Heavy lifting

Super crane lifts on an epic scale

Heavy lifting

Super crane lifts on an epic scale

Hard to believe it is already the last ICST magazine issue for this year. What seems like five minutes ago we were wondering what the New Year 2024 would hold for the industry and the world in general. Well, now we know, or most of it, anyway.

Looking back, one series of highlights for me has been the big lifts made at the Hinkley Point C nuclear power station construction project in the UK. Each one of the several big lifts made this year by Sarens’ SGC 250, also known as Big Carl, has been a milestone. The giant super heavy lift ring crane has moved the project on in leaps and bounds.

A similarly game-changing prospect is presented by the emergence of Mammoet’s latest super heavy lift ring crane, the SK6000. We have followed and documented its progress from the beginning but this year has seen it really take shape, to the point now where testing is complete and its next step will be for it to go to its first job.

We’ll also reckon on continuing to follow its progress as it makes its way out into the world. Being a moderately experienced parent, I can see how this is considered by at least a few people as being analogous to seeing a baby grow up and leave the nest.

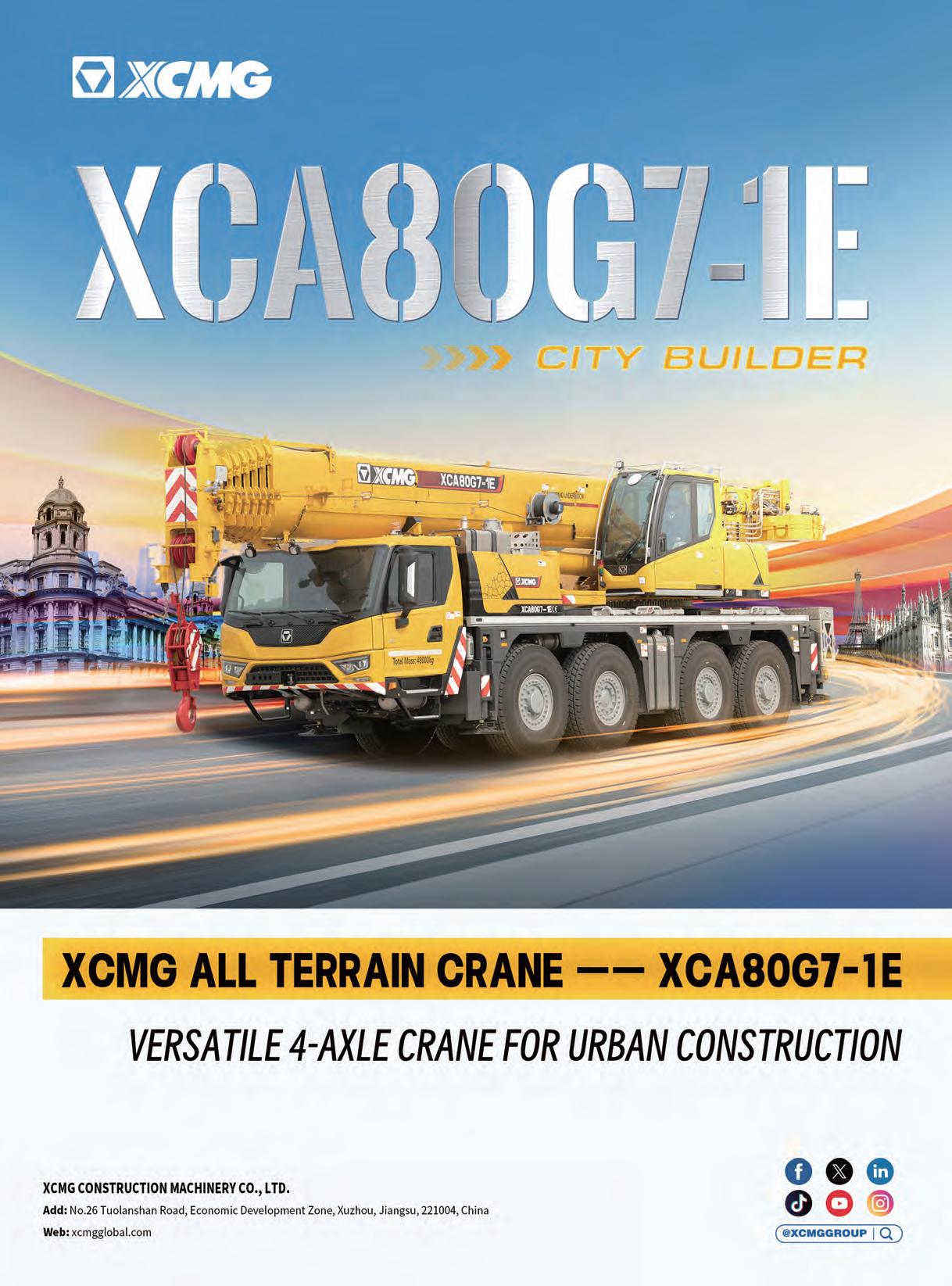

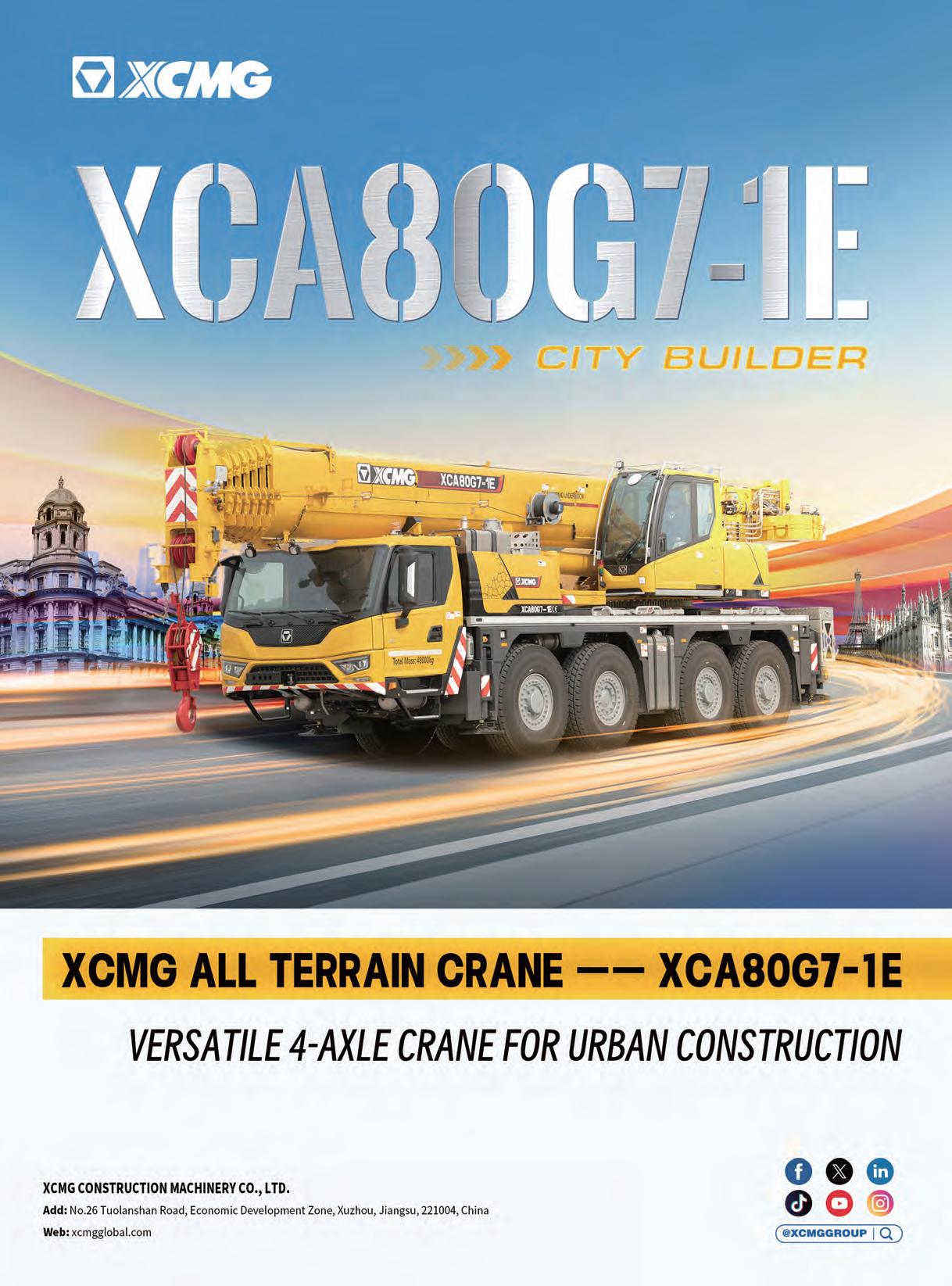

On a slightly smaller scale there was a certain amount of one-upmanship in the all terrain crane sector too. At the beginning of the year we reported what was claimed as the world’s largest AT, the 3,000 tonne capacity XCMG XCA3000, being put to work for the first time. Now, towards the end of the same year, we see the 4,000 tonne XCMG XCA4000 and delivery of the first unit of Sany’s 4,000 tonne all terrain crane, the SAC40000T.

While it may only really be a nominal maximum capacity in the ATs mentioned above, they still fit into the heavy lifting category (feature on page 13). More to the point, it still represents in excess of a 30 per cent increase from one end of the year to the other, which seems like quite something. Enjoy the issue.

ALEX DAHM Editor

&

Correspondence is welcome and should be sent to: The editor, International Cranes and Specialized Transport, Southfields, South View Road, Wadhurst, East Sussex TN5 6TP, UK

Representative Office

769, Poly Plaza, No.14, South Dong Zhi Men Street, Dong Cheng District, Beijing, PR China 100027. +86 10 6553 6676 | cathy.yao@khl.com

USA/CANADA PLUS AUSTRIA/EASTERN EUROPE/ GERMANY/IRELAND/KOREA/RUSSIA/ SPAIN/ SWITZERLAND/UAE

Matt Burk, Vice president sales

+1 312 4963314 | matt.burk@khl.com UK/SCANDINAVIA

John Austin, Marketplace/Classified advertising

+44 (0)1892 786245 | john.austin@khl.com

DACH & IBERIA Simon Battersby +44 1892 786223 | simon.battersby@khl.com

THE NETHERLANDS/LUXEMBOURG

Arthur Schavemaker

+31 (0)547 275005 | arthur@kenter.nl

FRANCE/BELGIUM Hamilton Pearman

+33 (0)1 45930858 | hpearman@wanadoo.fr

ITALY Fabio Potestà

+39 010 5704948 | info@mediapointsrl.it

TURKEY Emre Apa

+90 532 2343616 | emre.apa@apayayincilik.com.tr

CHINA Cathy Yao

+86 (0)10 65536676 | cathy.yao@khl.com

JAPAN Michihiro Kawahara

+81 (0)3 32123671 | kawahara@rayden.jp

USA/CANADA Bev O’Dell

+1 816 8861858 | bev.odell@khl.com

VP GLOBAL SALES Alister Williams

+1 843 637 4127 | alister.williams@khl.com

Chosen as the official magazine of the SC&RA (Specialized Carriers & Rigging Association)

European partner

Approved media partner for:

To subscribe to International Cranes and Specialized Transport or any of the magazines in the KHL portfolio go to: www.khl.com/free-subscription or call +44 (0)1892 784088 for details.

International Cranes and Specialized Transport is a monthly publication with a worldwide circulation. The annual airmail subscription rate is US$301, €258, £215. This issue of International Cranes and Specialized Transport is mailed on 31 October 2024. Material published in International Cranes and Specialized Transport is protected under international copyright law and may not be reproduced without prior permission from the publisher.

International Cranes and Specialized Transport (USPS 017 158) is published monthly by KHL Group and distributed in the US by DSW, 75 Aberdeen Road, Emigsville, PA 17318-0437. Periodicals postage paid at Emigsville, PA. Postmaster: Send address changes to International Cranes and Specialized Transport, c/o PO Box 437, Emigsville, PA 17318-0437.

Heavy lifts from super big cranes aid the construction of a plethora of global infrastructure and industrial projects. Niamh Marriott reports.

A welcome return to growth this year for most of the top 20 crane manufacturers in the world. Alex Dahm reports.

Specialist heavy lift contractor Vanguard claims victory as this year’s winner of the annual IC TopLift contest. ICST reports.

The specialized transport industry is making big moves smarter. Niamh Marriott rounds up the latest moves and news. 24

Can electric rough terrain crane alternatives really compete with diesel machines? Lucy Barnard reports.

EDITOR & EDITORIAL MANAGER Alex Dahm

alex.dahm@khl.com | +44 (0)1892 786206

DEPUTY EDITOR Niamh Marriott niamh.marriott@khl.com | +44 (0)1892 786208

EDITORIAL DIRECTOR Murray Pollok

NEWS WRITER Leila Steed

GROUP EDITORS Lindsey Anderson, Andy Brown, Catrin Jones, D.Ann Shiffler, Leila Steed, Euan Youdale

WORLDWIDE CONTRIBUTORS John Bowman, Australia; Graham Brent, USA; Marco van Daal, Aruba; Heinz-Gert Kessel, Germany; Richard Krabbendam, Netherlands; Tim Maughan, Japan; Brent Stacey, Australia; David Weston, UK

www.craneandtransportbriefing.com

New tower crane concepts for wind turbine installation. Part two of an epic series written by ICST special correspondent and global tower crane authority Heinz-Gert Kessel.

39

Get ready to learn and meet your peers at the upcoming STS organised by SC&RA. ICST checks out some highlights not to be missed.

40

Still somewhat distant but coming up fast is the 2025 mother of all construction equipment trade shows: bauma, held in Germany. ICST reports.

SC&RA CORRESPONDENT Mike Chalmers

SALES MANAGER Matt Burk matt.burk@khl.com | +1 312 496 3314

MARKETPLACE SALES John Austin

john.austin@khl.com | +44 1892 786245

CLIENT SUCCESS & DELIVERY MANAGER

Charlotte Kemp | charlotte.kemp@khl.com

CLIENT SUCCESS & DELIVERY TEAM Alex Thomson | alex.thomson@khl.com

DIRECTOR Peter Watkinson | peter.watkinson@khl.com HEAD OF FINANCE & HR Alison Filtness | alison.filtness@khl.com

FINANCE MANAGER Yasmin Toumi | yasmin.toumi@khl.com

CREDIT

How about that for a rigging job. Big Carl lowering the 423 tonne load into the reactor building

A 5,000 tonne capacity crane from Sarens was used to lift into place a 423 tonne steel ring at the UK’s

Sany’s new 4,000 tonne capacity all terrain crane. The SAC40000T has a nine axle carrier with special heavy duty axles and 23.5R25 tyres

Hinkley Point C nuclear power station construction project.

Lifted by the SGC-250 super heavy lift ring crane known

as Big Carl, it was the third and final steel liner element on the site’s second reactor building. The steel ring is 47

Crane and construction equipment manufacturer Sany handed over the first unit of its new 4,000 tonne capacity all terrain crane.

The Chinese manufacturer claimed it as the world’s largest all terrain wheeled mobile telescopic crane on a nine axle carrier. The SAC40000T was handed over to a Chinese crane company.

Wind energy is a key target application for this new giant. It has an 81 metre telescopic boom and up to 124 metres of jib can be added. Maximum lifting height is 200 metres. With 350 tonnes of counter weight it lifts a load weighing 376 tonnes to a height of 100 metres. The SAC40000T is designed for the next generation of wind turbines. The current 2,000 tonne class telescopic wheeled mobile cranes can build wind turbines up to 8 megawatts. This crane will be good for the 10 to 13 megawatt turbines coming in over the next 5 to 10 years, Sany said.

» UK-based GGR GROUP has launched a 42 tonne capacity pick and carry crane, the GF420.

Powered electrically, it comes with a 1,395 Amp-hour battery. GGR said its narrow – 2,090

mm – chassis and maximum lifting height of 13.8 metres make it ideal for use where space is limited. Its 180 degree rear wheel steering helps manoeuvrability. The extendable chassis allows it to achieve the maximum capacity and the counterweight slabs can also be removed for lighter loads.

» DAVIES CRANE HIRE in Wales has added a new fleet flagship in the form of a Liebherr LTM 1650-8.1 wheeled mobile telescopic crane. In addition to being the company’s largest crane its delivery marked its 45th anniversary in the crane rental business. The eight axle 700 tonner has 54 or 84 metre boom options.

It is a top specification unit that includes the VarioBase outrigger system and VarioBallast for the counterweight. There is also the full 90 metre luffing jib and Y-guying to give a 152 metre hook height and 112 metre maximum radius.

metres in diameter and 11.6 metres tall. It forms part of the inner containment wall and will be encased in two layers of concrete.

As the top of the three rings this last one also includes mountings for the rotating polar crane to be installed on top.

The steel dome over the building will be installed in 2025. This was done on the first reactor building in December 2023 and it is now ready for the reactor to be installed. Having learned from building the first reactor building, the second one has achieved efficiencies in its construction of between 20 and 30 per cent, according to an Hinkley Point C spokesperson.

Crane and materials handling equipment manufacturing group Cargotec reported its latest financials as a “seventh quarter in a row with good and stable results.”

Changes to the group in 2024 saw the partial demerger of Cargotec and formation of a separate Kalmar Corporation, the port crane and container handling business, at the end of June. After that Cargotec comprised loader crane maker Hiab and offshore crane and deck equipment manufacturer MacGregor.

For the July to September quarter orders received were up 14 per cent to €597 million while sales were down 1 % (or €8 million) to €590 million over the same period a year earlier.

Over the longer term, from January to September 2024, orders were up 10 %, to €1,833 million from €1,672 million in the first three quarters of 2023. Sales were flat at €1,833 million.

Crane and aerial platform manufacturer Tadano will expand on its diversification strategy with the acquisition of materials handling equipment and systems business IHI Transport Machinery Co. Ltd.

It is a crane and bulk materials handling manufacturing subsidiary of IHI Corporation in Japan.

The acquisition value is not being disclosed, Tadano told ICST.

The move, announced 6 November, is part of Tadano’s mid-term management plan to include a wider range of lifting equipment in its product portfolio.

With this acquisition Tadano will almost double its product offering in terms of the number of crane types it manufactures. It comes less than two months after Tadano announced its acquisition of crane manufacturer Manitex International headquartered in the USA.

» Dutch crane rental house KUIPHUIS has added another electric crawler crane to its fleet, bringing its total number of electric cranes to nine.

The latest addition is the third Spierings SK2400-R eLift crawler for the company and the ninth eLift model from the Dutch manufacturer. The eLift models

IHI Transport Machinery has more than 50 years of experience in engineering and manufacturing. Its product range includes large luffing jib tower cranes, ship to shore and other port cranes, large

IHI S-Movable Towercrane with legs installed

can operate entirely electrically, therefore emissions-free at the point of use.

Bob Bruijsten, Kuiphuis owner, commented on the latest additions, “After we became convinced of Spierings’ mobile crawler crane concept, we noticed that there are many construction sites where the eLift

offshore and floating heavy lift cranes, wind turbine cranes, industrial EOT cranes and equipment for bulk material handling.

IHI Transport Machinery reported net sales of JPY 73,389 million (US$ 477 million) in the last fiscal year and an operating profit of JPY 2,310 million ($15 million).

The part of the business being acquired by Tadano generated net sales of JPY 30,960 million ($200 million).

All 550 employees are to be retained, Tadano said. They are mainly at the Yasuura plant in Kure City, Hiroshima Prefecture.

Tadano said there will be synergies with its crawler crane manufacturing business in Germany.

Completion and final transfer of the business is projected to be in July 2025. It is likely that the IHI branding will be dropped in favour of Tadano.

concept comes into its own. The battery in the crawler crane solves local grid congestion for our customer, while still allowing the crane to operate at full capacity.

“This third crane, with a boom of no less than 50 metres, is very deployable for us on all possible construction sites in the Netherlands and even abroad.”

Topping our share price index this month is Singaporeheadquartered construction company Yongmao, with a 4.31 per cent change from last month, with Japanese manufacturer Kobe Steel and Chinese heavy equipment manufacturer Sany coming in close behind with 3.92 % and 3 % respectively.

Global market reach helped hydraulic crane and aerial work platform manufacturer Palfinger’s financial results for the first three quarters of 2024.

Group revenue was €1,745 million (slightly down on the same period a year earlier), earnings before interest and taxes (EBIT) was €158.7 million and the EBIT margin was 9.1 percent.

While order intake was still low in its core markets, including Europe, Palfinger reported positive development in Latin America, Asia and growth its marine crane sector.

New products also helped the results, including a new series of loader cranes, a marine crane for heavy loads, plus new access platforms.

Looking ahead Palfinger said it expected positive performance to continue in the APAC and LATAM regions and for marine cranes. For Europe, however, the company said it saw “no significant improvement in the economic environment” and said production capacity in EMEA would be further reduced.

Andreas Klauser, Palfinger CEO, commented, “Our geographical and product diversification has been a decisive resilience factor in the first three quarters. Given the volatile economic situation, we are actively tackling the challenges, increasing the attractiveness of our portfolio and implementing cost-cutting measures.”

Crane manufacturer Manitowoc reported a loss of US$7 million for the third quarter of 2024. Orders were also down, by 20 per cent, to $424.7 million from the same period a year earlier. Net sales were flat at $524.8 million while at the end of September the order backlog was still $742.1 million. Adjusted EBITDA was $26.2 million, down 21.3 % from the year before.

Commenting on the result Aaron Ravenscroft, Manitowoc president and CEO, said, “Given the soft results in Q3, we are expecting our full year adjusted EBITDA to be at the low end of our guidance. Strengthening our balance sheet remains our top financial priority.”

As a company Yongmao continues focusing on shareholder returns amid stable revenue, while some analysts have highlighted challenges from variable demand in China Kobe Steel has continued restructuring its operations, including issuing domestic bonds and revising earnings forecasts. The company said that these measures aim to support ongoing technological investments and operational adjustments

Showing a positive year on year trend is USA-based manufacturer Terex, who recently released its Q3 financial results. It reported net sales of $1.2 billion, a 6 per cent decline year-over-year, driven by reduced materials processing (MP) demand, partially offset by 2.4 % growth in aerial work platforms (AWP). The acquisition of Environmental Solutions Group (ESG) bolsters Terex’s portfolio in the waste and recycling market.

Guidance on the safe operation of cranes near overhead power lines has been published by the International Crane Stakeholders Assembly (ICSA).

Guidance –Safe Crane Operation in the Vicinity of Power Lines, is a 30 page document offering guidance for crane operations near

energised overhead power lines. It is also intended to assist regulatory authorities “when evaluating requirements to prevent power line contact.” It contains a section explaining electricity, including electromagnetic fields, induced voltage, arcing in air and other electrical hazards. The bulk

of the guide focuses on risk assessment. Topics include elimination of the hazard, engineering controls relating to crane design, remote operation, power line proximity detectors and use of non-conductive materials.

A large proportion of crane accidents are where a crane

The UK’s Health and Safety Executive (HSE) imposed a £750,000 (US$ 974,000) fine following the collapse of a large crane at Falmouth Docks.

On 10 May 2017 the crane operator at A&P Falmouth in the south west of England noticed the travelling port crane’s boom “was descending uncontrollably.” The operator managed to swing the crane away from the Royal Fleet Auxiliary (RFA) ship, Tidespring, it had been working above. The boom then landed on the quay, crushing a cage of acetylene cylinders.

It was declared a major incident by emergency services. An HSE investigation found A&P Falmouth had failed to properly maintain the crane. A third party, who inspected the crane, made recommendations regarding defects, which were not acted on by A&P Falmouth, HSE said. A&P pleaded guilty to breaching Sections 2(1) and 3(1) of the Health and Safety at Work etc. Act 1974.

boom or hoist rope makes contact with live overhead power lines. Concern has been growing in some countries at the number of fatal accidents that are avoidable. Detailed and appropriate site planning and operation is needed.

ICSA’s new document has been reviewed and jointly adopted by the following: Association of Equipment Manufacturers [AEM], Canadian Crane Rental Association [CCRA], The Crane Industry Council of Australia [CICA], The European Association of abnormal road transport and mobile cranes [ESTA], European Materials Handling Federation [FEM], Japanese Crane Association [JCA], Specialized Carriers & Rigging Association [SC&RA].

Smart Chart

Expands the customary circular work area to take advantage of the maximum available lifting capacity

Unrivaled Reliability

Unique Quality

Advanced control system with enhanced features

Reduced Fuel Consumption

• Fuel Monitoring

• Eco Mode System

• Automatic Pump Disconnect Take a closer look

Discover how Tadano RT cranes deliver maximum lifting performance with unrivaled reliability.

Tadano RT cranes give your business the next-generation features you need to work safer, faster and more effectively than ever. Tadano View gives your operators a birds-eye view of the crane’s surroundings on a large, multi-function display inside the cab. Reduce fuel consumption with Fuel Monitoring, Eco Mode and Automatic Pump Disconnect. And expand the working area to get the best crane performance in any outrigger extension setup with Smart Chart.

Take a closer look at what Tadano can do for your business. Learn which models are available in your region at tadano.com.

85-Ton| 80 mt Rough Terrain Crane

✓

Heavy lifts from super big cranes aid the construction of a plethora of global projects. NIAMH MARRIOTT reports

Heavy lifts are paramount for a plethora of global infrastructure and industrial projects, aiding the construction of mega offshore platforms and new power plants, as well as helping to build massive complexes in cities around the world.

As engineering demands grow more complex, the need for specialized equipment, innovative lifting techniques, and careful planning becomes ever more critical. Huge cranes, equipped with the latest technology, are reshaping the way we move and place the heaviest loads and are helping to drive progress across energy, construction and manufacturing industries worldwide.

As previously reported by ICST, a whopping 14,000 tonne capacity land-based crane is planned for construction by a division of China Petrochemical Corporation (Sinopec).

Sinopec Heavy Lifting and Transportation Co., Ltd. (SHLTC), based in Beijing, China, is planning to start construction of what will be – by a big margin – the world’s largest land-based crane of its type.

The new giant lattice boom super heavy lift crane, designed and developed in-house by SHLTC, will be used in China and further afield on the company’s projects, making major lifts in the industrial chemical, nuclear and offshore engineering sectors, the company said.

Construction is due to start in 2024 with testing completed by the end of 2026.

In October, Chinese heavy equipment manufacturer Sany delivered the world’s first 9 axle, 4,000 tonne all terrain crane, the SAC40000T, to a Chinese hoisting company, said to mark an historic milestone in crane design.

With the largest lifting capacity on the fewest axles, this machine is tailored for nextgeneration wind

Sany delivered the world’s first 9 axle, 4,000 tonne AT crane, the SAC40000T

turbine installation, the company says. It features an 81 metre full-extension boom, 124 metre jib, and a maximum lifting height of 200 metres. Capable of lifting 375 tonnes to 100 metres at an 18 metre radius and 200 tonnes to 185 metres at 30 metre radius, the SAC40000T addresses the growing demand for equipment to support clean energy advancements.

Built on a compact 22 metre 9-axle chassis – the shortest in its class – the crane offers unmatched manoeuvrability with a 16 metre steering radius and 18 per cent gradeability. It is designed for rapid assembly, with single-side superlift setup in under an hour and reeving times under 70 minutes.

The SAC40000T’s compact design sets a new industry benchmark, making it ideal for challenging terrain and high-demand wind energy projects, Sany added.

In describing the crane’s development, the product manager says, “We know there’s a growing need for powerful, precise equipment to drive clean energy forward. Current 2,000 tonne class can handle 7 or 8 MW turbines. But 10 to 13 MW turbines over the next 5 to 10 years? That’s why we bring 4,000 tonne AT to the table.”

As previously reported by ICST, Dutch heavy lift company Mammoet set a new benchmark in »

the lifting industry with the construction of what it claims as the world’s strongest onshore ring crane, the SK6000. A standout feature of this crane is its powerful rope winches, supplied by Liebherr.

The SK6000 is capable of operating entirely on electricity. Central to this functionality are the four Liebherr-supplied gear ring rope winches, each delivering a line pull of 600 kN, allowing the SK6000 to achieve its immense lifting capacity of 6,000 tonnes.

Both Mammoet and Liebherr worked closely to design and fine-tune the winches to meet the specific demands of the SK6000.

“Our collaboration with Mammoet showcases the versatility and strength of Liebherr’s drive technology,” says Markus Groeber, technical sales engineer, Liebherr Drive Technology. “For the SK6000, we equipped the winches with Liebherr’s own gear rings, gearboxes and electric motors, creating a system that offers unmatched lifting power.”

Heavy lifts for offshore work involve the precise handling and transportation of massive structures, such as platforms, turbines, or subsea equipment, often requiring specialized vessels and advanced engineering solutions.

Dutch offshore contractor Allseas successfully removed Shell UK’s 31,000 tonne Brent Charlie platform topsides from the UK sector of the North Sea.

The single lift removal by Allseas’ vessel Pioneering Spirit is one of the heaviest offshore lifts ever performed, the company says, and concludes years of engineering

and planning.

Edward Heerema, Allseas chairman, says, “It started in 2013, with Shell’s decision to award Allseas the contract for the engineering, preparation and removal of its four Brent platforms. The trust shown then in Allseas’ technical expertise served as a milestone in the 20 year development of Pioneering Spirit. At the time, the vessel was still under construction, but Shell’s belief in Allseas gave us the opportunity to showcase our single-lift technology.”

The Brent decommissioning project is unique in its scale and complexity, comprising four platforms – three concrete-based and one steel jacket. Allseas has played a key role, performing the engineering, preparation and removal of all four platforms.

Netherlands-headquartered Heerema Marine Contractors installed its first WTG monopile foundation project at the He Dreiht Offshore wind farm, currently Germany’s largest offshore wind farm by power supplier EnBW.

A major milestone was reached when its semi-submersible crane vessel Thialf installed all 64 WTG monopile foundations, with each monopile measuring approximately 70 metres in length and weighing 1,225 tonnes, and each transition piece being 32 metres long and weighing 607 tonnes.

“A key factor in our success was the dedication and expertise of our highly

Mammoet’s 6,000 tonne capacity onshore ring crane, the SK6000, is ready for market

skilled crew aboard the Thialf, who, together with our specialized subcontractors, executed excellent installation cycles,” says a spokesperson for the project. “

Jörn Däinghaus, project director for He Dreiht at EnBW underlines: “We are very pleased that our joint planning with Heerema Marine Contractors has enabled such an efficient and smooth installation of the foundations. This is a key milestone for

Sinopec plans to develop a 14,000 tonne capacity crane

»

Allseas removed the 31,000 tonne Brent Charlie and handed it over to Mammoet every offshore wind project.”

When completed, the He Dreiht wind farm is expected to have a capacity of over 960 MW. This project not only supports Germany’s energy transition, but also contributes to the European Union’s broader goals of reducing dependence on fossil fuels.

Huisman has been awarded another contract for the delivery of a large knuckle boom crane for a client in the offshore energy market.

The 550 tonne capacity knuckle boom crane will be equipped with Huisman’s secondary-controlled active heave compensation system, which features the latest technology in load control for various offshore environments and energy management, the company says.

The crane’s boom is optimised for versatile operations on a pipelay vessel, offering an extended reach ideal for lifting

objects onto the pipelay tower.

Huisman’s scope of work includes the complete range of engineering, production, installation, and testing.

This contract marks Huisman’s third significant knuckle boom crane contract announced this year. The company’s new range of knuckle boom cranes include the potential for full electric active heave compensation.

Marine engineer Seaqualize lifted 11 MW wind turbines to Van Oord’s offshore installation vessel the Aeolus to help complete the first commercial scale offshore wind farm in the USA.

It was the first time this operation was done using a new turbine feeder operation.

During the project, the Seaqualize HC750 and its operators were responsible for safely transferring more than 25,000 tonnes between the barge and the Aeolus. First, the HC750 followed the barge motions to ensure the Aeolus crane could safely connect with the component. Then, the HC750 tensioned the crane rigging, while keeping the wave heave motions compensated, and lifted the components off deck. This way, the turbine components such as towers, nacelles and blade racks, weighing up to 750 tonnes per piece, were protected from hitting the deck. After everything was safely lifted off, the HC750 placed the secondary lifting equipment back on the barge, for the next load out.

Wytze Kuipers, project manager for offshore wind at Van Oord says, “Many said feedering turbines in the open ocean would be too complex, especially in the winter season. But with good team work and innovations like the Seaqualize Heave Chief, we’ve shown it can be done.”

Eni UK Limited has awarded Scaldis a contract for the engineering, removal, transportation and disposal of six Eni Hewett platforms in the Southern North Sea of the UK.

The offshore operations are scheduled to take place in 2024, 2025 and 2026 with preparatory works and module lifts being carried out by the company's heavy lift vessel Rambiz, and the main lifts being executed by the heavy lift vessel Gulliver.

Scaldis successfully and safely lifted the first Eni Hewett platform this summer.

The heavy lift industry continues to push boundaries with groundbreaking innovations and record setting projects. ■

Figures used in this IC M20 table for November 2024 are from calendar year 2023 or the 12 month financial year to 31 March 2024. Where possible the year-onyear percentage change figures for sales revenue mentioned in the article are calculated in the reporting currencies of the manufacturers. This is to avoid the effect of exchange rate fluctuation. In some cases the figures are supplied by the manufacturers.

Where stated, the percentage changes are calculated from the figures given in the table which are conversions to US dollars from the various reporting currencies. For the figures in this year’s table, the exchange rates from the reporting currencies into US dollars are listed in the table below.

Each year’s table should be taken as a snapshot in that there are occasionally changes in one table made to the previous year’s figure the next year. For example, if new data for the year becomes available after one year’s table was published that data may be substituted in the next table. Attempts are made at appropriate explanation in those instances.

Some companies, often based in Asia, are changing their reporting from an April to March financial year to a January to December calendar year. Three quarters plus the next one will be used for the first year until a full new calendar year of figures is available.

US$1 = €0.94

US$1 = JPY 154

US$1 = CNY (RMB) 7.23

US$1 = RM (MYR) 4.47 Exchange rates on 19 November 2024 from xe.com (Note that the IC M20 table does not account for exchange rate

from year to year).

A welcome return to growth this year follows two years of decline in the combined total sales of the top 20 crane manufacturers in the world. ALEX DAHM reports

Most of the change in this year’s ICm20 crane manufacturer ranking is positive and the result of significantly higher crane sales in 2023 over the previous year. This year’s total is up a healthy 5.6 per cent on last year’s table, much more than a complete reversal of the previous year’s 10 % fall and the 4 % drop the year before that.

The combined total sales from cranerelated activity for the 20 largest crane manufacturers by revenue (sales in 2023) was US$33,568,385,966. That number is heading back towards the 2021 table’s alltime high of $36,944,945,662. This year’s

total is still 9 % down on that but catching up fast. It closely matches the 2020 total. The 2024 table total is $1,789,593,430 higher than last year. That equates to a lot more cranes delivered. Good news but there are already signs of change that may point towards it being unlikely to be repeated next year. Having said that, 17 of this year’s 20 had higher sales than last year, 10 of those being double digit rises. Of the three companies showing lower sales, only one was from China, the other manufacturers from there all having turned around their dramatic declines in sales since 2021. XCMG was down 11 % instead

of 41 % last year. Zoomlion was up 1.64 %, also a big turnaround from a 48 % decline last year.

Liebherr retains its top place, maintaining a similar size buffer between it and Konecranes in second place. To do this it managed a strong 12.7 % increase in sales over the previous year. Konecranes’ increase was 17.9 %.

The first change in the table is Cargotec in third, swapping with China’s XCMG, down to fourth. A 12.2 % increase from the Europe-based manufacturer versus an 11 % decline in sales precipitated this change.

Next year this will likely change back, partly because of recovery in China and strengthening exports but also as a result of major changes at Cargotec. It has separated Kalmar as a standalone business and just announced the sale of the MacGregor offshore crane and deck handling division.

The financial reporting to reflect this will change from the first quarter of 2025. Last year Kalmar’s contribution was just

over €2 billion and MacGregor’s was €733 million. Cargotec will just be the Hiab loader crane division and the name will be changed to reflect this by dropping Cargotec altogether. Its sales in 2023 were €1.79 billion which will see it move down to somewhere around tenth place in the ICm20.

Back to this year, the next three places, ZPMC, Zoomlion and Manitowoc, 5th, 6th and 7th, respectively, remain unchanged. All three showed increases in sales, the latter by an impressive 10 %. Sennebogen from Bavaria had a really good year, up nearly 27 % and heading towards the one billion milestone.

Also impressive is the recently rapidly expanding Tadano from Japan with its 23.6 % increase over the previous year moving it up one place to eighth. Next year its increase will likely be even bigger, supplemented by sales from recently acquired crane manufacturers Manitex in the USA and parts of fellow Japanese manufacturer IHI’s crane and materials handling business. All this helps it in its

long-held ambition to become the world’s largest crane maker.

The next six places, from 10th to 15th, are all unchanged from last year, even though all of them also showed increases in their sales, four of them in double digits. Just outside the top ten Columbus McKinnon, in 11th place, exceeded one billion dollars in revenue for the first time in its history and posted an 8.26 % increase in sales.

The next mover is loader crane manufacturer Fassi from Italy, up one place at 16. The Fassi family sold 70 % of its business to a London, UK-based private equity fund in January 2024, leaving the Fassi family with the remaining 30 %. Giovanni Fassi remains CEO at the company his father started in the 1960s.

Kobelco in 17th was displaced by Fassi while the remaining three, Manitex, Kato and Furukawa retain the same positions as last year rounding out the top 20. Kobelco sales were virtually flat due to the engine certification issue in Europe. The forecast is for Kobelco sales to increase by about 7.5 % in 2024. ■

www.liebherr.com

www.konecranes.com

www.cargotec.com

www.xcmg.com

www.zpmc.eu

www.zoomlion.com

www.manitowoc.com

www.tadano.com

www.sanygroup.com

www.palfinger.com

www.cmworks.com

www.sennebogen.de

www.link-belt.com

www.terex-cranes.com

www.hsc-cranes.com

www.fassi.com

www.kobelco-cranes.com

www.manitexinternational.com

www.kato-works.co.jp

www.uniccrane-global.com

The specialized transport industry has come a long way in tackling the challenge of moving massive equipment and structures. At the forefront of this progress is the self propelled modular transporter (SPMT), a game changer in hauling the seemingly impossible. These multi-axle machines have become the go-to solution for industries dealing with supersized loads like wind turbines, industrial reactors, and bridge components.

What is really exciting is how SPMTs are getting smarter and more adaptable. Engineers are coming up with clever ways to handle increasingly heavy and complex cargos while navigating tighter spaces and tougher terrains. With cuttingedge controls, better modular setups, and innovations in load-balancing tech, SPMT is meeting the growing demands of industries that constantly push limits.

The specialized transport industry is making big moves smarter and safer.

MARRIOTT rounds up the latest news

To construct NASA's new mobile launcher, Sarens used Scheuerle’s K24 SPMTs

transport company Tii Scheuerle.

“Modern SPMT designs emphasise greater flexibility and adaptability, with features to meet diverse requirements like high axle loads,” says a spokesperson for specialized

“Scheuerle offers SPMT options that are easily configurable for different transport tasks, including specialized versions like the SPMT SL (split type), which can adapt to various width requirements, widening systems and spacers, and an Arctic Package variant for extreme climates down to -40°C.

Global heavy lift leader Sarens played a key role in installing an innovative wooden bicycle and pedestrian bridge at the Vierarmen junction in Tervuren, Belgium, for its client Viabuild. The 278 tonne bridge spans 67.5 metres and is part of the F29 cycle highway connecting Brussels and Leuven.

For the installation, Sarens used four CS250 towers, eight axle lines of SPMT, custom transport stools, and 100 tonne jacks. Transporting equipment from across Europe required 24 trucks, with assembly completed in three days, thanks to meticulous planning at Sarens’ Wolvertem depot. The CS250 towers allowed efficient jacking under the pre-assembled bridge, meeting the eight-hour overnight road closure limit.

This landmark project is part of the ‘Werken aan de Ring’ programme, promoting sustainable mobility by creating safe, eco-friendly infrastructure. Constructed entirely from European wood, the bridge is the largest of its kind in Flanders, Sarens says. Manufacturer Amann contributed to the design and strength calculations and supplied custom wooden support blocks to protect the bridge during transport.

“The latest addition, Scheuerle Connect, integrates telematics, providing fleet management tools, remote diagnostics, and maintenance tracking for efficient operation and reduced downtime and can be even retrofitted in older generations.”

Scheuerle’s SPMTs have set benchmarks in heavy transport since their introduction. Over the decades, their models have continually pushed engineering boundaries to meet the diverse needs of industries worldwide.

“The original SPMT (1983) revolutionised the industry with modular designs allowing unlimited payloads and cross-generation compatibility,” says the spokesperson.

“The PowerHoss series (2015) introduced a compact, user-friendly model for loads starting at 80 tonnes, scalable through coupling additional units. The SPMT K24 (1980s) remains a versatile solution for diverse heavy loads, bolstered by an array of accessories. In addition, the InterCombi SPE offers a specialized option with electronic steering, dual tyres, and a lowered height for enhanced stability and adaptability.”

A five year manifesto for specialized transport in Europe has been published by the European Association of Abnormal Road Transport and Mobile Cranes (ESTA).

In the manifesto ESTA sets out its priorities for abnormal road transport over the next five years.

The manifesto, titled Competitive and Harmonised Abnormal Transport in Europe, will help support ESTA’s mission to improve safety and efficiency in Europe’s heavy transport sector.

Commenting on the move Ton Klijn, ESTA director, said, “There is a growing level of political activity in the transport sector as our national leaders become increasingly aware of the importance of the work being carried out by our members. Now it is essential that those same political leaders appreciate the need for a co-ordinated approach that crosses European borders and boundaries.”

The Îles d’Yeu and Noirmoutier offshore wind farm, 12 km from Île d’Yeu and 16 km from Île de Noirmoutier, is France’s fifth operational offshore wind project. Featuring 61 wind turbines with a capacity of 8 MW each, it will produce 1,900 GWh annually, powering approximately 800,000 people.

Longtime partner BOW Terminal engaged Mammoet to handle the marshalling, transport, and temporary storage of 400 tonne transition pieces (TPs) fabricated in Belgium. Traditionally, TPs are moved with crawler cranes or SPMTs, requiring complex assembly and rigging. For this project, Mammoet introduced the TPH800, an attachment that transforms SPMTs into giant forklifts, enabling faster, safer TP handling.

Each TP arrived at BOW Terminal Vlissingen by barge in groups of four, was lifted to the quay by a 1,200 tonne crawler crane, and placed on concrete supports. SPMT, equipped with the TPH800, collected the TPs, moved them to storage, and later transported them back to the quayside setup area.

Speaking on a recent project, Tii’s spokesperson added, “The Swiss heavy transport specialist Friderici Spécial has integrated four 6-axle SPMT PowerHoss modules from Tii Scheuerle into their fleet, marking a significant advancement in the renewal of Geneva Airport’s runway. These modules have been deployed as replacement chassis for two aging gantry cranes, enabling precise handling and manoeuvring of 180 tonne concrete slabs during overnight operations. This ensures that daytime flight schedules remain unaffected.

“The SPMT PowerHoss features

The TPH800, with its 800 tonne lift capacity, simplifies handling by slotting forklift-like beams under the TPs, securely locking them in place for transport.

1,200 capacity crawler helps on site

integrated drive units and plug-and-play operation, making it ideal for confined spaces such as tunnels, ware-houses, and runways. Its versatility extends beyond this project, offering solutions for industries such as energy, construction, and logistics.

“Friderici Spécial has also set a milestone by obtaining Swiss Motor Vehicle Control (MFK) approval, allowing the PowerHoss to operate on public roads. During testing, the modules demonstrated their capabilities in transporting heavy components like trans-formers and tunnel boring machine parts under challenging conditions, including con-fined spaces and steep inclines.

“This project showcases the flexibility, reliability, and cost-efficiency of the SPMT PowerHoss, proving its value as a multifunctional transport solution for longterm projects and beyond.”

Heavy lift giant Sarens recently purchased

Multiple challenges were overcome in a module move for a Saudi-based project

Express Global Logistics (EXG) in India transported and loaded out modules, each weighing up to 250 tonnes, for an energy project in Saudi Arabia.

The 14 modules, for a large green hydrogen project, were moved and placed using SPMT from Scheuerle. There were 48 axle lines of SPMT, two power pack units (PPU) and specially designed spacers.

The modules were 50 metres long, 12 metres wide and 18 metres tall. Together all the modules were 1,500 FRT (freight tonnes).

For the load out of eight of the modules it was a roll-on roll-off (RoRo) operation. On their SPMT the modules were loaded onto the vessel with ramp plates and stools before fastening for the voyage. The vessel was ballasted for stability.

The other six modules were transported on SPMT to the jetty and lifted into position on the vessel using crawler cranes.

additional Scheuerle SPMT K24 axle lines from Tii Group. The company now have nearly 2,000 SPMT K24 axle lines in its fleet.

Sarens uses SPMT K24 modular transporters for a broad spectrum of applications, including transporting oil-andgas platform modules, entire bridges, and other oversized and heavy components, in shipyards, construction, and mining sites.

German transport specialist Baumann has invested in Cometto self propelled modular transporter axle lines. In midOctober representatives from the company travelled to the Cometto factory in Italy to inspect the 24 axle lines of equipment they had ordered.

Navantia Seanergies also recently placed an order with Cometto for 72 axle lines of MSPE 48T self prepelled modular transporter. The Spanish offshore wind and hydrogen technology company will use its new equipment to move monopile foundations for wind turbines.

Many crane and specialized transport companies are finding a plethora of work in the wind energy sector. Luxembourg-based transport company Faymonville has created new products to help move large wind turbine components to their sites.

“Renewable energies have been an important topic for some time,” says a spokesperson for the family-run company.

The Faymonville Group’s recent WindMover Days event highlighted the company’s

dedication to the evolving wind power industry by showcasing specialized transport solutions for increasingly larger wind tower elements and rotor blades.

“The wind power industry in particular is subject to continuous development. Offshore systems and wind farms are growing continuously, as are the dimensions of the wind tower elements and rotor blades – and with them the transport challenges.”

Over four days, around 250 industry experts explored Faymonville’s high-tech offerings, including the WingMax flatbed trailer, Cometto BladeMax1000, and various self-steering and low loader trailers designed for efficient and safe wind turbine component transport. These innovations not only enhance transport capabilities but also reduce costs and environmental impact. ■

Specialist heavy lift contractor Vanguard claims victory as this year’s winner of the annual IC TopLift contest. ICST reports

Equipment user: Vanguard

Equipment used: Bespoke hydraulic gantry lifting systems

Location: South Africa

Specialist heavy lift contractor Vanguard up-righted the bark Europa, a 650 tonne, 44.5 metre long, 112-year-old sailing ship, after it tipped over in dry dock at Cape Town’s Victoria and Alfred waterfront in South Africa. Lacking space for a crane, Vanguard engineered a custom solution using telescopic hydraulic gantries and strand jacks.

The ship had slipped from its keel supports and rolled onto its starboard side during an operation to prepare for its return to the sea.

Working for US salvage

We selected the top ten shortlist but the decision was placed in the hands of you, our readers, to vote for your favourite lift and decide the number one spot in our 2024 IC TopLift competition. The results are in.

specialist Resolve Marine, Vanguard was contracted to engineer and perform an up-righting operation and to realign the vessel with the centre line of the track system in the dry dock. A crane lift was not possible because of insufficient space surrounding the vessel to set up a suitably sized machine.

The answer was to use two telescopic hydraulic gantry lifting systems, positioned over the vessel between its masts, to minimise any further impact on the masts and rigging. Once the 400 and 600 tonne capacity lifting systems were in place, two header beams were positioned between them and four 186 tonne capacity strand jacks were installed.

The strand jacks were mounted atop the header beams and rigged to custommade brackets on the keel at the bottom of the ship. Vanguard said this method provided a high degree of accuracy and enabled the team to lift and upright the vessel in a controlled and precise manner. After the vertical lift Vanguard completed a transverse skidding operation to realign the vessel with the dry dock track system.

With votes collated from our print and digital readership, aided by our social media channels, we had a large turnout of responses this year. We’d like to thank everyone who got involved and made the effort to submit a vote. All the shortlisted lifts were worthy contenders that helped showcase the innovation and groundbreaking achievements of our industry.

The standout winner taking first place this year is heavy lift contractor Vanguard, who used a bespoke hydraulic gantry lifting system to upright a 650 tonne ship in South Africa. A very close second place is

awarded to Allelys, who used a Liebherr LG 1550 all terrain crane to install a 160 tonne turbine and a 96 tonne generator through the roof of a 22.3 metre high turbine hall in the UK. Heavy lift giant Sarens’ 5,000 tonne capacity crane Big Carl takes the third place spot this year for its lifting work at Hinkley Point C nuclear power station, also in the UK, where it installed a 750 tonne polar crane.

The competition this year highlighted not only the technical prowess of the participating companies but also the incredible diversity of lifting projects undertaken globally.

If your company has completed a job in the last couple of months, or if you do one before August 2025 that you think merits entry into next year’s TopLift competition, and-or it would make an interesting site report for International Cranes and Specialized Transport magazine or its website, please send details to the editor, Alex Dahm, at alex.dahm@khl.com, or by post to: KHL Group, Southfields, South View Road, Wadhurst, East Sussex, TN5 6TP, United Kingdom.

Equipment user: Allelys

Equipment used: LG 1550 all terrain

crane

Location: England

UK-based heavy transport and lifting specialist Allelys minimised site disruption by using a crane to install a 160 tonne turbine and a 96 tonne generator through the roof of a 22.3 metre high turbine hall in the UK. The components were transported 33 miles (53 km) on specialized trailers and lifted into place by a Liebherr LG 1550 crane, overcoming structural challenges and space restrictions. The 22.3 metre building height meant the LG 1550 was configured with a luffing jib.

Equipment user: Sarens

Equipment used: SGC-250 ring

crane

Location: England

Sarens’ 5,000 tonne capacity crane, known as Big Carl, was used to install a polar crane weighing 750 tonnes at the Hinkley Point C nuclear power station construction project in the UK, one of the heaviest lifts made on the project to date.

The super heavy lift ring crane lifted and placed the polar crane into the first reactor building at the giant site in Somerset, south west England. Big Carl also installed the crane’s test weight structure, weighing another 715 tonnes.

The polar crane can rotate full circle inside the dome, lifting into place the reactor and the steam generators. When the plant is operational, the polar crane will be used for maintenance.

With the first batterypowered rough terrain cranes hitting the Japanese and North American markets this year, manufacturers and customers are watching closely. Can electric alternatives really compete with diesel machines which are becoming increasingly efficient and pushing the boundaries of lifting capacity?

LUCY BARNARD reports

Tadano’s eGR-1000XLL-1 rough terrain crane

Take a look at Tadano’s promotional video for its new EVOLT eGR-1000XLL-1 and you might be forgiven for thinking you had mistakenly clicked on the latest Ridley Scott sci-fi movie.

The slick three-minute video has a soundtrack oddly reminiscent of the Alien franchise and tells the story in glorious technicolour of a new power, to date untapped in its universe – in this case the company’s first fully electric rough terrain crane. Units have been delivered in Japan and the USA.

It shows the Japanese manufacturer has been ploughing a significant chunk of its marketing budget promoting the new 100 tonne capacity RT which the company sees as a major step in its goal to reduce emissions generated by its products by 35 per cent by 2030.

If the company can crack the highly competitive North American RT crane market with a battery-powered alternative, then the thinking is that the concept can be rolled out across other models.

“Tadano is assessing other models for potential electrification as part of its Green Solutions initiative,” says Lance Rydbom, director for product management and engineering at the company’s panAmerican operations. “We are committed to advancing our electric crane lineup, focusing on sustainability and efficiency. We aim to respond to customer demand for sustainable solutions.”

Certainly, North America remains the largest market for rough terrain cranes

which, unlike their all terrain cousins, have oversize earthmover tyres allowing them to move over rough surfaces and are usually prohibited from driving on public roads.

Yet exactly how much demand there is from customers for fully electric rough terrain cranes is a moot point – especially as many of the machines sold are required to work long hours on infrastructure or energy projects, or to maintain other machines in mines.

Tadano only launched it in the USA on 31 October and has so far provided no information on how sales have been going on either this model or its first battery electric RT crane, the 25 tonne capacity EVOLT eGR-250N which the company launched last December in Japan.

“This crane suits various applications, including urban construction projects, industrial facilities, and indoor projects,” says Rydbom. “Demand is expected to be highest in sectors requiring strict environmental and noise controls, such as metropolitan construction sites and renewable energy projects, where emissions reduction is prioritised.”

Tadano boasts that eGR-1000XLL-1 matches the lifting power and maneuverability of the company’s closest diesel equivalent, the GR-1000XLL-4, which Tadano launched in 2020.

The machine has a 100-tonne (90.7 metric tonne) lifting capacity and a 51-metre boom, reaching a maximum tip height of »

68.3 metres with full jibs.

Moreover, when operating, the electric machine makes almost no sound. At a recent demonstration at the Shido Plant in Japan, witnessed by Crane Briefing, the only discernable noise made by the model was when the boom hydraulics were engaged.

“The machine’s zero emissions and lower noise make it ideal for urban areas or indoor projects where quiet operation is beneficial,” Rydbom adds.

However, as with much electric construction machinery, the main sticking points for electric rough terrain cranes are likely to be with both the higher initial purchase cost when compared with a diesel alternative as well as concerns about running time.

“While conventional cranes have advantages in runtime length, the eGR1000XLL-1 minimises operational costs by eliminating fuel expenses and lowering maintenance needs due to its simplified electric drive,” Rydbom says. “Although battery runtime is finite, plug-in operation is possible for continuous work.”

He points out that the machine offers up to seven hours of lifting or five hours of lifting combined with 5.5 miles (8.7 km) of travel per charge. Charging options include a 480 Volt AC (normal charge: 4.5 to 5.5 hours) and CCS1 rapid charge (2 hours). It also features regenerative braking to recharge the battery during deceleration.

Meanwhile other rough terrain crane manufactures will be watching carefully to see how the market is receiving the first

fully electric machines.

Elsewhere, the appetite among manufacturers appears to be less concerned with ditching internal combustion engines and more interested in increasing the efficiency of the diesel models on offer and pushing the boundaries of lifting capacity while maintaining manoeuvrability.

Liebherr only re-entered the rough terrain crane market in 2017 after a thirtyyear absence having focused on its all terrain models which tend to be more popular in the European markets.

However, since then, Liebherr has invested heavily in the sector, launching a 90 tonne and 100 tonne model at ConExpo in 2017 and five years later, its 130 tonne capacity LRT 1130-2 at Bauma 2022.

A Liebherr LRT 11302.1 working on a large belt transfer station

Liebherr says one of the main reasons for this is that for all terrain cranes to be capable of lifting loads of up to 130 tonnes, they generally have to be a lot longer (usually comprising around 5 axles) while rough terrain cranes with their larger wheels can carry the same loads in a more compact form, taking up far less space on confined construction sites, industrial yards or refineries.

Although all powered by six-cylinder Cummins diesel engines, Liebherr says it has worked to minimise carbon dioxide emissions. Machines can be operated without restrictions on hydrogenated vegetable oil (HVO). Moreover, the company says even the 130 tonne version is designed so it can be transported easily on conventional low-loaders.

The LRT 1130 comes with a 60-metre telescopic boom, giving it a maximum hoist height of 85 metres and a maximum radius of 66 metres.

Its variable support base allows each outrigger to be extended to any length while the crane work is controlled by a load moment limiter which calculates the maximum load capacities for the current situation. The manufacturer says this spells greater efficiency for crane operators by ensuring higher lifting capacities over a support and means that ballast transport is often not required for many crane jobs.

Liebherr says it is working on new developments in the rough terrain sector but, although it plans to launch new mobile »

handling reach stackers for heavy handling lifting

– lifting capacity from 85 to 180 tons

With this unique loader crane, decades of expertise and the latest technology become the future of lifting solutions. The astounding outreach of 38.7 meters including the fly jib, a lifting moment of 124.8 mt, and the latest assistance systems, the PK 1650 TEC sets new standards in the heavy-duty loader crane segment.

LIFETIME EXCELLENCE

cranes at Bauma 2025, the company has no plans to launch any new RT machines.

Terex Rough Terrain Cranes, the Italyheadquartered rough terrain crane manufacturing arm of US giant Terex, has no such qualms.

So far this year the company has launched three new models, the TRT60, TRT80L and TRT100, while the company says it has plans to launch a new 50 tonne capacity model in the near future.

The TRT80L, which the company launched in June 2024, includes a longer 47-metre telescopic boom which can be extended with jib options of 9 and 17 metres.

Terex says the main reason behind the launch was to appeal to crane rental companies by enhancing the crane's versatility, making it suitable for a wider range of tasks.

Like Liebherr, Terex too highlights transport convenience as a highlight of its new 80 tonne capacity model, facilitated partly by its width of just 3 metres –something that also helps with manoeuvring

in confined spaces and on jobsites where space is restricted.

The company also points to its hydraulic system which features load sensing technology, allowing precise movements and load positioning.

And Terex doesn’t plan to stop there. The company says that in 2025 it has plans to further extend its range beyond its current maximum lifting capacity of 100 tonnes.

“We will not stop here and in 2025 we will showcase what is going to be the

biggest Terex RT in our offering and also a strategic return of Terex RT to a product range which used to be very successful for us,” says Giancarlo Montanari, general manager at Terex RT.

“The capacity of RTs is increasing but we are getting close to the limit of rough terrain cranes with two axles,” they add.

Italian manufacturer Locatelli too has been increasing the capacity of its RTs.

In April it showcased its new 100 tonne capacity Gril 110.100 RT crane at the Intermat 2024 trade show in Paris. The crane, which has a 47 metre boom in 5 sections, is now the biggest RT model in the company’s range, surpassing its previously range-topping 80 tonne capacity RT.

Meanwhile USA-based Manitowoc has been refreshing its offering by updating its 65 tonne and 80 tonne capacity Grovebranded rough terrain cranes.

The GRT765 and the GRT780 were both unveiled for the first time to dealers and customers at the company’s Crane Days event in Pennsylvania, USA, in May 2024, replacing the previous RT765E-2, RT770E and GRT880.

New tower crane concepts for wind turbine

installation. Part two of an epic series written by ICST special correspondent and global tower crane

authority HEINZ-GERT

This month’s report on tower crane applications for wind turbine erection projects continues with a close look at some more large luffing jib models.

Following on from last month’s look at IHI Shimizu’s unusual designs, we turn to fellow Japanese tower crane manufacturer Kitagawa Iron Works Co., Ltd. It collected field experience for its JCW1800 launched in 2020 when it was operated by TA Lift Co. This rental company for wind turbine installation tower cranes was jointly formed by Achia Co., an expert in heavy transport and rigging operations, and Toko Electrical Construction co., Ltd.

It was the first wind turbine installation tower crane designed in Japan. Up to 140 tonnes can be lifted at a 12.5 metre radius to 140 metres high in its JCW1800K version. Depending on the hook reeving, which can be changed using a remotely operated pin, the same crane can be used as a 95 tonne

The Kitagawa JCW1800K can be climbed down alongside its mast for heavy typhoon wind security

First unit of the Kitagawa JCW1800K on its second job site

Transporting the A-frame of the Kitagawa JCW1800K on SPMT

capacity JCW1600K. There is also the 70 tonne capacity JCW1400K. Up to a mast height of 75 metres the tower can be just 2.5 x 2.5 metres for easy transport on standard trucks. To reach a 91.4 metre free standing height, additional 3.2 x 3.2-metre-wide base tower sections are added. Note that no leg bracing is needed.

It follows the typical Japanese method of jacking the crane which allows insertion of up to two tower sections as one 15.2 metre long unit. A special cross-shaped undercarriage was also developed to speed up installation.

To further improve the fast relocation ability for wind farms Kitagawa also developed a specialized transport system for its JCW1800K. It uses self propelled modular transporter (SPMT). In this case

The compact machinery deck of the Kitagawa JCW1800K

the complete machinery deck, with the A-frame and base jib section (to keep the luffing ropes in place) is lifted on one SPMT carrier with the help of a 550 tonne capacity wheeled mobile crane in one lift.

The climbing unit and base tower section form another SPMT load. This method allows the centre of gravity of the crane components being driven around to be very low, helping stability.

At the time of writing one JCW1800K had been produced. According to Kitagawa it turned out that strict transport restrictions in Japan meant the accepted size of wind

turbine didn’t require a crane as big as the 1,800 tonne-metre class for the domestic market. TA Lift and Kitagawa, therefore, developed the smaller JCW1250 with a 95 tonne capacity at 12.5 metres radius.

A freestanding tower height of 80.9 metres and 51 metre jib giving a 130 metre working height can be reached with a counter jib radius of just 8.7 metres.

Its main innovation is that it will have an hydraulically foldable 16 x 16 metre crane base section with hydraulic levelling outriggers of the type well known on large mobile cranes. This base can be transported as a 23.2 metre long and 3.85 metre wide unit.

As is already the case with the JCW1800K, the smaller crane’s machinery deck, A-frame and jib base can be transported as one SPMT load with just a 4.2-metre-high centre of gravity. In contrast to the 107 tonnes of the JCW1800K, the smaller crane’s unit weighs 80 tonnes, allowing a smaller assist crane.

A large window in the cabin of the Kitagawa JCW1800K is to allow the best view of the load, especially when the jib is raised

Its method of inserting tower sections when climbing means it has a traditionally wide machinery platform. Kitagawa redesigned it, however, in such a way that by simply disconnecting the operator cabin and the access platforms, the width of that machinery deck can be reduced to 4.95 metres. A common feature of cranes in this class in Japan is an 8 to 10 metre wide machinery deck. These need a complicated and time consuming split deck design for transport.

Thanks to its compact machinery deck when rigged, the JCW1250K can be relocated more easily between turbine sites on a wind farm. Even the mast and jib sections are designed to allow transport in pairs, as 4.55 metre wide loads, on standard 3.0 metre wide SPMT modules.

Unlike the JCW1800K, the size of the tower section, even for the highest freestanding capacity, is kept to 2.05 x 2.05 metres. Again, no bracings are necessary between the tower base with the crossshaped legs which helps reduce installation time.

Kitagawa’s patented remote controlled rope reeving change device means the hook block can be used in six-fall operation for heavy loads up to 95 tonnes or in fast twofall mode for loads up to 25 tonnes.

In contrast to the original jib’s end section design, the sheaves for the hoisting rope have been placed offset from the central jib line to increase the length of tower section, to 17.6 metres, that can be inserted into the climbing unit as one unit. Again, this helps reduce installation time.

At the time of writing the first prototype of the JCW1250 had been manufactured »

10th Edition

25-27 September 2025 - Piacenza (Italy)

25-27 September 2025 Piacenza (Italy)

25-27 September 2025 - Piacenza (Italy)

A stiff and compact mast system allows economical free standing capacity on the Kitagawa

Transport for the Kitagawa JCW1250 base, including the mast climbing system

and two units were ordered. This model is suitable for 6 MW wind turbines with 120 metre hub height. It was jointly developed by Kitagawa, Toko, TA Lift and AKTIO Corporation. Delivery of the first unit was due in September with the second unit to follow later in the first quarter of 2025.

One of the many inherent design issues for tall free standing wind turbine tower cranes is the bending of the tower when lifting big loads. After placing the load, the crane driver has to compensate for the rearward movement of the tower. It all happens at very short – in most cases minimum – radius, where the load has to be placed in very smooth and exact positioning mode.

Strict earthquake safety regulations mean Japanese tower cranes generally have a stiff tower system with little mast deflection. It is very different on European and Chinese top slewing luffing jib tower cranes of corresponding capacity. At a 12.5 metre working radius around 3 metres of deflection has been

measured when using a 3.30 x 3.30 metre wide mast free standing at 110 metres.

Minimising mast deflection was one of the main motives for Krupinski Cranes of Poland to develop a completely new wind turbine tower crane. The concept is based on a bottom slewing tower crane design which can be traced back to the successful Peiner TN, VM and M series cranes of the 1970s. It culminated in 1979 with the giant, 2,000 tonne-metre class, VM2000 offering a 102 tonne capacity and 150 metre under hook height.

The new Krupinski KR2000A design study proposes 140 tonnes capacity and a 183 metre under hook height. When going beyond a 100 metre free standing tower this bottom slewing luffer has a loadtorque-balancing tensioner to the

Overview of the Krupinski KR2000

Overview of the Kitagawa JCW1250

Erecting the Krupinski KR2000 using a 120 tonne mobile crane

machinery deck. It provides additional stability for the tower and allows more free-standing height without adding to the square size of the tower.

Krupinski KR2000 mast installation and jib extension using a reach stacker

Additional benefits are that the centre of gravity is lower as the ballast and machinery platform with the hoisting and luffing winch and the climbing units are all installed at the crane’s base. Unlike those old luffers or the now common large top slewing types, Krupinski’s design is containerised for transport.

Nearly all the structural parts of the Krupinski crane are ISO-40’ or ISO-20’ container-sized modules or will fit inside those standard containers. Total transport »

The

KR2000’s mast jacking system

weight will be less than 600 tonnes and individual component weights will not exceed 25 tonnes. The whole crane is designed to be transported in 24 standard container loads.

To transport comparable luffing jib top slewing Chinese cranes that follow the original Krøll and Favelle Favco rope luffer designs requires much more oversized load transport. Examples are the width and height of the jib sections, plus the massive slewing ring section and the larger dimension tower segments. Often the crane’s components are more than 3 metres wide and 3 metres tall which means higher permits and more expensive low bed trailers.

In its studies Krupinski indicates a reduction in transport costs of more than three times for road transport under the restrictive North American and European laws. In addition, the size of assist crane is dramatically reduced by the initial rigging procedure thanks to the bottom slewing design.

Lifting height for the larger components is much less than with traditional European style top slewing climbing tower cranes. Krupinski expects a 120 tonne capacity telescopic boom crane to be sufficient for the basic rigging procedure. For climbing, to raise the height of the crane, just a reach stacker is needed.

A typical tower crane for this application takes a week or two for rigging. Krupinski claims it will be able to install the KR2000A in two or three days. In addition, investment

Krupinski’s crawler base design for its KR2000

Crawler mounted transport for the Krupinski KR2000

costs are said to be about half of the standard top slewing climbing tower crane in the same capacity range.

Climbing the crane with an innovative climbing rope system connected to a powerful 150 kW drive in a climbing container on the ground will improve the safety of the climbing procedure. Climbing time for each 11 metre tower section is expected to be around 10 minutes. An hydraulically supported bolting and unbolting mechanism helps speed up rigging.

A similarly safe crane position for a free-standing tower crane design can only be found on the Japanese cranes when climbing down alongside their own tower.

Thanks to their permanent magnet drives Krupinski cranes save up to 40 per cent on energy costs. A containerised 500 kVA power generator allows for the independent use of the crane.

In addition to economical transport and fast set up time, the crane’s wind resistance is another issue in this wind energy application. In service Krupinski claims a maximum allowable wind speed of 55 km/h. In an out of service position, with a folded down boom, 160 km/h is the maximum. With the crane climbed down to a 77 metre overall height it can withstand wind of more than 200 km/h.

How to park the Krupinski KR2000 in storm protection position

To reduce mobilisation time between turbine installation sites a crawler base, similar to the CC 3800 650 tonne capacity crawler crane carrier, is proposed by Krupinski to move under the portal base of the partly rigged crane. The manufacturer estimates the crawler carrier will reduce relocation time of the tower crane from one site to the next by at least two days.

In addition, one crawler carrier could be used for several KR2000A cranes on the same wind farm. Remote operation is also possible. It has a programmable PLC system allowing horizontal load movements with the luffing jib similar to that of a hammerhead crane with horizontal jibs. Wind and load influences are recognised and suppressed, with the control automatically adjusting the torque of the slewing drive based on the position of the boom, thanks to a sophisticated frequency converter controlled slewing drive. ■

Get ready to learn and meet your peers at the upcoming Specialized Transportation Symposium organised by SC&RA. ICST checks out some highlights not to be missed

Registration is open for the specialized transport event of 2025: the SC&RA’s Specialized Transportation Symposium. The next annual STS is in Charlotte, North Carolina, USA, from 18 to 20 February 2025.

Hundreds of peers from the heavy transport industry will congregate for a mix of education sessions, committee and other meetings, all topped with a good helping of networking.

Helping to set the scene and tone near the beginning of the event will be an economic outlook session. Carrying the title, 2025 Specialized Transportation Market Forecast, it will see experts offer analysis and opinion on the state of the US economy. Trends for the oversize and-or overweight load markets in 2025 will be identified and

Attendees will have the opportunity for one-on-one meetings with State Department of Transportation officials. Each will be 15 minutes and members need to sign up and register for appointments here: https://www.signupgenius.com/ go/10C0949A9AB2BABF4C25-52986858scra#/

To register for the 2025 Specialized Transportation Symposium see: www.scranet.org/sts2025

there will be a look at equipment financing.

Prior to that, however, the 2025 STS kicks off on 18 February with US state Department of Transport regional meetings. The morning is committee meetings attendees are very much encouraged to attend. They include the Permit Policy Committee, the Pilot Car Committee, and the Transportation Safety, Education and Training Committee.

There will also be a meeting of the AASHTO CTSO Freight Working Group. Attendees can find out the latest developments but also influence outcomes and help inform in decision-making and really be a part of the industry.

Recruiting and keeping good employees remains a major challenge across the industry. One of the breakout sessions, How to Attract and Retain NextGen Workers, aims to address this issue. In addition to best practice advice, an important element of the session will be how to manage the

now very diverse and transformative next generation entering the workforce.

Another perennial topic is addressed by the session titled, Permit Harmonisation: What Would You Do? Hear directly from the horse’s mouth, namely US Highway Patrol and DOT officials, about what they like to see relating to national, regional and corridor permit harmonisation.

Many of the sessions are informative and offer practical solutions related to insurance and risk management. One is about making accident reconstruction part of your overall safety protocol. The title of this one not to be missed is What Happened? Accident Reconstructions and Applications.

Another insurance-related session is titled, Insurance Decisions Impacting Your Future Success. It is a panel of experts offering assistance with preventing losses and working out what factors are negatively impacting your insurance rates. Telematics will be covered, as will effectively financing risk. ■

WHAT: Bauma 2025

WHERE: Messe München, Munich, Germany

WHEN: 7 to 13 April 2025

www.bauma.de

Still somewhat distant but coming up fast is the 2025 mother of all construction equipment trade shows:

Bauma, held in Munich, Germany. ICST reports

Work is well underway at the ‘new’ Messe site in Munich, Germany, for the next Bauma exhibition set for 7 to 13 April 2025. The larger exhibitors are already literally building their presence at the showground.

It promises to be a show that is back to full strength, according to the organiser Messe München. Event director Nicole Schmitt told ICST sister title Construction Briefing that she expects Bauma to be on a par with the size of the 2019 event. That year was a record for Bauma, with a total of 620,000 visitors from more than 200 countries.

Bauma 2025 has five key themes: climate neutrality, alternative drive concepts, networked construction, sustainable construction, and mining challenges.

In terms of the number of exhibitors Stefan Rummel, Messe München CEO, is also expecting a similar number to the 2019 event, when there were around 4,000.

Even more impressive is the area the show will occupy, somewhere in the region of 640,000 square metres. “With this size… we are also expecting a lot more visitors than in 2022,” says Rummel.

It was 2022 when Bauma was last held, soon enough after the pandemic for it to have impacted attendance. It brought in just

Nicole Schmitt, event director at show organiser Messe München in Germany

under 500,000 people and was still a vast show, dwarfing all others of its type around the world.

“Many of the customers who skipped 2022 due to the pandemic will be coming back,” says Schmitt.

While some European economies –Germany’s in particular – are facing headwinds, Schmitt says underlying demand for new construction machinery means exhibitors and attendees alike will

be out in force.

How to meet new regulations governing the construction industry, particularly when it comes to limiting carbon emissions, is one of the drivers behind that eagerness, Schmitt says. Sustainability and digitalisation will be at the forefront. The solution is to get the entire industry to talk to each other and form new solutions, Schmitt explains.

Joachim Schmid, managing director for construction equipment, plant engineering and mining at VDMA (German machinery and equipment manufacturers association) – which supports Bauma’s Innovation Hall –says the upcoming event is making an effort to highlight the newest of construction industry start-ups.

“Young talent and young companies are our main focus,” Schmid explains, referring to Innovation Hall and various exhibits there. He estimated around 85 start-ups will participate in this coming event’s Innovation exhibitions.

One of the largest single bodies of people to descend on Bauma next year will be around 15,000 students, who will join as

part of the Think Big programme.