£3.99

Are we heading for a sea of septoria at T1? page 8

In this issue...

Feeding foliars page 30

Sage advice on foliar N

Ahead of the Danes? page 62

Hidden in sight page 42

A case of mistaken identity?

Generation game page 88

Volume 25 Number 3

April 2023

March certainly made up for the lack of rain during February and,as I write at the start of the month,April is looking like a big improvement –– much more spring-like!

As a result, septoria is the watch word as the T1 fungicide timing approaches and it’s the first time for several successive springs that it’s been damp enough to get a foothold in crops. So could we be in for a disease year? That’s still in the lap of the gods but there’s certainly potential if conditions remain changeable.

Editor

Lucy de la Pasture

Deputy Editor

Janine Adamson

Sub-editor

Rachael Harper

Mike Abram

Janine Adamson

Heather Briggs

Adam Clarke

Melanie Jenkins

Rob Jones

Writers

Martin Lines

Lucy de la Pasture

Martin Rickatson

Guy Smith

Richard Styles

Andrew Wilson

Design and production

Brooks Design

Publisher

Steve Kendall

Commercial Director

Angus McKirdy

To claim two crop protection BASIS points, send an email to cpd@basis-reg.co.uk, quoting reference CP/120083/2223/g.

To claim two NRoSO CPD points, please send your name, NRoSO member number, date of birth and postcode to angus@cpm-magazine.co.uk

*the claim ‘best read specialist arable journal’ is based on independent reader research conducted by McCormack Media 2020

Editorial & advertising sales

CPM Ltd, 1 Canonbury, Shrewsbury, Shropshire SY3 7AG

Tel: (01743) 369707 E-mail: angus@cpm-magazine.co.uk

Customer Ser vice Kelsey Media, The Granary, Downs Court, Yalding Hill, Yalding, Kent ME18 6AL, UK

Reader registration hotline 01959 541444

Advertising copy Brooks Design, Tel: (01743) 244403 E-mail: fred@brooksdesign.co.uk

CPM Volume 25 No 3. Editorial, advertising and sales offices are at CPM Ltd, 1 Canonbur y, Shrewsbur y, SY3 7AG England. Tel: (01743) 369707. CPM is published eleven times a year by CPM Ltd and is available free of charge to qualifying far mers and far m managers in the United Kingdom.

Copyright Kelsey Media 2022. All rights reserved. Kelsey Media is a trading name of Kelsey Publishing Ltd. Reproduction in whole or in part is forbidden except with permission in writing from the publishers. The views expressed in the magazine are not necessarily those of the Editor or Publisher Kelsey Publishing Ltd accepts no liability for products and services offered by third parties.

To get a flavour of disease development before most fungicide decisions are made, we joined the Bayer Crop Doctor team on its annual tour across the country –– this year taking in sites in Scotland, Lincolnshire, the Cotswolds and Herefordshire (page 8). Then we catch up with the latest developments in rusts, adding a third rust –– stem rust ––to the annual review of virulence profiles by UKCVPS (page 16).

Still on the subject of diseases, Theory to Field dives into testing for those that can potentially contaminate grain, including ergot –– which appears to be on the rise –– and the mycotoxins produced in fusarium ear blight (page 24).

On page 30, there are insights into foliar nitrogen from Integrated Soils, with tips on how to make sure it gets into leaf tissues without causing scorch. We then meander into biostimulants, with a look at some products that may be known and others not so familiar (page 34).

With some oilseed rape crops succumbing to pest damage this spring, we find out more about winter stem weevil and how it may be being mistaken for cabbage stem flea beetle larvae. Could this pest have been responsible for some of the OSR failures in spring a few years ago? It seems to be a distinct possibility according to experts (see page 42).

That brings us nicely to varieties, with a look at an OSR variety that failed to get onto the AHDB Recommended List, but

many believe shouldn’t be discounted (page 47). With an eye on the future, we dip into the recent Association of Applied Biologists reports (page 50) and learn about research that could help shape the characteristics of wheat varieties yet to come. Then we round off with a look at hybrid rye, which could offer an alternative cereal in some rotations as market opportunities open up for the crop (page 52).

We kick off the Sustainable Farming section still on the subject of varieties, with an in depth look at Agrii’s sustainability scoring system to help identify the varieties with the most to offer (page 56). Then we nip over to Denmark, where CPM’s new deputy editor and head of digital, Janine Adamson, finds that, in many ways, UK regenerative farmers may well be in front of their esteemed Danish colleagues (page 62). And a massive welcome to Janine, whose writing skills and technical knowledge will bring a whole new dimension to the editorial team.

Uniquely positioned across the food supply chain, Frontier gets its new Sustainability in Practice series underway, answering some of the questions about a concept that can sometimes feel vague and intangible (page 67).

We jet off again in Machinery to bring a taste of India (page 80), home of a tyre manufacturing facility that occupies a massive 125ha. If on-farm generation of electricity is more your thing, then we have that covered in a second report from the West Country & Machinery Show on page 84.

Finally, dipping into Roots, we get to grips with potato viruses and look at how use of a soil conditioner throughout the rotation could help improve beet yields.

I hope you enjoy reading this April issue of CPM as much as I’ve enjoyed putting it together.

Editor’s pick

CPM (Print) ISSN 2753-9040 CPM (Online) ISSN 2753-9059

3 crop production magazine april 2023

Opinion

Smith’s Soapbox - Views and opinions from an Essex peasant…

Nature Natters - A nature-friendly perspective from a Cambridgeshire farmer.

Styles’ Stance - A tongue-in-cheek look at farming.

Talking taties - Plain talking from a Yorkshire root grower.

Crop Doctor – Setting up for a sea of septoria?

The Crop Doctor team tour around the UK to find a wet March may turn the tide when it comes to septoria.

Cereal disease – Yellow rust reigns but no surprises

Findings from UKCVPS’ annual stakeholder meeting put three cereal rusts under the spotlight.

Real Results Pioneers – On-farm reality

The story of the Real Results Circle and how its on-farm trials have provided insights to farmers.

Theory to Field – An eye on visible and subtle threats

How an in-depth surveillance project for contaminants is contributing to grain safety.

Forward-thinking farmers – Finesse through fine-tuning

A Herefordshire farmer is utilising innovative technologies to assist agronomy decisions on the farm.

Foliar Nutrition – Wising up on foliar N

Highlights from Integrated Soils’ recent webinar series, which looked at getting the most from foliar N.

Biostimulants – Providing a natural boost?

A look at a few of the products on the market that fall in this category but do very different things.

Bioscience in practice – Greening is believing

How a specialist biostimulant fits into a programme to raise productivity by boosting chlorophyll.

OSR pests – Hidden in plain sight

Could it be a case of mistaken identity? We find out more about a pest that’s causing damage to OSR.

Insider’s View – Gold flowering Granos

Some favourite OSR performers have fallen outside the AHDB RL. Could KWS Granos be one of them?

Plant breeding – Traits for the future?

We catch up with two researchers who presented at the Association of Applied Biologists conference..

Research Briefing – Rye not?

A roundup of recent trials which demonstrate the potential opportunities offered by hybrid rye.

Sustainable farming

Sustainable Solutions – Above and beyond

How Agrii’s Variety Sustainability Rating helps sort the wheat from the chaff when choosing varieties.

BASE-UK Conference – Large scale regeneration

More highlights from the 10th BASE-UK Conference, with Dyson Farming taking centre stage.

Regenerative Reconnaissance – Study tour enlightenment

A recent study tour to Denmark finds out the UK regen farmers may not be behind the curve in comparison.

Regenerative farming – Wider benefits of healthy soils

We join delegates at a regen farming day in East Sussex, hosted by Agreena and Fram Farmers.

Sustainability in Practice – Farming for a better future

Uniquely positioned in the supply chain, Frontier joins the dots about what sustainability means for growers..

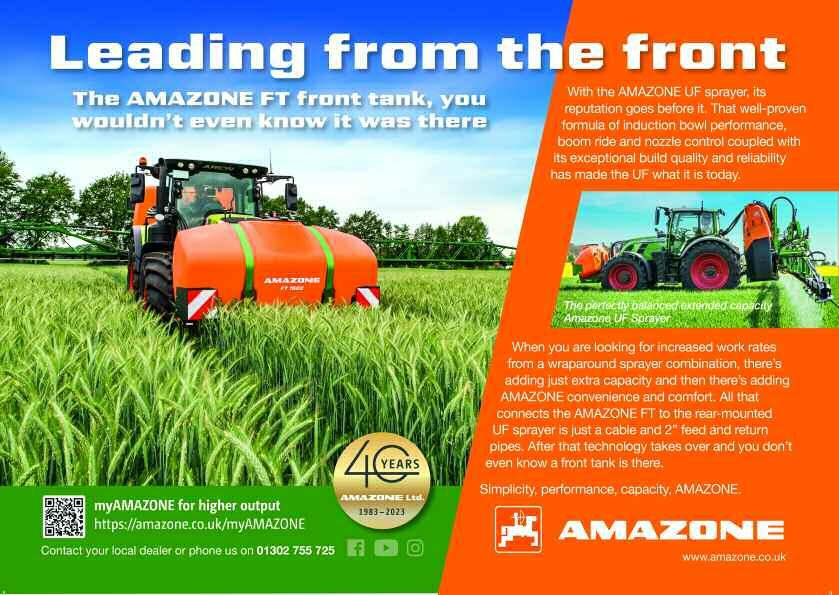

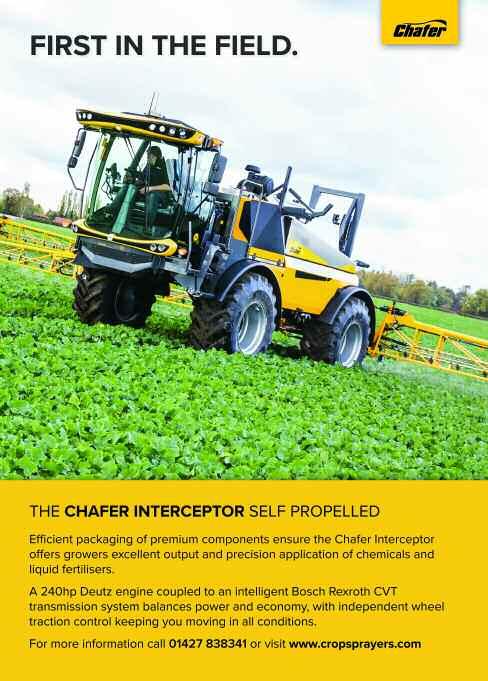

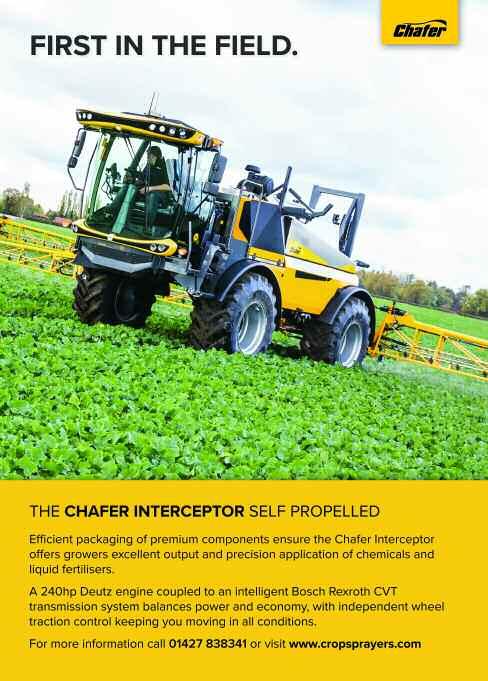

Sprayers – From small tweaks to high tech

We look at some of the latest developments in sprayers, both available now and in the near future.

Spraying technology – The future of spraying

A recent CHAP webinar explored whether it’s change for change’s sake when it comes to new tech.

World view – A taste of India

BKT recently hosted a tour of its massive tyre facility in India, with a taste of its farming thrown in.

On Farm Opinion – Chopper a firm favourite

A Devon contractor sticks with the same brand of forage harvester for eight renewals, so we find out why.

West Country Farming & Machinery Show – The generation game

On-farm electricity generation and battery storage came under the spotlight at a recent machinery show.

Potato viruses – Turning the tide on potato virus

Controlling the spread of potato viruses is no easy task. We find out about the issue.

Sugar beet agronomy – Healthy soil for healthy yields

A look at how a soil condition has improved soils within a rotation to the benefit of the sugar beet crop.

16 67 77 97

Machinery 56 59 62 65 67 71 77 80 84 88 92 97

Roots Technical 8 16 21 24 27 30 34 38 42 47 50 52 In this issue 5 crop production magazine april 2023

6 55 70 99

In a somewhat desperate attempt to get on top of the blackgrass menace that plagues our farm,we grew a fair acreage of spring wheat last year. By the time the blistering June/July drought and heatwave had done their worst,I ended up with a miserable yield of about 4-5t/ha.

As I stared forlornly at the yield

metre in the combine cab, I muttered to myself ‘never again,’ and consequently, we have no spring wheat this year. Six months later, I’m now fretting that this move to wall-to-wall autumn wheat might be a stupid mistake.

It turned out that as I blended out the low-yielding, but high-protein spring wheat with the high-yielding, low-protein winter wheat, I was managing to hit a very lucrative 13% protein, which in turn secured a remarkable £60–£70 milling premium over feed. I’d like to think this was down to my strategic planning, but the truth is that it was pure luck.

The other bit of luck was that because this milling blend of Crusoe and Mallacca was sailing into a certain north London mill

without many claims, I was keen to clear the grainstore as it seemed the mill was keen to have it. Consequently, by January the grainstore was empty just before the price crashed. So it turns out that while I was cursing away at my embarrassingly bad spring wheat yields at harvest time, I was painfully ignorant as to what it would be worth, which I now estimate to be somewhere north of £350 a tonne. But to ruin this smug tale of success, I’ve foolishly chosen not to grow spring wheat this year.

So this leaves the tricky decision as to how much spring fertiliser to put on the milling wheat this year. With nitrogen prices approaching £2/kgN last year, I was loathe to put on more than 160kgN/ha. Despite the fact this is 20% less than our usual rate, the surprise was that our yields were just about in line with our 10-year average. The negative fall-out was the low proteins. To compound matters, last year we only put on 15kgN/ha as a protein boosting head spray because we were worried about scorch in the drought and heat.

With fertiliser 35% cheaper this year at around £1.25/kgN, the simple answer is to go back to our usual 190 kgN/ha, with a 30kgN/ha protein boost on the ear. The joker in the pack now being what the wheat price will

Guy Smith grows 500ha of combinable crops on the north east Essex coast, namely St. Osyth Marsh –– officially the driest spot in the British Isles. Despite spurious claims from others that their farms are actually drier, he points out that his farm is in the Guinness Book of Records, whereas others aren’t. End of.

@essexpeasant

be this year. We have already banked a minimum £40 a tonne premium for 13% protein Crusoe for autumn 2023 delivery but, stupidly, we didn’t fix a base when we could have secured £300 per tonne plus. Such is hindsight…

It does feel as if this year is a return towards normality, whereas 2022 was a mind scrambling blip. But it’s only April so there’s plenty of time for a bit of market tumult. As usual, I expect I’ll only prove wise well after the opportunity to use that wisdom to good effect.

If there was a lesson to be learnt from last year, it was that old adage ‘ when it comes to making decisions, forget last season and remember the 10 before that.’ Having said that the Kremlin is not the place it was 10 years ago.

The milling wheat casino

6 crop production magazine april 2023

Selling grain seems to be as much about luck as judgement in these unpredictable times,especially as the bearish market turns boarish.

Setting up for a sea of septoria?

Crop Doctor

After successive years where March has seen the ground begin to dry out after the winter downpours,2023 appears to have bucked the trend. CPM met up with the Bayer Crop Doctor team to survey sites around the country and get a feel for the possible disease challenges ahead.

By Lucy de la Pasture and Janine Adamson

By Lucy de la Pasture and Janine Adamson

The spring equinox often marks the time when winter wheat crops go into stem extension,triggering the first fungicide application of the season in crops where a T0 is merited. In 2023,above average March rainfall may have put things on hold until the ground can travel

While that’s not a disaster in wheat crops which aren’t battling yellow rust, it has the potential to compromise the best laid fungicide plans in winter barley and oilseed rape crops.

Long Sutton,Lincolnshire

Kicking off Crop Doctor for the season saw the team visit David Hoyles’ farm at Long Sutton, Lincolnshire on 21 March. On first inspection, all plots looked much further ahead than expected given the 15 October drilling date, although per haps not so unusual for David’s crops which tend to get away quickly in the spring.

Leading the assessment was ADAS’ Jonathan Blake, who attributes this progression to the mild autumn growers experienced. “The crop plots looks like they were drilled a fortnight earlier, and while the canopies looks healthy, there’s a lot of septoria already present on lower leaves,” he says.

“There’s a sea of inoculum across all varieties, even KWS Extase, which is commended for its resistance package. It’s not surprising given the forward nature of the plants –– they’re behaving in a similar way to early drilled crops.

“We’d expect plant genetics to show through soon because varietal disease ratings are based on adult plants, not juveniles. But the severity in any given variety will also depend on the weather.”

The weather’s certainly been a challenge for David recently, who’s awaiting a dr y spell and for the ground to dry up. “We had a dry December through to February, then a very wet March [equal

There’s a sea of septoria inoculum across all varieties,even KWS Extase ”

to the sum of rainfall over the winter months], and now it looks like another fortnight of rain,” he says. “I’m hoping the crop can handle it though, given it grew up and away so quickly in the autumn.”

Diving into the specific varieties, comments continue to be septoria-themed. “Yes, a lot of septoria and also some stem-based browning, although it’s too early to identify the cause but eyespot would be a strong possibility,” comments Jonathan, while stood in a plot of Graham.

Having found septoria in every variety, it was two tiny orange-brown lesions in the Crusoe that created chatter among the Crop Doctor team. “That looks like brown rust to me, although the site is surprisingly clean of yellow rust,” says Jonathan.

“We’d usually see yellow rust by now but we had two sharp frosts recently,

“

8 crop production magazine april 2023 ▲

which is unusual for us and it has probably helped,” adds David.

Jonathan war ns him not to become complacent. “Right now, we have perfect yellow rust conditions so although it’s been knocked back, it’s likely to bounce back too. These damp conditions will also have an impact for our current septoria problem. When we retur n in around four weeks, I’d expect a sea of septoria.”

Conversation soon switches to the farm’s fungicide programme. David acknowledges the need to ‘get on’ and be timely, but has struggled with continual rain. “We’ve missed T0 in some fields, but might consider a T0.5 of something relatively cheap and cheerful if we can, based on tebuconazole and a strobilurin.

“It all depends on the risk, if it’s high I’ll go with Ascra Xpro (bixafen+ fluopyram+ prothioconazole), but if not, I’ll stick with the cheaper option. The crops are looking the best they’ve looked for four years, so we don’t want disease to take over.”

Aside from fungicides, David’s also planning a PGR spray and further micronutrition, which began earlier in the season. For nitrogen, the farm’s average is 180kg/ha.

Going through the Bayer variety plots one final time, Jonathan notes the onset of mildew. “It can be an issue for varieties such as Crusoe, KWS Zyatt and Skyfall at T0. However, my main ‘watchouts’ from today are septoria and yellow rust. The mild wet autumn has promoted the septoria and current conditions are suited to yellow rust which, as this region is

particularly prone, I’d expect to bounce back from the recent frosts.

“Given the autumn weather, growers will have to manage their expectations on varietal disease ratings, and knock them back by around 0.5, as these crops will be more septoria prone.”

Boghall Farm,Midlothian

Dodging heavy showers, the Scottish Crop Doctor team report septoria as the main finding in the Bayer variety demo plots at SRUC’s Boghall Farm, just outside Edinburgh.

“There are no huge differences between the 20 varieties here, all have septoria on the lower leaves with active pycnidia. But where there are differences, these are related to the growth habit and it’s the varieties with a prostrate habit that have the most septoria,” comments Prof Fiona Burnett, plant pathologist at SRUC.

“Where the leaves lie flat to the ground, the septoria is more easily spread by rain splash,” she adds.

According to Bayer’s Grant Reid, the varieties at the demo site are behind most commercial crops in the area, where septoria levels are more rampant. Fiona chimes in that the early drilling last autumn, August in places, followed by a warm autumn, a cold and dry spell early in the new year and then relentless rain through March has laid the foundations for a higher septoria season than has been seen in a number of years.

“In commercial crops, LG Illuminate stands out as a growthy variety that’s carrying high levels of septoria. There’s also stem-based browning evident this spring but whether it develops into eyespot or not, time will tell,” says Grant.

Fiona agrees that eyespot may be an issue this year “Early drilling and the relatively warm weather we’ve had are both drivers for the disease.”

Even though the plots at Boghall are a little behind, Grant notes the varieties have a good number of tillers so the potential is there and they should soon rocket on.

In winter barley, there’s more disease evident than there has been for a few years, with rhynchosporium, net blotch and mildew all easy to find, he adds.

“When the weather improves, the pressure will be on growers to get fer tiliser and early fungicides on so they’ll have to prioritise. In winter barley, the T0 timing may be missed if the ground won’t travel as crops will rush through the growth stages now.”

Fiona believes it won’t be a year to

Fiona Burnett says T1s will have to do a decent job with higher disease levels to contend with this year,but adds that it actually makes decision making easier than in a low disease pressure season.

scrimp on fungicides. “The expense of growing crops currently means getting disease protection on is a no brainer,” she says. “After all the March rainfall, T1s will have to do a decent job with higher disease levels to contend with this year But it actually makes decision making easier than in a low disease pressure season.”

She advises keeping diversity in the fungicide programme –– for wheat that means looking ahead at T2 and adopting

Some varieties are carr ying higher levels of septoria than might be expected,but adult plant resistance won’t have kicked in yet.

10 crop production magazine april 2023 Crop Doctor ▲ ▲

Yellow rust would normally be evident in crops by now but David Hoyles says two sharp frosts recently,which is unusual at Long Sutton,has probably helped subdue infection.

different chemistry at T1. “Where there’s eyespot, there’s a good case for prothioconazole plus an SDHI at T1. Folpet inclusion also helps disease control, resistance management and adds yield.”

The OSR at Boghall has reached stem extension, getting away from pigeons which have been problematic this year, says Grant. There is also unusual levels of disease to contend with. “We’re seeing increasing levels of light leaf spot (LLS) and phoma in crops from the Borders nor thwards from the results of SpotCheck sampling. There haven’t been any real issues with pests, though slugs have been active, and crops are well rooted so will romp away.”

Fiona reckons there’s a distinct risk they could become too tall if growers aren’t mindful.

On a positive note, Grant says the moisture in the ground will help spring barley crops get away quickly and they’re unlikely to be short of water in those early weeks where tilering is so crucial. It’s also likely that pre-emergence herbicides will work well too, giving growers one less thing to worry about where annual meadowgrass is a problem, he adds

Great Tew,Cotswolds

At the Great Tew Estate, farm manager and agronomist, Colin Woodward, is also grounded due to the March rainfall. Like David Hoyles, the rainfall in March ––63mm to date (22 March) –– equals the quantity that fell through the depths of winter.

Again, it’s septoria that’s the biggest cause for concern in the commercial crops, with visible lesions on the lower leaves of all Colin’s winter wheat varieties, even those with high resistance ratings. “The symptoms we’re seeing now are from septoria infection that would have been in its latent phase in Januar y-February. The effect of the March rainfall will be showing up when we visit again next month.”

Walking into a crop of mid-October sown LG Skyscraper, Jonathan isn’t surprised to see the levels of septoria it’s carrying on the lower leaves. However, the crop of nearby KWS Palladium does raise a few eyebrows.

“Palladium is rated 7.4 for septoria resistance but it’s currently looking very similar to the Skyscraper we’ve just been in, with more septoria than I’d expected,” says Jonathan. Popping into another field of KWS Extase, it tells a similar tale ––septoria lesions are ver y evident on the oldest leaves.

He goes on to explain that the AHDB Recommended List ratings are for adult plant resistance, which is assessed in June and July “Varieties differ with how they pick up disease over the winter, during the seedling phase septoria resistance may not have kicked in.”

A second field of Extase, drilled at the end of October after peas, proves to be much cleaner as far as septoria is concer ned but here, stem-based browning is Jonathan’s stand out observation. “The browning is higher on the stem than I’d expect –– where the fifth or sixth last leaf to emerge is dying back. Some of the lesions are penetrating,” he comments.

Also after peas and later drilled, Colin’s

field of Champion is looking good and relatively clean. Nearby KWS Dawsum is standing very erect, with residual septoria in the base but very little on the last leaf emerged.

Moving into a crop of SY Kingsbarn winter barley, there’s a full house of foliar diseases in the more fertile patches, with brown rust and net blotch of most concern.

Bayer’s Ben Giles says it seems to be a net blotch year and warns growers to keep an eye on spring barley because of the danger of high seed infection levels. “It’s a disease that can prove more difficult to control now [due to fungicide insensitivity] so it’s best to use a mix of chemistr y and keep rates up,” he advises.

Asked about his fungicide plans, Colin says no fungicide is planned for the winter wheat as all his varieties have an RL rating of 7 or above for yellow rust, which isn’t evident in the crop at the moment. PGRs, trace elements and herbicide, where required, will go on as a T0 at the end of March/early April.

“If the wet weather continues then I’ll look to increase fungicides at T1. I haven’t yet decided between Aviator (bixafen+ prothioconazole) or Ascra (bixafen+ fluopyram+ prothioconazole) for the Extase. Aviator has a higher loading of prothioconazole to tackle any eyespot,” he adds.

Folpet is likely be added to the T1 mix in the more disease prone varieties, such as Skyscraper, and where the barley is

Jonathan Blake and Colin Woodward assess disease levels in the commercial crops at the Great Tew Estate.

Stem-based browning is easy to find in KWS Extase at all the Crop Doctor sites spanning the countr y and at Great Tew,the lesions are found much higher on the stem (pictured).

Although there’s a full house of foliar diseases to be found on SY Kingsbarn at Great Tew,it’s net blotch and brown rust that are the primary concerns at the moment.

Jonathan Blake and Colin Woodward assess disease levels in the commercial crops at the Great Tew Estate.

Stem-based browning is easy to find in KWS Extase at all the Crop Doctor sites spanning the countr y and at Great Tew,the lesions are found much higher on the stem (pictured).

Although there’s a full house of foliar diseases to be found on SY Kingsbarn at Great Tew,it’s net blotch and brown rust that are the primary concerns at the moment.

12 crop production magazine april 2023 Crop Doctor ▲ ▲

At Callow in Herefordshire,eyespot lesions are penetrating in places in KWS Extase.

‘stressy’ to aid ramularia control.

But it’s the winter barley and OSR that will take priority at Great Tew. “The Kingsbarn will have a T0 of Prosaro (prothioconzole+ tebuconazole) to help with the net blotch.”

LLS is also making an appearance in Colin’s Matrix OSR crop, and Ben notes the Bayer SpotCheck service has been seeing high incidences of LLS in samples over the past two months. Colin is planning to apply a PGR –– Car yx (mepiquat-chloride+ metconazole) or Toprex (difenoconazole+ paclobutrazol) ––with tebuconazole or Prosaro plus trace elements when the ground will travel, followed by prothioconazole and a strobilurin at early flowering.

Callow,Herefordshire

After 5mm of overnight rain, the heavy ground at Callow –– just south of Hereford –– has done a pretty good job of mopping up the 70mm that has fallen so far in the month (to 22 March). Water is sitting in the tramlines but a strong gusty wind is doing its best to dry the soil.

This year the Bayer demo site is in one of the lower lying fields on the farm and developmental differences are showing up in the plots, which comprise 38 varieties and three blends, drilled 13 October, explains Bayer’s Gareth Bubb.

A quick overview of the plots reveals the most backwards looking varieties, which include RGT Grouse, LG Typhoon and LG Arkle, whereas leading the charge into spring are KWS Extase and Bamford.

Joined by Herefordshire-based

independent agronomist David Lines, Jonathan heads towards ‘indicator’ varieties and finds no sign of any yellow rust on either KWS Zyatt or Skyfall, though the latter has a few spats of mildew, which may be favoured by the microclimate in this particular field, points out Jonathan.

Crusoe also disappoints, with no brown rust on the notoriously susceptible variety but septoria is easy to find in all the plots. “Theodore is the cleanest but even with its 9.1 rating for septoria, there’s still some lesions on the oldest leaves, with black pynidia showing,” says Jonathan.

Extase follows the same pattern as the other sites, with more septoria than might be expected from its 7.8 rating, probably a reflection of its ‘leafy’ factor, he suggests. Eyespot lesions are also easy to find reflecting the variety’s weakness to this stem-based disease (rated 4).

Both David and Jonathan agree Palladium looks useful, a variety that Jonathan describes as a more conventional alternative to its fellow Group 2 variety, Extase, whose French parentage causes it to romp away at pace in early spring. “For its resistance to septoria (rated 7.4) and grain quality, Palladium looks like an easy swop,” he says.

David has a big acreage of Extase in the ground, with his clients favouring the septoria resistance offered by the variety in the more septoria prone region. “Although it takes off in the spring, it then seems to sit there and do nothing –– it’s a bit of a hare and tor toise effect,” he says.

Jonathan feels a little more wary of Extase’s rapid tendencies, pointing out that it’s a variety that when sown early has been caught at the important flowering phase by late frosts in the past.

David also reckons Oxford looks interesting. “It’s from the same stable as Theodore and Champion but without the question mark over specific weight, which has caused farmers in the area to avoid both varieties in spite of the other benefits they may offer,” he says.

Commenting on the septoria showing in the varieties, Jonathan says it’s ver y similar to Long Sutton, with the new leaves not yet showing any sign of infection, which will no doubt be lurking inside the leaf in its latent phase after all the wet weather during the month.

“Varieties aren’t reflecting the septoria resistance rankings in the RL, with the upper three leaves mostly clean at the moment. The degree of septoria currently is due to the leaf architecture and the rate

at which the oldest leaves are dying off,” he says.

Jonathan has analysed weather data at ADAS Rosemaund and found that between 15 October and 15 November in 2022, the temperature was 2-40C above average. “By the end of November we were 100 day degrees ahead of normal, which is equivalent to drilling 10 days earlier.”

Echoeing his original thoughts at Long Sutton on the RL ratings, he believes that this warm period at the backend of last year means resistance ratings (assessed on October sown wheat) should be viewed with this in mind. In effect, this means a mid-October drilled crop’s actual rating this season should be viewed as 0.5 lower than its official rating.

David reckons that this is something that he’d take into account anyway when walking the crop. Gareth agrees, saying that crops with a higher biomass are the ones likely to have higher levels of septoria infection and points out that early nitrogen has made some crops lush.

David’s clients have held off early nitrogen on the whole, even though the gound would have travelled in February. “Very few crops have needed early N. Where fertility is high, we’ve had 50-60kgN/ha sat in the crop’s canopy, so there hasn’t been a rush to get extra on.”

As to whether growers should be concer ned at the septoria low down in the crop, Jonathan says there’s little benefit to be had from fungicides at T0 so he advises them to focus on T1 where yellow rust isn’t a concern.

The Crop Doctor team will be returning on 18/19 April, just before the T1 timing, to bring you the latest disease developments. ■

Septoria is easy to find at Callow, where varieties aren’t currently reflecting their RL rating for septoria resistance.

14 crop production magazine april 2023 Crop Doctor ▲

Cereal disease

Diversity rules but no surprises

The pathogen causing yellow rust has been changing its virulence profiles faster than you can say ‘variety resistance’ of late. CPM was at the UKCPVS stakeholder event last month to find out the status quo between winter wheat varieties and the pathogen in 2022.

By Lucy de la Pasture

By Lucy de la Pasture

Although yellow rust is already making its mark in some crops this spring,there appears to be a calming of the waves, according to the results from last season’s UK Cereal Pathogen Virulence Sur vey (UKCVPS).

But that’s not to say that there’s a narrowing in diversity or that there aren’t virulence changes, there are, but change isn’t happening of the magnitude that caused choppy waters in 2011. That’s when the Warrior race (Pink Group) began to take over the population and some varieties soon broke down to yellow rust in spectacular fashion.

So what’s changed? Since 2017, the Red Group of yellow rust (formerly Warrior minus) has dominated the population and that didn’t change in 2022, according to NIAB’s Amelia Hubbard.

“Of the 24 genotypes we found in

testing, 23 of these were from the Red Group and just one was from the Pink Group. The most common pathotypes we found in 2022 were Red 26 (28%) and Red 24 (20%). Both of these have been around since 2016 and Red 24 was the most common pathotype in 2017.”

The new kids on the block were Red 84, Red 85 and Pink 18 –– all at 4% of the isolates tested. “Pink 18 is of particular interest as it has virulence for Crusoe,” adds Amelia.

The numbers assigned to the Red newcomers is an indication of just how much diversity now exists within this genetic group, which now extends to more than 80 different pathotypes with a large range of virulence profiles.

Achilles heel

As breeders have responded to the increasing threat from yellow rust, genetics has caught up in the race –– the AHDB Recommended List now boasts 18 winter wheat varieties with a yellow rust disease rating of 9. Strong resistance to one disease often comes at the expense of resistance to another and currently it’s brown rust that could prove to be the Achilles heel in some varieties –– with just one having a resistance of 9 and two with a rating of 8.

On the whole, varieties appear to be performing in line with their RL rating for brown rust, according to the newly introduced AHDB watch list and UKCVPS trials. However, one of the varieties rated as an 8 for resistance to the disease, Theodore, stood out in an RL trial in Devon.

Of the 24 genotypes we found in testing,23 of these were from the Red Group and just one was from the Pink Group. ”

The most common pathotypes found in 2022 were Red 26 (28%) and Red 24 (20%). Both of these have been around since 2016 and Red 24 was the most common pathotype in 2017, explains Amelia Hubbard.

“

16 crop production magazine april 2023 ▲

Cereal disease

3%, in addition to relatively high disease levels (up to 10%) in foci, much higher than would be expected for a variety rated as an 8,” notes Amelia.

UKCPVS growth room screening tests conducted in 2022, suggest that the Dorset isolate may be able to unlock a specific resistance (leaf rust, Lr) gene ––Lr24. Brown rust pathogens able to unpick the Lr24 lock haven’t been detected by UKCPVS since 2017. As a result, this solate of interest will be included in adult plant trials to help determine its significance to varieties, she adds.

in over 60 years and the disease has been spotted at different locations in subsequent years.

Although stem rust doesn’t usually come under the UKCVPS remit, two stem rust isolates were tested in 2022 on the full set of recommended and candidate varieties in seedling tests, explains Amelia.

Symptom development photos provide a clear picture of Theodore’s ability to check infection, notes Amelia, with only a slight pustule development which didn’t progress any further for the duration of the trial.

At the site, Theodore had a relatively high level of brown rust (18.8%) with only the notoriously brown rust susceptible variety Crusoe (3) having more disease (25.0%). The RL trial wasn’t the only Theodore anomaly noticed last year, UKCPVS received a brown rust sample from further down the coast in Dorset, ringing a few alar m bells that all may not be as it should.

“The sampler noted infection levels of

In general, Theodore has a reputation for being a strong performer against cereal rusts. In addition to its main ‘adult plant’ yellow rust rating of 9, it also resists yellow rust and brown rust at the young plant stage. The latter is a particular achievement –– being the only variety on the current (RL 2023/24) list to possess this trait. It also appears to resist wheat stem rust.

Although stem rust isn’t the disease that first comes to mind when considering r ust infections, UK conditions have become more conducive to stem rust infection over the past 25 years. In 2013, stem r ust was recorded in UK crops for the first time

RGT Wolverine was also able to limit pustule development, but all the other winter wheat varieties were highly susceptible to the disease in these seedling tests. Amelia concludes by urging growers and agronomists to keep an eye out for stem rust and to send any samples to Prof Diane Saunders at the John Innes Centre for testing in 2023.

A variety mix-up?

Giving an Integrated Pest Management (IPM) perspective at the UKCVPS meeting, Lise Nistrup Jørgensen, from the Agroecology department at Aarhus University in Denmark, examines the

Theodore was the anomaly in 2022,with brown rust overriding the Lr24 gene found in the South West.

▲

Cereal disease

benefits of variety mixtures.

Danish growers are leading the charge when it comes to making use of variety blends as an IPM tool, primarily to reduce fungicide usage and relieve selection pressure on both variety genetics and fungicides.

The eight principles of IPM are set out under EU directive 2009/128/EC, which considers the sustainable use of plant protection products. The first of these principles is to ‘prevent attack’, using IPM measures, such as growing resistant cultivars or mixtures, and using other cultural methods which include delayed sowing, adjusting fertilisation or ensuring a crop rotation which minimize the overall need for pesticides, says Lise.

“Typically, when we compare a mixture in trials, we always take the average of the three components and then we compare that with the output from the mixture to see if there is a benefit or a negative effect.”

Blend concept

The concept behind using a blend has two elements, says Lise. “The mixture should have less disease and that should bring us to a situation where we have less need for fungicide input. Another element of the concept is that we should disr upt selection pressure, both to fungicides and also in pathogen virulence, so that we reduce the risk of developing more virulent (aggressive) strains over time. Using variety mixes can’t solve these problems but it can slow down the selection processes.

“Other benefits could also be that the mixtures are more tolerant to various climate changes, such as having more winter hardiness or drought tolerance. We’ve also seen that variety mixtures can be less likely to lodge because they support one another and this has meant we’re able to reduce plant growth regulator inputs,” she adds.

In 2023, 39% of the winter wheat area in Denmark is sown in variety mixtures, says Lise. “There’s been a steep increase from 25% in 2021, and previous to that there was just 11% in 2020 and 5% in 2019. So there’s been a really major uptake of growing variety mixtures by the farming community, who are, in general, also sowing varieties with good resistance.”

Citing work by Kristoffersen et al, published in 2022, Lise highlights the reduction in septoria in variety mixtures compared with individual cultivars. “The average reduction was 14%, with a 24% reduction in septoria in a four-way variety

mixture under high disease pressure. The more varieties included that are susceptible to septoria, then the benefit is even bigger. The work also indicates that four cultivars is better than two,” she says.

Blends are often considered in the context of septoria reduction but in a 16 trials series, the effect on yellow rust is also notable, with a 30% reduction in disease. “In the trials we had a mix of a susceptible variety with a moderately susceptible and a resistant variety, and there was clearly a benefit. We only had six trials with brown rust and here we saw a 11% reduction in disease incidence.”

While disease reduction is to be welcomed, what’s the effect of growing a blend on yield? The answer very much depends on the disease susceptibilities of the varieties being grown in the mix and the number of fungicide applications applied.

“The smallest benefits are seen where

Chemistry backstop

Defending crops against two key diseases in wheat and barley –– septoria and ramularia, respectively –– isn’t just about having a robust fungicide programme, it’s also about getting the most out of and protecting the products being used.

According to Adama, adding folpet to a fungicide programme can increase valuable efficacy and extend green leaf area.Andrew Bailey,fungicide specialist at the company, highlights this is important because it helps to maintain and get the full value from the fungicide programme,as well as preserving sufficient canopy to intercept solar radiation to translate into yield.

“We’ve done a lot of work looking at the role of multi-sites in prolonging the life of single site chemistry,”he says.“Although there are new single site chemistry coming,resistance management is going to be really important to keep the new products as effective as possible.”

In high-risk scenarios,Andrew favours looking at key timings and starting earlier to get ahead of disease.“In this situation,apply at T0,T1 and T2 as three lots of 1 l/ha gives good results,” he says.

“Moderately susceptible varieties –– rated 5.0-5.9 –– respond well to applications of 1-1.5 l/ha at T1 and T2.Whereas moderately resistant varieties –– rated 6.0-6.9 –– would benefit from 1 l/ha at T1 and T2.Although these varieties have good resistance, this doesn’t remove the septoria epidemic,it just delays it. As a contact protectant,folpet works better

In stem rust,the shredding epidermis is a characteristic of the disease and Theodore is the only variety able to resist infection.

Folpet has also recently been granted approval for ramularia and net blotch in barley,adding to rhynchosporium which was already on its label, says Andrew Bailey.

in a fully protectant situation.”

Folpet has also recently been granted approval for ramularia and net blotch in barley,adding to rhynchosporium which was already on its label, says Andrew.

In winter barley,Andrew’s key message is that T2 is the crucial timing for folpet in any scenario. “Apply 1-1.5 l/h at growth stages 39-49 – the paint brush stage where the awns are just peeping –– as a partner to the other T2 products.

“We’ve seen improved protection against ramularia when folpet is used in a two-spray approach, and in protectant situations. Adama’s data also shows a reduction in net blotch compared with untreated situations,” he adds.

19 crop production magazine april 2023

▲

Cereal disease

varieties with good resistance are grown and several fungicides applied. So to put that into perspective, you won’t see a yield benefit if you just plaster your crops with fungicides,” says Lise.

Slower resistance development

Another finding of interest is that the progress of the CYP51 mutation (confers triazole resistance) in the septoria population is slower in variety mixtures than in the average for the component varieties, she concludes.

milling and soft wheat perspective, as well as feed wheat, in a three year trial series evaluating variety blends for yield, quality, disease and economic return at our site at Sutton Scotney.

“Here, we put together four milling wheat varieties –– KWS Zyatt, Crusoe, Skyfall and RGT Illustrious –– and compared them with the individual varieties grown as a straight,” she says.

According to Lise Jørgensen,there won’t be any yield benefit from growing a variety mixture if the crop is “plastered with fungicide”.

NIAB’s Dr Aoife O’Driscoll also touched on blends, referencing work being carried out in NIAB membership trials. “Lise mentioned the variety mixtures work that they’re looking at in Denmark, and how a lot of that work is based around feed wheat. So, we decided to look at it from a

The trial included three fungicide programmes; an untreated, a reduced rate fungicide programme of a third dose of Revystar XE (fluxapyroxad+ mefentrifluconazole) at T1 and Univoq (fenpicoxamid + prothioconazole) at T2 respectively, and a full fungicide programme based on a typical farm standard programme (tebuconazole at T0, Revystar XE at T1, Univoq at T2 and tebuconazole at T3), she notes.

“One of the many conclusions from the trial, was that under moderate to high yellow rust pressure, you can manage a variety like KWS Zyatt using a well-timed fungicide programme, but you could also manage it by growing it in a blend to create a barrier and dilution effect, helping to reduce inoculum, delay an epidemic and get the best use out of fungicides in that crop.

“The message we’re trying to get across with variety blends for disease control is that it’s not one management strategy over the other. It’s about using all the tools available to you in an integrated programme.” ■

Disease can be managed by using a blend of varieties so that fungicide inputs and selection pressures can be reduced.

▲

Real Results

Pioneers

On-farm reality

impetus for the launch of Real Results trials the following season, explains Steve Dennis, BASF’s head of business development.

“Growers were feeling a little jaundiced about small plot trials,” he recalls. “They are, and remain, the gold standard of testing products, but using the ADAS Agronomics system we could start doing farm-scale trials with growers without compromising the trial’s technical validity and statistical power.

“It was the first time we had the opportunity for farmers to do technically valid comparisons on farm.”

By Mike Abram

Back in 2016, it was a challenge by a Staffordshire grower to BASF’s claim that its SDHI fungicide programme would provide a £20/ha benefit over existing standards that provided the catalyst for the firm’s now long-running Real Results Circle

He was deeply sceptical and decided to do his own on-farm trial to compare BASF’s Adexar (fluxapyroxad+ epoxiconazole) followed by Librax (fluxapyroxad+ metconazole) with a programme using Aviator (bixafen+ prothioconazole) and his own farm standard, carried out using three 4ha blocks in a 25ha field.

It was the demonstration of the effectiveness of larger-scale on-farm trials that appealed to BASF and provided the

Technically robust

The main criterion for growers joining the initiative was as simple as wanting to take part, says Steve. “We wanted people who had bought into the principle because there was going to be some inconvenience involved with changing applications, meeting BASF or ADAS staff, and providing the data. They needed to be innovative and open-minded.”

Access to yield monitoring was also important as it allowed ADAS to run the full power of its Agronomics data analysis on a trial. “Every data point is used to do the statistical analysis.”

That’s important as it brings technical validity to the trials, he stresses. “Doing these trials might seem like a half field comparison with something else, but it’s technically robust.”

Each field is selected by the grower with help from ADAS to minimise background

variation using satellite imagery, and then monitored in season to give a view on disease development. Advice is given to mitigate tramline edge effects, while the full yield analysis gives statistical confidence.

“That’s part of the reason why the term Real Results was used. It’s not just real farms in real scenarios, it’s also real in terms of the analysis being robust.”

Around 50 farmers took part in those first Real Results trials in 2017 to compare the Adexar followed by Librax programme with their farm standard treatment. From 2019, it was BASF’s new Revystar ▲

Using the ADAS Agronomics system made it possible to carr y out farm-scale trials with growers without compromising the trial’s technical validity and statistical power,says Steve Dennis.

Ahead of a seventh season of Real Results, CPM looks back at how the circle of growers was formed and how the on farm trials have provided insights to fungicide use,aiding decision making in real-life scenarios.

21 crop production magazine april 2023

It’s not just real farms in real scenarios,it’s also real in terms of the analysis being robust ”

“

Real Results Pioneers

products in a ‘which fungicide’ series,” she says.

“That means there have been around 70 unique fungicide programmes employed by growers in 85 trials since 2020, so there is no large dataset comparing Revystar with another product.”

Discussion with the grower group has also helped formulate different objectives for the trials in each year.

site fungicides, used biostimulants or increased the rate of Revystar,” she explains.

That season appeared to be a low septoria pressure season around the spray application timings, resulting in lots of discussion about rates and use of fungicides, she recalls, but wet weather after T2 meant septoria quickly developed.

(mefentrifluconazole+ fluxapyroxad) that took centre stage, initially under an experimental permit before its commercial launch in 2020.

In total, 82 farmers have conducted 224 yielded trials since 2017, with 131 of them trialling Revystar, says Alice Johnston, grower community manager for BASF.

“The main thrust of the programme is to help growers learn how to get the best from the technology rather than directly compare

“For example, in 2021 we challenged the Real Results Circle to maximise productivity in wheat by building on a Revystar programme. In one programme they applied the standard BASF two-spray programme of 0.75 l/ha of Revystar at T1, followed by 1 l/ha of Revystar at T2.

“In the other treatment they took the same Revystar approach but were invited to add additional inputs they felt would increase yield –– an Agronomy Max treatment. Some chose to increase nitrogen or use more trace elements, others added strobilurin or multi-

Real decisions from two of the grower circle

On-farm trials are part of the fabric of Stody Estate in North Norfolk under farm manager Mike Wilton’s guidance.Whether it’s trialling different drills or trying to improve nitrogen use efficiency to the more typical fungicide and variety tests, there’s a desire to try new technologies or approaches,he explains.

“I like to keep in touch with new technology and have a look,if possible,before it becomes commercially available so I can make use of it in the most appropriate way when it’s launched.”

That was the case with Revystar,which he trialled as a member of the Real Results Circle. “When BASF first asked us to trial Revystar,I didn’t think they were using it at high enough rates, so we ran our own trial comparing 1.0 l/ha with 1.25 l/ha and it gave me the confidence to use it at the lower rate,”he says.

“While disease pressure was low, we didn’t see a significant uplift in yield.It wouldn’t stop me using robust rates when the disease pressure is higher, but I think it also started me thinking about loading actives,so you don’t expose one active majorly to a disease.”

He’s likely to use a combination of different actives in the coming season,he says,with rates and product choice dependent on the season rather than commodity or input prices.

“Fungicide programmes should be appropriate to what’s happening in the field,not world markets,” he explains.“You could argue in a low-price year,where a loss of yield could tip you from profit to loss,protecting your investment by the appropriate use of fungicides is more

important than when prices are higher and the risk of loss is lower.”

He considers T1 to be the most important spray of the programme.“It’s very hard to save money at T1 because you have a short plant and more unsettled weather –– ideal for disease development. If you can keep inoculum low at T1, then T2 has less to do and the opportunity to pare back and save money becomes easier.”

Current planning has either Revystar or Ascra (bixafen+ fluopyram+ prothioconazole) at T1, depending on variety,with Univoq (fenpicoxamid+ prothioconazole) as the likely choice at T2. All three have performed well in trials and commercially on farm,he says.

Being part of Real Results is about assessing whether the farm standard programme is passing muster as well as gathering information about BASF products and advice, says Russ McKenzie,who manages 140ha at Howson’s Lodge near Huntingdon,as well as providing consultancy advice.

“While we’ve sometimes seen yield slightly in favour of the Revystar programme,depending on variety profile, there’s usually not a huge amount between the two.It’s encouraging that what we’re doing on farm isn’t too far out.”

Having the trials on the farm is helpful to clear the fog between advertising,marketing and trials data,he adds.“It gives you confidence to pick the best or more appropriate product for your situation.”

The farm is trying to move away from more disease susceptible varieties,especially with lower

Of the 16 growers who engaged in the Agronomy Max trials, the average additional yield was just 0.1t/ha. “The optimum approach, however, was seen by the seven growers who used additional Revystar, with an average dose increase of 0.4 l/ha resulting in an average yield uplift of 0.25t/ha.

“Two of the three largest yield responses were achieved by growers who increased the Revystar rate.”

Last year, 11 group members investigated the best order to sequence innovative new chemistry, Revystar and Univoq (fenpicoxamid+ prothioconazole),

septoria ratings.However,where those varieties ––such as LG Skyscraper –– are still grown,he’s found Revystar to be a good fit commercially at T1, while it makes more sense on cleaner varieties at T2,he suggests.

“It’s also a welcome addition on barley. While we haven’t seen much of a problem with ramularia,it does give an option for boosting control at the later timing.”

With grain prices currently on a downward trend and pre-bought fertiliser at higher prices,the season is shaping up to be challenging,adds Russ.“Fungicide prices have gone up quite significantly,but you still have to look at it in terms of the yield response required to pay for a fungicide programme.

“It means we’ll have to look at different products in different situations based on the budget,”he concludes.

22 crop production magazine april 2023

Having the trials on the farm is helpful to clear the fog between advertising,marketing and trials data, says Russ McKenzie.

In Real Results on-farm trials,advice is given to mitigate tramline edge effects,while the full yield analysis gives statistical confidence.

▲

Real Results Pioneers

The case for small plot trials

While on-farm trials are extremely useful for providing real world evidence and experience, there’s some research that remains easier and more practical to do using small plot trials, highlights Steve.

One example is work BASF has conducted looking at the interaction between nitrogen and fungicide use,which has become especially relevant given the higher prices of both inputs.

“I think most growers would assume that if you reduce your nitrogen dose,the need for a fungicide like Revystar would decrease as you would decrease biomass and there would be less disease to control.

“But in our trials in 2022,under low to

comparing 0.75 l/ha of Revystar at T1 followed by 1.25 l/ha of Univoq at T2, with 1.0 l/ha of Univoq at T1 and 1.0 l/ha of Revystar at T2.

“In another protectant year, there was no difference in yield between the two approaches,” reports Alice. “Both programmes gave exactly the same average yield after Agronomics analysis of 12.3t/ha.

“That should give growers confidence that Revystar provides a comprehensive approach to disease control at either timing, regardless of disease pressure, and a flexible approach to managing workload on farm.”

This year’s trials are partly aimed at understanding how to manage disease pressure in early drilled crops. “A number of crops were drilled earlier than usual last autumn –– up to three weeks in some cases,” says Alice. “Understanding the implications of early drilling for increased septoria risk and effective management using fungicides with curative ability, where required, will be a key consideration for spring 2023.”

Overall, the four years of Revystar trials have confirmed what growers using the product commercially have seen –– its consistency, flexibility and reliability, says Steve.

“Growers are understanding the product and trusting it, now they can see the flexibility in use at both T1 and T2. It’s giving us the performance we were achieving from the previous generations of products used with a multi-site.

“It’s accepted that it’s the most curative product for septoria in the market,” he claims. “That gives growers a lot of flexibility in terms of timing.”

However, timing fungicides correctly can

moderate disease pressure that wasn’t the case. Our trials showed whatever dose of nitrogen you were putting on,you were getting the same return on investment from Revystar treatments –– altering your nitrogen dose did not alter your requirement for Revystar.

“With nitrogen,the return drops as you use more nitrogen,so each kilo is worth less than the kilo before.

“But with Revystar,you’re actually getting a bigger return on investment proportionally as you increase the rate from 0.75 to 1.0 l/ha than you do going up to 0.75 l/ha.So anyone thinking of trimming their rate of Revystar from 1.0 l/ha to 0.75 l/ha,that’s the bit

be challenging, he points out. “We did some research in 2021 with NIAB that showed it typically takes two weeks from the first flag leaf in a field to fully emerge to the last one.

“In that situation, when is the perfect time to spray? If you wait for all the flag leaves to emerge, the first ones will have been out for quite some time, which means you’d have to rely on some curative activity

“But equally, if you go earlier, before all of your flag leaves are out, then you’ll require higher levels of performance on leaf two. That’s because you have to make sure you’re reducing possible infection of the flag leaf from lesions on leaf two, so the chances are you’ll need curative activity in that situation as well,” he explains.

“Growers tend to think early means protect and late means curative but actually, because you’re managing leaf layers, it doesn’t mean that. Revystar is enabling

The Real Results Circle

BASF’s Real Results Circle farmer-led trials are now in their sixth year The initiative is focused on working with more than 50 farmers to conduct field-scale trials on their own farms using their own kit and management systems. The trials are all assessed using ADAS’ Agronomics tool which delivers statistical confidence to tramline,or field-wide treatment comparisons –– an important part of Real Results.

In a continuation of this series we follow the journey, thinking and results from farmers involved in the programme.The features also look at

you’re actually getting the biggest return on investment from.

“Going above that rate,you still get additional return but the rate at which the return accelerates starts to flatten off,”he explains.

In contrast,extra nitrogen does start to drive disease pressure when conditions are conducive to septoria development.So in a high disease pressure season,you do need more fungicide as you apply more nitrogen,he adds.

“It’s a complex story and the sort of thing you can only find out from replicated small-plot trials,so this is clearly the sort of gold star research we need to continue to do alongside the Real Results research.”

growers at T2 to have more flexibility around their T2 application timing, and the story is the same at T1 because you’ve still got a period for all your leaf threes to emerge,” he concludes. ■

some other related topics,such as environmental stewardship and return on investment.

We want farmers to share their knowledge and conduct on-farm trials.By coming together to face challenges as one, we can find out what really works and shape the future of UK agriculture.

To keep in touch with the progress of these growers and the trials,go to www.basfrealresults.co.uk or scan the QR code.

23 crop production magazine april 2023

Yield monitoring allows ADAS to run the full power of its Agronomics data analysis on a trial so that ever y data point is used to do the statistical analysis.

An eye on visible and subtle threats

is required to reduce the risk of any exceedances of limits for these in UK grain.

Since the mid-1980s the HGCA, which evolved into AHDB Cereals and Oilseeds, has been funding collaborative work with industry partners to determine levels of contaminants found in the main UK cereal crops.

As well as wheat, barley, and oats for human and animal consumption, testing extends to include by-products, such as wheat bran and oat hulls which are used in livestock rations.

In-depth testing

Its current phase, which started in 2016 and is due to end in August 2023, has seen AHDB collaborating with UK Flour Millers, the Maltsters Association of Great Britain (MAGB), the British Oats and Barley Millers’ Association (BOBMA) and Agricultural Industries Confederation (AIC), which represents British feed mills.

AHDB’s Dhan Bhandari says that the long-term project is largely driven by the limited amount of testing that’s carried out on farm.

Monitoring pesticide residues is also important for food safety standards, with the presence of more than 400 compounds being screened for, along with heavy metals

Worrying exceedances of key contaminants are rarely found in UK cereals before they’re sent for processing,which is a testament to the competence of growers who deliver wheat, barley,and oats for food and feed each year.

Although the bigger picture is positive, there are contaminants highlighted on the ‘watch list’, including ergot alkaloids and chlorpropham (CIPC) residues, and action

Growers monitor grain moisture and some quality characteristics, using the dipstick method to test grain for mycotoxins like DON and ZON. However, it’s grain processors that carry out more thorough testing for the presence of DON, ZON and their derivatives, T-2, and HT-2 toxins, and ochratoxin A, along with the presence of ergot sclerotia.

There are also masked versions of some mycotoxins that are only detectable once grain is ingested, so it requires specialist methodology to find them in raw materials ahead of entry into the food and feed chains.

Contaminants ver y rarely exceed the legal limits and it’s seasonal for some, such as mycotoxins caused by fusarium, says Dhan Bhandari.

“

We find that contaminants very rarely exceed the legal limits and it’s seasonal for some,like mycotoxins caused by fusarium.

”

Monitoring contaminants is vital to ensure UK cereals and their by-products are safe and produced to a high standard. CPM looks at trends from a much-valued monitoring project and what it can tell us about the cereal supply chain.

By Adam Clarke

24 crop production magazine april 2023

Theory to Field

like mercury, cadmium, arsenic, copper, and more recently, nickel, explains Dhan.

“Another is acrylamide, which can occur in cereals after the roasting process. All the testing for these substances is very expensive and a lot for individual companies to undertake alone,” he says.

This is where the project steps in, co-ordinating commercial intake samples that reflect what’s happening in fields or grain stores. In the past, testing has been carried out by Campden BRI, but Fera has taken on the contract through the most recent round of funding.

If exceedances of maximum limits (MLs) of mycotoxins, or maximum residue limits (MRLs) of substances like pesticides occur, Fera feeds back to the relevant body so industry is aware of an issue and can investigate, explains Dhan.

“When a sample is at its maximum level, it isn’t necessarily non-compliant as there’s some leeway which accounts for uncertainty of measurement around the result.

“However, if it’s confirmed as over the legal limit then the industry is in a good place to take action, stopping production if needs be, and investigate how a sample made it through the supply chain in the first place.”

Dhan adds that one of the main advantages of working collaboratively with the various independent bodies is the aggregation and sharing of data across industry, which is discussed at an annual meeting of stakeholders and published online.

Ergot alkaloids

“Generally, we find that contaminants very rarely exceed the legal limits and it’s seasonal for some, like mycotoxins caused by fusarium. In the past couple of years, ergot has been in the news, with elevated levels appearing in grain. This project has been instrumental in picking that up, with samples tested for 12 ergot alkaloids by a specialist lab, like Fera,” explains Dhan.

It’s one of only two accredited labs able to test for ergot alkaloids. Undertaking the process requires the facility to hold a Home Office license, permitting it to hold reference alkaloids that could be used in the synthesis of class A drug, LSD.

Leading the project’s testing efforts at Fera is Susan McDonald, with various teams at its York facility looking for mycotoxins, pesticide, and heavy metal residues in some 400 grain or grain by-product samples each year.

A balanced approach to contaminants

The AHDB-funded contaminants monitoring work has been invaluable in ensuring maximum limits on mycotoxins,such as ergot alkaloids, are achievable.

That’s the view of UK Flour Millers’ Technical Manager Joe Brennan,who adds that it contributes to an evidence-based approach to setting limits,ensuring consumer protection without significantly disrupting the supply of home-grown cereals.

He points out that when the European Commission (EC) consulted on setting MLs for ergot alkaloids,which could potentially be adopted in the UK*,the originally proposed level would have meant just under 500,000t of UK wheat would lose access to the milling market in a typical year.

With the independent data gathered by Fera’s monitoring of ergot alkaloids part of the collaborative project on contaminants,UKFM were able to make a firm case for increasing the limit to maintain a stable supply while still removing the most contaminated grain from the food market.

The Commission increased the limit to a level where only 150,000t of wheat would lose access to the market.While still a significant quantity,it’s

much more manageable for the supply chain, he says.

Joe hopes the dataset,which tests for a wide range of contaminants in each sample concurrently rather than in isolation,as in most European programmes, will help improve the limit setting process post-Brexit.

The EC sets its limits based on the 95th percentile theory, which looks at data for DON in milling wheat, for example, and sets a limit that removes 5% of the worst contaminated samples from the food chain.

“In theory, it’s a sensible approach that recognises DON isn’t wanted in cereals,but there’s also the requirement for continuity of supply.

“However, we find that the highest 5% of wheat samples for DON are not the same 5% of samples highest for ZON, or ergot alkaloids or other mycotoxins, so you get a cumulative effect of all these limits.

“In a bad season, you might end up restricting 10-20% of cereals from the food market, which could mean significant supply disruption and food waste,”explains Joe.

He hopes UK regulator, the Food Standards Agency (FSA),will set limits based on concurrent occurrence that is recorded in the UK dataset.

The project acts as eyes and ears for future contaminants that could become an issue, says Julian South.

Susan says there are rarely notable issues with well-known mycotoxins like DON and ZON and last year, the substances were at among the lowest level ever seen in testing due to the hot and dry weather. This is the converse to some of the 12 ergot alkaloids, which have been high in recent seasons.

After Brexit, the EU introduced a

▲

“The EU approach can result in quite a serious disruption to supply when conditions are against growers,so I hope we take a different approach.”

For Julian South,executive director at MAGB, the monitoring complements the due diligence already put in place by company members processing malting barley and provides a baseline survey of contaminants across the national crop.

Fera’s ISO17025 accreditation means the data is highly credible and its scientists can collate,interpret,and put meaning to the data from intake samples.

“Another benefit of the project is that Fera can tell us where we might need to move our analysis,acting as eyes and ears for future contaminants that could become an issue, because its remit stretches beyond grain,” says Julian.

“It’s an important project which we hope continues beyond its current round of funding,” he concludes.

*Note:The new EU limits for ergot sclerotia and alkaloids,which applied from 1 January 2022,are not in GB-retained EU law,but do apply to NI.

25 crop production magazine april 2023

Theory to Field

“But it does show the importance of the monitoring process and that industry is doing all it can to make sure UK grain quality is good,” she adds.

Dhan says there are a few reasons behind the high alkaloid levels, one of which is the increasing trend towards establishing mixed species margins around cereal fields. Ergot can infect grasses within these margins and act as a source of inoculum for surrounding crops at flowering, when they are most susceptible to infection, he explains.

Although ergot has been in the news lately due to elevated levels appearing in grain,it’s unlikely to cause ergotism and symptoms like hallucination.

regulation that lists the 12 ergot alkaloids and sets a ML based on the sum of all alkaloids found in each sample analysed. Fera follows the same protocol and the chemical test for them requires the sample to be milled much finer than for other substances, because if fragments of ergot sclerotia are not ground down and evenly distributed through the sample, results can be skewed, she explains.

Samples are then analysed by liquid chromatography-mass spectrometry (LC-MS), which separates compounds using organic solvents, then mass spectrometry is used to measure compounds based on molecular mass.

“When we started testing for alkaloids, we had high levels in the first year, then they seemed to drop again. However, in the past two years they’re right back up, particularly in milling wheat,” says Susan.

She adds that it’s not a huge concern, with the elevated levels extremely unlikely to cause ergotism, where consumers of tainted products can hallucinate.

Similarly, the proliferation of grassweeds within crop rotations is also providing a willing host for ergot, which helps the fungus to continue its lifecycle in cereals. Rather than being buried with a plough, reduced tillage or direct drilling is leaving sclerotia exposed on the soil surface, posing a greater risk to following crops.

Adapting management

“After sclerotia are produced in the ear of wheat, barley, or rye, and fall to the ground in the autumn, it’s temperature and moisture the following spring that will influence germination and release of spores that infect surrounding crops, so climate change could also be a factor,” suggests Dhan.

With policy taking farming down the path of more field margins and less tillage, improving risk assessments and adapting management is an immediate priority, he believes.

Dhan suggests one means of reducing risk could be mowing field margins before the grasses come into flower, reducing the amount of sclerotia returning to the soil as a source of inoculum. Using clean, certified seed also minimises risk, and where using home-saved seed it should be cleaned.

Later, at harvest, there’s potential to cut out risky areas first, reducing overall contamination in the bulk of the crop.

“It should be noted that cleaning is only effective to a point but if you overdo it, then sclerotia can be broken into much smaller fragments and are impossible to separate from grain,” explains Dhan.

He adds that diagnostics companies are developing a rapid test for ergot alkaloids, which could help growers identify problem grain stocks, but these are some way from commercial launch.

“AHDB has a useful factsheet on the management of ergot, which is a good resource,” says Dhan.

Away from mycotoxins, the project also closely monitors pesticide residues and although compounds are regularly found, they are generally below the MRL. Susan believes this underlines the good

practice in the UK when using plant protection products.

Put into context, throughout the duration of the current project, several thousand samples have been processed to look for residue of up to 400 pesticides, and just half a dozen have exceeded legal limits.

However, one notable compound that has been showing up is potato sprout suppressant chlorpropham (CIPC). Prior to its withdrawal in 2019, potato stores were routinely fogged with CIPC which impregnated the fabric of buildings, particularly concrete, and is almost impossible to remove.

“Studies have shown cleaning to only be partially effective because the chemical persists for many years,” says Dhan.

As the sprout suppressant is banned, its MRL is now limit of detection (LOD), so the advice is that if a store has ever been used to store potatoes, don’t put grain in it.

“Where that’s unavoidable, sampling and testing grain that might be at risk of contamination can help identify problems that could end up in rejected grains,” he concludes. ■

Research roundup

From Theory to Field is part of AHDB’s delivery of knowledge exchange on grower-funded research projects. CPM would like to thank AHDB for its support and in providing privileged access to staff and others involved in helping put these articles together.

For further info:

AHDB Project 21130040:Monitoring of contaminants in UK cereals used for processing food and animal feed (2016-22) is led by FERA,alongside industry partners UKFM, AIC, BOBMA and MAGB. Total AHDB sector cost for the project is £813,368.

26 crop production magazine april 2023

Monitoring pesticide residues is important for food safety standards,with more than 400 compounds being tested for.

A compound being detected annually during contaminant testing is the now-withdrawn potato sprout suppressant,CIPC.

▲

Finesse through fine-tuning

Forward-thinking farmers

A leaf sampling service is supporting Herefordshire farmer,Mark Wood,to live by his mantra of only treating a crop with what it needs.CPM unpicks the challenges this is helping to tackle.

By Janine Adamson

Sitting in the farm office on a rather bleak spring day with further snow forecast, you wouldn’t blame Mark Wood if he felt a little blue about the season ahead. Yet as he proudly shares home-reared bacon sandwiches,it’s his pragmatism that shines through.

“We don’t have a perfect scenario here so it’s important to be realistic,” he explains. “We farm by making the most of the soils and land that we have to try and overcome the weather extremes we experience. It’s highly variable at times and a sandy loam is quite unfor giving of that. Being efficient is essential.”

Thanks to Mark’s considered approach, Peter Clay Far ms is evolving. Centred around 1400ha of combinable crops, grassland and contract potatoes, a new far m shop and café is on the horizon.

“We’ve had to diversify to add value following the conclusion of our contract with a retailer. I don’t like putting a label on things, but it’s far ming smar ter. We run our pigs in woodland and graze the sheep in awkward areas of the farm. We were already going to far mers’ markets and selling direct to restaurants, it felt a natural next step,” he explains.

It’s clear that farm manager Mark isn’t afraid to try something new to achieve the best out of a situation. He’s even included triticale in this year’s rotation on lighter land, for inclusion in wild bird seed mixes.

Soil management

However, being located in south-east Herefordshire within the catchment of the phosphate-polluted River Wye means effective soil management is a priority Early drilling dates are a must due to the Environment Agency’s concerns about run-off, but thankfully his mantra is to only do what a field requires, be it cultivation, disease management or nutrition.

This makes Mark the ideal candidate for Bayer’s CropCheck –– a qPCR leaf sampling service. “Septoria is the only disease that grabs my attention, laughs” Mark. “Although we don’t have a blackgrass problem, pitfalls remain. For us, that’s overcoming septoria,” says Mark.