It is great to have had so many entries submitted for our 2024 ranking of the world’s largest crane-owning companies – the one and only IC100. Thank you to everybody who makes the effort each year to fill in and return an entry form, it is much appreciated and I would say well worth it, in terms of doing your bit to help make a credible ranking table for the industry.

As the IC100 charges towards its third decade, we are continuing to work hard on the endless task of adding new companies and getting more to submit entries more frequently. Whenever I become aware of new likely candidates for inclusion I endeavour to get them in and to start building trend data for the industry.

Likewise, if you own, work for, or know of any companies you think should be in the IC100 please do let me know and feel free to suggest them so we can include them next year. With your help we can build an even bigger and stronger resource from which the entire industry can benefit.

For the results of all this labour see this year’s IC100 table on page 13. It has been an exciting year of change and growth, with an increase in capability of more than 8 per cent over last year, which was also good, at just over 6 %. A fair bit of acquisition activity will have played a part in changes in the table too.

On a related note, I reckon close to half of the predominantly crane rental companies that appear in the IC100 also have a sufficient amount of specialized transport equipment to warrant entering our Transport 50 ranking.

The ICT50 is for owners of specialized trailers, self propelled modular transporter, long load dollies and other equipment for carrying oversize and-or overweight indivisible loads. If you think your company should be on this list please do complete and return an entry form as soon as possible. See the call for entries story in the news on page 6 for more information, or search Transport 50 on our website craneandtransportbriefing.com where you’ll find a link to the story and the T50 entry form.

ALEX DAHM Editor

Correspondence is welcome and should be sent to: The editor, International Cranes and Specialized Transport, Southfields, South View Road, Wadhurst, East Sussex TN5 6TP, UK MEMBER OF

CHINA OFFICE

Beijing Representative Office, Room 769, Poly Plaza, No.14, South Dong Zhi Men Street, Dong Cheng District, Beijing, PR China 100027. +86 10 6553 6676 | cathy.yao@khl.com

USA/CANADA PLUS AUSTRIA/EASTERN EUROPE/ GERMANY/IRELAND/KOREA/RUSSIA/ SPAIN/ SWITZERLAND/UAE

Matt Burk, Vice president sales +1 312 4963314 | matt.burk@khl.com

UK/SCANDINAVIA

John Austin, Marketplace/Classified advertising

+44 (0)1892 786245 | john.austin@khl.com

DACH & IBERIA Simon Battersby +44 1892 786223 | simon.battersby@khl.com

THE NETHERLANDS/LUXEMBOURG

Arthur Schavemaker

+31 (0)547 275005 | arthur@kenter.nl

FRANCE/BELGIUM Hamilton Pearman

+33 (0)1 45930858 | hpearman@wanadoo.fr

ITALY Fabio Potestà +39 010 5704948 | info@mediapointsrl.it

TURKEY Emre Apa

+90 532 2343616 | emre.apa@apayayincilik.com.tr

CHINA Cathy Yao

+86 (0)10 65536676 | cathy.yao@khl.com

JAPAN Michihiro Kawahara

+81 (0)3 32123671 | kawahara@rayden.jp

USA/CANADA Bev O’Dell

+1 816 8861858 | bev.odell@khl.com

VP GLOBAL SALES Alister Williams +1 843 637 4127 | alister.williams@khl.com

Max. Lifting Capacity : 75t x 3.0m

Boom Length : 10.0m to 30.1m

Side Deflection-Resistant Fully Powered Boom for All Lifting Tough 4-plate box boom structure with special welding quality standards, but lightweight

A Superstructure Designed to Take on Tough Jobs

The upper frame is designed to be durable for winch operation with high line pull.

The vertical layout of the main & aux. winches helps achieve a compact design and efficient weight balance.

*Winch

Engine Output

as the official magazine of the

(Specialized Carriers & Rigging Association)

European partner

Approved media partner for:

To subscribe to International Cranes and Specialized Transport or any of the magazines in the KHL portfolio go to: www.khl.com/free-subscription or call +44 (0)1892 784088 for details.

International Cranes and Specialized Transport is a monthly publication with a worldwide circulation. The annual airmail subscription rate is US$301, €258, £215. This issue of International Cranes and Specialized Transport is mailed on 17 June 2024. Material published in International Cranes and Specialized Transport is protected under international copyright law and may not be reproduced without prior permission from the publisher.

International Cranes and Specialized Transport (USPS 017 158) is published monthly by KHL Group and distributed in the US by DSW, 75 Aberdeen Road, Emigsville, PA 17318-0437. Periodicals postage paid at Emigsville, PA. Postmaster: Send address changes to International Cranes and Specialized Transport, c/o PO Box 437, Emigsville, PA 17318-0437.

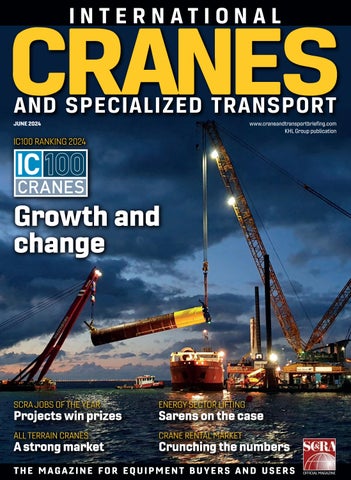

Sarens lifting monopiles at the Fryslân wind farm in the Netherlands, see p30.

EDITOR & EDITORIAL MANAGER Alex Dahm

alex.dahm@khl.com | +44 (0)1892 786206

DEPUTY EDITOR Niamh Marriott niamh.marriott@khl.com | +44 (0)1892 786208

EDITORIAL DIRECTOR Murray Pollok

NEWS WRITER Leila Steed

GROUP EDITORS Lindsey Anderson

Andy Brown, Catrin Jones, D.Ann Shiffler, Leila Steed, Euan Youdale

WORLDWIDE CONTRIBUTORS John Bowman, Australia; Graham Brent, USA; Marco van Daal, Aruba; Heinz-Gert Kessel, Germany; Richard Krabbendam, Netherlands; Tim Maughan, Japan; Brent Stacey, Australia; David Weston, UK

An exciting year with plenty of big changes, almost all universally positive, for ICST's 2024 iteration of the world's largest crane-owning companies. Alex Dahm reports.

Winners of the annual competition for hauling and rigging projects from the last twelve months. American Cranes and Transport reports.

Sarens’ commercial director Yannick Sel discusses what the crane industry needs to meet future energy demand. Niamh Marriott reports.

Focusing on the forecasts for the rental market in different regions shows a patchy but positive landscape. Niamh Marriott reports.

Compact and road-ready, all terrain cranes continue to be used globally on all manner of construction sites. Niamh Marriott reports.

SC&RA CORRESPONDENT Mike Chalmers

SALES MANAGER Matt Burk matt.burk@khl.com | +1 312 496 3314

MARKETPLACE SALES John Austin john.austin@khl.com | +44 1892 786245

CLIENT SUCCESS & DELIVERY MANAGER

Charlotte Kemp | charlotte.kemp@khl.com

CLIENT SUCCESS & DELIVERY TEAM Ben Fisher | ben.fisher@khl.com Alex Thomson | alex.thomson@khl.com

GROUP DESIGN MANAGER Jeff Gilbert

GROUP DESIGNER Jade Hudson EVENTS MANAGER Steve Webb

EVENTS DESIGN MANAGER Gary Brinklow

CREATIVE DESIGNER Kate Brown

CLIENT SUCCESS & DIGITAL DIRECTOR Peter Watkinson | peter.watkinson@khl.com HEAD OF FINANCE & HR Alison Filtness | alison.filtness@khl.com

FINANCE MANAGER

Toumi | yasmin.toumi@khl.com

CREDIT CONTROL Carole Couzens carole.couzens@khl.com | +44 (0)1892 786250

AUDIENCE DEVELOPMENT MANAGER Anna Philo | anna.philo@khl.com

US President Joe Biden will apply tariffs on US$18 billion of imports from China in a bid to protect American workers and businesses.

The US Government said, “China’s unfair trade practices concerning technology transfer, intellectual property, and innovation are threatening American businesses and workers. China is also flooding global markets with

artificially low-priced exports.”

In response after a review by the United States Trade Representative, President Biden is increasing the tariffs.

The tariff on imports of Chinese-made ship to shore (STS) container cranes is currently zero. “A 25 % tariff rate on ship-to-shore cranes will help protect US manufacturers from China’s unfair trade practices that have

led to excessive concentration in the market.”

The Government also said the move will “mitigate risks that could disrupt American supply chains.” It is part of a port security initiative where port crane manufacturing is brought back to the USA. The news follows reports of surveillance technology being incorporated in Chinese-built cranes operating at US ports.

Tower cranes made by Soima Cranes in Portugal will now be known as Stafford Tower Cranes. Stafford Crane Group acquired Soima in 2021.

Each model will have a new designation and the full range of tower cranes will be made available globally. The range

includes many models from 5 to 42 tonnes maximum load.

“We now have an extensive 2024-2025 modernisation and innovation programme in place to introduce new crane designs and models,” said Patrick N Stafford, SCG president. “All are our own designs from

» Crane and excavator manufacturer ATLAS in Germany has appointed Drive Products USA as a distributor for Atlas cranes in the US market.

Drive Products, headquartered in Elkhorn, Wisconsin, offers truck mounted equipment and services. It was started in 1983 by Greg Edmonds and is still a family-run

business, led by Robert Edmonds as president and CEO.

Atlas is a long-established manufacturer of hydraulic telescopic truck mounted loader cranes. Maximum load moment ratings are up to 60 tonne-metres, capacities are up to 13 tonnes and maximum reach is 22 metres.

our newly established Milano Tower Crane Hub design office. We are delighted to announce three new luffing crane models from 16 tonnes to 42 tonnes of a conventional design, with a further five models with a hydraulic luffing jib.”

The distinctive feature of this new family of hydraulic luffing cranes features “flat mode,” which enables the model to operates like a typical flat top trolley crane.

Stafford Tower Cranes is the new name for Soima Cranes

» BISHOP LIFTING has completed the acquisition of Oceanside Equipment, a wholesale distributor of rigging and mooring products. Based in Nova Scotia, and with a location in Newfoundland, Oceanside was founded in 1990.

Oceanside marks Bishop’s fourteenth acquisition since 2012.

The IC Transport 50 is an annual list that ranks the world’s largest specialized transport companies based on the total maximum carrying capacity of all their specialized transport equipment.

The listing is wellestablished and one-of-akind. A place in the T50 is a prestigious achievement receiving comprehensive publicity and marketing.

If your company owns specialized transport equipment used to move oversize and-or overweight loads you may be eligible.

The full ranking will be published in August.

It is also helpful for us to have a fleet list of all the transport equipment in your fleet, listed by type, make, model and capacity, so please feel free to include one with your completed entry form.

Download the 2024 IC T50 entry form from the website in the story headlined: IC Transport 50 – enter now for 2024 or contact editor Alex Dahm for a form.

Modular construction is a fast and relatively simple process when you have sufficient lifting capacity and enough space to set the crane.

French lifting company AUTAA Ile de France, part of GCA, had both of these requirements covered on a hospital construction project near Paris. It used its new 300 tonne capacity Grove GMK6300L-1 all terrain crane for the extension project. This perennially popular model on a six axle carrier helped assemble prefabricated modules. Its quiet operation were

Liebherr’s MK series of mobile folding construction cranes have officially arrived stateside.

MK cranes combine a self erecting type tower crane with a mobile carrier. Three are available for the USA. The 3, 4 and 5-axle models offer hook height up to 94 metres and lifting radii to 61 metres.

Three were ordered by Robert Kalhagen, Ideal Crane Rental president. “Tasks that previously required a larger crane with multiple counterweights and jib extensions can now be managed with a crane that carries its own counterweights

and can be set up in a fraction of the time,” said Kalhagen. “The MK 140-5.1, our larget MK crane, has a reach of more than 200 feet, a hook height of up to 309 feet and is fully operational in less than 30 minutes.”

MKs can operate in most American states, Liebherr said.

An MK mobile construction crane opening up for a customer presentation

valued as the hospital continued to operate during the expansion work.

Soon after delivery the crane was dispatched to the Saint Camille Hospital in Bry-sur-Marne, near Paris. The heaviest of the 21 modules weighed 21 tonnes.

Eric Grimaldi of GCA said, “The crane was compact enough to fit in the limited space on the job site, ensuring minimal disruption to hospital operations and allowing the ambulance traffic to continue uninterrupted throughout the work.”

Handing over the first three MKs for the USA. Left to right: Stefan Kohler, Liebherr-Werk Biberach head of MK sales; Lori and Robert Kalhagen, Ideal Crane Rental executive and president; Marco Guariglia, Liebherr-Werk Biberach managing director, sales

Crane, transport and industrial installation specialist Scholpp in Germany has expanded its fleet with two new Tadano AC 4.080-1 all terrain cranes.

The units are from a 2023 bulk order and are the third and fourth cranes to be delivered.

Discussing the crane choice, Heinz Schuh, Scholpp Ludwigshafen branch manager, said, “Not only is the crane extremely compact and manoeuvrable, it also has an impressively large 60 metre boom length.”

Scholpp said the cranes are easy to operate and can handle a large number of lifts even with standard equipment.

“The benefits here include the highly efficient singleengine design and, of course, the IC 1 Plus crane control system, which in many cases reduces costs by eliminating the need for separate counterweight trucks,” added Stephan Burkhardt, Scholpp Leonberg branch manager.

Handing over the fourth AC 4.080-1. Left to right: Roman Nierobisch, Scholpp; Michael Zieger, Tadano; Sascha Riotte, Scholpp

» MAZZELLA COMPANIES has purchased Piedmont Hoist & Crane based in North Carolina, USA.

Piedmont Hoist & Crane is now Mazzella Piedmont. Terms of the transaction were undisclosed.

Piedmont has developed into a specialized crane manufacturer.

» Italian crane manufacturer JEKKO has a new partnership, with South African supplier SkyJacks. The material handling and powered access solutions provider will be the exclusive

SkyJacks headquarters in Boksburg, South Africa

dealer for Jekko products in the region. SkyJacks will offer sales, rental, and after-sales support for Jekko products, ensuring customers have access to the full range of services.

Improved cabin design on both new crawler cranes

The newly upgraded 100 tonne capacity SCX1000A-3 from Sumitomo HSC

Sumitomo Heavy Industries Construction Cranes Co (HSC) in Japan has updated its 100 and 180 tonne capacity lattice crawler crane models.

The SCX1000A-3 and SCX1800A-3 have Stage V engines, a new load moment limiter system and other new safety features. Maximum boom and jib combination length is 51 + 28 metres on the 100 tonner.

Both models have the 209 kW Cummins B6.7 straight six diesel engine to EU Stage V emission standard. The control system includes ECO winch mode and the auto idle stop function to help reduce fuel consumption. This engine can also be run on biodiesel, Bio Diesel Fuel (BDF; B20) and hydrotreated vegetable oil (HVO) diesel alternative.

The new LMI has a 12.1 inch (300 mm) touchscreen and the operator interface includes a live readout of counterweight

Sumitomo Heavy Industries

Construction Cranes Co

■ Lifting capacity

SCX1000A-3: 100 tonnes at 3.8 metres

■ Lifting capacity

SCX1800A-3: 180 tonnes at 4.1 metres

■ Boom SCX1000A-3: 12 to 60 metres

■ Boom SCX1800A-3: 15 to 84 metres

specification, ground contact pressure, list and trim.

Improvements made to the cabin include heated seat with a lower headrest and insulating glass in the roof window to exclude more than 90 per cent of UV and mid-infrared light, the company said.

Outside, handrails are standard on the catwalks and machine access is improved by having bigger steps.

Finnish manufacturer Cargotec released its Q1 2024 financial report, stating that its orders received increased by 11 per cent and totaled EUR 653 million (US$ 705.9 million). The report said its sales had increased by 5 %.

Cargotec estimates Hiab’s comparable operating profit margin in 2024 to be above 12 %, Kalmar’s to be above 11 %, and MacGregor’s to improve from 2023. Kalmar is presented as discontinued operations due to the proposed demerger, which is to be completed by the end of June 2024.

Casimir Lindholm, Cargotec president and CEO, said, “The first quarter of 2024 provided a strong start for the year. All businesses combined our comparable operating profit amounted to EUR 137 million, and we delivered the best first quarter in Cargotec’s history. This was the fifth consecutive quarter with good results, despite complex business environment."

XCMG Machinery has announced a proposed 20 % increase in its annual dividend. The company's business income reached RMB 92.848 billion ($12.83 billion). The company was expected to introduce its first-ever ESG report soon after the time of writing.

World record: A mobile crane with a 90-meter telescopic boom – fully carried with 12-ton axle load! Our latest innovations, integrated for safe and powerful crane operation: ECOmode, ECOdrive, VarioBase®Plus, VarioBallast®, Auto-Ballast, SingleEngine concept and WindSpeed load charts for maximum safety when operating. The versatile and economic fast deployment crane with the record telescopic boom length brings any fleet to new heights! www.liebherr.com

Hiab, part of Cargotec, has won a major order worth €5 million for a special type of loader crane to be used in

offshore wind turbines.

All the cranes ordered are the 10 tonne-metre rated Hiab SWP, designed to handle

Italian rental company Mantovani Global Services has expanded its mobile crane fleet by adding a 150 tonne capacity wheeled mobile telescopic crane from Liebherr.

The LTM 1150-5.3 on a five axle carrier follows the recent deliveries of other five axle cranes, namely an LTM 1100-5.2 and an LTM 1250-5.1. Applications will include construction projects and naval ports.

See more on all terrain cranes in the feature on page 25.

DISCOVER IRIZAR SHANK HOOKS: NOW IN STOCK AT OUR

service operations on offshore wind turbines. It is a straight boom telescopic hydraulic loader type crane with up to four extensions. Type SWP2 offers an hydraulic outreach of 10.2 metres while SWP3 goes to 8.3 metres.

As standard, these cranes have the Hiab radio remote control type CD4 4F, the SpaceEvo electronic safety system and type V200 control valve. They are also painted

to EN/ISO 12944-2 class C3 for corrosion protection in the offshore application environment.

The cranes will be fitted in the turbine factory to very large wind turbines of 14 MW and larger, Hiab said. One crane is installed inside each wind turbine’s nacelle and can lift either from sea level or handle loads at the helicopter pad on top. There is enough winch wire for a lift height of 180 metres.

Chinese manufacturer XCMG Machinery has delivered a new 120 tonne capacity all terrain crane to Grúas Fraile in Spain.

Dealer DYM Impleparts in Guadalajara handled the sale.

This four axle XCA120 E is the first unit delivered in Spain of this model which is designed for the European market. It was launched in 2023 and has a 66 metre boom.

Irizar Forge is specialized in forging premium, heavy duty components for overhead-, gantry-, tower- and crawler cranes for onshore applications, up to 5000T SWL. Companies in industries such as steel mills, mining, nuclear, metal processing industry, construction and hydro have been satis ed users of our expertly forged Hooks (single, double, eye, shank) and Blocks since 1923. Why? Irizar Forge components provide great value –the very highest quality for the reliable performance you need to get the job done.

More and bigger change is a pervasive element of ICST’s table of the world’s largest crane-owning companies in its 2024 iteration.

That change is almost universally positive, continuing the return to growth that began last year after the pandemic.

Starting with the 2024 headline combined index figure for all 221 companies entered this year, the total of 37,712,101 points is 9.28 per cent up on the 34,510,957 points of 2023. Last year the overall number was 216 companies so there has been a net gain of five companies. This was achieved with the addition of 13 new or returning companies, positively offsetting the removal of eight companies, two due to acquisition and the remainder were just old data.

Turning to the IC100, this year’s total is

35,107,721 points, up an impressive 8.43 % on the 32,377,509 of 2023. Last year it was up 6.1 % on the previous year. The top 100 companies account for 93 % of the 221 company total figure, near enough the same as last year’s 94 %.

While nothing has changed at the top with Mammoet retaining its number one spot, its nearest rival, Sarens, is now ever so much nearer to it than ever before. Last year the gap between the two was 646,318 Index points but this year that has been slashed to less than half that, at 319,530 points.

In 2023, Sarens was 81 % the size of Mammoet while now it is 91 %. Mammoet is less than 2 % bigger than it was last year but Sarens is 13.58 % bigger. Add another »

An exciting year for the IC100 ranking of the world’s largest craneowning companies as it nears its third decade, writes ALEX DAHM

Companies are ranked by their IC Index, calculated as the total maximum load moment rating, in tonne-metres, of all cranes in a fleet. All companies in the list, plus prospects, have the opportunity to supply fleet information and the other requested data for inclusion in the ranking. Where companies supply full data the figure used is calculated by them.

In some cases, where data is lacking, we have based a company’s figure on an ICST estimate. In cases of insolvency, acquisition or lack of sufficient information, companies are withdrawn from the table.

While we make great effort to ensure the accuracy of information provided, it cannot be guaranteed and ICST accepts no liability for inaccuracies or omissions.

The IC100 Index will next be updated in the first quarter of 2025. If you think your company should be included, please contact ICST for an application form. Note that tower cranes are not in the IC100 because they appear separately in the IC Tower Index published in October's ICST Similarly, specialized transport equipment is also featured separately, in the IC Transport50, in the August issue of the magazine. Calls for entries in these tables are also issued and widely publicised like the ones for the IC100. Please look out for them at: craneandtransportbriefing.com and in the World Crane Week e-mail, and on our social media channels.

couple of blue and yellow super heavylift cranes before next May and next year’s IC100 could have a new leader.

Elsewhere in the top ten there has been more movement than usual but there are no new entries or leavers.

Contributing to some of the position changes may be a noticeable increase in the number of large crawler cranes, for example 2,000 and 4,000 tonne capacity models, often from the Chinese manufacturers, joining fleets. Some of the companies with these giants are Sanghvi, Sinopec, Hareket, Tiong Woon, Sarilar, SoP&G and Barkat. All have also made gains in the table this year.

Talking of gains, Aguado from Spain looks like one to watch. Mario Aguado told ICST he has invested tens of millions of euros in new equipment in the last three years.

Acquisitions have also affected the table, notably with Barnhart adding three more companies already in 2024, namely Baxter Crane and Rigging, White Crane and CR Holland. Also in the USA, Bay Crane has been especially acquisitive in recent years, adding to its portfolio United Crane and Rigging, Crane Rental Company, and Capital City Group, among others.

As a result of its acquisition of fellow Belgian rental company Michielsens, five years ago, Aertssen has combined the two

companies’ numbers as they have now been fully merged, operationally and saleswise, into one company. This has increased Aertssen’s IC Index from 184,598 to 224,907, (21.8 %) helping it gain one place, at 36.

Of the new or returning entries, the highest placed was Trungnam from Vietnam, at 24. It was followed by Singapore-based AsiaGroup in 60th place, absent from the table since 2019 when it was 43rd. Our next new entry is Premier Heavy Lift from India, in at 71st place. Then another welcome joiner, in 78th place, is Guindastes Tatuape from Brazil. Close behind is another new entry, Naser M. Al-Baddah & Partner General Trading & Cont. Co, also known as NBTC Group, from Kuwait, in at 81. Making a welcome return but just outside the IC100 in 102nd place is Hellmich from Germany. ■

Multifunctional and powerful

3 t load capacity at 23 m working height over 360°

- Fully hydraulic quick-change system for many equipment options

More safety and better vision

Extreme stability due to wide support area (4.5 m width) and 52 t operating weight

Elevatable and tiltable cab

Cost effective in transport

< 3 m transport width

Hydraulically unloadable counterweight (optional)

starting from 0.99 % 0 % down payment

Every year the winning projects in SCRA’s Job of the Year contest stand out against strong competition. Thanks to ICST sister magazine

AMERICAN CRANES AND TRANSPORT for this year’s reports

RIGGING: LESS THAN $150,000

Repurposing Barnhart’s tipstick innovation.

Barnhart was tasked with removing and replacing two 100,000-pound spindles at a steel mill in the USA. The timeline was tight and the task tricky. After a site visit, the company’s 150,000 pound capacity tipstick was determined as the best tool for the job.

Built for nuclear plant feedwater heaters, the tipstick could adjust its upper rigging point hydraulically to lift and level

The Barnhart 150,000-pound capacity tipstick allowed the team to manipulate the lifting point to control the spindles tipping angle. This allowed for a controlled rotation of the load during the lift and the ability to manoeuvre around obstacles

the spindle, bypassing obstructions. A small crane and the tipstick manoeuvred the spindle to the overhead crane. This controlled operation allowed both spindles to be removed and replaced in one 24 hour shift.

Meticulous planning addressed weight distribution and obstacles. Safety protocols were rigorously followed, including a Job Hazard Analysis. Crews overlapped for seamless communication during shift changes.

After completing the job, Barnhart was called back during the Christmas party because the new spindle dog bones were mis-labelled. The team quickly brainstormed and remobilised within 12 hours, supporting the spindles so the correct dog bones could be installed, getting the mill back online.

$150

Vanguard engineered a complicated lifting operation to upright the Europa.

At the Victoria and Alfred Waterfront Yard in Cape Town, South Africa, the sailing vessel Bark Europa slipped from its keel supports and rolled onto its starboard side during maintenance. The 650 tonne, 44.5 metre vessel was 1.2 metres off centre, lying at a 38 degree angle.

Resolve Marine subcontracted Vanguard to engineer and perform the uprighting operation. Europa was partially supported by the synchro-lift and transverse skid way, with limited access for cranes due to the concrete quay. The hull was

Using four hydraulic gantries and a strand jack system, the Vanguard team designed a bespoke solution to upright the Europa ship

pierced in several locations by the dollies, complicating the situation.

Vanguard considered various approaches, ultimately designing a bespoke solution. The vessel blocked the synchro lift, causing delays, and a storm was approaching. Vanguard’s team engineered a plan within a month, mobilising four hydraulic gantry systems to lift the vessel. Using 186 ton capacity strand jacks, they performed controlled lifts and transverse skidding to realign the vessel.

Safety was paramount, with measures including dollies clearance, fuel transfer, load-spreading spacers, and removal of sail rigging. The project took 1,600 man hours, involving engineering, operational, and project management activities.

BARNHART: The project involved arranging 10 prefabricated modules into two distinct stacks prior to their transfer into the building. Each stack was 60 feet high, 60 feet long and weighed 480,000 pounds

Barnhart provided custom designs and engineering to move ten prefabricated modules into two distinct stacks into a industrial building.

While on a job in Texas, USA, Barnhart was enlisted to arrange 10 prefabricated modules into two 60 foot high stacks, each weighing 480,000 pounds, within four weeks. The fabricator overlooked the installation process, prompting Barnhart to intervene with a custom design for each stack.

The modules lacked prefabricated lifting points so Barnhart designed and fabricated them. They provided two 12 point rigging systems for loading at the fabricator and assembly at the site.

Using a customised Barnhart Slide System, the modules were stacked and transitioned into the building. They were then manoeuvred laterally against a wall with minimal clearance and elevated 3 metres for leg installation. Barnhart’s 400 tonne capacity Liebherr LTM 1400 wheeled mobile crane assembled the modules. They were slid into the building and lifted using Pull-Up Gantry jacks (PUGS), then laterally transported to their final foundations with Barnhart’s slide beams.

Safety procedures included daily meetings, inspections, and job hazard analysis. Despite the owner’s insistence on 12 points of contact, Barnhart designed a

safe plan to navigate obstacles, including pre-existing pipes. It fabricated 61 custom lifting lugs and devised a strategy reducing necessary equipment by half while meeting deflection limits.

Barnhart completed the project in the four week timeframe.

On a tight timelime to avoid rolling blackouts, Barnhart removed and replaced a damaged stator between Louisiana and Missouri in the USA.

Barnhart was tasked with removing and replacing a failed stator at a Missouri, USA, power plant. Typically, stator replacements are planned 12 to 18 months in advance during scheduled outages, but this failure was unforeseen and occurred just before peak power production season, requiring rapid deployment.

The job involved removing a replacement stator from a Louisiana plant and transporting it to Missouri while concurrently extracting the damaged stator. The replacement weighed 720,000 pounds, and was 40 feet long, 14 feet tall, and 15 feet 4 inches wide. Barnhart quickly mobilised engineers, field specialists, supervisors, and commercial planners to both sites, creating a 3D model to engineer a solution.

A 500 ton hoist and a 70 foot gantry truck were critical tools. Despite the tight timeline, all engineering designs underwent independent third-party review. Soil conditions at the Louisiana site were assessed by a geotechnical engineering

Barnhart’s meticulous plan resulted in the project being completed in a 57-day timeframe, making three generator lifts – removing the damaged generator in Missouri, removing the replacement generator in Louisiana and installing the replacement generator in Missouri

firm, necessitating excavation and stabilisation.

Barnhart began removal activities in Louisiana, extracting Isophase buses and structural steel to access the generator. The project was completed in 57 days. It involved three generator lifts and more than 12,000 man-hours. This ensured the power plant resumed full production ahead of schedule, thereby avoiding potential grid disruptions.

Safety was paramount, with daily safety meetings and the use of a web-based safety app logging job hazard analyses. Barnhart’s commitment to safety ensured the rapid deployment did not compromise the crew’s well-being or project success.

160,000 POUNDS NET

Bragg Companies hauled two NASA rocket boosters from Space Port to Science Center.

Crowds of people were one challenge for Bragg Companies when it transported two NASA Solid Rocket Boosters from Mojave Space Port to the California Science Center in Los Angeles, USA.

The team quickly developed a trailer configuration, focusing on minimising length and height. The provided saddles, however, were too tall, so Bragg hired Rackley Trailers to design and manufacture

BRAGG COMPANIES: Thousands of people wanted to see the boosters as they made their way through Los Angeles

Sketch Pad

3D LiftPlan App

Rigging Designer

Eliminate paper and bring in a scaled jobsite with touch of button 3D LiftVision

Create and save simple or complex rigging for any lift equipment

Place your operators and/or customers in the seat “virtually” in any 3D Lift Plan you create!

six custom low-profile saddles.

Finding a suitable route through Los Angeles took several days and required extensive co-ordination with city and county, Los Angeles Public Works, LAPD, and the Mayor’s Office. Ensuring a smooth operation was crucial.

The trailer’s steerability made turns relatively easy, but the narrow streets, overhead obstructions, and booster length necessitated transport equipment manufacturer Scheuerle designing and manufacturing four 25 foot long deck sections for the MES 9Line trailers. Bragg’s meticulous planning ensured the boosters were delivered on time for the ceremony.

HAULING: 160,000 POUNDS TO 500,000 POUNDS NET

Omega Morgan transported six turbine runners across British Columbia.

Omega Morgan transported six turbine runners – the heaviest loads ever to cross British Columbia – more than 1,000 kilometres from Prince Rupert to Northern BC, Canada. The route study began in 2018, the project was awarded in 2019, and transport commenced in November 2020.

Various delays meant the final load was delivered in January 2023. “With so many moving parts, it took all of our resources on the specialized transportation team to make this project come together,” said Kai Ferrar, Omega Morgan engineering director. “We not only got the job done, but we did it with zero injuries or incidents.”

This job took 15,000 man hours and faced numerous challenges. There was only one viable route across seven maintenance districts. Plans for summer transport became more complex when winter deliveries were required. Constant weather monitoring and meticulous road closure plans were essential. The team navigated six avalanche zones, black ice, narrow roads, and rapidly changing weather.

The project involved transferring loads from ship to land, navigating extreme tide swings, winter mountain passes, and 110 bridges. Highway 16 closures and ensuring bush roads were solidly frozen were crucial. Co-ordination with Canada National Railroad was needed for track crossings and overhangs.

The complex route required 25

What’s behind the Deep South promise? An award winning heavy lift & heavy haul contractor with the breadth of services and depth of experience to be your go-to partner for projects of every size. With safety at our core, we put it all together with start-to-finish turnkey solutions that get your heavy cargo from fabrication facility to final destination. To learn more, please visit us at DEEPSOUTHCRANE.COM

traffic control personnel nightly, multiple engineering firms, and alignment across 16 entities. Daily communication involved a 51 person email string, a 57 page traffic management plan, and the most expensive permit in Omega Morgan’s history at US $43,000 per load.

A constantly changing route was a challenge for Transportes Muciño while hauling turbines and generators in Mexico.

Transportes Muciño handled the domestic and international transportation of turbines and generators, ranging from 44,000 pounds to more than 705,000 pounds, from Altamira and Progreso ports to sites in Guanajuato, San Luis Potosi, and Yucatan.

Bajio-Yucatan is attractive for foreign investment due to high and growing annual power consumption, exceeding two per cent growth. Modernising electricity generation plants is driving power market growth, reducing coal and oil use in favour of natural gas.

The project included vessel reception, transportation, rigging, and gas turbines.

Transportes Muciño overcame logistical challenges like Mayan train construction, highway reinforcements, train schedules, and civil works projects. The company fabricated and installed bridge reinforcements, including major shore-ups on Canada de la Muerte (a 30 metre deep glen), and constructed causeways, road pads, and road modifications.

Constant route changes due to Mayan train works, civil works on the Yucatan peninsula, and Progreso Port expansion complicated transport. They navigated around construction sites, causeways,

tollbooths, and an under-construction overpass, requiring eight jumper bridge crossings.

In Guanajuato, the team faced the Canada de la Muerte bridge shore-up, night transit in Silao, and causeway construction towards Salamanca. They also handled early vessel arrivals and found an alternative road for a hip turbine to avoid storage charges.

Western Mechanical transported a pedestrian bridge from barge to beach to downtown Toronto.

Working with Pinnacle Logistics Solutions, Western Mechanical was tasked by Walters to transport and deliver a 220 ton pedestrian bridge, 138 feet long, from the fabricator in Stoney Creek, Ontario, to downtown Toronto, Canada. This project, which bypassed the use of overhead cranes, required almost two years of planning.

The bridge was first transported over the road on a double-wide 12-line Goldhofer PST-E (SPMT), covering 11 miles with several tight urban turns before arriving overnight at the Port of Hamilton. From there, it was loaded onto a self-contained RO-RO barge and transported across Lake

Ontario to Toronto. The teams co-ordinated with city authorities to use park land as a barge landing site, enabling the bridge to be unloaded onto Jarvis Street during the night. The SPMT then navigated the bridge through tight turns and corridors from Sugar Beach to the final installation site.

Once clear of overhead structures, the bridge was super elevated using a gantry lift system to accommodate additional height supports. This brought the overall height of the load to 24 feet, aligning it closer to the required installation height. The final placement involved precise manoeuvring using hydraulic controls on the trailer and jack-and-slide equipment, positioning the bridge onto its bearing supports.

The limited footprint at the installation site, located over a TTC subway tunnel and adjacent to a four-storey parking garage, required much engineering. These efforts ensured the transport configuration would be safely accepted by the structure, including associated shoring at the gantry location.

The journey began in Hamilton, Ontario, and involved navigating tight turns and close proximity to structures, buildings, and utilities. Co-ordination was required with multiple stakeholders, including Walters, for loading and transport ideology, the City of Hamilton and their engineers for road transport, and Hamilton Utilities for clearing signs and light posts.

High trailer axle loadings gave rise to concern for underground infrastructure. Major city water main construction projects and new open excavations created obstacles just hours before transport. Crews laid three truckloads of steel plates to protect these temporary works.

Heavy pedestrian traffic meant the project was scheduled for evenings. TTC bus and train routes were diverted or cancelled during the move. ■

With this unique loader crane, decades of expertise and the latest technology become the future of lifting solutions. The astounding outreach of 38.7 meters including the fly jib, a lifting moment of 124.8 mt, and the latest assistance systems, the PK 1650 TEC sets new standards in the heavy-duty loader crane segment.

LIFETIME EXCELLENCE

Ahybrid combining the roadability of a truck mounted crane and the on-site manoeuvrability of a rough terrain crane, all terrains can both travel at speed on public roads and navigate rough terrain at the job site. To do this they can be specified with all-wheel steering and all wheel drive, AT cranes can have as many as 12 axles and nominal lifting capacity up to 2,000 tonnes.

Manufacturer Liebherr has a lion’s share of the all terrain market in several territories. The manufacturer is making strong moves in the USA, where its cranes are continually being added to American fleets.

A new Liebherr LTM 1100-5.3 all terrain crane is bound for the fleet of the USAbased All Family of Companies.

It’s the first five-axle crane worldwide with a width of 2.5 metres, an advantage when driving on roads and construction sites. The all terrain has 8 tonne axle loads for worldwide mobility, delivering

All’s new five axle 100 tonner, the Liebherr LTM 1100-5.3

major benefits when it comes to obtaining licences and route permits.

“The supreme roadability of the new Liebherr LTM 1100-5.3 will be a major benefit for our customers,” says Michael Liptak, president and CEO of All Family of Companies. “It is highly adaptable to the varying geographies our branches serve and will save customers time and money by not requiring additional road licences or additional truckloads to transport ballast.”

The LTM 1100-5.3 also has a capacity of 100 tonnes and a longer 61.8 metre telescopic boom for greater reach. The new AT can carry up to 17 tonnes of counterweights. At 75 per cent of the maximum ballast of 22.5 tonnes, this is a new record for mobile cranes worldwide. It allows the new LTM 1100-5.3 to perform most of its jobs as a taxi crane without additional ballast transport.

Elsewhere in the USA, Nichols Crane Rental recently took delivery of a new LTM 1230-5.1. The crane rental company provides crane services for projects across Illinois, Indiana and Wisconsin, with almost half its fleet consisting of Liebherr machines.

Liebherr also continues to prove popular in European markets. Italian rental company Mantovani Global Services recently expanded its fleet by adding a 150 tonne capacity LTM 1150-5.3. The new model follows the recent deliveries of a LTM 11005.2 and an LTM 1250-5.1 and will be used for different applications such as construction and naval port industries.

Owner Sandro Mantovani says, “Despite its dimensions, the crane is compact, has great manoeuvrability, and economic efficiency. The crane has a 66 metre telescopic boom and when fully extended, it can lift more than nine tonnes. It can complete lots of jobs without requiring additional ballast transport vehicles.”

Compact, manoeuvrable and road-ready, all terrain cranes continue to be used globally on all manner of construction sites. NIAMH

According to specialist market research company, Off-Highway Research, demand for all terrain cranes around the world has never been higher. Traditional markets are strong thanks to supply (finally) bouncing back, while there are surprisingly strong sales in some nontraditional markets.

In the boom years of 2022 and 2023, global sales of all terrain cranes were around the 4,000 unit mark, compared to the sales of 2,200 – 2,800 machines per year throughout the 2010s.

Initially the driver for this was a surge in demand in China in 2020 and 2021 thanks to stimulus spending. The 100 to 250 tonne classes are particularly popular, and in those boom years there was also very strong demand for heavy lift cranes for construction. China is served almost entirely by Chinese OEMs.

Mantovani’s third mobile crane is a Liebherr LTM 1150-5.3

As previously reported by ICST, Arabian Machinery & Heavy Equipment Co. (AMHEC) ordered 55 new Liebherr mobile cranes to meet the Kingdom’s building boom demand. Currently there is US$ 56 billion-worth of projects in the pipeline, and projections indicate this figure will surge to more than $90 billion by 2029.

The crane order is the biggest ever received by the Saudi Liebherr Co. Wheeled mobile telescopic cranes from five up to nine axles and from 100 to 800 tonnes capacity will be delivered to the lifting and transport specialist. Largest of the cranes in the order is the LTM 1750-9.1, AMHEC’s first on nine axles.

Deliveries from the order will begin later in the year, taking the AMHEC fleet to more than 400 cranes.

China’s largest crane and construction equipment manufacturer XCMG announced a premium crane brand called G2.

It said the move, launched in April 2024, is a series of models aiming to create greater value for end users and to pioneer innovation. XCMG said it has brought to bear its crane experience and that from 300,000 users gained in the last 61 years into the new G2 brand.

Petrolift’s Grove cranes will be set to work on wind turbines and petrochemical projects

More recently there has been a sharp rise in sales of AT cranes to Southeast Asia, where again Chinese OEMs exert a strong influence. This is partly due to an aggressive approach from them in light of the now tumbling domestic market. It also reflects the strength of the region’s commodity-producing countries, which are reaping the rewards

of several consecutive years of high global commodity prices.

The same applies to some extent to the Middle East and Latin America but, in these regions, the traditional big seller is the rough terrain crane, with truck cranes (again form China) proving much more popular in the last year or two. The traditional anchor market for all terrain

G2 series crane models are designed to offer a number of improved features, including reduced fuel consumption, increased operational efficiency, bigger cabins with better fields of view and reduction of maintenance time.

After its purchase of five all terrain cranes, a customer in Australia provided more than 200 suggestions for improvement, all now incorporated, the manufacturer says, contributing to the benefits of the new G2 series cranes.

Since the G2 announcement, Grúas Fraile in Spain has taken delivery of a XCMG

cranes is Europe. After a difficult period in the pandemic years when supply was badly disrupted, sales last year returned to something approaching normal levels but not the highs seen in the late 2010s.

Meanwhile North America shares some characteristics with Latin America and the Middle East in that rough terrain cranes are the high volume product. All terrain crane sales start above 100 tonnes, where rough terrain crane ranges start to fade out. There is very little market for lower capacity ATs in the region in the way there is in Europe.

Globally, the main reason that AT sales are booming is that the Chinese OEMs (namely Sany, XCMG and Zoomlion) have joined the party in the last five years. They now have a combined capacity to produce 1,500 all terrain cranes (if not more) per year. However, the main end markets for these machines is China.

all terrain. The four axle XCA120 E is the first unit delivered in Spain of this model which is designed for the European market. Launched in 2023, it has a 66 metre, seven section boom. A maximum tip height of 94 metres can be achieved.

Grove ATs, from manufacturer Manitowoc, also remain popular across Europe.

Polish crane rental company Robert Baran Crane Group Petrolift recently expanded its fleet with 21 new Grove all terrain cranes.

A mix of four, five, and six axle Grove cranes will join the company’s fleet this year. The first cranes in the latest order have already been delivered and set to work on several projects, including installing wind turbines and working on petrochemical and chemical plants.

“We love the GMK6300L-1,” says Robert Baran, founder and CEO of Robert Baran Crane Group Petrolift. “It’s extremely reliable and powerful, and a proven best-inclass machine. Now we’re at a stage where we need to expand our offerings; it was

natural to turn to Grove and we are looking forward to seeing the advantages and versatility of our new models paying off on jobsites across Europe.”

The company owns more than 40 of the 300 tonne model and was the first customer in Poland to own an extensive fleet of Grove GMK6300L-1s. The company has supplied equipment to every refinery, power plant, and wind farm built in the country. It is also highly active in the country’s major ports.

Germany-based crane rental company Schares has taken delivery of a new 100 tonne all terrain crane from Japanese

A lineup outside a factory in China of all types of crane from XCMG, which has just announced the new G2 premium series of all terrains

manufacturer Tadano, which has a lineup for all major crane markets around the world. It will be used for a range of jobs, including civil engineering projects, steel work, and lifts for the chemical industry.

Christoph Schares, managing director, said, “Its powerful lifting capacity, combined with a 59.4 metre main boom and an axle load lower than the 12 tonne limit, makes it an extremely cost-effective taxi crane.”

The team at Schares considers the AC 4.100L 1’s compact design to be another crucial advantage. “The AC 4.100L 1 is perfect for erecting large cranes,” added Eric Reichman of Schares, when going over the ways that the crane will be used. ■

85-Ton| 80 mt Rough Terrain Crane

✓ 5-section full power boom

✓ 208’ max tip height

✓ 19,200 pounds of counterweight

✓

The wind work vessel, weighing 23,000 tonnes, was transferred to sea on 800 axle lines of SPMT

Italy-based heavy load logistics provider Fagioli’s US division completed a world record ship transport weighing more than 23,000 tonnes on self propelled modular transporter (SPMT).

Fagioli used 800 axle lines of Scheuerle SPMT to transport the under-construction offshore wind turbine installation vessel. The vessel was moved from port facilities in Texas, USA, onto three barges from where it

was subsequently launched into the water.

In the process, Fagioli set three world records: for the largest number of axle lines under one load, the heaviest weight moved on SPMT and the heaviest load on wheels transferred onto barges.

The company used 28 power pack units (PPU) to move the 23,163 tonne ship, called Charybdis, which was built in the Seatrium AmFELS shipyard in Texas, USA. n

Heavy transport specialist Kahl Group has further expanded its fleet with orders for new equipment from fellow German company Goldhofer.

Kahl already has 100 self-propelled axle lines (type PST) and around 250 towed axle lines from Goldhofer. It is one of Europe’s largest vehicle fleets. Including split modules in the fleet gives Kahl a wider choice of vehicle width in being able to

configure 2,430 mm, 3,000 mm, 4,900 mm, 5,330 mm and up to 6,350 mm width combinations.

The order included 30 axle lines of the PST/ES-E (315) type, and 8 axle lines of PST/ ES-E (285) with variable track width.

Commenting on his choice Andreas Kahl, Kahl Group managing director, said, “We opted for the Goldhofer self propelled modules because they offer unique and unrivalled tractive power and performance, which

Cosmatos Shipping Services completed the deliveries of wind turbine towers, transformer parts and their accessories, at Thessaloniki Port in Greece.

A total of 45 wind turbine towers, two transformers and 32 packages with accessories arrived by ocean vessel and required safe and on time discharging at the port.

The tower sections ranged from 49 to 91 tonnes in weight. The two transformers weighed 71 and 110 tonnes.

Cosmatos Shipping took care of the ship’s husbandry, from removing the sea fastenings and unlashing the loads, to the stevedoring and cranage as well as being involved in the customs import formalities.

The company also arranged for the temporary storage of the main transformer at the Port open area. It also took care of moving the accessories to a covered area.

The larger of the two transformers weighed 110 tonnes

is essential for our challenging projects.“

Kahl also recently added 38 axle lines of the new Goldhofer FT Series heavy duty modules. FT Series is “a modular transport system offering a high degree of flexibility and investment security, as it can be adapted to handle different requirements and loads,” Goldhofer said.

Kahl is now equipped to handle a wider range of payloads

The company’s large fleet allows Kahl to transport payloads of up to 10,000 tonnes using its own equipment. It is also investing in new locations in northern and eastern Germany. n

What energy sectors are Sarens currently working in?

Broadly speaking, we work in offshore wind, onshore wind, as well as some gas fired power plants and coal, though we are reducing our involvement in that. The nuclear industry is very important for us, as is solar and hydrogen related projects, and we’re seeing more of them come up. Sarens have covered projects in pretty much every energy sector.

So you’re phasing out coal and increasing your nuclear sector involvement?

It’s not that we’re deliberately phasing out coal, there’s just fewer projects in the coal sector. In the early 2000s, there were still many coal-fired power plants being constructed, with some large projects in Germany, for example, but they’ve been completed.

Now we see that a lot of governments aren’t entertaining new coal projects anymore.

What do you see as the dominant energy source going forward?

Critical headroom considerations led to the design of a temporary lifting device on the South Carolina site

I think it’s really going to be a mix. Nuclear is seeing some increase in popularity, although it is susceptible to political views, and can be affected by changes in governments every few years or so. I think offshore wind

is really going to be the dominant sector for us moving forward. We also anticipate some work with gas related projects, as part of the petrochemical industry. It’s a

transition but there is still a demand for gas while the transition is being phased to more sustainable energy sources.

Do you see offshore wind overtaking gas and oil yet or is it still an even balance?

It’s roughly 50-50 at the moment but it will keep increasing, that’s for sure.

Can you tell me what’s going on in the nuclear sector? What are you working on there?

Some European governments indicated they want to be less dependent on gas for their energy supply, obviously, after what happened with Russia and Ukraine, and they’re revisiting some of their plans. Nuclear is therefore being revisited and there’s some decommissioning work going on. But other companies are saying that they will continue to operate for longer, and that will include some life extension works such as exchange of steam generators, reactor vessel heads, etc.

The UK and France have already signed for new nuclear power plants to be built.

Sarens provided engineering and supply of a barge spread and the PC 6800 crane for the installation of 89 monopiles at the Windpark Fryslân in the Netherlands

We’ve been involved in the nuclear sector since the 1960s. We’ve worked on both of the two power plants in Belgium since their inception. We’re proud of that work in our ‘home base’ country but we’ve been involved in many countries globally over the years with their nuclear efforts, such as in Korea and Finland, etc, so we’re everywhere.

Where is the demand for offshore wind coming from? Governments, regulations, customers or consumers?

I think it’s from all of them. It’s driven by individual countries and their governments and politicians because they are looking at more sustainable energy sources. It is important for governments to create the frameworks for these offshore wind projects, for operators and developers to be able to develop these types of projects.

“We have to work together with the bigger goal in mind, a more sustainable future.”

YANNICK SEL, Sarens’ commercial director of project solutions

We are currently working at Hinkley Point C in the UK, and we have signed a contract to work on the Penly power plant in France. We’re also looking into other new plants in UK and Europe.

Other countries, like Poland and the Czech Republic for example, are looking into building new nuclear power plants, too. It’s really interesting for us and there is quite a demand for our ring cranes.

We just completed work at Oconee Nuclear Station in South Carolina in the United States – a project we completed in just 12 days. We also involved in the Watts Bar nuclear facility in Tennessee.

Obviously in the UK we saw a bit of a hiccup with the last round of bidding where there were no developers interested, because the subsidies are going down and the costs and supply chain are actually going up. I think the whole world is looking for cleaner energy and that’s mainly driven by the politicians and what countries want to do.

What does Sarens consider to be the main challenges when it comes to transporting materials and equipment with wind work, both onshore and offshore?

Obviously, everything is getting larger and heavier. With subsidies becoming lower and lower, it’s all being pushed down into the supply chain. The industry is expecting newer and more innovative solutions but at the same time, the budgets that are available are becoming less and less. I think that is something we see as an issue.

The other issue we have is in terms of visibility. There are a lot of plans, obviously if all those plans become a reality, the supply chain will not be able to deliver. There will be real scarcity in the market, when it comes to equipment, especially with large equipment.

Everybody confidently says yes, operations are going to go ahead but then a couple of years down the line they may have to delay or cancel. It’s really that

Sarens' involvement on the Oconee Nuclear Station project, lifting two huge feedwater heaters, was completed in just 12 days

outlook that’s making it difficult, as it’s not as stable as we want it to be.

The other point I want to touch on is with floating offshore wind. There’s been a lot of different designs. Now I’m a big believer and champion of floating offshore wind but there are two big concerns.

First of all, there’s issues with the legal framework, and some countries don’t have it in place yet. That brings risk to the developers, where the costs are already higher, so they become less interested in taking those risks. Also, the design of the floaters are so varied, and a lot of the designers are start-up companies. They all expect and want support in terms of engineering and logistics – how to do the installation, the assembly, etc. It requires a lot of our engineering capacity as well. We really want to get engaged early on. We want to support all of them, finding solutions and drive the energy transition, but we know that some of the projects won’t be executed in the end.

Do you think there needs to be standardisation for floating offshore wind design?

I think there will be a lot of consolidation in the future, and there needs to be. For example, SBM Offshore and Technip Energies recently announced a joint venture. They both have their designs, »

and continue to take them to market, and ultimately, they are now one company.

Financing is a major issue, as has been indicated before. It is therefore that large players should step up and support these innovative projects.

What do you think the crane industry needs for future wind work that it doesn’t yet have?

We need larger crawler cranes and larger ring cranes for the installation and the integration of the wind turbines on top of the floaters. I think they’re definitely going to be needed.

They’re also needed in the nuclear sector too.

That’s where the question mark comes in and how real and tangible are those projects in certain pipelines? That is the big

question. People will need to commit early enough to secure those assets. Developers have their flow and by the time you’ve assigned equipment to a company it might already be too late, and you need to build a new one.

It’s really about getting the right outlook. Everyone looks only at their own projects, but I think sometimes we need to have thinking on a higher level, to also save costs.

We are looking at higher capacity ring cranes. We’re continually buying new equipment such as larger crawler cranes and we have our second [Liebherr] LR 12500 that just joined our fleet.

With our 2,500 tonne crawler crane, we’re continuously moving up the technical capacity with our equipment. We’re always trying to find new and better ways, smarter ways, of executing those projects so that we can also accelerate some of those energy transition projects.

Can you tell me about the latest wind energy project Sarens has been involved with?

The Moray West offshore wind farm project

was a good one. We were given a contract to marshall 60+ XXL-sized monopiles at Invergordon Port in Scotland. Each of the monopiles weighed close to 2,000 tonnes, making these the largest and heaviest ever to be handled. When completed, the farm will boast 60-plus wind turbines. We were acting as the principal contractor on that job and partnered with PSG. So, we provided a whole array of services to that project.

The other one we’re executing as we speak is the Hai Long offshore wind project in Taiwan, where we are involved in the jacket marshalling. It’s one of the largest projects that our client has ever undertaken. We came up with an innovative solution for jacket handling and we worked in close collaboration with our client with other areas such as the grillage and sea fastening, but we’re also doing the marshalling, the storage, etc.

In Taiwan, there’s a lot of earthquakes. A few weeks ago, while we were doing the offloading for this project, there was a small earthquake. All of this has to be considered in our planning and engineering. There were no issues during or after the earthquake as we were operating on the west side and the earthquake was on the east side.

Are there any other issues to do with the energy sector lifting or transport that the crane industry should know about?

I think an important thing to share is that with the current cranes that we already have, like our ring cranes or larger crawler cranes, we are already geared up for the next generation of offshore wind turbines, even up to 25 megawatts. Obviously, there’s only a handful of these cranes. The wind turbine manufacturers are under some slight political pressure to standardise. The race for even bigger wind turbines I think should also at some point, stop. We must make sure that there are enough critical assets available to execute all those projects. Politicians can make as many plans as they want, but the entire supply chain has to be able to deliver.

I think we all have to work together as an entire supply chain and really make these projects happen with the bigger goal in mind, a more sustainable future.

CATME speaker Andrei Geikalo, CEO of MYCRANE, the first global platform for online crane rental, on the tangible benefits of digitalization

As we prepare to meet many of our friends and partners at Cranes and Transport Middle East (CATME), the wellregarded KHL event taking place on October 1-2 in MYCRANE’s home city of Dubai, we wanted to share some of our latest developments from around the world.

For those who aren’t yet familiar with our mission to bring digitalization to the construction industry, you should know that MYCRANE has developed the first global platform for online crane rental.

But how do we help our users? Simply, you can save valuable time, energy and money by putting our platform to work for you. Digitalization means it’s no longer necessary to spend hours chasing multiple service providers by phone or email. Would you still pick up the phone to book a taxi? Probably unlikely…

Fortunately, there is a much more efficient way to source the lifting equipment you need. After registering for free at MYCRANE, you will be able to add an enquiry and you’ll soon hear from our crane rental partners. All responses and commercial offers are standardized, meaning the different quotations you’ll receive will be directly comparable.

Our service is just as valuable for crane owners, who can optimize their fleet utilization, and grow their business with MYCRANE.

As a company, we made a strategic decision to pay particular attention to the key markets where we see significant construction activity and therefore the potential to make the biggest impact – these include the Kingdom of Saudi Arabia, India and the USA.

In KSA, we’ve recently expanded our team by appointing Syed Ahmed Salman as VP sales, Middle East, and Zulnoon Bukhari, who joins as business development director, KSA.

Our new team members have a combined 45 years of experience and have hit the ground running, recently

registering a large number of crane rental companies, as well as industrial clients including Shibh Al Jazira Contracting, ALEC Contracting and Saudi Pan Kingdom Co. (SAPAC).

Meanwhile, our team in India has seen a surge in new client registrations and project enquiries, working with leading industrial names such as Larsen & Toubro (L&T), Tata Projects and KEC International.

KEC’s Amit Khurana, a MYCRANE registered customer, says it best when he describes the benefits we offer. “We particularly appreciate not having to manually contact different equipment providers with the same request, as MYCRANE allows us to conveniently post our requirements in one place, then receive a broad range of quotes in a standardized format, with all the information we need. This encourages efficiency and improves our business processes.”

MYCRANE India has been further bolstered by the appointment of two experienced external advisors.

Completing the trio of our focus countries is the USA, where the platform’s director of business development, Olga Dubinok, recently attended the SC&RA annual conference in Austin, Texas, where she enjoyed networking with the industry and spreading the word about MYCRANE.

As our minds begin to focus on CATME, we look forward to meeting and talking to KHL readers about the benefits of digitalization. ●

MYCRANE is the lunch sponsor of CATME. If you would like to arrange a meeting with the MYCRANE team virtually, in person, or at CATME, email info@my-crane.com

For free registration as a client or crane rental company, visit:

Focusing on the forecasts for the rental market in different regions shows a patchy but positive landscape. NIAMH MARRIOTT reports

The crane rental market worldwide remains significantly influenced by the oil and gas sector, though there is much development in wind farm work, particularly with new projects offshore.

Other renewable sectors are gaining in popularity and require the use of cranes but oil and gas remains prominent and cranes are still used for installation, maintenance and transportation of large pieces of

The equipment rental industry in the USA could reach US$79.2 billion this year, according to the latest forecasts from the American Rental Association (ARA).

In its updated forecast, the Association said the US equipment rental industry’s growth projection has increased since last quarter, with most current projections indicating a 9.7 per cent increase.

That represents an increase of 2.8 % on previous estimates, which forecast a total of $77.3 billion.

Tom Doyle, ARA vice president, programme development, says, “The 2024 ARA forecast through the lens of our exclusive rental revenue model, and survey results gathered from members, confirms the continuation of a growing rental industry.”

Scott Hazelton, managing director, S&P Global, adds, “There has been no serious bust, thus, there is no serious boom. The outlook remains steady and inflation is falling. The growth rates tail off in the future years, with growth of 3.8 % in 2025 and 3.1 % in 2026.”

According to Jeff Vance, senior vice president of operations services, Sunstate Equipment the S&P forecasts are in line with its own, which predict a softer winter and spring than usual and used equipment prices softening.

Elsewhere, Canada’s equipment rental revenue is projected to have 7.2 % growth this year, totalling $5.79 billion.

General tool and construction and industrial equipment (CIE) are both expected to see growth, with general tool revenue projected to be up by 6.8 % to $1.08 billion, up from last quarter’s projection of $954 million.

Revenue is projected to increase 9.7 % this year to $16.6 billion and investment is expected to expand in 2024 and beyond.

equipment for work in this sector.

Construction remains a massive sector for crane rental, with projects for housing, retail and commercial buildings, as well as transport hubs such as airports and railway »

Darryl Cooper, president, Cooper Equipment Rentals, says, “Our experience mirrors what ARA is reporting. Despite headwinds in the residential market, revenues are up, with western Canada stronger than eastern Canada.”

In terms of the supply chain, Sunstate said there has been a loosening, with fleet and parts easier to get hold of.

In addition, Vance said new vendors have been introduced into the market with new technology; “We’re doing a lot of investigation into electrification,” he says. “The power grid is always a topic in our minds. But, more electrification is coming, so we mu st be prepared to service our customers in those ways.”

The ARA says the rental industry in the USA could reach $79.2 billion this year. PHOTO: ONIONASTUDIO VIA ADOBESTOCK

stations helping to positively influence the industry’s forecasts. Regions like the USA and China dominate with mega construction projects and a plethora of plans but Europe, the Middle East and the rest of the world are also seeing a rise in work.

Many of these projects opt for crane rental services rather than outright purchase due to the substantial upfront costs. The high cost of not only new models but also the costs associated with crane operation and maintenance of existing fleets, is often a barrier to new, smaller companies entering the market.

There is also the skills shortage that often comes up in conversation – that a skilled but aging workforce is difficult to

replace, and the crane rental industry is making every effort to attract younger operators and skilled workers to the sector. Several upskilling training programmes

Martin Seban, director at KPMG, recently presented an overview of Europe’s rental industry current landscape and future outlook in a keynote session at the ERA Convention in Lisbon, Portugal.

Seban provided an updated forecast on individual European markets, showing mixed results.

In the UK, 2024 growth has been downgraded by 1.2 % to 1.5 %, and 2025 growth is expected to drop by 2 % to 2.5 %. Germany is now forecast to see 3 % growth in 2025, down by 1.4 % from earlier forecasts.

Spain and Italy have maintained steady investment due to EU financial support, with projected growth of 5.5 % and 3.5 % respectively next year.

The Nordic region faces the biggest downgrades for 2025, with Norway down by 5.1 %, Sweden by 2 %, and Finland by 2.8 %.

Seban noted that as the rental industry diversifies and targets new end markets, it becomes more connected to the global

are in place and offer promise, while other players have chosen to form partnerships and collaborate on projects to overcome equipment and worker shortages. ■

economy. He opened his presentation with a sobering statistic.

After a post-Covid GDP growth of 6.2 % in the Eurozone in 2021, the past two years saw more modest growth of 3.5 % and 0.5 %, respectively.

The outlook for the next 18 months is also uncertain, with forecast growth of 1.3 % for 2024 and 1.5 % for 2025.

Seban said, “Since 2023, we’ve seen a real slowdown in activity for various reasons, including inflation rates, which prompt central banks to raise interest rates, slowing the economy.”

Despite these challenges, Seban highlighted some positives: “The NextGen EU programme, which allocates up to €800 billion by 2027, is a significant opportunity. Based on the criteria, countries like Spain and Italy could see up to a 10 % GDP boost from EU financial support, whereas Germany and France might see less than 2 %.”

The construction industry shows a similar trend. After a 5.3 % recovery in 2021 and a 2.7 % increase in 2022, this year is forecast to see a 2.1 % decrease. Modest growth of 1.5 % is expected by the end of 2025.

Concerns are particularly acute in the residential construction market, which accounts for an estimated 49 % of construction activity in Europe.

KPMG has revised its outlook downward due to an “accentuated contraction of the new residential market,” leading to the lowest confidence in the sector since the pandemic began.

As of 2023, KPMG estimates that 65 % of the equipment rental industry in Europe is linked to construction. The slowdown in residential construction, declining customer confidence, and rising interest rates are therefore significantly impacting the rental industry.

Seban states, “Residential construction, in particular, is a significant portion of the business alongside non-residential, both suffering greatly and accounting for the major shifts in revenue generation across Europe. The impact varies by country due to market maturity and diversification, as well as the size of the construction segment.”

en Z (born between 1997 and 2012) is a digital-first demographic, with 54 per cent spending at least four hours a day on social media. With that in mind, recent research shows that 73 % of job seekers aged 18 to 34 have found their jobs through social media.

That said, according to Oxford Economics, Gen Z will account for 30 per cent of the global workforce by 2030. With fierce competition for talent affecting companies in every industry, it is vital for employers to tap into this talent pool sooner rather than later. Given the prevalence of social media in the daily lives of today’s young people, it begs the question: Are you on the right social media to attract younger talent?

Every company leader wants to find the silver recruitment bullet – that which will attract the most qualified drivers, operators,

SPECIALIZED CARRIERS & RIGGING ASSOCIATION

CHAIRMAN

Scott Bragg

Bragg Companies, Long Beach, California, USA

PRESIDENT

J Rozum

MSA Delivery Service, Canton, Michigan, USA

VICE PRESIDENT

Jim Sever

PSC Crane & Rigging, Piqua, Ohio, USA

TREASURER

Michael Vlaming

Vlaming & Associates, Vallejo, California, USA

ASSISTANT TREASURER

Harry Fry

Harry Fry & Associates, West Newbury, Massachusetts, USA

ALLIED INDUSTRIES GROUP

Mike Walsh

Dearborn Companies, Bridgeview, Illinois, USA

Matthew Rix

Pro Lift Rigging, Memphis, Tennessee, USA

TRANSPORTATION GROUP

David Yarbrough

Yarbrough Transfer

Winston-Salem, North Carolina, USA

PRESIDENT

Jennifer Gabel

JK Crane, Kenvil, New Jersey, USA

VICE PRESIDENT

Kate Landry

Deep South Crane & Rigging, Baton Rouge, Louisiana, USA

TREASURER

Stephanie Bragg

Bragg Companies, Long Beach, California, USA

technicians, riggers, etc. Job boards and referrals still play an essential role in recruitment, but it’s the role of social media that has exploded – and the road to success requires recruiting where talent is spending the most time.

As an example, 20 % of Gen Z spends more than five hours a day on TikTok – a key avenue for businesses looking to attract talent. You’ll find tens of millions of views of construction videos on TikTok. There are thousands of sub-categories that drill down even deeper into the subject matter, providing exposure to the types of jobs and lifestyles that industries can provide. This is extremely ripe territory for marketing your company to a younger and opted-in audience.

Taking it a step further, earlier this year, Sprout Social, a software company that helps businesses optimise their use of social media, tracked the use of social media platforms by age demographics, and discovered the following:

■ 18 to 29 years: Snapchat (41 %), TikTok (35 %), Instagram (32 %)

■ 30 to 39 years: LinkedIn (34 %), X/Twitter (34 %), Snapchat (33 %)

■ 40 to 49 years: LinkedIn (25 %), Facebook (22 %), X/Twitter (21 %)

■ 50 to 59 years: Facebook (29 %), LinkedIn (24 %), Pinterest (24 %)

It doesn’t take a genius to figure out where young people aren’t. They clearly don’t see the use in Facebook, LinkedIn or Twitter –which might be an eye opener for many companies.

Even still, according to Sprout Social, the most popular platform for Gen Z is actually YouTube, while Gen Z and millennials make up more than two-thirds of Instagram’s base.

Not much of the above should come as a surprise – seeing as how both of these generations largely grew up alongside tech. But if we want them to notice us, but more so, truly “reach” them, we have to not only exist where they exist, but learn to use the tools they’re using – talk the talk, walk the walk.

Authenticity has never been more important. As a final consideration, says Sprout Social, 40 % of Gen Z users prefer reels, stories or TikTok videos when seeing business ads on social media. And 67 % of those users are willing to engage with real people doing real things in social media ads. ■