Kesla is an expert in modern tractor equipment. With our decades of true hands-on experience in creating innovative solutions for tractors, we offer the best and most user-friendly tools for working anywhere from forests to farms and beyond. Never compromising on responsibility.

For us at Kesla, the needs of a chipping entrepreneur are the law. We understand that the entrepreneur wants to produce good quality chips efficiently with their chipper without long shutdowns. That is why we have invested in technology in our chippers, ensuring uniformly good chipping quality, excellent chipper availability and easy and quick daily maintenance.

Using Kesla-made

• Crane and chipper control with the same user interface and control system.

• 7-inch touch screen interface with optional languages.

• Extremely easy-to-use control system with a range of armrest options.

• Easy mounting of controls on the tractor.

Automatic feed cut-off.

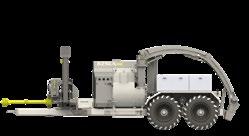

• Three chassis options.

• Optional drawbar steering & HD drive.

• Wide range of loaders from 8.5 m to 10.3 m.

• Two rotor options.

• Wide range of loader and chipper control options.

• Optimal balance between power demand and chip output.

• Optimal dimensioning of the feed table and chamber intake.

• Top of the size class screen area efficiency.

• High performance blower also for stock operations.

• Central lubrication as standard, automatic central lubrication as an option.

• Big, easy-to-access belts and heavy-duty tensioners.

• Dedicated chamber service platform.

• Quick replacement of screens and knives.

Amble storage space for knives, tools and spare parts as an option.

• The chassis is always designed for chipper use and loaders with up to 10.3 m reach.

• The chamber and rotor are made of strong, high-quality materials.

• All wear parts are designed to be easily replaced.

• The wear parts are designed according to the specific requirements of the operating environment

• The structure is made mainly of heavy-duty SSAB steel.

KESLA proCHIPPER is an electronic chipper control system that can also be used to control a KESLA loader feeding the chipper. The setting menus are accessible through an easy-to-use touch screen with several language options. Pre-set values for logs, small round wood and brushwood. The intuitive system makes it easy to adjust every function to your liking and store them in the system.

It is possible to order a remote control module for the chipper control system. The module enables remote communication with the chipper. With remote access, Kesla experts can perform fault diagnoses and update the operating system directly through the remote connection module.

A camera kit increases working efficiency and safety. The most popular kit includes chute and reversing cameras. The cameras are IP protected and heated, ensuring operation in all conditions.

SKF Multilube automatic central lubrication facilitates the daily life of chipper entrepreneurs. Just make sure that there is grease in the lubrication unit: the unit applies the correct amount of grease to each grease point.