrastructure, including data centers.

The integration-ready BESS features battery packs already used in off- and onhighway applications, meaning that it is already certified for transportation.

In recent application news, the company said its D5 U.S. EPA Tier 4 Final/Stage V dual-certification offroad diesel engine will power J&S Manufacturing’s entire portfolio of equipment for mining applications in North America. The engines have already been installed in a boom truck and scissor lift trucks used in underground mines in Northern Ontario, and more Volvo Penta-powered utility vehicles will follow. The engines will be supported by Wajax, Volvo Penta’s distribution partner based in Ontario, Canada.

Volvo Penta said its engines are optimized for mining applications and certified by the Mine Safety and Health Administration (MSHA) and CanmetMining. The D5 has service intervals of up to 1,000 hours and the company said all of its engines are designed based on the same platform, which simplifies everything from installation to service and the acquisition of spare parts.

In its marine business, Volvo Penta announced an expanded three-year global warranty with terms for commercial marine operators measured by years or total operational hours, whichever comes first. This new warranty applies to products delivered from 2025

onward and covers Volvo Penta branded transmissions, engines, control systems and accessories.

WABTEC CORP.

Pittsburgh, Pa.

www.wabteccorp.com

POWER RANGE

DIESEL: 2,008 to 6,933 hp

DUAL FUEL: 4,103 to 4,499 hp

Helsinki, Finland

www.wartsila.com

POWER RANGE

DIESEL: 1,004 to 27,893 hp

GASEOUS: 939 to 28,966 hp

DUAL FUEL: 939 to 28,966 hp

Wärtsilä said it will expand its technology center, Sustainable Technology Hub, with a $56 million (€50 million) investment, a move that is expected to enhance the company’s ability to meet the demand for sustainable technologies in marine and energy and to support fuel applications in the future. The nearly 8,000 sq.m. additon in Vaasa, Finland, is expected to be commissioned in 2028.

“The widely adopted target of reaching net zero in our industries in marine and energy around 2050 is the lifespan of a single vessel or power plant,” said Juha Kytölä, director, R&D and Engineering, Power Supply, Wärtsilä. “Thus, the technology decisions for new assets are being made now. It is therefore crucial for our customers that our solutions are fuel flexible and capable of running on sustainable fuels once these become more broadly available. This new investment in the Sustainable Technology Hub and new R&D testing capabilities will strongly support us in developing engines that can flexibly run on low- and zero-carbon fuels such as ammonia, hydrogen and methanol. These technologies and related services help our

An AGV carries a Wärtsilä engine block inside the company’s Sustainable Technology Hub in Finland.

customers reduce emissions, improve efficiency and lower costs.”

Opened in 2022, the center’s approach to collaboration and innovation involves Wärtsilä experts, customers, technology partners, academia and the surrounding ecosystem.

In other news, for marine applications, the company introduced a methane slip reduction solution for its Wärtsilä 50DF dual-fuel engine. While operating on LNG, the new “Spark Gas Conversion for Wärtsilä 50DF” is designed to reduce methane emissions up to 75% more than the standard 50DF engine. The solution is now available to all vessels with existing 50DF engines for diesel-electric propulsion, the majority of which are LNG carriers.

Adairsville, Ga.

www.yanmar.com

DIESEL: 5 to 208 hp

GASOLINE: 53 hp

GASEOUS FUEL: 60 hp

The newest addition to Yanmar America’s industrial engine lineup is the 4TN86DHT, about which the company said it offers a compact profile and flexible configuration, allowing for easy integration across a variety of OEM equipment. It does not use a diesel particulate filter (DPF), which eliminates the need for active regeneration cycles and reduces maintenance. The company said its streamlined

No Diesel Particulate Filter (DPF) means no active regeneration cycles. Simplified aftertreatment for consistent uptime and low maintenance — especially ideal for intermittent-use equipment and rental fleets.

Compact profile and adaptable configuration make the 4TN86DHT easy to integrate across OEM equipment — perfect for refreshing or diversifying your lineup.

Backed by over a century of Japanese engineering excellence and global service support.

Find your Distributor

Westquip Diesel Sales Ltd

780-960-5560 info@westquip.ca

Cascade Engine Center, LLC

800-238-3850 info@cascadeengine.com

Northstar Power LLC 515-964-6100 kaneytroy@northstarpowerllc.com

Crosspoint Power & Refrigeration 317-981-5027 joe.aschenbener@crosspointpandr.com

Engines, Inc. 870-268-3700 info@enginespower.com

Diesel-Bec, Inc. 450-434-3401 info@diesel-bec.com

McDonald Equipment Company 440-951-8222 r.brainard@mcdonaldequipment.com

M&L Engine 800-960-0068 sales@mlengine.com

Bell Power Systems, Inc. 860-767-7502 matthew.prior@bellpower.com

Mastry Engine Center 727-522-9471 pparrott@mastry.com

aftertreatment system ensures consistent uptime, making it especially valuable for intermittent-use equipment and rental fleets.

In addition to the new engine release, the company said it has continued to elevate its existing 4TN and TNV series engines. The 4TN101 and 4TN107 models deliver up to 155 kW while meeting EU Stage V and U.S. EPATier 4 Final emissions standards. With power density of 34 kW/L (4TN107), peak torque of 805 Nm, and fuel consumption approximately 10% lower than comparable models, the company said their compact designs ease integration into machinery without compromising visibility or comfort, and Yanmar’s proprietary DPF and SCR systems ensure long-term emissions compliance and operational reliability.

Yanmar’s 3TN86CHT and 4TN86CHT engines further extend the company’s high-efficiency offerings. Delivering 20% and 14% more power, respectively, than earlier models with the same displacement, these engines achieve 40.1 kW and 55.4 kW outputs and torque of up to 263 Nm. Enhanced turbocharging, strengthened components, and a compact form factor help OEMs with spatial constraints, said the company. The DPF supports cleaning intervals of up to 6,000 hours.

Yanmar said it has also empowered customers with parts and service support. In the last year, Yanmar has expanded its product catalog on its official parts eCommerce platform at buyyanmar.com. Customers can order Yanmar Genuine Parts directly.

Tomahawk, Wis.

https://zenithpp.com/

POWER RANGE

GASOLINE: 5 to 25 hp

GASEOUS FUEL: 15 to 400 hp

Zenith Power Products has been busy over the past several years. The company moved its headquarters and engine production from Abingdon, Va., to