Onboard Charger

Connected continuous operation

Electric Motor Powerhouse for crane hydraulics

HV Battery Pack

Energy storage for crane operation and AC

Generator

Self-generated electricity

Onboard Charger

Connected continuous operation

Electric Motor Powerhouse for crane hydraulics

HV Battery Pack

Energy storage for crane operation and AC

Generator

Self-generated electricity

Full performance without noise or emissions: The AC 4.070HL-1* with electric upper operates powerfully and quietly –perfect for indoor jobs, night work, or noise-sensitive environments. And the best part: it delivers the same lifting capacity as the diesel model. Lifting performance, load charts, and reach remain unchanged – maximum performance without compromise. Thanks to the flexible energy supply – battery, generator, or external power connection – you’re always ready to work, emission-free and independent.

* The AC 4.070HL-1 is not available in all regions.

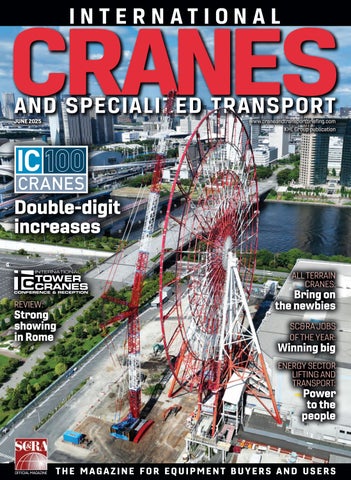

Welcome to the IC 100 issue, the one where we reveal the latest ranking of the world’s largest crane-owning companies in the original KHL top list. I was pleasantly surprised at just how much it has increased in 2025 from last year. A double-digit rise overall was rather more than expected.

Virtually all our IC 100 metrics showed increases over last year. One change I noticed is the number of companies where their largest crane is from China. This year there are 20, or one fifth, while three years ago there were eight and as recently as 2000 there were just two in the top 100.

Some welcome new and returning entries in the IC 100 also helped to mix things up a bit this year. Company acquisitions consolidating crane rental, cash injections from IPOs (initial public offerings) in the last year, plus other major fleet investments have seen big changes to the table’s crane fleet composition and capability. One look at the 2025 iteration of the IC 100 (starting on page 13) clearly shows this is a dynamic industry.

Talking of dynamic, I recently returned from the spectacular city of Rome and the well-received International Tower Cranes (ITC) conference. Thank you to all participants, including attendees, speakers and sponsors, for helping to make this a really interesting and worthwhile event.

Our review of the 2025 ITC starts on page 32 and look out for the videos and presentations from the event coming soon to craneandtransportbriefing.com

Back to the subject of our KHL top lists, by the time you read this there may still be time to complete an entry form for the IC Transport 50, like the IC 100 but for owners of fleets of specialized transport equipment. Probably at least half of the companies in the IC 100 also own enough of this kit to qualify for the T50.

Then, while we are on the subject, also coming up soon is the IC Tower Index for owners of, you guessed it, tower cranes. Feel free to submit an entry form or contact me about any of these top list ranking tables or, for that matter, anything else crane and-or transport related.

World Crane and Transport Summit 2025 18 and 19 Nov, Dublin, Ireland www.khl-wcts.com Tower Cranes North America 10 and 11 June 2026, Nashville, TN, USA www.khl-tcna.com

VICE PRESIDENT SALES PLUS USA/CANADA/KOREA/RUSSIA/UAE Matt Burk +1 773 610 9467 | matt.burk@khl.com BRAND MANAGER

PLUS DACH/IBERIA/CENTRAL EUROPE

Simon Battersby

+44 (0)1892 786223 | simon.battersby@khl.com

District, Beijing, PR China 100027. +86 10 6553 6676 | cathy.yao@khl.com

UK John Austin, Marketplace/Classified advertising

+44 (0)1892 786245 | john.austin@khl.com

BELGIUM/FRANCE Hamilton Pearman

+33 (0)1 45930858 | hpearman@wanadoo.fr

CHINA Cathy Yao

+86 (0)10 65536676 | cathy.yao@khl.com

ITALY Fabio Potestà

+39 010 5704948 | info@mediapointsrl.it

JAPAN Michihiro Kawahara

+81 (0)3 32123671 | kawahara@rayden.jp

Max. Lifting Capacity : 75t x 3.0m

Boom Length : 10.0m to 30.1m

Side Deflection-Resistant Fully Powered Boom for All Lifting Tough 4-plate box boom structure with special welding quality standards, but lightweight

A Superstructure Designed to Take on Tough Jobs

The upper frame is designed to be durable for winch operation with high line pull.

The vertical layout of the main & aux. winches helps achieve a compact design and efficient weight balance.

*Winch

Engine Output

as the official magazine of the SC&RA (Specialized Carriers & Rigging Association) European partner

Approved media partner for:

To subscribe to International Cranes and Specialized Transport or any of the magazines in the KHL portfolio go to: www.khl.com/free-subscription or call +44 (0)1892 784088 for details.

International Cranes and Specialized Transport is a monthly publication with a worldwide circulation. The annual airmail subscription rate is US$301, €258, £215. This issue of International Cranes and Specialized Transport is mailed on 26 June 2025. Material published in International Cranes and Specialized Transport is protected under international copyright law and may not be reproduced without prior permission from the publisher.

International Cranes and Specialized Transport (USPS 017 158) is published monthly by KHL Group and distributed in the US by DSW, 75 Aberdeen Road, Emigsville, PA 17318-0437. Periodicals postage paid at Emigsville, PA. Postmaster: Send address changes to International Cranes and Specialized Transport, c/o PO Box 437, Emigsville, PA 17318-0437.

The 2025 ranking of the world’s largest crane-owning companies shows a double-digit increase, surpassing last year’s growth. Alex Dahm reports.

The 2025 award winners highlight outstanding crane and rigging projects that set new industry standards for safety and innovation. ACT reports.

Building the future of energy relies on specialist cranes and heavy transport to lift, shift and install critical infrastructure. Niamh Marriott reports.

A thought-provoking International Tower Cranes conference was held in Italy last month, with keynote speakers from Terex Tower Cranes and Uperio. Alex Dahm reports.

From extended booms to zeroemission operations, the latest all terrain cranes combine power, reach and

Niamh Marriott reports.

EDITOR & EDITORIAL MANAGER Alex Dahm

+44 (0)1892 786206 | alex.dahm@khl.com

DEPUTY EDITOR Niamh Marriott

+44 (0)1892 786208 | niamh.marriott@khl.com

EDITORIAL DIRECTOR Murray Pollok

GROUP EDITORS Lindsey Anderson

Andy Brown Catrin Jones D.Ann Shiffler

Leila Steed, Euan Youdale

WORLDWIDE CONTRIBUTORS

John Bowman, Australia; Graham Brent, USA; Marco van Daal, Aruba; Heinz-Gert Kessel, Germany; Richard Krabbendam, Netherlands; Tim Maughan, Japan; Brent Stacey, Australia; David Weston, UK SC&RA CORRESPONDENT Mike Chalmers

BRAND MANAGER Simon Battersby +44 (0)1892 786223 | simon.battersby@khl.com

VICE PRESIDENT SALES Matt Burk +1 773 610 9467 | matt.burk@khl.com

MARKETPLACE SALES John Austin

+44 (0)1892 786245 | john.austin@khl.com

CLIENT SUCCESS & DELIVERY MANAGER

Charlotte Kemp | charlotte.kemp@khl.com

CLIENT SUCCESS & DELIVERY TEAM

Alex Thomson | alex.thomson@khl.com

Ben Fisher | ben.fisher@khl.com

Olivia Radcliffe | olivia.radcliffe@khl.com

GROUP DESIGN MANAGER Jeff Gilbert

GROUP DESIGNER Jade Hudson

CREATIVE DESIGNER Kate Brown

EVENTS MANAGER Steve Webb +44 (0)1892 786243 | steven.webb@khl.com

EVENTS DESIGN MANAGER Gary Brinklow

CLIENT SUCCESS & DIGITAL DIRECTOR

Peter Watkinson | peter.watkinson@khl.com

HEAD OF FINANCE & HR

Alison Filtness

Lifting and heavy transport specialists Fagioli and Denzai have an agreement to collaborate on projects around the world.

The deal will allow joint pursuit of projects while sharing equipment, expertise, and other resources to enhance efficiency and expand global service, Denzai said.

Kohki Uemura, CEO at Japan-headquartered Denzai and Fernando Bertoni, CEO at Italy-based Fagioli, signed the agreement on 13 May.

» A site visit was part of the 2025 INTERNATIONAL TOWER CRANES CONFERENCE in Rome, Italy, earlier this month. For our review of the popular event, see page 32.

» PT SANGGAR SARANA BAJA (SSB) has been appointed as the distributor for Terex rough terrain cranes in Indonesia.

Jakarta-based SSB will offer sales and aftermarket support for the full range of Terex RTs across the region.

SSB is an engineering company experienced in heavy lifting and the

“We believe our business alliance with Fagioli, one of the world’s leading heavy transport companies, will create new value that contributes to greater efficiency in our clients’ projects around the globe. Fagioli has a strong business presence in the United States, Europe, and Australia. This partnership offers geographical advantages and we believe it will generate synergies through the sharing of both companies’ customer networks,” Uemura said.

Fernando Bertoni said, “The fundamental benefit of this partnership is for our

present and future customers. For select projects, they will gain access to the best of both worlds: Denzai’s cranes, expertise, and resources

across Asia and the Middle East, and Fagioli’s heavy lifting, transport and engineering experience in Europe and North America.”

North Toronto Auction and Jardine Auctioneers have joined the Euro Auctions Group, reinforcing Euro Auctions’ presence in Canada.

Northern Ireland-based Euro Auctions has acquired North Toronto Auction (NTA) of Ontario, hot on the heels of its March acquisition of Jardine Auctioneers in New Brunswick. Euro Auctions now has five

equipment used to carry it out.

Terex rough terrain cranes from the 35 tonne capacity TRT 35 to the 100 tonne TRT 100 will be offered.

Adding Terex RTs to the SSB product portfolio

“enhances SSB’s lifting solution services with products manufactured with engineering know-how, technical

permanent sites in Canada.

“As family-run businesses, we see a strong alignment in the ethos, values, and customer commitment of both Jardine Auctioneers and North Toronto Auction, which mirror our own,” said Derek Keys, Euro Auctions Group founder and managing director. “The addition of these respected businesses, alongside Michener Allen, who

» BENNETT ON-SITE SERVICES, operating as BOSS Crane & Rigging and an affiliate of the Bennett Family of Companies in the USA, has expanded its geographic footprint, service areas and capabilities with the opening of two new locations in Orlando, Florida and Midland, Texas.

BOSS has opened a leased property at 9591 Recycle Center Road in Orlando. It includes a 2.5 acre yard. The company also operates out of a nearby rented office.

In Texas BOSS has also expanded its reach with a new location at 8801 West County Road 127 in Midland.

we acquired in 2023, further develops our coast-to-coast presence in Canada.”

NTA operates from a site near Toronto airport. Its existing brand and all 64 employees will be retained, with Rispin continuing as managing director.

Jardine Auctioneers is a familybusiness started 1982 by Frank and John Jardine.

BOSS’s 75US ton Tadano AT working in Florida

Construction firm Gilbane in the USA suspended work on the construction of a hospital in Cape Canaveral, Florida, after two people were killed in an incident involving a crawler crane. It happened on the site of the new US$410 million Cape Canaveral Hospital on Merritt Island. Work started in 2024 with completion originally scheduled for 2026. Gilbane Building Company is leading construction works.

Images of the scene suggest it was a 250 tonne capacity Manitowoc 999 lattice boom crawler crane involved in the incident. Another vehicle appeared to have been crushed by the collapsed boom.

The cause of the incident on 4 June was unknown at press time, although there were reported to be rain and strong winds in the area.

Austrian heavy transport and lifting contractor Felbermayr has acquired specialist Dutch industrial logistics company Jozef Hermans.

Family-run Hermans specializes in industrial relocation, mainly in Germany and in the Netherlands from its four depots. Jos Hermans, who took over as managing director in 2007, remains managing director at the newly acquired business.

The acquisition will strengthen Felbermayr in Western Europe. Commenting on the deal CEO Horst Felbermayr said, “Close to our site in Krefeld,

Jozef Hermans setting a press

Hermans’ warehousing and machine assembly business complements our service portfolio very well. We are delighted the existing team will remain on board and that Jos Hermans will continue to contribute his experience

Peter Stöttinger, Felbermayr Transport and Lifting Technology managing director, left, and Jos Hermans, Jozef Hermans managing director, marking the acquisition

precision, and a strong commitment to quality,” the manufacturer said.

Johan Budisusetija, SSB director, said of the deal, “We are delighted to be offering Terex rough terrain cranes for the Indonesian market. Not only will we deliver their highquality lifting solutions tailored to industry needs but we will

provide comprehensive after-sales service and technical support to optimally support our customers’ operations.

"This collaboration will enable SSB to offer world-class cranes focused on efficiency and productivity, equipped with safety systems that meet international standards," Budisusetija said.

and expertise as managing director.”

Jozef Hermans relocates machinery, production lines and entire companies. Headquartered in Venlo, it has 12 employees and has been operating for more than 85 years. The fleet includes about 12 cranes, several trucks, lifting and hoisting systems, plus self propelled transport units and semi-trailers.

For his part

Peter Stöttinger, Felbermayr Transport and Lifting Technology managing director, said, “The wide range of assembly equipment, electrically powered pick and carry cranes, and lifting frames, not to mention decades of experience in heavy installation and the company’s geographical location on the Dutch-German border, including a heavy goods warehouse, complement the Felbermayr Group’s service portfolio perfectly.”

» The new MANITOWOC facility near Sydney features expanded office, workshop and parts storage areas to enhance customer support across Australia. Manitowoc has relocated its Australian operations to a significantly larger facility just outside Sydney, tripling its previous footprint to

20,000 square metres. The new site includes expanded office space, a larger workshop, increased parts storage and dedicated areas for training, crane refurbishment through its Encore programme and sales support. The move is to bolster service and repair capabilities for both new and used equipment.

Topping our share price index this month is Austrian manufacturer Palfinger, with an 18.01 per cent increase, closely followed by Finnish manufacturer Konecranes (11.92 %), and American companies Terex (11.7 %) and Manitowoc (11.11 %).

Share prices are influenced by a range of factors, including recent major financial announcements and infrastructure investment plans in key global markets.

In the USA a government-approved US$2.9 billion in transportation infrastructure grants covering 529 projects, many of which involve rail and port upgrades, may unlock critical funding for freight-handling equipment and cranes.

The UK government announced a £725 billion, 10-year infrastructure plan, beginning with a £1 billion “structures fund” to repair bridges, flyovers, and tunnels, aimed at boosting transport capacity.

Germany launched a €500 billion, 12-year infrastructure and defence investment spree, prioritising around €10.5 billion for rail in 2025, alongside funding for broadband and bridge upgrades, after relaxing its constitutional debt limit.

China’s largest rental company

Horizon Construction Development is to acquire an 80 per cent share of Malaysian rental firm Tong Heng Ltd (TH). The remainer will be held by former majority owner Chan Heng Choy.

The price for the majority shareholding was RMB299 million (€37 million).

TH will become a subsidiary of Horizon Construction Development and the deal includes options to agree a future purchase by Horizon of the remaining 20 % stake.

TH is one of the largest

Mediaco lifts the 13 metre long bed using its Enerpac SL200 telescopic hydraulic lifting system

rental business in Malaysia, with a fleet spanning cranes, aerial platforms, e arthmoving equipment, power generators and more. It is headquartered in Masai, Johor Bahru, very close to Singapore, and has further rental locations in central and northern Malaysia.

For Horizon, the deal is a continuation of its international growth strategy which has seen it move into international markets, including Indonesia, Vietnam and Saudi Arabia. Horizon’s rental fleet is dominated by aerial platforms, scaffolding and formwork.

Zoomlion

*ICShareIndex,1Jan2011=100**LegacyICShareIndex,endApril2022(week17)=100

» Specialist contractor MEDIACO HEAVY LIFT did have an advantage in that it had previously installed the machine. The company used four legs of a telescopic hydraulic lifting system for the job in La Buffiere, France.

The 200 tonne capacity Enerpac SL200 towers were set up in gantry configuration to lift the machine tool bed and its turntable, loading them onto a flatbed truck.

First to be lifted was the bed section, weighing 46 tonnes and measuring 13 metres long, 2.2 metres wide and 2.7 metres high. It was moved to the loading point. With it suspended in the air its slide rails underneath were separated so the truck could reverse in for the gantry to lower the load onto the truck.

Next came the 41 tonne turntable. Following the same process this unit, with a diameter of 5.9 metres and 0.7 metres high, was then loaded onto a truck.

Clever and simple set-up processes for rapid deployment. As the smallest crane with Y-guying, it’s the perfect entry into the large crane class. This 6-axle crane is extremely flexible and economical thanks to a wide range of options and the familiar and proven technologies from Liebherr. Driver assistance systems guarantee safety on every road. www.liebherr.com

Liebherr LTM 1230-5.1 in

Crane rental specialist

Emerson Crane Hire in the south east UK has added a second 230 tonne Liebherr LTM 1230-5.1 mobile crane. It is one of four new cranes recently ordered from the manufacturer’s Ehingen factory in Germany.

Commenting on the latest addition Wayne Carr, Emerson Crane Hire sales and operations director, said, “We are delighted to announce the arrival of our second Liebherr LTM 1230-5.1, reinforcing our commitment to cutting-edge technology and industryleading equipment for our operators and customers. One of the other cranes on order is a 400 tonne capacity LTM 1400-6.1 on six axles.

Erected on an undercarriage, a Raimondi LR213 luffing jib tower crane is operating at a height of 322 metres with a 50 metre jib and a tip load of 3.3 tonnes in Dubai, UAE.

Marking a new region-wide milestone, the crane is aiding construction of a 75-storey residential building.

“With the deployment of the luffing LR213, Raimondi continues to demonstrate a presence on Dubai’s most relevant jobsites. This development underscores Raimondi’s steadfast commitment to innovative engineering and providing tailored solutions for the most demanding construction challenges,” said Wael Hasan, general manager at Raimondi Middle East.

The confined jobsite,

coupled with intricate technical challenges and contractor requirements, demanded a precision approach for machine deployment.

A previously installed crane

had to be removed after the building had reached a height of 100 metres so Raimondi then dealt with the complexity of working with an existing foundation.

Typically, crane foundation designs are based on the reaction forces provided by the crane manufacturer. In this case, Raimondi’s engineering team had to reverse the process, adapting the crane’s setup to comply with predetermined limits.

“We used a 6x6 base and progressively removed ballast blocks at each climbing stage, ensuring the base reaction remained within the studied allowable load limits. This adjustment was critical for maintaining stability while adhering to the site’s structural limitations,” Hasan explained.

The trend for heavy precast building units is driving demand for high-capacity tower cranes in Singapore.

Several large Potain flat

top tower cranes, a mix of MCT 565A and MCT 1005 models, are on a new government housing project in western Singapore.

The cranes, purchased by

» UK-headquartered lifting and moving equipment specialist LGH has expanded into Australia for the first time.

The move will see the company, formerly known as Lifting Gear Hire, open headquarters in New South Wales. The lifting tackle business already operates in the UK, USA, Germany, the Netherlands and Belgium. LGH said its fleet of hoists and clamps, jacking products, rigging equipment and general material handling gear will be available throughout Australia.

Ian Parkinson, chairman, described the expansion as the biggest step the company has made since first moving outside the UK. “LGH has always been focused on growth and expansion, this has been an important component for our current and future success."

The company first moved outside the UK in 1990.

Tiong Woon Corporation (TWC), are handling the heavy lifting required for the Jurong West N4C22 project, which features a growing emphasis on precast construction.

Singapore’s Housing & Development Board (HDB) regulations mandate the use of pre-assembled bathroom units (PBUs) in new apartment buildings, driving demand for cranes capable of lifting these large, heavy components. On the Jurong West project, the Potain cranes are handling all precast elements, including the 22 tonne dual-PBUs.

Additional Potain cranes will be installed on the site in the coming weeks, each working on a separate tower block.

Boom length up to 78 m, jib inclusive

Telescoping under load

Work on up to 4° incline*

Powerful Pin Boom for pick & carry with up to 100 % load

Reliable and up-to-date technology

Intuitive control

Innovative self-assembly system

HVO ready

*with reduced load charts

For further information sennebogen.com/6203

Bernhard Kraus

SENNEBOGEN

Maschinenfabrik GmbH 94315 Straubing, Germany bernhard.kraus@sennebogen.de

For 2025 the IC100 top list ranking the world’s largest crane-owning companies shows even stronger growth than last year with a double digit increase.

Solid growth and a few significant disruptors characterise this year’s IC100 top list which ranks the world’s biggest crane companies according to their equipment fleet’s lifting capability.

Looking at the overall headline totals, we had 214 companies with a combined total fleet capability of 41,843,287 points, up 11 per cent on 2024’s 37,712,101 and more than 20 % up on the 2023 total of 34,510,957 points.

That total increase is even more impressive when you consider last year there were 221 companies, seven more than this year. The full number fluctuates as this year nearly 20 companies were removed, some as a result of consolidation, mainly in the USA, while the

There are 1,137 more wheeled mobile cranes in the 2025 IC100 than last year, up 4.2% on the year before

There are 338 more lattice cranes in the IC100 than last year, up 4.0%

remainder were either due to old data or being defunct. Then there were at least ten new or returning entries, four of which are in the top 100.

And so the top 100 is where we focus. Its combined total IC Index in 2025 is 39,320,900 points, up an even more impressive 12 % on 2024’s top 100 total of 35,107,721.

Everything else is up too in the top 100. The total number of employees, at 93,887, was up 8.6 % on the 86,486 of 2024. It is up more than any year in at least the last decade.

Wheeled cranes were also up, with a total of 28,251 units, up 4.2% on the 27,114 of 2024. It is the biggest percentage increase in the last five years. The total number

There are 7,401 more employees in the IC100 companies than last year, up 8.6%

There

Denzai KK from Japan using its Liebherr LR 12500 on S-Oil’s Shaheen Project in Ulsan, South Korea

of lattice boom cranes, at 8,668, was up 4 % on the 8,330 units among the top 100 companies in 2024.

At 1,626, even the number of company branches or depots was up, by five (0.3 %) on the 1,621 of 2024’s top 100.

Among the top 20 largest companies, however, the number of depots was 608, up »

Companies are ranked by their IC Index, calculated as the total maximum load moment rating, in tonne-metres, of all cranes in a fleet. All companies in the list, plus prospects, have the opportunity to supply fleet information and the other requested data for inclusion in the ranking. Where companies supply full data the figure used is calculated by them.

In some cases, where data is lacking, we have based a company’s figure on an ICST estimate. In cases of insolvency, acquisition or lack of sufficient information, companies are withdrawn from the table.

While we make great effort to ensure the accuracy of information provided, it cannot be guaranteed and ICST accepts no liability for inaccuracies or omissions.

The IC100 Index will next be updated in the first quarter of 2026. If you think your company should be included, please contact ICST for an application form. Note that tower cranes are not in the IC100 because they appear separately in the IC Tower Index published in October's ICST. Similarly, specialized transport equipment is also featured separately, in the IC Transport50, in the August issue of the magazine. Calls for entries in these tables are also issued and widely publicised like the ones for the IC100. Please look out for them at: craneandtransportbriefing.com and in the World Crane Week e-mail, and on our social media channels.

by 8.4 % on the 561 total of 2024. A fair few such expansions have been reported in ICST over the last year.

Staying with the top 20 the number of employees, at 35,396, was up by an even higher 9.2 %, on the 32,424 total last year and by a higher percentage than any year in the last ten.

It is interesting to note, in terms of the number of cranes owned by the top 20 companies, both were down – unlike the top 100. Wheeled cranes, at 9,066 units, were down 5.2 %, or 494 units, on the 9,560 of 2024, while the number of lattice cranes was 4,137, down 155 units (3.6 %) on the 4,292 total last year.

Harder to fathom are the numbers in the Top 10 Sample (actually of seven companies but that is a long old story). This is a group of companies remaining from a top ten many years ago, updated each year since.

In the 2025 Top 10 Sample it starts off well, with the Index up 12 % to 13,174,140 points, from 11,762,377 in 2024. It is all downhill from there, however, with fewer depots and employees, plus the numbers of cranes in both categories is down. Even the capacity of largest crane is down.

As usual, the first and second placed companies remain the same. Mammoet in first place has increased its capability by 7.9 % in the last year while for Sarens, in

second place, it is 9.6 %. Once again, the gap has narrowed between the two global giants of the industry. It is now an 8 % difference, down from 9.7 % last year, 22 % in 2023 and a yawning 42 % difference back in 2020.

Moving down the table, the first of our disruptors is Maxim, back in the top 10, ahead of Buckner, pushing it and Sanghvi down one place. BMS in 6th retains its position as does Sinopec at 7th, both having added a lot more to their fleets in the last year than Lampson, now in 8th.

Rounding out the top 10 is another disruptor, Shanghai Tengfa, now calculating its fleet capability using the correct tonnemetre ratings instead of nominal tonnage capacity (see Notes for the IC100 box).

Highest placed new or returning company is Bay Crane at 24th. This acquisitive US business has been absent from the table for many years. Thanks go to ICST sister magazine American Cranes and Transport and its ACT100 ranking for its return.

Then the three new entries in the top 100 are Urmilla from India at 46, Saraiva from Brazil at 79 and Pollisum from Singapore, in at 98. Entering the top 100 from just outside are Transportes Montejo from Colombia and Northwest Crane and Davis Crane from the USA. All help broaden the geographic spread of the table and are very welcome. ■

Mammoet worked on the loadout of a 3,150 tonne jacket for an offshore gas platform which will be powered entirely by wind energy

Though there is also still a considerable continued investment in oil & gas, and nuclear power, the energy sector is undergoing a sizeable change. There is a strong global push towards renewables, especially wind power.

This greener landscape is driving demand for highly specialized lifting and transport solutions. As renewable projects scale up in size and complexity, and conventional energy infrastructure demands heavier and more precise installation, the role of expert lifting and transport providers is more central than ever.

Manufacturers like Liebherr are supplying crawler and tower cranes tailored for wind turbine assembly and modular nuclear builds, while heavy lift giants Sarens and Mammoet are deploying self propelled modular transporter (SPMT) and bespoke lifting and jacking systems to move transformers, reactor components and offshore platform modules with millimetre precision.

Wind power, particularly with new offshore wind farms, is leading the charge towards renewables. In response, the lifting and

From wind to nuclear, building the future of energy relies on specialist cranes and transport to lift, shift and install critical infrastructure. NIAMH

MARRIOTT reports

Fagioli planned and executed the loadout of a 23,120 tonne offshore wind turbine installation jack-up vessel

Mammoet will provide SPMT to transport monopiles and other components to port for a large wind farm in the

transport industry is stepping up to meet the scale and complexity of new infrastructure demands.

A potential obstacle for new wind farms in the USA is President Trump’s executive order temporarily halting offshore wind lease sales in federal waters and pausing the approvals, permits and loans for both onshore and offshore wind projects. Elsewhere however, new wind farms are being planned and built.

Crane manufacturers continue to produce cranes for taller and heavier wind turbine components. “As OEMs introduce new turbine models, increasing hub heights require larger crawler cranes for onshore turbine erection,” says Buckner HeavyLift’s Brian Miller. “The Liebherr LR 11000 has become the preferred choice, as it can efficiently install wind turbines with hub heights up to 120 metres without the need for a derrick, streamlining mobilisation, padto-pad relocation and reducing setup time.”

It’s not just cranes that are proving popular, as demand for SPMT continues to rise. Heavy lift equipment provider NXGEN expanded its fleet with an additional 100 axle lines of Scheuerle SPMT.

LR 11000

Japanese transport and lifting specialist contractor Denzai also added a total of 48 lines of SPMT to its equipment fleet. That deal is for eight modules of German manufacturer Goldhofer’s PST-ES-E (315),

each with 6-axle lines. Denzai says it will use the new equipment for offshore wind energy generation construction projects with delivery scheduled in early 2026.

The recent loadout of the 23,120 tonne B212Charybdis offshore wind turbine installation jack-up vessel by lifting and heavy transport specialist Fagioli highlights the rising scale of specialized transport in the energy sector. Built in Texas, USA, the project required 880 axle lines of Scheuerle SPMTs, 28 power packs, three semi-submersible barges from Norway, plus tugboats and spacer barges to handle the vessel’s immense size.

While the project did break three world records, what stands out is the orchestration of technology and expertise necessary to handle the vessel’s size and configuration.

The growing dimensions of offshore wind vessels pose engineering challenges, especially in US shipyards not traditionally geared for such scale.

Global collaboration was essential, with Fagioli coordinating equipment fleets across Europe, Asia, and the USA, integrating hydraulic and electronic systems into one remote-control command. »

This kind of complex operation is becoming more common as the energy industry pushes further into offshore wind and other renewable infrastructure.

Elsewhere in the world, heavy lift giant Mammoet recently worked on the loadout of a 3,050 tonne topside and 3,150 tonne jacket for the N05-A platform, the first offshore gas platform in the Dutch North Sea powered entirely by wind from the nearby 113.4 MW Riffgat offshore wind farm. This electrification is expected to reduce carbon emissions by over 85 per cent.

Part of the GEMS project on the Netherlands-Germany border, Mammoet supported assembly and transport at HSM Offshore’s Rotterdam facility using mobile cranes, sheerlegs, and SPMT.

A key challenge was loading both large structures onto the same barge, an unusual approach to shorten the schedule, which required complex engineering and a spud leg barge for mooring due to the combined heavy loads. The loadout was completed in two days using four 32 axle lines of SPMT.

Mammoet’s involvement demonstrate how specialized transport supports the growth of renewable and low-carbon

Heavy lift giant Mammoet has expanded its electric powered transport fleet with the addition of two Eco500 units from Cometto

Smith Crane and Construction's 1,200 tonne Liebherr LTR 11200 crawler crane, erecting turbines at the Harapaki wind farm in New Zealand. To lift the nacelle the crane

offshore energy infrastructure. Mammoet has also been selected as a key contractor by SeAH Wind. It will provide SPMT for the Hornsea 3 Offshore Wind Project. SeAH Wind will supply monopile foundations to the wind farm for installation approximately 120 kilometres off the Norfolk Coast in the North Sea. On completion it will be the world’s largest

When your project calls for specialized equipment or expert insight, Deep South Crane & Rigging is here to support you. With a deep inventory and decades of experience, we offer tailored solutions for complex lifts and heavy transport. From our powerful VersaCrane™ fleet to custom-engineered bridge systems, cantilever bars, gantries, and more, we deliver the tools and expertise to keep your project moving forward.

Whether you’re up against a tight timeline, a one-of-a-kind lift, or a critical transport challenge, we’re ready to step in to meet your project’s demands with precision. Let’s DEEPSOUTHCRANE.COM

the cutting edge of what can be lifted and transported.”

With nuclear infrastructure experiencing a resurgence as part of the global drive for low-carbon energy, major construction projects like Hinkley Point C nuclear station in the UK are pushing the limits of heavy lifting and precision engineering.

Late last year, Sarens’ 5,000 tonne capacity SGC-250 ‘Big Carl’ crane lifted a 423 tonne steel ring into place - the third and final liner ring for the second reactor

building. Measuring 47 metres in diameter and 11.6 metres high, the ring forms part of the inner containment wall and includes mountings for a polar crane used in refuelling.

The steel dome for this reactor building will be installed this year, following the approach used on the first reactor, which saw its dome placed in December 2023.

Sarens also continues to support major oil and gas projects, recently providing heavy haulage solutions for developments in Indonesia. These projects include the West Belut development, the Sisi Nubi AOI Project (Packages A & B), and the Terubuk L & M fields, which play a significant role in boosting Indonesia’s oil and gas production, demonstrating the demand for oil and gas remains high.

The company has collaborated on high-

Heavy haulage specialist Hofmann used its Cometto 1,000 tonne-metre rated BladeMax1000 blade lifter for the first time for a wind farm project in Germany.

Dutch crane manufacturer Huisman has won an order to supply a 5,000 tonne capacity crane. The new giant is a tub mounted crane to go on a new offshore heavy lifting vessel. Application will be in the Japanese offshore wind market.

profile projects such as Saudi Aramco’s Marjan Field in the Middle East, Pertamina’s refinery upgrades in Balikpapan, and Qatar Energy’s North Field Oil projects.

The current scope of work, which began in June 2024 takes place at the Meitech Eka Bintan yard. Sarens is using a variety of specialised equipment, including load cells ranging from 150 tonnes to 600 tonnes, and up to 56 SPMT axles with 4 PPUs. One of the most challenging lifts involves a jacket weighing 1,100 tonnes. ■

We provide an unlimited range of state-of-theart trucks & trailers with the latest technology, capable of handling any capacity or type of cargo, ensuring efficient and reliable delivery for both small and large-scale needs.

✓ 46 - 202 ft 6-section pin & latch boom

✓ 7 boom extend modes provide superior capacities: EM1-EM7

✓ Optional 42'-71' 2-piece, bi-fold, on-board hydraulic off-set fly available

✓ (1) or (2) 25 ft lattice fly extensions available

✓ 334 ft maximum tip height

✓ New generation operator’s cab and drivers cab

Heavy transport specialist Collett and Sons is adding 36 axle lines of modular transporter to expand its fleet.

The new Goldhofer THP/SL-L modules will be a first for the UK company. They are due to be up and running by August. With the new equipment Collett will be better able to handle those more complicated transport projects.

Each axle line has a capacity of 26.1 tonnes and a deadweight of 2.77 tonnes. Flexibility was a key requirement for Collett to allow configuration of the equipment to suit specific load requirements.

Mark Howe, UK Goldhofer sales representative, said, “We’re delighted to see Collett and Sons add the Goldhofer

THP/SL-L modular axle lines to their fleet.

The versatility and high-performance capabilities of the THP/SL-L are an ideal fit for the complex and challenging transport projects Collett takes on. We look forward to supporting them in delivering these exceptional services to their customers.” n

Shaking on the deal for 36 modular axles from Goldhofer. Mark Howe, UK Goldhofer sales representative, left, and David Collett, Collett and Sons managing director

Oshkosh Defense in the USA has received a US$27.6 million order from the US Army for 55 Medium Equipment Trailers.

The METs are designed and built by Dutch trailer manufacturer Broshuis in the Netherlands. Oshkosh said the MET “supports the Army’s modernisation efforts and meets evolving logistics and transport demands.”

MET is a six-axle drop deck trailer hauled by the Oshkosh Enhanced Heavy Equipment Transporter System (EHETS) M1300 tractor.

It is used to transport combat vehicles weighing up to 60 tonnes. These include the

Bradley armoured multi-purpose vehicle (AMPV), Paladin self-propelled howitzer, and field artillery ammunition support vehicles (FAASV).

The MET design meets European Highway Road Network Accessibility (RNA) requirements for payloads up to 45 tonnes, Oshkosh said. The trailer’s adjustable height hydraulic suspension helps it cope with 4 metre high overpasses and to ford water obstacles.

The trailers are scheduled to have been produced by June 2026. n

Broshuis builds the medium equipment trailer (MET) for Oshkosh to supply the US Army

The European specialized transport and crane association ESTA has called again for development of abnormal load transport corridors in a network across the region. These would be for use by the military and by industry. The proposals were outlined in

a new ESTA background paper sent to MEPs in early 2025. It was produced in response to the European Commission’s White Paper on Defence

Readiness 2030 where military mobility was a key issue.

A debate followed the publication about the

importance of transport infrastructure in supporting Europe’s security and economy. Abnormal transport is key for military mobility around Europe and further afield.

Ton Klijn, ESTA director, said, “We welcome the publication of the White Paper for Defence

as well as the recognition of the military transport as a key enabler of European resilience.

“Although significant progress has been made in recent years, there remain considerable obstacles to moving troops and equipment unhindered across the

China Cosco Shipping Corporation Ltd. (COSCO) has expanded its fleet of Scheuerle self propelled modular transporter (SPMT).

The Chinese shipping giant acquired more 48 tonne capacity axle lines and some power pack units (PPU).

Heavy duty transport equipment manufacturer TII Scheuerle in Germany supplied equipment in several configurations. They also have the extra durability of the polyfill tyre option where the tyres are filled with polyurethane foam.

COSCO and its subsidiaries will use the new equipment for heavy transport operations, including offshore and infrastructure projects. Modules can be combined to transport components

weighing thousands of tonnes.

Commenting on the deal Filippo Baldassari, TII Group managing director, said, “Our SPMTs are the global standard and are used worldwide when maximum

precision and safety are required under extreme conditions. We are proud to have had COSCO as a strong and future-orientated partner at our side for many years.”

The All Family of Companies is investing in its heavy-haul operations by training more drivers on the use of its Faymonville HighwayMax trailers in the USA.

An all-day training session was held near its Cleveland, Ohio, headquarters, bringing together a dozen drivers from branches across Ohio, Pennsylvania, West Virginia, Indiana and Illinois.

HighwayMax is a nine-axle, extendable trailer offering a legal payload of 170,000 pounds (77 tonnes). It uses hydraulically steered pendular axles to provide manoeuvrability in confined space. Axle spacing can be adjusted up to 22.5 feet (6.9 metres) between three axle groups. Each axle can steer independently up to 60 degrees and can also be lifted as needed.

For the training All brought in Shannon

EU. Military mobility, like abnormal transport, faces significant administrative and infrastructural barriers.

“Current non-harmonised procedures often cause severe delays in the issuance of crossborder permits. This is why the EU and member states need to immediately simplify and

Richardson, US Faymonville representative at Hale Trailer. It began with Faymonville’s onboard software, the Faymonville Analytical Loading Capacity Organizer (Falco), which allows simulation of load scenarios. It mirrors All’s 3D lift planning software for cranes, allowing teams to virtually plan and test load configurations before a move.

Drivers then did hands-on training, learning how HighwayMax differs from traditional heavy-haul equipment. The trailer’s axles steer in sync with the truck so drivers can make tight turns without the wide swings typically required for such loads.

The session also covered best practices for axle alignment, strategies to reduce fuel consumption by lifting unneeded axles,

streamline regulations and procedures.”

Proposals to streamline and harmonise rules for European abnormal transport operators are part of the planned revisions to the Weights and Dimensions Directive. It is making its way through the legislative process.

Faymonville has been expanding its footprint in North America and is building a new manufacturing facility in Arkansas

and operating the trailer’s hydraulic decklowering system, which can adjust from 41 inches down to 24 inches (1,000 down to 600 mm). n

ESTA said the policy is now all the more relevant, what with Europe’s growing defence requirements. “Given the growing importance of military transport due to current defence and security challenges, it is important to facilitate cross-border operations for abnormal road

transports,” Klijn continued.

“These corridors should include the roads with a high economic relevance and based on the road network, road pavements, bridges and other specific road structures, that are classified as adequate to carry abnormal road transports.”

The annual Specialized Carriers and Rigging Association Job of the Year is an eagerly anticipated contest and this year was no exception. Thanks to ICST sister magazine American Cranes & Transport for this year’s story on the winning projects

RIGGING UNDER US$300,000: BARNHART CRANE & RIGGING

Barnhart Crane & Rigging was awarded a project that involved the complicated removal and replacement of an isophase fan at a power plant in the USA. The fan had to be dismantled into four sections, each with an unknown centre of gravity. Replacement consisted of three sections with offset centres of gravity.

Standard operating procedures were followed for all equipment used, and a 100hour safety standdown was implemented to reinforce awareness of hazards, particularly pinch points and the dangers of working around suspended loads.

Barnhart’s experienced team knew immediately they would have to think outside the box. “Innovation played a crucial

role in this project,” said Barnhart’s Eric Cantrell. “This was the perfect job to use the company’s custom Tipstick tool. Our engineers made modifications to an existing Barnhart 27K Tipstick to accommodate the fan sections, minimising the required headroom.”

The project required ingenuity, using multiple unconventional rigging and lifting devices, including the Barnhart counterweight cantilever system, known as MOCCS; the custom Barnhart 27K Tipstick; a 75 US ton Lift Systems Mobilift, a 100 ton slide and multi-lift jacks to facilitate both removal and installation.

RIGGING $300,000 TO $1 MILLION:

In removing and replacing a refractorylined carbon monoxide line, the Mountain Crane Services team developed an innovative rigging solution that was safe and efficient.

Mountain Crane Service in the USA applied its experience and know-how to a project that involved the removal and replacement of a 36 to 42-inch (914 to 1,067 mm) refractory-lined carbon monoxide line within a highly time-sensitive framework.

A key challenge was the lack of overhead clearance for a crane, plus obstructions below preventing the use of a jack-and-slide operation. The solution was a self-propelled modular transporter (SPMT) and a stinger clamp system.

It enhanced efficiency and provided safer working conditions at height, addressing the overall challenges of the positioning of the CO line. An assist crane was brought in for the offloading of the carbon monoxide line, allowing for a smooth and secure operation.

Mountain Crane Services replaced a refractory-lined carbon monoxide line using SPMT and a stinger clamp system

Mountain Crane’s in-house engineering team, in close collaboration with the field team, designed and executed the rigging plan, eliminating the need for traditional bull rigging methods.

“Remarkably, the Mountain Crane Service team engineered and mobilised the necessary equipment in under one month, a feat that speaks to our expertise and agility,” said Mountain Crane’s Tyler Poulsen.

RIGGING $1 MILLION TO $3 MILLION: BRAGG COMPANIES

Bragg Companies relocated the Space Shuttle Endeavour, two solid rocket boosters and the external tank-94 from storage to the new Samuel Oschin Air and Space Center in California, USA, for the vertical Go for Stack exhibit.

Bragg engineered, 3D printed, fabricated and mounted key components without access to vital NASA data from the Shuttle programme, including lifting lugs, tailing lugs and spreader bar bolster frames for the external tanks, plus jacking frames and slings for the Endeavour.

Specification sheets for the solid rocket boosters, the ET-94, and the Shuttle were not necessarily accurate, requiring precise field verification. ET-94 was 47 metres long, 8.4 metres in diameter and weighed 30 tonnes. Endeavour stood 18 metres tall, 37 metres long, had a 24 metre wingspan and weighed 80 tonnes.

At a crowded jobsite shared with an elementary school, stadiums and museums, there was one tree-lined entrance with limited build and breakout areas. Elevation changes and high centre-of-gravity moves added complexity. Public access to the Museum remained open, so much of the lifting was done at night.

Supporting the project were a Liebherr LR 1750 crawler crane and LTM 1400 wheeled mobile, Enerpac 100 tonne Cube Jack system, 20 lines of Goldhofer SPMT and a 200 US ton J&R Power Rotator.

ET-94 was jacked up using the Cube Jack before being transported on a 20 line SPMT with custom jacking frames. Clearances were tight as ET-94 was guided to the lift area. The cranes and the Power Rotator, upended and flew ET-94 into the display building, lowering it through a 39.6 metre scaffold with millimetres to spare. The main crane had a boom height of 124 metres and a 54 metre radius. ET-94’s delicate foam exterior required extreme caution.

Endeavour was disconnected from its seismic isolators using the Cube Jack System, lifted onto jacking frames and moved to the South Lawn on SPMT. The Cube Jack was reintroduced to lift Endeavour 12 feet to remove the jacking frames and install bolster towers with custom lashing for its next move. The shuttle was carefully

maneuvered down a slope, around a corner and over a building onto State Street, with as little as 8 inches of clearance.

Late one night, the Endeavour was connected to a vertical sling and upended using the LTM 1400 and LR 1750. The gross load was 118 tonnes at a 46 metre radius. Endeavour was slowly lowered into the building and then mated to the ET-94 tank for final assembly.

Barnhart was asked if it could help install 150 mechanical, electrical, plumbing (MEP) modules at a semiconductor facility construction site in the USA.

The customer had planned to fabricate the 6 x 6 metre modules on site and then transport and install them one by one.

Barnhart asked if there was a more efficient way to accomplish this. Further investigation showed this method would cause the steel and pipe installer to make hundreds and hundreds of field welds at a height of almost 10 metres off the ground. Some of the pipes were as large as 1.6 metres in diameter.

Barnhart Lift Tables (LT50s) and Jack Masters were the solution. They would lift these large footprints of pipe and steel, some weighing as much as 113 tonnes, from grade to a height of 7.9 metres.

Each lift arrangement was unique and required attention to detail to ensure operation was done appropriately. First, Barnhart installed Jack Masters to lift the module to a height of 1 metre.

Barnhart developed two new rigging tools, the Barnhart Lifting Table and Barnhart Jack Masters, and greatly enhanced the schedule and safety at a semiconductor facility construction site supporting the installation of 150 MEP modules

Set on stands, the Lift Tables were moved into position to make the main lifts, up to 7.9 metres in a single stroke. Holding valves on the lift tables allowed work at height, making hundreds of bolted connections to securement plates in the ceiling.

This method allowed customer to plan the fabrication, it meant fewer welders and less scaffolding and it helped increase safety by reducing the number of hours working and welding at height. Barnhart saved approximately three months on the project schedule, completed 41 MEP Module area lifts, and brought two brand new tools to market.

HAULING LESS THAN 160,000 POUNDS: QSL TRANSPORT (formerly Transport Watson)

QSL Transport in Canada hauled 51 oversized piping rack modules 22 km in an operation that had to be conducted at night and represented several unparalleled challenges due to the winter season, the extreme dimensions of the modules – as big as 45 x 6 x 6.4 metres – and narrow roads.

As the most direct route had 975 low power lines it had to be discounted. A route

Despite numerous obstacles, QSL Transport moved 51 oversized piping rack modules at night over seven weeks, relying on expert planning and execution

was developed along narrow country roads. The trailer configuration had to be adjusted, tight turns had to be navigated, electrical poles replaced, and roads were reinforced.

Oversized loads weighing as much as 100 tonnes had to be accommodated. Obstacles included 150 power lines, 10 power poles had to be relocated, roads had to be reinforced with steel plates.

Custom-configured multi-axle trailers were used, designed to comply with strict municipal axle weight restrictions of 10,000 pounds (4.5 tonnes) per axle.

To manage disruptions and safety issues, a traffic management plan (TMP) was developed to co-ordinate the 15 full road closures.

From October to December 2024, 40 oversized pipe rack modules were transported, at night, twice a week, for seven weeks. Each convoy, consisting of three trucks, was supported by safety personnel, including two police escorts, six private road escorts and six bucket trucks to lift overhead power lines.

Barnhart was contacted to remove four Wartsila engines from a storage facility and move them to a new location in the USA.

The four engines were 10.4 x 4 x 4.5 metres (length, width, height). Each one weighed 178 tonnes.

In terms of equipment to transport them

Barnhart Crane & Rigging navigated the hauling of four Wartsila engines, each weighing 178 tonnes, some 57 km

multiple lines of SPMT were chosen due to pier loading concerns. A 500 tonne slide and gantry were used to remove the engines from the buildings and stage them over at the dockside.

Specialized shipping frames designed and fabricated by Barnhart helped meet height and weight restrictions along the route. At more than 100 metres long the trailer combination was reported to be the longest load ever permitted in the US state of Washington.

“The team worked with city, state and county authorities to locate a route of about 45 miles though the I-5 Corridor to their final location in Centralia Washington,” said Barnhart’s Olof Anderson. “At first there were major concerns with leaving the Port of Olympia but because of the expertise and tenure of the Barnhart LAX team they came up with a plan to back the trailer out of the port nearly 1.5 miles, remove a single tree

and work though a residential area until reaching I-5.”

The LAX team completed the four round trip moves in less than a month without any incidents.

Edwards Moving & Rigging completed a complex transport of four Class 7 radioactive components from Florida to a disposal site in Texas, USA.

The journey began with a barge transport from Florida to Texas, followed by a 1,600 km road haul on Goldhofer THP-SL with hybrid dollies, and a Faktor 5 girder bridge. Overcoming challenges such as 150-plus bridge crossings, contraflow movements and infrastructure modifications, the Edwards team demonstrated its expertise.

In Florida the components were loaded onto a deck barge using a 3-file, 12-line Goldhofer PST. They arrived at Rockport Terminal, Texas and were prepared for the over the road transport. The nine months of planning involved co-ordination with the Texas Department of Transportation and various transportation districts, as well as third-party bridge engineering for 158 bridges.

The Faktor 5 girder bridge combination spread the weight over 384 wheels. It was pulled by Kenworth C500 prime movers and a Goldhofer AD-Drive.

“Rigorous safety measures were

Using 880 axle lines of Scheuerle SPMT, Fagioli transported the Charybdis offshore wind turbine installation vessel (WTIV) weighing more than 23,000 tonnes

implemented, including health and safety protocols, equipment safety, securing the load as per the over-the-road standard for Class 7 hazardous materials,” said Edwards’ Jennifer Schuster. “The 30-day road transport covered 991.5 miles, with extensive planning ensuring no damage to infrastructure or disruption to the public.”

The components were offloaded at the disposal site using a 3-file, 12-line Goldhofer trailer and a 900 ton gantry system, marking the completion of the project.

Fagioli set three world records in the execution of a project to load out the B212-Charybdis Offshore Wind Turbine Installation jack-up vessel.

Fagioli planned and executed the loadout of the WTIV built by Seatrium Amfels in Brownsville, Texas, USA. A total of 880 axle lines of SPMT, 28 power packs, three semisubmersible barges, four spacer barges and up to 10 tugboats were used on the job. Technical mooring procedures and a crew of more than 50 were all essential.

In the process, Fagioli set three world records: largest number of axle lines under one load, heaviest weight ever moved on SPMT, and heaviest load on wheels transferred onto multiple barges.

The central SPMT group with 340 axles was 150 and 115 feet away from the two side groups, each with 200 axles. Ensuring communication between the 28 power packs was a major challenge. Several generations of equipment were used, requiring extensive vetting and compatibility testing. Long hydraulic hoses connected two groups for threepoint support, enabling control from a single box.

Preparations took a year, factoring in equipment readiness, weather, tides and port traffic. Multiple governing bodies were involved, and the loadout date shifted several times, complicating availability of the assets.

By loadout day the vessel was 1,500 tons heavier but still within the capacity of the equipment. The first step involved positioning SPMT under the vessel, confirming load distribution, centre of gravity and operation. Alignment required 20 hours, using 30 ton winches, spacer barges, ramps and ballasting.

The vessel was then moved slowly over ramps onto the barges, with constant checks on stability, SPMT, winches, barges, and tugboats. Once in position, the vessel lowered its jack-up legs into the water and transferred weight from the SPMT to the barges. This step was challenging due to hydraulic and electronic connections spread across three moving platforms.

Among the project’s key innovations were the hydraulic and electronic integration of 880 axle lines and 28 power packs from different generations moved together by a single remote control, both on land and on three separate barges.

From extended booms to zero-emission operations, the latest all terrain cranes combine power, reach and sustainability to meet the demands of modern lifting. NIAMH MARRIOTT reports

Blending the high speed road performance of a truck mounted crane with the off-road agility of a rough terrain crane, all terrain cranes are built for versatility in application.

Due to their all wheel steering, they can handle uneven ground on job sites with ease while still travelling on public roads. This crane type has between 2 and 12 axles and the largest have a capacity rating of 4,000 tonnes. Having said that, it might arguably be a misnomer to describe anything much bigger than about 400 tonnes as “all terrain” but the same technology continues all the way through.

Several new models have been launched already this year and in the months before that. Back in September 2024, Link-Belt revealed its latest all terrain, the 200 tonne capacity 225|AT, which is the third in the company’s range of 5 axle ATs, and sits between its 150 tonne capacity 175|AT and the 275 tonne capacity 300|AT. The crane is now ready for delivery.

Designed, built and tested at Link-Belt’s factory in Lexington, Kentucky, USA, the new model was launched at the company’s CraneFest event.

It includes a 14 to 62 metre six section latching boom, a 13 to 22 metre two piece hydraulic offsetable SmartFly, a 2.4 metre heavy lift jib, one or two 7.6 metre lattice fly extensions, and a maximum tip height of 101.8 metres with full attachment.

Smart features include Link-Belt’s Pulse 2.0 operating system and its wireless rigging remote system.

Andrew Soper, product manager for telescopic truck and all terrain cranes says the North American AT market is extremely competitive, with 11 models in the 111 to 150 tonne range, five models in the 151 to

Link-Belt’s latest is the third AT in the company’s range of 5-axle all terrain cranes

Designed, built and tested at Link-Belt’s factory in Lexington, Kentucky, USA, the new 225|AT was launched at the company’s CraneFest event in September last year

219 tonne range, and nine models in the 220 to 300 tonne range.

The new crane was developed alongside the 300|AT, which was launched back in 2023 at the ConExpo trade show in Las Vegas, USA.

The 225|AT features improved reach, larger capacities and more counterweight than its predecessor, the 185 tonne ATC-3210.

Power comes from a Cummins X15 diesel carrier engine but the company also says that the new model can be powered by hydrogenated vegetable oil (HVO), as it has a dual-tank system.

There were several new models on show at Bauma 2025, the giant German trade fair back in April, including Liebherr’s latest.

The German manufacturer’s newest model is the LTM 1150-5.4E, a 150 tonne capacity wheeled mobile telescopic crane with both diesel and electric drive. This five axle crane includes a battery for

autonomous, untethered operation and can also be plugged into the grid for charging and full power use. Its 400 kW diesel engine meets EU Stage V emissions standards and can also run on HVO, reducing CO₂ emissions by up to 90 per cent.

Running on electricity, it produces zero exhaust emissions at the point of use and is significantly quieter, Liebherr says.

The crane’s 111 kW electric motor is liquid cooled, high speed, and delivers nearly the same performance as the six cylinder diesel engine. It powers the pump transfer gearbox in the superstructure via a distributor gear.

The standard diesel version transmits drive mechanically through the slew ring into the superstructure, while the electric version uses the same driveline, switching between diesel-hydraulic and electro-

hydraulic modes via a transfer gearbox.

The LTM 1150-5.4E builds on technology used in the compact Liebherr LTC 1050-3.1E, first introduced at Bauma back in 2022. Unlike its predecessor, the new 150 tonne model features a 1.5 tonne, 99 kWh battery pack with integrated charger, mounted at the rear.

Crane and construction equipment

This allows for autonomous operation of up to four hours without grid power. When connected, even a modest 16 or 32 Amp supply is sufficient for full operation, as the battery compensates for peak demand and charges simultaneously from the mains grid connection.

Also on show at Bauma was Japanese manufacturer Tadano’s new 250 tonne all terrain with a 79 metre main boom, the AC 5.250L-2.

Self erecting extensions are available from 5.8 to 30.0 metres. The overall system length is 109 metres, making it good for urban applications such as positioning

Tadano’s AC 5.250L-2 is good for urban applications

manufacturer Sany handed over the first unit of its new 4,000 tonne capacity all terrain crane back in November 2024, to a Chinese crane company.

The Chinese manufacturer claims it as the world’s largest all terrain wheeled mobile telescopic crane on a nine axle carrier.

Wind energy is a key target application for this new giant. It has an 81 metre telescopic boom and up to 124 metres of jib can be added. Maximum lifting height is 200 metres. With 350 tonnes of counterweight it lifts a load weighing 376 tonnes to a height of 100 metres at a radius of up to 18 metres.

heavy equipment over obstacles and assembling large tower cranes.

The crane delivers a maximum load moment of 736 tonne-metres and lifts 105 tonnes with a 13.5 metre main boom at a 7.0 metre working radius. An optional heavy lift attachment increases capacity to 138.7 tonnes.

Optimised for mobility, the AC 5.250L2 can be configured with 10 × 6 or 10 × 8 drive options on 406 mm steel wheels while meeting axle load limits for public roads.

It has the IC1 Plus crane control system for realtime load capacity monitoring.

Power comes from a 396 kW (530 hp) MercedesBenz diesel engine that complies with EU Stage V and US EPA Tier 4 Final exhaust emission standards. It has fuelsaving functions such as an Eco Mode and a start-stop system.

Manufacturer Manitowoc’s Grove showed a hybrid 5 axle all terrain crane at Bauma, which is available in two versions. The new GMK5150L-1e (60 metre boom) and GMK5150XLe (68.7 metres) offer as much as a full day (five hours) of emissions-free lifting, the manufacturer says.

It has a fully electric upper works for crane operation. Loads charts are the same as for the diesel versions. The battery

Grove’s new 150 tonne capacity hybrid all terrain crane is available in two versions, with 60 or 68.7 metre boom

offers a capacity of 180 kW-h. Charging can be done by plugging the crane into a grid connection or from a 170 kW generator mounted onboard the crane in the carrier. The running time can be extended to around 20 hours when the crane is connected to the electricity grid via its cable.

Most of the driveline remains as per the diesel version, including the independent Megatrak suspension and the axles with disc-brakes all round.

“These new plug-in hybrid cranes deliver more sustainable lifting and boost owners’ environmental credentials,” says Florian Peters, Manitowoc senior product manager for all terrain cranes.

“They can drive to the job site using HVO fuel to power the efficient Mercedes-Benz engine and reduce carbon emissions by up to 90 per cent while simultaneously charging the batteries. Then, they can set up and use clean electricity to handle the lifting tasks. There’s also a massive reduction in noise pollution – a great advantage when operating in a city centre.” ■

Baldini Group has added a 250 tonne capacity Grove

GMK5250XL-1 all terrain crane to its fleet

A thought-provoking International Tower Cranes conference was held in Rome last month. ALEX DAHM reports

The eighth International Tower Cranes conference in Rome, Italy, on 3 and 4 June was a strong event with valuable, thought-provoking content and extensive networking opportunities.

Hosting more than 160 delegates, the global conference is well-established as the leading conference for the tower crane sector worldwide.

ITC 2025 attendees came from 22 countries in Europe, North and South America, the Middle East and Asia. More than 70 companies were represented, the majority tower crane owners from rental companies and construction contractors. The largest number was from Italy.

They were there to network with peers and to learn from the speakers in the extensive programme of interesting and informative presentations. Topics tackled included, engineering challenges, legislative changes, new technology, the current position and outlook for the industry, recruitment and retention of workers, and more.

A range of issues were discussed, including difficulties in funding tower cranes, plus the way that lower rental

rates on older equipment, after it has been paid off, are having a negative impact on the sale of new cranes. More positively, there was mention of how increased safety and regulation can help drive demand for new cranes. New technology on the latest models enhances jobsite productivity, reliability and performance, further encouraging implementation of new or upgraded equipment.

Opening keynote speaker was Francesco Aiello, Terex Tower Cranes general manager. He gave an introductory overview of change and developments in the tower crane sector, including a range of industry challenges, from a manufacturer’s

Federico Della Puppa, head of analysis and strategies at Smart Land, talked about the way that a break in investment, resulting from global uncertainty, a lack of preparation and the non-linear economy, could be a good thing for the equipment rental industry. For a contractor renting equipment instead of buying it requires less commitment and may be a more attractive proposition, especially in the short term.

Opening keynote speaker: Francesco

Aiello, Terex

Tower Cranes

general manager

The shift in construction activity in many markets, for example, where residential construction has fallen dramatically but civils work is up, requires a similar change of focus in terms of the size, type and quantity of new equipment required from manufacturers.

Growth in industrial and energy sector construction, plus the proliferation of data centres, is also similarly affecting things. Demand for larger tower cranes, in the 500 to 1,000 tonne-metre range, is increasing while smaller models, in the 100 to 300 tonnemetre range are far less busy.

Attracting new people to enter the industry in terms of both recruitment and retention was a recurring topic. Tania Colatriano, CEO at Colatriano Group, and Daniela Niederstätter, Board member at Niederstätter and Rentmas founder, discussed major efforts being made in this area, especially concerning the rapid pace of changing technology, and attracting women and young people to become part of the industry.

The engineering challenges panel discussion highlighted potential issues with the upcoming revision of the EN 14439 standard

A crane-owner’s perspective on the industry was given in the afternoon keynote presentation by Philippe Cohet, founder and board vice chairman at Uperio. His focus was on the future and sustainability. Cohet outlined the company’s approach to matters of the environment, social responsibility and governance (ESG). For larger companies he discussed the ESG reporting element as a requirement alongside financial reporting. Cohet also flagged up the need to manage the growing demand for electricity as more and more machines on jobsites switch to

A full conference room all day was a good indication of it being an interesting programme

Practical implementation of a remotely operated tower crane, from a ‘hybrid virtual’ cabin on the ground, was shown by Radius Group’s Teddy Holt and Aviv Carmel from Skyline Cockpit

electric power – an emerging challenge. Issues surrounding legislation were discussed in the round table session on engineering challenges in the sector. In January 2027, the newly revised machinery regulation EN 14439 takes effect and the existing DIN and FEM standards will be obsolete. With this and other regulatory changes their implementation on existing cranes will be a challenge for manufacturers.

The day before the main conference included a tour of Rome’s major monuments

Transforming the way tower cranes are powered on site was the topic of a lively discussion in the second panel session. It was hosted by Steve Bradby, Select Plant Hire engineering leader

combined with an interesting site visit, courtesy of Italian construction contractor Ricci, working on a new luxury hotel for Mercati, the Aldrovandi in Villa Borghese. Look out for more reporting on the event, further articles and for the presentations, all coming soon. ■

In partnership with SC&RA, Tower Cranes North America will be on 10 and 11 June 2026 at Music City Center in Nashville, Tennessee. The event will start with a networking reception on 10 June and a full day of presentations and a table-top tradeshow will be held on 11 June. The conference will include a networking lunch and closing reception.

KHL and SC&RA have started planning the programme and welcome input from the tower crane sector regarding topics of interest and suggestions for suitable speakers. Please contact International Cranes and Specialized Transport editor Alex Dahm (+44 1892 786206) or American Cranes & Transport editor D.Ann Shiffler with your ideas and suggestions at alex.dahm@khl.com or d.ann.shiffler@khl.com

round the world, construction equipment markets are undergoing a period of dramatic divergence – some regions surging on infrastructure demand, others consolidating and recalibrating under cost pressure and population dynamics.

At the centre of it all lies a question of readiness: is the industry agile enough to evolve with the pace of these global shifts?

India provides perhaps the most compelling example of rapid transformation. According to recent analysis by Maximize Market Research, the country’s construction equipment market is expected to double by 2030 – growing from US$7.8 billion in 2023 to $14.3 billion. A nearly nine per cent annual growth rate places India among the fastest-expanding equipment markets in the world, fuelled primarily by strategic government initiatives like the Smart City Mission and the Pradhan Mantri Awas Yojana housing programme.

These policies, designed to modernise infrastructure and accelerate urban development, are a direct response to India’s shifting demographics. By 2036 it’s projected that 600 million

SPECIALIZED CARRIERS & RIGGING ASSOCIATION

CHAIRMAN

J Rozum

MSA Delivery Service, Canton, Michigan, USA

PRESIDENT

Jim Sever

PSC Crane & Rigging, Piqua, Ohio, USA

VICE PRESIDENT

Harry Fry

Harry Fry & Associates, West Newbury, Massachusetts, USA

TREASURER

Michael Vlaming

Vlaming & Associates, Vallejo, California, USA

SC&R FOUNDATION

PRESIDENT

Kate Landry

Deep South Crane & Rigging, Baton Rouge, Louisiana, USA

ASSISTANT TREASURER

Keith Settle

Oxbo Mega Transport Solutions Houston, Texas, USA

ALLIED INDUSTRIES GROUP

Troy Geisler

Talbert Manufacturing Rensselaer, Indiana, USA

CRANE & RIGGING GROUP

Peter Juhren

Morrow Equipment Salem, Oregon, USA

TRANSPORTATION GROUP

Joanna Jungles

Anderson Trucking Service

St. Cloud, Minnesota, USA

VICE PRESIDENT

Tyler Henley

Mazzella Companies

Oklahoma City, Oklahoma, USA

TREASURER

Shelly Gayring

Select Crane Sales

Fort Pierce, Florida, USA.

people – nearly 40 per cent of the population – will live in cities. As this urban migration continues, the corresponding need for machinery, workforce, technology and logistics will reshape not just the Indian market, but the regional competitive landscape.

That said, recent policy incentives under India’s National Infrastructure Pipeline and the PM Gati Shakti initiative are also accelerating demand and attracting foreign investment.

For international manufacturers this represents a major inflection point. Companies like JCB, Komatsu, Caterpillar and Volvo stand to gain but opportunities extend well beyond machine sales. Support infrastructure – training, parts distribution, maintenance and data-driven service platforms – will be critical differentiators. The companies that succeed won’t just deliver machines; they’ll deliver ecosystems.

Elsewhere in Southeast Asia, growth remains strong. Vietnam continues to experience an infrastructure boom, particularly in transport and power. Demand for lifting, rigging and heavy transport solutions is growing alongside high-speed rail developments, urban transit expansion and power grid upgrades. Thailand, meanwhile, is seeing a surge in both commercial and residential builds, creating a strong outlook for mid-sized cranes, material handlers and mobile transport gear.

By contrast, more mature markets like Japan and much of Europe are focused less on volume expansion and more on cost efficiency and technological optimisation. Defensive consolidation and digital innovation are defining strategies. As a result, fleet owners are investing in telematics, automation and hybrid-electric platforms to squeeze more productivity from leaner operations.

Looking further northeast, China and South Korea continue to double down on artificial intelligence, autonomous operation and IoT-integrated machine control. What’s emerging is a vision of connected jobsites, where disparate equipment communicates seamlessly across platforms to deliver measurable efficiencies in speed, fuel use and operator oversight.

Taken together, these trends highlight a shifting balance in the global equipment landscape. In some regions, the challenge is how to scale – in others, how to streamline. But across the board, the call is clear: adapt or get left behind. ■

Coming out of the recent SC&RA Annual Conference in Arizona, USA, Association leadership was already turning its attention to the second half of the year – with transportation priorities firmly aligned around safety, enforcement and deeper engagement with regulatory stakeholders.

According to Chris Smith, SC&RA vice president, transportation, the direction moving forward is clear. “We’re really leaning into safety and enforcement advocacy,” he said, “which includes a significant step toward better communication with law enforcement – an area that can be uniquely challenging.”

To help guide that effort, SC&RA committees developed a document titled Principles of Fair Enforcement – an initiative that began at the Specialized Transportation Symposium in North Carolina, USA, early in 2025, and was nearly finalised at the Annual Conference. “That document will serve as our outline for how we communicate with law enforcement moving forward,” Smith explained.

One area SC&RA is heavily leaning into in 2025 is safety and enforcement advocacy, including a significant step toward better communication with law enforcement

IMAGE: ©PRECISION

HEAVY HAUL

Chris Smith, SC&RA vice president, transportation

for accountability without alienating them.”