TECHNIQUES, SEQUENCES, OR PROCEDURES OF THE CONTRACTOR, SAFETY PRECAUTIONS AND PROGRAMS OF THE CONTRACTOR, THE ACTS OR OMISSIONS OF CONTRACTOR, OR THE FAILURE OF CONTRACTOR TO CARRY OUT THE WORK IN ACCORDANCE WITH THE CONTRACT DOCUMENTS.

J. INSTALL ALL MATERIALS AND PRODUCTS IN STRICT ACCORDANCE WITH MANUFACTURER'S RECOMMENDATION AND APPLICABLE ICC REPORTS.

K. CONTRACTOR SHALL REMOVE PROMPTLY AND LEGALLY ALL ACCUMULATED DEBRIS, PROTECT ALL EXPOSED PORTIONS OF WORK FROM ELEMENTS, AVOID OVER-LOADING STRUCTURE AND SECURELY STORE ALL ITEMS TO BE USED FOR CONSTRUCTION. COMBUSTIBLE DEBRIS SHALL NOT BE ALLOWED TO ACCUMULATE INSIDE THE BUILDING. COMBUSTIBLE DEBRIS, RUBBISH, AND WASTE MATERIAL SHALL BE REMOVED FROM THE BUILDING DAILY. BURNING OF WASTE MATERIAL IS NOT PERMITTED. ALL AREAS SHALL BE LEFT IN A BROOM CLEAN CONDITION ON A DAILY BASIS.

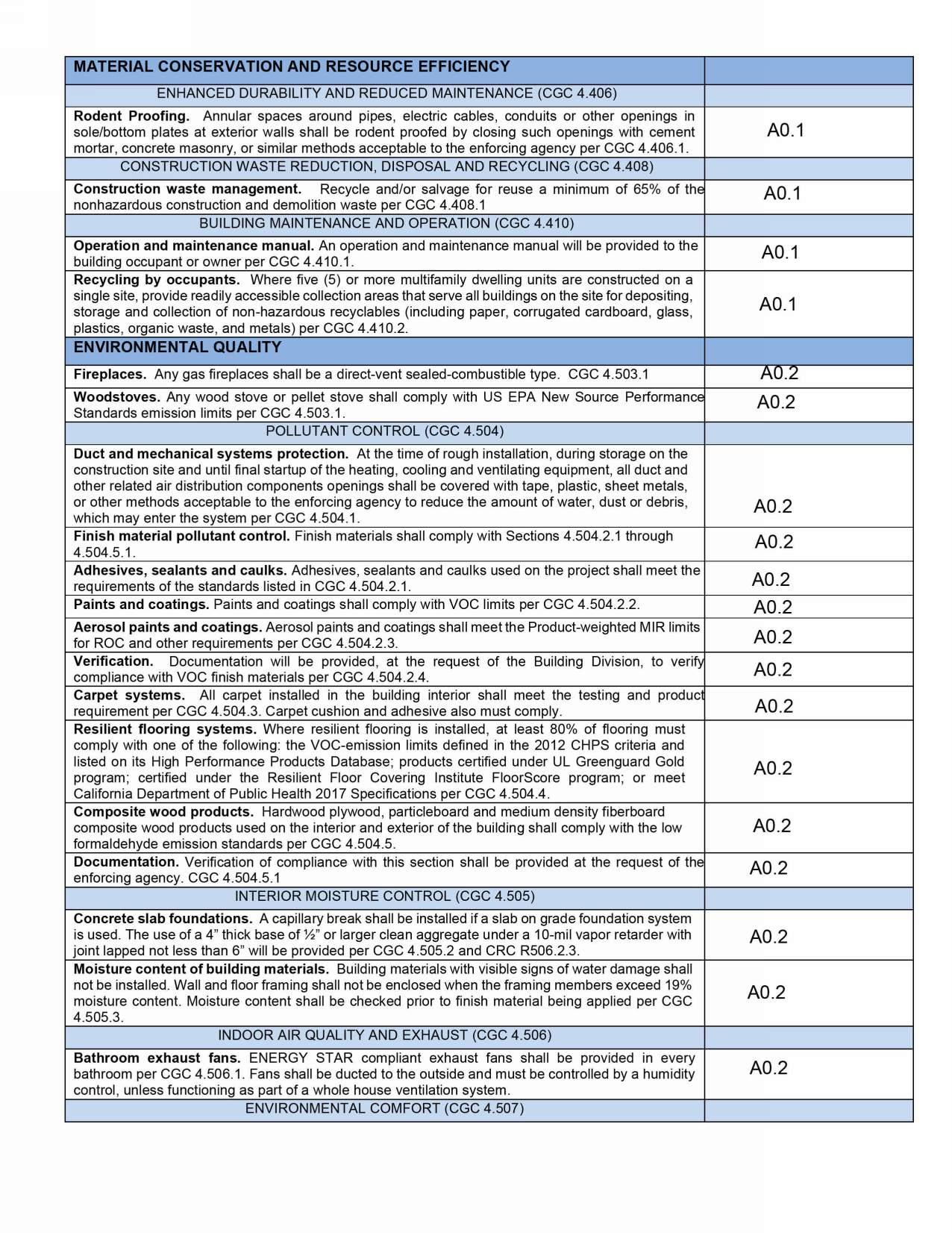

L. A MINIMUM OF 65% OF THE NON-HAZARDOUS CONSTRUCTION AND DEMOLITION WASTE MUST BE RECYCLED AND/OR SALVAGED FOR REUSE IN ACCORDANCE WITH A LOCAL WASTE MANAGEMENT COMPANY. MAINTAIN DOCUMENTATION TO DEMONSTRATE COMPLIANCE AS REQUIRED BY THE ENFORCING AGENCY.

M. WHERE MATERIALS, EQUIPMENT, APPARATUS, OR OTHER PRODUCTS ARE SPECIFIED BY MANUFACTURER, BRAND NAME, TYPE, OR CATALOG NUMBER SUCH DESIGNATION IS TO ESTABLISH STANDARDS OF DESIRED QUALITY AND STYLE AND SHALL BE THE BASIS OF THE BID. MATERIAL SO SPECIFIED SHALL BE FURNISHED UNDER THE CONTRACT UNLESS A CHANGE IS AUTHORIZED IN WRITING. ACCEPTANCE OR REJECTION OF THE PROPOSED SUBSTITUTIONS SHALL BE SUBJECT TO APPROVAL OF THE ENGINEER. IF REQUESTED BY THE OWNER, THE CONTRACTOR SHALL SUBMIT FOR INSPECTION SAMPLES OF BOTH THE SPECIFIED AND PROPOSED SUBSTITUTE TERMS.

N. CONTRACTOR SHALL VERIFY LOCATION OF UNDERGROUND UTILITIES PRIOR TO START EXCAVATION. ALL EXISTING UTILITIES AND CITY SERVICE ARE TO BE MAINTAINED, KEPT IN SERVICE, AND PROTECTED AGAINST DAMAGE DURING CONSTRUCTION. ANY EXISTING UTILITIES TO BE ABANDONED SHALL BE PROPERLY DISCONNECTED, PLUGGED OR CAPPED AS REQUIRED BY CODE OR SOUND CONSTRUCTION PRACTICE.

O. THE CONTRACTOR SHALL TAKE ALL NECESSARY PRECAUTIONARY MEASURES TO PROTECT THE PUBLIC AND ADJACENT PROPERTIES FROM DAMAGE THROUGHOUT CONSTRUCTION.

P. ELECTRICAL CALCULATIONS AND WIRE SIZING SHALL BE PROVIDED BY A LICENSED ELECTRICAL CONTRACTOR. CONTRACTOR SHALL VERIFY LOCATION, FIXTURE TYPES AND EQUIPMENT WITH OWNER PRIOR TO INSTALLATION.

Q. WHEN FIRE SPRINKLER SYSTEM IS REQUIRED IT SHALL BE INSTALLED IN ACCORDANCE WITH NFPA AND LOCAL REGULATIONS. THE CONTRACTOR SHALL SUBMIT SHOP DRAWINGS TO THE GOVERNING JURISDICTION FOR PERMIT.

R. LOCAL BUILDING DIVISION STANDARD APPROVED PLANS SHALL BE KEPT AT THE SITE AND SHALL NOT BE USED BY WORKERS. ALL CONSTRUCTION SETS SHALL BE KEPT

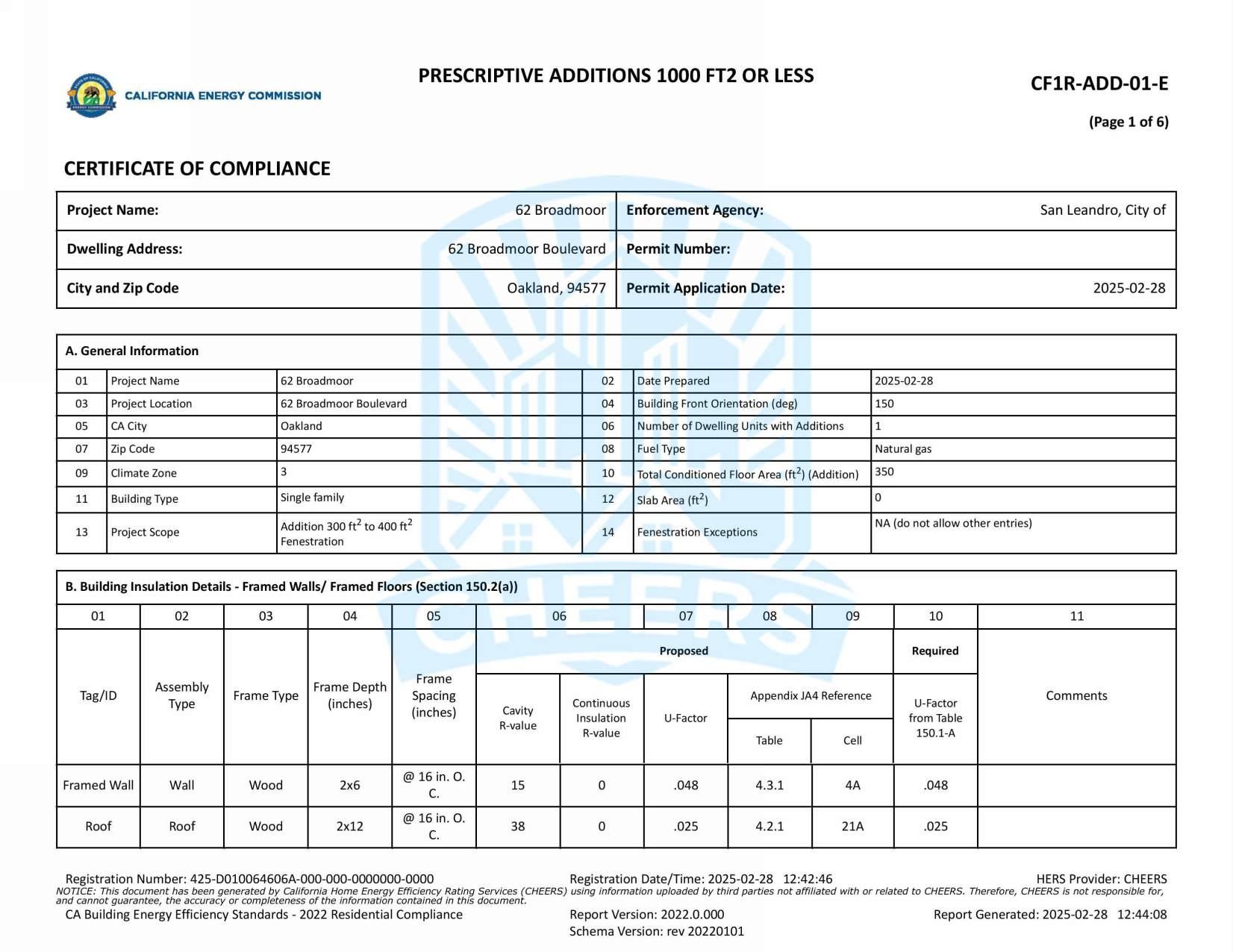

CONSTRUCTION TYPE: V-B STORIES: 2

EXISTING BUILDING AREA: 2184 SF (E) FIRST FLOOR: 1354 SF (E) SECOND FLOOR: 830 SF

PROPOSED BUILDING AREA: 2534 SF (+350 SF) (N)

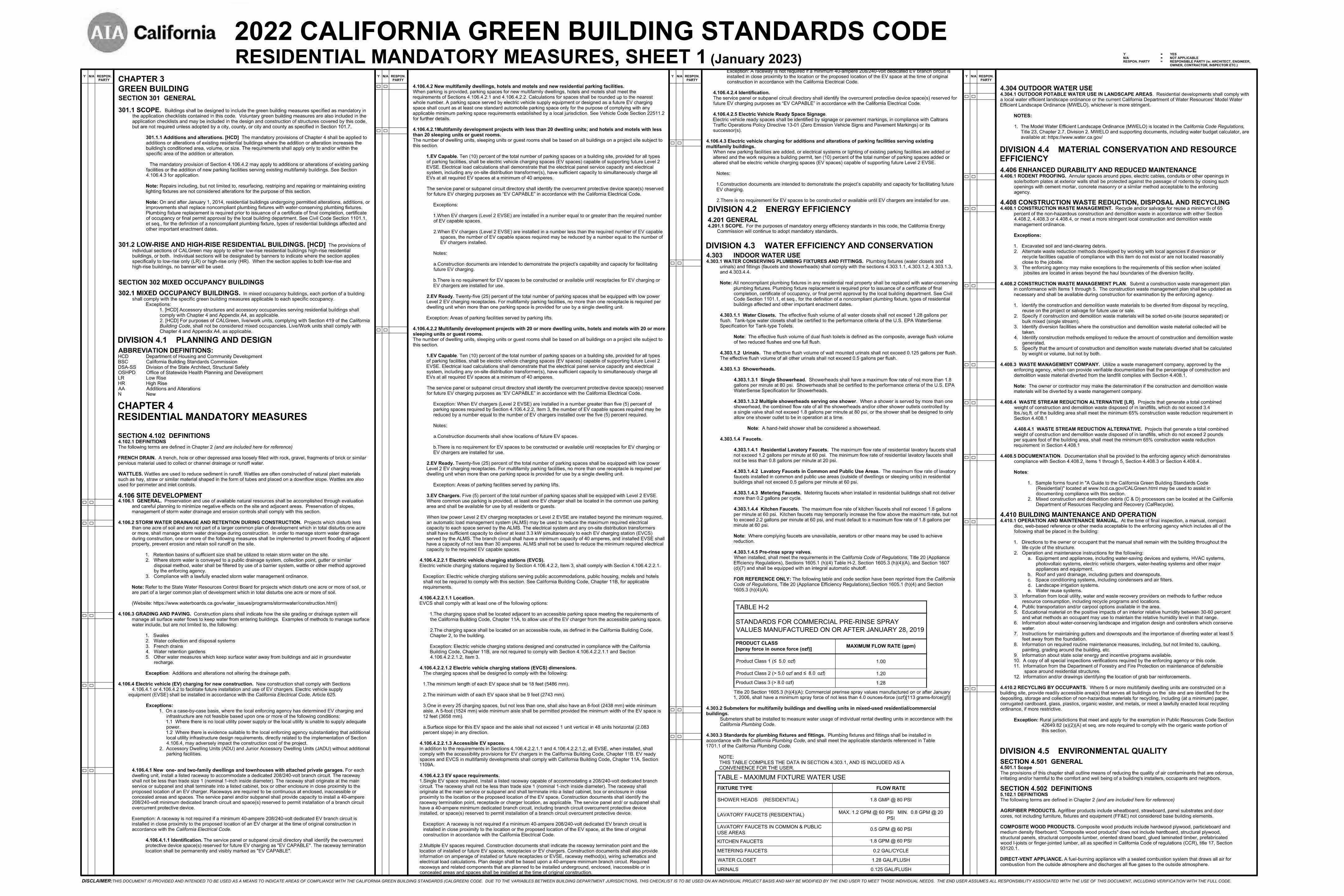

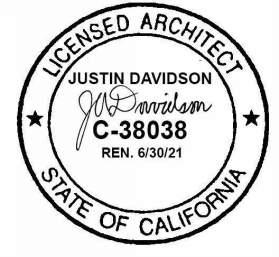

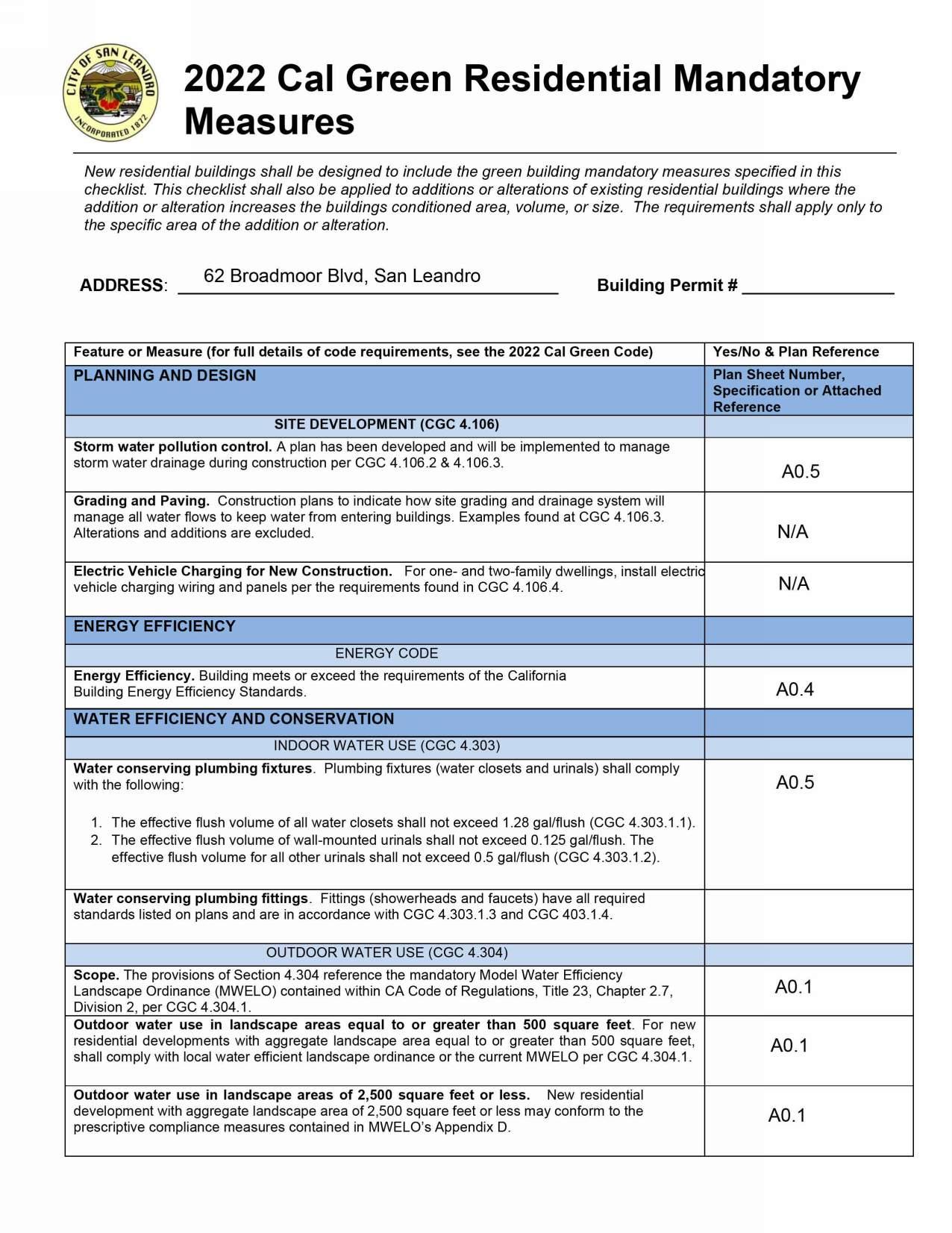

ALL CODES REFERENCED ARE TO BE USED AS AMENDED BY THE STATE OF CALIFORNIA AND LOCAL JURISDICTION. (ALL CODES MAY NOT APPLY TO EVERY PROJECT)

2022 CALIFORNIA BUILDING CODE (CBC) 2022 CALIFORNIA MECHANICAL CODE (CMC) 2022 CALIFORNIA PLUMBING CODE (CPC) 2022 CALIFORNIA ELECTRIC CODE (CEC) 2022 CALIFORNIA ENERGY CODE (Cal Green) 2022 CALIFORNIA RESIDENTIAL CODE 2021 INTERNATIONAL BUILDING CODE 2021 UNIFORM MECHANICAL CODE

UNIFORM PLUMBING CODE

NATIONAL ELECTRICAL CODE 2022 CALIFORNIA HISTORICAL BUILDING CODE CITY OF SAN LEANDRO ORDINANCES

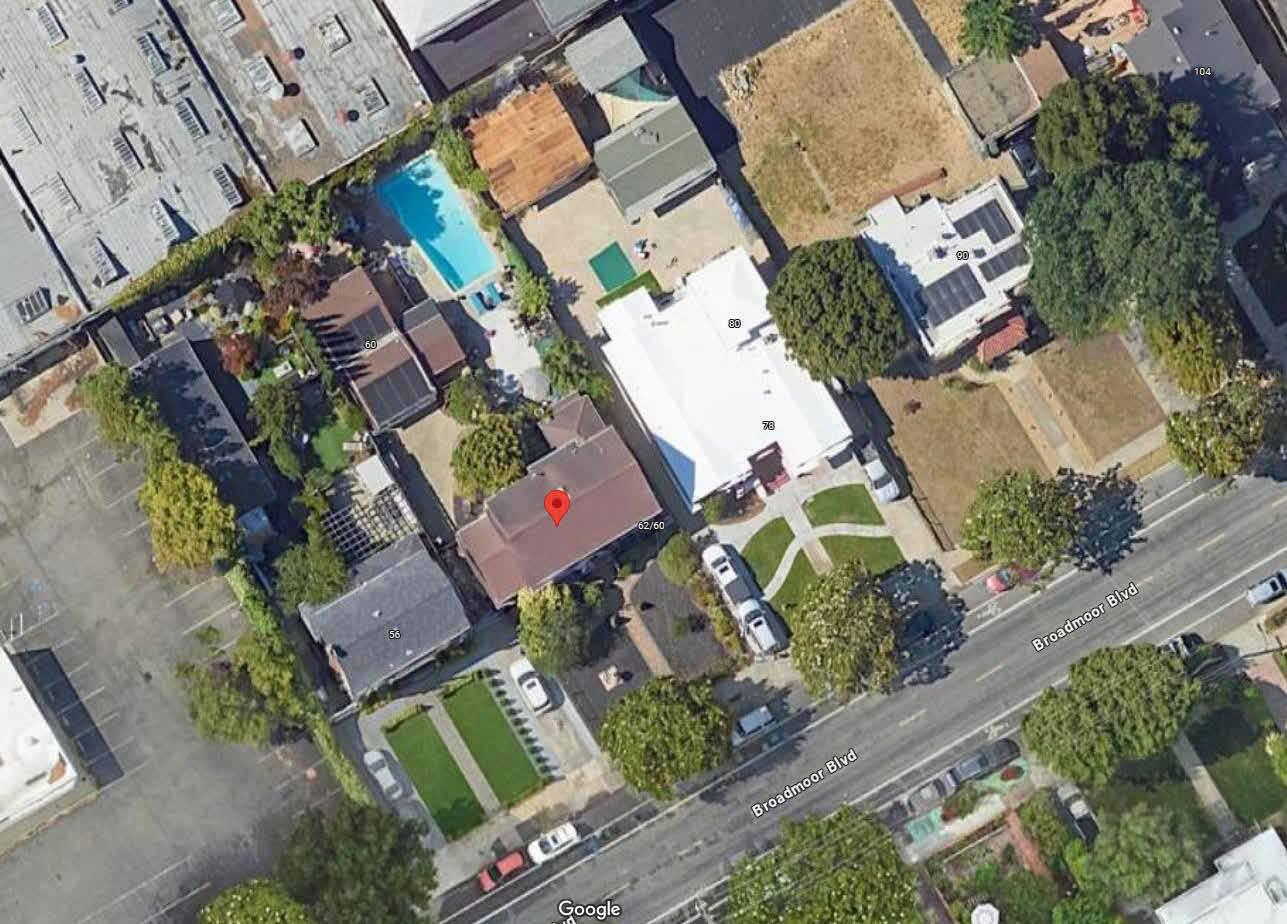

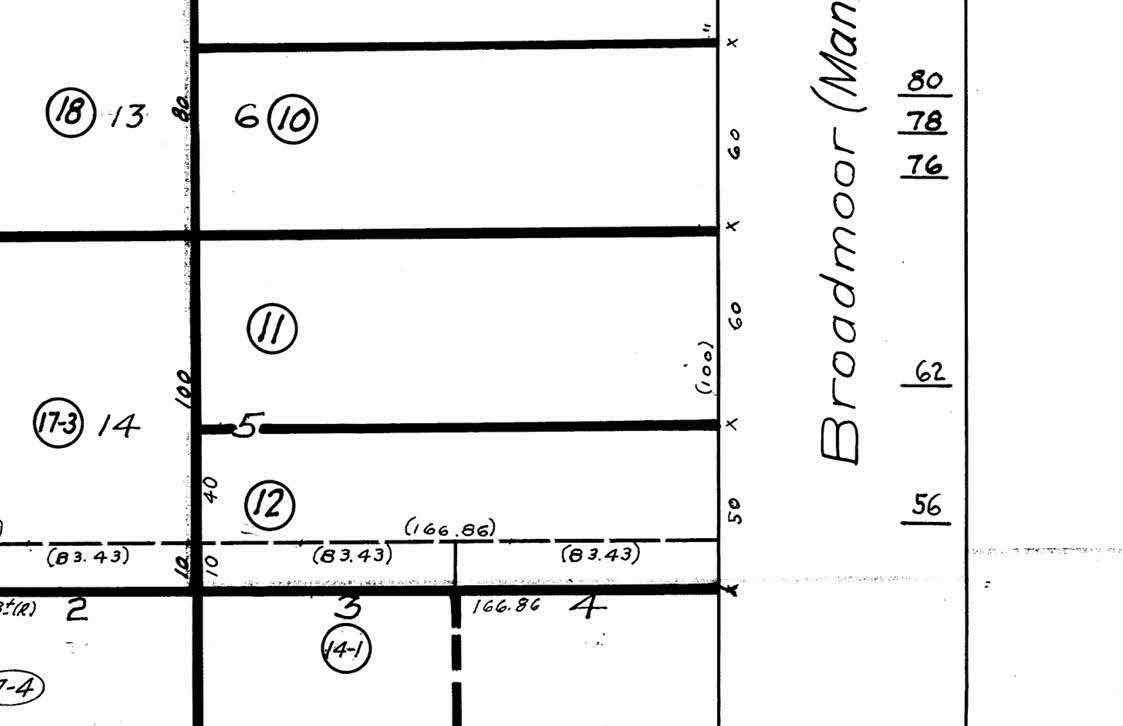

ASSESSOR'S PARCEL MAP

Construction Best Management Practices (BMPs)

Construction projects are required to implement the stormwater best management practices (BMP) on this page, as they apply to your project, all year long.

Materials & Waste Management Equipment Management & Spill Control Earthmoving

Non-Hazardous

Materials

Berm and cover stockpiles of sand, dirt or other construction material with tarps when rain is forecast or if not actively being used within 14 days.

Use (but don’t overuse) reclaimed water for dust control.

Hazardous

Materials

Label all hazardous materials and hazardous wastes (such as pesticides, paints, thinners, solvents, fuel, oil, and antifreeze) in accordance with city, county, state and federal regulations.

Store hazardous materials and wastes in water tight containers store in appropriate secondary containment, and cover them at the end of every work day or during wet weather or when rain is forecast.

Follow manufacturer’s application instructions for hazardous materials and be careful not to use more than necessary. Do not apply chemicals outdoors when rain is forecast within 24 hours.

Arrange for appropriate disposal of all hazardous wastes.

Waste Management

Cover waste disposal containers securely with tarps at the end of every work day and during wet weather.

Check waste disposal containers frequently for leaks and to make sure they are not overfi lled. Never hose down a dumpster on the construction site.

Clean or replace portable toilets, and inspect them frequently for leaks and spills.

Dispose of all wastes and debris properly. Recycle materials and wastes that can be recycled (such as asphalt, concrete, aggregate base materials, wood, gyp board, pipe, etc.)

Dispose of liquid residues from paints, thinners, solvents, glues, and cleaning fl uids as hazardous waste.

Construction Entrances and Perimeter

Establish and maintain effective perimeter controls and stabilize all construction entrances and exits to suffi ciently control erosion and sediment discharges from site and tracking off site.

Sweep or vacuum any street tracking immediately and secure sediment source to prevent further tracking. Never hose down streets to clean up tracking.

Maintenance and Parking

Designate an area, fi tted with appropriate BMPs, for vehicle and equipment parking and storage.

Perform major maintenance, repair jobs, and vehicle and equipment washing off site.

If refueling or vehicle maintenance must be done onsite, work in a bermed area away from storm drains and over a drip pan or drop cloths big enough to collect fl uids. Recycle or dispose of fl uids as hazardous waste.

If vehicle or equipment cleaning must be done onsite, clean with water only in a bermed area that will not allow rinse water to run into gutters, streets, storm drains, or surface waters.

Do not clean vehicle or equipment onsite using soaps, solvents, degreasers, or steam cleaning equipment.

Spill Prevention and Control

Keep spill cleanup materials (e.g., rags, absorbents and cat litter) available at the construction site at all times.

Inspect vehicles and equipment frequently for and repair leaks promptly. Use drip pans to catch leaks until repairs are made.

Clean up spills or leaks immediately and dispose of cleanup materials properly.

Do not hose down surfaces where fl uids have spilled. Use dry cleanup methods (absorbent materials, cat litter, and/or rags).

Sweep up spilled dry materials immediately. Do not try to wash them away with water, or bury them.

Clean up spills on dirt areas by digging up and properly disposing of contaminated soil.

Report signifi cant spills immediately. You are required by law to report all signifi cant releases of hazardous materials, including oil. To report a spill: 1) Dial 911 or your local emergency response number, 2) Call the Governor’s Offi ce of Emergency Services Warning Center, (800) 852-7550 (24 hours).

Schedule grading and excavation work during dry weather.

Stabilize all denuded areas, install and maintain temporary erosion controls (such as erosion control fabric or bonded fi ber matrix) until vegetation is established.

Remove existing vegetation only when absolutely necessary, and seed or plant vegetation for erosion control on slopes or where construction is not immediately planned.

Prevent sediment from migrating offsite and protect storm drain inlets, gutters, ditches, and drainage courses by installing and maintaining appropriate BMPs, such as fi ber rolls, silt fences, sediment basins, gravel bags, berms, etc.

Keep excavated soil on site and transfer it to dump trucks on site, not in the streets.

Contaminated Soils

If any of the following conditions are observed, test for contamination and contact the Regional Water Quality Control Board:

- Unusual soil conditions, discoloration, or odor.

- Abandoned underground tanks.

- Abandoned wells

- Buried barrels, debris, or trash.

Paving/Asphalt Work Concrete, Grout & Mortar Application

Avoid paving and seal coating in wet weather or when rain is forecast, to prevent materials that have not cured from contacting stormwater runoff.

Cover storm drain inlets and manholes when applying seal coat, tack coat, slurry seal, fog seal, etc.

Collect and recycle or appropriately dispose of excess abrasive gravel or sand. Do NOT sweep or wash it into gutters.

Do not use water to wash down fresh asphalt concrete pavement.

Sawcutting & Asphalt/Concrete Removal

Protect nearby storm drain inlets when saw cutting. Use fi lter fabric, catch basin inlet fi lters, or gravel bags to keep slurry out of the storm drain system.

Shovel, abosorb, or vacuum saw-cut slurry and dispose of all waste as soon as you are fi nished in one location or at the end of each work day (whichever is sooner!).

If sawcut slurry enters a catch basin, clean it up immediately.

Store concrete, grout, and mortar away from storm drains or waterways, and on pallets under cover to protect them from rain, runoff, and wind.

Wash out concrete equipment/trucks offsite or in a designated washout area, where the water will fl ow into a temporary waste pit, and in a manner that will prevent leaching into the underlying soil or onto surrounding areas. Let concrete harden and dispose of as garbage.

When washing exposed aggregate, prevent washwater from entering storm drains. Block any inlets and vacuum gutters, hose washwater onto dirt areas, or drain onto a bermed surface to be pumped and disposed of properly.

Dewatering

Discharges of groundwater or captured runoff from dewatering operations must be properly managed and disposed. When possible send dewatering discharge to landscaped area or sanitary sewer. If discharging to the sanitary sewer call your local wastewater treatment plant.

Divert run-on water from offsite away from all disturbed areas.

When dewatering, notify and obtain approval from the local municipality before discharging water to a street gutter or storm drain. Filtration or diversion through a basin, tank, or sediment trap may be required.

In areas of known or suspected contamination, call your local agency to determine whether the ground water must be tested. Pumped groundwater may need to be collected and hauled off-site for treatment and proper disposal.

Painting & Paint Removal

Painting Cleanup and Removal

Never clean brushes or rinse paint containers into a street, gutter, storm drain, or stream.

For water-based paints, paint out brushes to the extent possible, and rinse into a drain that goes to the sanitary sewer. Never pour paint down a storm drain.

For oil-based paints, paint out brushes to the extent possible and clean with thinner or solvent in a proper container. Filter and reuse thinners and solvents. Dispose of excess liquids as hazardous waste.

Paint chips and dust from non-hazardous dry stripping and sand blasting may be swept up or collected in plastic drop cloths and disposed of as trash.

Chemical paint stripping residue and chips and dust from marine paints or paints containing lead, mercury, or tributyltin must be disposed of as hazardous waste. Lead based paint removal requires a statecertifi ed contractor.

Landscaping

Protect stockpiled landscaping materials from wind and rain by storing them under tarps all year-round.

Stack bagged material on pallets and under cover.

Discontinue application of any erodible landscape material within 2 days before a forecast rain event or during wet weather.

1/4"

6.

5.

SPECIALINSPECTIONS

ACI318:17.8.2 X ACI318:17.8.2.4 X INSPECTANCHORSCASTINCONCRETE X ACI318:17.8.2

ACI318:Ch.19,26.4.3,26.4.41904.1,1904.2,1908.2,

ACI318:26.4,26.12

ACI318:26.5

ACI318:26.5.3-26.5.5 1908.9

NOTES:

1. REINFORCEMENTDEVELOPMENTLENGTHANDSPLICELENGTHAREINACCORDANCEWITHACI318-14

2. NOTATIONS

dbNOMINALBARDIAMETER(in)

LDTENSIONDEVELOPMENTLENGTH(in)FORREINFORCEMENTSATISFYINGTHEFOLLOWINGREQUIREMENTS: SLABSANDWALLS: CLEARSPACING>2db,ANDCONCRETECLEARCOVER>db BEAMSANDCOLUMNS: CLEARSPACING>db,ANDCONCRETECLEARCOVER>db

LTDEVELOPMENTLENGTHOFTOPBARSINTENSION=1.3xLD(in)

LBDEVELOPMENTLENGTHOFBARSORDOWELSINCOMPRESSION=1.9db(in)

LSBTENSIONLAPSPLICELENGTHFOROTHERTHANTOPBARS=1.3xLD(in)

LSBTTENSIONLAPSPLICEOFTOPBARS=1.69xLD(in)=1.3xLSB

LCTIEDCOLUMNLAPSPLICEINCOMPRESSION=30xdb(in)

LCS:SPIRALCOLUMNLAPSPLICEINCOMPRESSION=22.5xdb(in)

3. MULTIPLYVALUESINTHETABLEBY1.5IFCLEARSPACINGORCONCRETECOVERDONOTMEETTHEREQUIREMENTSFORLDINNOTE2.

4. TOPBARS:HORIZONTALBEAMREINFORCINGWITHMORETHAN12INCHESOFCONCRETECASTBELOW.

5. THEDEVELOPMENTANDSPLICELENGTHSAREBASEDONREINFORCEMENTSTRENGTHFy=60KSIANDNORMALWEIGHTCONCRETE.

6. THEDEVELOPMENTLENGTHISONLYFORUNCOATEDORZINCCOATEDREINFORCEMENT.

REINFORCINGBARDEVELOPMENT-SPLICELENGTHTABLES

SCALE:NTS

4.

3.

ANDPRIORTOREMOVALOFSHORESANDFORMSFROM BEAMSANDSTRUCTURALSLABS INSPECTFORMWORKFORSHAPE,LOCATIONAND DIMENSIONSOFTHECONCRETEMEMBERBEING FORMED NON-STRUCTURALSLABSONGRADE

ACI318:Ch.26.8

ACI318:26.11.2

ACI318:26.10 X X X

ACI318:26.11.1.2(b) NOTREQUIRED NOTREQUIRED 1705.3

FLOORDIAPHRAGMTOBE3/4"T&G PLYWOOD(P.I.=48/24),GLUED& NAILED.FORNAILINGCALLOUT,SEE GENERALNOTESONSHEETS1.0AND S1.1.PLACELONGDIRECTIONOFALL PLYWOODPERPENDICULARTOFLOOR JOISTSANDSTAGGERENDLAPS.

INTERIORFTG F1.5/1.5

b=1'-6" =1'-0" WALLFTGTYP

b=1'-6" =1'-0" (E)WALLFTGTYP (VERIFY)

ANCHORAGEATEXISTING STEMWALL

SEEDETAILB/S3.1FOR ANCHORAGEATEXISTING STEMWALL

b=1'-6" =1'-0" (E)WALLFTGTYP (VERIFY)

FOUNDATIONNOTES

1.COORDINATEDIMENSIONSWITHARCHITECTURALPLANS.DIMENSIONSARECONTROLLEDBYTHEARCHITECTURALDRAWINGS.ANY DISCREPANCYINDIMENSIONBETWEENARCHITECTURALANDSTRUCTURALDRAWINGSMUSTBEBROUGHTTOTHEENGINEER’SATTENTION.

2.COORDINATEWITHMECHANICALANDPLUMBINGDRAWINGSFORSIZEANDLOCATIONOFPENETRATIONSTHROUGHFOOTINGSANDSLAB. SEE2/S3.0FORPIPEUNDERORTHROUGHFOOTINGDETAIL.

3. INDICATESFOOTINGMARK.SEESCHEDULEFORSIZEANDREINFORCEMENT.COLUMNFOOTINGSSHALLBECENTEREDON COLUMNSUNLESSNOTEDOTHERWISE.

4. INDICATESESTIMATEDTOPOFFOOTINGS.TOPOFFOOTINGELEVATIONWILLVARYWITHFINALGRADEELEVATION.GCTO COORDINATEWITHCIVILANDARCHITECTURALDRAWINGSTOVERIFYTHATTHEBOTTOMOFALLFOOTINGSAREATLEAST2'-0"BELOWTHE FINALFINISHEDGRADE.PLINTHSATCOLUMNSANDSTEMWALLSATCONTINUOUSFOUNDATIONMAYBEREQUIREDTOACCOMMODATETHE FINALGRADEVARIATIONS.

5.CONCRETESLABORFTGSHOULDBEPLACEDOVER6MILVAPORBARRIERON4INCHOFGRAVELORCRUSHEDROCKOVERFIRM UNDISTURBEDSOILORENGINEEREDCOMPACTEDBACKFILL.

6.CONTINUOUSFOOTINGSMAYBESTEPPEDTOACHIEVETHEMINIMUMDEPTHPER3/S3.0

7.SEEGENERALNOTESANDSPECIALINSPECTIONSONS1.0ANDS1.1FORADDITIONALINFORMATION.

8. INDICATESSHEARWALLTYPEPERS3.0SEESHEARWALLSCHEDFORMOREINFO.

9.SEES3.0FORSIMPSONHOLDOWNSCHEDULE.

10. INDICATESEXTENTOFLOADBEARINGWALLS.

11. INDICATESEXTENTOFSHEARWALL.

FOUNDATIONSCHEDULE

TAG SIZE REINF

F1.5/1.5 1'-6"X1'-6"X1'-0" #4AT6"OC EAWAY(BOT)

CEILINGFRAMINGNOTES

1.REFERTOARCHITECTSFLOORPLANFORDIMENSIONS.

2.ALLEXTERIORWALLHEADERSSHALLBESUPPORTEDBY(2)2x6BEARINGSTUDSPER8/S3.0U.N.O.ONTHEPLANS.

3.SEETHEGENERALNOTESANDSPECIALINSPECTIONSONSHEETSS1.0ANDS1.1FORADDITIONALINFORMATION.

4.ALLGIRDERSANDHEADERSSHOWNONPLANAREFLUSHBEAMS.UNO.

5. INDICATESEXTENTOFWOODSHEARWALLS.SEES3.0FORSHEARWALLSCHEDULEANDTYPDETAILS.

WX

6. INDICATESSHEARWALLTYPEPERS3.0SEESHEARWALLSCHEDFORMOREINFO.

7. INDICATESEXTENTOFLOADBEARINGWALLS.

SIMPSONMSTI72

(SEENOTE#3OFROOF FRAMINGNOTESFOR ROOFDIAPHRAGMINFO)

ROOFFRAMINGNOTES

1.COORDINATEDIMENSIONSWITHARCHITECTURALPLANS.

2.COORDINATEWITHARCHITECTURALANDMECHANICALPLANSFORLOCATIONANDSIZEOF ROOFOPENINGS,IFOCCURS.

3.ROOFDIAPHRAGMTOBE1/2”CDX(P.I.=48/24)PLYWOODAPPLIEDDIRECTLYOVERROOF JOISTS/TRUSSES,SEES1.0FORNAILING.PLACELONGDIRECTIONOFPLYWOODSHEETS PERPENDICULARTOROOFJOISTS/TRUSSESANDSTAGGERLAPS.

4.LAYOUTOFALLEXTERIORWALLOPENINGSTOBECO-ORDINATEDW/ARCHTDWGS.REPORTTO ENGINEEROFRECORDINCASEOFANYDISCREPANCY.

5. INDICATESEXTENTOFWOODSHEARWALLS.SEES3.0FORSHEARWALLSCHEDULE ANDTYPDETAILS.

6.SEETHEGENERALNOTESONSHEETSS1.0ANDSPECIALINSPECTIONSONSHEETS1.0ANDS1.1 FORADDITIONALINFORMATION.

7.ALLEXTERIORBEAMS/HEADERSSHALLBEMINIMUM(2)2X6UNO.W/MIN(2)2XBEARINGSTUD ATEACHENDOFBEAM/HEADERU.N.O.

8.ALLPOSTSUPPORTINGHEADER,GLBANDROOFGIRDERSATUPPERLEVELSNEEDTOBECONT ALLTHEWAYTOFOUNDATION.

SUPPORTSAW-CUTTINGEQUIPMENT,&WITHIN 24HOURSOFSLABPOUR).

SAW-CUTBARSWITHOUT

NOTE: 1.ANYJOINTMAYBEACONTROLJOINTORCONSTRUCTION JOINT,ATCONTRACTORSOPTION.

PIPESLEEVE,2"LARGER THANPIPE.WRAP BTWNPIPE&SLEEVE W/ACOMPRESSIBLE MATERIAL

BOREDHOLESMAXSIZE HOLESHALLBE60%OFWIDTH

21DIAHOLEFOR2x4,3x4

35 16DIAHOLEFOR2x6

5 8MINEDGEDISTANCE

NOTCHESMAXDEPTH40%OF WIDTH

8MINEDGE DISTANCE

13 16DEEPNOTCHFOR2x4,3x4

23 16DEEPNOTCHFOR2x6

d d

STUD STUD

INTERIORNONBEARINGWALLS

1.THISDETAILSHOWSPERMISSIBLELOCATIONSOFPIPES,CONDUITS,ETCUNDERBEARINGWALLS.

2.STEPFTGEASIDEOFPIPESOSLEEVE&PIPEWILLPENETRATESTEMWALL. 3.CONCBACKFILLNOTREQUIREDBYSTRUCTURALENGINEERUNDERNON-BEARINGWALLFTGWHEN MECHANICALEXCAVATIONISLESSTHAN1'-0"DEEPBY1'-0"WIDE.UNLESSNOTEDOTHERWISE

BOREDHOLESMAXSIZE HOLESHALLBE40%OF WIDTH2x4-1.4"(1")DIA HOLE2x62.2"(216")DIA HOLE

BOREDHOLESINDOUBLE STUDSMAXSIZEHOLEIN DOUBLESTUDSSHALLBE60% OFWIDTH(NOMORETHAN TWOADJOININGDOUBLE STUDSTOBEBORED)

PORTIONOFSTUDREMAININGATNOTCHESORHOLESSHALLBESOUNDWOODWITHOUTEXCESSIVE STRENGTH-REDUCINGPROPERTIESSUCHASKNOTS,SPLITS,EXCESSIVESLOPEOFGRAIN,ETC. *

NOTCHATEND

2x4-1.4"(1")DIAHOLE 2x6-2.2"(216")DIAHOLE

NOTCHESMAXIMUMDEPTH SHALLBE25%OFWIDTH 7 8DEEPNOTCHFOR2x4,3x4 1"DEEPNOTCHFOR2x6

EXTERIORWALLS&BEARINGWALLS

2SOLIDBLOCKING(EXCEPTWHEREENDSOFJOISTS ARENAILEDTOAHEADER.BANDORRIMJOISTORTO ANADJOININGSTUDORBYOTHERAPPROVEDMEANS)

NOTCHEDNOTPERMITTEDWITHIN MIDDLETHIRDOFSPAN.BUT BOREDHOLESAREPERMITTED

BOREDHOLESALSOPERMITTED

NOTCHESWITHIN1/3SPANEAEND

NOTE: 1.HOLESANDNOTCHESMAYBEALLOWEDACCORDINGTOIBC2308.5,WHICHISPICTORALLYREPRESENTED HERE,PROVIDEDTHATSTRUCTURALENGINEERSAPPROVALINWRITINGISOBTAINEDPRIORTOPROCEEDING. 2.FORPERMITTEDLOCATIONSOFHOLESINWEBSOFREDI-JOISTS,SEEREDI-JOISTSSHOPDRAWINGS.

LOCATEEXTERIORPANELJOINT ATRIMJOIST&PROVIDEPANEL EDGENAILINGPERSCHED

FLOORJOISTS

STUDS(USE3xSTUD ATPANELEDGES WHERESHOWNIN SHEARWALLSCHED)

DOUBLETOPPL

RIMJOIST

BLKGREQDATALL PANELEDGES(USE3x WHEREINDICATEDIN SHEARWALLSCHED)

PLWDSHTGW/FACE GRAINPERPENDICULAR ORPARALLELTOSTUDS

EDGENAILINGSEESCHED

NAILPANELFIELDAT12"OC(TYP)

BOTPL(USE3xWHEREINDICATED INSHEARWALLSCHED)

0.148"Øx3"AT4"OC 0.148"Øx3"AT3"OC 0.148"Øx3"AT2"OC 0.148"Øx3"AT2"OC 0.148"Øx3"AT3"OC

SHEARWALLSCHEDULE

A35CLIPAT6"OC 0.162"Øx3½"AT4"OC 0.162"Øx3½"AT3"OC 2ROWS0.162"ØAT5"OC 2ROWS0.162"ØAT4"OC 2ROWS0.162"ØAT3"OC "ØAT32"OC "ØAT32"OC "ØAT16"OC "ØAT16"OC "ØAT16"OC (2) 2SW2 15 32TWOSIDE0.148"Øx3"AT2"OC 3x 2ROWS0.162"ØAT3"OC "ØAT8"OC (2) 3x 3x 3x 3x 3x 3x HGA10KTAT6"OC HGA10KTAT4"OC

NOTES:

(1)INSTALLPANELSEITHERHORIZONTALLYORVERTICALLYDIRECTLYONSTUDS.

(2) WHERESHEATHINGISAPPLIEDONBOTHSIDESOFWALL,PANELEDGEJOINTSSHALLBESTAGGEREDSOTHATJOINTSONOPPOSITE SIDESOFTHEWALLARENOTLOCATEDONTHESAMESTUDS.

(3)BLOCKINGISREQUIREDATALLPANELEDGES.

(4)PROVIDESHEARWALLSHEATHINGANDNAILINGFORTHEENTIRELENGTHOFTHEWALLSINDICATEDONTHEPLANS.ENDSOFFULL HEIGHTWALLSAREDESIGNATEDBYEXTERIOROFTHEBUILDING,CORRIDORS,WINDOWSORDOORWAYSORASDESIGNATEDON PLANS.SEEPLANSFORHOLDOWNREQUIREMENTS.(ALTERNATENOTE:WALLSDESIGNATEDASPERFORATEDSHEARWALLSREQUIRE SHEATHINGABOVEANDBELOWALLOPENINGS).

(5) SHEATHINGEDGENAILINGISREQUIREDATALLHOLDOWNPOSTS.EDGENAILINGMAYALSOBEREQUIREDTOEACHSTUDUSEDIN BUILT-UPHOLDOWNSPOSTS.REFERTOTHEHOLDOWNDETAILSFORADDITIONALINFORMATION.

(6)INTERMEDIATEFRAMINGTOBEWITH2xMINIMUMMEMBERS.FIELDNAILING12"OC(SEEDETAIL6/S3.0).

(7)BASEDON0.131"Øx11"LONGNAILSUSEDTOATTACHFRAMINGCLIPSDIRECTLYTOFRAMING.USE0.131"Øx22"NAILSWHERE INSTALLEDOVERSHEATHING.

(8)FRAMINGCLIPS:A35ORLTP5ORAPPROVEDEQUIVALENT.PROVIDEAT24"OCATNON-SHEARWALLS.

(9) WHEREPLATEATTACHMENTSPECIFIES(2)ROWSOFNAILS,PROVIDEDOUBLEJOIST,RIMOREQUAL.ATTACHPERDETAILS. (10)ANCHORBOLTSSHALLBEPROVIDEDWITHSTEELPLATEWASHERSMIN3"x3"x0.25".LOCATEPLATEWASHERSWITHIN1"OFTHE EDGEOFTHEBOTTOMPLATEONTHESIDESWITHSHEATHING.EMBEDANCHORBOLTS7"MINIMUMINTOTHECONCRETE. (11)PRESSURETREATEDMATERIALCANCAUSEEXCESSIVECORROSIONINTHEFASTENERS.PROVIDEHOT-DIPPEDGALVANIZEDNAILS (ELECTRO-PLATINGISNOTACCEPTABLE)ANDCONNECTORPLATES(FRAMINGANGLES,ETC)FORALLCONNECTORSINCONTACTWITH PRESSURETREATEDFRAMINGMEMBERS(SEEGENERALNOTESFORREQUIREDGALVANIZINGTHICKNESS).

(12)APARATEDORIENTEDSTRAND-BOARD(OSB)SHEATHINGOFTHESAMETHICKNESSMAYBEUSEDINPLACEOF15 32SHEATHING PROVIDEDTHATALLSTUDSARESPACEDAT16"OCORCLOSER.

(13)WHEREWOODSHEATHING(W)ISAPPLIEDOVERGYPSUMSHEATHING,CONTACTTHEENGINEEROFRECORDFORALTERNATENAILING REQUIREMENTS.

(14)ATADJOININGPANELEDGES,(2)2xSTUDSNAILEDTOGETHERMAYBEUSEDINPLACEOFASINGLE3xSTUD.DOUBLE2xSTUDSSHALL BECONNECTEDTOGETHERBYNAILINGTHESTUDSTOGETHERWITH3"LONGNAILSOFTHESAMESPACINGANDDIAMETERASTHE PLATENAILING.

(15)ALLSILLPLATEANCHORBOLTSSHALLBECAST-IN-PLACEEXCEPTWHERENOTEDOTHERWISEONPLAN&DETAILS.ADHESIVEOR EXPANSIONANCHORSMAYNOTBEUSEDWITHOUTPRIORWRITTENAPPROVALFROMTHEENGINEEROFRECORD.(SPECIAL INSPECTIONWILLBEREQUIRED). (16)"W"=SHEARWALLSSHEATHEDWITHAPARATEDCDXOROSB "SW"=SHEARWALLSSHEATHEDWITHAPARATEDSTRUCT1.

FULLHEIGHTMEMBER(S): (2)2x_MINATEXTWALL, (2)2_MINATINTWALL, ORHOLDOWNCOMPRMBR PERSCHED INFILLWALL

ATROOFLVLPROVIDESIMPSON"H8" HURRICANETIESFORHDRSUPPORTING OUTRIGGERSAND"H6"TIESFORHDR

10dAT6"OC

2x6BLKG

2x6BRACE AT6'-0"OCW/ (6)10dAT TOPBLKG

10dAT3"OCTO OUTRIGGERS

2x6BLKG(VENTHOLESPER ARCHT) SIMPSON"A35"AT12"OC

2x6AT24"OCOUTRIGGERS

SIMPSON LUS26

TRUSSES

A34ANCHORBOTHSIDES OF2X6(STAGGERED)

16dPLTOPLSEESHEARWALL SCHED

SEEARCHT (2'-0"MAX)

10dAT6"OC 2x6AT16"OC

SIMPSONA35PER SHEARWALLSCHED

2xBLKGBTWNSTUD

2x6AT16"OC(4xSTUDS WHEREREQ'DBY SHEARWALLSCHED)

2xRAFTERSAT16"O.C.

BOUNDARYNAILING

BLOCKINGW/12d TOENAILSAT4"O.C.

SIMPSONH2.5AATALL RAFTERSTOTOPPLATE S.A.D.

2xRAFTERSPER FRAMINGPLAN

2xCEILINGJOIST PERPLAN

PROVIDE(4)16dNAILS ATRAFTERTOCEILING ATJOISTCONN.

CONT.SYP#2-2xDBL.TOP PLATE16dNAILS4"O.C.

2xSTUDS@16"O.C. STUDWALL

WALLSHEATHINGPER SHEARWALLPLAN

2xSTUDAT16"OC (3xSTUDSATPANELEDGESWHERE REQDBYSHEARWALLSCHED)(TYP)

JOISTPERPLAN PLWDSHTGPERPLAN SIMPSON'LB210' TOPFLANGE HANGER 2x10JOIST

2xSTUDAT16"OC (3xSTUDSATPANELEDGES WHEREREQDBYSHEARWALLSCHED)(TYP)

"ØA.BOLTSPERSHEARWALL SCHED(4'-0"OCWHERENOT SHEARWALLTYP)

#5AT16"OC(H) #5AT16"OC(V)

(2)#5CONT 2xPTPL (2)#5CONT

2xSTUDAT16"OC (NAILINGANDHOLDOWN PEROTHERDETAIL CALLOUTSONFOUNDATION PLAN(NOTSHOWNFOR CLARITY)

(E)STUDWALL (E)SHTG 4"EMBEDED (DRILLANDSETW/EPOXY) DONOTUNDERMINE(E)FTG. BACKFILLW/CONCIFNEEDED

(E)T/FTG -2'-0"(VERIFY) 4"EMBED,TYP (E)PT2XPL

#5DWLSAT16"OC(DRILLINTO(E) ANDSETW/EPOXY)ESR3187 2xPTPL

ROUGHEN(E)CONCSURFACETO1/4" AMPLITUDEANDAPPLYBONDING AGENTBEFORECONCPOUR

SCHED(4'-0"OCWHERENOT SHEARWALLTYP)

EDGENAILING PERGENERAL NOTES (E)SHEARWALLS

(N)2xBLKGBTWN (E)SWSTUDS, ALIGNEDW/(N) ROOFENDJOIST

(N)2xBLKGBTWN (E)SWSTUDS, ALIGNEDW/(N) CEILINGENDJOIST

(N)ROOFENDJOISTORLEDGER W/(2)ROWSOF1/4"X41/2"SDS SCREWSTOEASTUDOF(E)SWAT 16"OC (E)FLOOR/CEILINGJOIST

(N)ROOFSHTG PERPLAN

2xBLKG AT16"OC

(N)ROOFJOIST PERPLAN SIMPSONLUS HANGER ATBOTHENDS

(N)CEILINGENDJOISTORLEDGER W/(2)ROWSOF1/4"X41/2"SDS SCREWSTOEASTUDOF(E)SWAT 16"OC

BOTOF(N)CEILING

SIMPSONDTCCLIPAT TYP24"OCU.O.N. STUDSAT 16"OCTYP. U.O.N.

FLOORJOISTORBLKG. ASNECESSARY

DTCCLIPEA. SIDEEA.JOIST

PARTITIONSTUD WALLPERPLAN .0157HILTIPOWERDRIVEN PINS1-1/2"EMBEDMIN.INTO AT16"OC

(E)DOUBLETOP PLATE(WO) (E)DOORHEADER (E)WALLTO BEDEMO

(E)2XTRIMMEDSTUD

(4)16dNAILS ATEACHSTUD (TYP) (N)2XSTUDSAT16"OCAS IN-FILLFRAMING. PROVIDESHTGONBOTHSIDES TOMATCHWITH(E)WALLSHTG NAILW/8dAT12"OC (NONSTRUCTURALIN-FILL)

(E)FINISHFLOOR

(E)PLATE

(4)16dNAILSAT EACHSTUD(TYP) 2XPTD.FSILLPLATEW/GALVANIZED 0.145"X3"POWDERACTUATEDSHOTPIN W/1"WASHERAT32"OC,6"TO10"FROM EAENDOFEACHSEGMENT.USESIMPSON PDPWL-300MGSHOTPINPERICCREPORT ESR-2138OREQIV.FASTENERRATEDFOR PRESSURETREATEDWOOD

(E)(2)2xTOPPL'S

(2)2x_MINATEXTWALL, (2)2x_MINATINTWALL, ORHOLDOWNCOMPRMBR PERSCHED

BRGSTUDSPERPLAN TOPOFPL ELEV

(2)2x6HEADER(MIN)

ATROOFLVLPROVIDESIMPSON"H8" HURRICANETIESFORHDRSUPPORTING OUTRIGGERSAND"H6"TIESFORHDR SUPPORTINGROOFTRUSSES

(E)(2)2_ FULLHEIGHT STUDS

(2)2x6HEADER(MIN)

ATROOFLVLPROVIDESIMPSON"H8" HURRICANETIESFORHDRSUPPORTING OUTRIGGERSAND"H6"TIESFORHDR SUPPORTINGROOFTRUSSES

BRGSTUDSPERPLAN