Keaton Cox Designer

(206)-660-7461

Skill set

Personal Professional

Organized Leader Goal-Oriented Passionate Hard-Working

Work Experience

Adobe Suite Revit Rhinocerous Sketching Problem Solving

Keaton.cox@wsu.edu 3521 210th PL SE Bothell, WA 98021

Education

Accomplishments

Leadership

Community Service

I am currently enrolled in the Washington State University Master of Architecture program. I am a young hard working architectural designer with experience in the professional design industry. Throughout my education and experience, I am confident that I have developed the skill sets needed to be a great employee.

Caron Architecture July 5th-August 15th 2022

Alexa’s Cafe & Catering 2016-Present

Washington State University

Located in Bothell, Washington, this job has helped me develop my communication skills.

Achieved AXP hours in practice management, programming & analysis, and project planning & design. Enrolled in One-Year Accelerated M.Arch Program - Graduating May 2023 Washington State University Pullman, WA

Bothell High School Graduated 2018 - 3.9 GPA - Honor Society

B.S. Architectural Studies - 3.76 GPA - Honor Roll Bothell, WA

Pullman, WA

2019-Present Dean’s List

2014-2018 Honor Society

2019-2020 Architecture Class of 58 Scholarship 2018 Track & Field 4A State Champion

Delta Sigma Phi 2018-2019 Vice President of Recruitment

Palouse Stream Clean Hopelink

Maltby Foodbank Jubliee Thrift Shop

VFW-Redmond

Planted trees and picked up garbage. Collected non-perishable food items. Stocked shelves and did other needed tasks.

Organized furniture and cleaned up the shop. Did yard work to clean up VFW’s surroundings.

Selected Work

The Hangar HydroWall

The Commons K.W. Hall Handmade Models

Beneath Unity

Location: Post Falls, Idaho

Project Type: Adaptive Reuse

Academic Year: Graduate Area: 250,000 SF

Software Used: Rhino, Revit, Lumion

Group Members: Lorenzo Carbone, Camree Kunze

For this project, the programs on the site will relate to what the Idaho Veneer Company was managing in terms of their closed-loop system and how they provided jobs for people that lived in Post Falls. Furthermore, the programs will relate to three community values that stood out during the site analysis which are to support water conservation, promote natural systems, and enable residents to live and work in Post Falls. Through these three values, the closed-loop systems of water, agriculture, and the local economy instantly came to mind, not only because they related to the community values, but they can all relate to one another. The program is strategically placed to coordinate the interaction from all closed-loop systems within the building and the overall site plan. They are positioned so the process of the system can function more efficiently, just like the veneer company.

Step 1: Identify surrounding influences. Remove existing shell.

Step 2: Keep existing structure.

Step 3: Add ETFE roof to unify existing buildings.

Step 4: Add residential. High density on the north and low density south.

A

A B

Connection of ETFE roof to wall assembly.

B C C

Daylighting analysis. Two layer ETFE with fritting and rain suppression.

High summer sun and low winter sun into the living building machine.

Three stages of the operable panel system.

Daylighting analysis. Rainwater runoff from the roof structure.

ETFE roof structure modularity in the plaza.

Pump system for water filtration.

Ground Floor of Existing Building

Greenhouse Render

Ground Floor of Existing Building

Greenhouse Render

Main Entry

The Hangar

Location: Seattle, WA

Project Type: Mixed-Use

Academic Year: 4th Area: 100,000 SF

Software Used: Rhino, Revit, Lumion

Group Members: Jill Carlson, Will Danielson, Anne Speight

Virtual Tour:

The Hangar is a place for learning. The first floor provides a showcase experience for the community and visitors of South Lake Union to learn about the history of SLU, Vulcan’s impact on surrounding area, and the work that is being produced in the incubator spaces above.

The Hangar is a place for collaboration. Our first and second floors provide a variety of shared workspaces for the community to interact in and learn from one another.

The Hangar is a place for innovation. A community maker space, located on South end of the first floor, encourages innovation and interaction as it opens to the street scape and invites people passing by into the experience through large bi-folding hangar doors.

Step 1: Maximize building mass on site. Step 2: Uniting two intersecting masses.

Step 3: Creating exterior spaces at the SW and NE corners. Step 4: Incorporating a notch to maximize views.

Step 5: Blurring the street scape and following roof setbacks.

Step 6: Final building mass with shading devices and terracing.

East Elevation South Elevation

Southeast View Northwest View Northeast View Southwest View

East Elevation South Elevation

Southeast View Northwest View Northeast View Southwest View

Southeast View

Building for Control Model

HydroWall

Location: Yakima, WA

Project Type: Visitor Center

Academic Year: Graduate Area: 1,400 SF

Software Used: Rhino, Revit, Lumion

Group

Trombe Walls only work in specific latitudes and climates. Most precedents for these walls are in desert climates. By changing the thermal mass and adding a piping system, we are predicting to expand the range of efficacy. A secondary pipe system will be placed into the ground to act as cooling system. Furthermore, by replacing concrete/masonry material with water, it will lower both the costs and the environmental impact.

Members: Theo Clarke, Jake McCornackTrombe Wall for Baseline Waterwall for Proposed

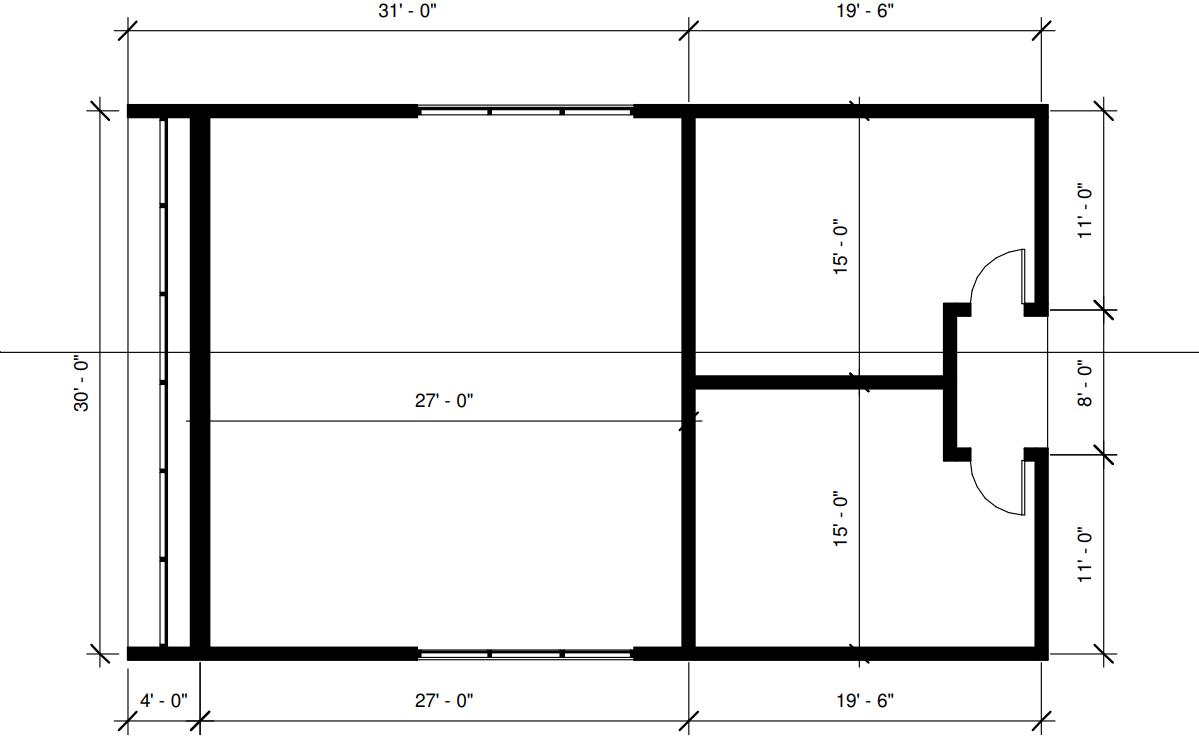

Proposed Floor Plan

Low Winter Sun

The plan and sections located on the left of this page are demonstrating how our models will be implemented into an actual design. This is a standard design for a trombe wall system. We are including a slanted roof so only the low winter sun can get into the interior. Trombe walls only heat up the room directly behind it, so we are proposing to have a piping system that expands the whole floor for the purpose of a bigger impact through design.

Insulation

Wood Shell Glass Concrete Wall Concrete Floor

Acrylic Water Tank

Plastic Water Pump

Insulation Wood Shell Glass Concrete Floor

Wood Floor Frame

The exploded axon diagrams above are demonstrating how the control and experimental models will be constructed before testing. As you can see, the control has a solid concrete wall to symbolize the trombe wall system, while the experimental has an acrylic water casing that will contain the water within it. The main difference in the plan view is the piping system that is implemented into the floor for the experimental model.

Testing Results: 8 Days Testing Results: Optimal Results

Testing Results: Pump On Testing Results: Pump Off

The main things to point out from these graphs are one, the waterwall was able to retain more heat from the sun and was able to distribute the hot water through the piping system to the back room of the model. This ultimately caused the back room of the experimental to be hotter than the back room of the controlled. Two, when the pump was on for the experimental, you were able to see a temperature increase in the back room from when the pump was off. Finally, even though the trombe wall turned out to be an effective passive heating strategy, the proposed waterwall system was able to produce better results.

This building will offer multi-family housing for families, studio apartments for young professionals, an assisted living facility for seniors, and common commercial and outdoor courtyard space for the community. Our intergenerational housing complex will offer safe and affordable living while encouraging a connection between residents and the surrounding community. This project will provide studio, one-bedroom, and two-bedroom apartments for residents, as well as connecting activity space, communal garden, study lounges, communal kitchens, and a spa/salon.

Massing Progression

Massing Progression

West Elevation Render

K.W. Hall

Location: Pullman, WA

Project Type: Lecture Hall

Academic Year: 4th Area: 34,000 SF

Software Used: Rhino, Revit, Lumion

Group Member: Will Danielson

Our project is focusing on the connection between art and science. While working with this connection, we concluded that art and science are connected because they are forever changing. Furthermore, architecture could incorporate this connection between art and science by having the art being the expressive, more experimental portion of our design and having the science being the purposeful portion. K.W. Hall will serve the purposes of leisure, knowledge, and relaxation, all while connecting itself to this idea of art and science.

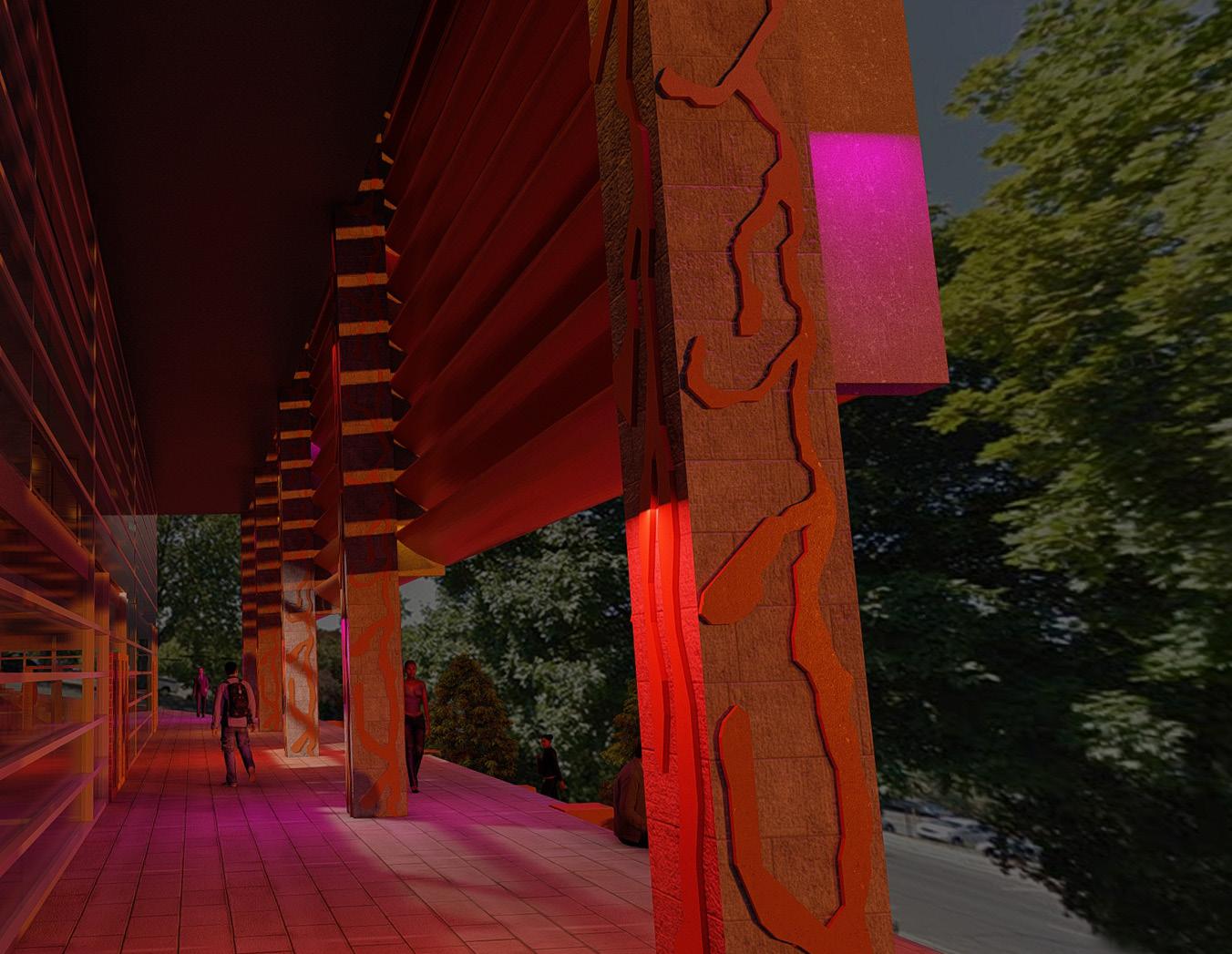

West Entrance at Night

Structure Diagram

Handmade Models

Years: 2nd and 4th

These handmade models are showing how my variety of project types got reflected into 3D physical form. Attached to each model are some hand drawn and digital parti diagrams. Each model was constructed with white chipboard at 1/16” scale and perfectly cut with a box cutter and glued into place. Although handmade models are starting to become more uncommon in architecture, I find it a great way for me to showcase the intended look of my buildings.

Academic

Academic

Keaton Cox Cell: 206-660-7461 Email: Keaton.cox@wsu.edu