make & made BLEU

Hey there! I’m Jothirmaii, a product designer with a genuine passion for creating innovative and user-friendly solutions. I love blending functionality with a touch of fun, making everyday experiences a little brighter. My curiosity drives me to explore new ideas and connect with people, ensuring that every product I design not only meets their needs but also brings a smile to their faces.

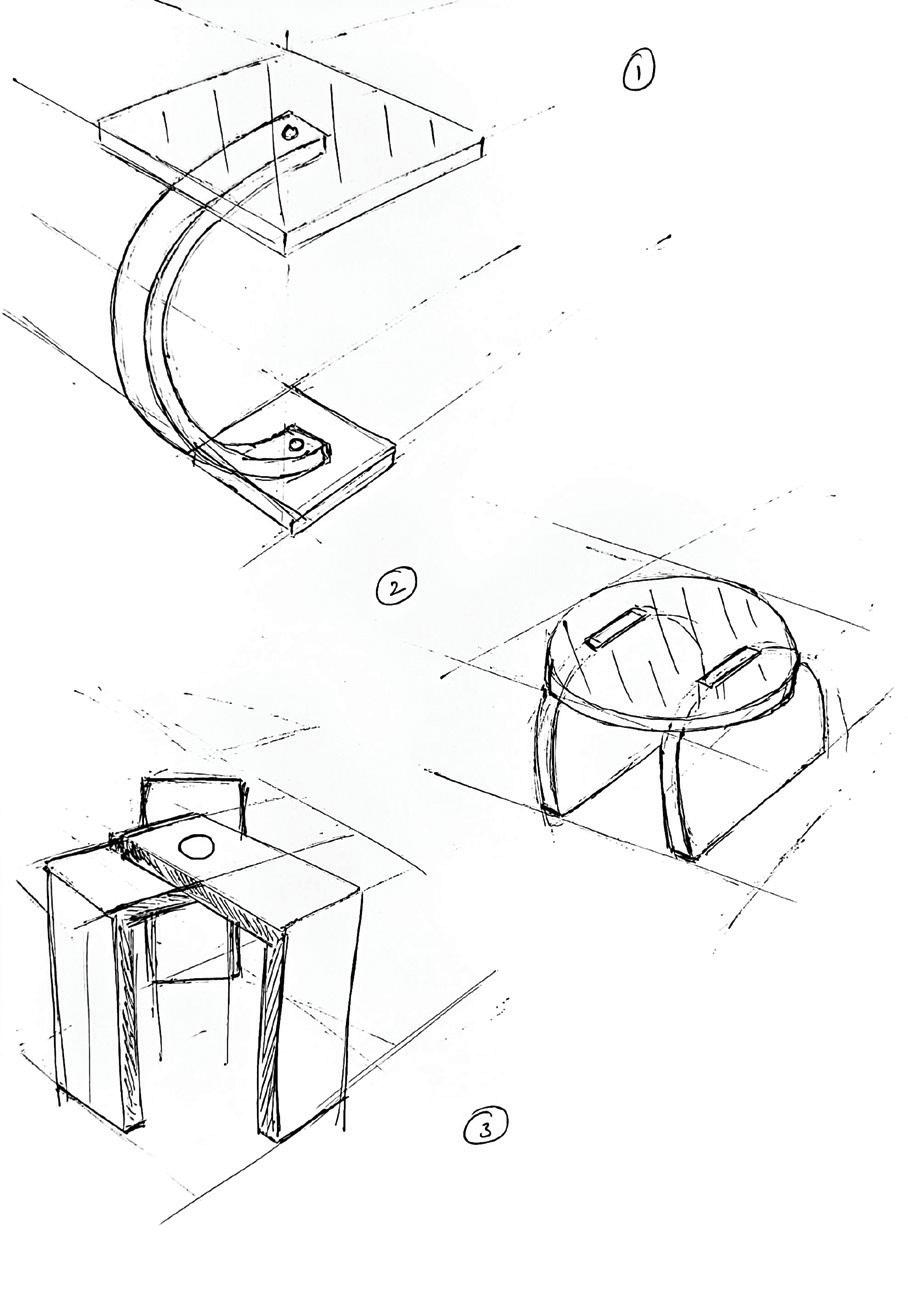

I’m excited to share my latest project— Bleu - a stool crafted from recycled plastic and wood scraps. This endeavor not only showcases my commitment to sustainability but also embodies my belief in thoughtful design as a powerful medium for storytelling and expression. In this book, I’ll guide you through the design process, my inspirations, and the unique features that make this stool a meaningful addition to any space.

This “Make & Made” module delves into the versatility of materials, focusing on the potential future of stools. Through this project, we explore the materiality of recycled plastic and experiment with innovative joinery techniques. The following pages present an in-depth examination of both recycled plastics and wood, with the final model incorporating a composition of 70% recycled plastic and 30% (or less) wood.

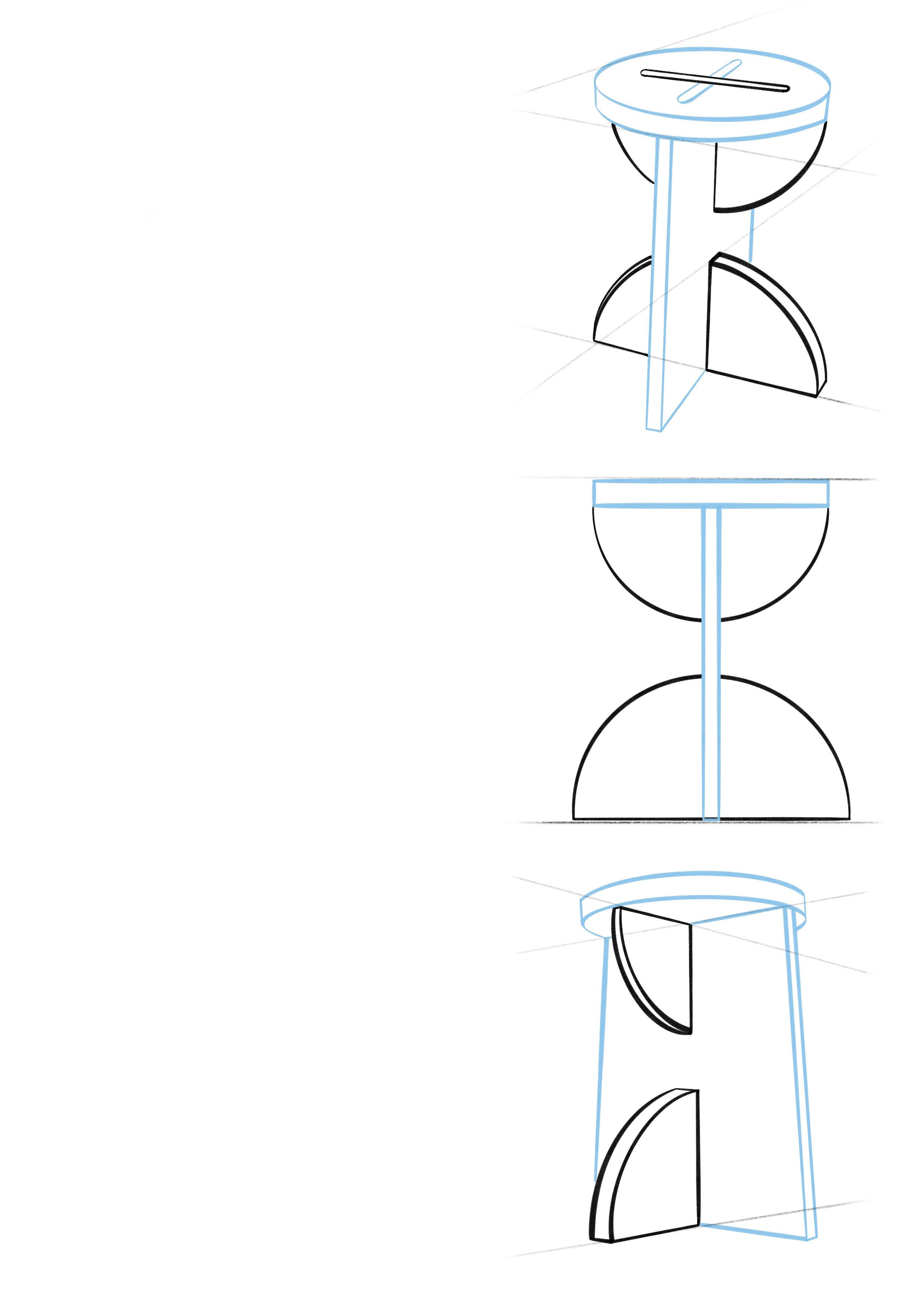

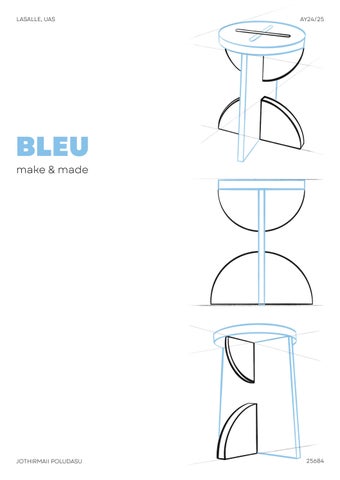

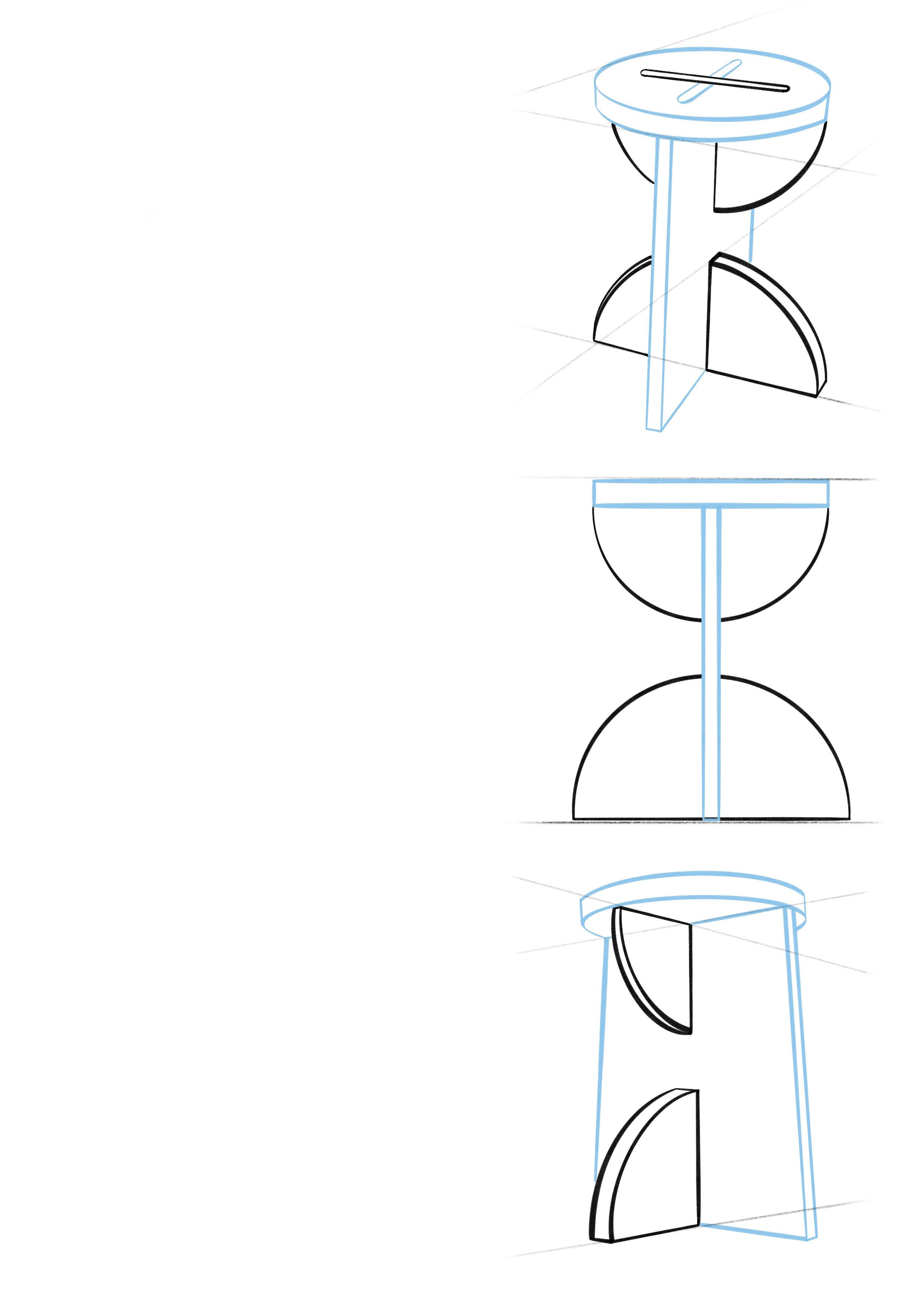

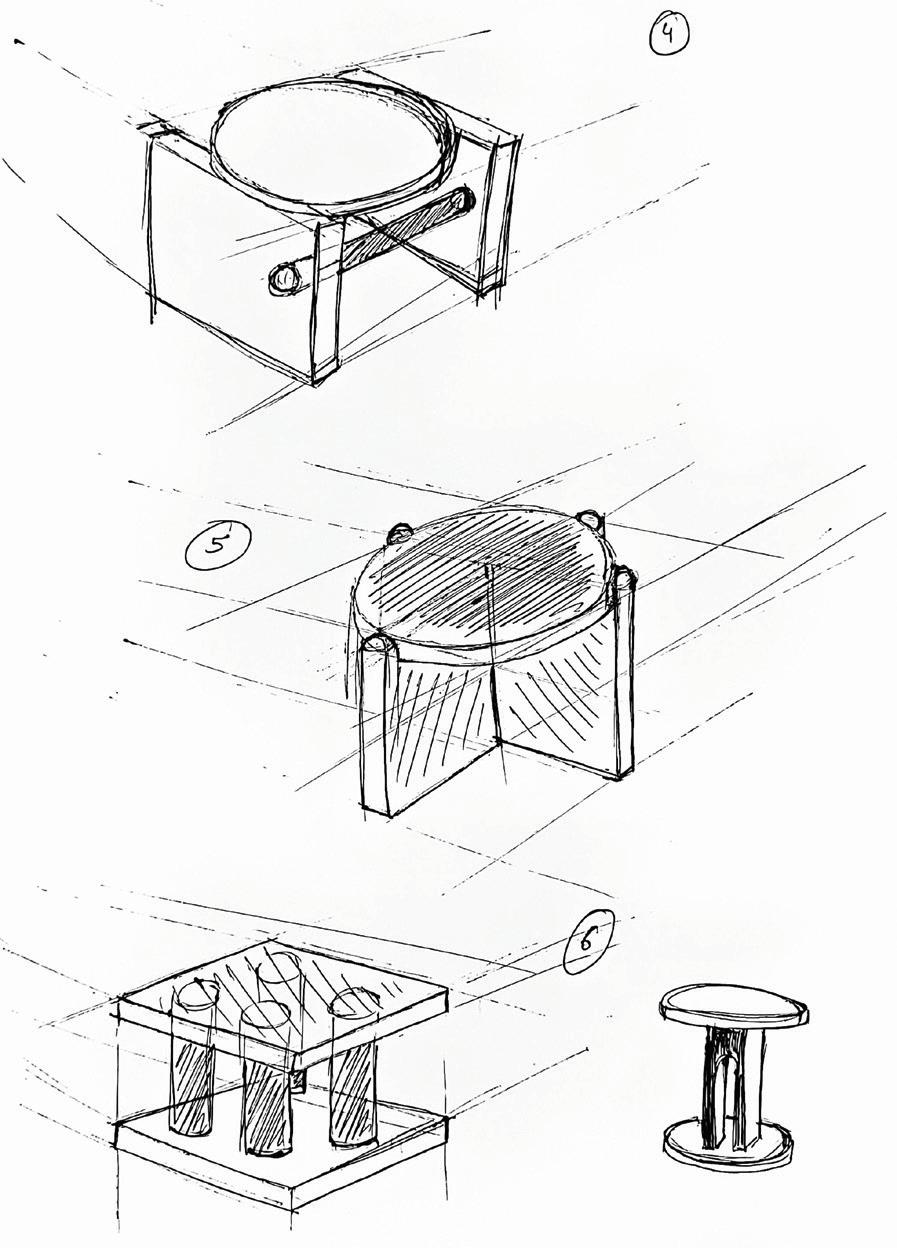

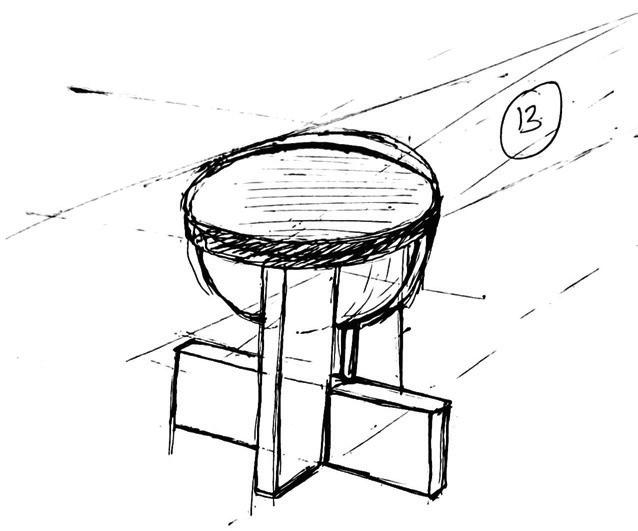

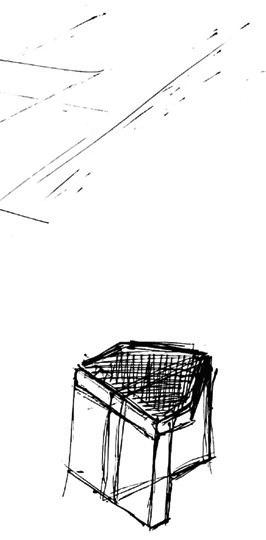

The stools illustrated here are a thoughtful blend of material exploration and refined joinery techniques, demonstrating the creative possibilities within sustainable design. Each piece merges functionality with artistry, showcasing the beauty and versatility of combining recycled plastics and wood.

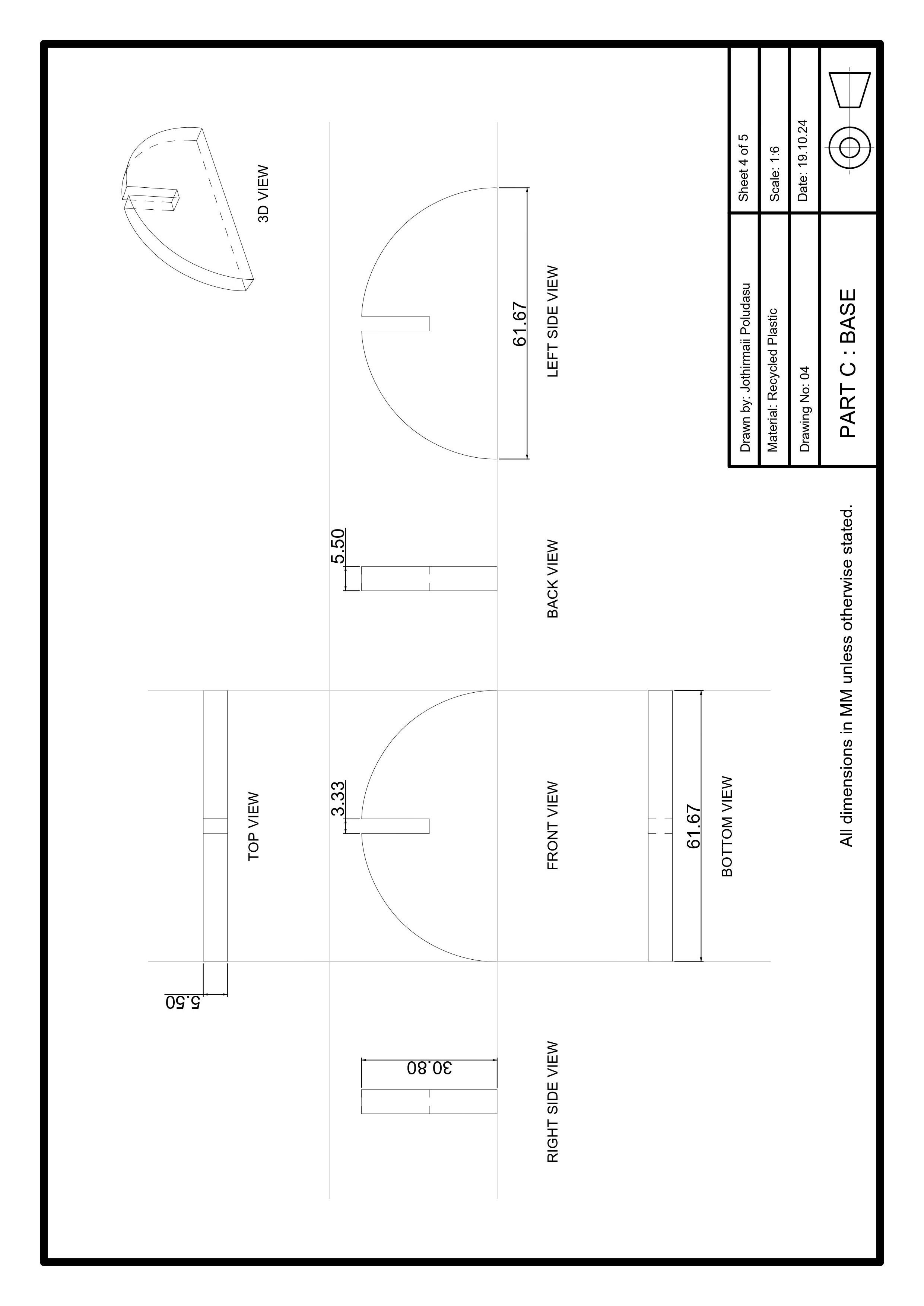

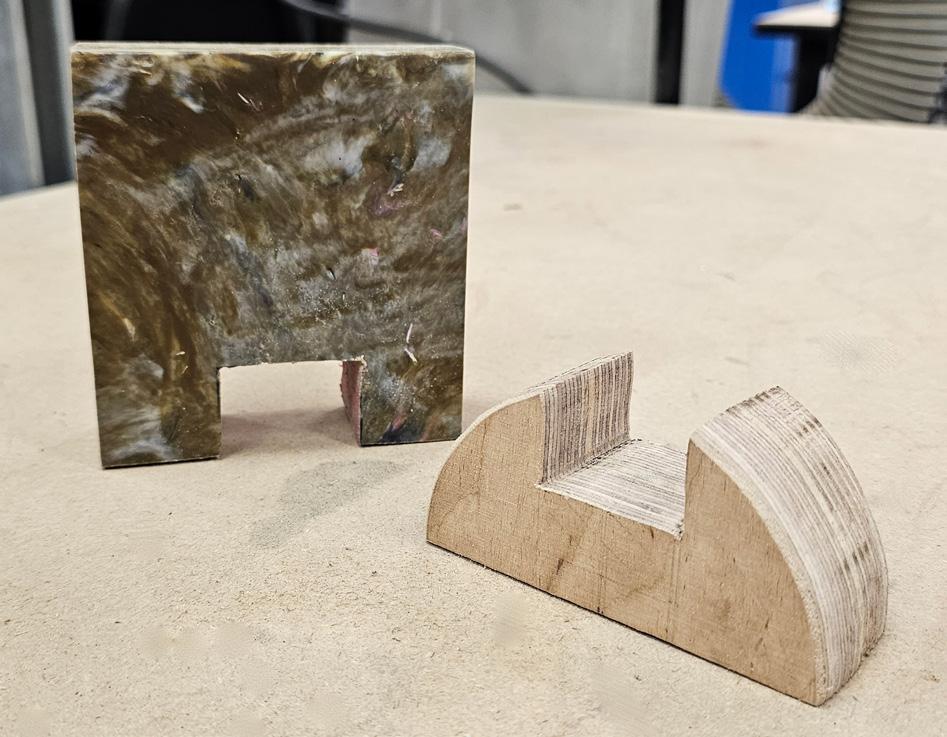

The construction of these 1:5 scale stool models has offered me invaluable insights and a deeper understanding of the processes involved in creating the final 1:1 model. By working at this scale, I’ve been able to experiment with different material placements and joinery techniques, allowing me to refine my design approach and address potential challenges early on. This hands-on experience has been instrumental in shaping my vision for the final product, ensuring that it not only meets functional requirements but also showcases the unique characteristics of the materials used.

1:5 Scale

“Imagine a stool that dances and sophistication, where of Memphis design meets elegance. Its design captures energy of asymmetry, and geometric forms sophisticated, refined and angle feels like a creativity with balance, has

taken on a life of isn’t just a stool; it’s an a world where colors whisper, harmony, and the joy of its place in timeless, - Jothirmaii

dances between whimsy where the playful spirit meets a graceful, modern captures the dynamic asymmetry, with vibrant hues brought to life in a palette. Each curve a brushstroke, merging balance, as if geometry itself of quiet poise. This piece an invitation to sit within whisper, forms flirt with of the unexpected finds timeless, refined beauty.”

Poludasu

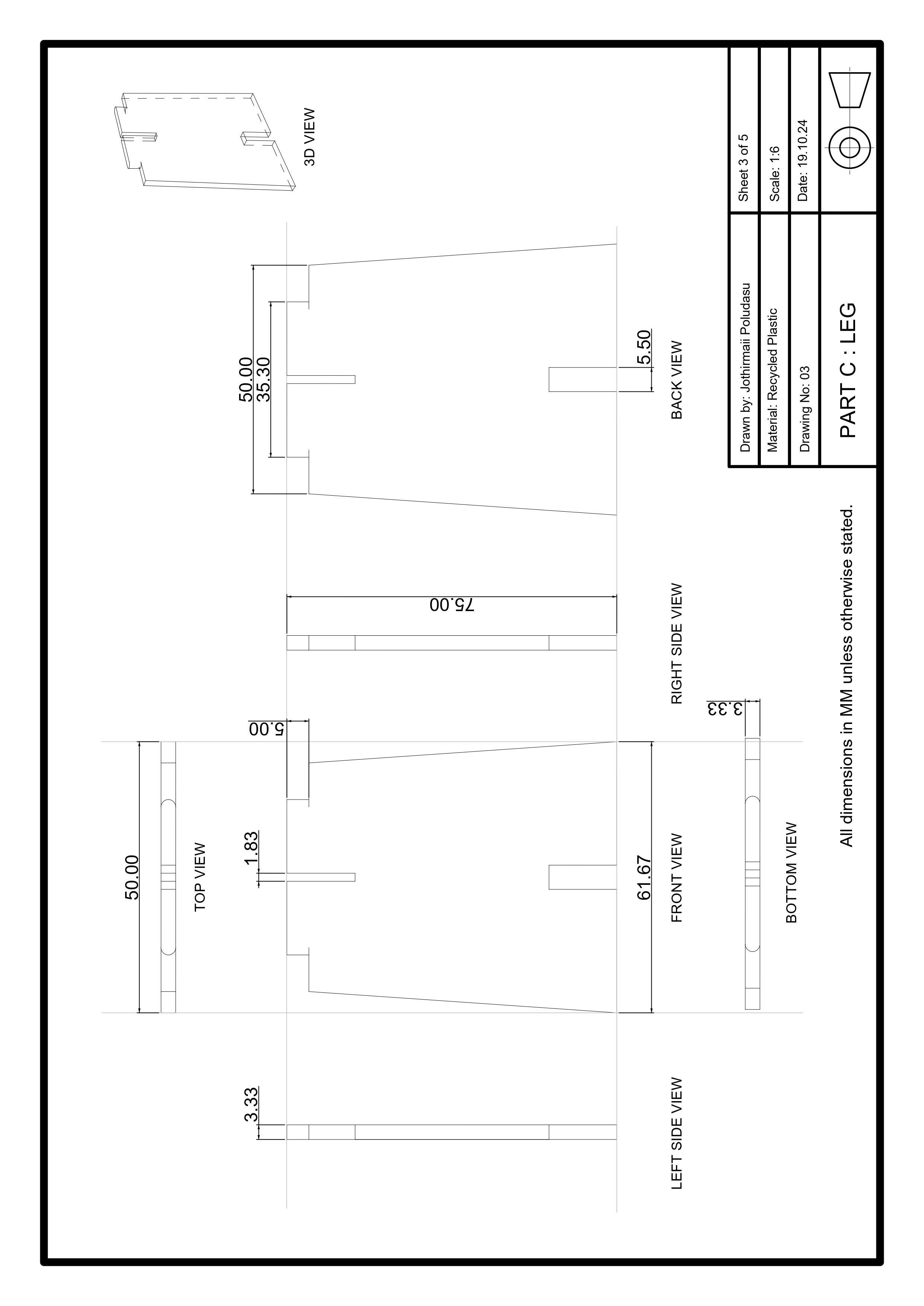

The evolution of this stool has involved several enhancements in size, shape, and construction. Initially, the legs presented a challenge; the original design featured legs with a uniform width, which raised concerns regarding stability. Additionally, the rectangular shape of the second leg created an unbalanced appearance. Finally, the rectangular shapes of the mortise and tenon joint on the seat top conflicted with the stool’s organic form.

In the second iteration, the stool leg was redesigned into a trapezium shape, which is wider at the base to enhance stability. The second leg was transformed into a semi-circle, creating a more seamless appearance and adding a sense of symmetry and dynamism to the overall design. Additionally, the mortise and tenon joints were given curved sides, contributing to a cohesive and unified look for the stool.

The assembly process begins with preparing all components, followed by spray-painting the wood in a matte black finish. Finally, each piece is carefully slotted together for a secure and cohesive fit.

In my proof of concepts, I explored the feasibility of mortise and tenon joinery using two recycled plastic pieces of varying thicknesses, as well as slit and slot joinery with a combination of recycled plastic and a semi-circular wood piece.

Through these trials, I discovered that precision is crucial to the success of my stool. I also found that sanding plastic, particularly along the curved edges for the mortise and tenon joinery, is challenging and time-consuming. Since powered tools can melt the plastic, I am limited to handsanding, which demands careful, gradual shaping. Additionally, I realized that making the joinery too tight—such as by using a mallet—risks cracking the plastic, so the fit must be precise but not overly forceful.

In selecting the wood for this project, I made a thoughtful choice in alignment with the project’s brief, which specified the use of scrap wood. My options were limited to pine, plywood, birch plywood, and metranti. Given the desired thickness and hardness, I found birch plywood to be the most suitable.

Additionally, as an engineered wood, it offers the advantage of not warping due to humidity. While I regret that I wasn’t able to showcase the beautiful natural layers of the birch plywood, I opted to spray paint it black to complement the blue and black color scheme of the stool.

For the plastic, I used recycled plastic boards from Plastify and Semula, made using type 2 HDPE and type 5 Polypropylene (PP).

During my search for birch plywood in Singapore, I came across Roger & Sons, where I was warmly greeted by their inhouse dog, who did a great job keeping me entertained on that hot afternoon. Fortunately, the workshop had birch plywood scraps available in my desired size, which I was able to take at no cost.

I had a productive visit to Plastify’s workshop, where I gained valuable insights into the world of recycled plastics. During my time there, I participated in a hands-on session that showcased their manufacturing processes. We also discussed the various types of plastics that can be recycled, along with their advantages and disadvantages. This experience enhanced my understanding of their strength, flexibility, and durability, which will inform the types of joinery I can utilize in my designs.

With limited availability of recycled plastic boards from Plastify in the dimensions needed for my stool, I chose to source additional materials from Semula to meet the project requirements.

This section presents the development of the 1:1 stool, including details on its assembly process.

“Stools are the quiet allies of creativity— small enough to be overlooked, but sturdy enough to support even the heaviest ideas.”