I strive to amplify the inherent harmony between nature and the built environment, recognizing humanity as an integral participant in enhancing available resources. My approach to architecture is holistic, guided by a philosophy where co-creation and thoughtful development shape meaningful spaces.

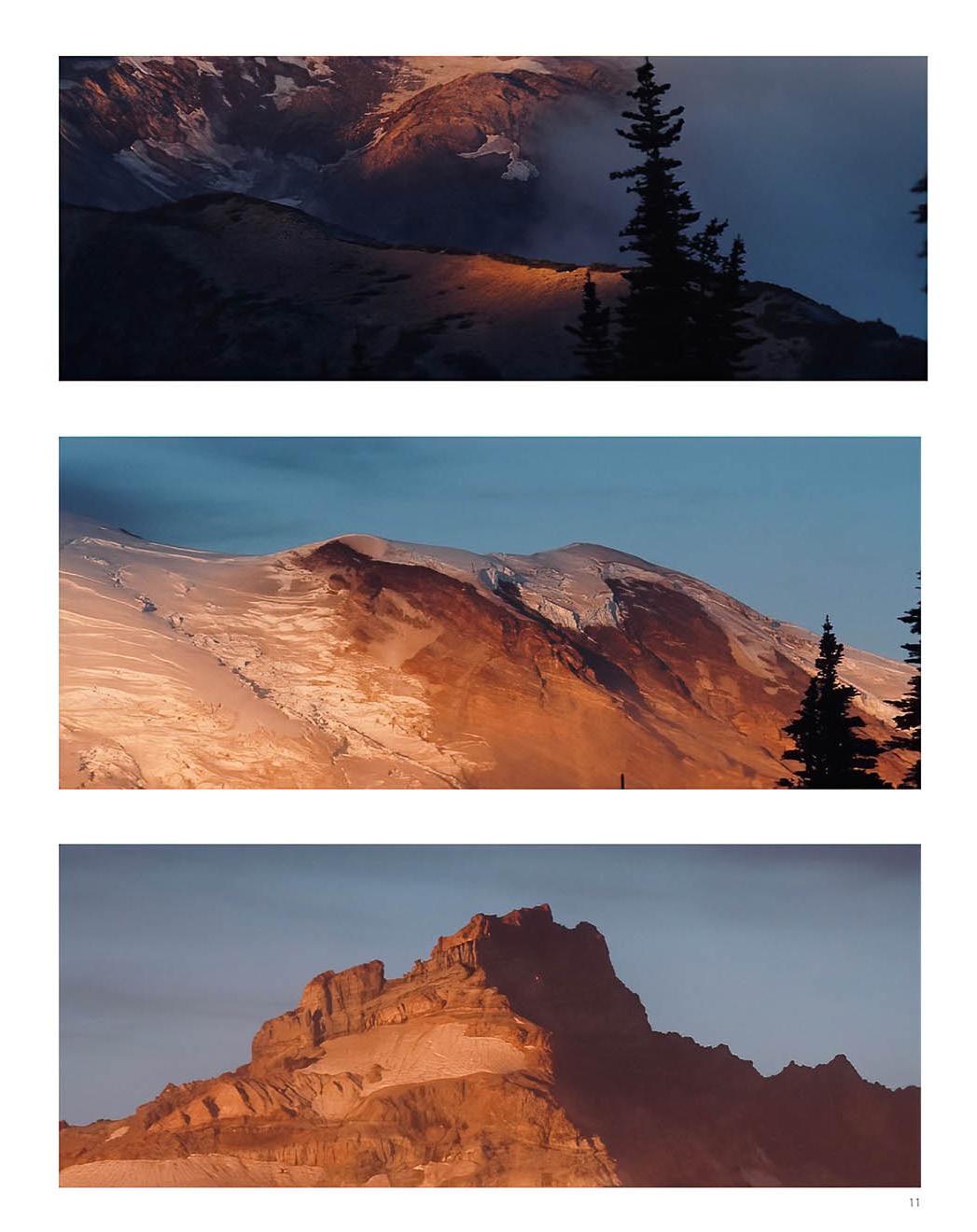

Seattle, Washington

Responsible Poductive Environments

Puntarenas, Costa Rica

San Jose, Costa Rica

Snoqualmie, WA

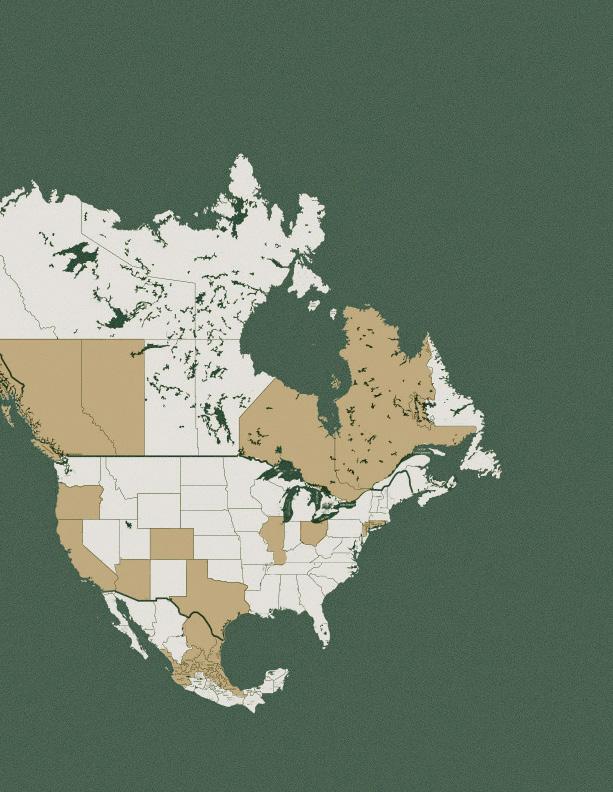

USA - Canada-Mexico

ReHome

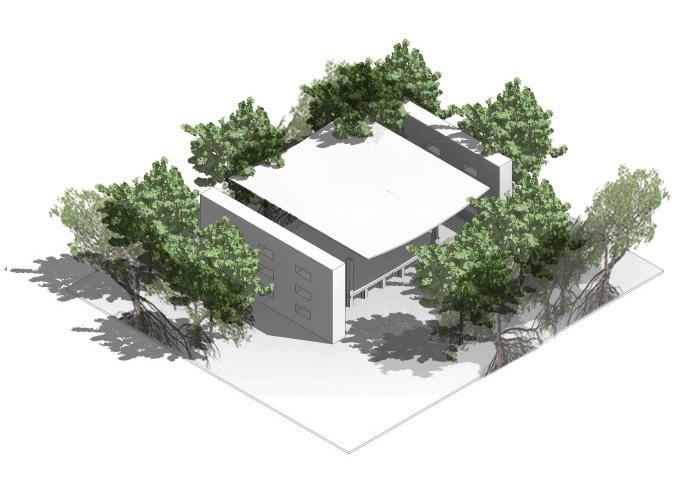

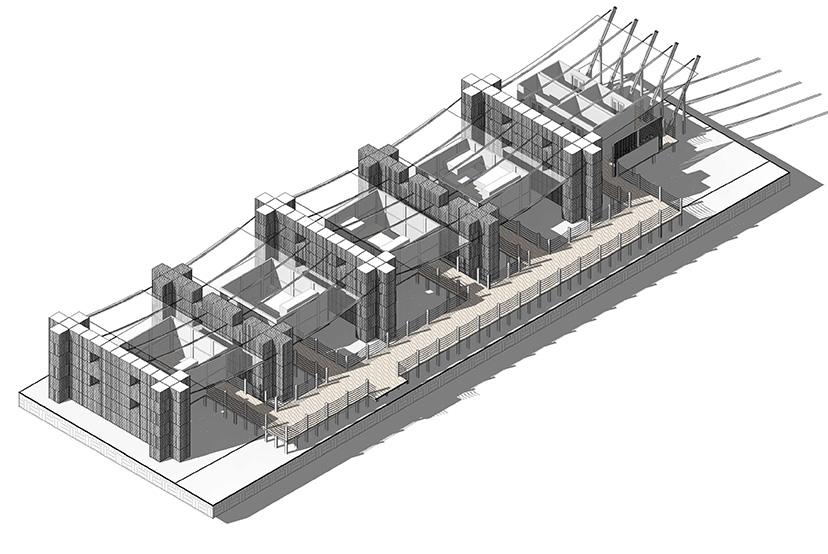

Location: USA, Seattle, Washington

Professional Work: Coates Design

Project Type: Residential, ReUse

Project Phase Contribution: Construction Documents, Construction Administration

Year: 2022

Programs: Revit, Photoshop

Website: https://rehomeproject.com/

The ReHOME project offered me the chance to engage deeply in the construction administration process, where I handled RFIs, participated in CA meetings, and conducted site visits. The project is dedicated to enhancing community living by introducing three new residential units adjacent to an existing farmhouse, all constructed using recycled and repurposed materials. These eco-friendly structures were built with the generous contributions of both professionals and volunteers, reflecting a strong commitment to sustainability.

Each unit is thoughtfully designed with two private sleeping areas, a comfortable social space, and a bathroom, balancing the need for privacy with opportunities for communal interaction. Through the use of sustainable materials and active community involvement, ReHOME not only meets essential living requirements but also promotes values of sustainability and social responsibility. The project enriches the local environment and fosters stronger ties within the community, creating a model for responsible and meaningful development.

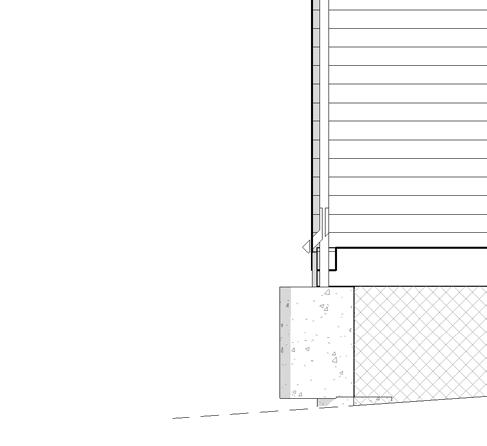

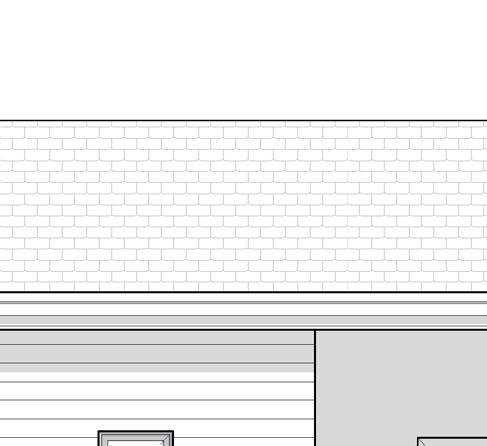

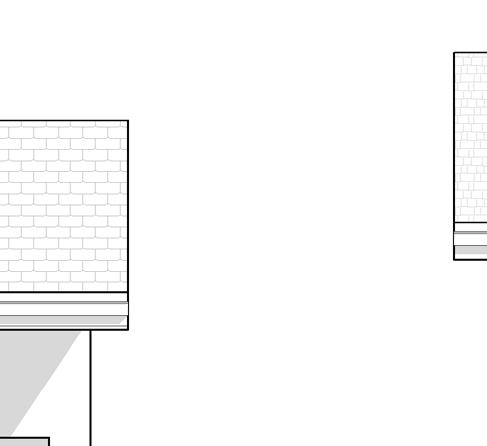

Longitudinal Section

2 ROOF PLAN

1 FRONT ELEVATION

GUIDE-SIDE

TRANSITION WITH DOOR-SIDE

GUIDE MOUNTED TO PER MFR. CUT AROUND MOUNTING MOUNT PLATE ATOP AS RECOMMENDED

JAMB

TRANSITION (WHERE ALIGNED WITH DOORJAMB

WEATHER BARRIER OVER HEAD FLASHING, TYP.

SIDING PER ELEVATIONS

GA. PRE-FINISHED

FLASHING, TYP

ALUM. CLAD

PER SCHED.

FLASHING w/ 1" MIN

DAM. TURN UP

4" MIN.

MFR. REQ'TS) OVER WEATHER LIQUID FLASHING @ ROUGH

OPENING:

-APPLY LIQUID FLASHING OVER ENTIRE INSIDE OF R.O. (OR PER MFR. REQ'TS) -EXTEND LIQUID FLASHING MIN. 1" OUTSIDE R.O., ON FACE (OR PER

MFR. LIQUID OPENING: -APPLY ENTIRE INSIDE OF (OR MFR. -EXTEND FLASHING OUTSIDE ON FACE

TYP. WALL ASSEMBLY

FASTENING: -CLADDING ATTACHMENT COMPONENTS SUCH AS CLIPS, FURRING

STRIPS OR BATTENS, ETC. SHALL BE FACTORED INTO THE OVERALL ATTACHMENT REQUIREMENTS FOR THE WEATHER BARRIER SYSTEM.

BARRIER

ONLY MANUFACTURER'S FASTENERS

SIDING PER ELEVATIONS HDR PER STRUCT.

WEATHER BARRIER CORNERS: INSIDE AND OUTSIDE CORNERS CAN BE CONTINUOUS, OR IF A VERTICAL JOINT OCCURS WITHIN (24”) HORIZONTALLY, AN OVERLAP OF A MINIMUM OF (12”) IN BOTH DIRECTIONS PROVIDING A DOUBLE LAYER AT THE CORNER IS REQUIRED.

CONT. LOW EXP. FOAM AIR SEAL

FLOOR FINISH OVER TYPICAL WOOD FRAMED FLOOR ASSEMBLY SEALANT & BACKER ROD @ INTERIOR PERIMETER OF DOOR

-USE ONLY MANUFACTURER'S APPROVED/RECOMMENDED FASTENERS AND RECOMMENDED FASTENER SPACING.

WEATHER CORNERS: INSIDE CORNERS CAN BE CONTINUOUS, OR IF A VERTICAL JOINT OCCURS (24”) HORIZONTALLY, OF A DIRECTIONS A DOUBLE CORNER IS GWB w/ BEAD

24 GA. PRE-FINISHED MTL FLASHING, TYP LAP WEATHER BARRIER OVER HEAD FLASHING, TYP.

HEADER PER STRUCT

OPEN WITH LAYER A BARRIER MINIMUM 50% PER

OPEN JOINT CLADDING SYSTEMS WITH NARROW JOINTS: -SINGLE LAYER WEATHER BARRIER: INSTALL A SINGLE LAYER OF BLACK, UV-STABLE WEATHER BARRIER WITH MINIMUM 50% HORIZONTAL OVERLAP AND PER MANUFACTURER'S REQUIREMENTS.

BARRIER: INSTALL STANDARD STANDARD OVERLAPS, BLACK, BARRIER STANDARD

-DOUBLE-LAYER WEATHER BARRIER: INSTALL ONE LAYER OF STANDARD WEATHER BARRIER WITH STANDARD OVERLAPS, THEN INSTALL ONE LAYER OF BLACK, UV-STABLE WEATHER BARRIER WITH STANDARD OVERLAPS.

OPEN JOINT CLADDING SYSTEMS WITH WIDE JOINTS: -MAXIMUM WIDTH OF OPEN JOINTS SHALL BE 3/8".

OPEN WITH -MAXIMUM OPEN BE

-MAXIMUM JOINT SHALL

-MAXIMUM % OF OPEN JOINT AREA ALLOWED SHALL BE NO MORE THAN 10% OF WALL AREA

NEW ALUM. CLAD DOOR PER SCHED.

CAVITY SHALL DEEP 30

-RAINSCREEN DRAINAGE CAVITY SHALL BE MINIMUM 1/2" DEEP

-INSTALL OPEN JOINT CLADDING SYSTEMS WITHIN 30 DAYS OF INSTALLING WEATHER BARRIER

LAYER STANDARD BARRIER OVERLAPS. INSTALL UV-STABLE ALL

-SINGLE LAYER WEATHER BARRIER: INSTALL STANDARD WEATHER BARRIER WITH STANDARD OVERLAPS. INSTALL BLACK, UV-STABLE SELF-ADHESIVE TAPE AT ALL HORIZONTAL AND

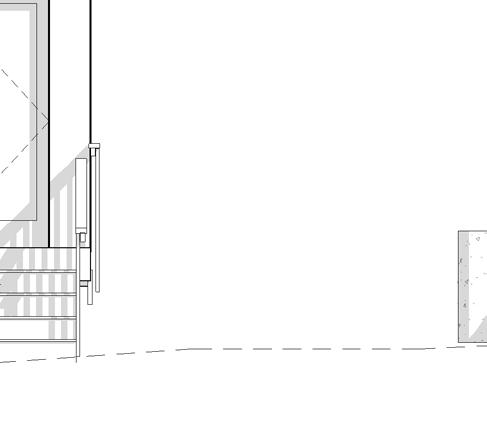

PAN FLASHING w/ 1" MIN BACK DAM. TURN UP JAMBS 4" MIN. SET IN SEALANT LIQUID FLASHING AT ROUGH OP0ENING, TYP. DECK

DOOR @ WD DECK BARN-TYPE Outswing Door @ wood deck Window

SEALANT & BACKER ROD @ INTERIOR PERIMETER OF WINDOW WOOD JAMB EXTENSION

WINDOW w/o SCAL E 3" = 1'-0" 2 OUTSWING

WEATHER BARRIER o/ SHEATHING

WEATHER BARRIER o/ SHEATHING

FULLY TAPE FLASHING TO WRB

FULLY TAPE FLASHING TO WRB VENTED EXTERIOR CLADDING

HEADER PER STRUCT

HEADER PER STRUCT

SEALANT & BACKER ROD @ INTERIOR PERIMETER OF WINDOW

SEAKABT & BACKER ROD @ INTERIOR PERMIMETER OF WINDOW

5/8" GWB w/ MTL. CORNER BEAD TYP.

5/8” GWB w/ MTL. CORNER BEAD TYP.

WOOD JAMB EXTENSION

6" TALL METAL HEAD FLASHING w/ END DAMS

JAMB/HEAD FLASHING

JAMB/HEAD FLASHING & ROD @ INTERIOR OF

EXTERIOR WALL

2x6 WD STUD EXTERIOR WALL (TYP. U.N.O.)

2X6 WD STUD EXTERIOR WALL (TYP. U.N.0.)

w/o Casing

VENTED EXTERIOR CLADDING LAP WEATHER BARRIER OVERNAILING FLANGE, TYP.

6” TALL METAL HEAD FLASHING w/ END DAMS JAMB/HEAD FLASHING LAP WEATHER BARRIER OVERNALING FLANGE, TYP.

24GA PRE-FIN MTL TRIM

24GA PRE-FIN MTL TRIM

EXTERIOR INTERIOR WOOD JAMB EXTENSION

24GA PRE-FIN MTL 1/2"

SEALANT & BACKER ROD CONT. AIR SEAL

EXTERIOR CLADDING WEATHER BARRIER OVERNAILING FLANGE, TYP. PER

SEALANT & BACKER ROD CONT. AIR SEAL

WINDOW PER SCHEDULE

WINDOW PAN FLASHING w/ 1" BACKDAM. TURN UP JAMBS 4" MIN

PRE-FIN. METAL TRIM, TYP.

VENTED EXTERIOR PAN TURN UP HEAD FLASHING w/ DAMS TO &

VENTED EXTERIOR CLADDING

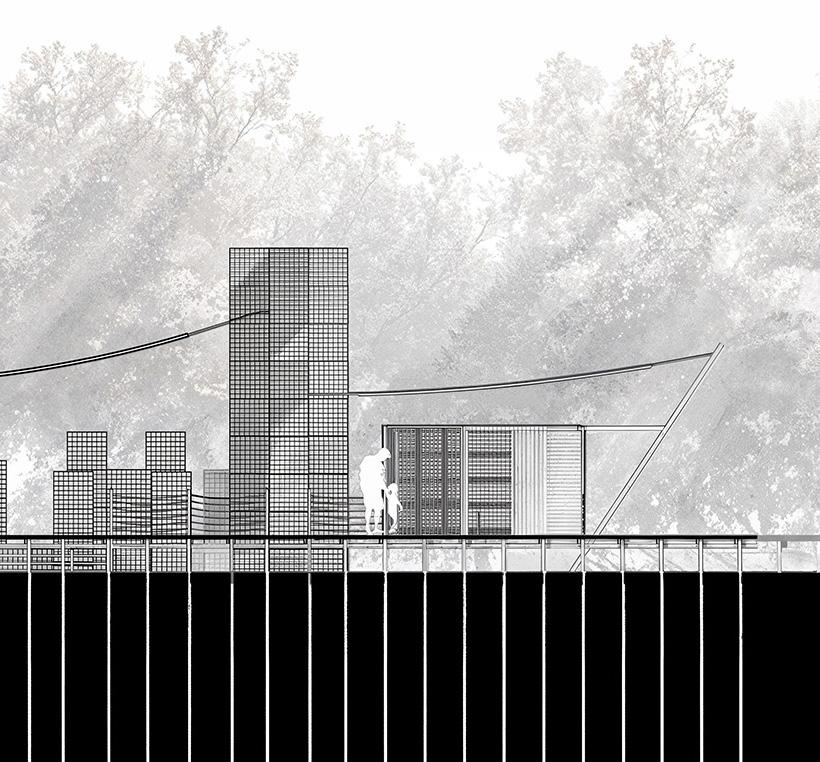

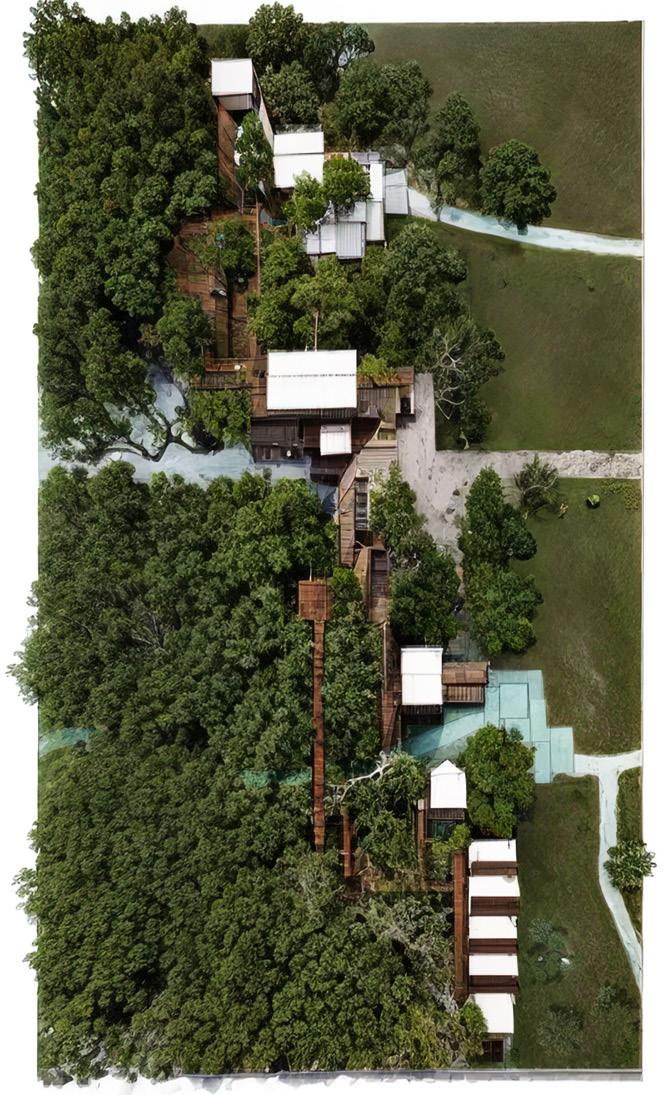

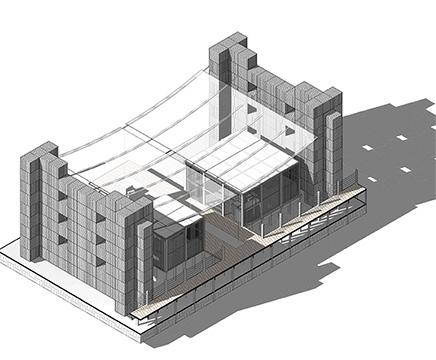

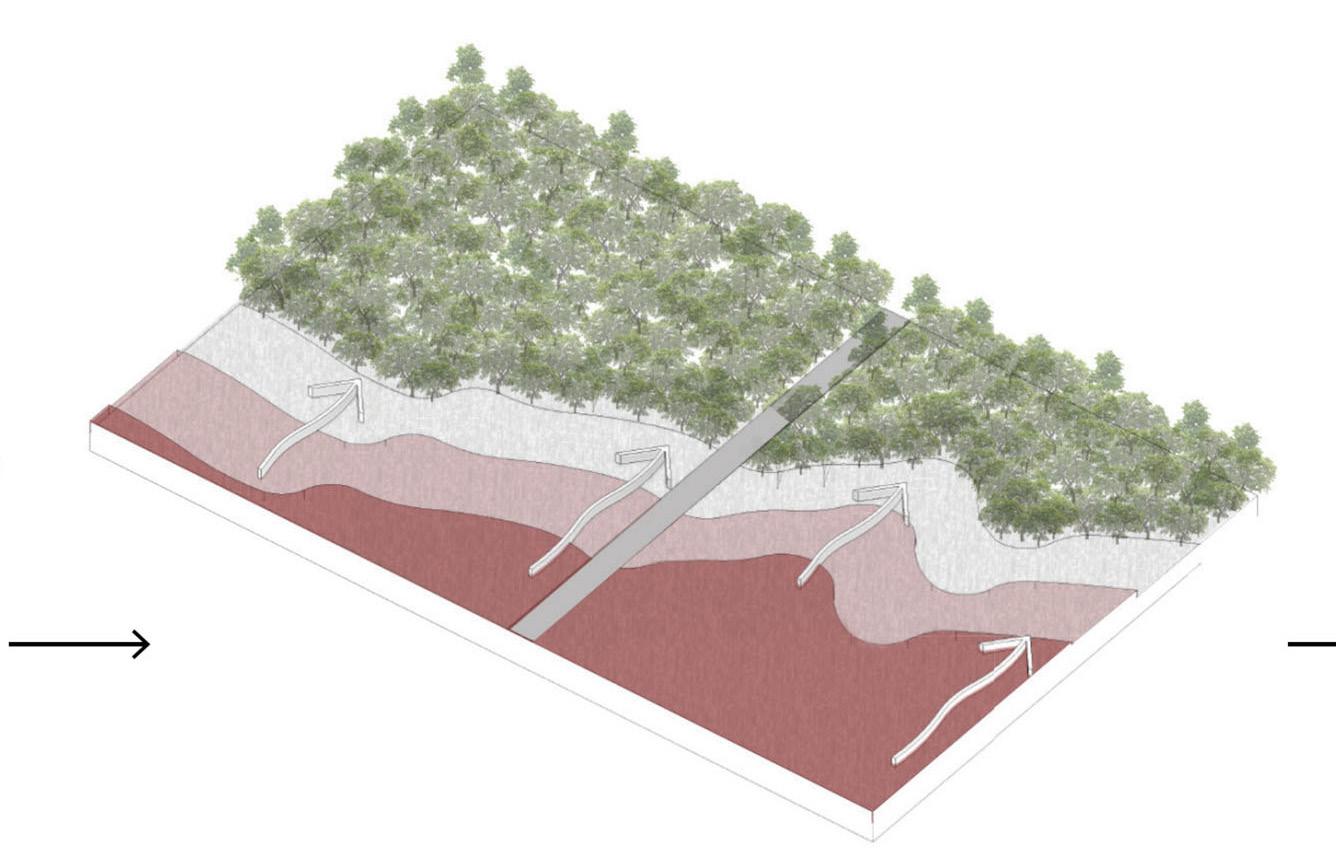

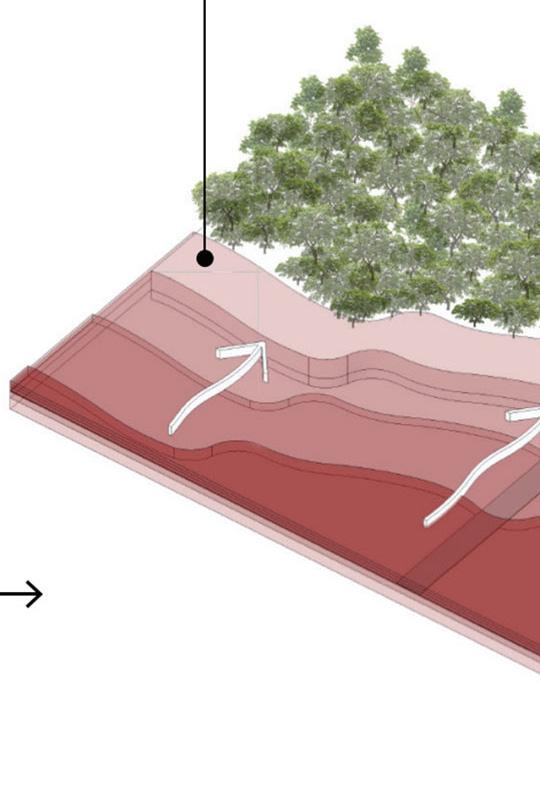

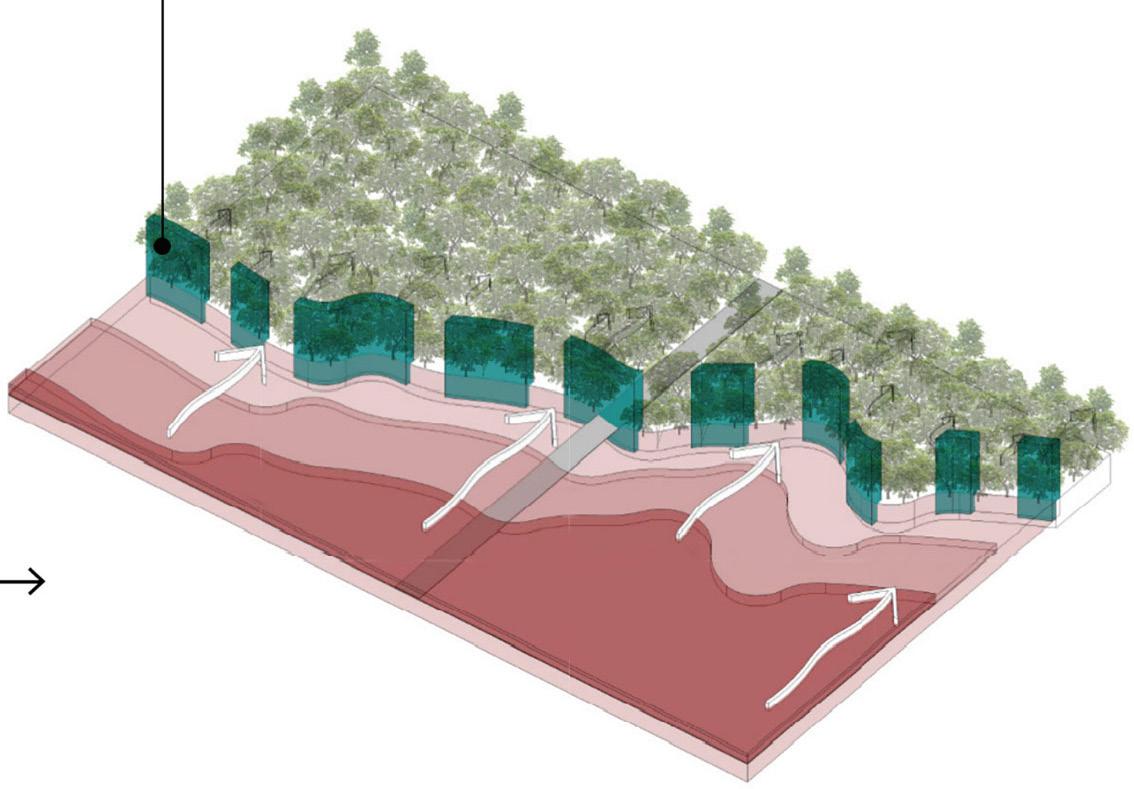

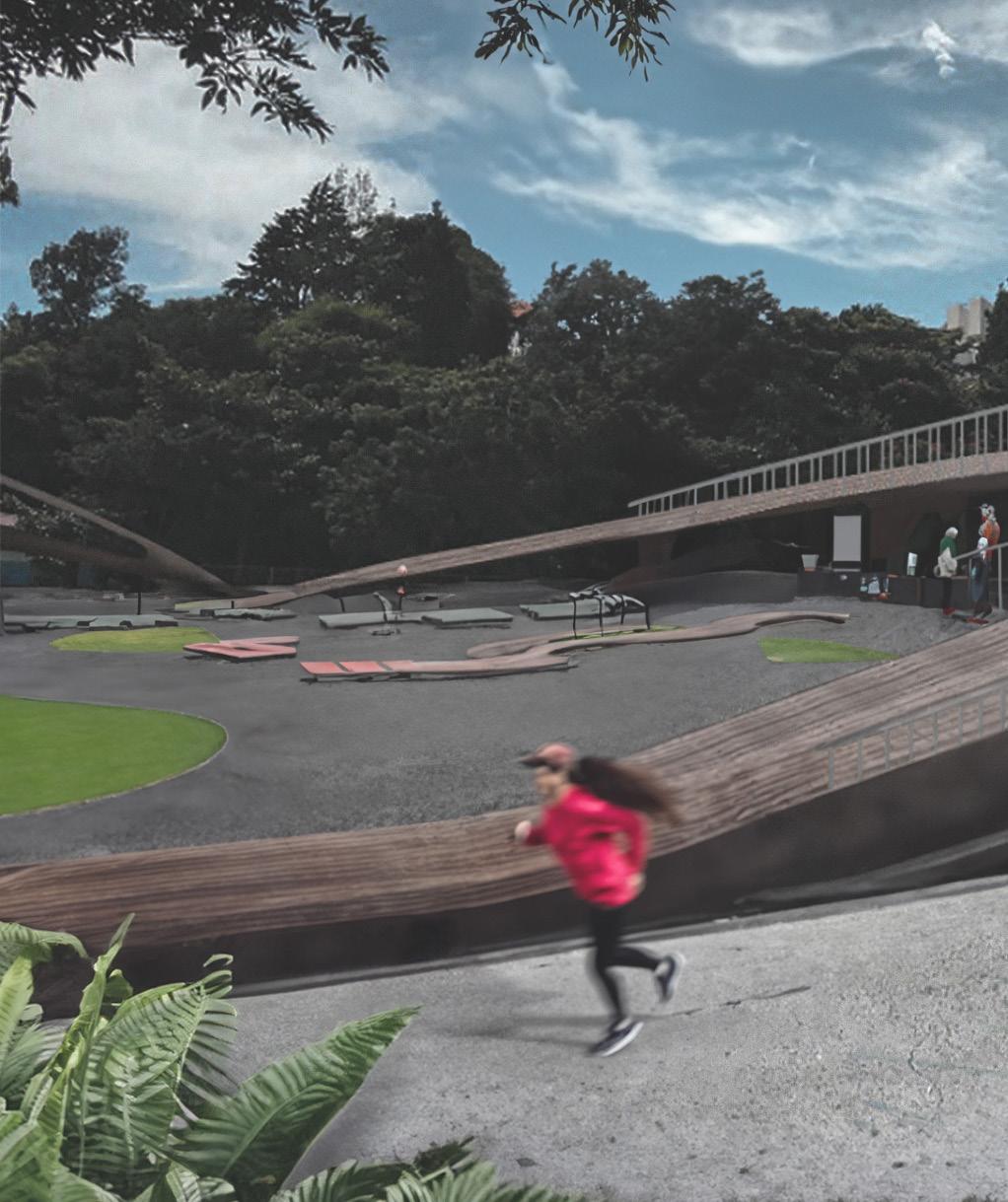

Responsible Productive Envirionments

Location: Puntarenas, Costa Rica

Academic Work: Thesis Project

Awards: Green Building Council Contest, 50 Talents Exhibition – Ideas for a Better World, Semifinalist in BeChangeMaker, Semifinalist in Cornell’s Costal Solutions Fellows Program, Simposio – Sustainable Construction: Climate Change (presentation)

Year: 2019

Programs: Revit, Lumion, Photoshop, Ilustrator

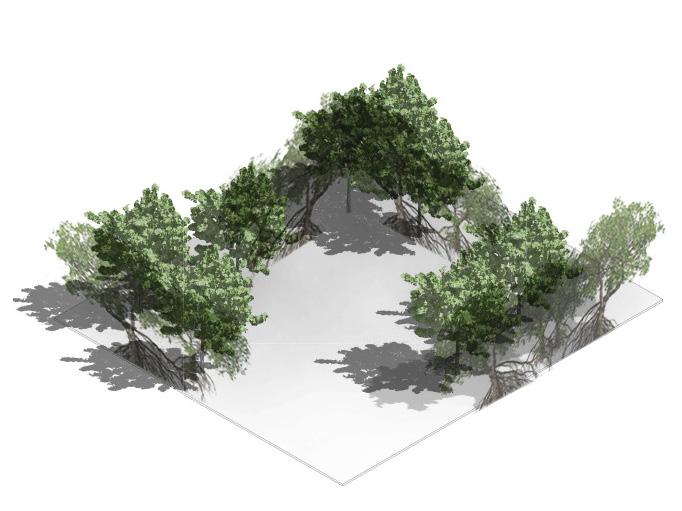

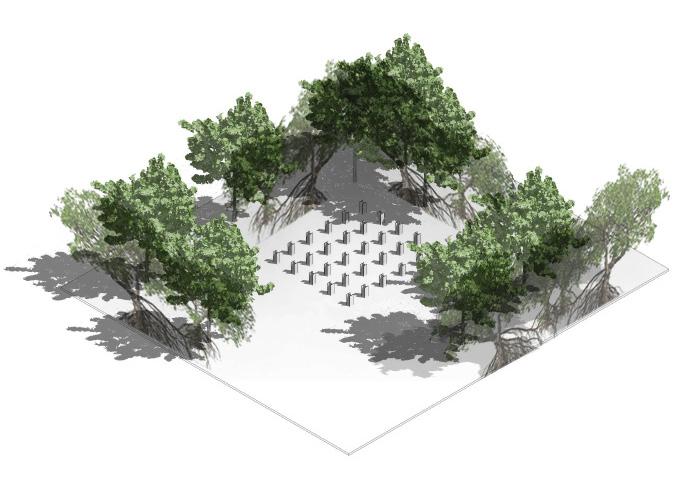

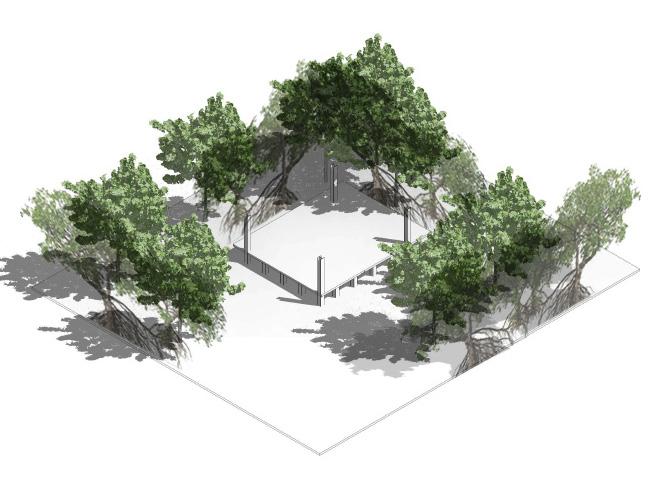

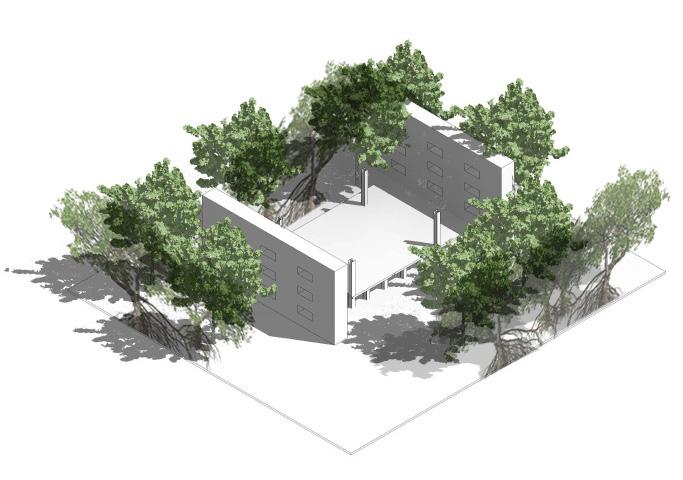

This project deeply engages with the mangrove’s boundaries, using the density and openness of the trees to blur the lines between interior and exterior spaces. This design strategy emphasizes a harmonious integration with the natural environment, promoting sustainability. The project fosters a continuous interaction with the mangrove, creating a seamless connection that merges the built and natural environments. Some elements of the project will be integrated directly into the mangrove, while others will be strategically placed at its edge, ensuring full area integration.

Additionally, this previously unused space will benefit the community, encouraging a positive contribution to the area. The project promotes inclusivity by inviting the community to interact with the mangrove, fostering a sense of belonging while maintaining ecological respect. This approach ensures that the space is used thoughtfully, enhancing community engagement without exploiting or damaging the natural surroundings.