REFRIGERATION

Kelvion Air Coolers, Condensers, Gas Coolers, Plate Heat Exchangers

PRODUCT OVERVIEW

TABLE OF CONTENT Kelvion gastro FM & slim FM Air Cooler ......................................................................................................................................... 4 Kelvion KCB / KCC Air Cooler 6 Kelvion KDC Air Cooler ....................................................................................................................................................................... 8 Kelvion MCC Air Cooler 10 Kelvion KSC Air Cooler 12 Kelvion CMK Air Cooler ..................................................................................................................................................................... 14 Kelvion CML Air Cooler 16 Kelvion CSK und CBK Air Cooler ....................................................................................................................................................18 Kelvion CSL und CBL Air Cooler 20 Kelvion GSK und GBK Air Cooler .................................................................................................................................................. 22 Kelvion GSL und GBL Air Cooler 24 Kelvion KVB Air Cooler .................................................................................................................................................................... 26 Kelvion MCK Air Cooler 28 Kelvion SG classic Air Cooler 30 Kelvion SG commercial Air Cooler.................................................................................................................................................32 Kelvion CDK Air Cooler 34 Kelvion CDL Air Cooler .....................................................................................................................................................................36 Kelvion CBF / CSF Air Cooler 38 Kelvion R/GF-D Condenser und Gas Cooler .............................................................................................................................. 40 Kelvion R/GF-S Condenser und Gas Cooler 42 Kelvion R/N/GF Condenser und Gas Cooler 44 Kelvion R/GV-M Condenser und Gas Cooler ..............................................................................................................................46 Kelvion R/GV-T und R/GV-L Condenser und Gas Cooler 48 GBH Plate Heat Exchanger............................................................................................................................................................. 50 GBH-HP Plate Heat Exchanger 52 GVH-HP Plate Heat Exchanger ......................................................................................................................................................54 Gasketed Plate Heat Exchanger 56

FRESHNESS IN REFRIGERATION & COUNTERS

⊲ The Küba gastro FM & gastro slim FM is the mighty mini for tough refrigeration challenges that cooling counters or food storage units can pose: Horizontal or vertical air discharge options are available, depending on space restrictions.

⊲ The air discharge from either side ensures that the air in the refrigerated cabinet is always distributed evenly, considerably reducing cooling times Defrost can be retrofitted for chilled operation Quality powder high-grade, food-safe powder coating: Suitable for unpacked or acidic chilled be for easy cleaning gastro slim with cross-flow With an installed width of only 75 mm the gastro slim FM can fit behind center columns in most cooling counters.

Küba gastro FM & Küba gastro slim FM

UNITS

––

⊲ Electric

⊲

coated edges with

goods ⊲ All casing components can

removed

or maintenance ⊲ Küba

FM

fan:

Commercial Air Coolers CAPACITY RANGEYOUR BENEFITS 110 W - 340 W 100 W - 280 W tL1= 5°C | t0= -5°C | DT1 = 10K | R404A tL1= 0°C | t0= -8°C | DT 1= 8K | R744 | 60 bar Kelvion gastro FM & slim FM Air Cooler

⊲ Drip tray (Plastic) ⊲ Drip tray (Aluminum) ⊲ All HFC units are available ex stock ⊲ All Küba gastro slim FM units are CO2-ready and available ex stock. ⊲ Tube System: Staggered ⊲ Tube spacing: 33 x 38 mm | Ø 10 mm ⊲ Fin spacing: [in mm] A = 4.5 ⊲ Single injection via copper pipe for brazing connection MATERIAL TUBE FINS CASING END PLATE Aluminum þ þ þ Copper þ Aluminum epoxy-resin-coated Aluminum/Steel protective coating Steel sendzimir zinc-plated Stainless Steel FM(O)A 8x1 = 400 FM(O)A 0x1, 0x2 = 406 FM(O)A 8x1 = 75 FM(O)A 0x1, 0x2 = 107 FM(O)A 8x1D = 324 - 438 FM(O)A 0x1D = 238 - 273 FM(O)A 0x2D = 273 - 378 With our product selection software Kelvion RT Select you can configure our products and spare parts easily and very detailed for your customer. Reliable support during the project planning phase and time savings by means of a detailed selection is guaranteed. HEAT EXCHANGER VARIANTS & ACCESSORIES NOTE DEFROST FANS þ Standard execution | ü Available as a variant | ü« Standard for NH3 Casing and Heat Exchanger powder coated (RAL 9010) AIR DIRECTION & DIMENSIONS [in mm] MATERIAL Cross-Flow: Ø 40 mm Axial: Ø 90 mm ⊲ AC Technology þ DEFROST COIL DRIP TRAY Electric ü ü Hot Gas Cold Gas Brine www.kelvion.com © Kelvion • All rights reserved • Subject to changes • 12/18

Commercial Air Coolers Kelvion KCB / KCC GREAT FOR SMALL COLD ROOMS 0.4 kW - 2.0 kW 0.6 kW - 1.8 kW ––CAPACITY RANGEYOUR BENEFITS ⊲ The compact Kelvion KCB / KCC is primarily designed for ensuring the quality cooling of packed and open goods. ⊲ Drip trays can be specified with horizontal or vertical drain ⊲ High-grade powder coated coil and casing offer best corrosion protection . ⊲ An integrated air baffle plate ensures optimal airflow ⊲ Drip trays can be hinged to give access to the bottom for cleaning or maintenance ⊲ With its low silhouette and the horizontal condensate drain you get the most out of your cold room space ⊲ Large cooling surfaces and short defrosting times offer maximum cooling quality. tL1= 0°C | t0= -8°C | DT 1= 8K | R744 | 45/60 bar tL1= 0°C | t0= -8°C | DT1 = 8K | R404A [SC2] Kelvion KCB / KCC Air Cooler

⊲ Additional Heater (Delivery not mounted) ⊲ Electric Heater (Delivery not mounted) ⊲ All HFC and CO2 units are available ex stock. ⊲ Tube System: Staggered ⊲ Tube spacing: 33 x 38 mm | Ø 10 mm [1-2 mot.] 33 x 38 mm | Ø 12 mm [3 mot.] ⊲ Fin spacing: [in mm] A = 4.5 | B = 7.0 ⊲ Single injection via copper pipe for brazing connection HEAT EXCHANGER VARIANTS & ACCESSORIES NOTE DEFROST MATERIAL MATERIAL TUBE FINS CASING END PLATE Aluminum þ þ þ Copper þ Aluminum epoxy-resin-coated Aluminum/Steel protective coating Steel sendzimir zinc-plated þ Stainless Steel Powder Coating [RAL 9010] þ þ þ þ FANS AIR DIRECTION & DIMENSIONS 176 515 [in mm] Ø 200 mm⊲ EC Technology þ Fixed speed DEFROST COIL DRIP TRAY Electric ü ü Hot Gas Cold Gas Brine þ Standard execution | ü Available as a variant | ü« Standard for NH3 With our product selection software Kelvion Select RT you can configure our products and spare parts easily and very detailed for your customer. Reliable support during the project planning phase and time savings by means of a detailed selection is guaranteed. www.kelvion.com © Kelvion • All rights reserved • Subject to changes • Version 01 • 12/20 KCB 201-S = 428 | KCB 201-4/6 = 528 | KCB 202-4/6 = 928 | KCC 203-4/6 = 1,328

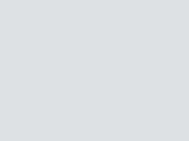

Kelvion KDC DRAUGHT-FREE VENTILATION AND QUIET OPERATION 1.4 kW - 23 kW 1.7 kW - 23 kW 2.8 kW - 37.7 kW –⊲ Kelvion KDC: Fans offer considerable energy cost savings and long life ⊲ Fans offer a choice of high or low speed ⊲ Reduced weight compared with current range ⊲ Drip tray hinged on both sides to give access to the bottom for cleaning or maintenance ⊲ CAL® distributor option available ⊲ Draft-free air circulation and quiet operation: pleasant conditions‚ for people in working spaces ⊲ Guides the air across the ceiling and far into the room ⊲ Smooth surfaces: Easy to clean ⊲ Option: 45 / 90 bar CO2 / R744 version Commercial Air Coolers CAPACITY RANGEYOUR BENEFITS tL1= 0°C | t0= -8°C | DT 1= 8K | R744 | 45/90 bar tL1= 0°C | t0= -8°C | DT1 = 8K | R404A [SC2] tL1= +16°C | tS1= +4°C | tS2= +8°C | Water [SC10] Kelvion KDC Air Cooler

⊲ 0-10V EC fanset to be confirmed ⊲ Insulated drip tray ⊲ Condensate pump in the drip tray ⊲ Multiple injections via CAL® distributor ⊲ 45 or 90 bar maximum operating pressure possible ⊲ Large or small water side pressure drop circuit ⊲ Top plate cover ⊲ Tube System: staggered ⊲ Tube spacing: 38 x 33 mm | Ø 12 mm ⊲ Fin spacing: [in mm] A = 4.5 | B = 7.0 KDC 351 = 317 | KDC 352 = 323 KDC 353 = 329 | KDC 354 = 335 KDC 355 = 341 | KDC 356 = 347 KDC 351 = 922 | KDC 352 = 1472 | KDC 353 = 2022 | KDC 354 = 2572 | KDC 355 = 3122 | KDC 356 = 3672 1.010 [in mm] MATERIAL TUBE FINS CASING END PLATE Aluminum Copper Aluminum epoxy-resin-coated Aluminum/Steel protective coating Steel sendzimir zinc-plated Stainless Steel With our product selection software Kelvion RT Select & Goedhart selection program , you can configure our products and spare parts easily and very detailed for your customer. Reliable support during the project planning phase and time savings by means of a detailed selection is guaranteed. HEAT EXCHANGER VARIANTS & ACCESSORIES NOTEMATERIALS FANS AIR DIRECTION & DIMENSIONS DEFROST Ø 350 mm⊲ ESM technology ⊲ 1/N/PE 230V 50/60Hz ⊲ 2 speed operation ⊲ Protection class IP54 ⊲ Internal thermocontact DEFROST COIL DRIP TRAY Electric Hot Gas Cold Gas Brine Standard execution | Available as a variant Casing powder coated (RAL 9010) KDC 351-S = 1072 | KDC 352-S = 1772 | KDC 353-S = 2472 www.kelvion.com © Kelvion • All rights reserved • Subject to changes • 07/22

Commercial Air Coolers Kelvion MCC SPACE-SAVING DESIGN IN COLD ROOMS FOR FOOD SERVICE 1.5 kW - 10 kW 1.5 kW - 11 kW –⊲ Low-Silhouette Design: The Kelvion MCC is a power pack in small spaces , such as gas stations, catering and retail. ⊲ Hygiene and protection of chilled goods are priority: All component parts are easy to access and simple to clean ⊲ The MCC provides reliable cooling power in temperature ranges both below and above 0°C, due to our Kelvion temperature security. ⊲ Best air guidance through built-in baffle plate The integrated baffle-plates guide the cold air across the ceiling and thereby far into the room ⊲ Even distribution of cold air guarrantees chilled goods natural appearance and their taste. Retention of their full value is therefore ensured. ⊲ Smooth surfaces: Easy to clean 2.3 kW - 16 kW CAPACITY RANGEYOUR BENEFITS tL1= 0°C | t0= -8°C | DT 1= 8K | R744 | 45/60 bar tL1= 0°C | t0= -8°C | DT1 = 8K | R404A [SC2] tL1= +16°C | tS1= +4°C | tS2= +8°C | Water [SC10] Kelvion MCC Air Cooler

⊲ Electric Heater HR ⊲ Tube System: Staggered ⊲ Tube spacing: 33 x 38 mm | Ø 12 mm ⊲ Fin spacing: [in mm] A = 4.5 | B = 7.0 ⊲ Single/Multiple injection via Venturi Distributor MATERIAL TUBE FINS CASING END PLATE Aluminum þ þ Copper þ Aluminum epoxy-resin-coated ü Aluminum/Steel protective coating ü ü Steel sendzimir zinc-plated þ Stainless Steel 315 626 MCC-30x-S = 872 - 1,372 | MCC-30x-4 = 972 - 2,772 | MCC-30x-6 = 972 - 2,772 [in mm] HEAT EXCHANGER VARIANTS & ACCESSORIES NOTE DEFROST FANS AIR DIRECTION & DIMENSIONS MATERIAL Ø 300 mm⊲ AC Technology þ ⊲ EC Technology ü Controllable speed ü Fixed speed ü DEFROST COIL DRIP TRAY Electric ü ü Hot Gas ü Cold Gas ü Brine þ Standard execution | ü Available as a variant | ü« Standard for NH3 Casing powder coated (RAL 9010) With our product selection software Kelvion Select RT you can configure our products and spare parts easily and very detailed for your customer. Reliable support during the project planning phase and time savings by means of a detailed selection is guaranteed. www.kelvion.com © Kelvion • All rights reserved • Subject to changes • 03/21

Commercial Air Coolers Kelvion KSC & MSC SUPERIOR COOLING FOR COMMERCIAL APPLICATIONS 0.8 kW - 50.1 kW 0.8 kW - 58 kW 1.2 kW - 88.2 kW –CAPACITY RANGEYOUR BENEFITS ⊲ Kelvion KSC/MSC offers you the latest development of our range of commercial air coolers ⊲ Efficient and competitive solution for basic applications in supermarkets, warehouses or cold stores ⊲ Side covers, drip tray and inner drip tray are hinged and removable to ensure accessibility during installation or inspection ⊲ Round corners on casing offers attractive design for easy cleaning ⊲ Latest generation EC technology with reduced current consumption and a great system performance ⊲ Pre-wired fans for fast and reliable electrical connections (only KSC) ⊲ 45 / 90 bar CO2 options available tL1= 0°C | t0= -8°C | DT 1= 8K | R744 | 45/90 bar tL1= 0°C | t0= -8°C | DT1 = 8K | R404A [SC2] tL1= +16°C | tS1= +4°C | tS2= +8°C | Water [SC10] Kelvion KSC Air Cooler

⊲ Shut-Up ® ⊲ Adapter for Air Hose & Shut Up® (KSC 30, MSC) Sock connection with air straightener function ⊲ Finned-tube Heaters KSHR / SHR Z & MSHR / SHR Z ⊲ Double-walled, insulated Drip Tray ⊲ Hinged Fans ⊲ CAL® Distributor ⊲ CO2 45/90 bar ⊲ Water / brine execution ⊲ Corrosion protection in 4 options ⊲ Tube System: Staggered ⊲ Tube spacing: 33 x 38 mm | Ø 12 mm ⊲ Fin spacing: [mm] R = 4.0 | B = 7.0 ⊲ Multiple injection via Venturi Distributor ⊲ Internal cleanliness according to DIN 14276 ⊲ Delivery with approx. 5 PSI overpressure HEAT EXCHANGER VARIANTS & ACCESSORIES NOTE DEFROST MATERIALS FANS Ø 230 mm Ø 300 mm Ø 400 mm Ø 500 mm AIR DIRECTION & DIMENSIONS KSC23 = 339 KSC30 = 418 MSC40 = 576 MSC50 = 728 KSC23 = 403 KSC30 = 453 MSC40 = 590 MSC50 = 590 KSC23 = 760 - 2,110 | KSC30 = 810 - 2,310 | MSC40 = 1,330 - 4,030 | MSC50 = 1,430 - 4,430 [mm] MATERIAL TUBE FINS CASING END PLATE Aluminum þ þ þ Copper þ Aluminum epoxy-resin-coated ü Aluminum protective coating ü ü Stainless Steel ü ü ü ⊲ EC | ESM Technology KSC 23: 2 speed; IP55 KSC 30: 4 speed; IP54 MSC 40: 0-10V; IP54 MSC 50: 0-10V; IP54 DEFROST COIL DRIP TRAY Electric ü ü Hot Gas ü Cold Gas Brine þ Standard execution | ü Available as a variant | * upon request Casing powder coated (RAL 9010) With our product selection software Kelvion Select RT you can configure our products and spare parts easily and very detailed for your customer. Reliable support during the project planning phase and time savings by means of a detailed selection is guaranteed. www.kelvion.com © Kelvion • All rights reserved • Subject to changes • Version 02 •06/22

Customized Air Coolers Kelvion CMK blast freezer (Cu/Al) THE SOLUTION FOR BLAST CHILLING & FREEZING CAPACITY RANGEYOUR BENEFITS ⊲ For blast chilling and freezing application: Specially designed for quick chilling and freezing of food products; large scale kitchens, bakery products, pizza and vegetables meat or sausages, fish, poultry and the production of ice cream ⊲ Application optimized: refrigerant distribution and circuiting ⊲ Optimized heat exchanger geometry and an aerodynamically intergrated fan system: Higher specific power, reduced fan speed and air velocity through the coil and significantly reduced current consumption ⊲ Blow-through fans achieve an optimal air speed ⊲ Quick freezing process: Minimize the weight loss and conserving the qualities of the food product. Standard 50 Pa or 100 Pa external pressure available ⊲ CAL® distributor option available ⊲ Long-term assurance: future-proof, highly efficient, ErP fans ⊲ Construction for adjustable floor mounting (optional) ⊲ Optimized ratio price/kW 13 kW - 116 kW 12 kW - 115 kW 27 kW - 206 kW HFO/HFK tL1= -18°C | t0= -25°C | DT = 7K [SC3] | R404A tL1= -18°C | t0= -25°C | DT =7K [SC3] | Up to 60 bar tL1= 5°C | tin= -7°C | tout= -4°C | E-glycol 37% Kelvion CMK Air Cooler

With our product selection software Kelvion RT Select & Goedhart selection program , you can configure our products and spare parts easily and very detailed for your customer. Reliable support during the project planning phase and time savings by means of a detailed selection is guaranteed. ⊲ Coil block: Copper tubes | Aluminium fins ⊲ Tube System: Aligned - 15 mm o.d. ⊲ Tube spacing: 50 x 50 mm ⊲ Fin spacing: [in mm] B = 7,0 | K = 10,0 | L = 12,0 HEAT EXCHANGER VARIANTS & ACCESSORIES NOTE DEFROST DEFROST FAN COIL DRIP TRAY ELECTRIC HOT GAS WATER BRINE (integrated circuit) FANS Ø 560 mm Ø 630 mm ⊲ AC Technology ⊲ EC Technology ⊲ 60 Hz ⊲ -40°C applications ⊲ Safety switch AIR DIRECTION & DIMENSIONS ⊲ Insulated fan heating ⊲ Insulated drip tray and/or fan plate ⊲ Hinged fans (new optimized solution!) ⊲ Up to 60 bar with CO2 ⊲ Side cover plates over the bends ⊲ Multiple injections via CAL® distributor ⊲ Stepless adjustable legs 50-200 mm ⊲ Pre-painted / Powder coating CMK56. = 843 - 943 CMK63. = 976 - 1076 CMK56. = 1.316 - 2.916 CMK63. = 1.516 - 3.516 MATERIALS MATERIAL COIL BLOCK CASING FAN GUARDTUBE FINS END PLATE Aluminium Copper Aluminium Goldlack coating Aluminium AlMg Steel sendzimir zinc-plated Epoxy spray finishing (RAL9010) Powder coating (RAL9010) Epoxy spray finishing (RAL 9005) Stainless Steel V2A (304) * CMK56. = 1850 CMK63. = 2050 Standard execution | Available as a variant * see Kelvion range CML [in mm] www.kelvion.com © Kelvion • All rights reserved • Subject to changes • 12/18

Customized Air Coolers Kelvion CML blast freezer (StSt/Al) THE SOLUTION FOR BLAST CHILLING & FREEZING CAPACITY RANGEYOUR BENEFITS ⊲ For blast chilling and freezing application: Specially designed for quick chilling and freezing of food products; large scale kitchens, bakery products, pizza and vegetables, meat or sausages, fish, poultry and the production of ice cream ⊲ Application optimized: refrigerant distribution and circuiting ⊲ Optimized heat exchanger geometry and an aerodynamically integrated fan system: Higher specific power, reduced fan speed and air velocity through the coil and significantly reduced current consumption ⊲ Blow-through fans achieve an optimal air speed ⊲ Quick freezing process: Minimize the weight loss and conserving the qualities of the food product. Standard 50 Pa or 100 Pa external pressure available ⊲ Long-term assurance: future-proof, highly efficient, ErP fans ⊲ Construction for adjustable floor mounting (optional) ⊲ Optimized ratio price/kW 14 kW - 126 kW 12 kW - 114 kW 25 kW - 225 kW tL1= -18°C | t0= -25°C | DT = 7K [SC3] | NH3 pump tL1= -18°C | t0= -25°C | DT =7K [SC3] | Up to 60 bar tL1= 5°C | tin= -7°C | tout= -4°C | E-glycol 37% Kelvion CML Air Cooler

With our product selection software Kelvion RT Select & Goedhart selection program , you can configure our products and spare parts easily and very detailed for your customer. Reliable support during the project planning phase and time savings by means of a detailed selection is guaranteed. ⊲ Coil block: Stainless steel 304 tubes | Aluminium fins ⊲ Tube System: Aligned - 15 mm o.d. ⊲ Tube spacing: 50 x 50 mm ⊲ Fin spacing: [in mm] B = 7,0 | K = 10,0 | L = 12,0 HEAT EXCHANGER VARIANTS & ACCESSORIES NOTE DEFROST DEFROST FAN COIL DRIP TRAY ELECTRIC HOT GAS WATER BRINE (integrated circuit) FANS Ø 560 mm Ø 630 mm ⊲ AC Technology ⊲ EC Technology ⊲ 50/60 Hz ⊲ -40°C applications ⊲ Safety switch AIR DIRECTION & DIMENSIONS ⊲ Insulated fan heating ⊲ Insulated drip tray and/or fan plate ⊲ Hinged fans (new optimized solution!) ⊲ 45 / 60 bar with CO2 ⊲ Side cover plates over the bends ⊲ Stepless adjustable legs 50-200 mm ⊲ Pre-painted / Powder coating CMK56. = 843 - 943 CMK63. = 976 - 1076 CMK56. = 1.316 - 2.916 CMK63. = 1.516 - 3.516 MATERIALS MATERIAL COIL BLOCK CASING FAN GUARDTUBE FINS END PLATE Aluminium Stainless Steel V2A (304) Aluminium Goldlack coating Aluminium AlMg Steel sendzimir zinc-plated Epoxy spray finishing (RAL9010) Powder coating (RAL9010) Epoxy spray finishing (RAL 9005) Copper * CMK56. = 1850 CMK63. = 2050 Standard execution | Available as a variant * see Kelvion range CMK [in mm] © Kelvion • All rights reserved • Subject to cnahges • 12/18 www.kelvion.com

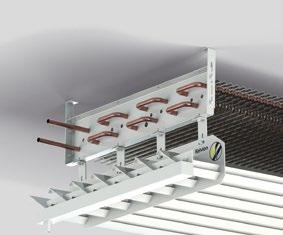

Customized Air Coolers Kelvion CSK & CBK air coolers (Cu/Al) FLEXIBLE FOR DEMANDING REFRIGERATION TASKS CAPACITY RANGEYOUR BENEFITS ⊲ Powerful when needed: High performance due to optimized circuit design ⊲ Optimized heat exchanger geometry and an aerodynamically integrated fan system: Higher specific power, air velocity through the coil limited to avoid water splashing and low energy consumption. ⊲ Blow-through (Kelvion CBK) or draw-through (Kelvion CSK) ⊲ For cooling and freezing applications like distribution centers, cold stores and production rooms ⊲ Flexible power spectrum due to numerous variants and configuration possibilities (plain or internally enhanced copper tubes) ⊲ Highly efficient fans , ErP 2015, low noise level ⊲ Easily accessible and easy to clean components: Hinged drip tray and removable cover plates ⊲ Easy installation: Delivered on a wooden frame for easy mounting ⊲ Powder coated driptray 6.4 kW - 184 kW 7.3 kW - 167 kW 6,4 kW - 257 kW –tL1= 0°C | t0= -8°C | DT 1= 8K | R744 | 60 bar tL1= 5°C | tin= -7°C | tout= -4°C | E-glyol 37% tL1= 0°C | t0= -8°C | DT1 = 8K | R404A [SC2] Kelvion CSK und CBK Air Cooler

⊲ Coil block: Copper tubes | Aluminium fins ⊲ Tube system: Aligned ⊲ Tube pattern: 50 x 50 mm ⊲ Fin spacing: [in mm] R = 4,0 | B = 7,0 | K = 10,0 © Kelvion • All rights reserved • Subject to changes • Version 01 • 09/21 HEAT EXCHANGER VARIANTS & ACCESSORIES NOTE DEFROST DEFROST FAN COIL DRIP TRAY ELECTRIC ü ü ü HOT GAS ü ü WATER ü ü SECONDARY CIRCUIT ü ü FANS Ø 450 mm Ø 500 mm Ø 560 mm Ø 630 mm Ø 800 mm ⊲ AC Technology 4 - 6 Pole Delta/Star (2 speeds) ⊲ EC Technology 0-10V | Modbus ⊲ 50 | 60 Hz AIR DIRECTION & DIMENSIONS C.K45 = 680 C.K50 = 780 C.K56 = 880 C.K63 = 1.080 C.K80 = 1.280 C.K45 = 1.356 - 7.656 | C.K50 = 1.456 - 6.456 | C.K56 = 1.556 - 7.056 | C.K63 = 1.656 - 7.656 | C.K80 = 2.056 - 6.856 [in mm] C.K45 = 630-880 C.K50 = 730-980 C.K56 = 850-1.100 C.K63 = 840-1.090 C.K80 = 1.070-1.320 MATERIALS With our product selection software Kelvion Select RT, you can configure our products and spare parts easily and very detailed for your customer. Reliable support during the project planning phase and time savings by means of a detailed selection is guaranteed. þ Standard execution | ü Available as a variant * see Kelvion range C.L MATERIAL COIL BLOCK CASING DRIP TRAY FAN GUARDTUBE FINS END PLATE Aluminum þ þ ü Copper þ Aluminum Goldlack coating ü Aluminum Almg ü ü Steel sendzimir zinc-plated ü ü 2K-spray painting (RAL9010) þ Powder coating (RAL 9010) ü þ Powder coating (RAL 9005) þ Stainless Steel V2A (304) ü* ü ü ü Stainless Steel V4A (316) ü* ü ü ⊲ Defrost sock (CSK) ⊲ Air throw streamer (CSK) ⊲ Diffusor (with air operated damper) (CBK) ⊲ Hinged fans and/or driptray ⊲ Polyester driptray ⊲ Suction hood fan side (-CBK) or fin side (-CSK) ⊲ Insulated drip tray (anti-condensation heating optional) ⊲ Feet for floor mounting and insulation disks ⊲ Design pressures 28 | 40 | 60 bar ⊲ CAL distributors optional www.kelvion.com

Customized Air Coolers Kelvion CSL & CBL air coolers (StSt/Al) FLEXIBLE FOR DEMANDING REFRIGERATION TASKS CAPACITY RANGEYOUR BENEFITS ⊲ Powerful when needed: High performance due to optimized circuit design ⊲ Optimized heat exchanger geometry and an aerodynamically integrated fan system: Higher specific power, air velocity through the coil limited to avoid water splashing and low energy consumption. ⊲ Blow-through (Kelvion CBL) or draw-through (Kelvion CSL) ⊲ For cooling and freezing applications like distribution centers, cold stores and production rooms ⊲ Flexible power spectrum due to numerous variants and configuration possibilities (plain or internally enhanced copper tubes) ⊲ Highly efficient fans , ErP 2015, low noise level ⊲ Easily accessible and easy to clean components: Hinged drip tray and removable cover plates ⊲ Easy installation: Delivered on a wooden frame for easy mounting ⊲ Powder coated driptray 6.4 kW - 164 kW 6.4 kW - 268 kW 7,7 kW - 224 kW tL1= 0°C | t0= -8°C | DT 1= 8K | R744 | 60 bar tL1= 5°C | tin= -7°C | tout= -4°C | E-glyol 37% tL1= -0°C | t0= -8°C | DT = 7K [SC2] | NH3 pump 6.7 kW - 173 kW tL1= 0°C | t0= -8°C | DT 1= 8K | R404A | SC2 Kelvion CSL und CBL Air Cooler

⊲ Coil block: Stainless steel tubes | Aluminium fins ⊲ Tube System: Aligned ⊲ Tube spacing: 50 x 50 mm ⊲ Fin spacing: [in mm] R = 4,0 | B = 7,0 | K = 10,0 HEAT EXCHANGER VARIANTS & ACCESSORIES NOTE DEFROST DEFROST FAN COIL DRIP TRAY ELECTRIC HOT GAS WATER SECONDARY CIRCUITING FANS Ø 450 mm Ø 500 mm Ø 560 mm Ø 630 mm Ø 800 mm ⊲ AC Technology 4 - 6 Pole Delta/Star (2 speeds) ⊲ EC Technology 0-10V | Modbus ⊲ 50 | 60 Hz AIR DIRECTION & DIMENSIONS C.L45 = 680 C.L50 = 780 C.L56 = 880 C.L63 = 1.080 C.L80 = 1.280 C.L45 = 1.356 - 7.656 | C.L50 = 1.456 - 6.456 | C.L56 = 1.556 - 7.056 | C.L63 = 1.656 - 7.656 | C.L80 = 2.056 - 6.856 [in mm] C.L45 = 630-880 C.L50 = 730-980 C.L56 = 850-1.100 C.L63 = 840-1.090 C.L80 = 1.070-1.320 MATERIALS With our product selection software Kelvion RT Select , you can configure our products and spare parts easily and very detailed for your customer. Reliable support during the project planning phase and time savings by means of a detailed selection is guaranteed. Standard execution | Available as a variant * see Kelvion range C.K MATERIAL COIL BLOCK CASING DRIP TRAY FAN GUARDTUBE FINS END PLATE Aluminum Copper * Aluminum Goldlack coating Aluminum Almg Steel sendzimir zinc-plated 2K-spray painting (RAL9010) Powder coating (RAL 9010) Powder coating (RAL 9005) Stainless Steel V2A (304) Stainless Steel V4A (316) www.kelvion.com © Kelvion • All rights reserved • Subject to changes • Version 01 • 09/21 ⊲ Defrost sock (Adapter connection, integrated) - CSL ⊲ Air throw streamer -CSL ⊲ Diffusor (with air operated damper) - CBL ⊲ Hinged fans and/or driptray ⊲ Polyester driptray ⊲ Suction hood fan side (-CBL) or fin side (-CSL) ⊲ Insulated drip tray (with anti-condensation heating) ⊲ Feet for floor mounting and insulation disks ⊲ Design pressures 28 - 70 bar

Customized Air Coolers Kelvion GSK & GBK air coolers (Cu/Al) FAST AVAILABILITY AT ECONOMIC COST CAPACITY RANGEYOUR BENEFITS ⊲ Quick delivery times due to optimized coil block design: Standard coil block design gives the high performance needed ⊲ Numerous options and variants: The Kelvion GBK | GSK can be perfectly matched to individual customer requirements –especially for complex refrigeration applications. ⊲ High performance air coolers with aligned tube system ⊲ Blow-through (Kelvion GBK) or draw-through (Kelvion GSK) ⊲ Medium temperature cooling and deep freezing down to -40°C t L1 ⊲ Cooling of unpacked goods such as meat, bakery products, fruits and vegetables or frozen goods ⊲ Highly efficient fans , ErP 2015, low noise level ⊲ All component parts are easy to access and simple to clean: Hinged drip tray and removable cover plates ⊲ Easy installation: Delivered on a wooden frame for easy mounting ⊲ Powder coated driptray 6.5 kW - 121 kW 7.3 kW - 125 kW ––tL1= 0°C | t0= -8°C | DT 1= 8K | R744 | 60 bar tL1= 0°C | t0= -8°C | DT1 = 8K | R404A [SC2] Kelvion GSK und GBK Air Cooler

⊲ Coil block: Copper tubes | Aluminium fins ⊲ Tube system: Aligned ⊲ Tube pattern: 50 x 50 mm ⊲ Fin spacing: [in mm] B = 7,0 | K = 10,0 ⊲ Defrost sock (Adapter connection, integrated) - (GSK) ⊲ Air throw streamer (GSK) ⊲ Diffusor (with air operated damper) (GBK) ⊲ Hinged fans and/or driptray ⊲ Suction hood fan side (-GBK) or fin side (-GSK) ⊲ Insulated drip tray ⊲ Design pressures 28 | 40 | 60 bar www.kelvion.com © Kelvion • All rights reserved • Subject to changes • Version 01 • 09/21 HEAT EXCHANGER VARIANTS & ACCESSORIES NOTE DEFROST DEFROST FAN COIL DRIP TRAY ELECTRIC HOT GAS FANS Ø 450 mm Ø 500 mm Ø 560 mm Ø 630 mm Ø 800 mm ⊲ AC Technology 4 Pole Delta/Star (2 speeds) ⊲ EC Technology 0-10V | Modbus AIR DIRECTION & DIMENSIONS G.K45 = 760 G.K50 = 860 G.K56 = 960 G.K63 = 1.160 G.K80 = 1.360 G.K45 = 1.416 - 3.216 | G.K50 = 1.516 - 3.516 | G.K56 = 1.616 - 3.816 G.K63 = 2.916 - 5.416 | G.K80 = 3.816 - 5.416 [in mm] G.K45 = 880 G.K50 = 980 G.K56 = 1.100 G.K63 = 1.090 G.K80 = 1.320 MATERIALS With our product selection software Kelvion Select RT, you can configure our products and spare parts easily and very detailed for your customer. Reliable support during the project planning phase and time savings by means of a detailed selection is guaranteed. Standard execution | Available as a variant * see Kelvion range G.L MATERIAL COIL BLOCK CASING DRIP TRAY FAN GUARDTUBE FINS END PLATE Aluminum Copper Aluminum Almg Steel sendzimir zinc-plated 2K-spray painting (RAL9010) Powder coating (RAL 9010) Powder coating (RAL 9005) Stainless Steel V2A (304) *

Customized Air Coolers Kelvion GSL & GBL air coolers (StSt/Al) FAST AVAILABILITY AT ECONOMIC COST CAPACITY RANGEYOUR BENEFITS ⊲ Quick delivery times due to optimized coil block design: Standard coil block desigh gives the high performance needed ⊲ Numerous options and variants: The Kelvion GSL | GBL can be perfectly matched to individual customer requirements –especially for complex refrigeration applications ⊲ High performance air coolers with aligned tube system ⊲ Blow-through (Kelvion GBL) or draw-through (Kelvion GSL) ⊲ Medium temperature cooling and deep freezing down to -40°C t L1 ⊲ Cooling of unpacked goods such as meat, bakery products, fruits and vegetables or frozen goods. ⊲ Highly efficient fans , ErP 2015, low noise level ⊲ All component parts are easy to access and simple to clean: Hinged drip tray and removable cover plates ⊲ Easy installation: Delivered on a wooden frame for easy mounting ⊲ Powder coated driptray 7.7 kW - 153 kW 6.4 kW - 119 kW tL1= 0°C | t0= -8°C | DT 1= 8K | R744 | 60 bar tL1= -0°C | t0= -8°C | DT = 7K [SC2] | NH3 pump –6.7 kW - 126 kW tL1= 0°C | t0= -8°C | DT 1= 8K | R404A | SC2 Kelvion GSL und GBL Air Cooler

⊲ Coil block: Stainless steel tubes | Aluminium fins ⊲ Tube System: Aligned ⊲ Tube spacing: 50 x 50 mm ⊲ Fin spacing: [in mm] B = 7,0 | K = 10,0 HEAT EXCHANGER VARIANTS & ACCESSORIES NOTE DEFROST DEFROST FAN COIL DRIP TRAY ELECTRIC HOT GAS FANS Ø 450 mm Ø 500 mm Ø 560 mm Ø 630 mm Ø 800 mm ⊲ AC Technology 4 - 6 Pole Delta/Star (2 speeds) ⊲ EC Technology 0-10V | Modbus ⊲ 50 | 60 Hz AIR DIRECTION & DIMENSIONS [in mm] MATERIALS With our product selection software Kelvion RT Select , you can configure our products and spare parts easily and very detailed for your customer. Reliable support during the project planning phase and time savings by means of a detailed selection is guaranteed. Standard execution | Available as a variant * see Kelvion range G.K MATERIAL COIL BLOCK CASING DRIP TRAY FAN GUARDTUBE FINS END PLATE Aluminum Copper * Aluminum Almg Steel sendzimir zinc-plated 2K-spray painting (RAL9010) Powder coating (RAL 9010) Powder coating (RAL 9005) Stainless Steel V2A (304) G.L45 = 760 G.L50 = 860 G.L56 = 960 G.L63 = 1.160 G.L80 = 1.360 G.L45 = 1.416 - 3.216 | G.L50 = 1.516 - 3.516 | G.L56 = 1.616 - 3.816 G.L63 = 2.916 - 5.416 | G.L80 = 3.816 - 5.416 G.L45 = 880 G.L50 = 980 G.L56 = 1.100 G.L63 = 1.090 G.L80 = 1.320 ⊲ Defrost sock (Adapter connection, integrated) - (GSK) ⊲ Air throw streamer (GSK) ⊲ Diffusor (with air operated damper) (GBK) ⊲ Hinged fans and/or driptray ⊲ Suction hood fan side (-GBK) or fin side (-GSK) ⊲ Insulated drip tray ⊲ Design pressures 28 | 40 | 60 bar www.kelvion.com © Kelvion • All rights reserved • Subject to changes • Version 01 • 09/21

⊲ Meat processing, cheese cellars, rooms for cut flowers or small cold rooms , are just a few examples of use.

⊲ Kelvion KVB Gravity Coils can be used in cold rooms, where noise matters most, or if draft should be avoided.

⊲ Kelvion KVB evaporators consequently ensure ideal maturation climates for cheese and sausage or meat production.

⊲ Constant conditions and the controlled climate in a maturation cellar are absolutely decisive. Every cheese has its very own requirements.

⊲ Uniform conditions as well as little as possible air circulation are the prerequisite for outstanding cheese and sausage products.

⊲ Moist and even cooling are hallmarks of the gravity approach to cold room design.

Kelvion KVB NO DRAFT GRAVITY COILS FOR CURING ROOMS 0.6 kW - 4.4 kW 0.8 kW - 6.2 kW 0.7 kW - 7 kW –

CAPACITY RANGEYOUR BENEFITS tL1= +10°C | t0= 0°C | DT1 = 10K | R404A tL1= 8°C | t0= -6°C | R744 | 60 bar tL1= +16°C | tS1= +4°C | tS2= +8°C | Water [SC10] Customized Air Coolers Kelvion KVB Air Cooler

⊲ Louvred drip tray TWJ ⊲ Tube System: Aligned ⊲ Tube spacing: 50 x 50 mm | Ø 15 mm ⊲ Fin spacing: 8.5 mm ⊲ Max. Operating Pressure: 32bar Water/Brine Execution: 16bar 150 420 - 1,020 1,115 - 2,885 MATERIAL TUBE FINS CASING END PLATE Aluminum Copper þ Aluminum epoxy-resin-coated þ Aluminum/Steel protective coating þ Steel sendzimir zinc-plated Stainless Steel ü ü HEAT EXCHANGER VARIANTS & ACCESSORIES MATERIALS FANS þ Standard execution | ü Available as a variant | ü« Standard for NH3 AIR DIRECTION & DIMENSIONS [in mm] DEFROST DEFROST COIL DRIP TRAY Electric ü ü Hot Gas Cold Gas Brine www.kelvion.com © Kelvion • All rights reserved • Subject to changes • 04/21

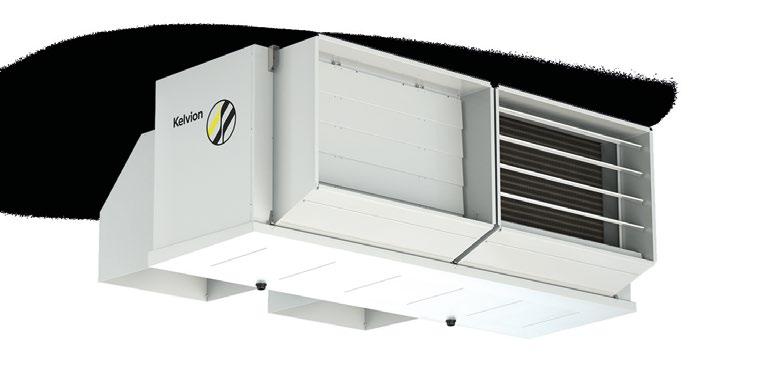

Kelvion MCK PROFESSIONAL CEILING TYPE UNIT COOLER 1.5 kW - 9.4 kW 1.8 kW - 11 kW 2.6 kW - 17 kW –⊲ The Kelvion MCK lives up to its name for complex cooling tasks in smaller cooling rooms. ⊲ Applications in which an efficient ceiling evaporator is required. ⊲ Variants for protection against corrosion make him suitable for aggressive ambient air. ⊲ With it´s versatile versions , the Kelvion MCK is designed to take on the most challenging of environmental conditions (i.e. cold rooms which are accessed frequently ). ⊲ Due to its configuration, the Kelvion MCK is able to maintain all temperature ranges with maximum precision ⊲ Draught-free air flow in rooms with low ceilings. CAPACITY RANGEYOUR BENEFITS tL1= 0°C | t0= -8°C | DT1 = 8K | R404A [SC2] tL1= 0°C | t0= -8°C | DT1 = 8K | R744 | 45/60 bar tL1= +16°C | tS1= +4°C | tS2= +8°C | Water [SC10] Customized Air Coolers Kelvion MCK Air Cooler

⊲ Electric Heater HR ⊲ Doubled, insulated Drip Tray ⊲ Plastic fan guard ⊲ Tube System: Aligned ⊲ Tube spacing: 50 x 50 mm | Ø 15 mm ⊲ Fin spacing: [in mm] A = 4.5 | B = 7.0 ⊲ Single/Multiple injection via CAL® Distributor Ø 300 mm⊲ AC Technology þ ⊲ EC Technology ü Controllable speed ü Fixed speed ü 315 669 MCK-30x-4 = 1.080 - 1.780 | MCK-30x-5 = 1.080 - 3.180 | MCK-30x-6 = 1.080 - 3.180 MATERIAL TUBE FINS CASING END PLATE Aluminum þ þ Copper þ Aluminum epoxy-resin-coated ü Aluminum/Steel protective coating ü ü Aluminum/zinc coated steel þ Stainless Steel ü« ü ü HEAT EXCHANGER VARIANTS & ACCESSORIES NOTE AIR DIRECTION & DIMENSIONS [in mm] DEFROST MATERIAL FANS DEFROST COIL DRIP TRAY Electric ü ü Hot Gas ü Cold Gas ü Brine ü þ Standard execution | ü Available as a variant | ü« Standard for NH3 Casing and Heat Exchanger powder coated (RAL 9010) With our product selection software Kelvion Select RT you can configure our products and spare parts easily and very detailed for your customer. Reliable support during the project planning phase and time savings by means of a detailed selection is guaranteed. www.kelvion.com © Kelvion • All rights reserved • Subject to changes • 03/21

Küba SG classic THE ESTABLISHED SOLUTION FOR SENSITIVE PRODUCTS 0.9 kW - 23 kW 1.2 kW - 28 kW ––⊲ Versatility in application: Available for all current HFCs, as well as for CO2 direct expansion, up to 60 bar operating pressure ⊲ Extended capacity range up to 23 kW (HFC), up to 28 kW (CO2) ⊲ High-performance air cooler with aligned system of tubes ⊲ Large heat exchange surface: Dehydration of chilled goods stays as low as possible ⊲ Rapid turnaround of goods in the cold room feasible ⊲ High energy efficiency with ErP compliant AC fans, speed adjustable ⊲ Medium Temperature Cooling & Freezing down to -25°C t L1 ⊲ Fast availability of HFC - and CO2 units at the best value for money CAPACITY RANGEYOUR BENEFITS Customized Air Coolers tL1= 0°C | t0= -8°C | DT1 = 8K | R404A [SC2] tL1= 0°C | t0= -8°C | DT1 = 8K | R744 | 45/60 bar Kelvion SG classic Air Cooler

⊲ Flange for Shut-Up® ⊲ Shut-Up ® ⊲ Doubled, insulated Drip Tray ⊲ Tube System: Aligned ⊲ Tube spacing: 50 x 50 mm | Ø 15 mm ⊲ Fin spacing: [in mm] B = 7.0 ⊲ Single/Multiple injection via Venturi Distributor SG02x = 360 SG03/04x = 460 SG05/06x = 560 SG07/08x = 560 SG09/10x = 660 SG02x = 429 | SG03x = 440 | SG04x = 451 | SG05x = 570 SG06x = 538 | SG07/08x = 618 | SG09/10x = 688 SG02x = 565 - 1,015 | SG03/04x = 665 - 1,215 | SG05/06x = 815 - 1,375 SG07x = 915 - 2,175 | SG08/09x = 1,065 - 2,625 | SG10x = 2,375 - 3,375 MATERIAL TUBE FINS CASING END PLATE Aluminum þ þ þ Copper þ Aluminum epoxy-resin-coated Aluminum/Steel protective coating Steel sendzimir zinc-plated Stainless Steel HEAT EXCHANGER VARIANTS & ACCESSORIES NOTE AIR DIRECTION & DIMENSIONS [in mm] DEFROST MATERIAL FANS Ø 250 mm Ø 300 mm Ø 400 mm Ø 500 mm ⊲ AC Technology þ DEFROST COIL DRIP TRAY Electric þ þ Hot Gas ü Cold Gas ü Brine þ Standard execution | ü Available as a variant | ü« Standard for NH3 Casing and Heat Exchanger powder coated (RAL 9010) With our product selection software Kelvion RT Select you can configure our products and spare parts easily and very detailed for your customer. Reliable support during the project planning phase and time savings by means of a detailed selection is guaranteed. www.kelvion.com © Kelvion • All rights reserved • Subject to changes • 12/18

Küba SG commercial THE SOLUTION FOR COMPLEX CHILLED GOODS 0.6 kW - 46 kW 0.6 kW - 58 kW 0.4 kW - 65 kW 0.6 kW - 55 kW CAPACITY RANGEYOUR BENEFITS tL1= 0°C | t0= -8°C | DT1 = 8K | R404A [SC2] tL1= 0°C | t0= -8°C | DT1 = 8K | R744 | 45/60 bar tL1= 0°C | t0= -8°C | DT1 = 8K | R717 [SC2] Customized Air Coolers ⊲ Numerous options and variants: The Küba SG commercial can be perfectly matched to individual customer requirements –especially for complex refrigeration applications ⊲ Fan system with air straightener – precisely matched to the heat exchanger – provides greater air throw at lower air resistance and higher air volume. ⊲ Medium temperature cooling and deep freezing until -35°C t L1 ⊲ High performance air coolers with aligned tube system ⊲ Minimal dehumidfication thanks to large surfaces. ⊲ Cooling of unpacked goods such as meat, bakery products, fruits and vegetables or frozen goods ⊲ Long term security : highly efficient ERP-ready fan systems which already exceed tomorrows requirements. ⊲ All component parts are easy to access and simple to clean: The hinged drip tray and the hinged fans (except SG 23) are already included in the basic version. tL1= +16°C | tS1= +4°C | tS2= +8°C | Water [SC10] Kelvion SG commercial Air Cooler

⊲ Shut-Up ® (Flange for textile sock or Shut-Up, integrated) ⊲ Wall Ring Heating WH ⊲ Defrost Hood ⊲ Finned Tube Heaters SGHR / SGHRZ ⊲ Doubled, insulated Drip Tray ⊲ Tube System: Aligned ⊲ Tube spacing: 50 x 50 mm | Ø 15 mm ⊲ Fin spacing: [in mm] A = 4.5 | B = 7.0 | L = 12.0 ⊲ Single/Multiple injection via Küba CAL® Distributor DEFROST COIL DRIP TRAY Electric ü ü Hot Gas ü ü Cold Gas ü ü Brine ü ü ⊲ AC Technology þ ⊲ EC Technology ü Fixed speed ü Adjustable speed ü ⊲ Protection Grid ü SG23 = 347 SG30 = 449 SG35 = 554 SG45 = 652 SG23 = 455 | SG30 = 453 SG35 = 624 | SG45 = 662 SG23 = 760 - 2,560 | SG30 = 960 - 3,320 | SG35 = 1,130 - 3,930 | SG45 = 1,330 - 4,930 MATERIAL TUBE FINS CASING END PLATE Aluminum þ þ Copper þ Aluminum epoxy-resin-coated ü Aluminum/Steel protective coating ü ü Steel sendzimir zinc-plated þ Stainless Steel ü« ü ü HEAT EXCHANGER VARIANTS & ACCESSORIES NOTE AIR DIRECTION & DIMENSIONS [in mm] DEFROST MATERIAL FANS Ø 230 mm Ø 300 mm Ø 350 mm Ø 450 mm þ Standard execution | ü Available as a variant | ü« Standard for NH3 Casing and Heat Exchanger powder coated (RAL 9010) With our product selection software Kelvion RT Select you can configure our products and spare parts easily and very detailed for your customer. Reliable support during the project planning phase and time savings by means of a detailed selection is guaranteed. www.kelvion.com © Kelvion • All rights reserved • Subject to changes • 12/18

Customized Air Coolers Kelvion CDK (Cu/Al) DUAL PERFORMANCE #KELVION REFRIGERATION CAPACITY RANGEYOUR BENEFITS ⊲ For production and food preparation areas: Specially designed for where people are working like butcheries and dairies ⊲ Application optimized: refrigerant distribution and circuiting ⊲ High level of customization possible thanks to a comprehensive list of variants and accessories ⊲ Suitable for synthetic (HFK, HFO) and natural (CO2, Hydrocarbons) refrigerants ⊲ Quick and easy to clean: standard hinged end covers and optional hinged drip trays and hinged fan(s) ⊲ CAL® distributor option available ⊲ Long-term assurance: future-proof, highly efficient, ErP fans ⊲ Construction for flush ceiling mounting ⊲ Optimized ratio price/kW ⊲ Reduced splashing risk ⊲ Optimized air distribution over the coils by internal air guidance 6,9 kW - 129 kW 6,9 kW - 137,4 kW 4,4 kW - 74,7 kW HFO/HFK tL1= -0°C | t0= -8°C | DT = 7K [SC2] | R404A tL1= -0°C | t0= -8°C | DT =7K [SC2] | Up to 60 bar tL1= 5°C | tin= -7°C | tout= -4°C | E-glycol 37% Kelvion CDK Air Cooler

CDK45. = 1.290 - 3.750 | CDK50. = 1.490 - 4.550= = = = = 1.590 - 4.950 CDK63. = 1.690 - 5.350

With our product selection software Kelvion RT Select & Goedhart se lection program , you can configure our products and spare parts easily and very detailed for your customer. Reliable support during the project planning phase and time savings by means of a detailed selection is guaranteed. ⊲ Coil block: Copper tubes | Aluminium fins ⊲ Tube System: Aligned - 15 mm o.d. ⊲ Tube spacing: 50 x 50 mm ⊲ Fin spacing: [in mm] R = 4,0 | B = 7,0 | K = 10,0 HEAT EXCHANGER VARIANTS & ACCESSORIES NOTE DEFROST DEFROST FAN COIL DRIP TRAY ELECTRIC ü ü ü HOT GAS ü ü WATER ü ü BRINE (integrated circuit) ü FANS Ø 450 mm Ø 500 mm Ø 560 mm Ø 630 mm ⊲ AC Technology ⊲ EC Technology ⊲ 60 Hz ⊲ Speed control ⊲ Safety switch AIR DIRECTION & DIMENSIONS ⊲ Insulated fan heating ⊲ Insulated drip tray and/or fan plate ⊲ Hinged fans (new optimized solution!) ⊲ Up to 60 bar with CO2 ⊲ Multiple injections via CAL® distributor ⊲ Anti-condensation heating in drip tray ⊲ Defrost sensor tube ⊲ Fan cabling MATERIALS MATERIAL COIL BLOCK CASING FAN GUARDTUBE FINS END PLATE Aluminium þ þ Copper þ Aluminium Goldlack coating ü Aluminium AlMg ü ü Steel sendzimir zinc-plated ü Epoxy spray finishing (RAL9010) þ Powder coating (RAL9010) ü Epoxy spray finishing (RAL 9005) þ Stainless Steel V2A (304) ü* ü ü CDK45. = 597 CDK50. = 597 CDK56. = 710 CDK63. = 841 þ Standard execution | ü Available as a variant * see Kelvion range CDL [in mm] www.kelvion.com © Kelvion • All rights reserved • Subject to changes • 08/20

CDK45.

1190-1690 CDK50.

1240-1750 CDK56.

1350-1800 CDK63.

1420-1870 CDK56.

|

Customized Air Coolers Kelvion CDL (StSt/Al) DUAL PERFORMANCE #KELVION REFRIGERATION CAPACITY RANGEYOUR BENEFITS ⊲ For production and food preparation areas: Specially designed for where people are working like butcheries and dairies ⊲ Application optimized: refrigerant distribution and circuiting ⊲ High level of customization possible thanks to a comprehensive list of variants and accessories ⊲ Suitable for synthetic (HFK, HFO) and natural (NH3, CO2, Hydrocarbons) refrigerants ⊲ Quick and easy to clean: standard hinged end covers and optional hinged drip trays and hinged fan(s) ⊲ CAL® distributor option available ⊲ Long-term assurance: future-proof, highly efficient, ErP fans ⊲ Construction for flush ceiling mounting ⊲ Optimized ratio price/kW ⊲ Reduced splashing risk ⊲ Optimized air distribution over the coils by internal air guidance 8,6 kW - 169 kW 6,9 kW - 121 kW 4,4 kW - 74,2 kW tL1= -0°C | t0= -8°C | DT = 7K [SC2] | NH3 pump tL1= -0°C | t0= -8°C | DT =7K [SC2] | Up to 60 bar tL1= 5°C | tin= -7°C | tout= -4°C | E-glycol 37% Kelvion CDL Air Cooler

With our product selection software Kelvion RT Select & Goedhart se lection program , you can configure our products and spare parts easily and very detailed for your customer. Reliable support during the project planning phase and time savings by means of a detailed selection is guaranteed. ⊲ Coil block: Stainless steel tubes | Aluminium fins ⊲ Tube System: Aligned ⊲ Tube spacing: 50 x 50 mm ⊲ Fin spacing: [in mm] R = 4,0 | B = 7,0 | K = 10,0 HEAT EXCHANGER VARIANTS & ACCESSORIES NOTE DEFROST DEFROST FAN COIL DRIP TRAY ELECTRIC ü ü ü HOT GAS ü ü WATER ü ü BRINE (integrated circuit) ü FANS Ø 450 mm Ø 500 mm Ø 560 mm Ø 630 mm ⊲ AC Technology ⊲ EC Technology ⊲ 60 Hz ⊲ Speed control ⊲ Safety switch AIR DIRECTION & DIMENSIONS ⊲ Insulated fan heating ⊲ Insulated drip tray and/or fan plate ⊲ Hinged fans (new optimized solution!) ⊲ Up to 60 bar with CO2 ⊲ Multiple injections via CAL® distributor ⊲ Anti-condensation heating in drip tray ⊲ Defrost sensor tube ⊲ Fan cabling MATERIALS MATERIAL COIL BLOCK CASING FAN GUARDTUBE FINS END PLATE Aluminium þ þ Copper ü* Aluminium Goldlack coating ü Aluminium AlMg ü ü Steel sendzimir zinc-plated ü Epoxy spray finishing (RAL9010) þ Powder coating (RAL9010) ü Epoxy spray finishing (RAL 9005) þ Stainless Steel 304 þ ü ü CDL45. = 597 CDL50. = 597 CDL56. = 710 CDL63. = 841 þ Standard execution | ü Available as a variant * see Kelvion range CDK [in mm] www.kelvion.com © Kelvion • All rights reserved • Subject to changes • 08/20 CDL45. = 1.290 - 3.750 | CDL50. = 1.490 - 4.550CDL45. = 1190-1690 CDL50. = 1240-1750 CDL56. = 1350-1800 CDL63. = 1420-1870 CDL56. = 1.590 - 4.950 | CDL63. = 1.690 - 5.350

Kelvion CBF | Kelvion CSF HIGH PRESSURE ZONE: CO2 OR PROPANE UP TO 90 BAR Customized Air Coolers 7.4 kW - 40.1 kW 7.0 kW - 35.7 kW 5.9 kW - 48.9 kW –CAPACITY RANGEYOUR BENEFITS tL1= 0°C | t0= -8°C | DT 1= 8K | R744 | 45/90 bar tL1= 0°C | t0= -8°C | DT1 = 8K | R404A [SC2] tL1= +5°C | tS1= -7°C | tS2= -4°C | E-Glykol 37% 90UPCO2TO BAR ⊲ Operating pressures up to 90 bar ⊲ Optimized for natural refrigerants like R744 (CO2) and R290 (Propane) ⊲ For cooling and freezing application ⊲ Low internal volume ⊲ Circuiting optimized for application ⊲ Tube pattern designed for longer run times at freezing conditions ⊲ Large number of options and accessories ⊲ Designed-to-order air coolers available on request ⊲ Highly efficient fans ⊲ Easily accessible and easy to clean components ⊲ Long-term assurance: highly efficient, ErP 2015 fans ⊲ Blow-through (Kelvion CBF) or draw-through (Kelvion CSF) Kelvion CBF / CSF Air Cooler

KELVION CSF draw-through CAPACITY RANGE 7.0 kW - 35.7 kW tL1= 0°C | t0= -8°C | DT1 = 8K | R744 | 90bar HEAT EXCHANGER Coil block : Copper tubes | Aluminium fins Tube system : Aligned Fin spacing : 7,0 | 10,0 mm FANS - ☑ AC Technology 450mm ☑ EC Technology CO2/HFO/Carbon Refrigerants ☑ 38 bar ☑ 60 bar ☑ 90 bar APPLICATIONS KELVION CBF CAPACITY RANGE 7.0 kW - 35.7 kW tL1= 0°C | t0= -8°C | DT1 = 8K | R744 | 90bar HEAT EXCHANGER Coil block : Copper tubes | Aluminium fins Tube system : Aligned Fin spacing : 7,0 | 10,0 mm FANS - ☑ AC Technology 450mm ☑ EC Technology CO2/HFO/Carbon Refrigerants ☑ 38 bar ☑ 60 bar ☑ 90 bar APPLICATIONS © Kelvion • All rights reserved • Subject to changes • Version 01 • 08/20 KELVION CO2 90 BAR PORTFOLIO www.kelvion.com NOTE þ Standard execution | ü Available as a variant MATERIALS MATERIAL TUBE FINS CASING END PLATE FAN GUARD Aluminum þ ü þ Copper þ Aluminum Goldlack coating ü Aluminum AlMg ü ü ü Steel sendzimir zinc-plated þ Epoxy spray finishing (White) þ Epoxy spray finishing (RAL 9005) þ Stainless Steel V2A (304) ü ü Stainless Steel V4A (316) ü With our product selection software Kelvion selec tion program, you can configure our products and spare parts easily and very detailed for your customer. Reliable support during the project planning phase and time savings by means of a detailed selection is guaranteed. ⊲ Defrost sock (Adapter connection, integrated) -draw ⊲ Air throw streamer -draw ⊲ Diffusor (with air operated damper) -blow ⊲ Hinged fans and/or driptray ⊲ Suction hood fan side (-blow) or fin side (-draw) ⊲ Insulated drip tray (with anticondensation heating) ⊲ Feet for floor mounting and insulation disks VARIANTS & ACCESSORIES DEFROST FAN COIL DRIP TRAY ELECTRIC ü ü ü HOT GAS ü ü WATER ü ü SECUNDAIR CIRCUITING ü DEFROST

DESIGNED FOR QUICK AND EASY INSTALLATION

⊲ Our smallest heat exchanger: increasingly popular with refrigeration and air conditioning condenser applications.

⊲ Orientation: The unit can be installed either vertically or horizontally, floor or wall mounted, by using the optional mounting legs.

⊲ Fans are the highest quality and efficiency: when matched to the case / orifice design offer extremely low noise levels.

⊲ Coil manufacture: from seamless 5mm copper tube employing the latest extended inner surface technology, mechanically expanded into aluminium fin.

⊲ Casework: All external surfaces are oven cured at 180°C ensuring an even, flexible and durable gloss finish (grey RAL 7032) with excellent corrosion protection properties and tolerance to UV exposure.

⊲ Eurovent certify-all: independent certification for thermal performance, power consumption, sound data and unit air volumes for standard products under scheme limits.

Condensers & Gas Coolers Kelvion R/GF-D Flatbed Condenser and Gas cooler

3.88 - 32.08 kW tL1= 25°C | t0= 40°C | DT = 15K [SC1] 1.8 kW - 38.9 kW tL1= 30°C | PR1= 90 bar | tR1= 110°C | tR2= 35°C [SC20] CAPACITY RANGEAPPLICATION & BENEFITS Kelvion R/GF-D Condenser und Gas Cooler

APPLICATION ATMOSPHERE TUBE MATERIAL FIN MATERIAL TUBE PLATE Commercial Application Cu Cu, Al, AV Al DIMENSIONS 666 ⊲ Fin Type: F ⊲ Standard Fin spacing: [mm] F = 2.1 ⊲ Fin material: Al ⊲ Tube Diameter: [mm] F = 5 ⊲ Tube material: Cu © Kelvion • All rights reserved • Subject to changes • Version 01 • 09/18 HEAT EXCHANGER NOTEOPERATING ENVIRONMENT GUIDANCE ⊲ AC fan control ⊲ EC Fan Control ⊲ Fansets (Units are supplied as standard with no fansets) ⊲ Isolators VARIANTS & ACCESSORIESCONTROLS OPTIONS OPTION DESCRIPTION Basic Units As standard, units are supplied unwired. Terminal Box Standard option: junction box fitted on the coil end plate, spring clamp terminal blocks Fan-speed Controller Single phase TRIAC for AC options and a gauge transducer for EC option, Pressure controlled. Isolators Isolators available on request FANS 1807mm697mm 1257mm ⊲ AC fan control ⊲ EC Fan Control Ø 350 mm www.kelvion.com Selection and Pricing on all products can be performed on the Selection Software which can be downloaded from our website www.kelvion.com

A HEAT EXCHANGER THAT’S RELIABLE AND &

⊲ Kelvion has taken the popular RF-SJ, and re-engineered with a 5mm coil. This will enable those already enjoying the compact solution for commercial refrigeration to get additional benefits of an even higher efficiency coil.

⊲ This product has been optimised for the capacity range between the RF-D and the larger R/GF condenser.

⊲ The R/GF-S uses the features from previous ranges, such as profiled side plates and versatile leg arrangements to ensure the high level of quality Kelvion’s customers expect will be met.

⊲ The popular F-Fin has been configured for this range to achieve optimised thermal performance within a given footprint.

⊲ The new 5mm coil from Kelvion is perfect for CO2 applications; allowing for a cost efficient solution to small scale CO2 applications

⊲ CE Marked, PED compliant, UL and Eurovent Certified: Kelvion products can be supplied from SEP up to category IV

Kelvion R/GF-S Condenser and Gas cooler

EFFICIENT 6.38 - 183.0 kW CAPACITY RANGEAPPLICATION

BENEFITS

tL1= 25°C | t0= 40°C | DT = 15K [SC1] 9.5 kW - 174.3 kW tL1= 30°C | PR1= 90 bar | tR1= 110°C | tR2= 35°C [SC20] Condensers & Gas Coolers Kelvion R/GF-S Condenser und Gas Cooler

APPLICATION ATMOSPHERE TUBE MATERIAL FIN MATERIAL Commercial Application Cu Al, AV, AlMg, Cu, Bg Within 20 miles of the Sea Cu Cu, Bg, AlMg ⊲ Fin Type: L, F ⊲ Fin spacing: [in mm] L = 2.1 | F = 2.1 ⊲ Fin material: Cu, Al, Av, AlMg, Bg ⊲ Tube Diameter: [in mm] L = 9.5 | F = 5 ⊲ Tube material: Cu HEAT EXCHANGER DIMENSIONS NOTEOPERATING ENVIRONMENT GUIDANCE ⊲ AC Fan Control ⊲ EC Fan Control ⊲ Isolators ⊲ Sub-Cooling ⊲ Alternative Fin Material VARIANTS & ACCESSORIESCONTROLS OPTIONS OPTION DESCRIPTION Kelvion SmartControl Connected to the Kelvion cloud to give live operational data Unwired Installer wires directly to fan terminal boxes. Junction Box Single or twin according to unit model. Staged Control Motor switchgear with or without controller. Speed Control EC, inverter or triac. Simple condenser controller For use with condensers fitted with EC fan sets. Selection and Pricing on all products can be performed on the Selection Software which can be downloaded from our website www.kelvion.com FANS 828 972 ⊲ AC fan control ⊲ EC Fan Control ⊲ Ø 500mm, Ø 630mm ⊲ Min IP 54 ⊲ 4, 6, 8 Pole ⊲ Single or 3 phase ⊲ 50/60 Hz ⊲ 1 - 4 fans MODULE (Q) 1000mm MODULE (A) 1200mm 1232 mm 1432 mm 2232 mm 2632 mm 3432 mm 3832 mm 4232 mm 5032 mm 875 HORIZONTAL OPERATION FLOOR MOUNTED VERTICAL UNIT OPERATION O/A Lengths for Q & A modules Refer To Table NOTE: The Tube material will suit fin Material www.kelvion.com © Kelvion • All rights reserved • Subject to changes • Version 01 • 09/18

IMPROVED ENERGY EFFICIENCY, QUIETER OPERATION

⊲ The Flatbed range has been developed specifically to reflect the latest market requirements. Reduced footprint, lower noise level, improved capacity density and the greatest flexibility through configurable options to suit all requirements. Coil configurations of 5, 8, 10, and 12mm are available in the variety of length, width and height variants, ensuing the most efficient solution is always offered across all potential applications.

⊲ The special plate work form developed by Kelvion allows for supporting coils up to 12m in length, giving significant strength and forms an integral part of the heat exchanger support structure.

⊲ A comprehensive collection of fan sets are available from various premium manufacturers. This ensures that the best fan is always selected and balanced against the model and application variant. High energy efficiency, low noise and flexible control options all ensure the best possible solution is offered.

⊲ Eurovent certify-all: independent certification for thermal performance, power consumption, sound data and unit air volumes for standard products under scheme limits.

⊲ CE Marked, PED compliant and UL Certified: Kelvion products can be supplied from SEP up to category IV

Condensers & Gas Coolers Kelvion R/N/GF Flatbed Condenser and Gas cooler

24 kW - 1409 kW 11 kW - 1330 kW tL1= 25°C | t0= 40°C | DT = 15K [SC1] tL1= 25°C | t0= 40°C | DT = 15K [SC1] 30.6 kW - 1423.6 kW tL1= 30°C | PR1= 90 bar | tR1= 110°C | tR2= 35°C [SC20] CAPACITY RANGEYOUR BENEFITS Kelvion R/N/GF Condenser und Gas Cooler

⊲ Fin Type: Condensers: L, T, F Gas Coolers: F, T, G ⊲ Standard Fin spacing: [mm] L = 2.1 | T = 2.3 | F = 2.1 | G = 2.1 ⊲ Fin material: Cu, Al, Av, AlMg, Bg ⊲ Tube Diameter: [mm] L = 9.5 | T = 12 | F = 5 | G = 8 ⊲ Tube material: All types: Cu, St/St: T fin only HEAT EXCHANGE DIMENSIONS 1333 Module A 1200mm (x Per row 1 or 2) Module B 1500mm (x Per row 1 or 2) Module C 1800mm (x Per row 1 or 2) Modue D 2100mm (x Per row 1 or 2) NOTEOPERATING ENVIRONMENT GUIDANCE ⊲ Legs Extended & Hinged fan plate ⊲ Control Box & Isolators ⊲ Sub cooling ⊲ Multi sections ⊲ Adiabatic System ⊲ Packing & Stacking ⊲ Alternative Fin Material & Special Paint ⊲ Mounted Receivers and Frames ⊲ Customised Housing VARIANTS & ACCESSORIESCONTROLS OPTIONS Selection and Pricing on all products can be performed on the Selection Software which can be downloaded from our website www.kelvion.com FANS P2*-2260mm P1*-2260mm N*-1578mm M*-1130mm W H L OPTION DESCRIPTION Kelvion SmartControl Connected to the Kelvion cloud to give live operational data Unwired Installer wires directly to fan terminal boxes Junction Box Single or twin according to unit model Staged Control (AC Fan sets) Motor switchgear with or without controller. Speed Control EC, inverter or triac Modbus Options for control communication of fan and control APPLICATION ATMOSPHERE TUBE MATERIAL FIN MATERIAL Commercial Application Cu or St/St Al, AV, AlMg, Cu, Bg Industrial Application Cu or St/St (NH3 must be St/St) Al, AV, AlMg, Cu, Bg Within 20 miles of the Sea Cu Cu, Bg, AlMg Waste Disposal Cu Al, AV, AlMg, Cu, Bg NOTE: The Tube material will suit fin Material ⊲ AC Normal ⊲ AC High power ⊲ EC Standard ⊲ EC High power ⊲ EC Low power Ø 800 mm Ø 810 mm Ø 900 mm Ø 910 mm ⊲ Min IP 54 ⊲ 6, 8, 12 Pole and EC ⊲ 1 & 3 phase ⊲ 50/60 Hz ⊲ 1 - 20 fans www.kelvion.com © Kelvion • All rights reserved • Subject to changes • 08/19

IMPROVED CAPACITY DENSITY AND QUIETER OPERATION &

⊲ R/GV-M V-Profile configuration is suitable for many applications: The single row of fans and narrow V angle make it ideal for installation requiring a high capacity density – small footprint. The many combinations of fin type, coil rows and module lengths make it possible to perfectly balance capacity, fluid pressure loss, internal volume and refrigerant charge. As well as standard copper tubes for 32, 45 and 120 bar, options are available with stainless steel tubes for 32 bar (NH3) and 120 bar CO2 on request.

⊲ The R/GV-M ranges are available with the latest fanset innovations. Kelvion independently tests and balances coils against all possible coil configurations to ensure optimum fan performance when on the unit. The result is the perfect combination every time for the range of potential unit configurations.

⊲ Eurovent certify-all: independent certification for thermal performance, power consumption, sound data and unit air volumes for standard products under scheme limits.

⊲ CE Marked, PED compliant and UL Certified: Kelvion products can be supplied from SEP up to category IV

Kelvion R/GV-M Condenser and Gas cooler

CAPACITY RANGEAPPLICATION

BENEFITS

7.4 kW - 520 kW tL1= 25°C | t0= 40°C | DT = 15K [SC1] 7.0 kW - 490 kW tL1= 30°C | PR1= 90 bar | tR1= 110°C | tR2= 35°C [SC20] Condensers & Gas Coolers Kelvion R/GV-M Condenser und Gas Cooler

⊲ Fin Type: L, T, G ⊲ Standard Fin spacing: [mm] L = 2.1 | T = 2.3 | G = 2.1 ⊲ Fin Material: Cu, Al, Av, AlMg, Bg ⊲ Tube Diameter: [mm] 9.5 | 12 | 8 ⊲ Tube material: Cu, St/St HEAT EXCHANGE NOTEOPERATING ENVIRONMENT GUIDANCE ⊲ Control Box & Isolators ⊲ Sub cooling/Multi sections ⊲ Alternative Fin Material ⊲ Special Paint ⊲ Adiabatic System ⊲ Mounted Receivers ⊲ Extended Legs ⊲ Customised Housing VARIANTS & ACCESSORIESCONTROLS OPTIONS FANS MF, MK & MC H 1669 W 1230 O/ALL DIMENSIONS 2866 mm 3466 mm 3866 mm 4181 mm 5081 mm 5681 mm 6681 mm 5481 mm 1030 MTG CTRS Module MK (1600mm) Module MC (1800mm) Module MF (1300mm) ⊲ AC Normal ⊲ AC High power ⊲ EC Standard ⊲ EC High power ⊲ EC Low power Ø 800 mm Ø 910 mm ⊲ Min IP 54 ⊲ 6, 8, 12 Pole and EC ⊲ 1 & 3 phase ⊲ 50/60 Hz ⊲ 1 - 4 fans APPLICATION ATMOSPHERE TUBE MATERIAL FIN MATERIAL Commercial Application Cu or St/St Al, AV, AlMg, Cu, Bg Industrial Application Cu or St/St (NH3 must be St/St) Al, AV, AlMg, Cu, Bg Within 20 miles of the Sea Cu Cu, Bg, AlMg Waste Disposal Cu Al, AV, AlMg, Cu, Bg NOTE: The Tube material will suit fin Material OPTION DESCRIPTION Kelvion SmartControl Connected to the Kelvion cloud to give live operational data Unwired Installer wires directly to fan terminal boxes. Junction Box Single or twin according to unit model. Staged Control (AC Fan sets) Motor switchgear with or without controller. Speed Control EC, inverter or triac. Modbus Options for control communication of fan and control www.kelvion.com Selection and Pricing on all products can be performed on the Selection Software which can be downloaded from our website www.kelvion.com © Kelvion • All rights reserved • Subject to changes • Version 01 • 09/18

IMPROVED CAPACITY DENSITY AND QUIETER OPERATION &

⊲ R/GV-T/L V-profile extends the versatility of the V Profile range: The V-Profiled has been developed specifically to reflect the latest market requirements. Reduced footprint, lower noise level, improved capacity density and the greatest flexibility through configurable options to suit all requirements. Coil configurations of 5, 8, 10, and 12 mm are available in the variety of length, width and height variants, ensuing the most efficient solution is always offered across all potential applications.

⊲ A comprehensive collection of fan sets are available from various premium manufacturers. This ensures that the best fan is always selected and balanced against the model and application variant. High energy efficiency, low noise and flexible control options all ensure the best possible solution is offered.

⊲ Eurovent certify-all: independent certification for thermal performance, power consumption, sound data and unit air volumes for standard products under scheme limits.

⊲ CE Marked, PED compliant and UL Certified: Kelvion products can be supplied from SEP up to category IV

Kelvion R/GV-T and R/GV-L Condenser and Gas cooler

CAPACITY RANGEAPPLICATION

BENEFITS

13.2 kW - 2805 kW tL1= 25°C | t0= 40°C | DT = 15K [SC1] 12.5 kW - 2655 kW tL1= 30°C | PR1= 90 bar | tR1= 110°C | tR2= 35°C [SC20] Condensers & Gas Coolers Kelvion R/GV-T und R/GV-L Condenser und Gas Cooler

⊲ Fin Type: F, L, T, G ⊲ Standard Fin spacing: [mm] F, G, L = 2.1 | T = 2.3 ⊲ Fin Material: Cu, Al, Av, AlMg, Bg ⊲ Tube Diameter: [mm] 5 | 8 | 9.5 | 12 ⊲ Tube material: Cu, St/St HEAT EXCHANGE 2929 NOTEOPERATING ENVIRONMENT GUIDANCE ⊲ Control Box & Isolators ⊲ Sub cooling ⊲ Multi sections ⊲ Alternative Fin Material ⊲ Special Paint ⊲ Adiabatic System ⊲ Customised Housing VARIANTS & ACCESSORIES FANS (T) Medium (L) Large L H 2521 W 2260 W 2503 DIMENSIONS CONTROLS OPTIONS ⊲ AC Normal ⊲ AC High power ⊲ EC Standard ⊲ EC High power ⊲ EC Low power Ø 800 mm Ø 810 mm Ø 900 mm Ø 910 mm ⊲ Min IP 54 ⊲ 6, 8, 12 Pole and EC ⊲ 1 & 3 phase ⊲ 50/60 Hz ⊲ 1 - 20 fans 2180 MTG CTRS1880 MTG CTRS 4 Fans 6 Fans 8 Fans 10 Fans 12 Fans 14 Fans 16 Fans 18 Fans 20 Fans A 2400 3600 4800 6000 7200 8400 9600 10800 12000 B 3000 4500 6000 7500 9000 10500 12000 C 3600 5400 7200 9000 10800 APPLICATION ATMOSPHERE TUBE MATERIAL FIN MATERIAL Commercial Application Cu or St/St Al, AV, AlMg, Cu, Bg Industrial Application Cu or St/St (NH3 must be St/St) Al, AV, AlMg, Cu, Bg Within 20 miles of the Sea Cu Cu, Bg, AlMg Waste Disposal Cu Al, AV, AlMg, Cu, Bg NOTE: The Tube material will suit fin Material OPTION DESCRIPTION Kelvion SmartControl Connected to the Kelvion cloud to give live operational data Unwired Installer wires directly to fan terminal boxes. Junction Box Single or twin according to unit model. Staged Control (AC Fan sets) Motor switchgear with or without controller. Speed Control EC, inverter or triac. Modbus Options for control communication of fan and control www.kelvion.com Selection and Pricing on all products can be performed on the Selection Software which can be downloaded from our website www.kelvion.com © Kelvion • All rights reserved • Subject to changes • Version 01 • 09/18

KEEPING COOL. EVEN AT HIGH PRESSURES.

These brazed plate heat exchangers were specifically designed for the efficient and environmentally friendly refrigerant R410a. At pressures up to 45 bar / 653 psi, the heat exchangers of the GBH-Series offer the widest variety and flexibility in terms of size, different connections, flow arrangements and accessories.

Equipped with the proven technical features such as Safety ChamberTM , Delta InjectionTM and Full Flow SystemTM heat exchangers of the GBH-Series are ideal for a variety of high-pressure applications in the fields of industry and refrigeration/air-conditioning to serve the highest customer requirements with its diversity.

GBH-Series | Brazed Plate Heat Exchangers

⊲ HIGH PRESSURE RESISTANCE ⊲ COMPACT DESIGN ⊲ WIDE RANGE OF APPLICATIONS ⊲ ROBUST CONSTRUCTION PLATE HEAT EXCHANGERS ADVANTAGESDESIGN & FUNCTION GBH Plate Heat Exchanger

GBH 10,00+2,24xN 1,50+0,13xN 0,070 50

GBH 300 45 124 173 73 120 12,20+2,24xN 0,95+0,06xN 0,030 50

GBH 400 124 335 73 281 12,30+2,25xN 1,60+0,12xN 0,065 100

GBH 500 124 532 73 478 10,00+2,23xN 2,25+0,20xN 0,100 100

GBH 600L 45 250 386 162 307 13,40+2,27xN 7,80+0,295xN 0,158 150

GBH 700L/M 45 271 532 200 460 10,90+2,29xN 7,05+0,47xN 0,230 150

GBH 800 45 271 532 161 421 13,60+2,34xN 10,70+0,50xN 0,221 260

GBH 900 45 271 802 161 690 11,30+2,31xN 13,60+0,80xN 0,399 260

GBH 1000H/M 45 386 875 237 723 20,80+2,33xN 29,20+1,15xN 0,600 360

Also available as an advanced evaporator with a special “Delta InjectionTM “ distribution system for the refrigerant inlet.

GBH 400-AE 45 124 335 73 281 12,30+2,25xN 1,60+0,12xN 0,065 100

GBH 500-AE 45 124 532 73 478 10,00+2,23xN 2,25+0,20xN 0,100 100

GBH 700M-AE 45 271 532 200 460 10,90+2,29xN 7,05+0,47xN 0,230 150

GBH 800-AE 45 271 532 161 421 13,60+2,34xN 10,70+0,50xN 0,221 260

GBH 900-AE 45 271 802 161 690 11,30+2,31xN 13,60+0,80xN 0,399 260

GBH 1000H-AE 45 386 875 237 723 20,80+2,33xN 29,20+1,15xN 0,600 360

© Kelvion • All rights reserved • Subject to changes • Version 02 • 10/21 www.kelvion.com ALWAYS A SUITABLE SOLUTION AT HAND The brazed plate heat exchangers from Kelvion offer tailor- made solutions for the widest range of application. We configure the most economically favorable model for you from the wide range of available sizes and the numerous optional features. We adapt this with individually positioned connections to meet your specific requirements. We need following information to select your optimum heat exchanger ⊲ Required temperature range ⊲ Flow rates or required heat load ⊲ Maximal permitted pressure drop ⊲ Required working conditions SPECIFICATIONS ⊲ Plate Material: Stainless steel AISI 316L / 1.4404 ⊲ Brazing Material: Copper FEATURES ⊲ Safety ChamberTM (model 600L, 700, 800, 900, 1000) ⊲ Delta InjectionTM (model 400, 500, 700M, 800, 900, 1000H) ⊲ Full Flow SystemTM (model 100, 200, 220, 240, 300, 400, 500) PERFORMANCE LIMITS ⊲ Working temperature: -196°C to +200°C / -321°F to +392°F ⊲ Working pressure: up to 45 bar / 653 psi APPROVAL ⊲ PED (CE) Type Pressure Dimensions L-Dimension* Weight* Volume Max. number of plates bar A [mm] B [mm] C [mm] D [mm] [mm] [kg] (Litre/ Channel) GBH 100 45 74 204 40 170 8,00+2,23xN 0,65+0,050xN 0,025 50 GBH 200 45 90 231 43 182 10,00+2,24xN 0,85+0,06xN 0,030 50 GBH 220 45 90 328 43 279 10,00+2,25xN 1,10+0,09xN 0,046 50

240 45 90 464 43 415

45

45

The specifications contained in this brochure are intended only to serve the non-binding description of our products and services and are not subject to guarantee. Binding specifications, especially pertaining to performance data and suitability for specific operating purposes, are dependent upon the individual circumstances at the operation location and can, therefore, only be made in terms of precise requests. APPLICATION EXAMPLES: ⊲ Heat pumps for heating and hot water ⊲ Evaporators in air-conditioning systems ⊲ Process cooling ⊲ Economizer ⊲ Subcoolers and condensers *N = number of plates

HIGH PRESSURE BRAZED PLATE HEAT EXCHANGERS

For the highest mechanical and thermal requirements. The GBH-HP-Series are brazed plate heat exchangers with a pressure frame. They are designed for transcritical and subcritical CO2 systems and industrial applications with system pressures up to 140 bar.

GBH-HP | Brazed Plate Heat Exchangers

⊲ HIGH PERMANENT PRESSURE RESISTANCE ⊲ LONG LIFETIME ⊲ LOW INVESTMENT COSTS ⊲ SOLID FRAME CONSTRUCTION ⊲ CO2 IN A TRANSCRITICAL AREA PLATE HEAT EXCHANGERS ADVANTAGESDESIGN & FUNCTION GBH-HP Plate Heat Exchanger

GBH-HP 400H 140/140 195 410 73 281 74.40+2.35xN 44.25+0.290xN 0.065 100

GBH-HP-DW 400H 120/120 195 410 73 281 74.40+2.35xN 44.25+0.290xN 0.065 100

GBH-HP 500H 140/140 195 600 73 478 72.00+2.28xN 64.25+0.330xN 0.100 120

GBH-HP-DW 500H 140/140 195 600 73 478 74.30+2.30xN 64.65+0.410xN 0.100 120

GBH-HP 700L 140/130 340 621 200 460 113.40+2.34xN 185.45+0.700xN 0.230 150

GBH-HP 700M 140/130 340 621 200 460 113.40+2.34xN 185.45+0.700xN 0.230 150

GBH-HP 1000H 130/130 500 1050 237 723 153.80+2.33xN 611.40+1.490xN 0.600 360

Also available as an advanced evaporator with a special Delta InjectionTM distribution system for the refrigerant inlet

GBH-HP 500H-AE 140/140 195 600 73 478 72.00+2.28xN 64.25+0.330xN 0.100 120

GBH-HP 700M-AE 140/130 340 621 200 460 113.40+2.34xN 185.45+0.700xN 0.230 150

GBH-HP 1000H-AE 130/130 500 1050 237 723 153.80+2.33xN 611.40+1.490xN 0.600 360

Also available with Distribution Technology EQ-Pipe

GBH-HP 400-EQ 140/140 195 410 73 281 74.40+2.35xN 44.25+0.290xN 0.100 100

GBH-HP-DW 400H-EQ 120/120 195 410 73 281 74.40+2.35xN 44.25+0.290xN 0.100 100

GBH-HP 500H-EQ 140/140 195 600 73 478 72.00+2.28xN 64.25+0.330xN 0.100 120

GBH-HP-DW 500H-EQ 140/140 195 600 73 478 74.30+2.30xN 64.65+0.410xN 0.100 120

GBH-HP 700M-EQ 140/130 340 621 200 460 113.40+2.34xN 185.45+0.700xN 0.230 150

GBH-HP 1000H-EQ 130/130 500 1050 237 723 153.80+2.33xN 611.40+1.490xN 0.600 360

© Kelvion • All rights reserved • Subject to changes • Version 03 • 09/21 www.kelvion.com ALWAYS A SUITABLE SOLUTION AT HAND The brazed plate heat exchangers from Kelvion offer tailor- made solutions for the widest range of application. We configure the most economically favorable model for you from the wide range of available sizes and the numerous optional features. We adapt this with individually positioned connections to meet your specific requirements. We need following information to select your optimum heat exchanger ⊲ Required temperature range ⊲ Flow rates or required heat load ⊲ Maximal permitted pressure drop ⊲ Required working conditions SPECIFICATIONS ⊲ Plate Material: Stainless steel AISI 316L / 1.4404 ⊲ Brazing Material: Copper FEATURES ⊲ Safety ChamberTM (model 700, 1000) ⊲ Delta InjectionTM (model 500, 700M, 1000) ⊲ Full-Flow SystemTM (model 400, 500; except GBH-HP-DW 500H) ⊲ Double-Wall-Safty-heat exchanger (type GBH-HP-DW 400 H, GBH-HP-DW 500 H) ⊲ Distribution technology EQ-Pipe (model 400, 500, 700, 1000) PERFORMANCE LIMITS ⊲ Working temperature: -40°C to +150°C ⊲ Working pressure: up to 140 bar APPROVAL ⊲ PED (CE) The specifications contained in this brochure are intended only to serve the non-binding description of our products and services and are not subject to guarantee. Binding specifications, especially pertaining to performance data and suitability for specific operating purposes, are dependent upon the individual circumstances at the operation location and can, therefore, only be made in terms of precise requests. APPLICATION EXAMPLES: ⊲ CO2 heat pumps ⊲ CO2 supermarket cooling ⊲ Oil cooling ⊲ Industrial heating and cooling ⊲ Power plant technology *N = number of plates Type Pressure Dimensions L-Dimension* Weight* Volume Max. number of plates bar A [mm] B [mm] C [mm] D [mm] [mm] [kg] (Litre/ Channel)

GVH-HP | Brazed Plate Heat Exchangers

HIGH PRESSURE –ALSO IN STAINLESS STEEL

With the brazed plate heat exchangers of the GVH-HP-Series Kelvion offers the ideal solution for industrial applications with high operating pressures. VacInox, our especially developed, free of non-ferrous metals solder material is used, to meet the increased demands in relation to corrosion resistance, high temperature and pressure requirements. Thanks to this new, unique and revolutionary technology for the robust connection of stainless steel plates both a compact design and high corrosion resistance can be achieved. A pressure frame ensures maximum safety in mechanical and thermal requirements at pressures up to 46 bar/667 psi. The product range includes connection diameters from DN15 to DN100.

Copper-free, brazed plate heat exchangers of the GVH-HP-Series use the knowledge transfer within Kelvion and combine the advantages of brazed and gasketed heat exchangers.

⊲ FREE OF NON-FERROUS METALS ⊲ CORROSION RESISTANT ⊲ HIGH THERMAL EFFICIENCY ⊲ HIGH OPERATING PRESSURES PLATE HEAT EXCHANGERS ADVANTAGESDESIGN & FUNCTION GVH-HP Plate Heat Exchanger

© Kelvion • All rights reserved • Subject to changes • Version 01 • 04/21 www.kelvion.com ALWAYS A SUITABLE SOLUTION AT HAND The brazed plate heat exchangers from Kelvion offer tailor- made solutions for the widest range of application. We configure the most economically favorable model for you from the wide range of available sizes and the numerous optional features. We adapt this with individually positioned connections to meet your specific requirements. We need following information to select your optimum heat exchanger ⊲ Required temperature range ⊲ Flow rates or required heat load ⊲ Maximal permitted pressure drop ⊲ Required working conditions SPECIFICATIONS ⊲ Plate Material: Stainless steel AISI 316L / 1.4404 ⊲ Brazing Material: VacInox FEATURES ⊲ Safety Chamber TM (model 700, 1000) ⊲ Delta InjectionTM (model 500, 700M) ⊲ Full Flow System TM (model 500) ⊲ Distribution technology EQ-Pipe (model 500, 700) PERFORMANCE LIMITS ⊲ Working temperature: -40°C to +150°C / -40°F to +302°F ⊲ Working pressure: up to 46 bar / 667 psi APPROVAL ⊲ PED (CE) The specifications contained in this brochure are intended only to serve the non-binding description of our products and services and are not subject to guarantee. Binding specifications, especially pertaining to performance data and suitability for specific operating purposes, are dependent upon the individual circumstances at the operation location and can, therefore, only be made in terms of precise requests. APPLICATION EXAMPLES: ⊲ Ammonia refrigeration plants ⊲ Evaporators and condensers in cascade systems *N = number of plates Type Pressure Dimensions L-Dimension* Weight* Volume Max. number of plates bar A [mm] B [mm] C [mm] D [mm] [mm] [kg] (Litre/ Channel) GVH-HP 500H 46 195 600 73 478 74.30+2.28xN 64.60+0.330xN 0.100 150 GVH-HP 700L 46 340 621 200 460 118.20+2.34xN 188.80+0.700xN 0.230 150 GVH-HP 700M 46 340 621 200 460 118.20+2.34xN 188.80+0.700xN 0.230 150 GVH-HP 1000L 46/30 500 1050 237 723 156.10+2.33xN 612.85+1.490xN 0.466/0.733 200 Also available as an advanced evaporator with a special Delta InjectionTM distribution system for the refrigerant inlet GVH-HP 500H-AE 46 195 600 73 478 74.30+2.28xN 64.60+0.330xN 0.100 150 GVH-HP 700M-AE 46 340 621 200 460 118.20+2.34xN 188.80+0.700xN 0.230 150

Gasketed Plate Heat Exchanger

QUALITY AND FLEXIBILITY AT ITS BEST

The gasketed plate heat exchangers reveal what passion, scientific curiosity and technological expertise can achieve.

The facts: high efficiency at low operating costs, greater application possibilities at lower investment costs. Continuous further development of the plate series targeted to meet your demands concerning the thermo-dynamic and fluid-dynamic performance also ensures that you can achieve maximum economic efficiency.

The range of plate corrugations, connection sizes, plate widths and lengths enable them to be flexibly and effectively designed for individual application requirements.

In addition, maintenance-friendly assembly and sealing technologies are applied, which assure that service and maintenance costs are kept low.

⊲ MADE TO MEASURE FOR YOUR REQUIREMENTS ⊲ OPTIWAVE DESIGN FOR HIGHEST EFFICIENCY AND LOWEST FOULING ⊲ POSLOC ASSEMBLY FOR A PERFECTLY ALIGNED PLATE PACK ⊲ ECOLOC GASKET SYSTEM FOR EASY & RELIABLE FIXATION AND REMOVAL PLATE HEAT EXCHANGERS ADVANTAGESDESIGN & FUNCTION Gasketed Plate Heat Exchanger

OPTIWAVE DESIGN exclusive plate corrugation pattern allows even flow distribution across the entire plate surface thereby maximizing heat transfer while minimizing fouling rates, plate count, and cost..

ECOLOC GASKET SYSTEM gaskets work in perfect combination with our plates to ensure worry free operation. Our chamfered opening allows each gasket to settle into position and also prevents the lock tab from being severed. can be easily installed without tools or adhesive and self-seat during closing. It takes just seconds to replace a gasket making maintenance quick and easy.

POSLOC ASSEMBLY

Kelvion’s trademarked PosLoc plate design allows the GPHE plates to self-align and tightly seal every time the unit is closed. This feature virtually eliminates plate pack snaking, even if the frame is out of alignment and after repeated servicing. This distinctive feature provides you with years of stress free maintenance and operation.

ONE FRAME FOR ALL if the medium or requirement changes, there is no greater flexibility. of the N series plates be used in the same frame of

Kelvion’s N Series GPHEs feature an advanced frame design with a wide variety of plate choices, configurations, and port sizes. The interior N Series plates are the most technologically advanced heat transfer plates on the market with features for cient processing of all products, including those with high viscosities and fouling making the N Series the superior choice for your most challenging heat

Kelvion’s N Series GPHEs feature an advanced frame design with a wide variety of plate choices, configurations, and port sizes. The interior N Series plates are the most technologically advanced heat transfer plates on the market with features for cient processing of all products, including those with high viscosities and fouling making the N Series the superior choice for your most challenging heat

© Kelvion • All rights reserved • Subject to changes • Version 01 • 12/18 www.kelvion.com HIGHLIGHTS N-SERIES NT SERIES ⊲ Flexible solution for all applications ⊲ Wide range of widths and lengths ⊲ Extensive range of plate & gasket materials NW SERIES ⊲ Widest herringbone plate gap ⊲ For media containing small and round particles NC,NA,NG,NQ SERIES ⊲ AHRI certified plate series ⊲ For HVAC applications NX SERIES ⊲ Perfect fit for narrow temperature profiles ⊲ Increased pressure resistance ⊲ Higher heat transfer rates NF SERIES ⊲ Real Free Flow gap without contact points ⊲ Constant gap width ⊲ For media containing particles and fibers LWC SERIES ⊲ Laser welded cassettes ⊲ Hermetically sealed flow gap for hazardous media ⊲ Assures high process reliability ND SERIES ⊲ Double-wall plate for highest process safety ⊲ No intermixing of media K°SKID ⊲ Dual module of two redundant heat exchangers ⊲ Assures 24/7 operation ⊲ No unwanted downtimes NH SERIES ⊲ High pressure resistance at low pressure drop ⊲ Available in special materials NP SERIES ⊲ Highest performance plate ⊲ Perfect fit for extremely low temperature differences ⊲ Highest pressure resistance NL SERIES ⊲ Large herringbone plate gap for gentle media treatment ⊲ For shear-sensitive and highly viscous media

Even

All

can

with varying numbers

plates.

Kelvion

Gaskets

Kelvion’s

material

e

tendencies

transfer specifications. LASER-WELDED CASSETTES HERRINGBONE CORRUGATIONS WITH VARIOUS STYLES FREE FLOW GAP

www.kelvion.com