First French Clothing Company, from birth to 12 years old

First French Clothing Company, from birth to 12 years old

First French dress company, from birth to 12 years old

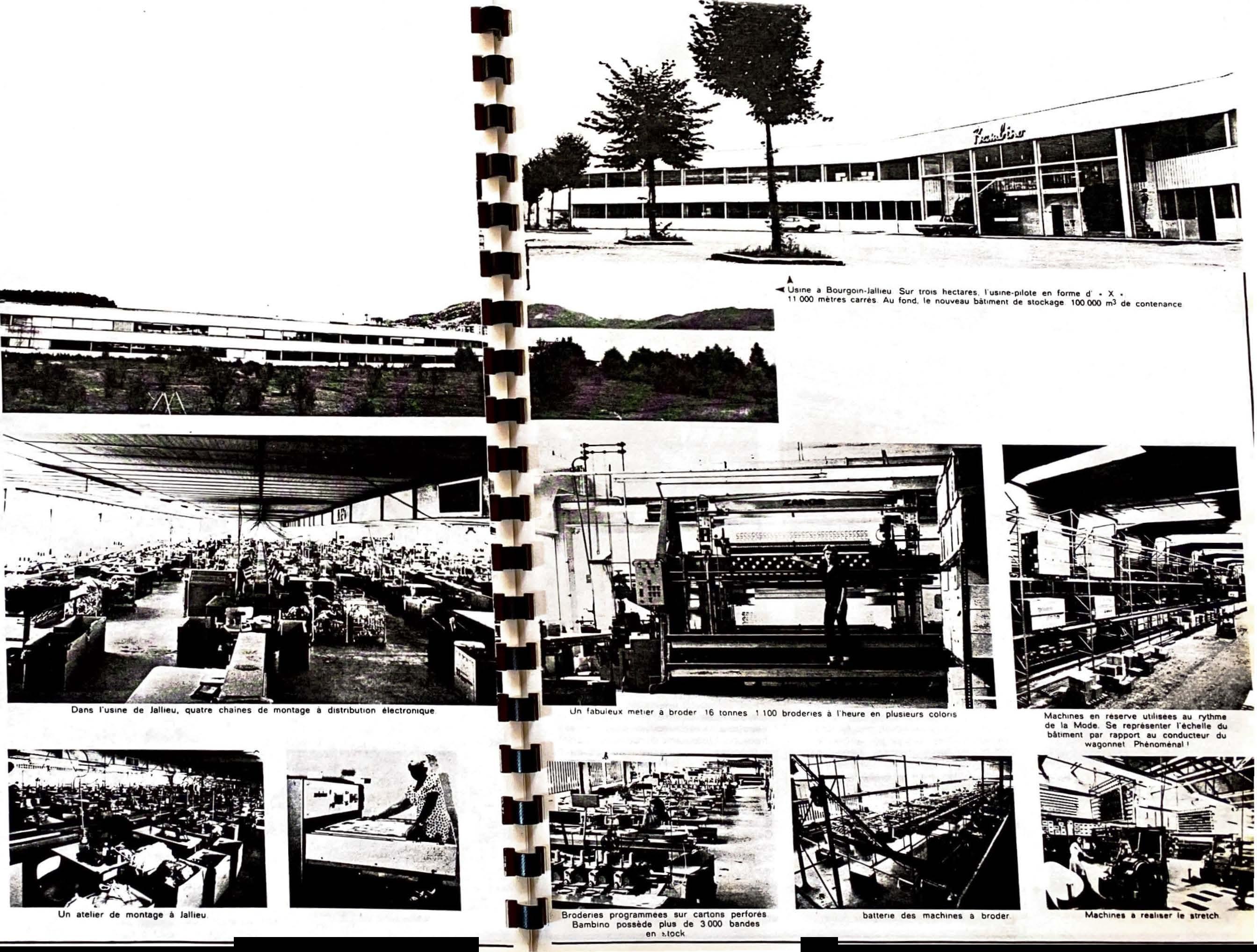

First French dress company, from birth to 12 years old • 70 million turnover forecast for 1977 of which 27% is exported • The most efficient computer in the clothing industry for the Rhone-Alpes region • A machine screen worth more than ten million • 17,000 square metres of workshop • 100,000 cubic meters of storage • More than 600 employees • 4 points of attache: Lyon. Paris. Bourgoin-Jallieu, Vichy • Three Collections per year: Spring-Summer, Classes-Autumn. Winter-Gifts • 1,500,000 meters of fabrics used annually

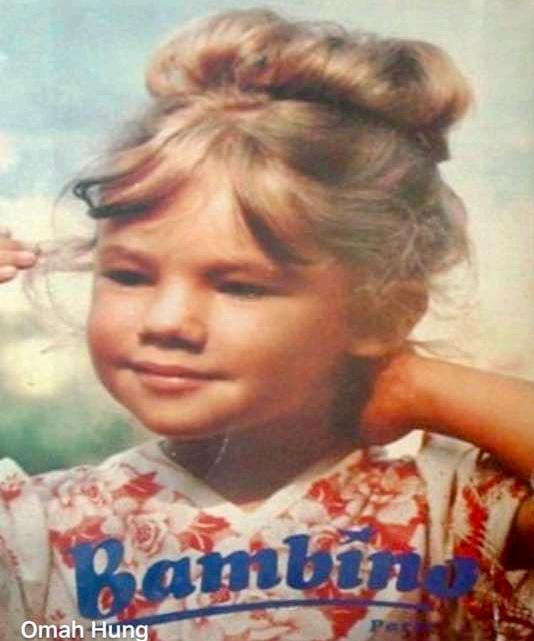

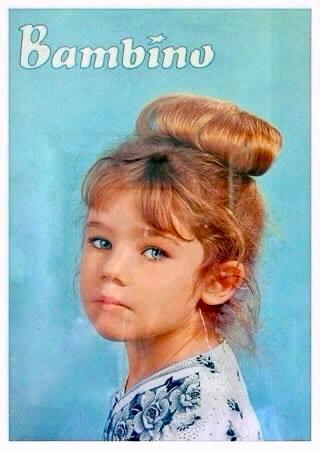

BAMBINO

Boys' and girls' layette dresses and sets • Boys' and girls' layette coats • Car jackets

• Stretch layette 0 to 3 years old • Crib, car and cot sets • Pouches and a whole range of special items for Gifts • Babies' dresses from 2 to 6 years old • Girls' dresses from 4 to 12 years old • Coats for girls and boys from 4 to 12 years old • Girls' and boys' trousers , from 1 to 12 years old • Skirts and Blouses 1 to 12 years old

•Coordinated sweaters 1 to 12 years old • UnderSweaters 1 to 14 years old • Panties 1 to 6 years old • Dressing gowns and pajamas for boys and girls 1 to 12 years old • Boys and girls aprons 3 months to 12 years old

•bathing suits boys and girls.

What a long way since then and which resulted in the huge production tool that Bambino became in 1977! The only point in common: The manufacture of children's clothing, and the Bambino brand, a flamboyant name punctuated by a star.

First podium of this spectacular success many due to repeated stays in the US made by Francois Bordy, thanks to the first successes acquired dearly in a modest Workshop on Rue Crequi in Lyon and to his first savings!

From the USA, Francois Bordy has brought back a fiery entrepreneurial spirit, an implacable will to succeed in what he undertakes, a curiosity constantly on the alert to keep up to date and discover all the new technical progress allowing him to begin to implement working methods

then practically unknown in Europe, François Bordy was the first:

• To delivered its initial production in boxes, the hand- embroidered Layette-Gift

•

•

To remove a debauchery of colors in collections, limiting itself to white alone • Industrialization leading to significant savings and hence unbeatable selling prices •. And we may continue by remembering that he was still one of the first to offer his articles on hangers and under covers And we can continue this enumeration, recalling that The first computer • purchased • in France was by Bambino. Thanks to this, Bambino began to establish rigorous forecast sales statistics. to control exactly all incoming fabrics and supplies. billing. staff pay, all things

absolutely unheard of at the end of 1966 in French clothing. Then Francois Bordy, to get rid of the terrible slack times of the offseasons, decided to release not two but three Spring • Summer collections a year. ClassesAutumn. Winter-Gifts. And always the first! He decided to stagger the delivery of orders over several months. providing the workshops with perfectly planned production programs Certainly, it was not easy. This new sales formula upset all the traditions of the market, but the high quality of the articles and their delightful presentation were a valuable asset. And, little by little, the system was adopted by the whole branch with the same concern for maximum profitability of production. Francois Bordy was beginning to build up a fantastic fleet of machines. whose worth

A cutting room in Lyon

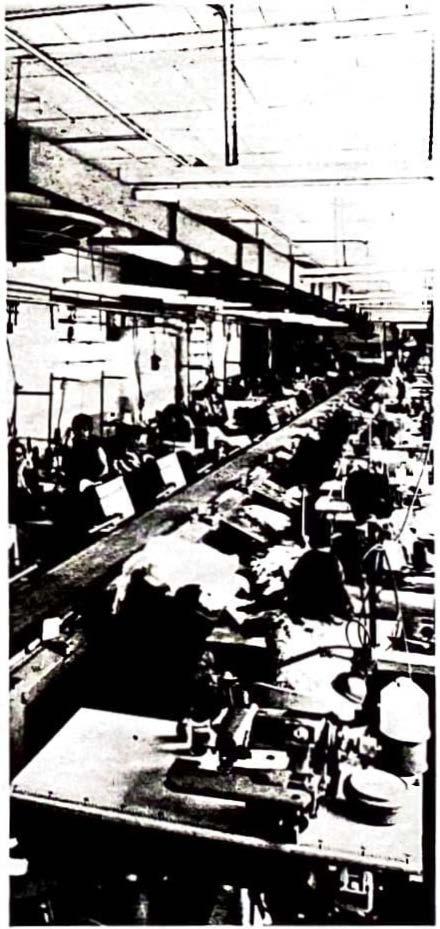

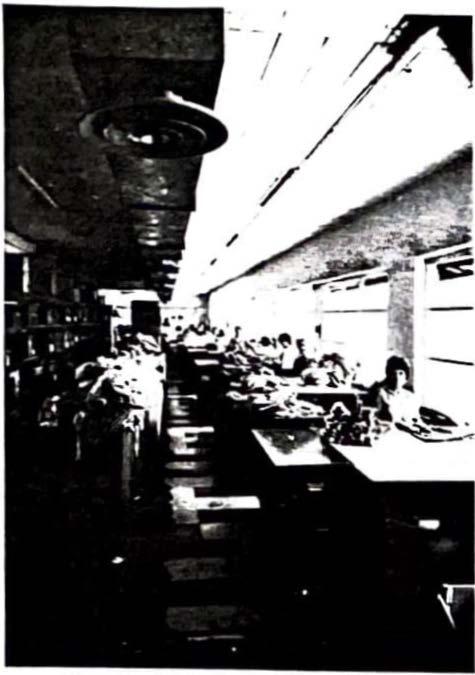

Electronic distribution assembly line

Other Electronic distribution assembly line

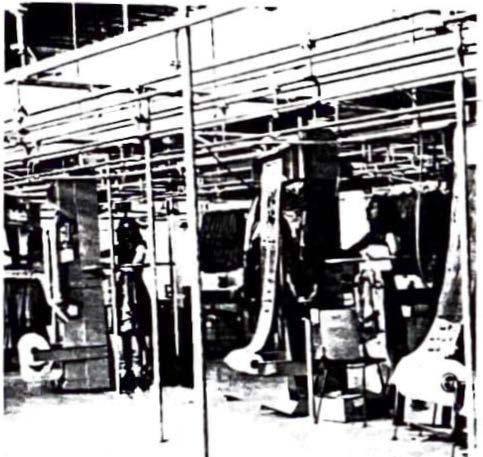

Assembly line at Vichy

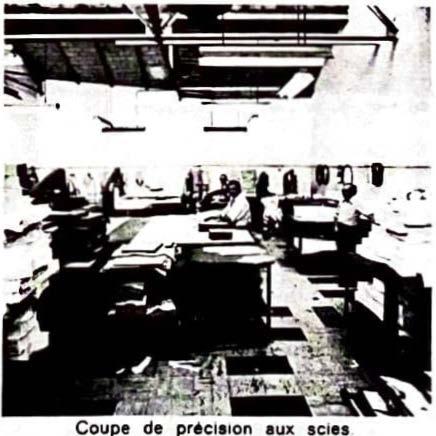

Precision cutting with saws

A cutting room in Lyon

Electronic distribution assembly line

Other Electronic distribution assembly line

Assembly line at Vichy

Precision cutting with saws

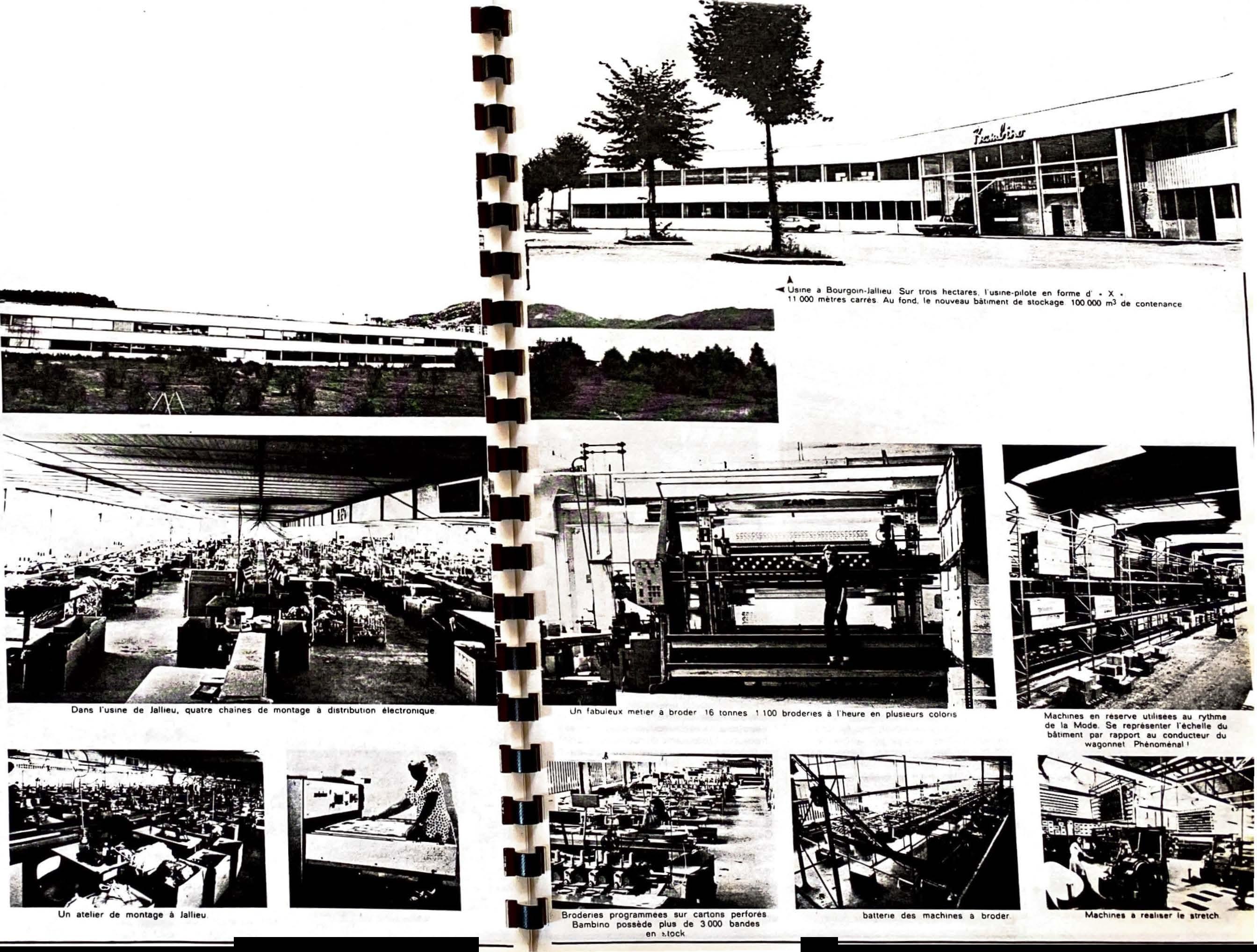

today is valued at more than 10 million Francs, leaves you speechless. At the start of this phenomenal investment, this postulate of the CEO: if I am the first to own a smocking machine, for example, when Fashion is going to be smocking, avoiding any subcontracting. I arrive on the market first and hands down. As for the amortization of the equipment, it is all the more rapid as the Bambino sales are important And thanks to its constant renewal Bambino is present as a priority new product which constitutes for the brand precious sales assets By virtue of this postulate, we find in the Bambino factories an incredible number of extraordinary machines Let us name a few Machines for making plastic presentation boxes (6,000 per day) for making hangers, covers. Machines making templates for collars and pockets. Machines for making biases, ribs and all kinds of stitching. Quilting machines, stretch machines, transfers. the zippers to the desired length. pleating machines. a fantastic bench of embroidery machines, one of which weighs 16 tons! is currently unique in France. The possession of all this equipment explains why we never engages in rearguard combat at Bambino, under the pretext of having to use old-fashioned tools at all costs. Of course the maintenance of such a fleet is entrusted to highly qualified technicians who, under the competent direction of Messrs. Castral and Delair, have the difficult task of keeping the machines in constant working order, each having to run almost constantly in the various workshops, which are installed in Lyon. Bourgoin-Jallieu and Vichy.

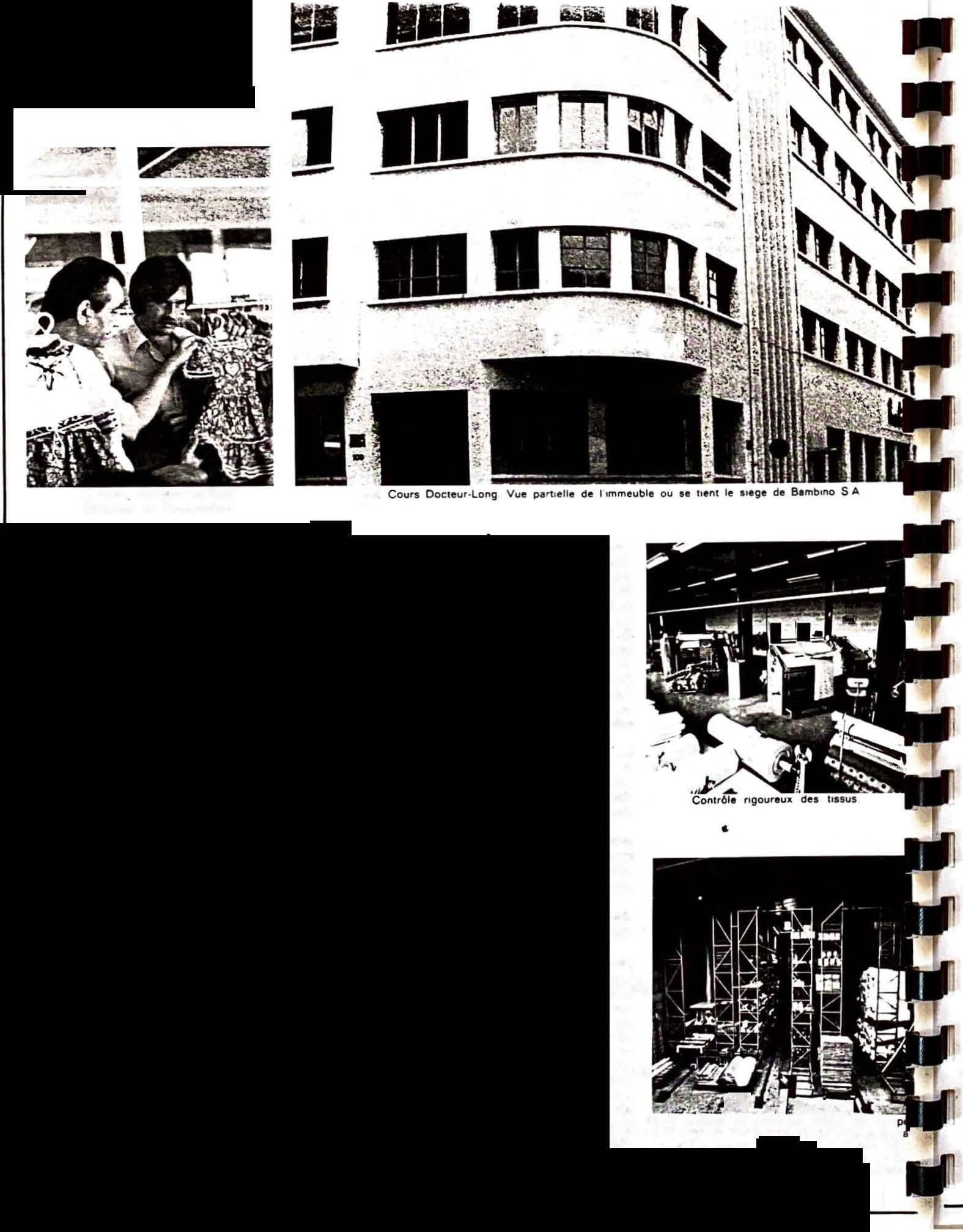

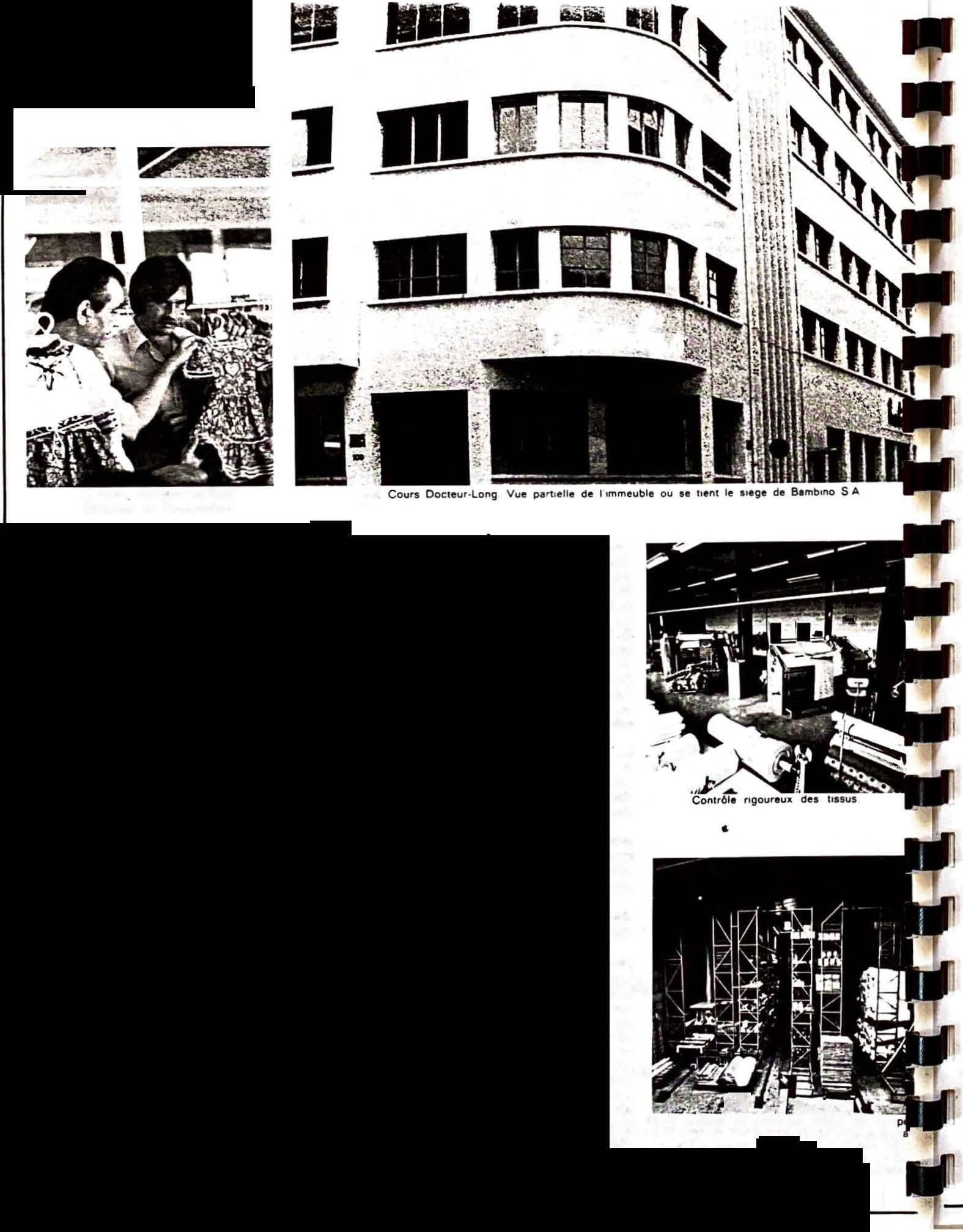

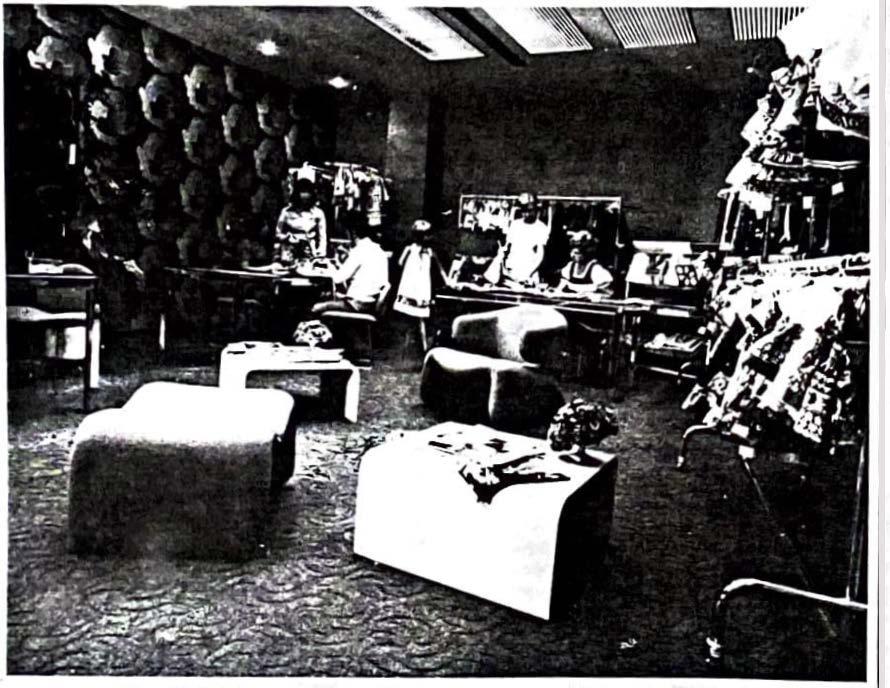

Lyon-Montchat - 100, Cours Doctor Long. this is where Bambino's head office is located, in a vast 5,000square meter building spread over four levels and grouping: On the ground floor, the showroom, all grace and freshness. and the Customer reception service

• On the second floor, the IT department is placed under the responsibility of Mr. Coquard, who has an IBM 3 model 15 computer, versatile in its applications and flexible in the execution of the countless programs that he must use.

A transfer machine

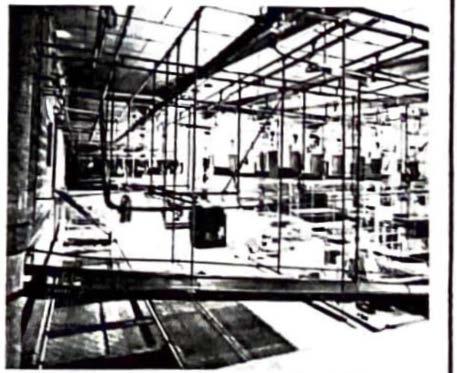

An assembly workshop in Jallieu

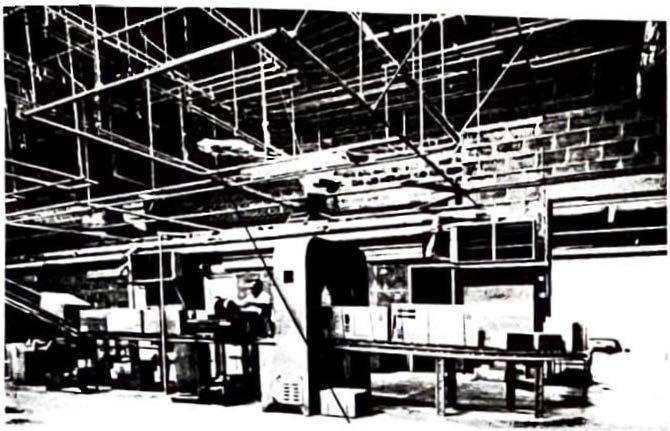

In the Jallieu plant, four electronic distribution assembly lines

A transfer machine

An assembly workshop in Jallieu

In the Jallieu plant, four electronic distribution assembly lines

• On the 3rd floor. in a flowery symphony. reigns Madame Duvlllard. Director of Style Offices. It's there that. in the biggest secret is born. EVERY SEASON. the Bambino Fashion, which will become The Fashion for so many little girls from France and everywhere else. On this floor too, patronages are developed. and we proceed to extremely thorough studies of size templates and conformations.

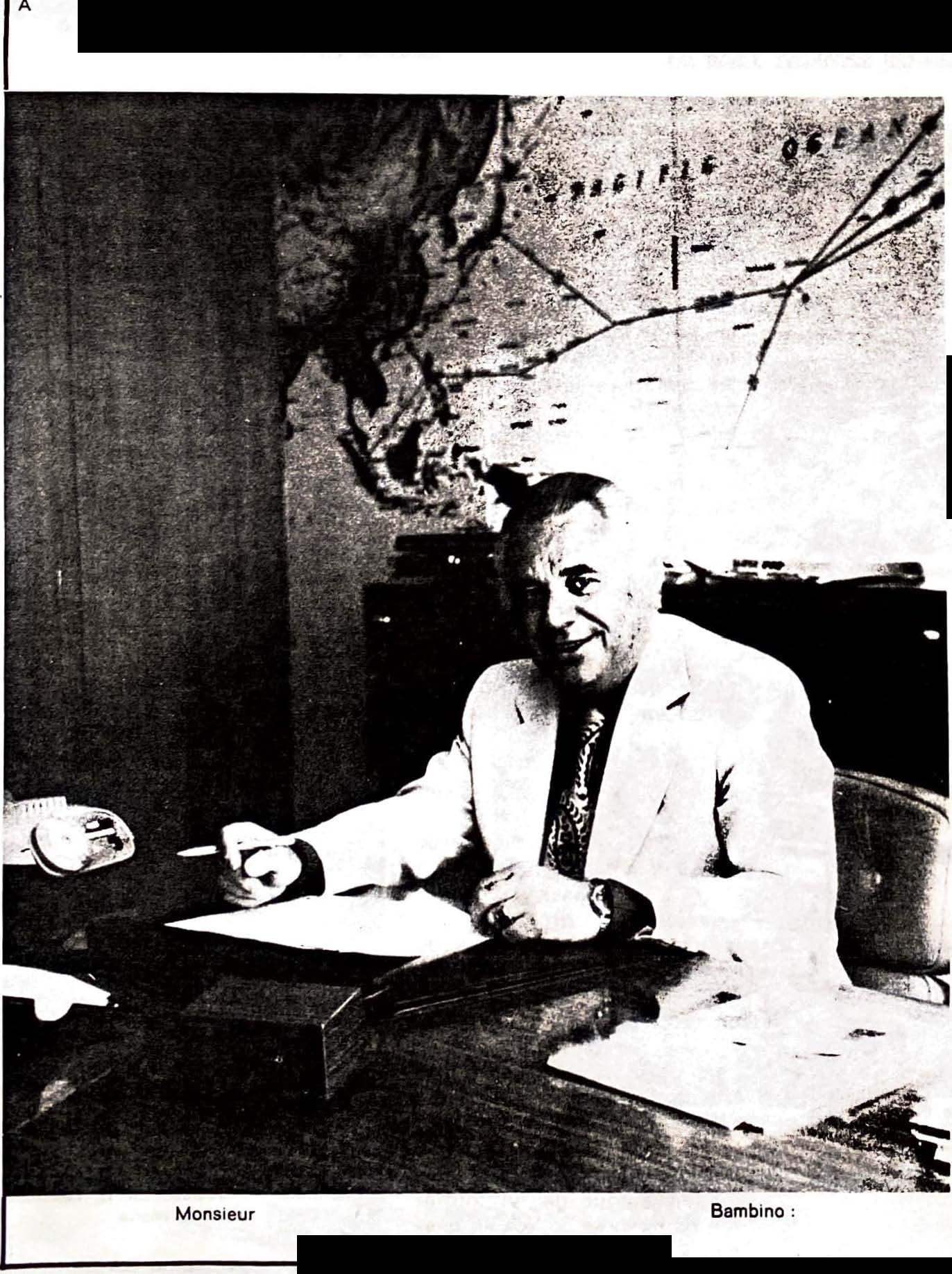

• And it is on the fourth floor that next to the administrative offices is the huge panoramic office - 150 square meters in area - of Mr. Francois Bordy. An office commensurate with the company and its CEO. who likes to receive. organize meetings, and who patiently puts in place, pawn by pawn, all the means and structures which will allow the achievement of medium and long-term objectives of 100 million in turnover within five years or less to finally reach these 200 million which would be for him the true crowning of his career • So. he said, I will finally be able to rest and live “free”. by indulging in my favorite distractions, traveling. the boat. idleness in the sun. and good tables • Mr. Bordy being a very fine gourmet.

In the meantime, he continues, I organize myself as if I had to face double my needs. I always invest and build in the bad times of the economy. when no one is pressed by work and we can get better prices or conditions. Generally, we do the opposite. That’s another point of view... Anyway, my overall plans are still established five years in advance.

Note: special assembly and verification chains, requiring a profusion of machines of all kinds, and occupying a hundred people, producing dresses, snack dresses, sets and aprons, are spread over the four levels of the Bambino building, the Doctor Long course, while in a building in front of the Headquarters. on 2,000 m2 are installed: a large cutting room, with ultra-modern techniques,

Some of the packaging machines (putting on hangers and under covers)

• In VICHY, in two large assembly workshops, layette articles are made, and always Bambino designer dresses. It was towards the end of the 1950s that the idea of a new form of factory idea was born at Bambino’, which later largely made its way!

But who, at the time, Immediately came up against the skepticism of everyone, including architects. It was a question of finding a way to ensure in a factory a better distribution of fluids (all forms of energy used. such as driving force, pneumatic energy, heating, air conditioning). After much research, the project took the form of an “X” construction, which became François Bordy’s Number One objective. The final studies were entrusted to the vast technicality of Mr. Castral, and in July 1968 an absolutely revolutionary production unit was inaugurated, which has now become the Pilot Factory of:

• Bourgoin-Jallieu.

Built in shape Of “X” on 11,000 square meters. it is at the intersection of the jambs

✓•

All clothes circulate, on overhead conveyors, on hangers and under covers, to prevent them from wrinkling or compacting.

that are located the soul, mind, brain and command posts of the whole, as well as maintenance services, elevators, stairs, changing rooms, refectories and offices. A service of corridors bypass this central point, on the ground floor and on the first floor. In the jambs of the “X” were im-planted, on the one hand the cutting and assembly chains, on the other special machine batteries, ironing, and packaging. This factory houses a surprising machine park, at the cutting edge of the news, and attracts foreign observers, especially American and Japanese, who remain speechless in front of the very last building in Jallieu: The building reserved for storage and expeditions.

storage,

It was in 1972 that the constant expansion of the Firm’s sales required that these two positions be completely redesigned. A new and imposing construction, with a total volume of 100,000 cubic meters, was then started, as an extension of the “X” where manufacturing continued. and was connected to it by a tunnel. This system is unique in Europe. became permanently operational in 1976, after many alterations. It is difficult to explain. using remarkable techniques. of which only engineers would speak with clarity and simplicity For us, who have seen it in layman's terms. we will simply evoke it with some lyricism, rather than as scientists!

Brand new and very cost-very high-coed equipment. The huge building, with a total length of 120 meters, and 60 meters wide, is hermetically sealed, without doors or windows, except for a single access for trucks or trailers delivering the raw materials. It is divided into two unequal parts, in the direction of its length. - one housing stocks of fabrics and other various supplies. the other Clothing. On the woven side, a transtockeur with the automatic grip of pallets moves tirelessly, in the greatest silence and in all directions, horizontally and vertically simultaneously. It can move from one driveway to another by automatic ferry. The lighting of the whole, provided by steam lamps of

Storage exit to shipment. Items have been previously sorted by Customer Orders.

All clothes circulate, on overhead conveyors, on hangers and under covers, to prevent them from wrinkling or compacting As far as the eye can see, finished items, waiting to be packaged. Set of perspectives in the storage silo. We move there in . transtockeurs Storage capacity of the silo: 100,000 m3 Bourgoin Jallieu factory. From right to left: exit from the factory in X •. finished clothes, destined for via a hermetically sealed tunnel.The journey is fully programmed electronically.• Mercury is calculated in such a way that the color of the fibers stored there permanently about 400,000 meters) cannot be altered in any way.

•On The Clothing Side, It’s fabulous. The Bambino manufactures, completed and packaged in the “X” factory, are combined in swings immediately taken care of by a whole system of conveying, crisscrossed by rails and pneumatic switches and controlled by an electronic brain.

•Crossing the tunnel uniting the buildings, these swings arrive at the entrance to the storage bays where small transtockers circulate that will take them to the exact cell, reserved for each of them, according to their type. Thus, every day, 20,000 parts are handled, the total storage capacity being currently 20000 Parts, the total storage capacity is currently 800,000 pieces; given the constant rotations, 350 to 400,000 items are constantly waiting in the storage silo for their shipping turn. When this time comes, the transtockeurs collect the parts to be delivered, according to instructions transmitted by computer. These pieces are then grouped again but this time by Customer, in swings that resume their journey through the multiple branches of a new “ConvoYeur” aerial, also ordered electronically And pneumaticLying. And this is how the orders reach the shipping service, where, securely packaged, conveyor belts and other conveyors will take them to the embarkation dock.

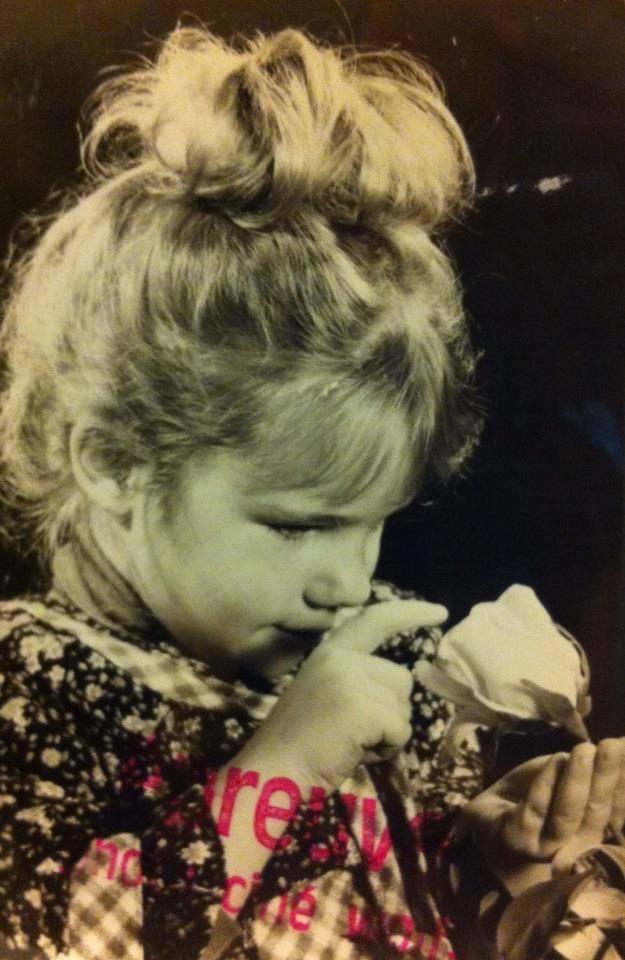

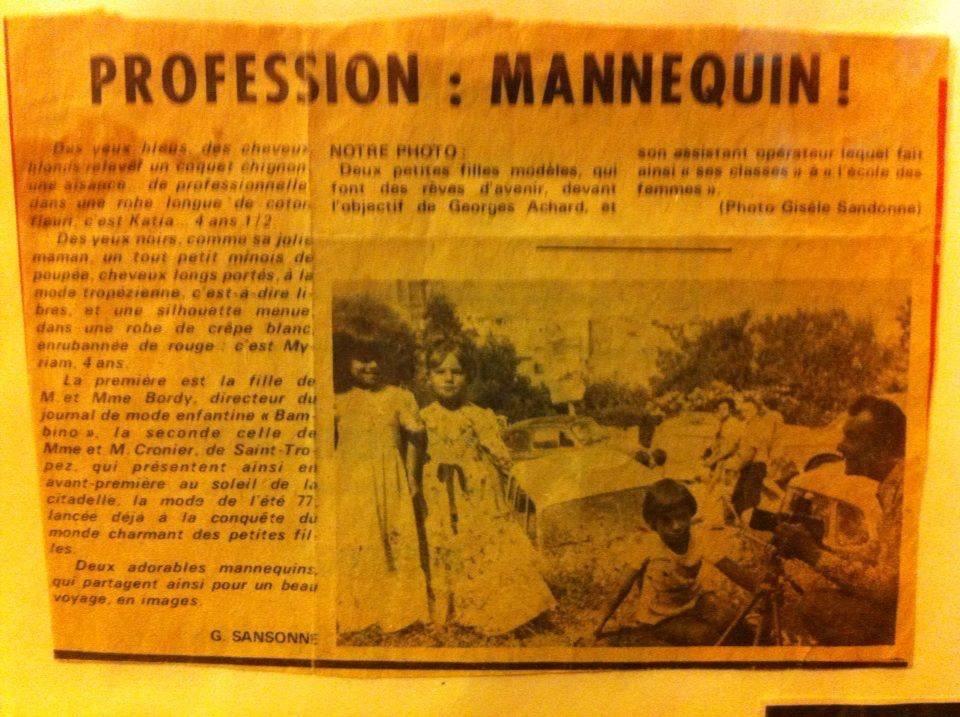

• The importance of the material means available to Bambino, and the description of which we have dwelled, as they offer so much interest, leaves us very little room to talk about the Bambino Marketing led by Mr. G.-J. Achard. one of the first to have faith in the star Bambino, since he has been following her for 20 years now (what a beautiful birthday!). M. G.-J. Achard has full responsibility for sales and publicity..

of the Bambino Company. By sales. we mean: 3,000 points of sale in France (all independent retailers), 1,500 for export, in many countries such as those of the Common Market. Switzerland, Austria, the Scandinavian countries. the D.O.M. And T.O.M. Black Africa. Canada, Japan, the Middle East. Offices in Cologne, Turin, Brussels. And also, a magnificent Sales Team (20 Permanent Representatives Abroad. 23 in France). This Team, perfectly dosed, combines “old drivers” with young elements, all animated in the same “childish” spirit, without losing sight of the particular interests of each of their Customers. This dynamic team has the merit of ensuring, against all odds, the constant extension of the Bambino figure since its creation. And we don’t see what could stop this ascent P.D.G. Careful. leaving the widest Shares in self-financing, and who has

•Never recorded a deficit exercise. supported by totally loyal collaborators, Mr. Bordy had the intelligence to surround himself • with men stronger than him in their specialty • This is surely one of the reasons for his success. as well as the house principles with which we never compromise

•Stride style, in the line of Fashion.

•Irreproachable quality of the manufactures. very strictly verified.

•Prices studied as accurately as possible.

• Extreme care given to the condition.

• Bambino has risen to the very first row in the layette dress market. babie and girls. Aware of its position as a leader, more than ever. the Bambino S.A. Company is determined to continue an exemplary ascent in every respect.