Karthik Doddaballapura

Mechanical Engineer

Karthik Doddaballapura

Mechanical Engineer

Passionate Mechanical engineer with keen interest in product engineering and management. Mechanical engineer from Visvesvaraya Technological University & Masters in Automobile Engineering fromCoventryUniversity.

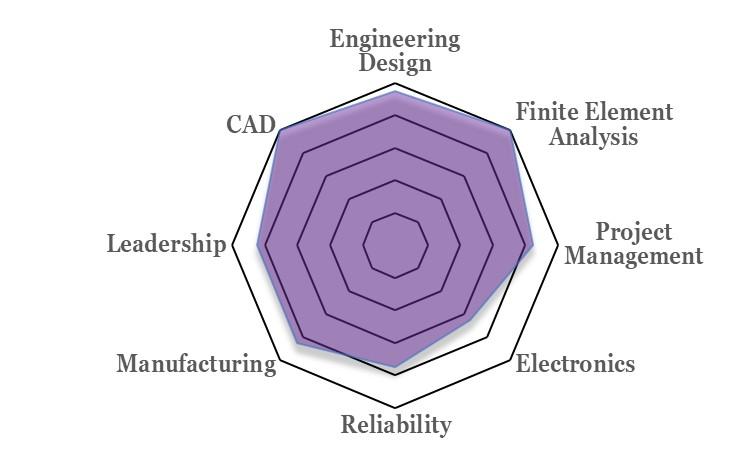

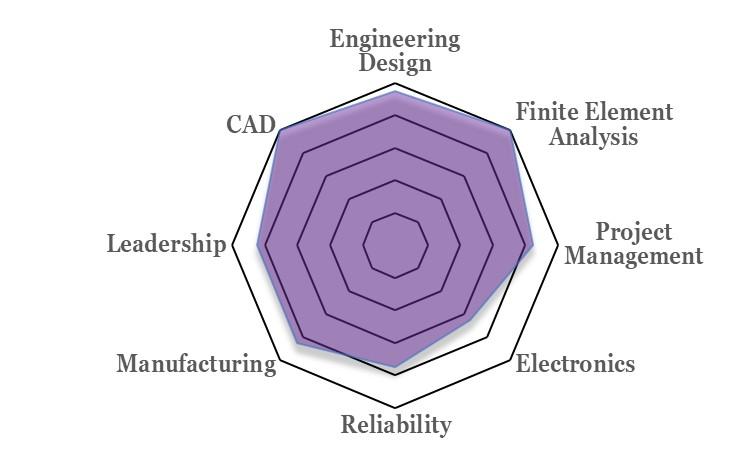

With over 15 years of product design and development experience comprising of Electronic Power Packages, Molded products and heavy engineering equipment’s design. I have managed product design from ideatoreliability.

My product engineering and management experience has given expertiseon mechanical,electricaland optical engineering . I have gained key expertise in Structural, Thermal, Thermo-Mechanical & Vibration simulations. I have also worked on scripting to help automate and improvise workflow. Tool experience include Solidworks professional, Fusion360,Inventor,ANSYS&Python.

My keen interest to help design better products has led to use efficient design methodology and process like DRBFM-Level4expert(DesignReview

Based on Failure Mode) , FMEA, PPAP, 8D,DFMandDFR.

I am currently enrolled to PEO and in process of obtaining P.Eng. I have completed my CAEM and now working onobtainingmyPMPcertification.

Karthik Doddaballapura

SKILLS WORK EXPERIENCE

CAD / CAE

Phone number: Email Website

Experience

Karthik Doddaballapura

416 833 8067

Karthik.Doddaballapura@gmail.com

https://www.linkedin.com/in/karthikdoddaballapura/

Education

June 2019Senior Mechanical and Manufacturing Engineer

Hyperion Sensors

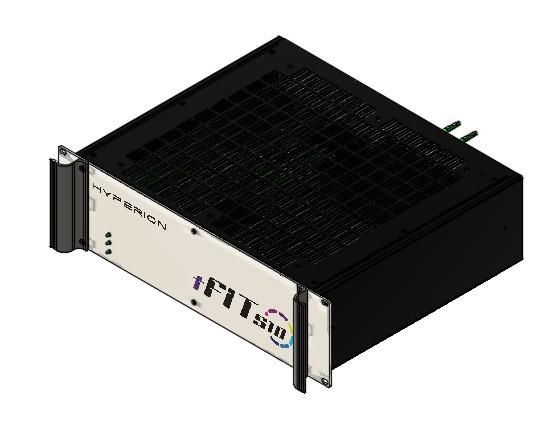

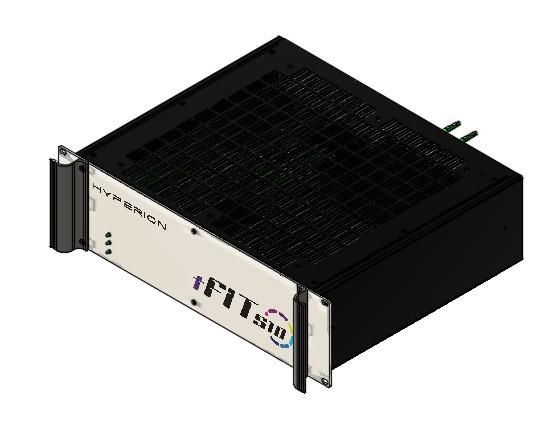

Hyperion is a startup which aims at distributed condition monitoring system, providing real time data and intelligence for utility grid assets

October 2010 – April 2019

Associate Project Manager

Robert Bosch

Bosch is a leading supplier of technology & services in the areas of Mobility Solutions, Industrial Technology, Consumer Goods, and Energy & Building Technology

July 2005 – Octboer 2010

Design Engineer

Tantra Infosolutions

Tantra strives to provide services to a wide range of manufacturing industries-from automobile, aerospace and heavy engineering industries, to machine tools and consumer durable

2009 - 2012

Master of Science – Automotive Engineering

Coventry University

2001 - 2005

Bachelor of Engineering - Mechanical Visveswaraya Technological University

Achievements

• Solidworks CSWP 2009

• Paper presentation at ICEPT 2016, China

• Paper presentation at ANSYS regional conference, Bengaluru 2017

Design and manufacture commercial version of Distributed condition monitoring system

across utilities.

• Manage complete product engineering comprising of optical, hardware, softwareandmechanicalengineering

• Design layout for Optical and electrical parts.

• Opticalfiberlayoutandcableharness.

• GenerateBOMandpartsdatasheet.

• Sourcevendors&budgeting.

• Conductfinalproductvalidation.

• Manufacturingandqualityguidelines.

Tools

• AutodeskFusion360.

• OpenBOM..

• Agile.

• QSA

• DesignValidation

Conduct experiment on optical fiber to differentiate strain & temperature.

• Lead Optical and hardware engineer to design the test of differentiating strain and temperature inopticalsignal.

• Design test jig to get response for temperature (heating pad) and strain(usingmicrometer).

• AnalyzedatacomingfromBOTDA

• Characterize strain and temperaturecoefficient.

Karthik Doddaballapura

11.35 11.30 Brillouin frequency shift (GHz) 11.25 11.20 11.15 11.10 60 50 40 30 Fibre length (m) 20 10 1 0.5 0 0 N o r m a l z e d n t e n s t y ( a u ) Strainchange Temperature change Pump light Probe light

tFIT is optical-electrical product that works on the principle of Brillouin optical time domain analysis, to measure temperature

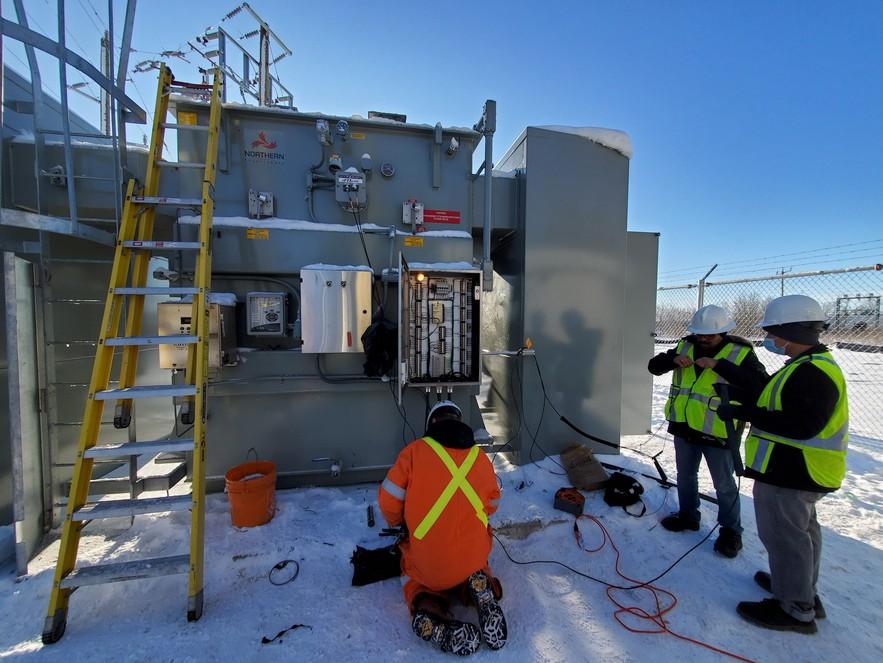

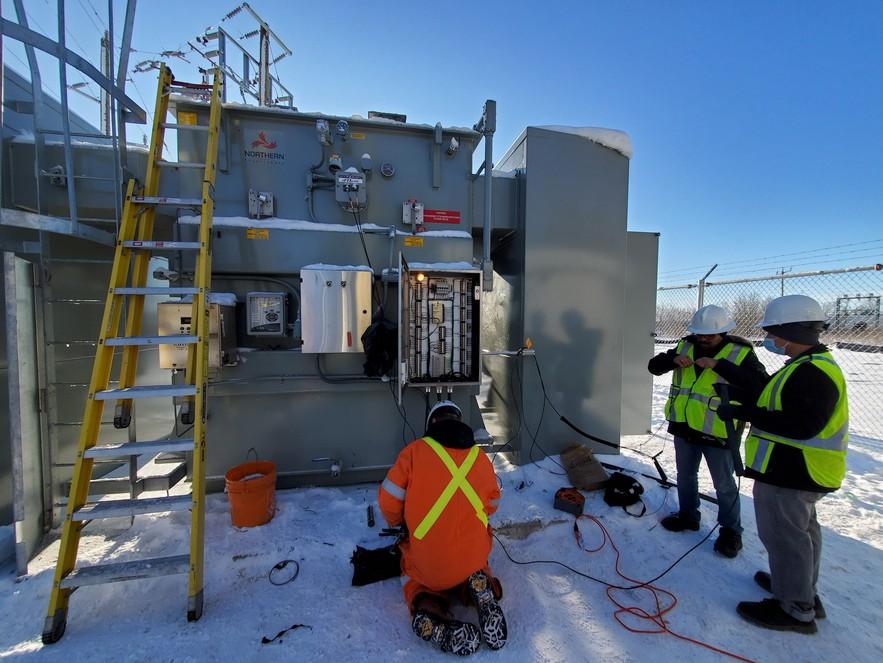

Installation and Quality check

• SuperviseproductQC.

• Mapping fiber installation and layout preparation

• Supervise fiber installation and splicing.

• Installunitandsetupconfiguration.

• Run through engineering demo for Energyutilitycompanies.

• Successfully lead the fiber installation procedure in the core of transformer – which is first smart transformer in the world.

Conduct technology demonstration and testing

• Project in charge for setup and demonstration of technology to customers

• Supervise EMC testing and analyze results and make design changes accordingly.

Karthik Doddaballapura

Installation at Transformer

Installation at Underground Mine

Technology demonstration EMI / EMC testing

Installation at Sub station

ESP – Product engineering and management.

ESP is Electronic Stability Program is a scalable braking system which offers maximum flexibility in terms of vehicle automation and safety.

• Project manager for Design & reliability.

• Structural,vibrationandthermalFEA ofPCBandhousing.

• Supervisereliabilitytesting.

• LeadDRBFMand8Dstudies.

• Co-ordinate with PPAP and Quality team.

• Conductfinalproductvalidation.

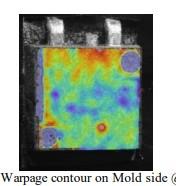

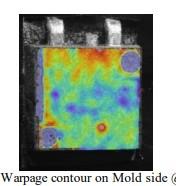

• Perform warpage measurement and vibrationtesting.

Tools

• Solidworks.

• ANSYS

• 8DandDRBFM.

• Reliabilityanalysis.

• DesignValidation

Centra Gateway – Product engineering and management

CGW is the central communication node, acts as a router (for in-vehicle communication and through the CCU to the outside) .

• Supervise design and reliability testing.

• Thermo-mechanical FEA of plastic housing.

• PCBstructuralanalysis

• LeadDRBFMand8Dstudies.

• Co-ordinate with PPAP and Quality team.

• Conductfinalproductvalidation.

• Perform warpage measurement and vibrationtesting.

Tools

• Solidworks.

• ANSYS

• 8DandDRBFM.

• Reliabilityanalysis.

• DesignValidation

Karthik Doddaballapura

Design & testing of I-Trams

iTraMS is an end-to-end Vehicle to Infrastructure (V2I) ecosystem. First of its kind at Bosch, I lead the design team on this challenging task of working across cross functional team.

• Design layout for Optical and electricalparts.

• Team lead for design and development.

• Optical fiber layout and cable harness.

• GenerateBOMandpartsdatasheet.

• Sourcevendors&budgeting.

• Conductfinalproductvalidation.

• Conduct8D,DFMandDRBFM.

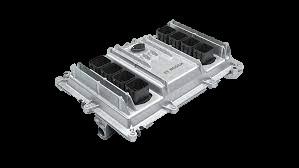

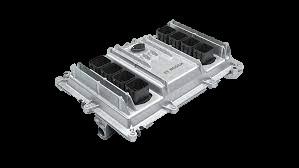

MD1CE100 electronic engine management is the central control unit and the heart of the engine management system for large engines

• PCB structural and vibration analysis

• Warpagemeasurement

• Thermo-mechanicalanalysis.

Tools

• Solidworks.

• ANSYS

• 8DandDRBFM.

• Reliabilityanalysis.

• DesignValidation

Tools

• Solidworks.

• ANSYS

• 8DandDRBFM.

• Reliabilityanalysis

Karthik Doddaballapura

Design commercial ECU

–MD1CE100

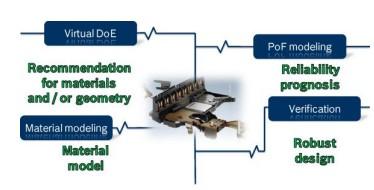

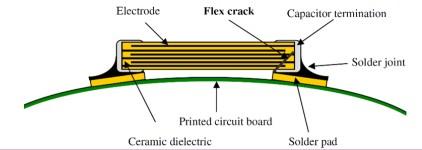

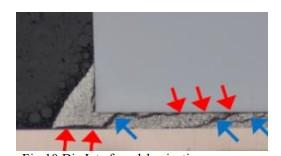

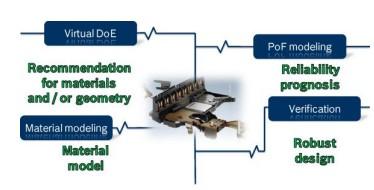

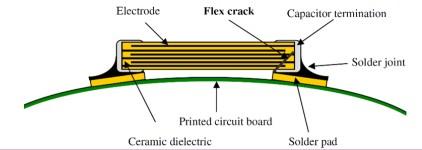

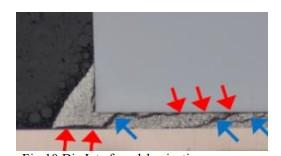

Simulation Based Selection of the Molding Compound for Power Packaging

D2PAK is a surface mount semiconductor package. This method of virtual DoE saved on an average 5% development cost and 9% of design lead time.

• Conductwarpagemeasurement.

• DefineandConductDoE

• Thermo-mechanicalanalysis.

• Report generation and paper presentation.

Tools

• Solidworks.

• ANSYS

• Warpage.

• DesignofExperiments

Process improvement - AutoNDH

In-Circuit Test which is performed on a populated Printed Circuit Board (PCB) to test the electrical functionality of mounted components, structural FEA to ensure support mounts are as per design is performed for every variant and automation of this saved 7% cost on project and zero defects.

• Lead the manufacturing improvementprocess

• StaticstructuralanalysisifPCB.

• Report andeCADfilegeneration

• Fixturemanufacturingmadeeasy.

Tools

• Solidworks.

• ANSYS

• Python.

• MSPowerpoint

Karthik Doddaballapura

3D Modeling and drawing of ML30 RTG cranes

• 3D CAD modeling and manufacturingdrawingwithGD&T.

• Cableharnessdatabasecreation.

• Training customer on cable harness.

Tools

• AutodeskInventor

3D Modeling and drawing of bakery conveyor systems

• 3D CAD modeling and manufacturingdrawingwithGD&T.

• Engineeringcalculations.

Tools

• Solidworks.

Played a major role to achieve ISO certification in 2008

Doddaballapura

Karthik

Paper presentation

All the papers and case study presented across (external and internal) were not only aimed at innovation but also improve existing processes.

• https://www.ansys.com/content/dam/product/structures/robert-bosc h-act-case-study.pdf

• https://ieeexplore.ieee.org/document/7583251

Hobbies and interest

• AvidSoccerfan

• Cricket

• Hikingandwildlifephotography

• Historyandtravelling

https://www.instagram.com/karthikdoddaballapura_photos/?hl=en

Karthik Doddaballapura

Thank you for taking time to go through some of my work in my portfolio. I believe most of my work showcased here has given an overview of my credentials and potential. If you want to know more, please do reach out me.

E-Mail : Karthik.Doddaballapura@gmail.com

Ph: 416-833-8067

Karthik Doddaballapura

Thank you

Karthik Doddaballapura

Mechanical Engineer

Karthik Doddaballapura

Mechanical Engineer