RESEARCH

GARDEN ANTHROMES

Research Project with the Bartlett School of Architecture

Research project developed with Marcos Cruz, Brenda Parker, Guillem Peruxet, Ayelen Franceschini, Jingyuan Meng, Satyam Gyanichandani, Yifan Shi and Pradeep Devadass, from the Bio-ID community.

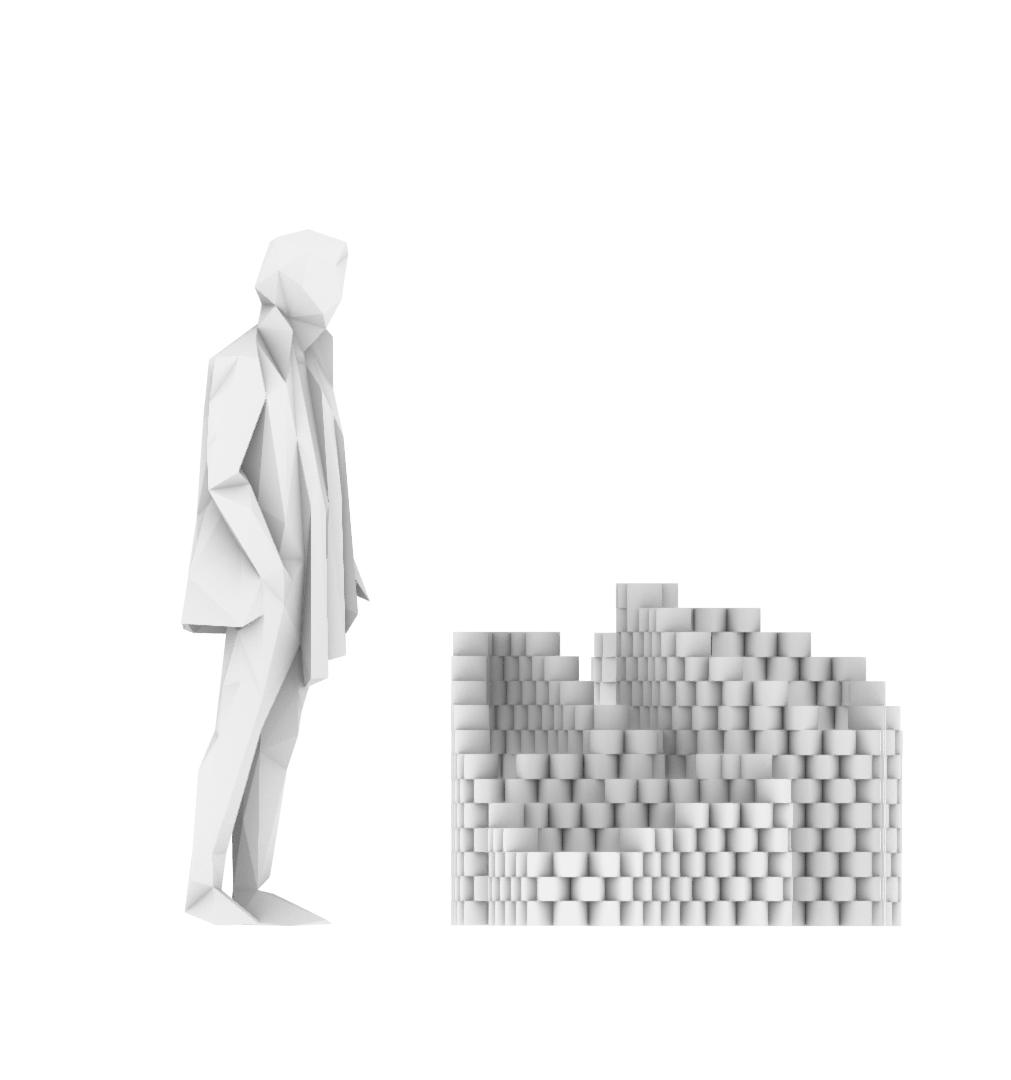

Landscape project involving the 3D printing of large scale soil ‘anthromes’, anthropogenic biomes for soil remediation, designed for a brownfield site in East London.

These structures will act as a display of a set of plant species currently present in the site, help with the analysis of the bioremediation potential of said species, and finally degrade back into the ground.

This project explores the possibilities and complications that the scaling up of a 3D printing process with a soil based material bring, as well as the potential of the use of biologically based polymers in soil construction.

London, UK 2023

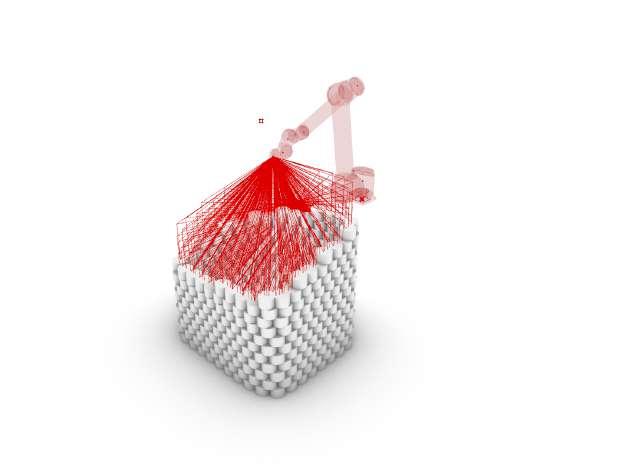

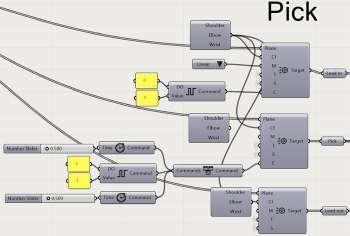

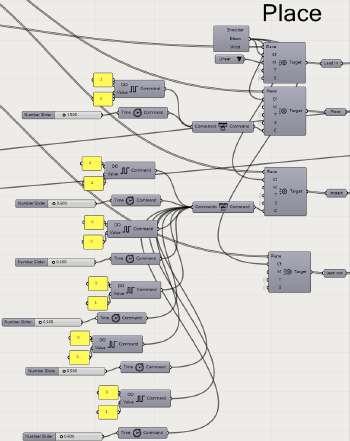

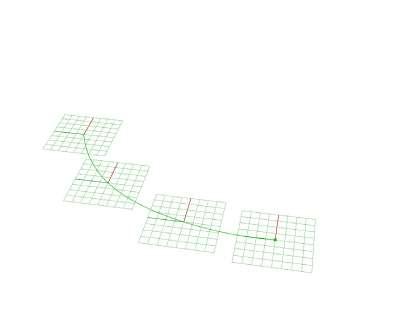

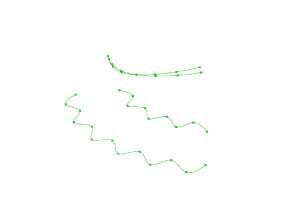

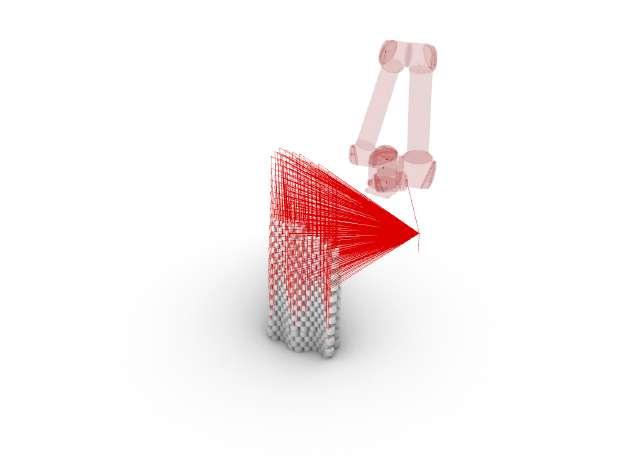

The toolpath was programmed to alternate between a ‘pickup’ plane and a ‘place’ plane, to sequentially pick up bullets and place them in the workspace to assemble the structure.

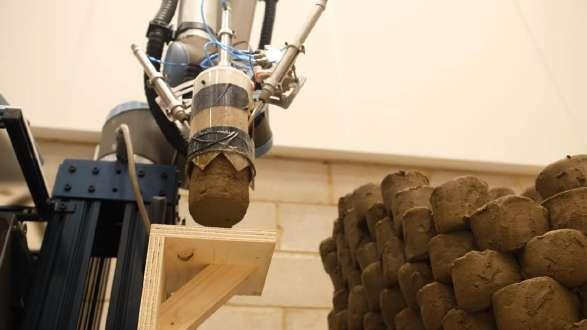

A specially designed end-effector was fabricated with the help of Design for Manufacturing MArch students Dianxiong Qu and Chun Liu.

The structures were printed on campus on recycled pallets and transported to the site on trucks.

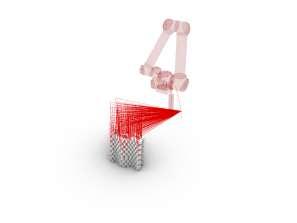

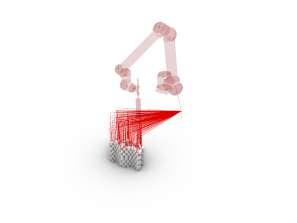

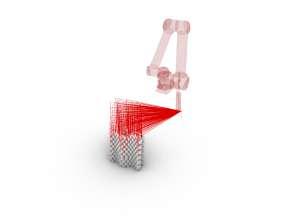

UR-10 robotic arm and pneumatic end effector used

Robotic assembly of structure

UR-10 robotic arm and pneumatic end effector used

Robotic assembly of structure

Assembled structures, awaiting transportation

Video footage by Nicholas Bennett

Video footage by Nicholas Bennett

Opposite Page: Dr. Marcos Cruz & Dr. Brenda Parker on site.

Weathered Garden Anthrome pictures by Marcos Cruz.

Opposite Page: Dr. Marcos Cruz & Dr. Brenda Parker on site.

Weathered Garden Anthrome pictures by Marcos Cruz.

TERRA EX-MACHINA

Bio - Integrated Design MArch - Y2 Project

London, UK 2022

Project developed within the specialization module of the Bio-ID MArch.

Research conducted on robotic fabrication with a soil + biopolymer material.

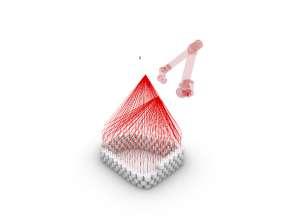

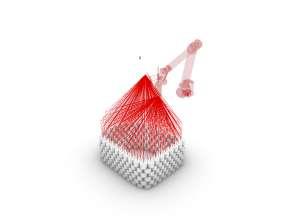

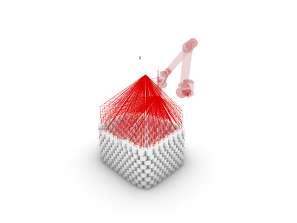

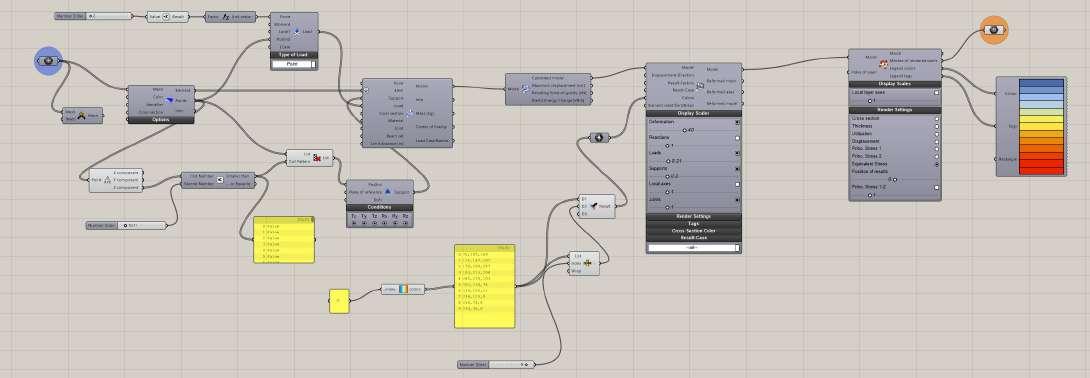

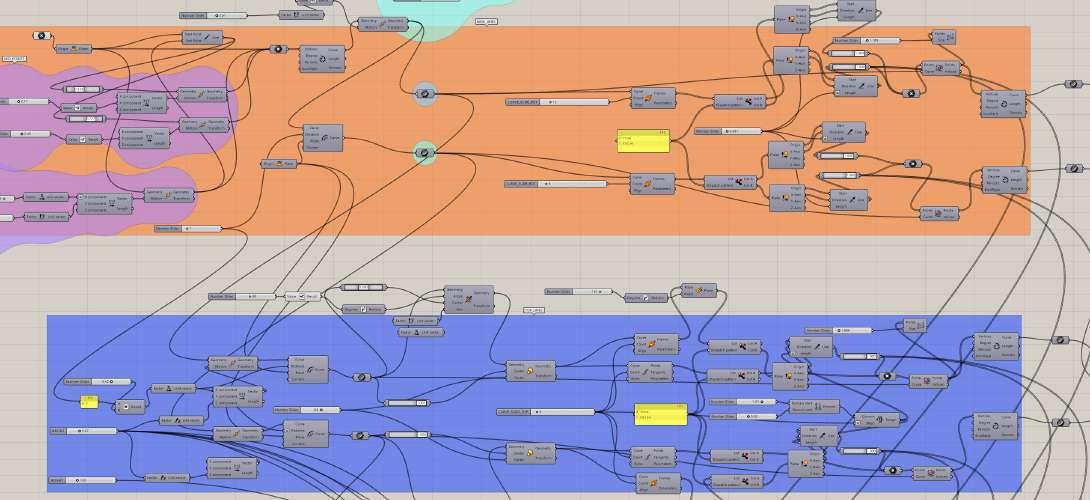

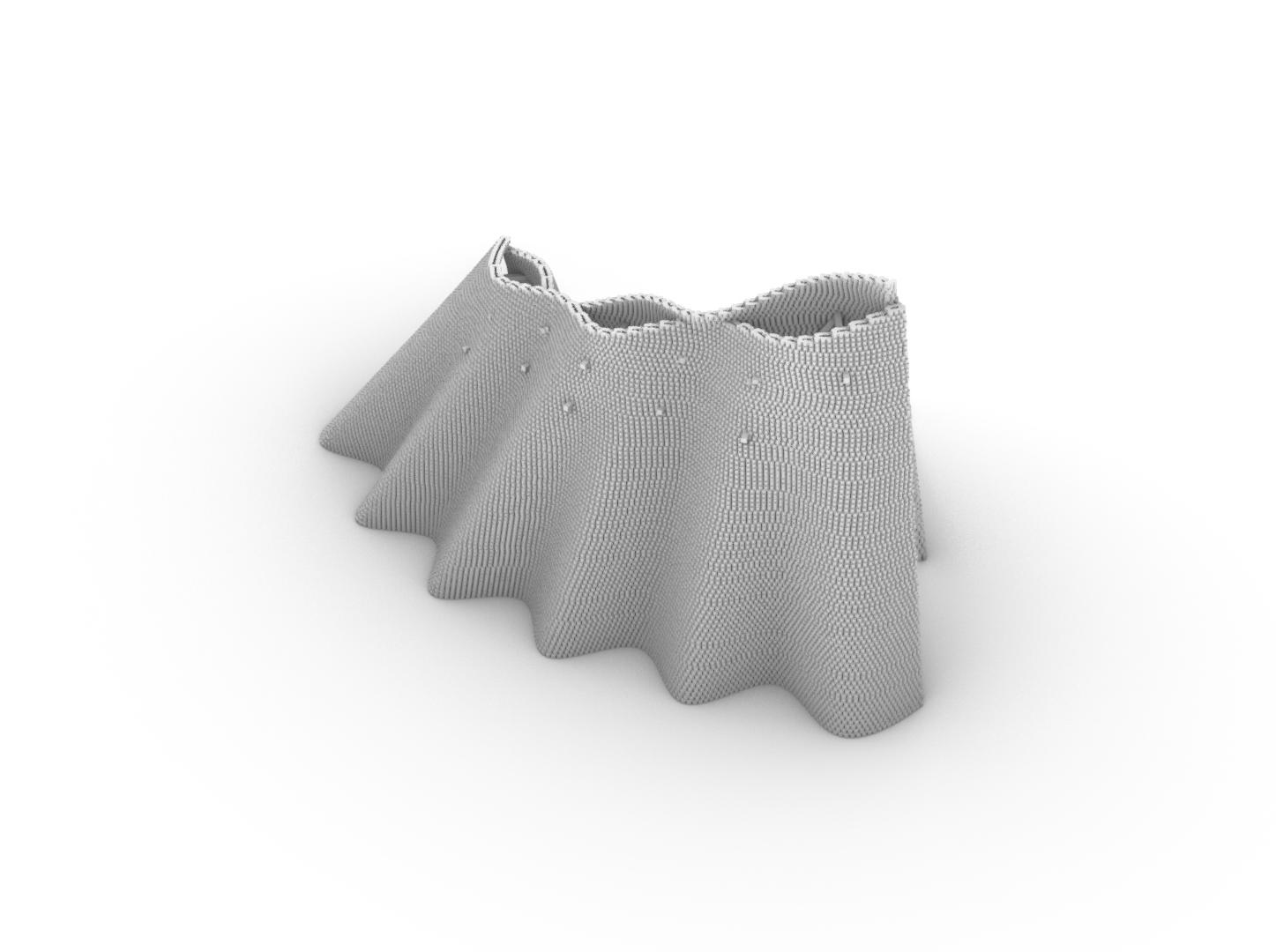

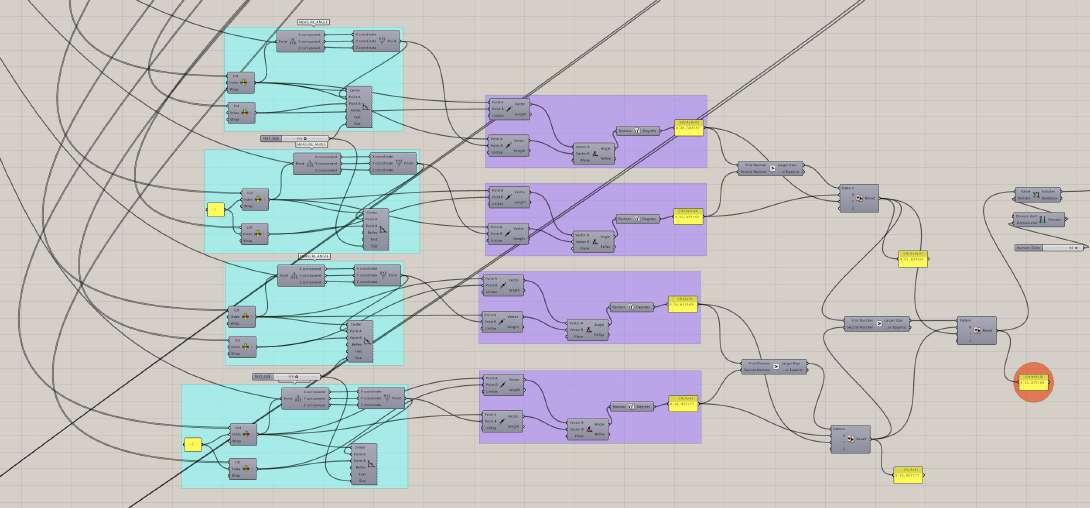

Impact printed structures were produced with a UR-10 robotic arm and a pneumatic end effector, designed to position discrete soil units and impact them into place.

This project explores the possibilities that the use of biologically based polymers in improved soil mixes could bring in the framework of impact printing as a fabrication and construction method, with the goal of producing self-supporting structures in complex threedimensional geometries, built with non-pollutant, programmable and biodegradable soil mixes.

C2

Raw Soil

Biopolymer Treated Soil

C2

Raw Soil

Biopolymer Treated Soil

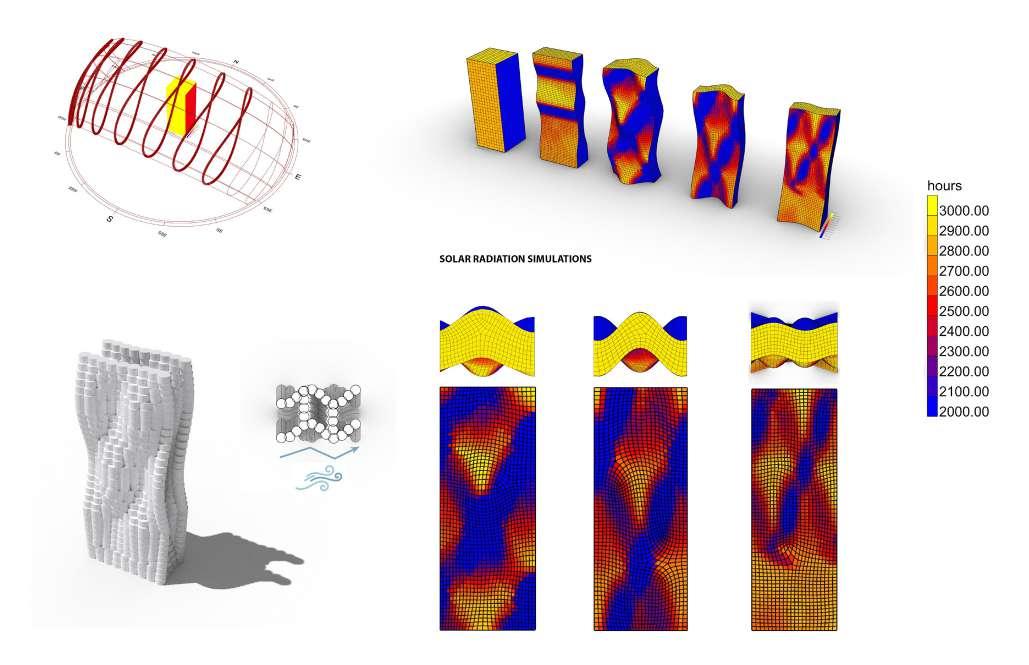

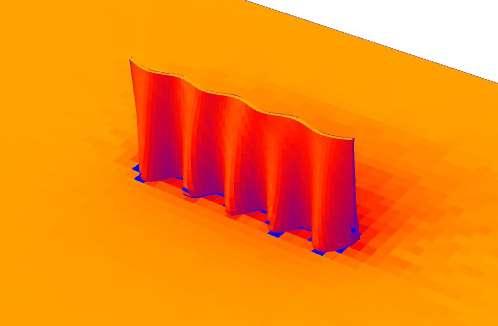

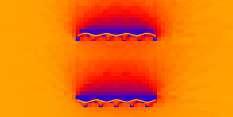

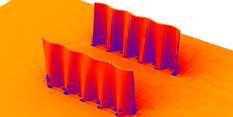

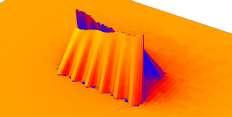

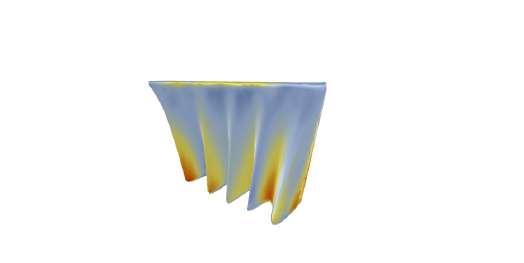

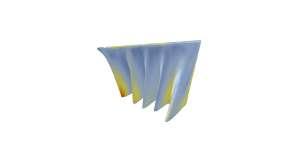

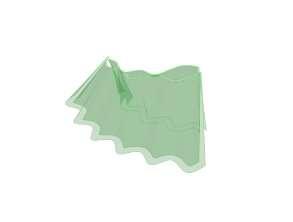

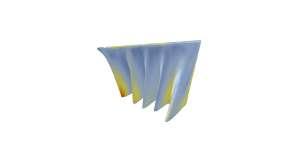

With the goal of testing the possibilities of the impact printing robotic fabrication process, and the potential of the soil+biopolymer mix, a set of iterations of self shading structures were produced. These iterations were informed by solar radiation simulations and structural simulations.

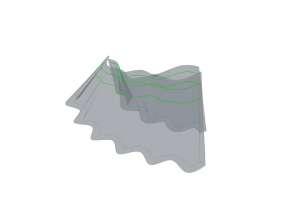

Double layered structures were produced, with an ondulating gesture that produced different degrees of self shading.

The structures were printed with the help a segmented box structure, and dry soil was filled around each printed layer, to act as an adaptable formwork while the material dried. Multiple walls were printed until the optimal material and toolpath parameters were achieved.

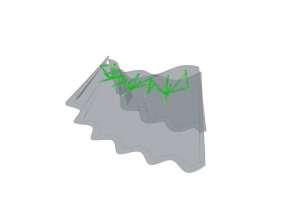

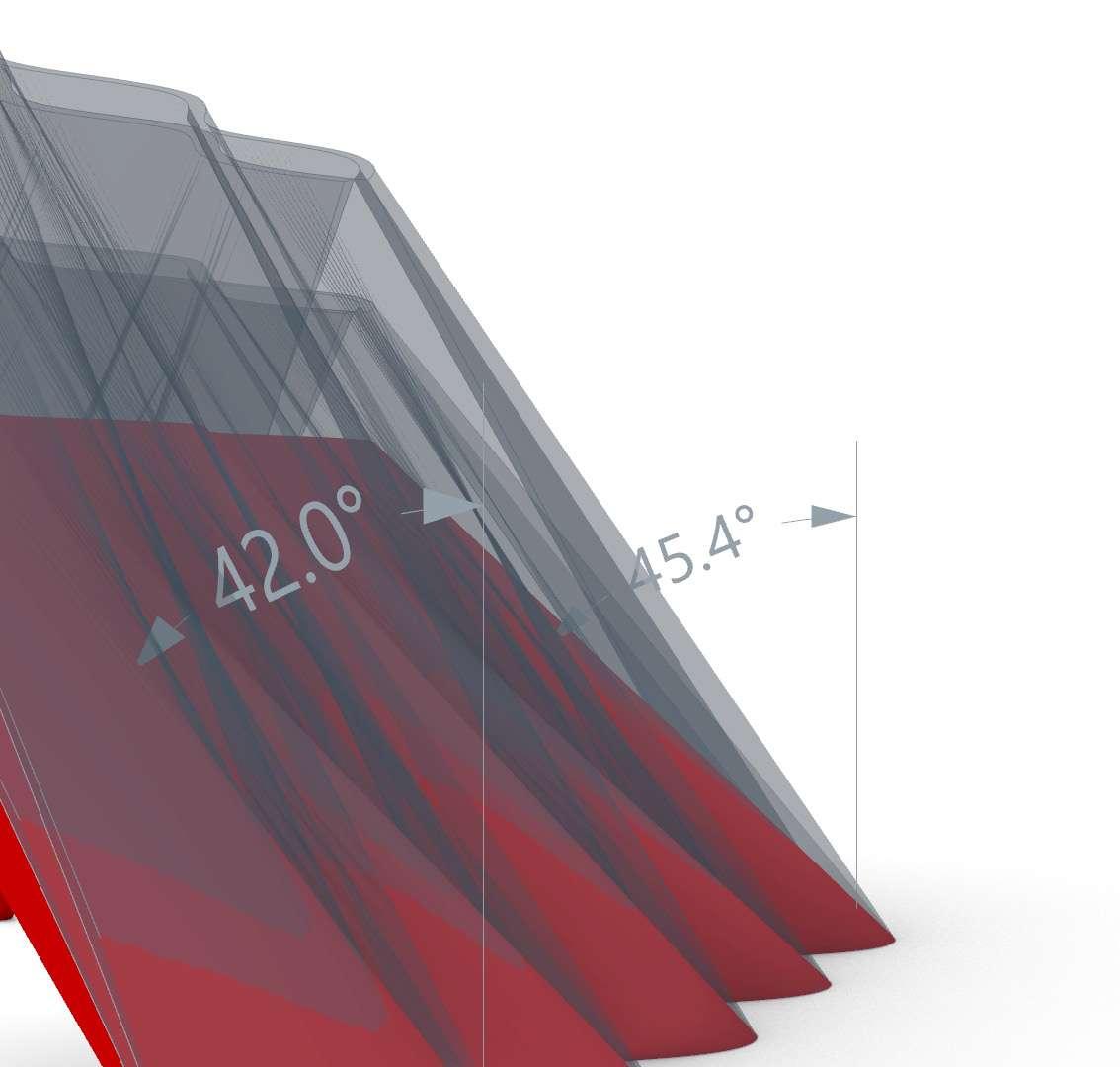

Structural simulations were conducted on the geometries of the structures, to identify and try to predict problematic sections.

Portions of code were written to perform comparative structural stress tests, to inform the form finding process.

The deformation simulations proved to be surprisingly accurate in predicting the way that the collapsed structures would behave.

The final print, dubbed Wavy Wall (WW), showed a stable deformation scheme and very low structural stress levels according to the simulations.

BUILD UP, BREAK DOWN, GROW ANEW

Bio - Integrated Design MArch - Thesis Project

Project developed with Bio-ID MArch students Itamar Lilienthal and Laetitia Morlie.

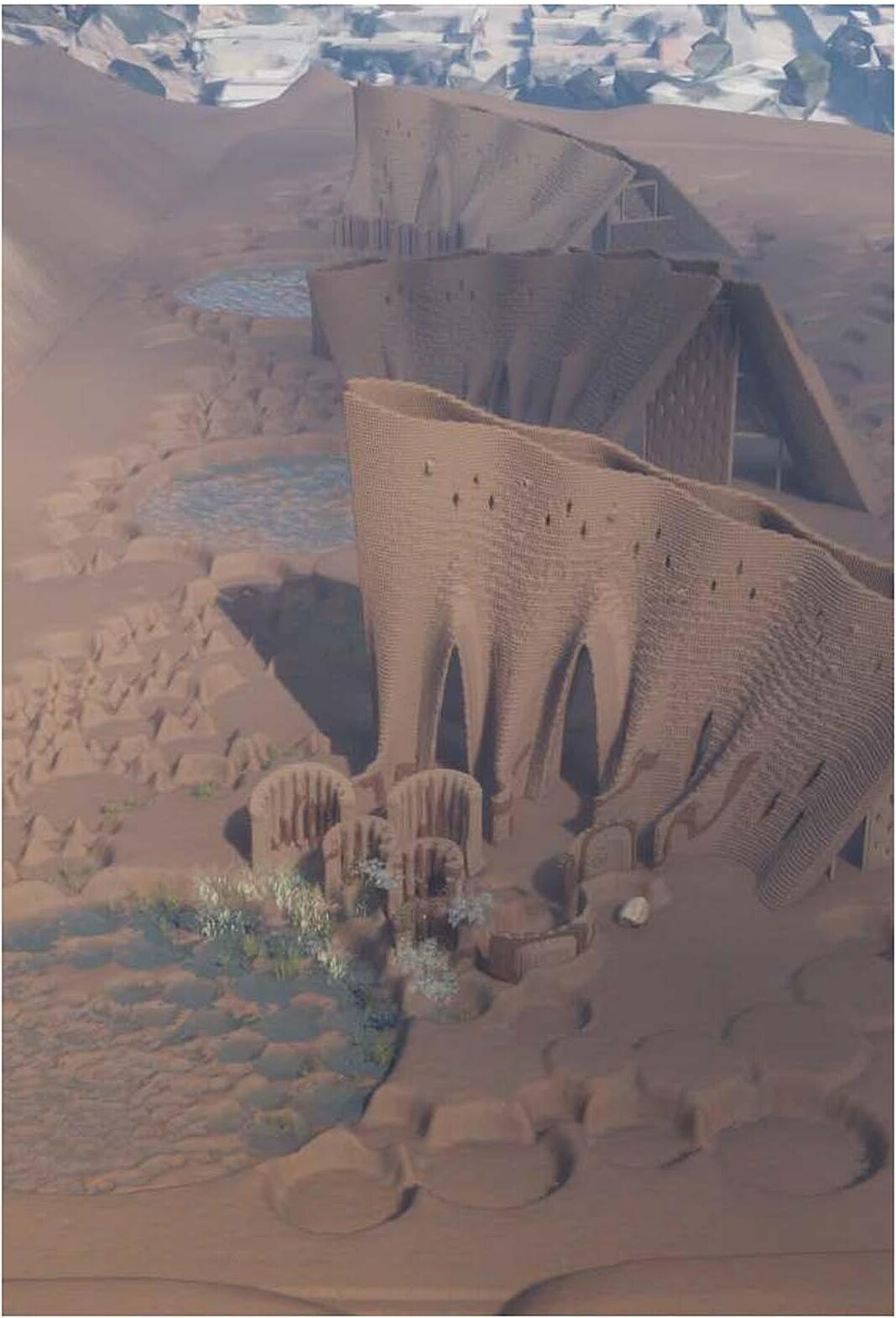

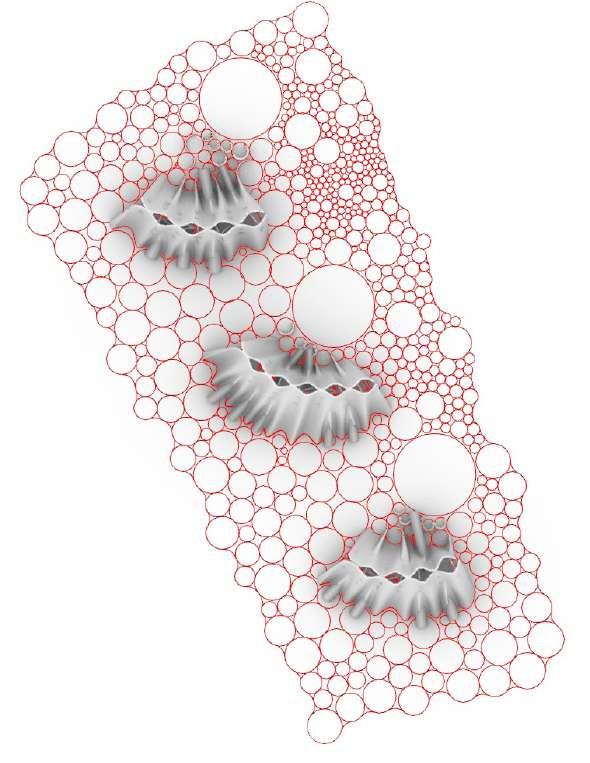

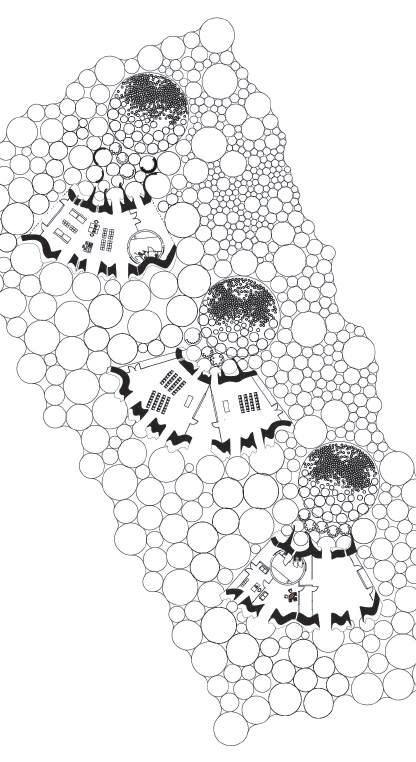

Situated in Tijuana, at the border between Mexico and the United States, this project was designed to contribute to soil resilience by developing biologically active soil constructions contributing to the survival and release of cells into the ground for plant-bacteria symbiosis (and soil health).

The buildings were conceived around the use of multi-material soil 3D printing as the main construction method, particularly impact printing with a biopolymer enriched soil mix, in a material gradient that would allow for certain specific sections of the buidings to degrade and release plant-growth enhancing bacteria into the surrounding area.

London, UK 2023

Through the controlled degradation of the building, some of the plant species found in the estuary north of the border would be reintroduced into the Los Laureles settlement.

The allocation of the degradable and non degradable materials in the production of the building was heavily informed by environmental and structural simulations.

Overview from the north

Overview from the north

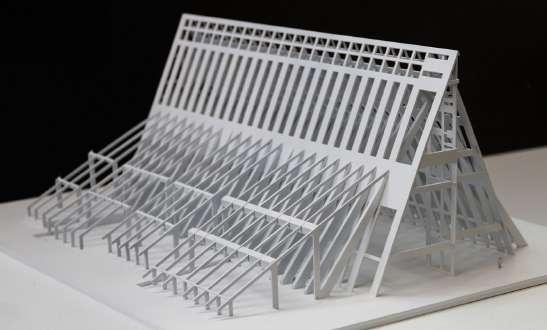

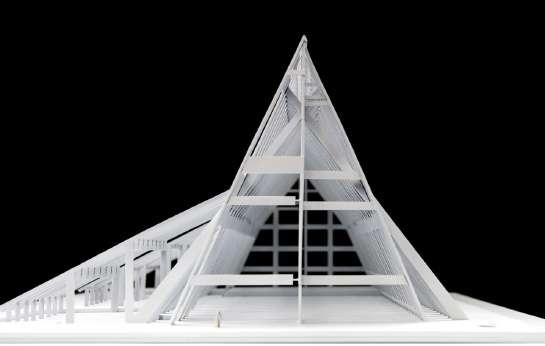

Structures were produced from an initial curve, offsetted and copied with a determined height, to form a compressive A-frame type structure.

The code was designed to allow a high degree of control on the base curves, with the purpose of producing a controlled ondulating pattern on the main walls, to allow for the iterative testing of structural stability and self shading properties.

Angle constraint code Model by author

Angle constraint code Model by author

A section of the code was written to analyze the angle of the walls according to a maximum estimate informed by the fabrication process. This analysis would give a visual cue in the model if any angle in the model would exceed a determined number.

Circle packing pattern Code and illustration by author

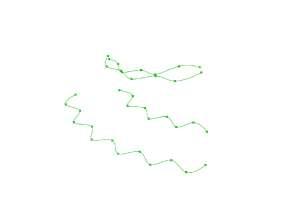

As a guideline to organize the elements on the site, a circle packing pattern was produced with attractor points, using the building position as well as the vernal pools as the attractors, producing variations on the radius of the circles.

Overview from the north Renders by Itamar Lilienthal

Overview from the north Renders by Itamar Lilienthal

Robotic assembly of structure

Robotic assembly of structure

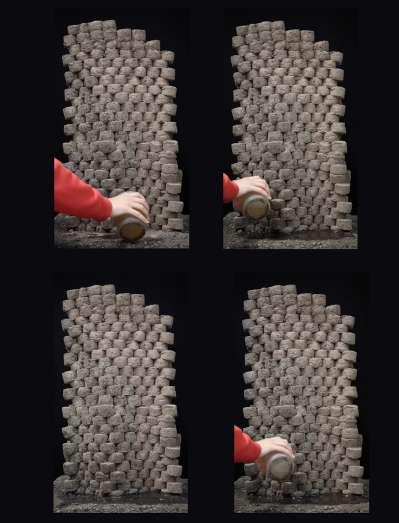

Multi-material models were printed using a UR-10 robotic arm and a specially designed end effector, using two main material mixes, one treated with a biodegradable polymer and one with a high clay content, which represents the degradable material that would release the plant growth promoting bacteria.

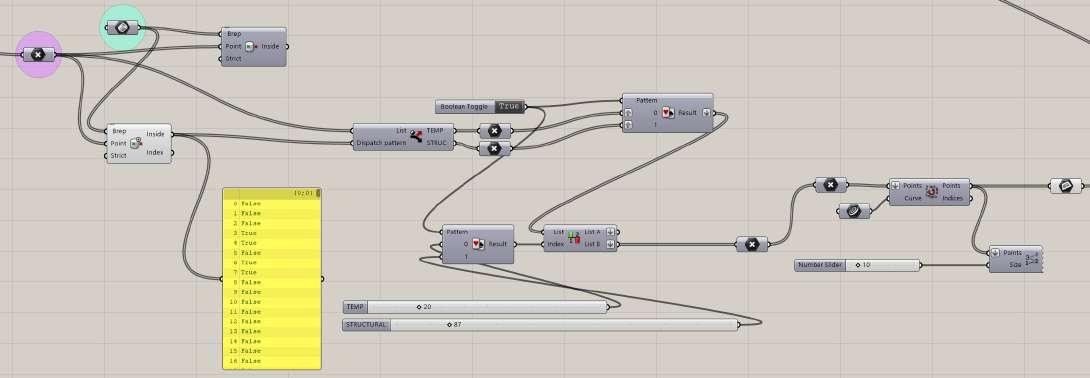

A section of code was written to separate the targets of both materials for the printing process, through the use of a point-in-brep analysis process.

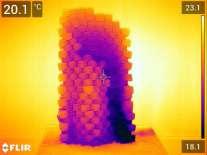

Tests were conducted to assess the water resistance of the printed structure, since the main erosion source would be rainfall and moisture absorbed through capilarity. The biopolymer treated bullets proved to be quite water resistant, while the clay based bullets showed the predicted degradation. Thermography confirmed the distinct water absorption behavior of the two materials.

Water erosion and bacterial release tests conducted by Laetitia Morlie

Project render Illustration by Itamar Lilienthal

Project render Illustration by Itamar Lilienthal

PROFESSIONAL PRACTICE

CELAYA’S NEW CATHEDRAL

Celaya, Mexico

Client: Archidiocese of Celaya

Responsibilities:

Conceptual Design

Project Design

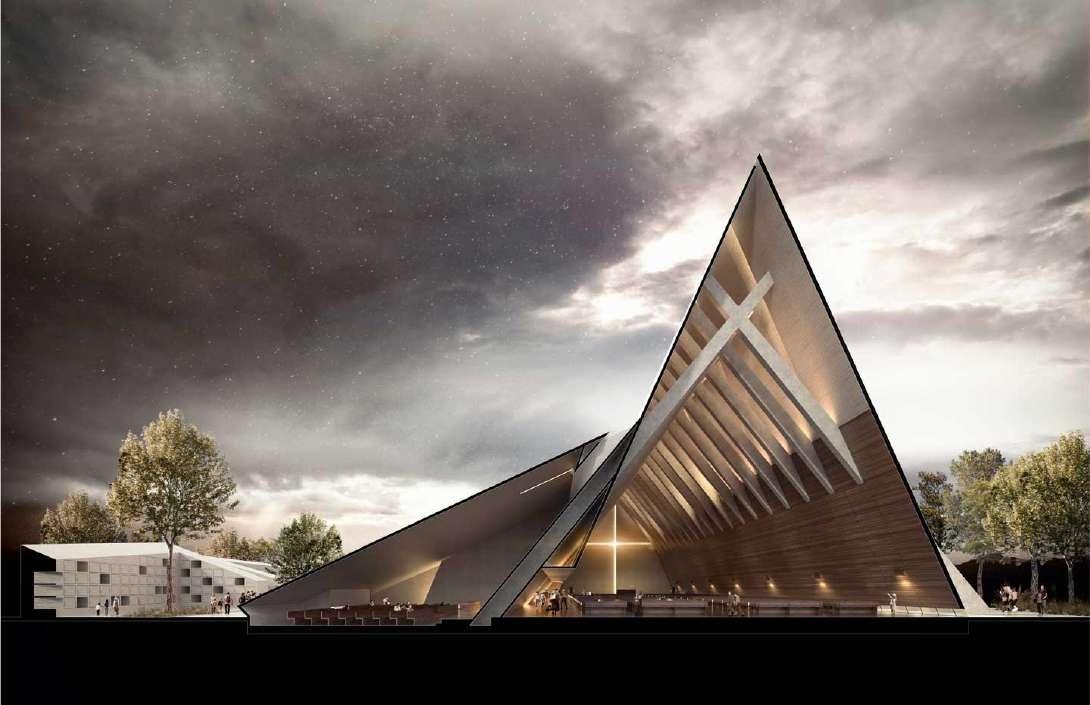

Project developed as a part of the project development team of Gaeta-Springall Architects, for the New Christian Cathedral of Celaya, awarded by competition to the firm in 2015.

Opposite page: Renderings by Óscar Juárez and Aldo Urban

National Competition - First Place 2016

Gaeta-Springall Architects

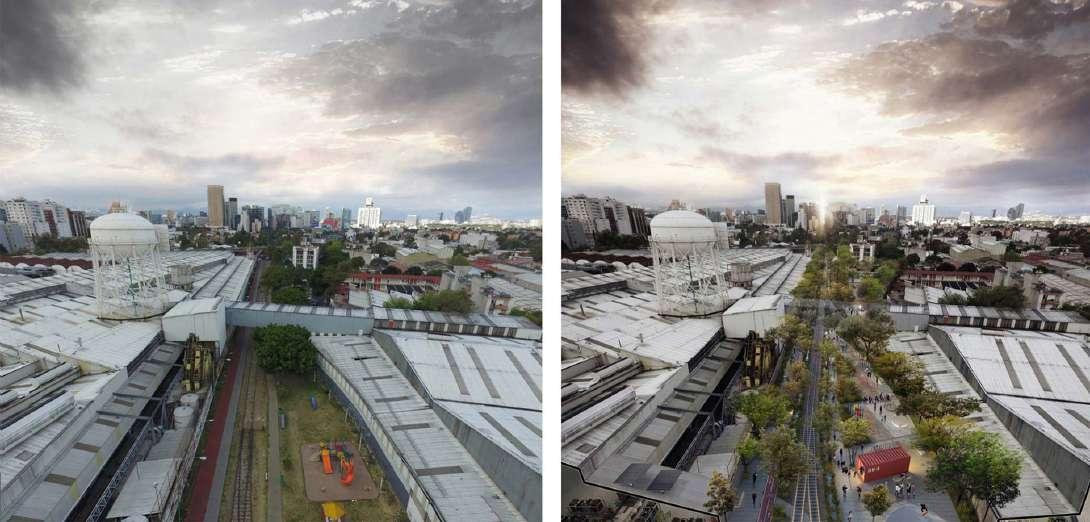

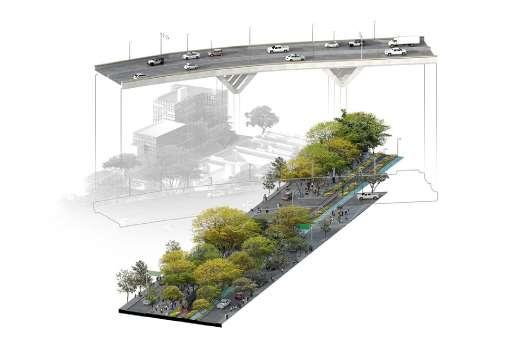

CUERNAVACA RAILROAD LINEAR PARK

CDMX, Mexico

Client: Mexico City

Responsabilities:

Conceptual Design

Project Design

Gaeta-Springall Architects

International Competition - First Place 2017

Project developed as a part of the conceptual design and competitions team of GSa. International competition won in 2017, to design a 4.7 km long park across the north west sector of Mexico City, along the old tracks of the Cuernavaca Railroad.

Opposite page: Renderings by Óscar Juárez and Aldo Urban

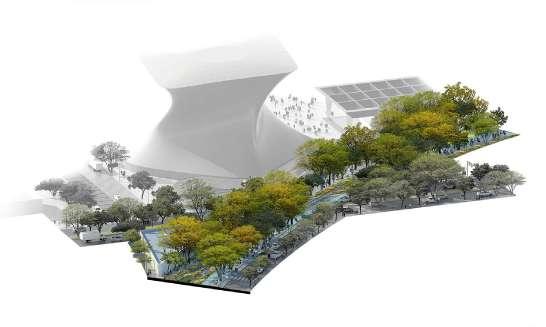

TEC MONTERREY CENTRAL PARK

Client: Tecnológico de Monterrey

Responsabilities:

Project Coordination

Conceptual Design

Project Design

Project developed as project coordinator for GSa. National competition won in 2017, to design the Central Park of the Ciudad TEC master plan for the Tecnológico de Monterrey Campus in Monterrey.

Renderings by Óscar Juárez and Aldo Urban

Gaeta-Springall Architects

National Competition - First Place Monterrey, Mexico 2017

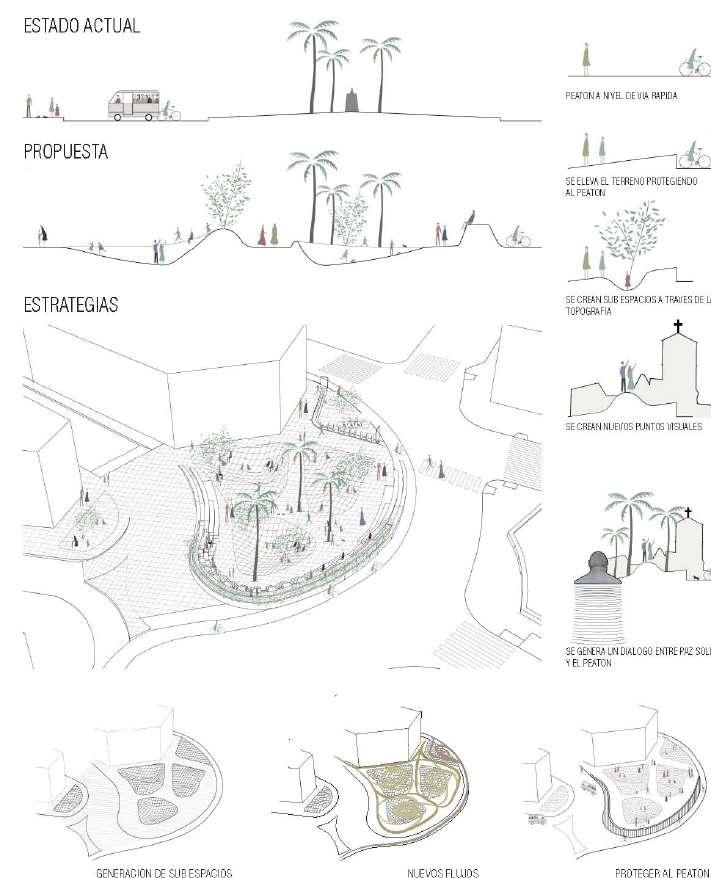

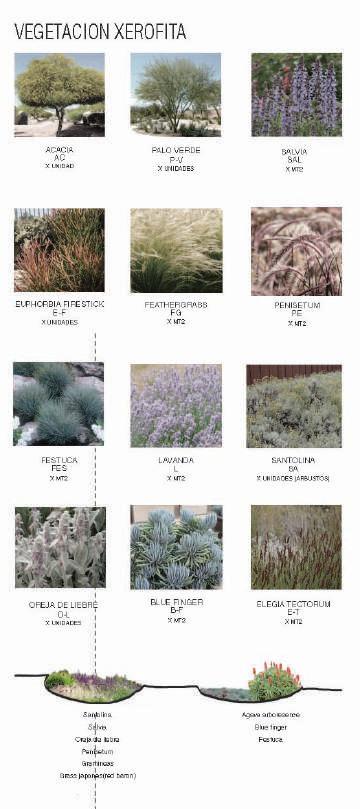

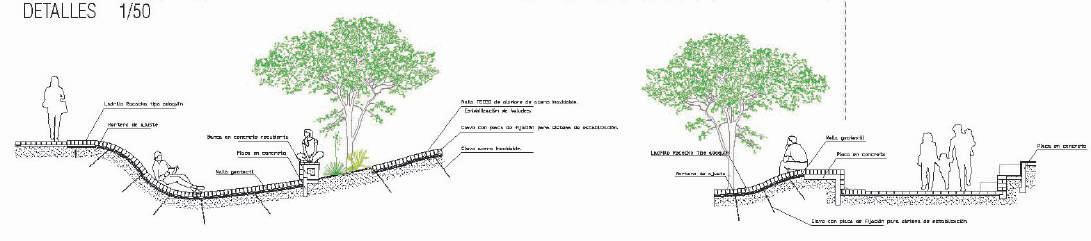

Client: City of San Isidro, Lima

Responsabilities: Conceptual Design

PAZ SOLDÁN PLAZA

Lima, Peru 2018

National Competition - Honourable Mention

National competition for the design of a small square in the district of San Isidro, in Lima city. Designed with architects Nadia Cabrera, Juan Pablo Calderón, Ariana Valcárcel, Vittorio Zolezzi in collaboration with artists Noah Alhalel and Pierina Seinfeld.

HIGH PERFORMANCE SCHOOL - PIURA

Project Execution: Banco de Crédito del Perú

Project Design: De la Piedra Arquitectos

Responsabilities:

Agreement Coordination

Project Design Supervision

Project developed as agreement coordinator and design supervisor for the Work for Taxes team of the National Educational Infrastructure Program (PRONIED) of the peruvian Ministry of Education. Project for the High Performance School of city of Piura.

Renderings by COSAPI

Ministry of Education

Piura, Peru 2020