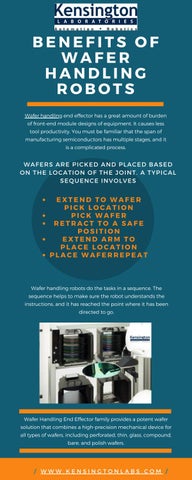

BENEFITS OF WAFER HANDLING ROBOTS Wafer handling end effector has a great amount of burden of front-end module designs of equipment. It causes less tool productivity. You must be familiar that the span of manufacturing semiconductors has multiple stages, and it is a complicated process.

WAFERS ARE PICKED AND PLACED BASED ON THE LOCATION OF THE JOINT. A TYPICAL SEQUENCE INVOLVES

EXTEND TO WAFER PICK LOCATION PICK WAFER RETRACT TO A SAFE POSITION EXTEND ARM TO PLACE LOCATION PLACE WAFERREPEAT

Wafer handling robots do the tasks in a sequence. The sequence helps to make sure the robot understands the instructions, and it has reached the point where it has been directed to go.

Wafer Handling End Effector family provides a potent wafer solution that combines a high-precision mechanical device for all types of wafers, including perforated, thin, glass, compound, bare, and polish wafers.

/ WWW.KENSINGTONLABS.COM /