Products for articulated vehicles semi-trailers trailers

Products for articulated vehicles semi-trailers trailers

You will find these products in this catalogue

Disclaimer: This document is subject to change without notice. The information presented herein may be updated, amended, or revised at any time.

Selected Operating Instructions, Repair Manuals and Maintenance Instructions, which are referred to or appear in this catalogue, are applicable to the genuine product as manufactured/supplied by JOST Australia.

Where applicable, each product complies with the requirements of the Australian Design Rules (ADR’s) 62/01, and the corresponding Component Registration Number (CRN) is detailed on the JOST Australia CRN List at the front of this catalogue.

For any enquires regarding JOST CRN’s, please contact your local JOST Australia branch.

A.B.N. 60 001 081 778

JOST Australia Pty Ltd is a Quality Endorsed Company (QEC Lic. 10166), and complies to AS/NZS ISO 9001 and AS4801 for the following capability:

The registration covers the Quality Management System for the assembly and fitting of equipment for the truck and trailer industry including fifth wheels, landing gear systems, turntables, towing gear, hubodometers, mounting plates and associated replacement parts and accessories; the distribution of hydraulic hoists, pumps, valves, spare parts and accessories to the truck, industrial trailer.

JOST Australia Pty. Ltd.

Toll Free 1 800 811487 www.JOSTaustralia.com.au

Sydney: (02)9838 8100

Brisbane: (07) 3272 5777

Melbourne: (03) 8368 8222

Perth: (08) 9355 4137

Adelaide (08) 8260 4055

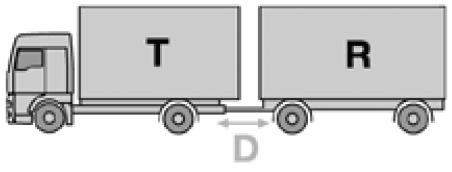

Note: All D-Values have been transcribed directly from the original Component Test Reports. (Current from 14th April 2003)

Product Stock No CRN & D-Value Specification

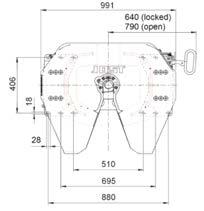

JSK32AV 26278 D-Value: 160 kN

JSK36DV1 26277 D-Value: 170 kN

JSK36CV 41444 D-Value: 190 kN 150mm, 170mm, 185mm, 220mm, 250mm & 300mm pedestals

JSK37CZ 41876 D-Value: 190 kN

170mm, 185mm, 220mm, 250mm & 300mm pedestal

JSK37E 36821 D-Value: 190 kN (Same plate construction as JSK37CZ, but with pivot pedestals)

JSK37EW 36821 D-Value: 190 kN (Greaseless version of JSK37E)

JSKSLE37E 42707 D-Value: 190 kN

JSK37CZW 41876 D-Value: 190 kN 150mm, 170mm, 185mm, 220mm, 250mm & 300mm pedestals (Greaseless version of JSK37CZ)

JSK37CWS 41876 D-Value: 190kN 150mm, 170mm, 185mm, 220mm, 250mm & 300mm pedestals (Greaseless Sensor version of JSK37CZ)

JSK37CZS 41876 D-Value: 190kN 150mm, 170mm, 185mm, 220mm, 250mm & 300mm pedestals (Greaseable Sensor version of JSK37CZ)

JSK37CX 45374 D-Value: 240kN 150mm, 170mm, 185mm, 220mm, 250mm & 300mm pedestals

JSK37027 38553 D-Value: 200kN

JSK37070 38553 D-Value: 200kN

JSK38C1

JSK38C2

JSK38G1 24327 D-Value: 260 kN

JSK38G2

LP39CS

DR39CS 45373 D-Value: 275kN

DR37CX 45372 D-Value: 240kN

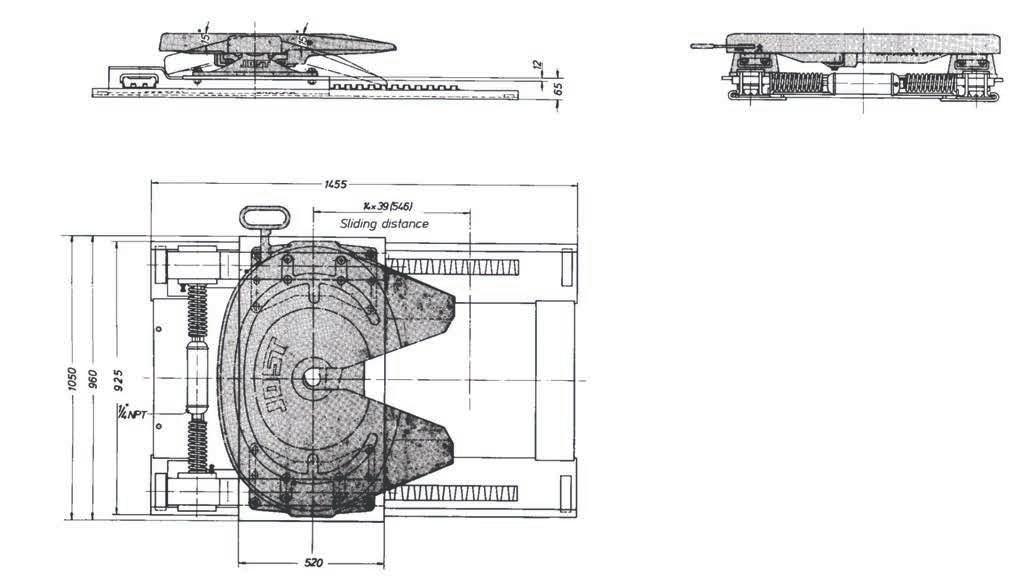

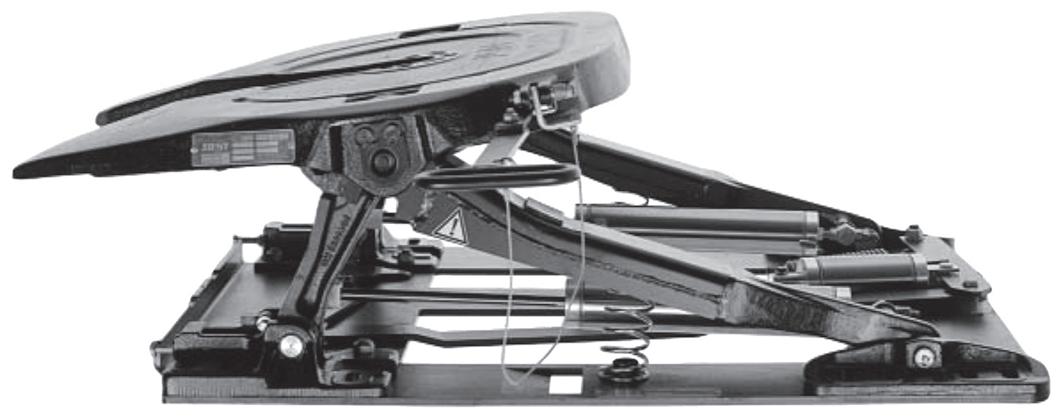

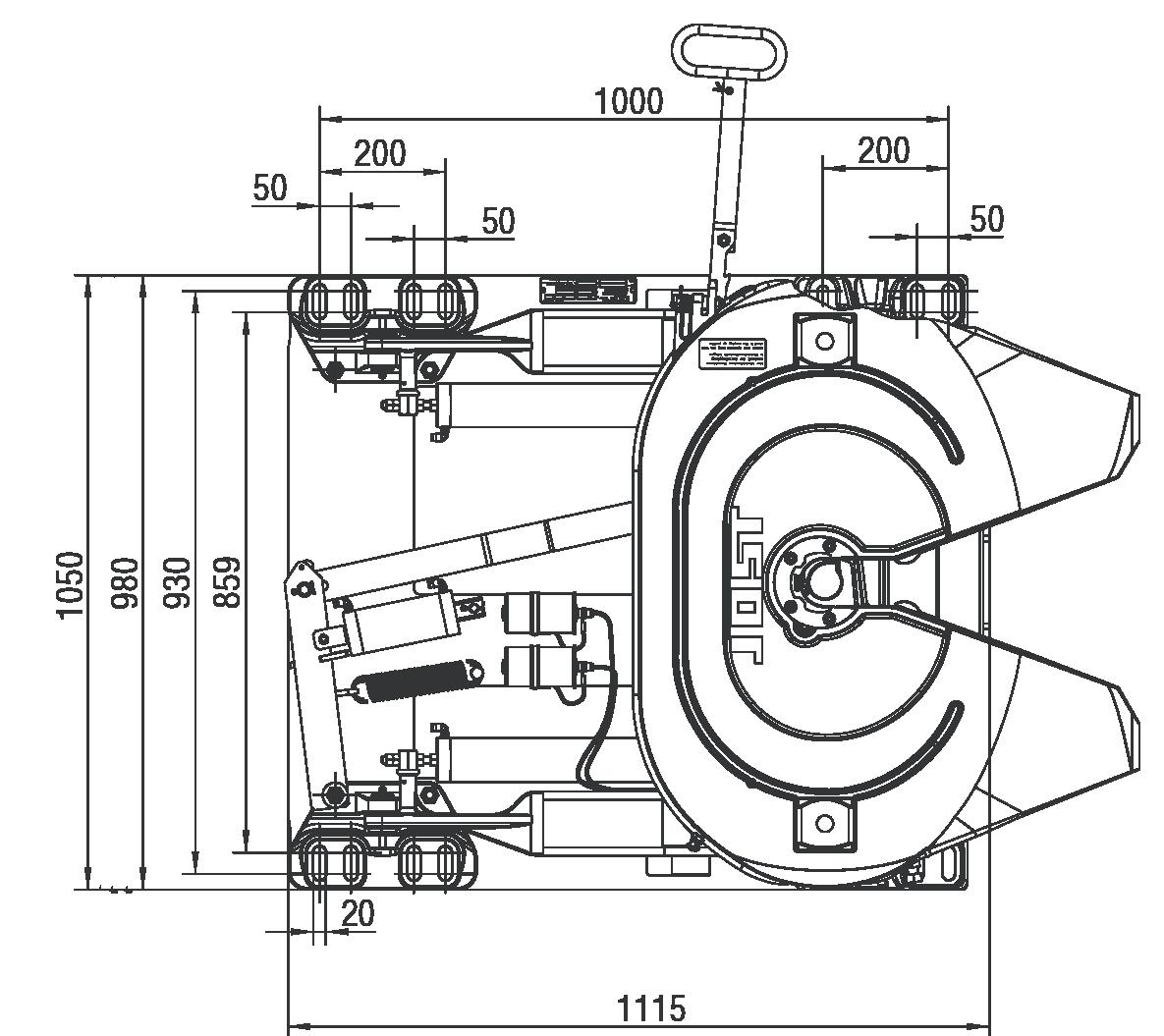

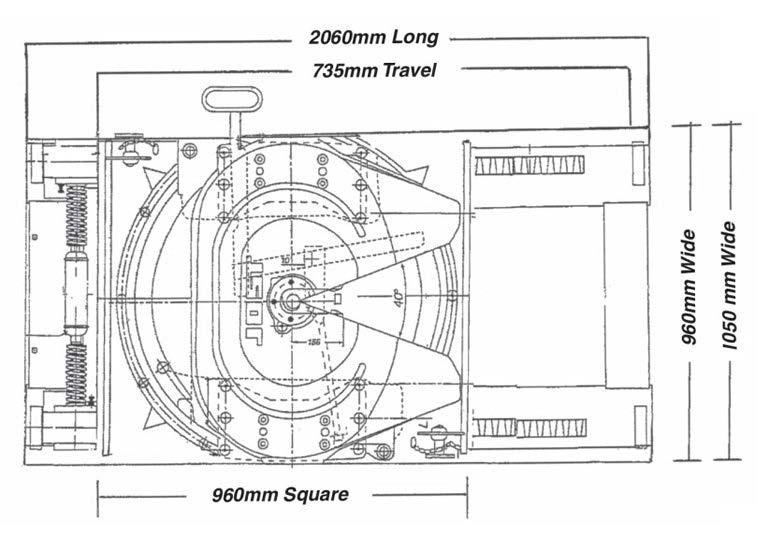

EVM SLIDER 26167 D-Value: 190 kN For use with JSK36CV150 with EVM Slider

EVM SLIDER 26169 D-Value: 190 kN For use with JSK37CZ150 with EVM Slider

EVP SLIDER 26168 D-Value: 190 kN For use with JSK36CV150 with EVP Slider

EVP SLIDER 26170 D-Value: 190 kN For use with JSK37CZ150 with EVP Slider

EVPLP SLIDER 24836 and 26170 D-Value: 190kN

JSKSLE SLIDER 42707 D-Value: 190kN

SO36CV 24844 D-Value: 162.4 kN

SO37CZ

Product Stock No

KZ1008, KZ1010, KZ1012, KZ101216

KZ091201 (Part of the KZ0908 Assembly)

KZ1516

KZ1016

KZ1408, KZ1410, KZ1412

KZ1416

KZ1706, KZ1707, KZ1710, KZ1712

KZ101216

KP2108

KP2210

BPCRM650M

FEA Approved **

FEA Approved **

FEA Approved **

FEA Approved **

FEA Approved **

152 kN

42kN WITHOUT THE BALL

17kN USED WITH BALL

** Finite Element Analysis (FEA) has been approved for Kingpins by the Austrailian Standards Committee (Refer: Supplement 1-2002 to AS 2175-1995) as an alternative to physical testing.

Product Stock No

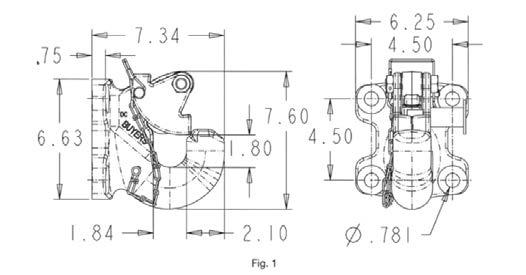

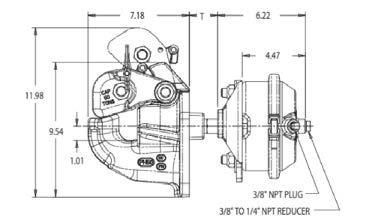

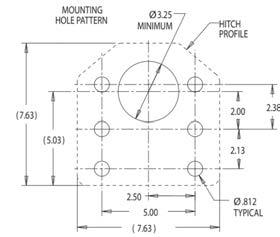

RO500 Rockinger Coupler

RO500B66000B

RO500B66500B

ROE57005

ROCKINGER 400

ROCKINGER 243U130

260 kN (At ZERO download)

200kNWITH 2500 KG DOWN LOAD

285 kN WITH 1000KG DOWN LOAD

30kN WITH 350 KG (MAX ) DOWNLOAD

Product Stock No

ROE57374 (Replaces JOST ZO46)

ROCK57394 (50mm Weld-In) (Replaces JOST ZO59)

ROE57272 (50mm Weld-In) (Replaces JOST ZO58)

ROCK57254 (50mm) (Replaces JOST ZO60)

JOST0063126

JOST106B2H

JOST106B2R

JOST57254E

191 kN

191 kN

125kN

260kN

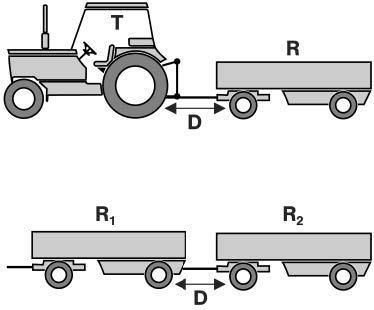

This graph provides a g u ide only; for compliance purposes refer to AS1773-1996. For applications falling within the shaded area a D-value calculation is necessary and must be carried out according to AS1773-1996 Appendix A

and is applicable only to JOST

Note: This chart was developed for JOST

Mass (Tonnes)

Theoretical towing capacity (in tonnes) of the coupling system based on tractor mass (tonnes) and coupling D Value (kN)

Calculation as follows: D Value (kN) = g . (TxR)/(T+R) or Gravity (9.81ms-2) X (Tractor Mass (t) X Trailer Mass (t))/(Tractor Mass (t) + Trailer Mass (t))

Example of 10t Tractor with a 74kN rated coupling equates to being able to tow a trailer with 30.7 tonne mass (in orange)

20 .04.2 3.73.43.23.13.02.92.82.72.72.62.6

22 .05.14.54.1 3.83.63.43.33.23.13.03.02.9

.06.35.44.84.44.1 3.93.83.63.53.43.43.3

26 .07.96.45.65.14.74.54.34.1 4.03.93.83.7

28 .0 10 .07.86.75.95.45.14.84.64.44.34.24.1

30 .0 13 .09.57.96.96.25.85.45.25.04.84.64.54.44.34.24.24.14.0 4.04.03.93.93.8

32 .0 17 .7 11 .99.48.07.16.56.15.85.55.35.15.04.84.74.64.64.54.44.44.34.34.24.2 34 .0 26 .0 15 .1 11 .39.48.27.46.96.46.15.95.65.55.35.25.15.04.94.84.74.74.64.64.5

.0 44 .4 19 .9 13 .8 11 .09.48.47.77.26.86.56.26.05.85.65.55.45.35.25.15.05.04.94.9 38 .0 122 .6 27 .8 17 .2 13 .1 10 .99.68.78.07.57.16.86.56.36.16.05.85.75.65.55.45.45.35.2

40 .0210 .5 43 .4 22 .1 15 .8 12 .7 10 .99.88 .98.37.87.57.16.96.76.56.36.26.15.95.85.85.75.6

70 .0 -9.112 .216 .724 .037 .773 .0368 .4 146 .9

72 .0 -8.811 .615 . 721 .932 .956 .8151 .4 342 .9

.0

76 .0 -8.310 .714 .119 .026 .640 .472 .6235 .1 245 .2 87 .5

78 .0 -8.010 .413 .517 .824 .535 .658 .5132 .2 1300 .0 123 .1

80 .0 -7.910 .012 .916 .922 .732 .049 .493 .4421 .1 200 .9 86 .9

82 .0 -7.7-9.712 .416 .121 .329 .243 .173 .0186 .4 503 .2 117 .3 69 .6 50 .9 41 .0 34 .8 30 .6 27 .5 25 .2 23 .4 21 .9 20 .7 19 .7 18 .9

84 .0 -7.5-9.512 .015 .420 .027 .038 .460 .4121 .71161 .0 176 .2 86 .8 59 .6 46 .4 38 .6 33 .5 29 .9 27 .2 25 .1 23 .4 22 .0 20 .9 20 .0

86 .0 -7.4-9.211 .614 .819 .025 .134 .751 .991 .5279 .5 338 .0 113 .6 71 .1 53 .1 43 .2 36 .9 32 .5 29 .4 26 .9 25 .0 23 .5 22 .2 21 .1

88 .0 -7.2-9.011 .314 .218 .123 .631 .945 .873 .9162 .1 2731 .0 160 .9 87 .1 61 .6 48 .6 40 .8 35 .5 31 .8 28 .9 26 .7 25 .0 23 .5 22 .3

90 .0 -7.1-8.811 .013 .717 .322 .329 .541 .162 .5115 .6473 .7 267 .6 111 .1 72 .7 55 .3 45 .4 39 .0 34 .5 31 .2 28 .6 26 .6 25 .0 23 .6

92 .0 -7.0-8.710 .713 .316 .721 .227 .637 .454 .490 .8223 .2 731 .4 150 .8 87 .8 63 .6 50 .8 42 .9 37 .6 33 .7 30 .7 28 .4 26 .5 25 .0

94 .0 -6.9-8.510 .512 .916 .120 .226 .034 .548 .575 .3148 .21109 .3 229 .3 109 .6 74 .3 57 .5 47 .6 41 .0 36 .4 33 .0 30 .4 28 .3 26 .5

96 .0 -6.8-8.310 .212 .615 .519 .424 .632 .143 .864 .7112 .1325 .1 457 .1 143 .9 88 .7 65 .7 53 .0 45 .1 39 .6 35 .6 32 .5 30 .1 28 .2

98 .0 -6.7-8.210 .012 .215 .018 .623 .430 .140 .257 .090 .8193 .8 9800 .0 205 .6 108 .8 76 .1 59 .6 49 .7 43 .1 38 .4 34 .9 32 .1 29 .9

100 .0 -6.6-8.1-9.811 .914 .617 .922 .328 .437 .251 .276 .9139 .6526 .3 349 .4 139 .1 89 .7 67 .7 55 .2 47 .2 41 .6 37 .5 34 .3 31 .8

102 .0 -6.5-7.9-9.611 .714 .217 .321 .426 .934 .746 .667 .0110 .1261 .5 1065 .7 189 .8 108 .5 77 .9 61 .8 51 .9 45 .2 40 .4 36 .7 33 .9

104 .0 -6.4-7.8-9.511 .413 .816 .820 .625 .632 .642 .959 .691 .4176 .31097 .5 292 .6 135 .7 91 .0 69 .8 57 .5 49 .4 43 .7 39 .4 36 .2

106 .0 -6.4-7.7-9.311 .213 .516 .319 .924 .530 .839 .853 .978 .6134 .2371 .6 610 .5 178 .9 108 .5 79 .7 64 .0 54 .1 47 .4 42 .4 38 .6

108 .0 -6.3-7.6-9.211 .013 .215 .919 .223 .529 .337 .349 .369 .3109 .1227 .013200 .0 257 .9 133 .3 92 .3 71 .9 59 .7 51 .5 45 .7 41 .4

110 .0 -6.2-7.5-9.010 .812 .915 .518 .622

26.228.330.232.033.635.236.638.039.240.441.542.643.644.545.446.347.147.948.649.349.9 50.651 .2

27.229.431.533.535.337.038.640.141.542.944.145.346.547.548.649.550.551.352.253.053.754.555.2

28.030.432.734.836.838.640.442.043.645.146.547.849.150.251.452.553.554.555.456.457.258.158.9

28.831.333.736.038.140.142.043.745.447.048.650.051.452.754.055.256.357.458.559.560.461.462.3

29.432.134.637.039.241.443.445.347.148.850.552.053.554.956.357.658.960.161.262.363.464.465.4

30.032.835.437.940.342.544.646.748.650.452.253.855.457.058.559.961.262.563.865.066.167.268.3

30.533.436.138.741.243.545.847.949.951.953 .755 .557.258.960.461.963.464.866.167.468.769.971.0

31.434.537.440.242.845.347.850.152.354.556.558.560.462.263.965.667.368.870.471.873.274.675.9

31.834.937.940.843.546.148.651.153.455.657.759.861.863.765.567.369.070.772.373.875.376.878.2

.736.039.242.345.348.150.953.556.158.560.963.265.467.569.671.673.675.577.379.180.882.584.1

33.036.439.642.845.848.751.554.256.859.461.864.266.568.770.872.974.976.978.880.682.484.185.8

34.838.542 .245 .849.352.756.059.262.465.468.471.374.276.979.682.384.987.489.992.394.696.999.2 32.0 34.938.742.446.049.653.056.359.662.865.968.971.974.777.680.383.085.688.290.793.195.597.9100.2 33.0 35.038.842.646.249.853.356.760.063.266.369.472.475.378.180.983.786.388.991.594.096.498.8101.2 34.0 35.139.042.846.450.053.556.960.363.566.769.872.875.878.781.584.387.089.792.394.897.399.7102.1

35.0 35.239.142.946.650.253.857.260.663.967.170.273.376.379.282.184.987.790.493.095.698.1100.6103.0

36.0 35.339.243.146.850.554.057.560.964.267.570.673.776.879.782.785. 588 .391.093.796.398.9101.4103.9

37.0 35.439.443.247.050.654.257.761.264.567.871.074.277.280.283.286.188.991.794.497.099.6102.2104.7

38.0 35.539.543.347.150.854.558.061.464.868.171.474.677.780.783.786.689.592.395.097.7100.4103.0105.5

39.0 35.639.643.547.351.054.758.261.765.168.571.774.978.181.284.287.190.092.995.698.4101.1103.7106.3

40.0 35.739.743.647.451.254.958.462.065.468.872.175.378.581.684.687.690.693.496.299.0101.7104.4107.0

Example of 10t Tractor towing 30t Trailer in green above D Value = 9.81 X (10x30)/(10+30) D Value = 9.81 X 300/40 D Value = 73.575 kN With Compliments from D Value = 73.6 kN

Theoretical D Value (kN) calculations based on tractor and trailer mass (in tonnes)

Calculation as follows: D Value (kN) = g . (TxR)/(T+R) or Gravity (9.81ms-2) X (Tractor Mass (t) X Trailer Mass (t))/(Tractor Mass (t) + Trailer Mass (t))

L-series = for farm carts and trailers with a speed up to 30 km/h (18m.p.h.).

N-series = for heavy farm carts and light truck trailers with a speed above 30 km/h (18 m.p.h.).

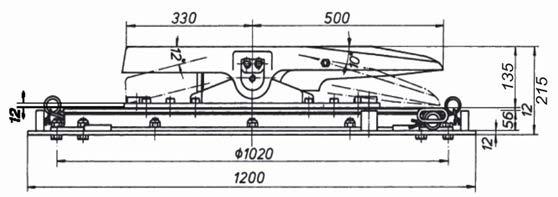

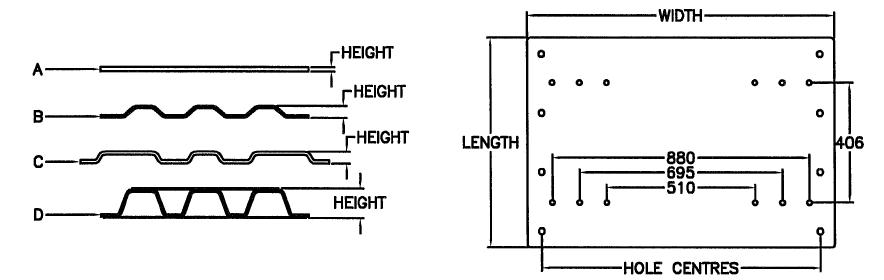

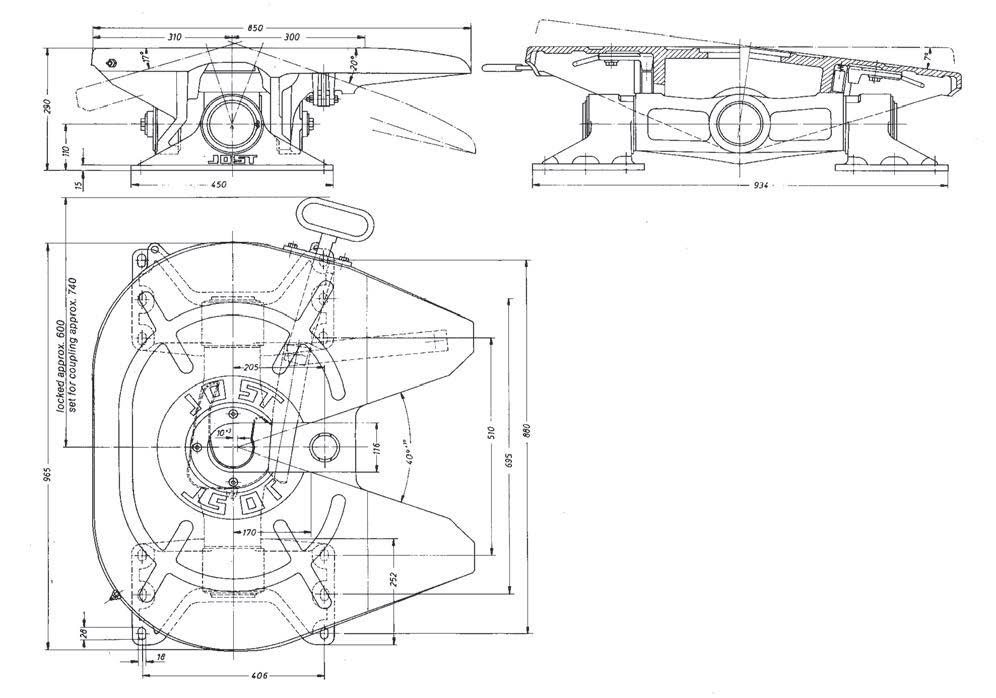

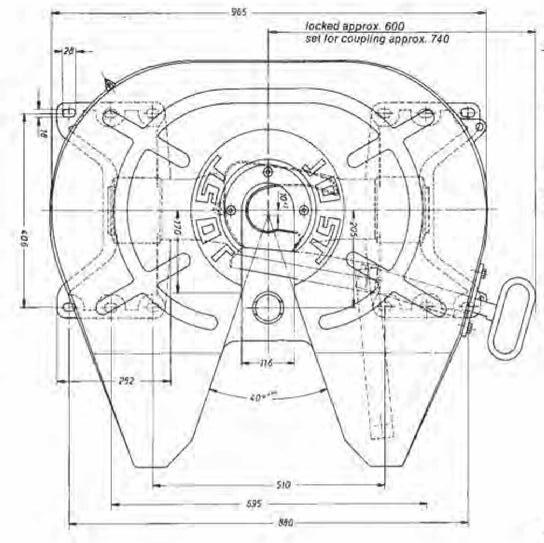

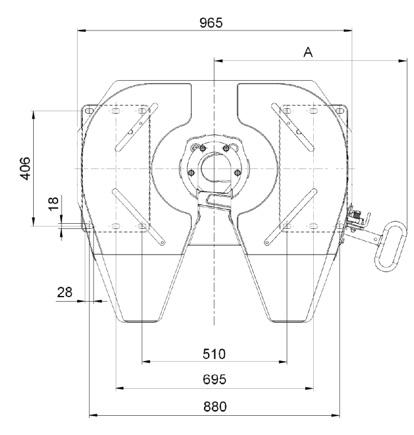

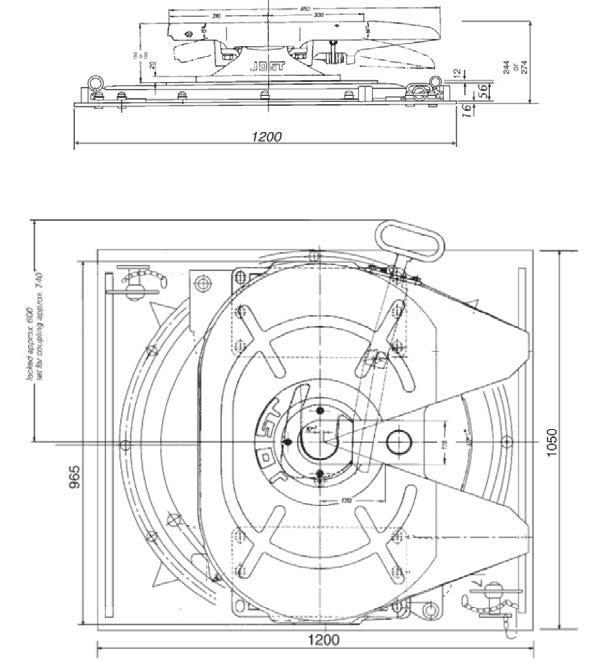

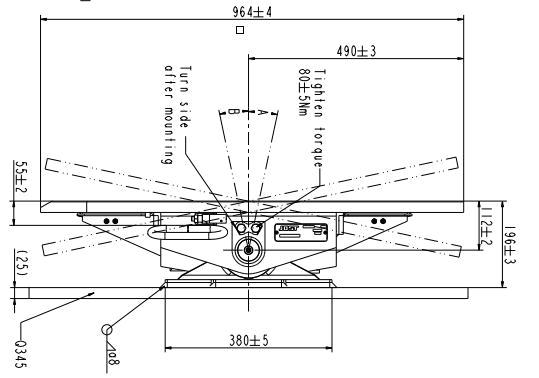

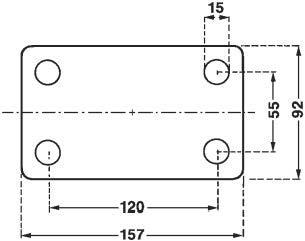

Slewing rings are supplied undrilled and primed in black for corrosion protection. The measurements are subject to our standard tolerances. For the turntables of the N series the load limits are only valid for operation on paved roads and under conditions prevailing in Europe.

The axial load can be exceeded by 30 to 50% on the turntables of the N series if the speed is below 30 km/h (18 m.p.h.).

See reverse for fitting and maintenance instructions. The right to alter specifications is reserved.

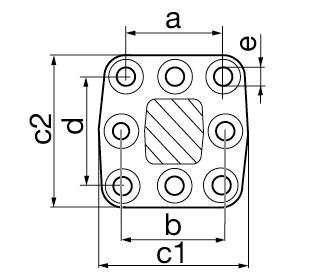

plate

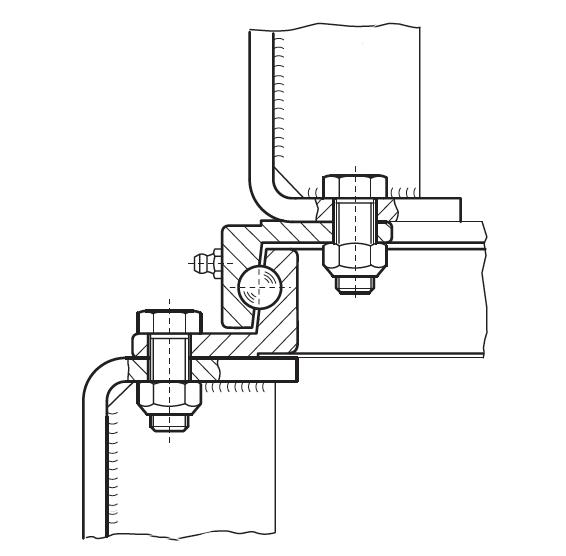

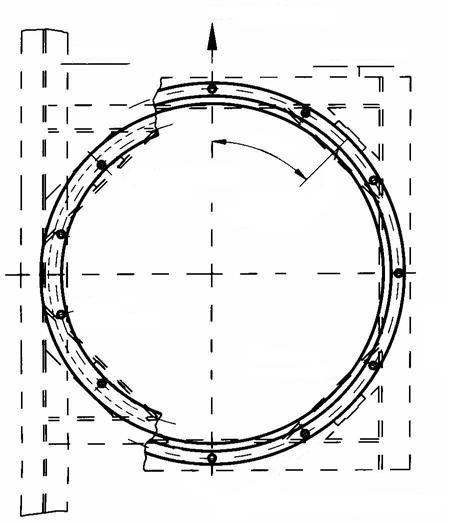

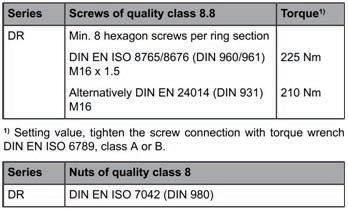

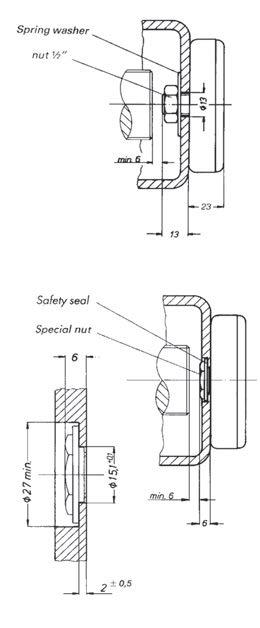

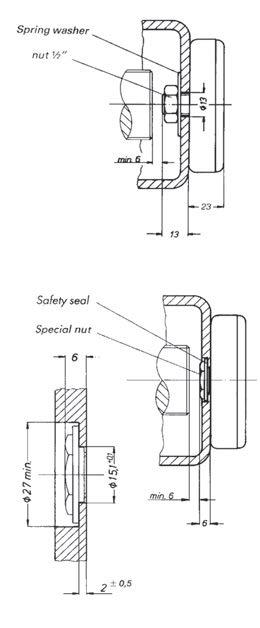

Hexagon bold DIN 931 M 10 resp. M 12-8.8 tightened to 49 resp. 85 Nm or preferably according to DIN 960/961 M 10 × 1,25 resp. M 12 × 1,5 tightened to 52 resp. 89 Nm Alternative mounting with head bolt underneath, counter nut also admissible. Direction of motion

Hexagon nut DIN 980 M10 resp. M12-8 or preferably M 10 × 1,25 resp. M 12 × 1,5 X

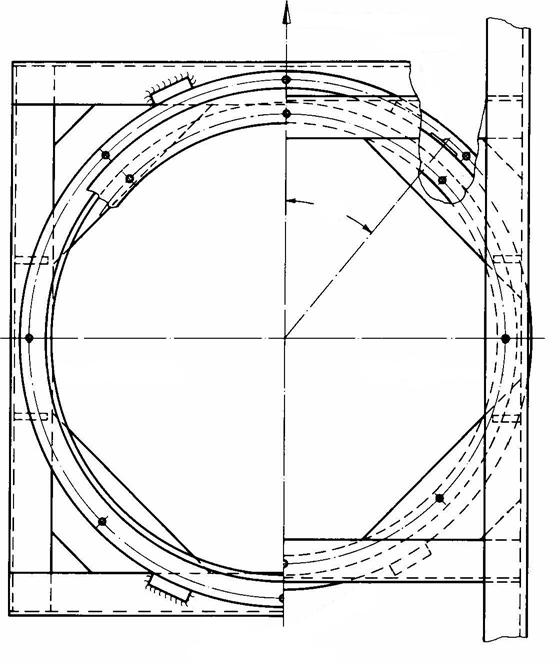

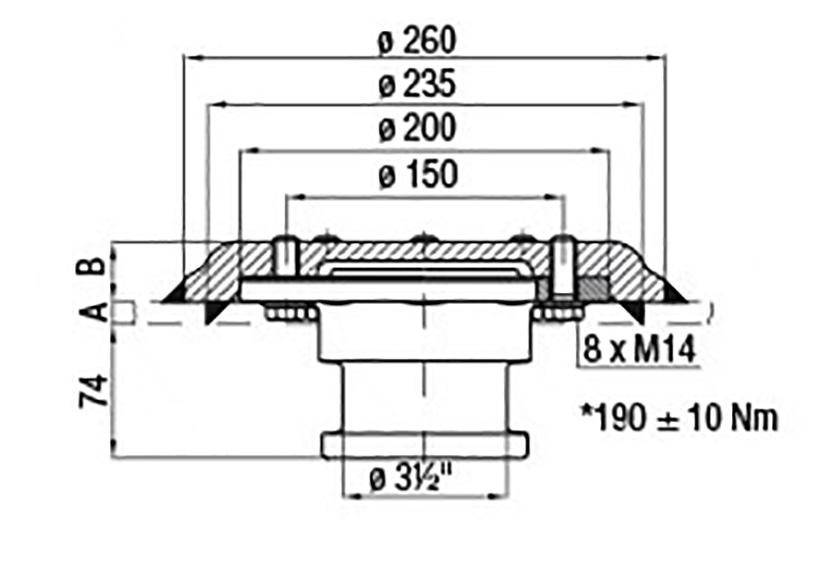

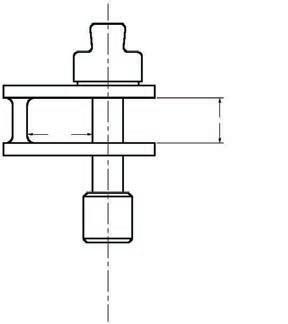

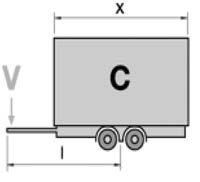

1. The ball bearing turntable must be mounted on a completely flat (max. unevenness 1mm) and horizontally and vertically rigid base with at least 50% of the circumference adequately supported. Particular attention should be paid to the support of the web section area containing the ball bearing races. Any unevenness under the flanges can be corrected with metal strips or by filling in with plastic metal.

2. Each flange must be attached with a minimum of 8 high tensile bolts grade 8.8, preferably M 10 × 1,25 (3/8 − 24) or M 12 × 1,5 (7/16−20) for sizes below 650 mm (25 5/8”) dia. 4 to 6 bolts are adequate. In case of operation under adverse conditions, we recommend the use of bolts with enlarged contact surface (such as Tensi Lock or Verbus Ripp), or to increase the number of bolts. The thickness of paint between turntable and frame should not exceed 50mm to guarantee the fit to be friction-tight.

3. To ease the shear load on the mounting bolts at least four blocks should be welded on immediately adjoining each flange. The ball bearing turntable must not be mounted by means of welding.

4. JOST turntables are lubricated with a lubricant suitable for the type of operation and the adherent operating conditions before they leave the factory, however, the turntable must be adequately re-lubricated with high quality ball bearing grease (lithium saponified, NLGI class 2) before the trailer is put into operation for the first time. The relubrication should build up a collar of grease in the gap between the 2 rings of the turntable thus preventing ingress of grit and water into the ball races.

5. The ball bearing turntable must be lubricated according to use but at least once a month with a lubricant suitable for the type of operation and the adherent operating condition (lithium saponified, NLGI class 2). While lubricating the A-frame should be turned so that the grease is evenly distributed and a collar of grease is being built up in the gap between the 2 rings. The tightness of the mounting bolts should also be checked.

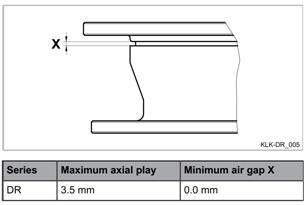

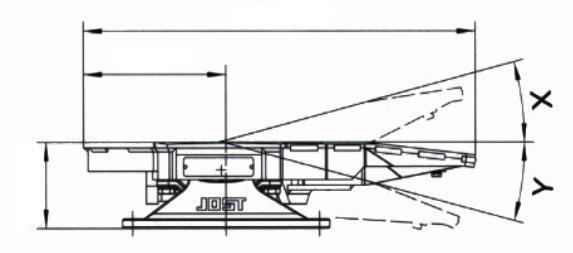

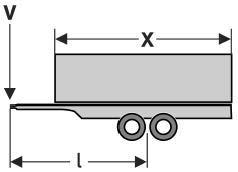

6. Ball bearing turntables are subject to wear. The limit of wear is reached when there is 2,5 mm axial play. This is the case at the very latest when the air gap X = 1 mm at any point on the circumference of the turntable.

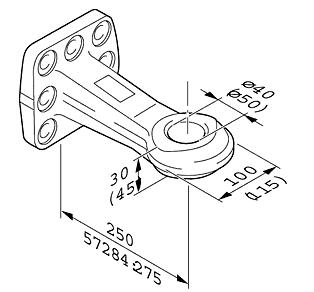

For drawbar trailers and special trailers

For drawbar trailers and special trailers

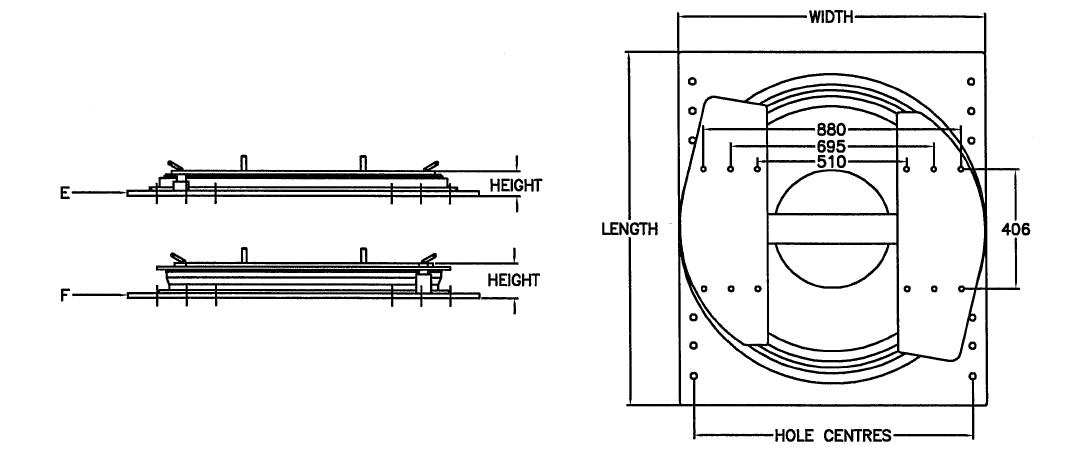

Note: SO100024 used in SO assembly Ball bearing turntables are supplied undrilled. *drilled and primed in black for corrosion protection.

The measurements are subject to our standard tolerances.

The above axial loads are applicable if the slewing ring is mounted to the front axle of the trailer with three/four axles at speeds of up to 105 km/h (65 mph).

They can be exceeded by 10% for full trailers with two axles.

In case of speeds below 30 km/h (18 mph) the axial loads can be exceeded by 20%.

If required axial loads exceed the data permitted for turntables of series HE/SO, please ask for slewing rings of series KDL900, which allow axial loads up to 250 kN.

In case of use above the steered axle and above the fifth wheel on semi-trailers with rear axle steering please enquire as to the load data giving details of the vehicle.

The load limits are only valid for operation on paved roads and under conditions prevailing in Europe.

See reverse for fitting and maintenance instruction

Alternative mounting with bolt head underneath counter nut also admissible Direction of motion

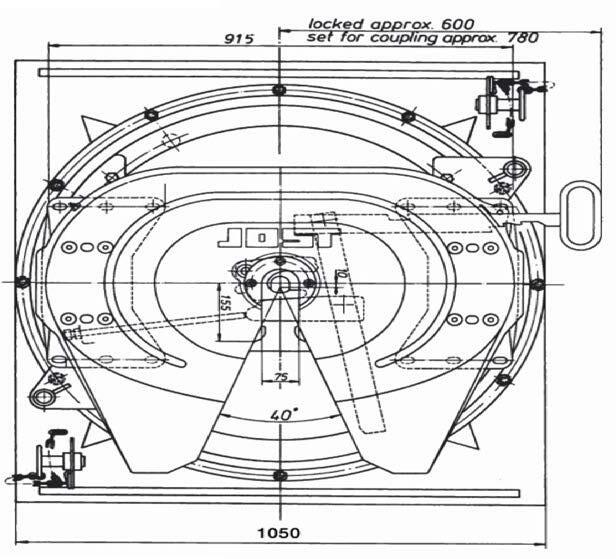

1. The ball bearing turntable must be mounted on a completely flat (max. unevenness 1mm) and horizontally and vertically rigid base with at least 50% of the circumference adequately supported. Particular attention must be paid to the support of the web section area containing the ball bearing races. Any unevenness under the flanges can be corrected with metal strips or by filling in with plastic material.

2. Each flange must be attached with at le ast 8 h igh tensile bolts, M 16 x 1,5 of grade 8.8. Do not drill in the area of the type plate ball insertion hole which should be at less than 30° to the direction of travel. In case of operation under adverse conditions, we recommend the use of bolts with enlarged contact surface (such as Tensi Lock or Verbus Ripp), or to increase the number of bolts from 8 to 12 per flange. This applies in particular to type HE130022 The thickness of paint between turntable and frame should not exceed 50 mm to guarantee the fit to be friction-tight.

3. To ease the shear load on the mounting bolts at least four blocks should be welded on immediately adjoining each flange. The ball bearing turntable must not be mounted by means of welding.

4. JOST ball bearing turntables are suitably lubricated before they leave the factory, Before the trailer is put into operation for the first time, however, they should be re-lubricated with a high quality lithium saponified turntable grease of NLGI class 2 through all the grease nipples. The re-lubrication should build up a collar of grease in the gap between the 2 rings of the turntable thus preventing ingress of grit and water into the ball race. If a central lubrication system is to be used the quantity of lubrication nipples should be increased (please specify when ordering) and the above mentioned grease specification observed, however NLGI consistency class min 1.

Hexagon bold DIN 931 M 16-8.8 tightened to 210 Nm, or preferably according to DIN 960/961 M 16 x 1,5 - 8.8 tightened to 225Nm

Hexagon nut DIN 980 M 16-8.8 or preferably M 16 x 1,5 - 8

5. The ball bearing turntable must be lubricated according to use but at least once a month with a high quality lithium saponified turntable grease of NLGI class 2. lubricant suitable for the type of operation and the prevailing operating conditions. While lubricating the A-frame should be turned so that the grease is evenly distributed and a collar of grease is being built up in the gap between the 2 rings. The tightness of the mounting bolts should also be checked

6. Ball bearing turntables are subject to wear The limit of wear is reached when there is 3,5 mm axial play. This is the case at the very latest when the air gap X = 0 mm at any point on the circumference of the turntables.

shaped profile

The measurements are subject to our standard tolerances.

Model

KDL9006W Supplied Pre-Drilled

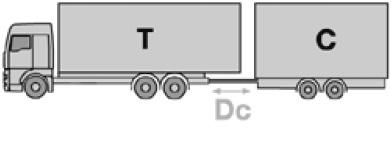

Typical applications: Fridge Vans Stock Crate D-Value Rating*: 240kN

• Slewing rings are supplied primed for corrosion protection.

• Material C45.

• Ball race hardened.

• 8 conical lubrication nipples AM 8 × 1 according to DIN 71412.

*As tested in a JOST assembly

The below axial loads are applicable if the slewing ring is mounted to the front axle of a trailer at speeds of up to 105 km/h (65 m.p.h.). If it is to be used in self steering systems or above a fifth wheel please contact us for the maximum permissible loads by submitting construction data.

M 16 x 1,5 – 8 resp. M 16 – 8 Direction of

Welded stops above and below

1. The slewing ring must be mounted on a completely flat (max. unevenness 1mm) and rigid base with at least 50% of the circumference adequately supported. Particular attention must be paid to the support of the web section area containing the slewing ring races. Any unevenness under the flanges can be corrected with metal strips or by filling in with plastic metal.

2. Each flange must be attached with at least 12 high tensile bolts M 16 × 1,5 of at least grade 8.8. Do not drill in the area of the ball insertion hole, which should be at less than 45° to the direction of travel. The thickness of paint between slewing ring and mounting should not exceed 50 microns to guarantee the fit to be friction-tight.

3. To ease the shear load on the mounting bolts in the case of horizontal force at least 4 blocks should be welded on immediately adjoining each flange. The slewing ring must not be mounted by means of welding.

4. JOST slewing rings are initially lubricated before they leave the factory. Before they are put into operation for the first time however they must be adequately re-lubricated with ball bearing grease (lithium saponified, NLGI class 2). Whilst

Hexagon bold DIN 960

M 16 x 1,5 – 8.8 tightened to 225 Nm; alternatively M16 – 8.8, tightened to 210 Nm, according to DIN 931

Alternative mounting with head bolt underneath, counter nut also admissible.

Hexagon nut DIN 980

lubricating the slewing ring should be turned so that the grease is evenly distributed. If a central lubrication system is to be used we recommend increasing the number of grease nipples (please state on order) and using a high quality lithium saponified ball bearing grease of at least NLGI class 1.

5. The slewing ring must be lubricated according to use but at least once every 3 months or 25,000 km, using a high quality ball bearing grease (lithium saponified, NLGI CLASS 2). Whilst lubricating the A-frame should be turned so that the grease is evenly distributed.

The tightness of the mounting bolts should also be checked at regular service intervals.

6. Slewing rings are subject to wear. The limit of wear is reached when the axial play is 3.5 mm. This is at the latest the case when the distance X < 8 mm at any point on the circumference.

Wear Limits

Radial play - max. 3.0mm

Axial play - max. 2.5mm

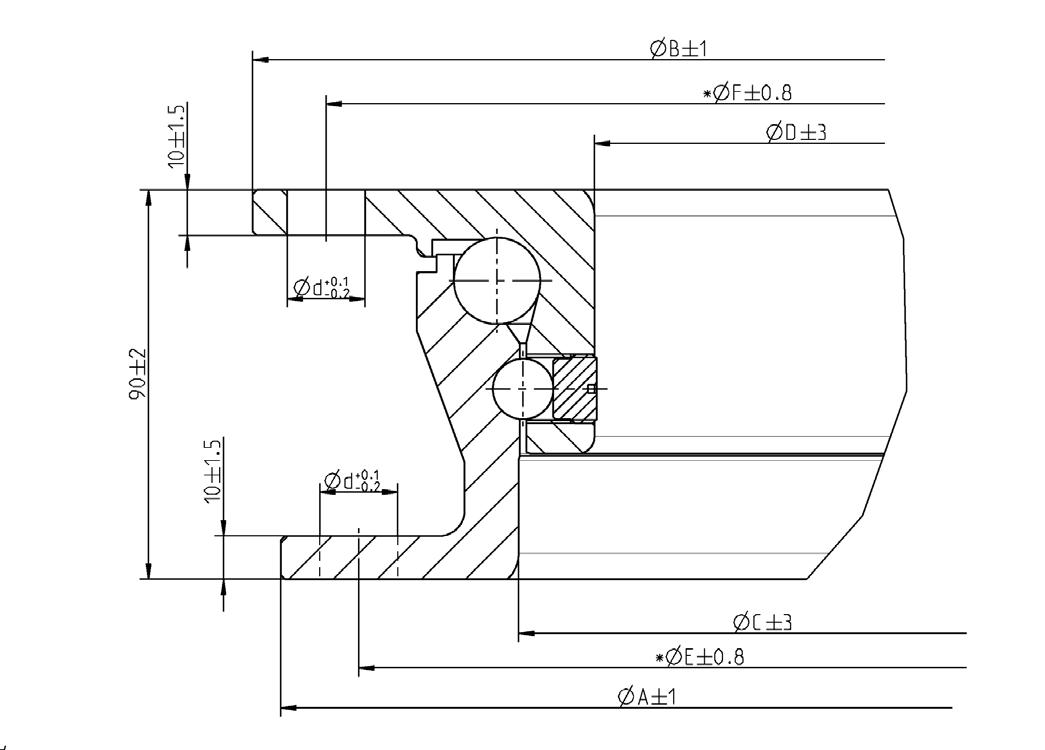

Model

Double Row Ballrace KLK Series

Typical applications: Dairy Tankers, Tri Axle Tippers

D-Value Rating: 275kN

• Ballraces are supplied E-coated.

• 8 lubrication points enable the best possible distribution of grease.

• Lbryrinth seal.

• Supplied drilled/undrilled.

The specified axle loads for KLKDR series relate to use where the slewing ring is mounted on the front axle of a trailer with three axles and fifth wheel steering, travelling at speeds of up to 100kph (65mph). On dual-axle trailers, the specified axle load can be exceeded by 10% of 20% at speeds below 30kph (18mph).

KLKDR4100010K

KLKDR210010K

KLKDR110020

KLKDR4200010K

KLKDR4400010K

Note: The pre-drilled hole pattern on the KLKDR41AS010K is suited only for a DR assembly replacement. Other ballraces are undrilled as standard. For any special drilling requirements please contact JOST Australia.

Note: The above ratings are in accordance to ADR requirements.

The measurements are subject to our standard tolerances.

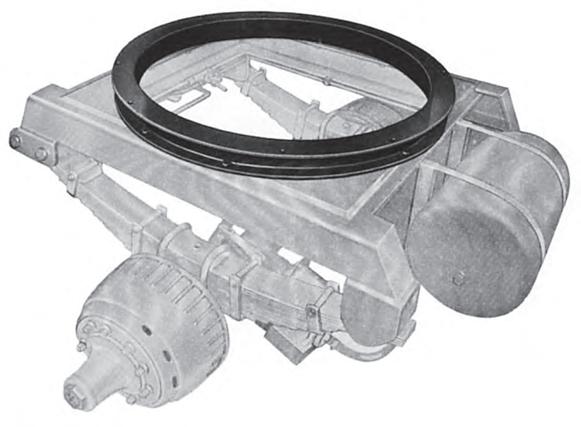

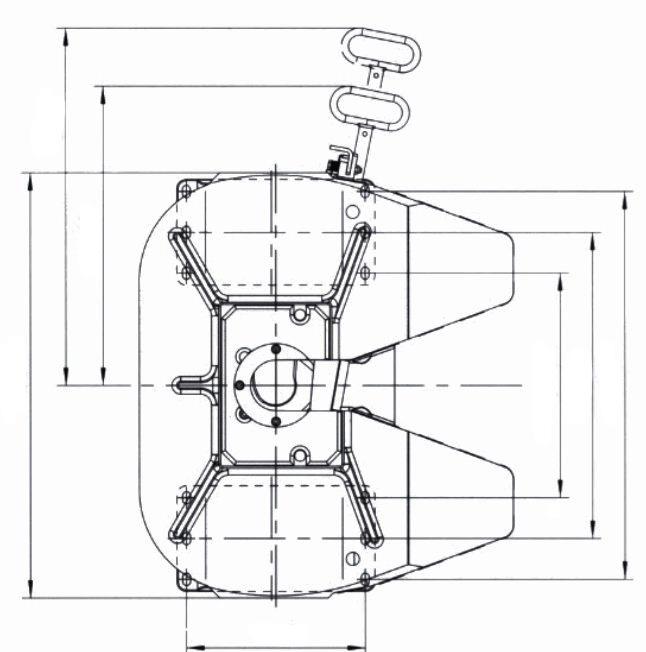

The ball bearing turntables enable the rotation of the pivot support towards the trailer frame. Thanks to the functional design, the axial loads are ideally supported and the thrust and tractive forces which occur when driving are transmitted in an optimal fashion.

The advantages at a glance:

Premium force transmissions for the highest demands

• The extra large support balls transmit the axial loads ove a wide area directly onto the vertical bar of the ring parts

• Horizontal forces in pull or push direction, as well as the moment load resulting from braking and centrifugal forces, are supported by the interplay of the two ball rows

• Lifting forces are transmitted by the smaller radial ball

• Optional fastening using splined bolts, making additional welding of thrust plates unnecessary

Durable construction with very little wear

• The use of high-strength steel ensures the greatest possible surface quality

• Cold-twisting of tracks by shrinking the ball gearing turnable reduces wear to a minimum and increases

• A robust labyrinth seal protects the tracks from dirt, even in extreme conditions

• The practiculary large grease reservior resulting from the free space between the tracks guarantees smooth running thanks to opium lubrication.

• 8 lubrication points enable the best possible distribution of grease within the tracks with just minimal rotation (+/- 20°) during lubrication.

• Optionally available with pre-assembled lubrication block to ensure ideal access to the lubrication points or as preparation for connection to a central lubrication system.

Note: D-values may vary when used in conjunction with additional JOST products that have been tested and carry a CRN number. Contact your local JOST branch for further details.

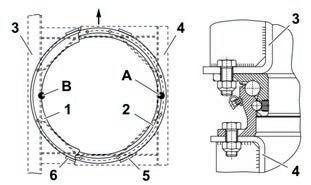

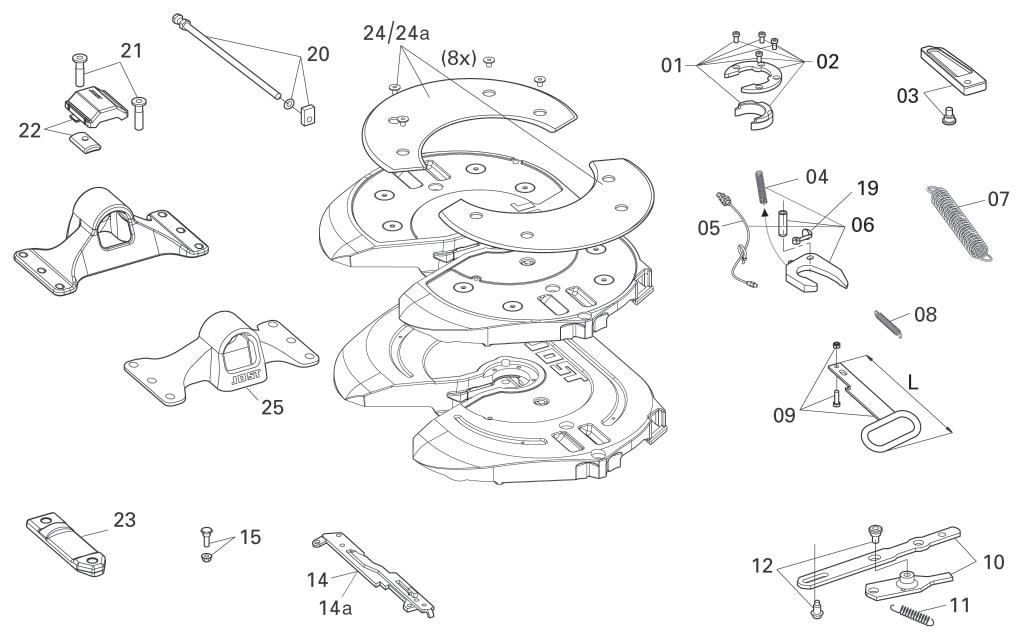

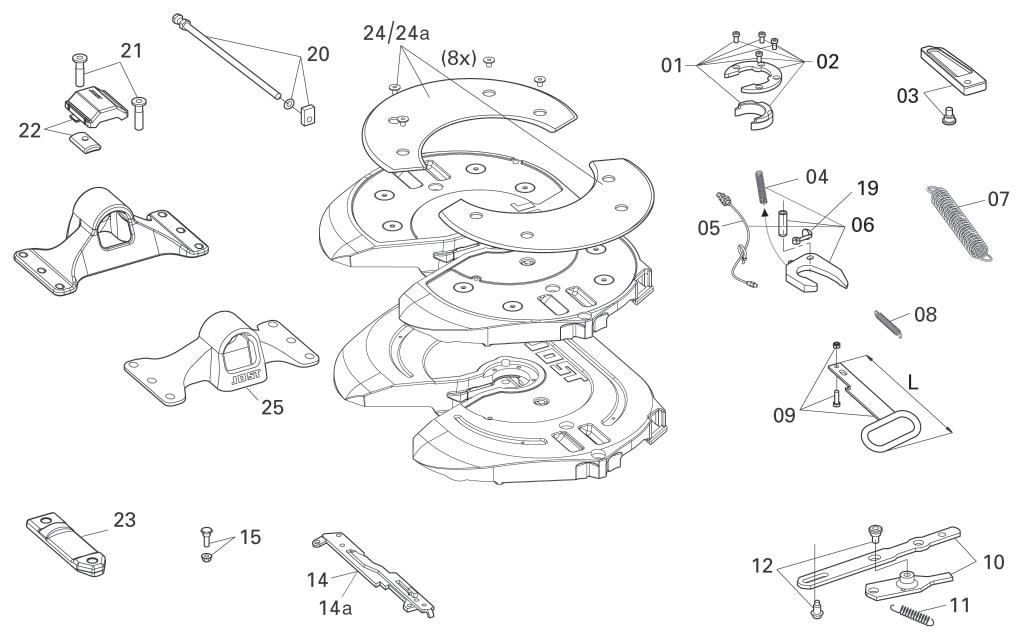

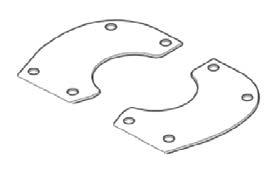

1.Upper ring

2.Lower ring

3.Chassis

4.A-frame

5.Thrust plates bottom

6.Thrust plates top

A.Position of the type plate

B.Position of the ball earing lling hole

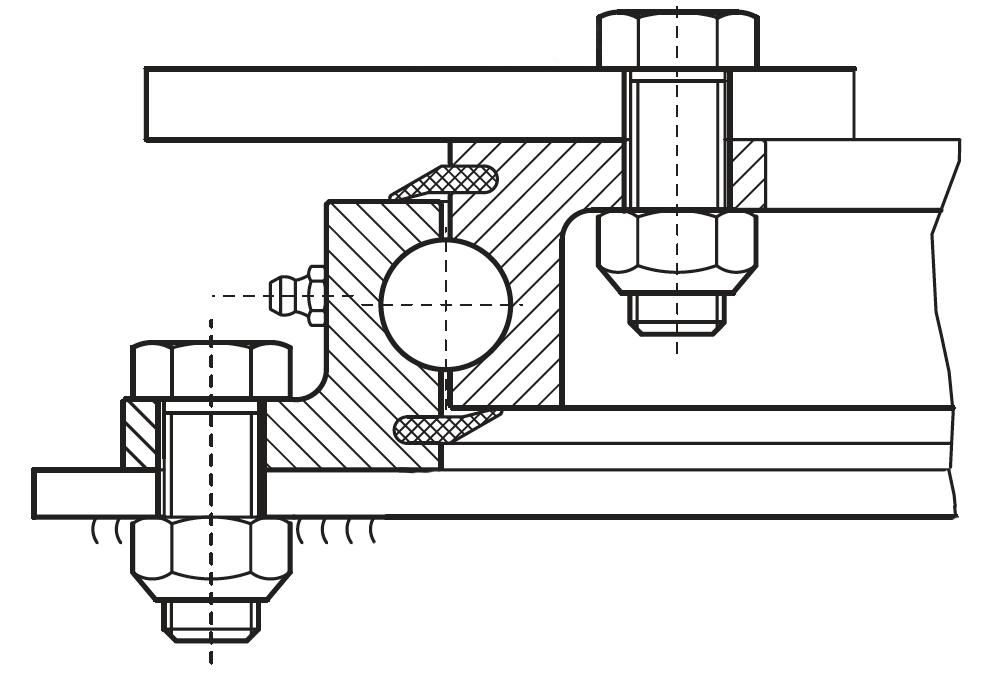

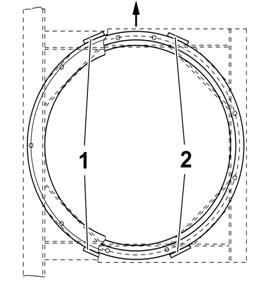

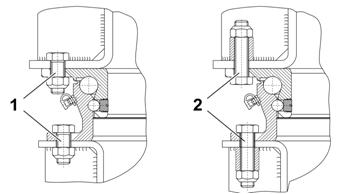

1.Standard mounting.

The ball bearing turntable must be tted on a at (max. offset 1mm) support construction that provides torsional, longitudinal and lateral rigidity. To ensure there is an adequate transfer of force, at least 50% of the ange surfaces must be supported with weight-bearing structures. The bearing zone must be distributed evenly in and lateral to the direction of travel and be designed so that the ball bearing turntable is supported in the area of its vertical pro le bars, i.e the ball race-ways. Larger planarity deviations can be compensated with shim panels. With undrilled turntables, the following must be noted with drilling the fastening holes.

• That no drill chips or cutting uid gets into the raceway.

• That no holes are drilled in the vicinity (+/- 15mm) of the ball insertion hole or in the vicinity of the welds.

• That the type plate is placed at 90 degrees to the right of the vehicle and the ball insertion hole is placed at 90 degrees to the left of the vehicle to remove the smaller cross-sections from the area under maximum stress.

• The lubricating nipples are easily accessible.

• Free motion of the swivel movement is ensured.

Special fastening

Screws of strength class 8.8 must be used for fastening. The screw connections must be secured using state of the art methods to prevent them coming loose.

Do not secure the ball-bearing turntable by welding. In general, the layer thickness of the paint build-up must be no more than 170 µm per component in the screws grip area so that a perfect friction lock is guaranteed without settling.

The values shown are guide values for a coefficient of friction µtot. = 0.14. Further information is available in VDI 2230. Tighten screws with a suitable tool diagonally. In case of fastening with a low number of screws or small screw size, at least the same overall stability must be achieved.

In more arduous operating conditions, we recommend installing screws with a spacer sleeve or increasing the number of screws in order to maintain the correct pre-tensioning force. With different screw connections, as shown in position (1) and (2), free movement of the turntable must be absolutely guaranteed, especially in the area of the lubricating nipples and the type plate.

When used on single axle bogie steering systems at axle loads of up to 10t, the standard hole patterns can be used as per the JOST product data sheet in combination with splined bolts for attachment to the vehicle without the use of thrust plates.If the axle load of the bogie is greater than 10t, we recommend using at least 12 securing points per ring, distributed as evenly as possible, with splined bolts.In order to ensure that the tting of the turntable or slewing ring is under as little strain as possible, a positional accuracy for the hole pattern of 0.6mm and a drilling diameter of 18 +/-0.1, should be observed.More detailed information can be found in our installation instructions for JOST splined bolts.

To relieve the thrust force on screws subject to horizontal forces, the tted ball bearing turntable must be attached to the anges with four pre-welded thrust plates and there must be no play between the components. Use the welding methods set out by the trailer’s manufacturer for this purpose. In cases of special fastenings with JOST splined bolts there are no trust plates required, if the requirements speci ed in ‘special fastening’ are met.

The JOST DR series has a permanent cathode dip coating. The CDC offers the ideal surface sealing method and therefore excellent protection against corrosion. Thanks to the evenly thin coating, it may be painted over at any time.

Fastening set KLE0000500 (16 screws M16 x 1.5 x 55 - 8.8, 16 nuts M16 x 1.5 – 10 and 8 thrust plates.

Min. 8 JOST splined bolts M16 x 55-10.9 per ring section and matching JOST nuts M16-10.9, tightening torque 300Nm. Fastening set KLE0000300 (16 splined bolts and nuts) Fastening set KLE0000400 (24 splined bolts and nuts)

Standard ball bearing turntables are supplied with light basic lubrication. Before commissioning, the turntable must be given a thorough re-lubrication over all lubricating nipples with a high quality rolling bearing grease (lithium soap, NGLI consistency class 2), with a closed bead of grease sealing the bearing clearances against the penetration of dirt and spray water. We recommend the use of JOST high performance lubricant (SKE005670000). Where a central lubricating system is used, a high quality rolling bearing (lithium soap, NLGI consistency class min. 1) should be used. At least 6 lubricating nipples should be connected.

The ball bearing turntable must be lubricated at least every 8,000 to 10,000km, or once a month, with a high quality rolling bearing grease (lithium soap, NLGI consistency class2). This is done by swivelling the bogie backwards and forwards until as closed a bead of grease as possible comes out from the entire length of the bearing clearances or sealing lips. We recommend the use of JOST high performance lubricant (SKE005670000).

• If the ball bearing turntable is used in forced steering systems, the servicing instructions of the manufacturer must be observed.

• The screw connections must be checked as part of the vehicle inspections, but no later than 50,000km, to ensure they are tightened to the prescribed tightening torque.

• Check for wear.

• Ball bearing turntables and their fastening elements, must be checked for excessive corrosion, damage or cracks.

• Only use the speci ed lubricating grease for servicing work.

• The servicing work should only be completed by trained personnel.

• Do not change the installation area de ned by the trailer’s manufacturer.

• The assembly work may only be completed by authorised specialists.

• Instructions from the trailer’s manufacturer must be observed e.g. the type of fastening and support construction.

• The installation guidelines provided by the trailer’s manufacturer must be complied with.

Technical modi cations reserved. The latest information can be found at www.jostaustralia.com.au or www.jost-world.com

Note: JOST ball races are initially lubricated before they leave the factory. Before they are put into operation for the rst t ime however they must be adequately re-lubricated with ball bearing grease.

JOST ball races – Lithium Sapon ed, NLGI class 2. (Use class 1 grease if a central lubrication system is to being used)

BPW Double Row – BPW special long life grease ECO-Li 91 Lithium Complex Grease.

The grease must not be mixed with other calcium base or sodium base lubricants.

Ball races should be lubricated at least every 25,000klm or every 3 months, or sooner depending on the application. Under extreme or arduous operating conditions greasing may be required weekly. The ball race should be rotated during greasing to ensure that the grease is distributed evenly.

The tightness of the mounting bolts should also be checked at regular service intervals.

Ball races are subject to wear. It is recommended that the ball race be replaced when the wear limits are reached.

Jost KDL 900/6 Radial Play max 3.0mm – Axial Play max 3.5mm (< 01.2010)

Jost KDL

BPWDK9014

Jost KLK DR Series

900/6W Radial Play max 3.0mm – Axial Play max 3.5mm (> 01.2010)

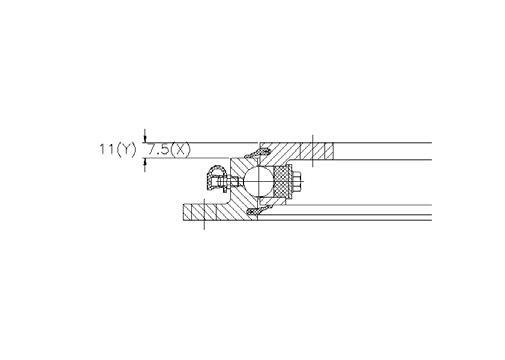

Refer to Figure 1: (Y New Ball Race 11mm) (X Measurement =7.5mm has reached wear limit)

Radial Play max 2.0mm – Axial Play max 3.0mm (< 06.2012)

Radial Play max 2.0mm – Axial Play max 3.0mm (> 06.2012)

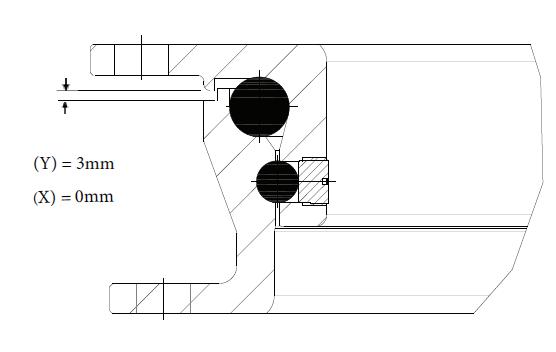

Refer to Figure 2: (Y New Ball Race 3mm) (X Measurement = 0mm has reached wear limit)

Note: X and Y measurement pictured below refer to axial movement

KDL900 Series

KLK DR & DK9014 Series

Ball bearing turntables and slewing rings are parts for tting onto trailers and agricultural vehicles to connect the A-frame t o the trailer chassis so it can swivel. They are the products which started the success story of JOST in 1952. Today, they are used on all the world‘s roads. And not only that: They are also used in agriculture, at airports and railway stations, in mining and in a wide range of special applications, such as in TRIDEC forced steering. The ball bearing turntables are subject to constant further development, so that they impress with their innovative bene ts and proven quality time and again.

E-coating

• Premium corrosion protection

• Additional top coat on request

Verified safety

• Tested in accordance with ECE R55

• Environmental management in accordance with ISO 14001

• Quality management in accordance with ISO/TS 16949

Weight advantage

• Up to 10 kg lighter than comparable products

Splined bolt

• A ssembl y ki t wi t h s p ecia l s cr ews, mak ing use o f a d di t ional welded t hrust plates unnecessary

Ite m n umbe r KLE 0 00030 0 (1 6 pieces) It em num b er K LE 0 00040 0 (2 4 pieces)

Mounting kit KLE0000500

ItemDescription per kit

01Hexagon screw M16x1,5x55 16

02Hexagon nut M16x1,5 16

03Stop block 8

Central lubrication manifold

•M ake s l ubricatio n ea sier

•M ake s con nectio n to central lubrication system easie r Item num b er K LE000020 0

High performance lubricant

•J OST hi g h pe rformance lu b rican t for in itial g reasin g or fo ll o w-u p lu b ricatio n in a p ractica l refi ll set It em num b er SK E0 056 70000

Low maintenance

• Low maintenance version for HE and KDL available

Ball bearing turntables KLKHE and SO

E-coated

Standard or low maintenance (HE series)

Drilled or undrilled

Lubrication manifold (optional)

Splined bolts (optional)

E-coated

Low maintenance

Drilled or undrilled

Hardened bearings

Lubrication manifold (optional)

Splined bolts (optional)

Customer-specific drilling patterns

• Even in small batch sizes

Ball bearing turntables KLKL and N

• E-coated

• Undrilled

• L series: Agricultural trailers and transportation devices up to 30 km/h

• N series: Heavy agricultural trailers and light truck trailers over 30 km/h

Ball bearing turntables KLKND

• E-coated

• Drilled or undrilled

• Lubrication manifold (optional)

maintenance

The application of ball bearing turntables and slewing rings depends on the permissible axial load. JOST ball bearing turntables and slewing rings cover an axial load range of between 7.5 and 250 kN.

All load data for the KDL, HE, SO, ND, L and N series apply for operation in pivot support steering systems on paved roads and under the transport conditions common in Central Europe.

JOST standard ball bearing turntables are supplied with a thin base coating of lubricant. Before it is used for the rst time the ball bearing turntable must be lubricated thoroughly. See JOST installation and operating instructions.

Connection to the central vehicle lubrication system is possible (grease is essential, rather than oil).

The low-maintenance versions of ball bearing turntables and slewing rings mean they do not have to be maintained for up to three years or 300,000 km. After this period they must be serviced in the same way as standard turntables. The low-maintenance models are distinguished by a green type plate and by the letter “W” at the end of the item number. Maintenance conditions differ when tted to steered semi-trailers or in the case of heavy conditions of use. The maximum storage period for maintenance-free ball bearing turntables and slewing rings is three years.

Refer to Jost website www.jostaustralia.com.au for further details and instructional videos.

1

2

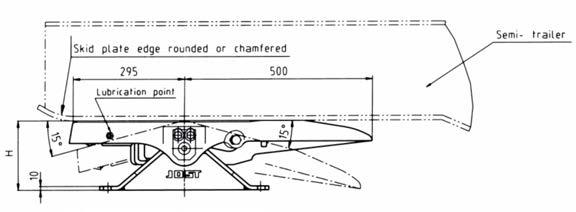

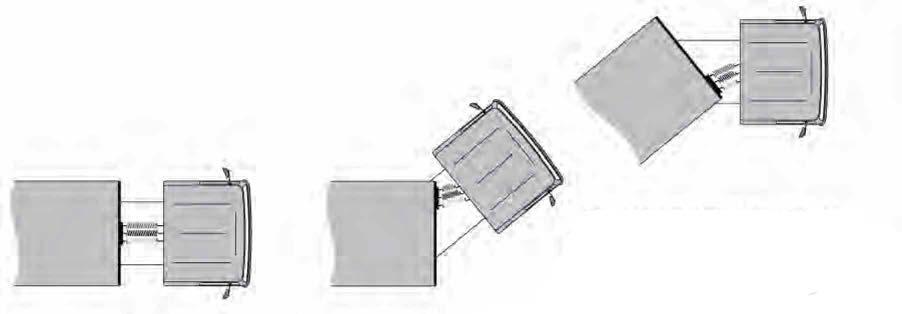

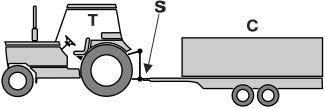

Failure to ensure that trailer rubbing plate is set below the fifthwheel plate when coupling up could result in loss of your trailer or damage to your truck or trailer.

Regardless of whether you have air or spring suspension, ALWAYS follow the coupling CODE to ensure the king pin is securely engaged with the fifthwheel. This following coupling CODE is issued by JOST Australia Pty Ltd.

The fifthwheel must be angled down to the rear of the truck and the mechanism in the pre-set position.

Ensure that the trailer rubbing plate is below the height of the fifthwheel plate (refer Diagrams 1 and 2).

Reverse the truck slowly under the trailer, aligning the king pin with the centre of the fifthwheel.

Continue reversing until the mechanism locks and secures the king pin.

Pull forward against the trailer brakes to ensure engagement of the king pin in the fifthwheel.

Visually check to see that there is no gap between the fifthwheel plate and trailer rubbing plate and that the king pin is secured correctly within the fifthwheel mechanism.

Finally, ensure that the automatic secondary locking device is engaged (as per Diagram 3). If it is not engaged, the whole coupling up procedure must be repeated.

Note: Pending the fifthwheel model, coupling code may vary.

Diagram 3

Failure to read, understand and follow the important information contained above may result in a hazardous condition or cause a hazardous condition to develop.

ensure that you get a when coupling!

1

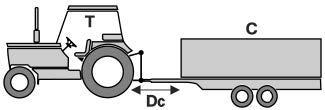

2

Failure to ensure that the trailer rubbing plate is set level with the fifthwheel plate when coupling up, could result in loss of your trailer or damage to your truck or trailer.

Regardless of whether you have air or spring suspension, ALWAYS follow the coupling CODE to ensure the king pin is securely engaged with the fifthwheel. This following coupling CODE is issued by JOST Australia Pty Ltd.

The fifthwheel must be angled down to the rear of the truck and the mechanism in the pre-set position.

Ensure that the trailer rubbing plate is level with the height of the fifthwheel plate (refer Diagrams 1 and 2).

Reverse the truck slowly under the trailer, aligning the king pin with the centre of the fifthwheel.

Continue reversing until the mechanism locks and secures the king pin.

Pull forward against the trailer brakes to ensure engagement of the king pin in the fifthwheel.

Visually check to see that there is no gap between the fifthwheel plate and the trailer rubbing plate and that the king pin is secured correctly within the fifthwheel mechanism.

Finally, ensure that the automatic secondary locking device is engaged (as per Diagram 3). If it is not engaged, the whole coupling up procedure must be repeated.

Diagram 3

Failure to read, understand and follow the important information contained above may result in a hazardous condition or cause a hazardous condition to develop.

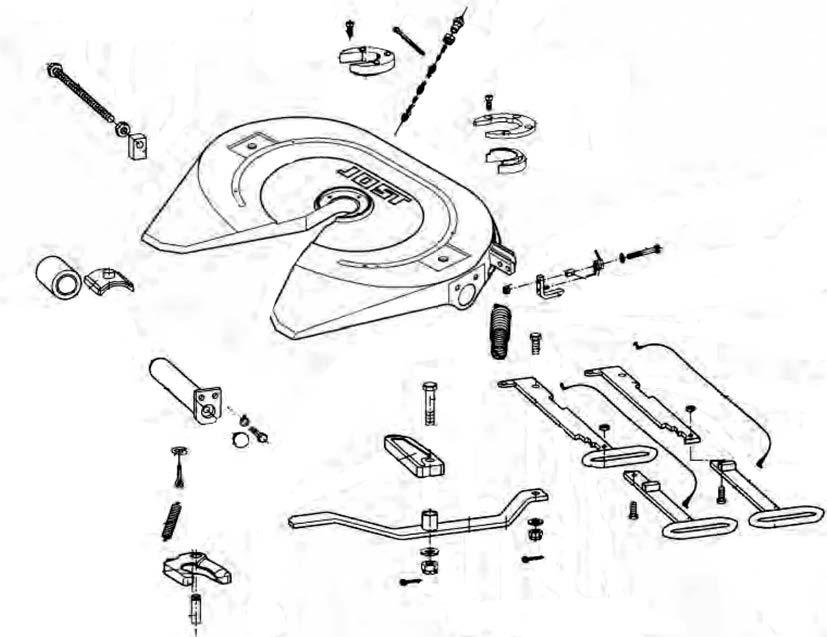

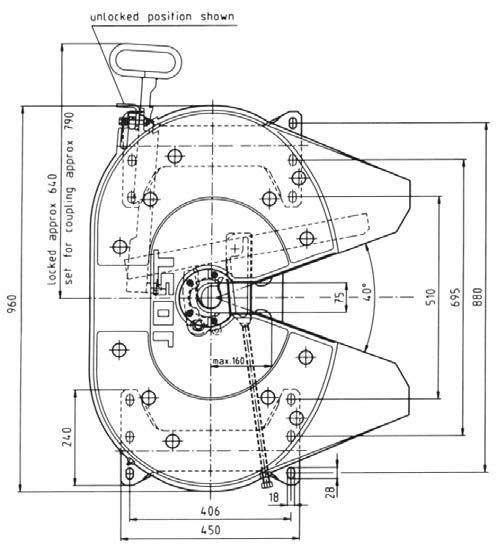

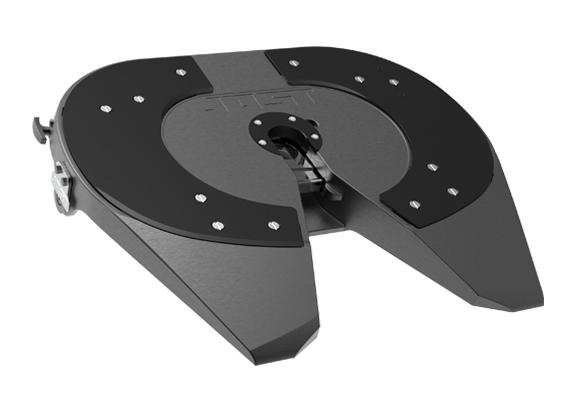

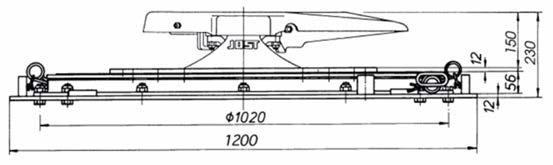

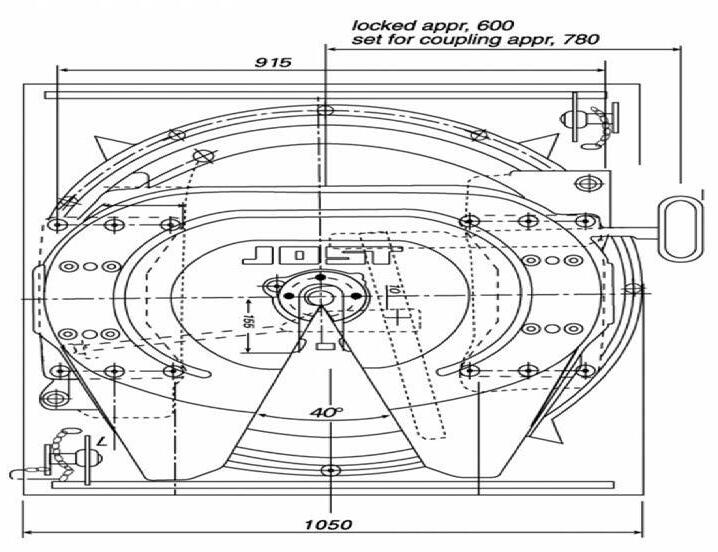

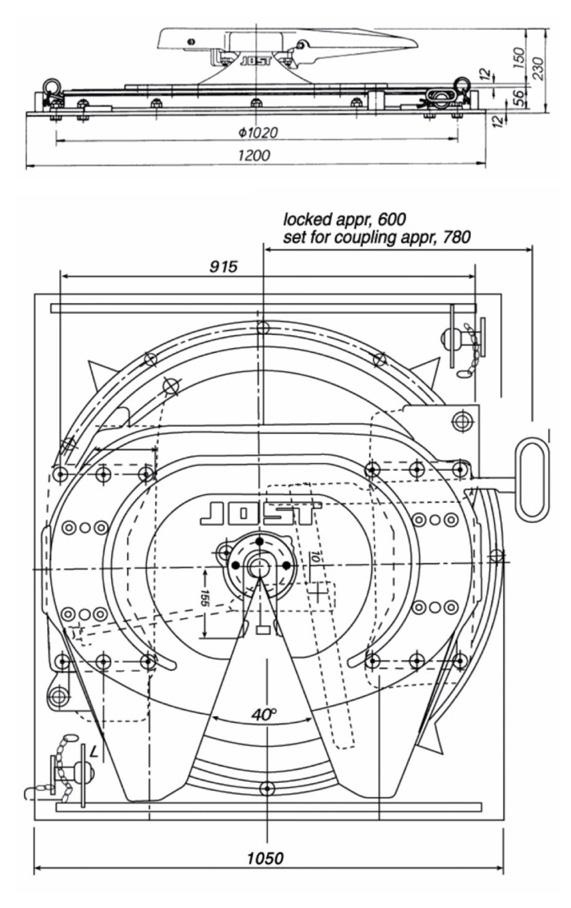

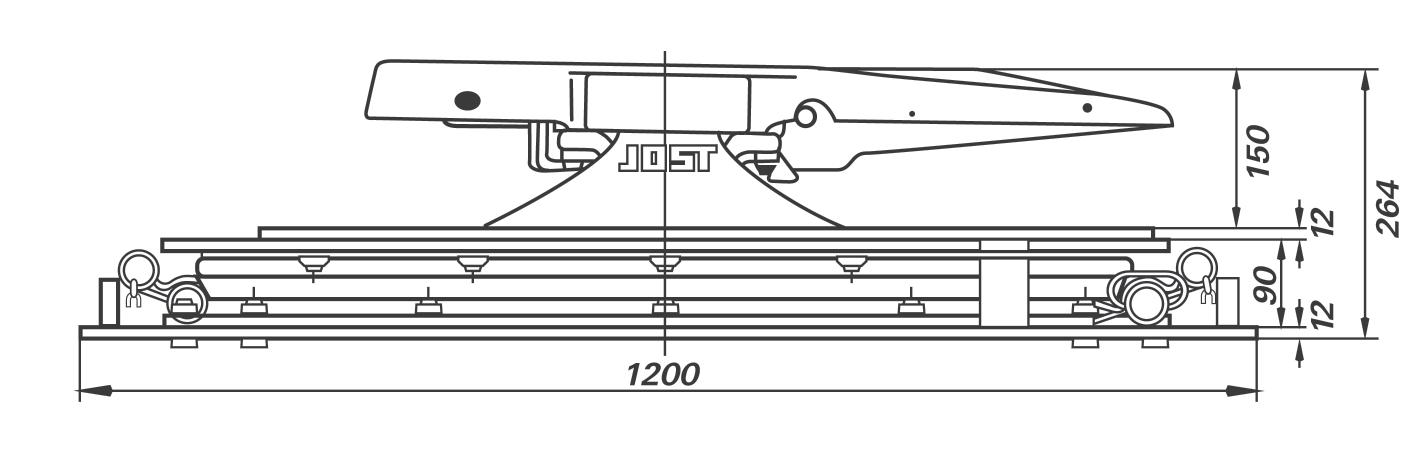

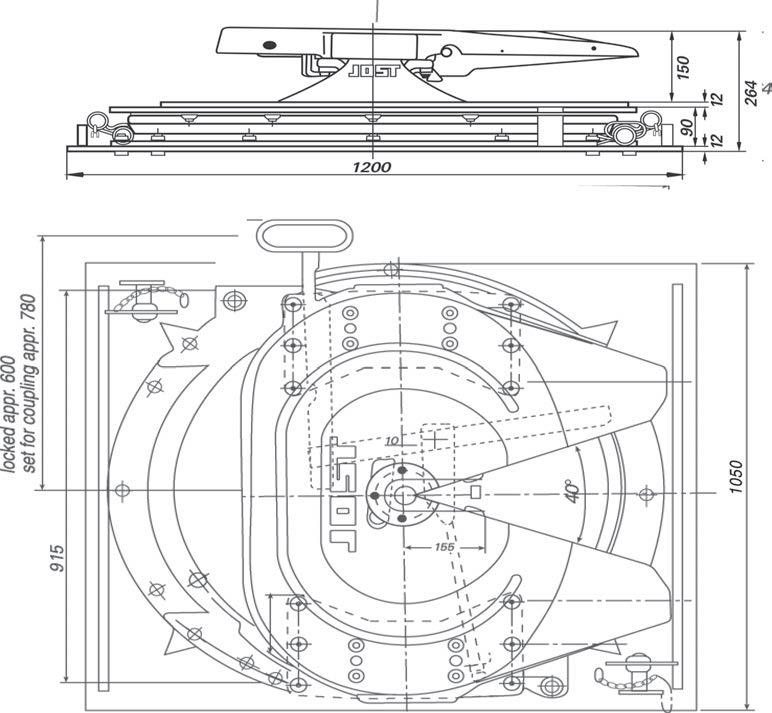

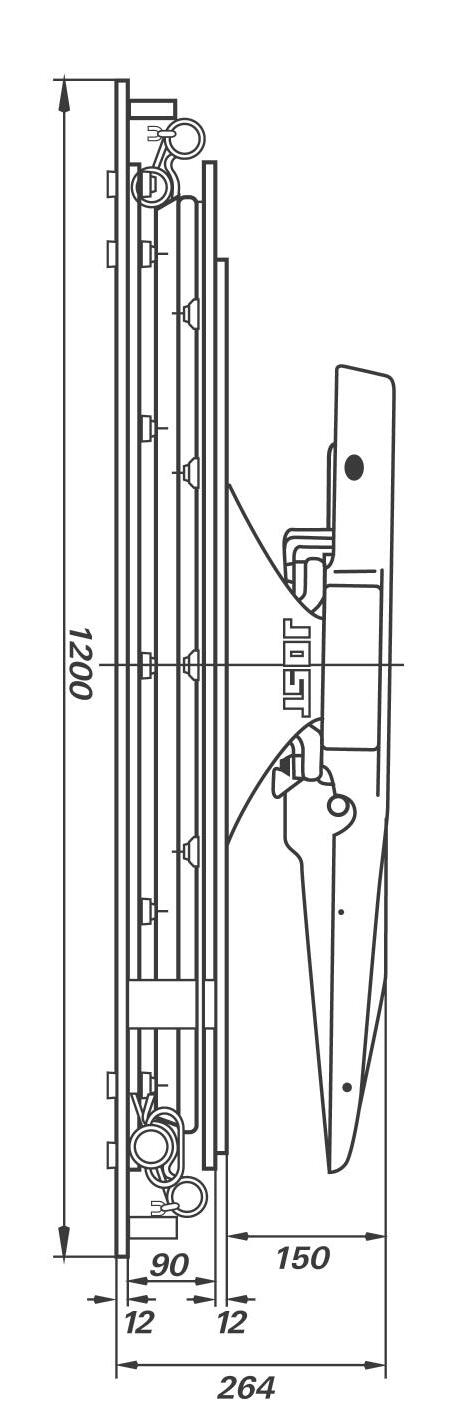

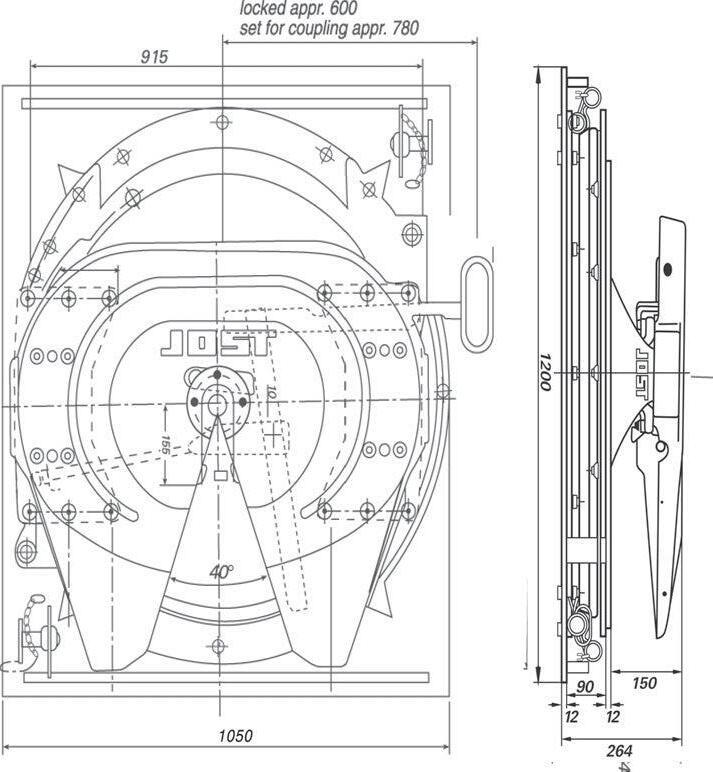

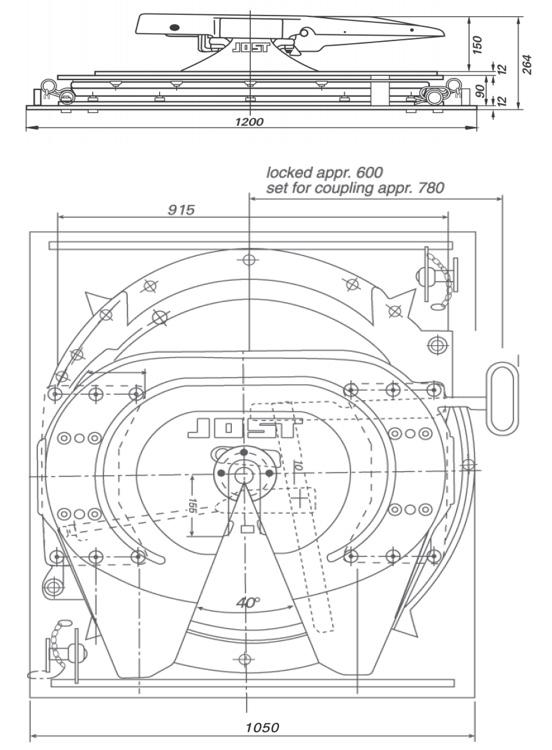

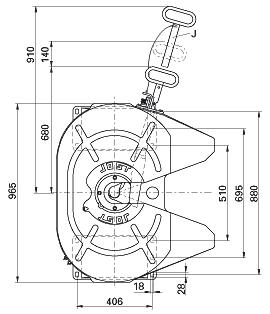

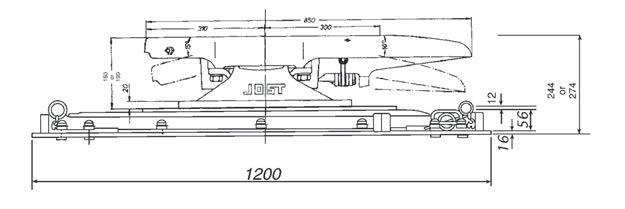

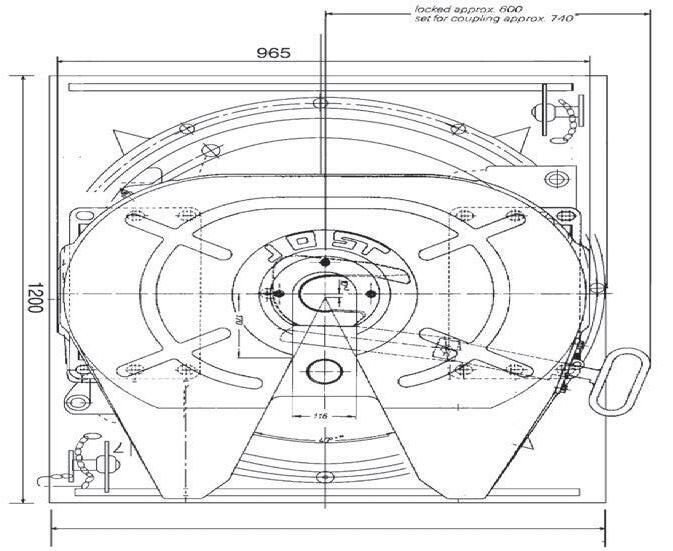

Locked with spring latch closed

• Automatic setting to couple up

• Fully adjustable wear

• Easy maintenance

Set for coupling

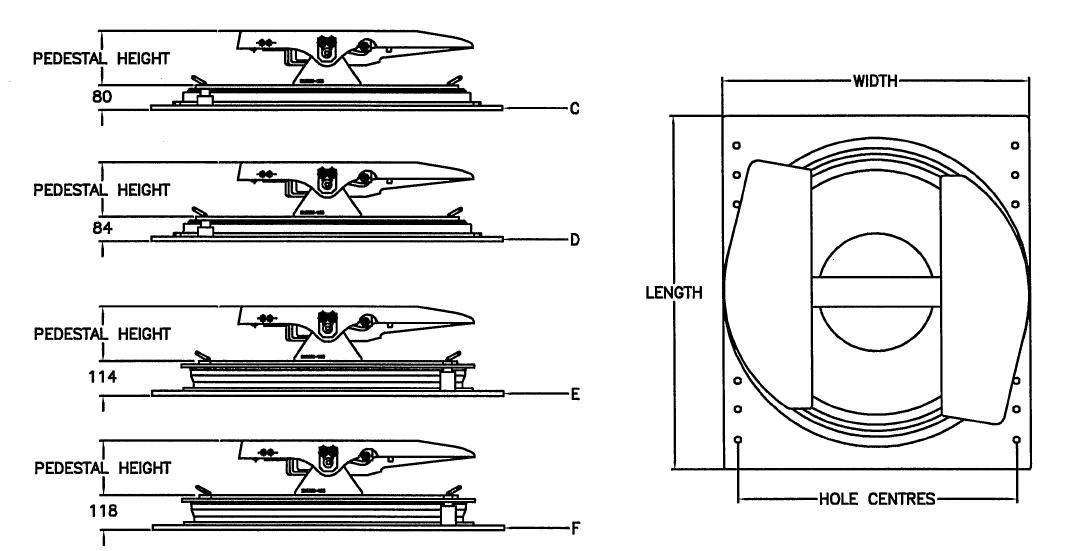

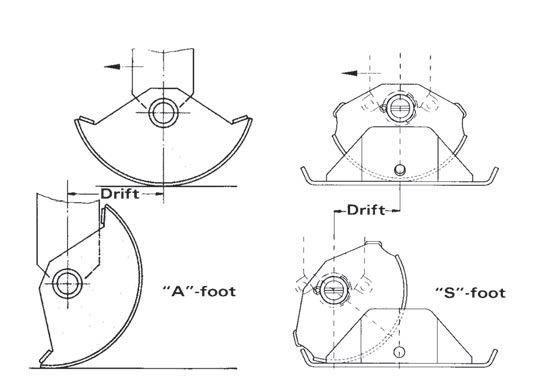

Type of mounting

E=

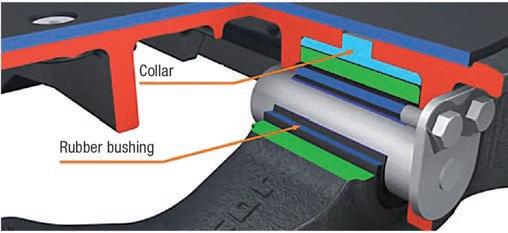

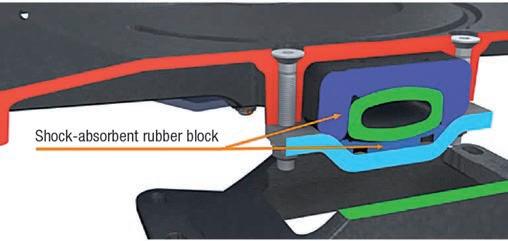

Pivot bearing mounting

Slack and maintenance free.

Oil and grease resistant

C = Rubber mounting

Shock absorbing by large rubber pads.

Slack and maintenance free. Oil and grease resistant

Selection criteria, maintenance, mounting instructions and user information for the top plate liner

The fifth wheel must be angled down to the rear of the truck and the mechanism in the present condition. Ensure that the trailer rubbing plate is level with the height of the fifth wheel plate. Reverse the truck slowly under the trailer aligning the king pin with the centre of the fifth wheel.

Continue reversing until the mechanism locks and secures the king pin. Pull forward against the trailer brakes to ensure engagement of the king pin in the coupling.

Visually check to see that there is no gap between the fifth wheel plate and the trailer rubbing plate and that the king pin is secured correctly within the fifth wheel mechanism.

Ensure lock catch is secured in the locked position.

Selection Criteria

The main characteristics of the JOST low maintenance fifth wheel coupling JSK37 are there excellent sliding properties (equivalent to a well lubricated fifth wheel) and their long life.

The fifth wheel was designed in particular for articulated vehicles with high mileage which are rarely uncoupled and run for long periods between services, e.g. tankers and tilts.

This high quality, low maintenance fifth wheel will offer you a long life span if you

• Couple up carefully: the fifth wheel should be at the same height as the skid plate (air suspension vehicles are advantageous)

• Make sure that the skid plate resp. guide rails to the skid plate are the correct size. They should have no sharp edges, steps or welding seams in the coupling up area.

• Ensure a flat, smooth surface of the skid plate and contact area.

• Grease the skid plate lightly to protect it from corrosion. The liner is not adversely affected by grease.

if these points are not observed the liner may be damaged.

Articulated vehicles with more complex load requirements (e.g. on building sites) and/or semi-trailers with rigid chassis (e.g. tankers) are liable to increase wear on the liner.

The liner is bolted onto the fifth wheel and can be easily replaced.

Lubrication of the liner is not necessary.

The fifthwheel has only one lubrication point for the lock jaw

Uncouple at the latest every 50,000 Km or six months, depending on usage. Clean the fifth wheel with liner and the skid plate. Check the liner for damage and wear. Lubricate the lock jaw and king pin with high pressure grease (EP) with MoS2 or graphite additive (e.g. L21M,Esso universal grease M or Shell Retinax AM).

The grease nipple on the edge of the fifth wheel plate is for lubricating the lock jaw and king pin between service.

The life expectancy of the lock jaw and king pin depend on effective lubrication before being put into service and after every cleaning operation.

For further information please refer to the JOST repair instruction booklet.

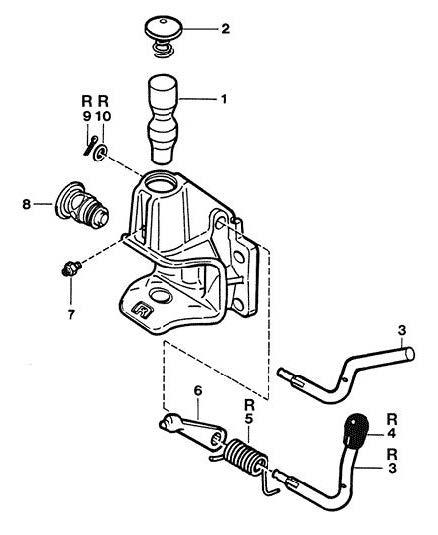

Models JSK37 Series

Replacement lock jaw

See JOST repair instructions page 9 resp.14

Thread M 8 x 1 for conical grease

nipple BM 8 x 1 DIN 71412 or cylindrical screw coupling M 8 x 1 with flexible tubing

Lubrication tubing, complete

The drawing shows JSK37 C-Z

The fifth wheels JSK37CZ and JSK37E Series are supplied with additional lubrication for the lock jaw and the king pin.

In order to connect the fifth wheels to the central lubrication system of the prime mover it is necessary to replace the 4 grease nipples under the fifth wheel plate and the 2 at the side with suitable screw couplings and connect them to flexible tubing, which is in turn joined up to a distributor unit compatible with the respective central lubrication system.

As a lubricant we recommend grease or liquid grease. Fifth wheels with central lubrication should be thoroughly cleaned and inspected for wear, damage and correct functioning at least once a year, or at the latest after 50,000 km, and repaired if necessary. Before coupling up again the fifth wheel and the king pin should be manually lubricated with high pressure grease (EP) with MoS2 or graphite additive.

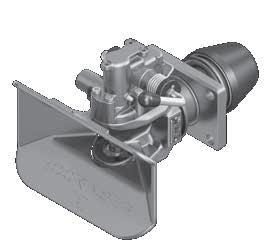

Integrated cartridge, protected under the fifth wheel plate. 3 year life span

The special multi-stage thermal coating on the jaws makes its surface highly durable.

Guaranteed safe and automatic for 3 years

JOST, the market leader in the area of couplings for trucks and trailers, remains on it’s innovative course. The new development LubeTronic saves time and money and simplifies the day-to-day life of drivers and freight forwarding companies.

Always lubricates safely

• The special coating on the lock jaw makes the surface extremely durable. This allows the lock jaw to be operated with a minimal amount of lubricant.

• Excellant emargency running properties allow the coating to handle short-term operating even without lubricant.

• Outstanding lubricant qualities thanks to novel lubricants from high-performance grease and continuous lubrication.

• Temperature range: -20°C to +70°C

• Electronic dose dispensing reduces both costs and enviromental impact

• Completely sealed and immersion tested (IP 68)

Simple maintenance

• LubeTronic is easy to mount

• Self-regulating system with electronic monitoring signal on the cartridge

• Guaranteed 3 year life span

• Maintenance time savings

• Potential upgrading of all low-maintenance couplings

• Very light and compact

• With shockproof metal bracket

• Not recommended for usage in the construction industry

• Repair kit (complete) with cartridge: Order No. SKE004070000

JOST, the market leader in the area of couplings for trucks and trailers, remains on it’s innovative course. The new development LubeTronic saves time and money and simplifies the day-to-day life of drivers and freight forwarding companies.

The lock of the fifth wheel holds the king pin firmly in place; it used to be one of the last maintenance-intensive elements in the system. LubeTronic allows this system to run practically maintenance-free for three whole years. The grease is discharged in a electronically controlled manner; the lock and king pin are always optimally lubricated. JOST guarantees automatic and safe operation of the LubeTronic for three years. The lubrication cartridges discharges it’s lubricant in a constant, uniform manner over a wide temperature range from -20 to +70 degrees Celsius and the entire system has been underwater-tested according to IP 68.

The LubeTronic retrofit kit includes a specially coated lock, which, together with the electronically regulated lubrication cartridge, is a system patented by JOST. The coating makes the surface of the lock particularly resistive and durable, so that even minimal quantities of the lubricating grease are sufficient. This is efficient and eco-friendly at the same time. The coating is so efficient that it even allows running without lubricant for short periods, although this is not recommended!

The lock holds the king pin and with it, the entire support system, coupled firmly with the traction engine. So far, regular lubrication by hand or by means of an expensive central lubrication was required, because the lock and king pin wear quickly without lubrication and have to be replaced. The traditional lubrication aids - which are mostly lubricating cartridges operated with overpressure - discharge grease smoothly and uniformly only within a narrow temperature range. All the maintenance procedures for the fifth wheel, which are not only uncomfortable and time-consuming, but above all, relevant for safety, are rendered redundant by LubeTronic.

Pressed Steel

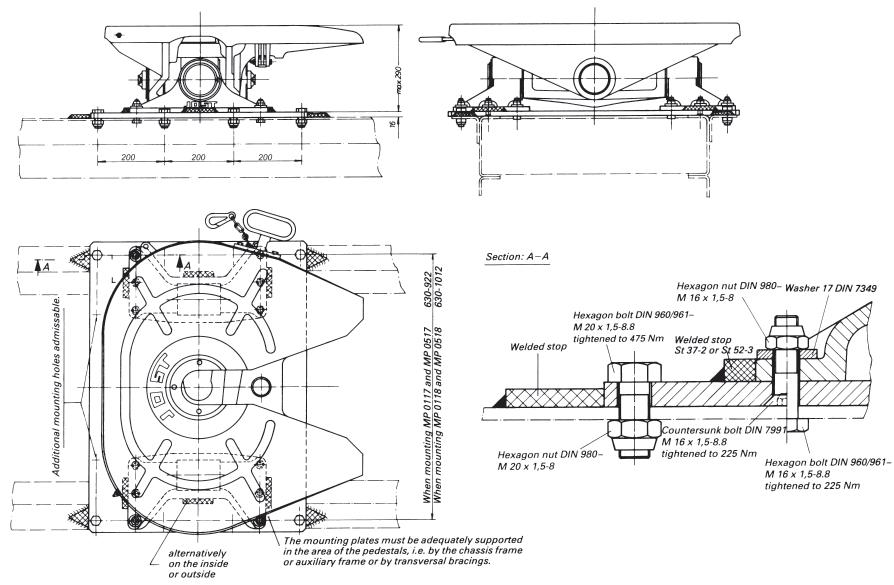

Mounting must be carried out in accordance with our instructions.

Application: General Freight Tipper work

For use with single trailers and B Double (not Road Train)

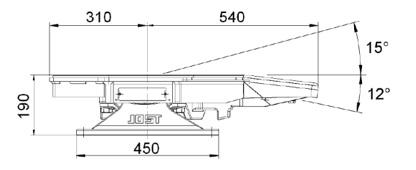

D-value 152 kN

Approval Number E1 55R-01 0301 Weight approx.

(bolt on feet) (for 150mm height)

Available with Fabricated-weld on Pedestals upon request.

Bolt on Pedestals 185 SK929440 1 20a Fabricated Pedestals 130 SK2920130 1 20b Fabricated Pedestals 150 SK2920150 1

Fabricated Pedestals 170 SK2920170 1

Pedestals 185 SK2920185 1

Fabricated Pedestals 195 SK2920195 1

205 SK2920205 1

215 SK2920215 1

*Note 300mm non weldable pedestals

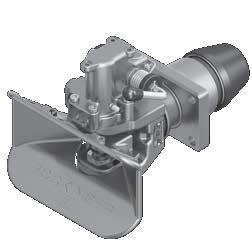

Applications: Tanker General freight Fridge van B-double Road train

The fifth wheel comes standard with bolt on/weld on feet.

The fifth wheel coupling can be linked to the central lubrication system of the prime mover.

Lock jaw and wear ring can be replaced without difficulty in a few minutes with the fifth wheel still in position.

Shock absorbing large rubber pads. Oil and grease resistant.

Mounting must be carried out in accordance with our instructions.

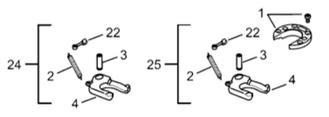

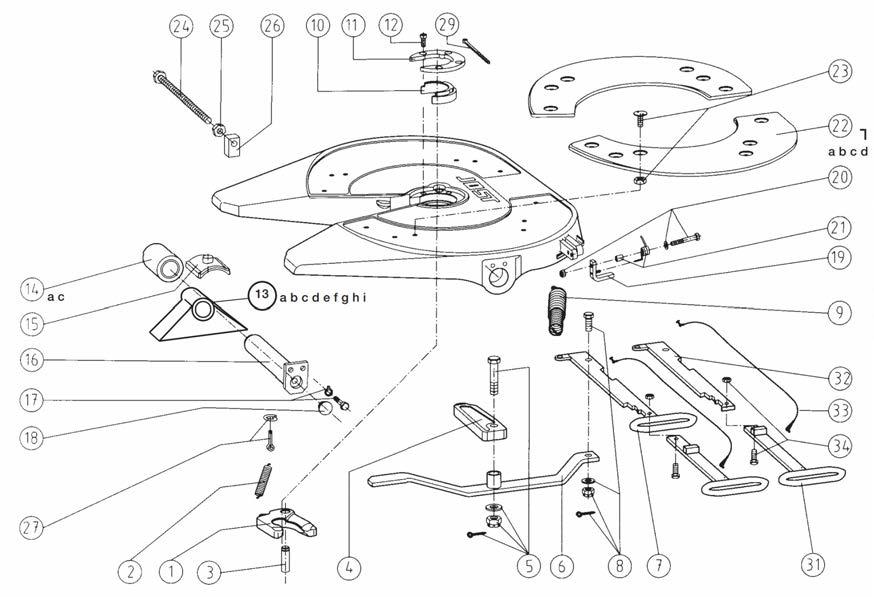

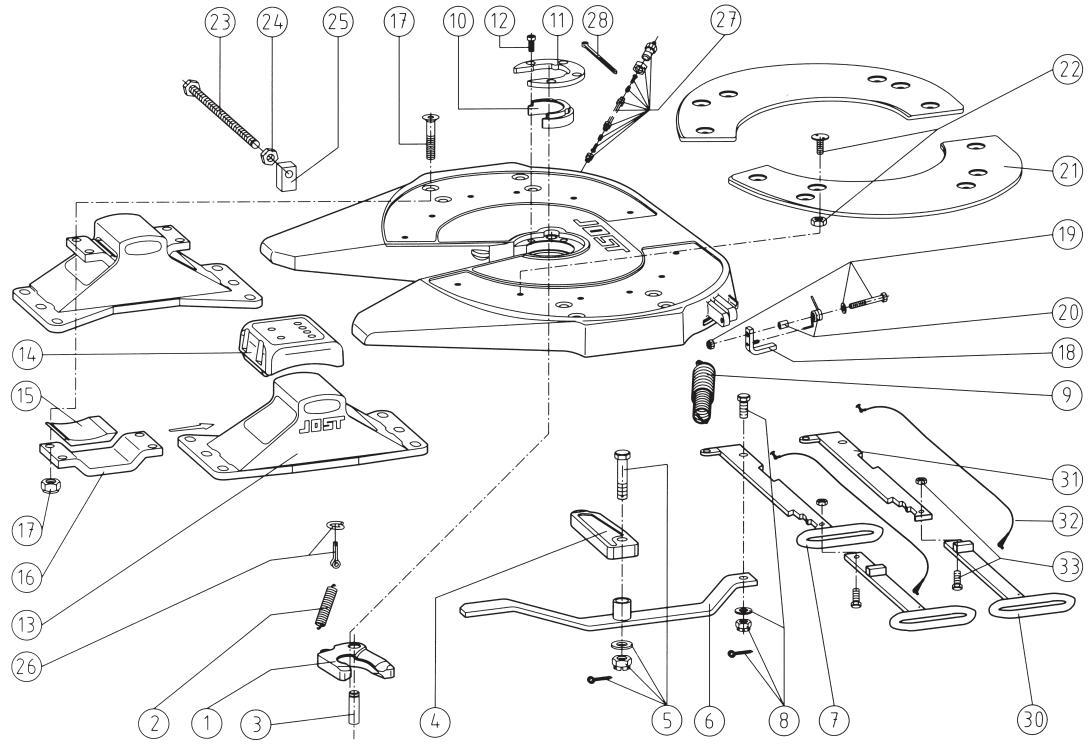

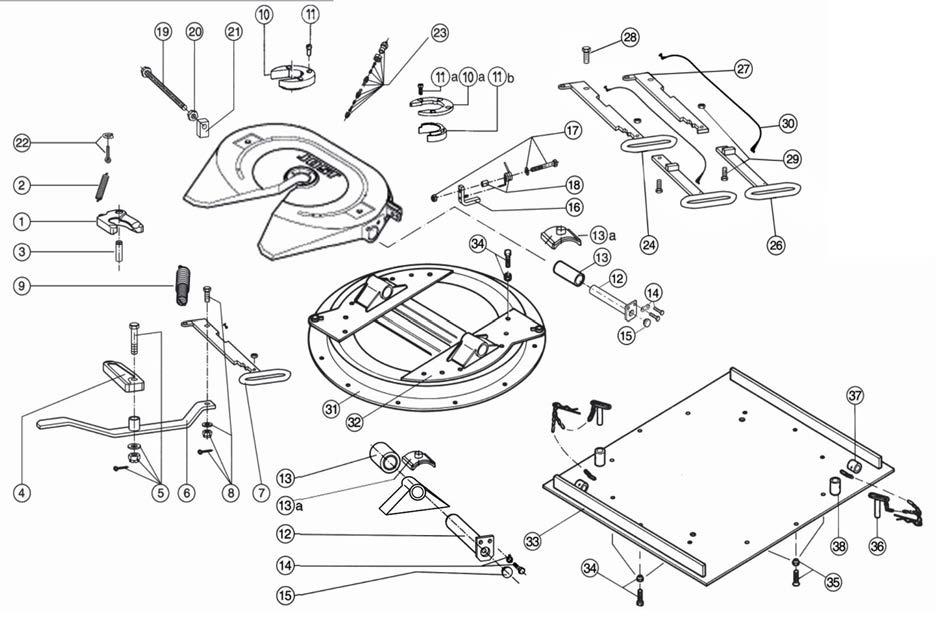

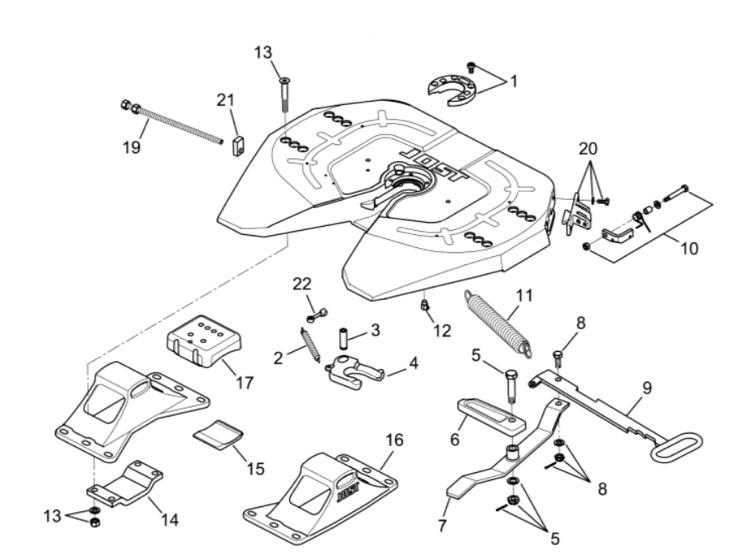

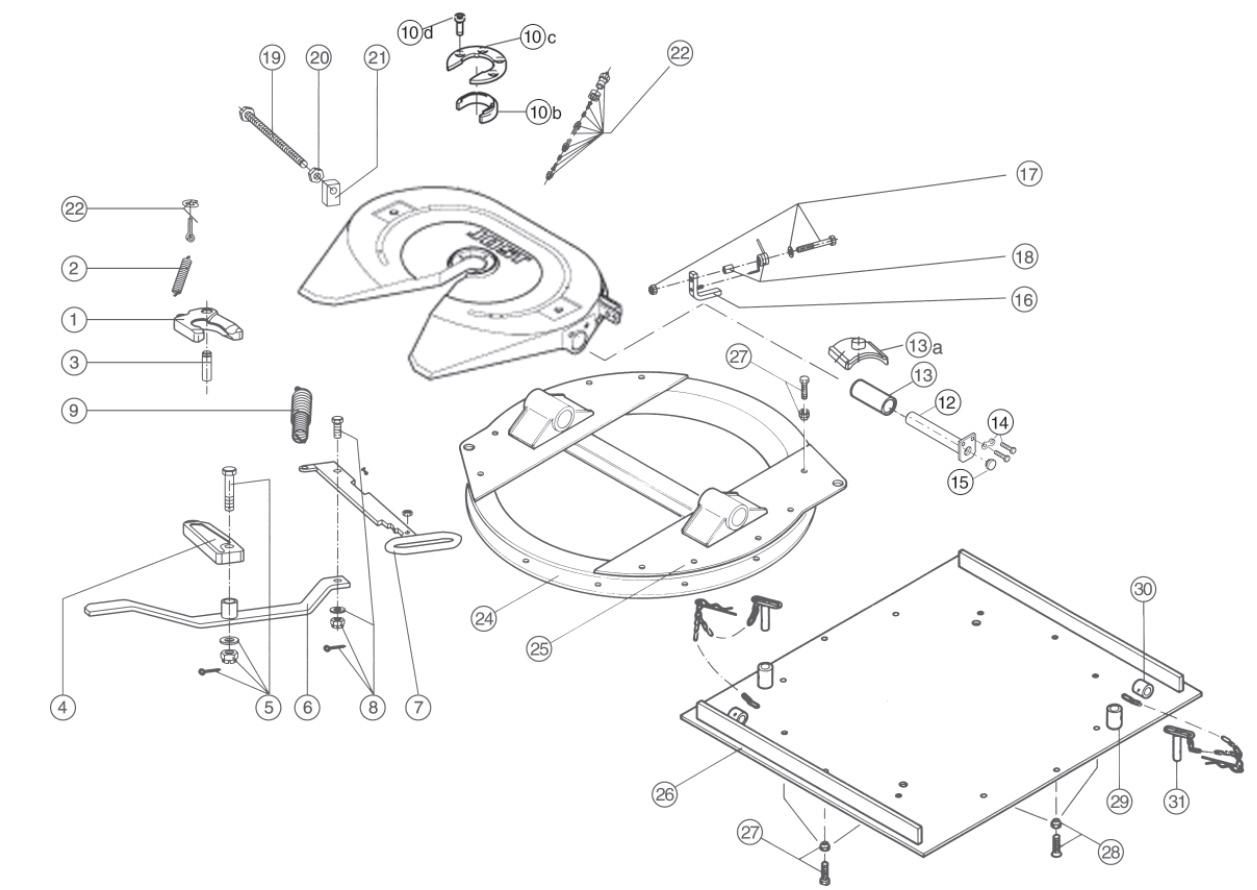

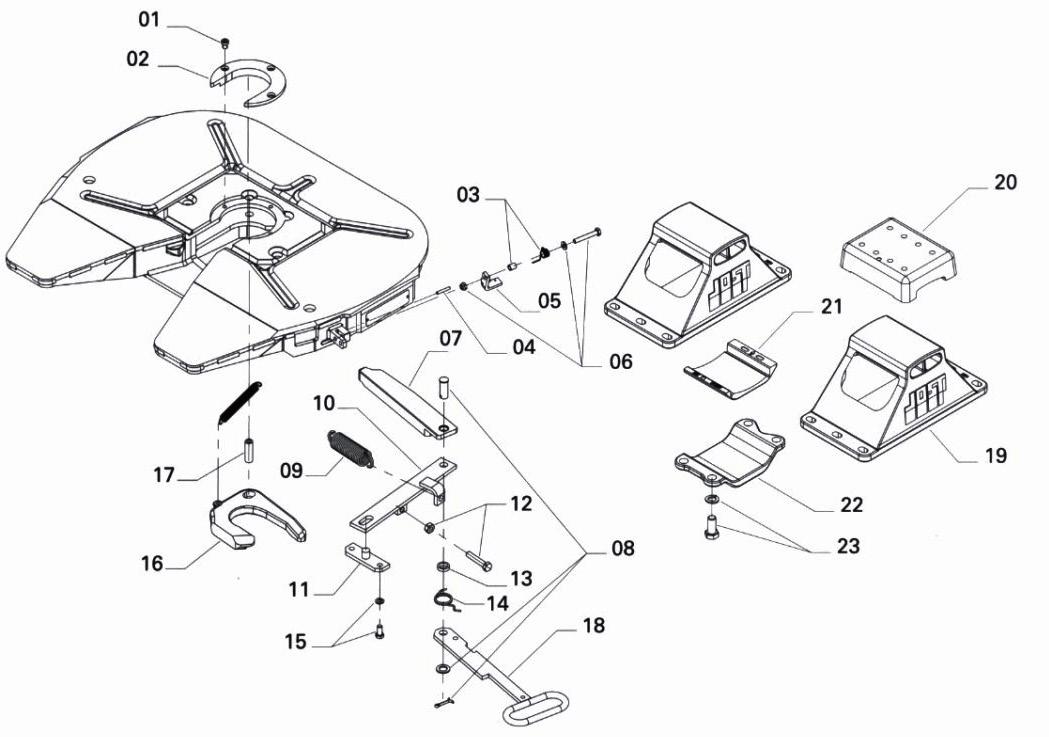

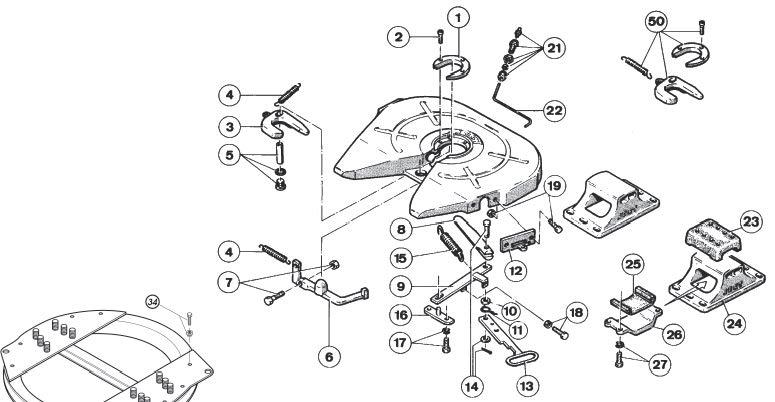

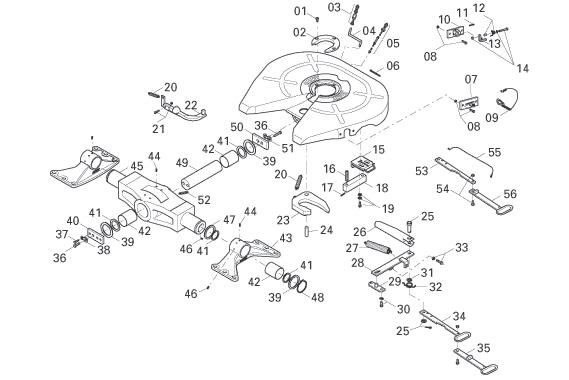

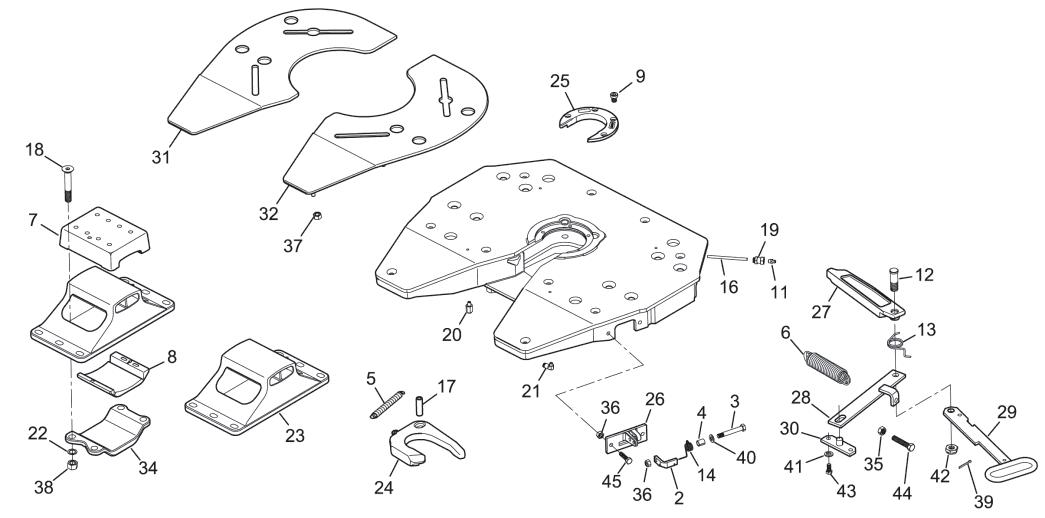

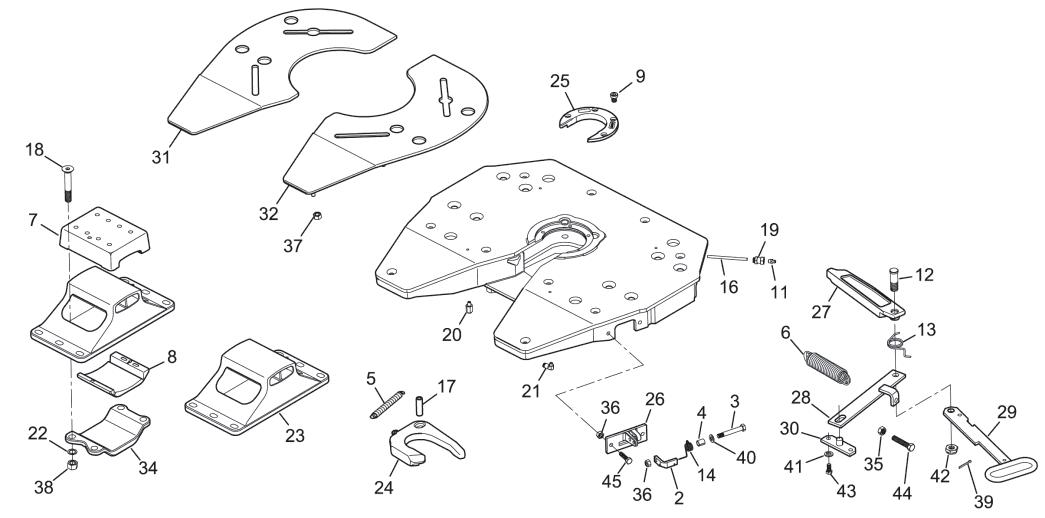

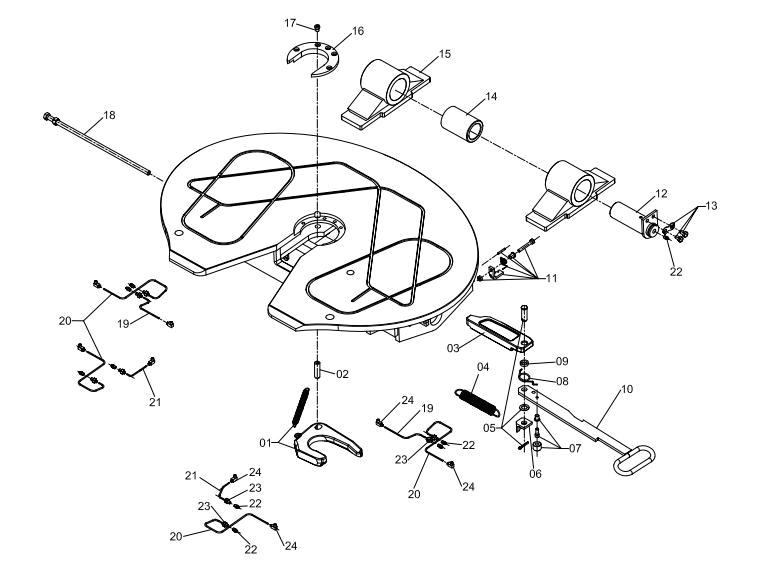

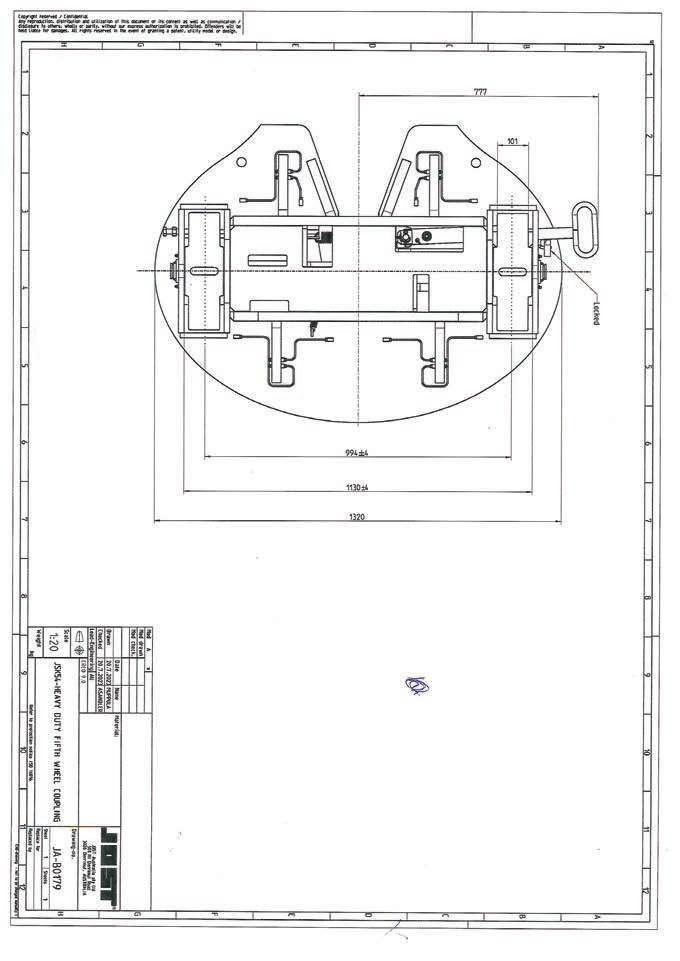

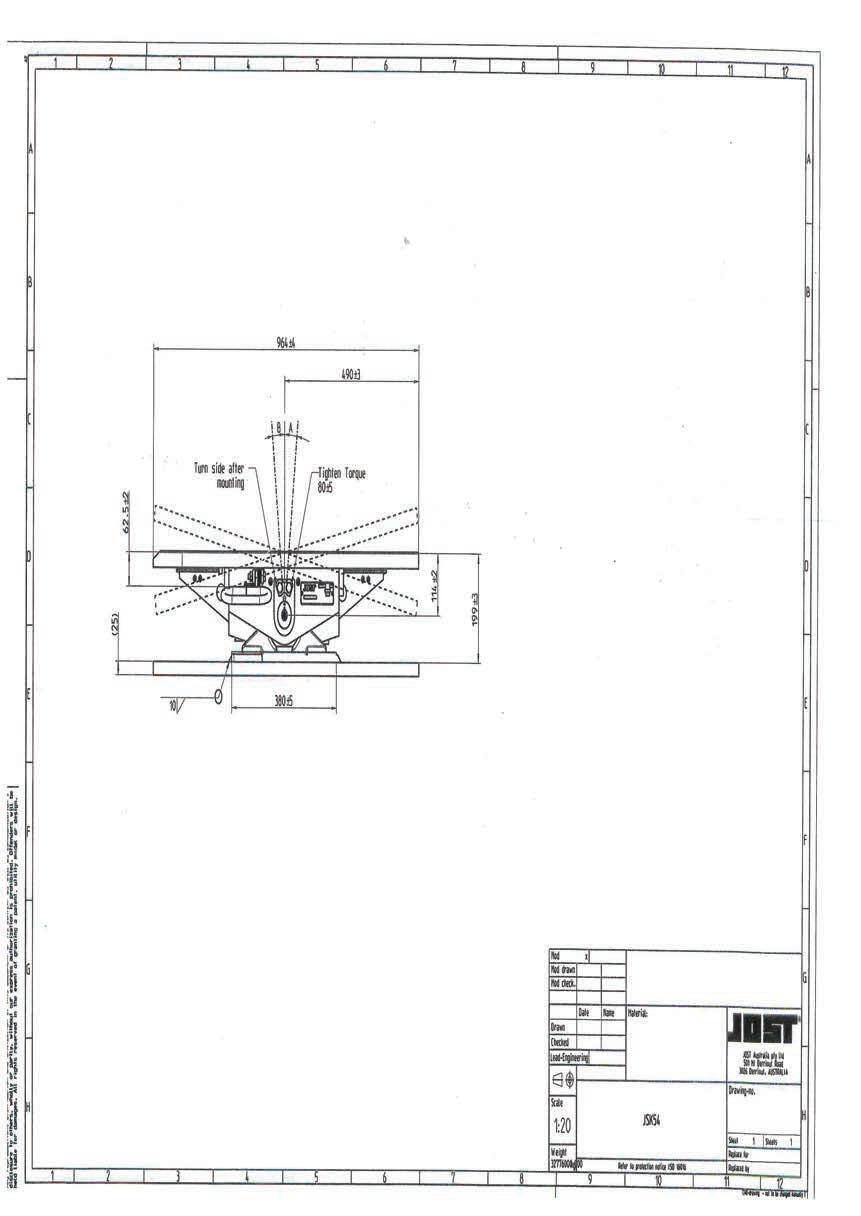

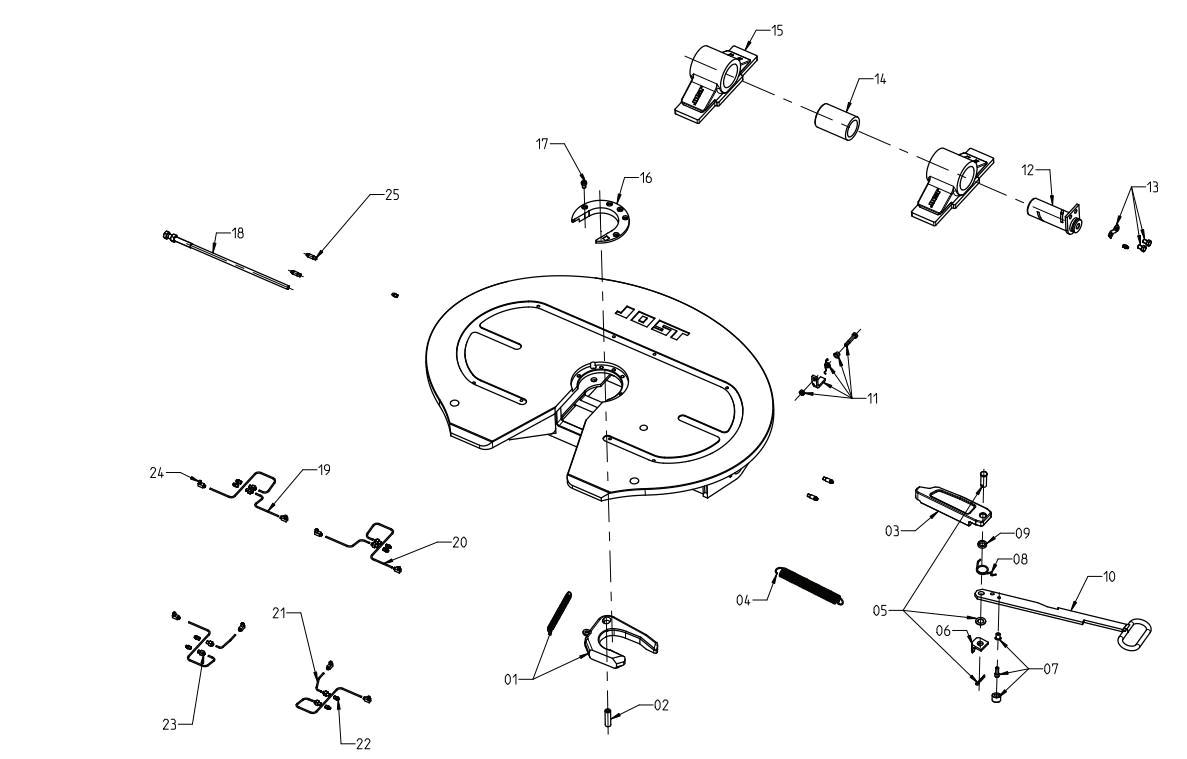

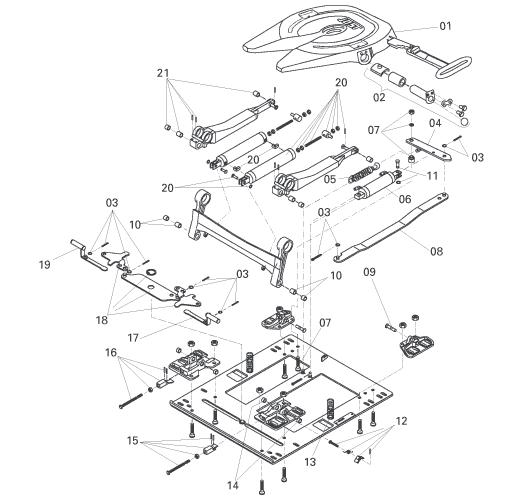

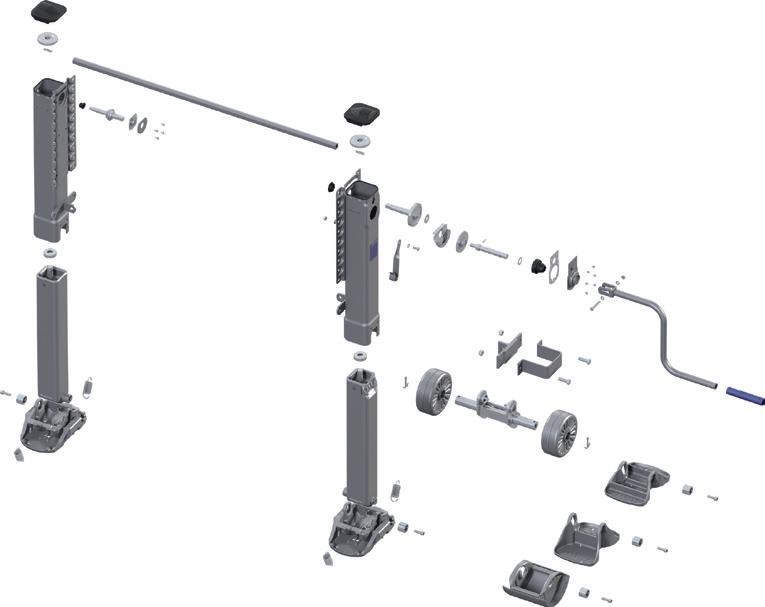

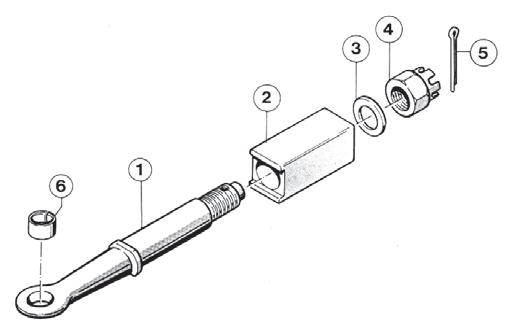

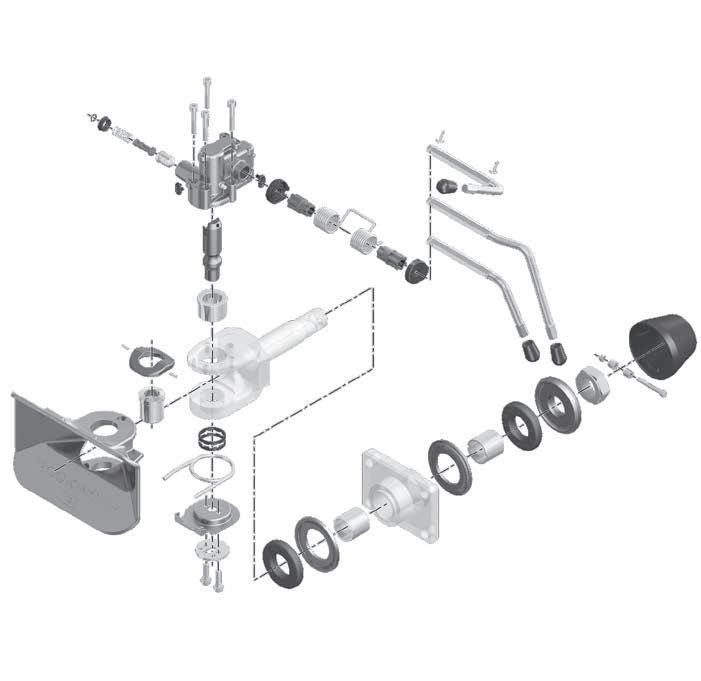

Fig. Description Part No.

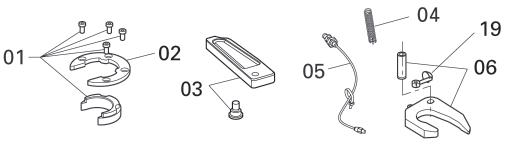

01 Lock jaw

02 Lock jaw spring

03 Pivot for lock jaw, compl.

04 Locking bar

05 Locking bar bolt, compl.

06 Lever

07 Operating handle

08 Socket head bolt

09 Double tension spring

10 Wearing ring

11 Head bolt

SK1489Z

SK847

SK210667

SK320506

SK322101

SK310518

SK310515

SK1513

SK310520

SK210519

SK212107

12b Pedestal (150 mm) Bolt on\Weld on SK210402X

12c Pedestal (170 mm) Bolt on\Weld on SK210421X

12a Pedestal (185 mm) Bolt on\Weld on SK210401X

12d Pedestal (220 mm) Bolt on\Weld on SK210418X

12e Pedestal (250 mm) Bolt on\Weld on SK210414X

12f Pedestal (300 mm) Non Weldable

13 Upper rubber cushion

14 Lower rubber cushion

15 Mounting bracket

Fig.

01, 02, 03, 10, 11

02, 03

01, 02, 03, 08, 10, 11, 18,

13, 14, 16

28, 29, 30

SK210420

SK1259

SK210525

SK1372 Fig. Description

No. 16 Socket head bolt, compl. with nut

Spring hook Pre 1996

Lubrication fitting

SK212115

SK1974

SK1436

SK212178

SK320507

SK312111

SK312152

SK3105115

SK1513

SK242150

SK352102

*Note 300mm non weldable pedestals

Applications: Stock crate Fridge van Tanker B-double Road train

Sturdier fifth wheel coupling plate, with central relief to avoid load concentration on the coupling system. A heavy-duty fifth wheel coupling for operation in arduous conditions.

Pedestals fixed by 6 bolts. Hole areas have been reinforced.

Lock jaw and wear ring can be replaced without difficulty in a few minutes with the fifth wheel still in position. Mounting must be carried out in accordance with our mounting instruction.

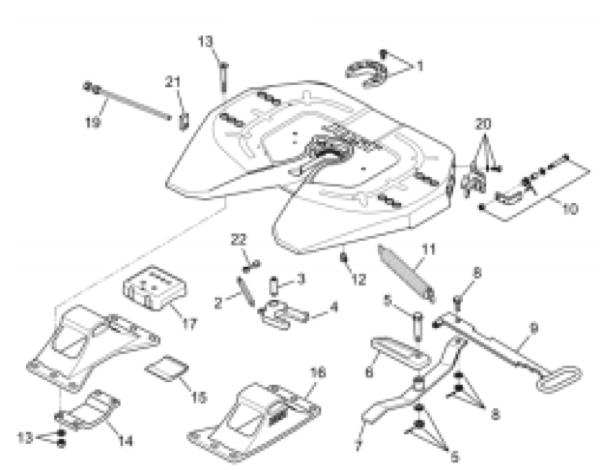

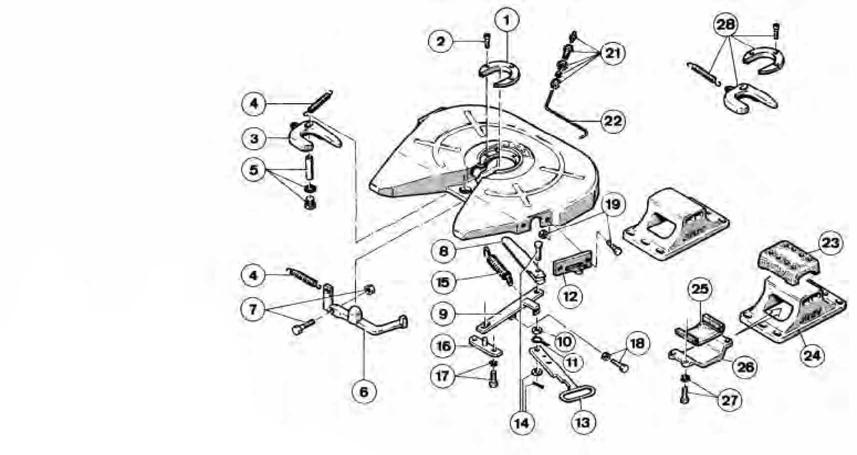

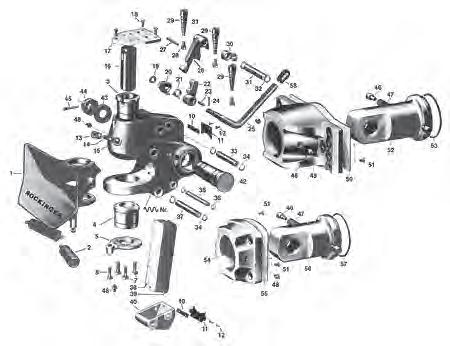

Fig. Description

01 Wearing ring and bolts

02 Lock jaw spring

QR00269J00

SK847 03 Pivot

04 Locking jaw

05 Bolt (complete)

06 Locking bolt

07 Lever with bushing

SK210667

SK1489Z

SK322101

SK320506

SK310518

SK1513

SK310515

SK312152KIT

14 Mounting bracket

15 Lower rubber cushion

QR00215J01

SK21025

16a Pedestal (150mm) SK210402X

16b Pedestal (170mm)

SK210421X

16c Pedestal (185mm) SK210401X

16d Pedestal (220mm) SK210418X

16e Pedestal (250mm) SK210414X

16f Pedestal (300mm)

17 Upper Rubber Cushion

19 Adjustment screw

20 Guide latch complete security

SK210420

SK1259

AD01148B80

QR00270J00

21 Guide with thread SK320507

22 Pin with eyelet SK212204

SK212169CX

The right to alter specifications is reserved.

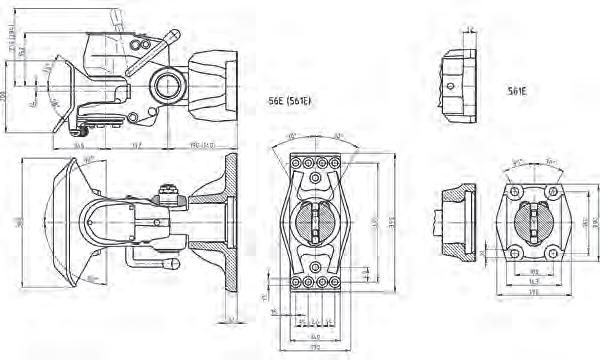

Applications: Highway Work Tipper Work

Lock jaw and wear ring can be replaced without difficulty in a few minutes with the fifth wheel still in position. Available with extended operating handle (240mm) on demand.

Mounting must be carried out in accordance with our instructions.

Mounting hole pattern in accordance with DIN standard 74081 and ISO standard 3842. Suitable for all types of rear axle steering systems.

CTA-036821

CTA-036821

13e

13f

The right to alter specifications is reserved.

Applications: Highway work Tipper Work

Low maintenance fifth wheel coupling:

• maintenance free top plate

• maintenance free rubber cushioned pivot bearings

• maintenance free wear ring

• only one remaining grease point the lock jaw (little grease required)

Lock jaw and wear ring can be replaced without difficulty in a few minutes with the fifth wheel still in position.

Available with extended operating handle (240mm) on demand.

Mounting must be carried out in accordance with our instructions.

Mounting hole pattern in accordance with DIN standard 74081 and ISO standard 3842. Suitable for all types of rear axle

SK310595

SK310405

SK312128

JS110112

SK312152

SK352103

SK312159

SK3105/130L

SK3105/130R

bolt (new style) SKT 001006000

screw SK310597

13a Cast Pedestals 6 inch (155.8mm) SKE-6IN-W

13b Cast Pedestals 7 inch (181.2mm) SKE-7IN-W

13c Cast Pedestals 8 inch (206.6mm) SKE-8IN-W

13d Cast Pedestals 9 inch (232.0mm) SKE-9IN-W

13e Bolt on Pedestals 150mm

13f Bolt on Pedestals 170mm

13g Bolt on Pedestals 185mm

SK2904/42

SK2904/41E

SK2904/40

Fig. Repair Kits Part No.

1, 2, 3 Repair kit for locking device SK322152Z

1, 2, 3, 8, 10, 12, 28 Repair kit for locking device SK3121060Z

10, 11, 12 Repair kit for wearing ring SK310494

SK212178

bolt, compl. SK212204

tubing, compl. SK310802

SK312113

handle, grip SK3105113

Latch cord, compl. SK352102

Socket head bolt, compl. SK242150

Lubetronic grease cartridge SKE003110310

Fig.Repair Kits Part No.

22aSteel Inserts 6 bolt LH

SK4001L 22aSteel Inserts 6 bolt RH SK4001R

22Steel Inserts (6 bolt) kit SK4000

14, 15, 16, 17, 18 22,23 Repair kit for top plate liner 10mm (6 bolt) kit

Repair kit for bearing SK3121061

19, 20, 21 Repair kit for spring latch SK312152 Kit

SK3106007

Handle extension, compl. SK3121063

Applications: Tanker

General freight Stock crate Fridge van B-double Road train

Low maintenance fifth wheel coupling:

• maintenance free top plate

• maintenance free rubber cushioned pivot bearings

• maintenance free wearing ring

• only one remaining grease point the lock jaw (little grease required)

Lock jaw and wearing ring can be replaced without difficulty in a few minutes with the fifth wheel still in position.

Available with extended operating handle (240mm) on demand.

Mounting must be carried out in accordance with our instructions.

Mounting hole pattern in accordance with DIN standard 74081 and ISO standard 3842.

*Note 300mm non weldable pedestals

Lockjaw

Operatinghandle(standard)

Pedestal(150mm) bolt on\weldable

Pedestal(170mm) bolton\weldable

Pedestal(185mm) bolt on\weldable

Pedestal (220mm) bolt on \weldable

Pedestal(250mm) bolton\weldable

Pedestal(300mm)bolton

Upperrubbercushion

SK3105-93 SK3121-55

SK2104-02X SK2104-21X SK2104-01X SK 2104-18X SK2104-14X SK2104-20 SK1259

13a Pedestal (150mm) bolt on\weldable SK210402X

Lowerrubbercushion

13b Pedestal (170mm) bolt on\weldable SK210421X

SK2105-25 SK1372

13c Pedestal (185mm) bolt on\weldable SK210401X

13d

Pedestal (220mm) bolt on\weldable SK210418X

Repairkitforlockingdevice

SK3221-52Z

13e Pedestal (250mm) bolt on\weldable SK210414X

13f

Repairkitforwearingring 10,11,12

Repairkitforbearing 14,15,17

SK3105-94

SK2121-69Z

Pedestal (300mm) bolt on SK210420

Repairkitforspringlatch 18,19,20

Repairkitforspringlatch 19,20,21

SK3121-52

SK3121-59

SK Repair kit for top plateliner (4 bolt)

Therighttoalterspeci cationsisreserved

JostAustraliaPty.Ltd.

SK2121-15

Countersunkbolt,compl. 8 18 SK3121-52 Latch 19 SK3521-03 Boltforspringlatch 20 SK3121-59 Springnoosewithspacer 21a

SK Topplateliner,righthand(6bolt) 3105-12910R 21b

SK Topplateliner,lefthand(6bolt) 3105-12910L 21c

SK3105/130L Topplateliner,righthand(newstyle) 21d SK3105/130R Topplateliner,lefthand(newstyle) 22a SK3121-062 Countersunkbolt,compl. 22bHexalobularbolt(newstyleboltonly) 12 SKT001006000

Adjustingscrew

Eyebolt,compl.

Lubricationtubing,compl.

SK3105-97

SK2121-78 Hexagonnut

SK3205-07

SK2122-04

SK352103

only) SKT 001006000

SK3108-02

SK3121-13 Tubingclamp

SK3105-113 Extendedhandle,grip

SK3105-115 Extendedhandle,lowerpart

SK2421-50 Socketheadbolt,compl. PartNo.

nut SK212178

SK320507

bolt, compl. SK212204

SK3521-02 Latchcord,compl.

tubing, compl. SK310802

1,2,3 SK Repairkit for top plateliner (6 bolt)3106-007

SK4000 SteelInsertsKit8mm(6bolt)

SteelInserts6boltLH

SteelInserts6boltRH Kit

SK4001L/8mm

SK4001R/8mm

Handleextension,compl. SK3121-063 21,22

Repairkitforspringlatch

SK3121-52Kit

SK312113

SK3105113

Repair Kits

Sydney (02)98388100

Brisbane (07)32725777 TollFreeSydney1800811487

Melbourne (03)93609001 www.jostaustralia.com.au

Fig. Repair Kits

01, 02, 03 Repair kit for locking device

Part No.

SK322152Z

10, 11, 12 Repair kit for wearing ring SK310594 14, 15, 17 Repair kit for bearing SK212169Z 18, 19, 20 Repair kit for spring latch SK312152 19, 20, 21 Repair kit for spring latch Kit SK312159 21, 22 Repair kit for top plate liner (6 bolt) SK3106007

The right to alter specifications is reserved

Perth (08)93554137 8/08 17

Fig. Repair Kits

Part No. 21, 22a Steel Inserts Kit 8mm (6 bolt) SK4000 22 Steel Inserts 6 bolt LH SK4001L 22 Steel Inserts 6 bolt RH SK4001R 30, 32, 33 Handle extension, compl. SK3121063 18, 19, 20 Repair kit for spring latch SK312152 Kit

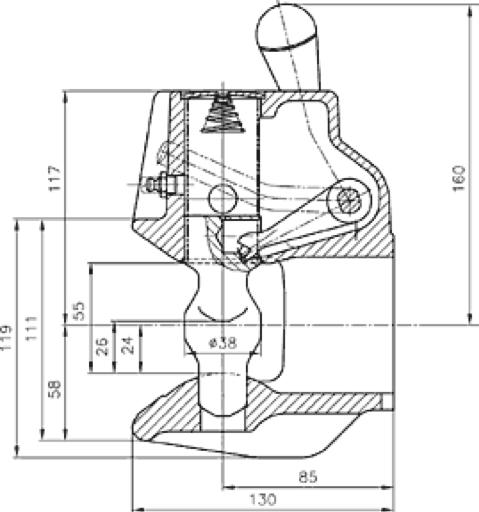

The fifth wheel coupling complies with the following directives/ standards: 94/20/ EC - Class G50, DIN 74081, ISO 3842. Suitable for mounting 2” king pins (50) as per 94/20/EC, DIN 74085, ISO 337 and steering wedges as per 94/20/EC, DIN 74085, AS/NZS 4968-1:2003.

Repair and retrofit kits

Features

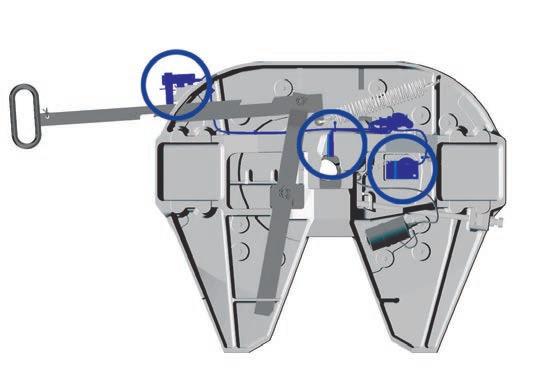

• Safety solution with remote dash display

• Road-Train rated – 190kN

• JSK37C 3 point sensor with dash display

• Connections sensor, king pin sensor and coupling height sensor.

• Integrated dash display available (truck specific)

• Extended handle for easy operation

• Optional lubetronic technology.

• Greaseable and greaseless options available

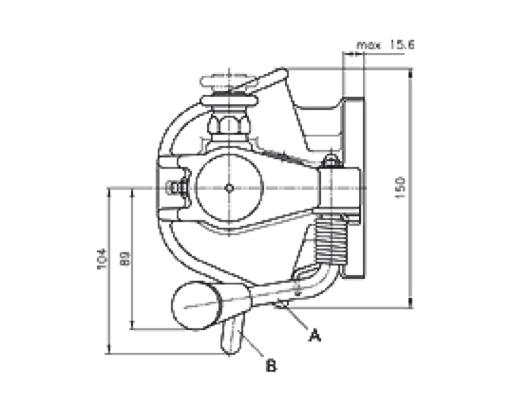

A = sensor for connection status

B = sensor for king pin

C = sensor for coupling height

Advantages at a glance

• Sensors provide best possible safety during the coupling process

• Increased safety even in poor visibility

• A remote display processes the signal and displays it in the driver’s cab

SparepartsJSK36+37

• A sensor permanently monitors the connection status

• A second sensor controls the position of the king pin

• An additional third sensor monitors the contact locking position and displays it in the driver’s cab.

• The sensors are located in protected zones on non-moving parts

• Electromagnetical compatibility according to highest standards

• Also suitable for use in the transport of dangerous goods (ADR)

ItemDescription

with07

03 Retaining plate for trailer sensor with 08

1 03Retainingplatefortrailersensor with08 SKE003220100 1 04Retainingplatefortrailersensor with09 SKE004650000 1

04 Retaining plate for trailer sensor with 09

1

1

004650000 1

053-sensorcableharnesswithretainingplateforlockingsensor-JSK36 with06,07,08,09,10 SKE002040400 1

05 3-sensor cable harness with retaining plate for locking sensor - JSK37 with 06, 07, 08, 09, 10

053-sensorcableharnesswithretainingplateforlockingsensor-JSK37 with06,07,08,09,10

display with 3 sensors - 24V

SparepartsJSK40+42 01Latchplatewithlockingmagnet with06

1

1

1

1

1

1

1

Applications: Fridge van Roll back application Tipper Work

Low maintenance fifth wheel coupling:

• maintenance free top plate

• maintenance free rubber cushioned pivot bearings

• maintenance free wear ring

• only one remaining grease point the lock jaw (little grease required)

Lock jaw and wear ring can be replaced without difficulty in a few minutes with the fifth wheel still in position.

Mounting must be carried out in accordance with our instructions.

Pneumatic operation

Also available in low profile ball race assembly

Fig. Description Part No.

01 Cushion ring bolt

02 Cushion ring plate

03 Cushion ring insert

04 Pivot pin for lock jaw

05 Collar

06 Bracket pin

SK7312155

SK310593

SK310592

SK7210667

SK7310595

Fig. Description

21 ¼" split lock washer

22 Release arm assembly

23 Locking bar

24 Cable spring

SK7030305

SK7901637

SK320506

SK7100504

SK1489LZ

SK847

SK7310447

SK7310405 07 Tab washer

08 ½ 13 × ¾ hex bolt

SK7020215 09 Air cylinder

SK210669

SK210670

SK7010103

SK7322101

SK7902013 10 Locking bar bolt assembly

11 ³⁄8" dia. × ¾" lg slic pin

12 Pivot bolt assembly

13 ³⁄8 16 locknut

14 ³⁄8" SAE flat washer

SK7010501

SK71513

SK7040102

SK7030201

15 Handle guide SK7901632

16 ³⁄8 16 × 11.4" button screw

17 Pull cable assembly

18 Thandle air release

19 Lock/unlock plate weldment

20 ¼20 × ¾" hex head cap screw

0136

SK7020602

SK7901646

SK7101200

SK7901622

SK7020228

SK7902008

SK7010201

SK7901005

SK7320507

SK310520

SK7900505

SK5000L&R

SK310802

SK7502016

SK3121027

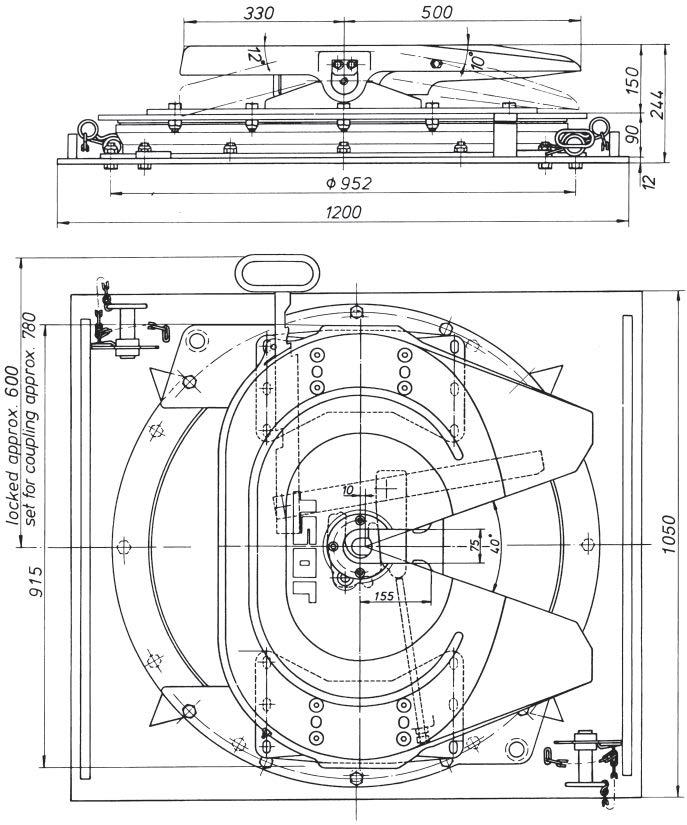

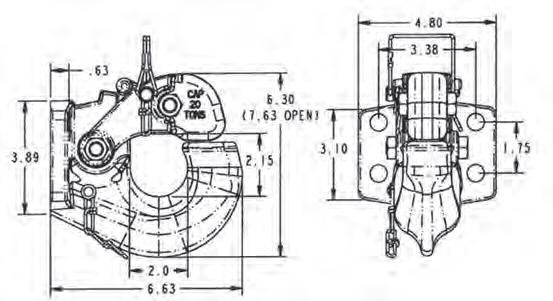

Application: Highway work Tipper work

also available with: 16mm Base Plate

LP37E 16 mm 20mm Base Plate

LP37E 20 mm

*Note thicker base plate determines extra weight **Note other heights available on request

D-Value

190 kN

Overall height 234 mm

Imposed load 20000 kgs

Weight approx. 356 kgs (for 16mm base plate)

Approval Number

Twin lockouts.

JSK37E -CTA-036821 LP Subassembly -CTA-047151

Flush bolt heads on mounting plate in chassis mounting zone. Wear ring easily removed from above on JSK37E fifth wheel. Mounting must be carried out in accordance with our instructions.

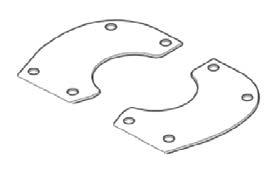

Half Moon c/w 130mm or 150mm Ped. SK370402

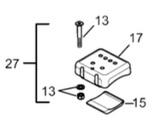

33a Base plate (12mm) incl. 56, 57, 58

SK370612

33b Base plate (16mm) incl. 56, 57, 58 SK370616

33c Base plate (20mm) incl. 56, 57, 58 SK370620

Hex. bolt compl.

SK372104

Countersunk bolt compl. SK372105

Lock out pin compl. with chain (old style) SK370610 36a Lock out pin compl. with R clip (new style) SK370609

SK370604

Tube lock out (old style) SK370605

38a Tube lock out (new style) SK370504

Application: Stock crate Fridge van General freight Tankers

also available with:

16mm Base Plate

20mm Base Plate

LP37CZ 16mm

LP37CZ 20mm

Narrow chassis width available ie European spec

*Note: thicker base plate determines extra weight and height.

**Note: other heights are available on request

D-Value

190 kN

Overall height 234 mm

Imposed load 20000 kgs

Gross comb. weight 135000 kgs

Weight approx. 367 kgs

(for 12mm base plate)

Approval Number

Twin lockouts.

JSK37CZ -CTA-041876

LP Subassembly -CTA-047151

Flush bolt heads on mounting plate in chassis mounting zone. Cast type unit equipped with external king pin grease point for additional lubrication to the jaw. Wear ring easily removed from above on JSK37CZ fifth wheel. Mounting must be carried out in accordance with our instructions.

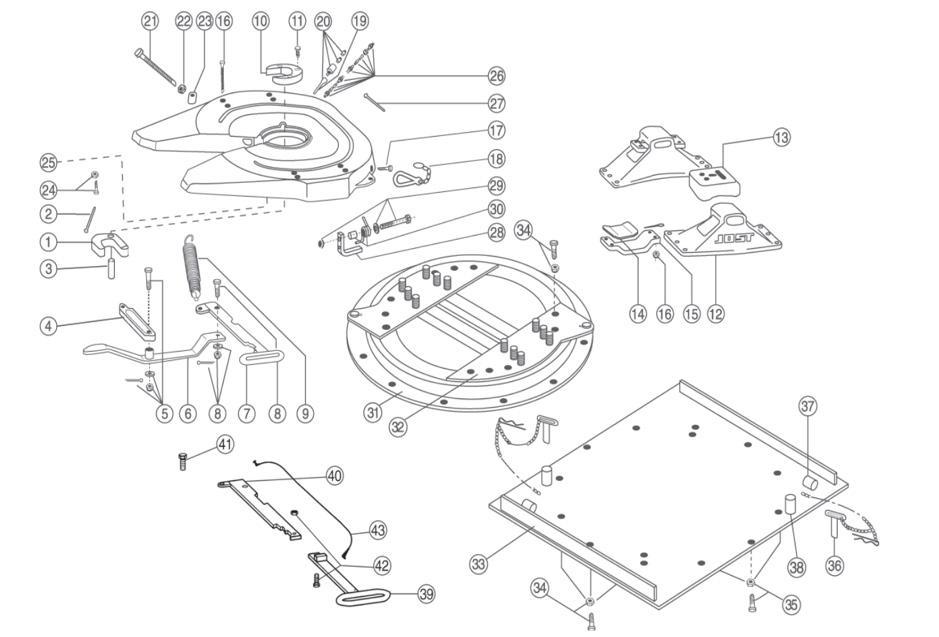

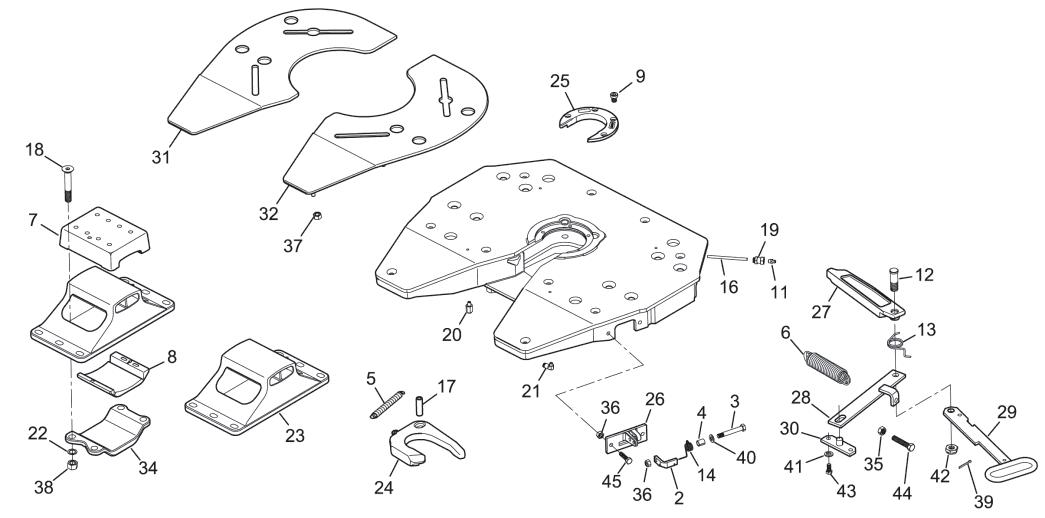

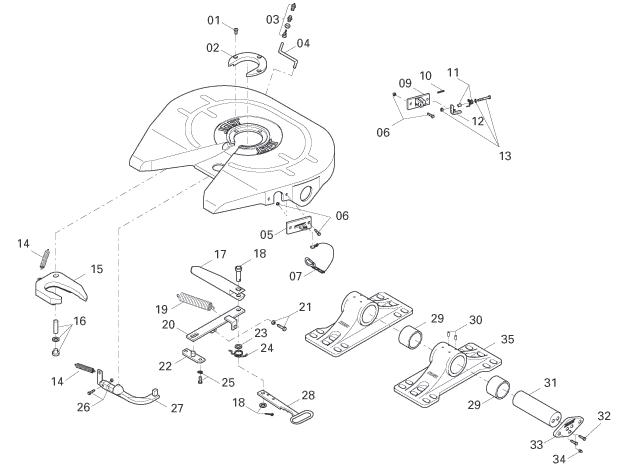

Fig. Description

01 Lock jaw

02 Lock jaw spring

03 Pivot for lock jaw, compl.

04 Locking bar

05 Locking bar bolt, compl.

06 Lever

07 Operating handle

08 Head bolt

09 Double tension spring

10 Wearing ring

11 Socket head bolt

12 Pedestal (185mm)

Pedestal (170mm)

Pedestal (150mm)

13 Upper rubber cushion

14 Lower rubber cushion

15 Mounting bracket

SK1489Z

SK847

SK210667

SK320506

SK322101

SK310518

SK310515

SK1513

SK310520

SK210519

SK212107

SK210401X

SK210421X

SK210402X

SK1259

SK210525

SK1372

16 Socket head bolt, compl. SK212115

17 Split pin

18

SK1974

Fig.

01, 02, 03, 10, 11, 26

01, 02, 03, 26

01, 02, 03, 08, 10, 11, 18, 26

13, 14, 16

Repair kit for locking device

Repair kit for locking device

Repair kit for locking device

Repair kit for rubber bearing

28, 29, 30 Kit for latch

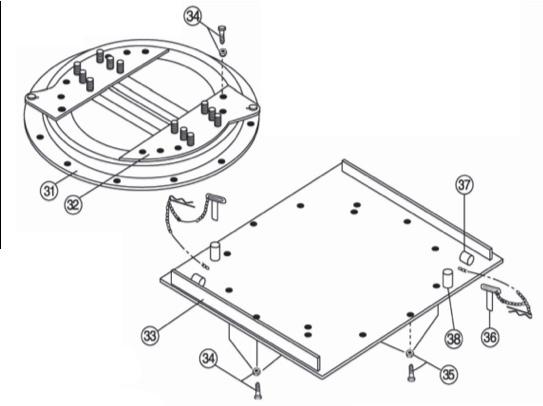

Eye bolt compl. SK212204 25 Grease nipple SK312111

Lubrication tubing with Fig. 27 SK310802

Tubing clamp SK312113 28 Spring Latch 1996 onwards SK312152 29 Bolt for Spring Latch SK3521/03

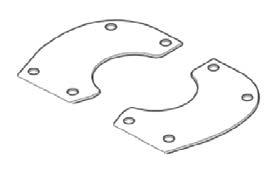

30 Spring for Latch SK3121/59 31 Ball bearing

KDL9006W

32 Half moon compl. SK370629

33a Base plate (12mm) incl. 36, 37, 38 SK370612

33b Base plate (16mm) incl. 36, 37, 38 SK370616

33c Base plate (20mm) incl. 36, 37, 38 SK370620

34 Hex. bolt compl.

SK372104

35 Countersunk bolt compl. SK372105

36 Lock out pin compl. with chain (old style) SK370610

36a Lock out pin compl. with R clip (new style) SK370609

37 Tube park old style SK370604

38 Tube lock out (old style) SK370605

38a Tube lock out (new style) SK370504

39 Handle Extension

SK3105113

40 Internal Operating Handle SK3105115

41 Head Bolt SK1513

42 Extended Handle Bolt SK242150 43 Cable Extension SK352102

SK322150Z

SK322152Z

SK312150Z

SK212169Z

SK312152 KIT

Application: General freight Tankers Fridge van Stock crate

also available with:

16mm Base Plate

LP37CX 16mm

20mm Base Plate LP37CX 20mm

Narrow chassis width available ie. European spec

*Note thicker base plate determines extra weight and height.

**Note: other heights are available on request

D-value 240kN

Overall height 234mm

Imposed load 24000 kgs

Weight approx. 367 kgs (for 12mm base plate)

Approval Number

Twin lockouts.

JSK37CX -CTA-045374

LP Subassembly -CTA-047151

Flush bolt heads on mounting plate in chassis mounting zone. Cast type unit equipped with external king pin grease point for additional lubrication to the jaw.

Wearing easily removed from above on JSK37CX fifth wheel.

Mounting must be carried out in accordance with our instructions.

Fig. Description Code

01 Wearing ring and bolts

02 Lock jaw spring

03 Pivot

04 Locking jaw

05 Bolt (complete)

06 Lock bar

07 Lever with bushing

08 Head bolt

09 Lever handle

10 Latch kit

11 Double tension spring

12 Fitting

13 Complete countersunk bolt

14 Mounting bracket

15 Lower rubber cushion

16 Pedestal (150mm)

16a Pedestal (170mm)

16b Pedestal (185mm)

16c Pedestal (220mm)

16d Pedestal (250mm)

16e Pedestal (300mm)

QR00269J00

SK847

SK210667

SK1489Z

SK322101

SK320506

SK310518

SK1513

SK3105/15

SK312152KIT

SK3105/20

SK312111

SK212115

QR00215J01

SK21025

SK210402X

SK210421X

SK210401X

SK210418X

SK210414X

SK210420

Fig. Description

17 Upper Rubber Cushion SK1259

19 Adjustment screw AD01148B80

20 Guide latch complete security QR00270J00

21 Guide with thread SK320507

22 Pin with eyelet SK212204

31 Ball bearing KDL9006W

32 Half mon complete SK370629

33a Base plate (12mm) inc 36, 37, 38 SK370612

33b Base plate (16mm) inc 36, 37, 38 SK370616

33c Base plate (20mm) inc 36, 37, 38 SK370620

34 Hex bolt complete SK372104

35 Countersunk bolt complete SK372105

36 Lock out pin compl with chain (old style) SK370610

36a Lock out pin compl with R clip (new style) SK370609

37 Tube park (old style) SK370604

38 Tube lock out (old style) SK370605

38a Tube lock out (new style) SK370504

locking claw - items 1, 2, 3, 4, 22 SK322150CX 27 Base plate fastening kit - items 13, 15, 17 (with 4 screws)

SK212169CX

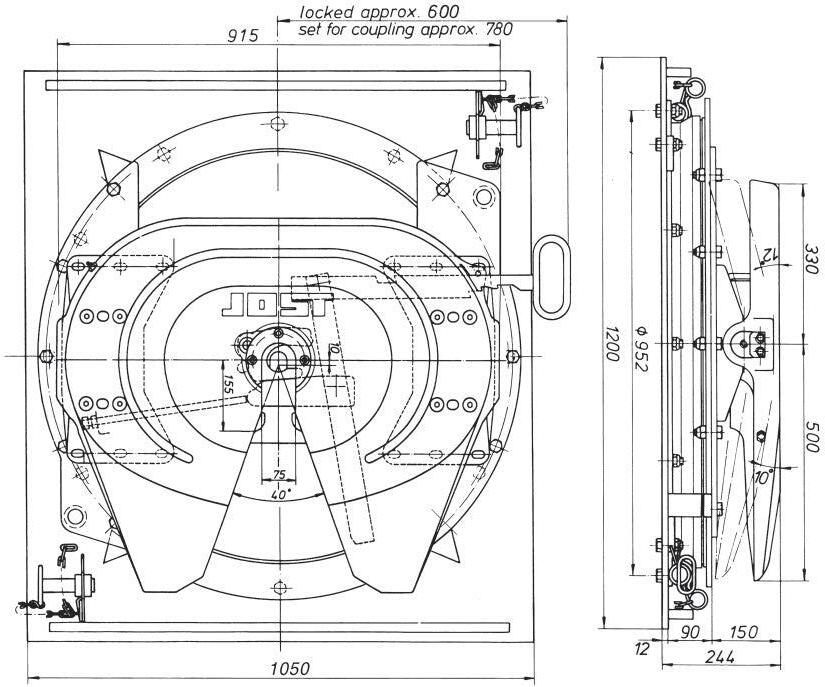

Application: General Freight Tankers

also available with:

16mm Base Plate

DR37CZ 16mm

DR37CZ 20mm

*Note thicker base plate determines extra weight

mm

Gross comb. weight

190 kN

DR Subassembly -CTA-060153

Flush bolt heads on mounting plate in chassis mounting zone. Cast type unit equipped with external king pin grease point for additional lubrication to the jaw. Wearing ring easily removed from above on JSK37CZ

23 Guide piece

for

compl.

(185mm) SK210401X Pedestal (170mm) SK210421X Pedestal (150mm) SK210402X

head bolt, compl. SK212115 17 Split pin SK1974

18 Spring hook SK1436 19 Lubrication fitting SK1989

SK320507

24 Eye bolt compl. SK212204

25 Grease nipple SK312111

26 Tubing compl. SK3353008

27 Tubing clamp SK312113

28 Spring Latch 1996 onwards SK312152

29 Bolt for Spring Latch SK3521/03

30 Spring for Latch SK3121/59 31 Ball bearing KLKDR41AS010K

32 Half moon compl. SK370640

33a Base plate (12mm) incl. 36, 37, 38 SK370630

33b Base plate (16mm) incl. 36, 37, 38 SK370631

33c Base plate (20mm) incl. 36, 37, 38 SK370632

34 Hex. bolt compl. SK372104

35 Countersunk bolt compl. SK372105

36 Lock out pin compl. with chain (old style) SK370509

36a Lock out pin compl. with R clip (new style) SK370514

37 Tube park (old style) SK370604

38 Tube lock out (old style) SK370510

38a Lockout tube (new style) SK370515

39 Handle Extension SK3105113

40 Internal Operating Handle SK3105115

41 Head Bolt SK1513

42 Extended Handle Bolt SK242150

43 Cable Extension SK352102

Fig. Repair Kits Part No.

01, 02, 03, 10, 11

01, 02, 03

01, 02, 03, 08, 10, 11, 18

13, 14, 16

28, 29, 30

Repair kit for locking device

Repair kit for locking device

Repair kit for locking device

Repair kit for rubber bearing

Latch Kit

SK322150Z

SK322152Z

SK312150Z

SK212169Z

SK312152 KIT

Application: Highway work Tipper work

also available with: 16mm Base Plate

DR37E 16mm 20mm Base Plate DR37E 20mm

*Note thicker base plate determines extra weight **Note only available on weld on feet

190 kN

268 mm

20000 kgs

135000 kgs

394 kgs

Complies with ADR 62, 63

JSK37E -CTA-036821 DR Subassembly -CTA-060153

Flush bolt heads on mounting plate in chassis mounting zone. Wearing ring easily removed from above on JSK37E

01 Jaw SK1489Z

02 Jaw Spring SK847

03 Jaw Pivot SK210667

04 Locking Bar

05 Lock Bar Bolt

06 Release Lever

07 Operating Handle

SK320506

SK322101

SK310518

SK310515

08 Head Bolt SK1513

09 Double Tension Spring SK310520

10a Wear Ring Three Bolt

10b Wear Ring Four Bolt

10c Wear Ring Insert

10d Wear Ring Bolt

11 Wear Ring Bolt

12 Swivel Pin

13 Pedestal Bush

SK210519

SK310592

SK310593

SK312155

SK212107

SK310405

SK290520

13a Collar SK310595 14 Swivel Pin Bolt SK312128

Fig.

01, 02, 03

12, 13, 13a, 14, 15

01, 02, 03, 08, 11, 23, 28

10b, 10c, 10d

16, 17, 18

Repair kit for locking device

Repair kit for locking device

Repair kit for locking device

Repair kit for wear ring

Repair kit Latch

Fig. Description Part No. DR 37 E 15 Swivel Pin Plug JS 110112 16 Spring Latch SK312152 17 Bolt for Spring Latch SK352103 18 Spring for Latch SK312159 19 Adjusting Screw SK310597 20 Hex Nut

SK212178 21 Guide Piece

SK320507 22 Eye Bolt Complete

SK212204 23 Grease Line Complete

24 Ball bearing

SK310802

KLKDR41AS010K

25 Half moon cw 130mm Ped. SK370511

26a Base plate (12mm) incl. 56, 57, 58 SK370630

26b Base plate (16mm) incl. 56, 57, 58 SK370631

26c Base plate (20mm) incl. 56, 57, 58 SK370632

27 Hex. bolt compl.

28 Countersunk bolt compl.

SK372104

SK372105 29 Tube lock out (old style)

29a Tube lock out (new style)

30 Tube park

31 Lock out pin compl. with chain

SK370510

SK370515

SK370604

SK370509

31a Lock out pin compl. with R clip (new style) SK370514

SK322152Z

SK3121061

SK3121060Z

SK310594

SK312152 KIT

Application: General freight Tankers Fridge van Stock crate

also available with:

16mm Base Plate

20mm Base Plate

DR37CX 16mm

DR37CX 20mm

*Note thicker base plate determines extra weight

Overall height

268 mm

Imposed load 24000 kgs

Weight approx. 405 kgs (for 12mm base plate)

D-Valve 240kN

Approval Number

Twin lockouts.

JSK37CX -CTA-045374 DR Subassembly -CTA 060153

Flush bolt heads on mounting plate in chassis mounting zone. Cast type unit equipped with external king pin grease point for additional lubrication to the jaw.

Wearing ring easily removed from above on JSK37CX fifth wheel.

Fig. Description Code

01 Wearing ring and bolts

QR00269J00

02 Lock jaw spring SK847 03 Pivot SK210667 04 Locking SK1489Z

05 Bolt (complete) SK322101

06 Locking bolt SK320506

07 Lever with bushing SK310518

08 Head bolt SK1513

09 Lever handle SK3105/15

10 Latch kit SK312152KIT

11 Double tension spring SK3105/20 12 Fitting SK312111

13 Complete countersunk bolt SK212115 14 Mounting bracket QR00215J01

15 Lower rubber cushion SK21025

16 Pedestal (150mm) SK210402X

16a Pedestal (170mm) SK210421X

16b Pedestal (185mm) SK210401X

16c Pedestal (220mm) SK210418X

16d Pedestal (250mm) SK210414X

16e Pedestal (300mm) SK210420

17 Upper Rubber Cushion SK1259 19 Adjustment screw AD01148B80

20 Guide latch complete security QR00270J00

21 Guide with thread SK320507

22 Pin with eyelet SK212204

31 Ball bearing KLKDR41AS010K

32 Half mon complete SK370640

33a Base plate (12mm) inc 36, 37, 38 SK370630

33b Base plate (16mm) inc 36, 37, 38 SK370631

33c Base plate (20mm) inc 36, 37, 38 SK370632

34 Hex bolt complete SK372104

35 Countersunk bolt complete SK372105

36 Lock out pin compl with chain (old style) SK370509

36a Lock out pin compl with R clip (new style) SK370514

37 Tube park (old style) SK370604

38 Tube lock out (old style) SK370510

38a Tube lock out (new style) SK370515

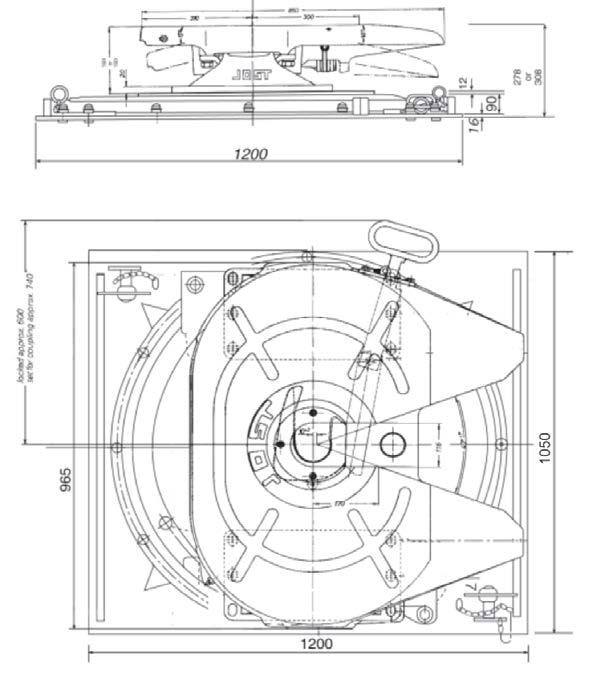

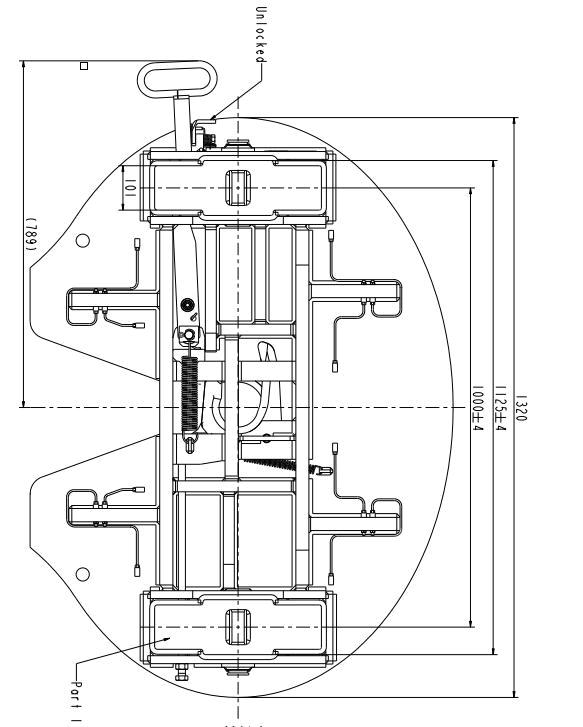

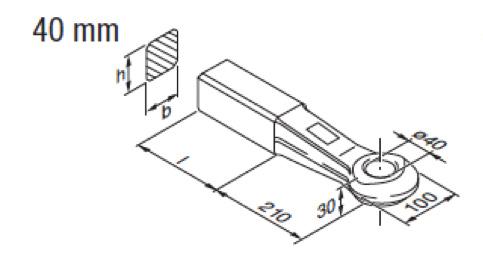

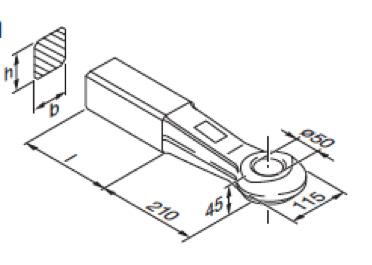

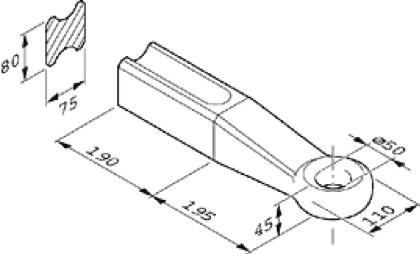

Note: Height is measured with fifthwheel and pedestals assembled together, refer example above. (Example, 16mm plate with 185 mm Pedestals= 201 mm overall)

255mm Pedestals, with 16mm Plate

If using a 37-027 narrow spec fifthwheel, 15 mm is to be added to the overall height. Other base plate options available. Custom styles and drilling available. For further information please contact your local JOST branch

*D-value and imposed load rating reduced if combination height exceeds 300 mm

Other base plate options available. Custom styles and drilling available. For further information please contact

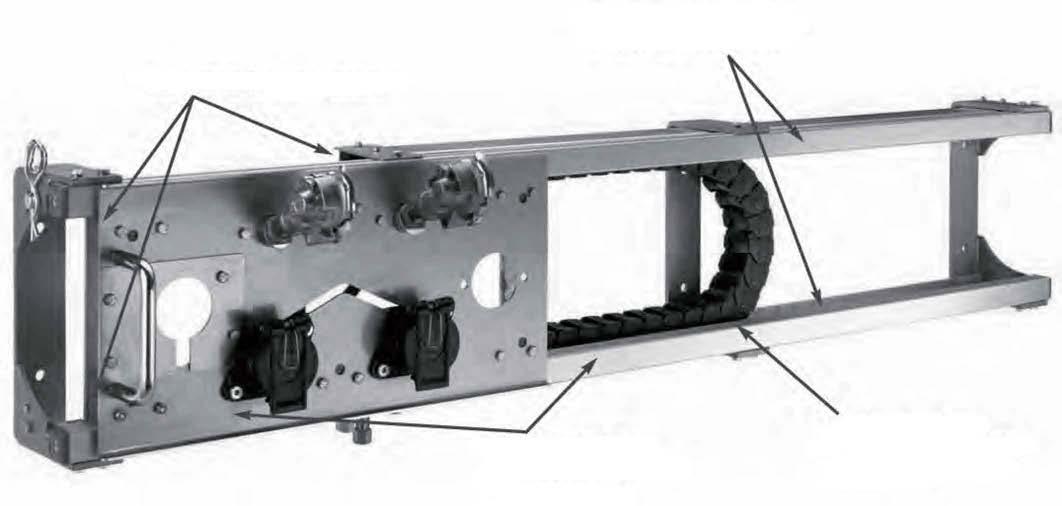

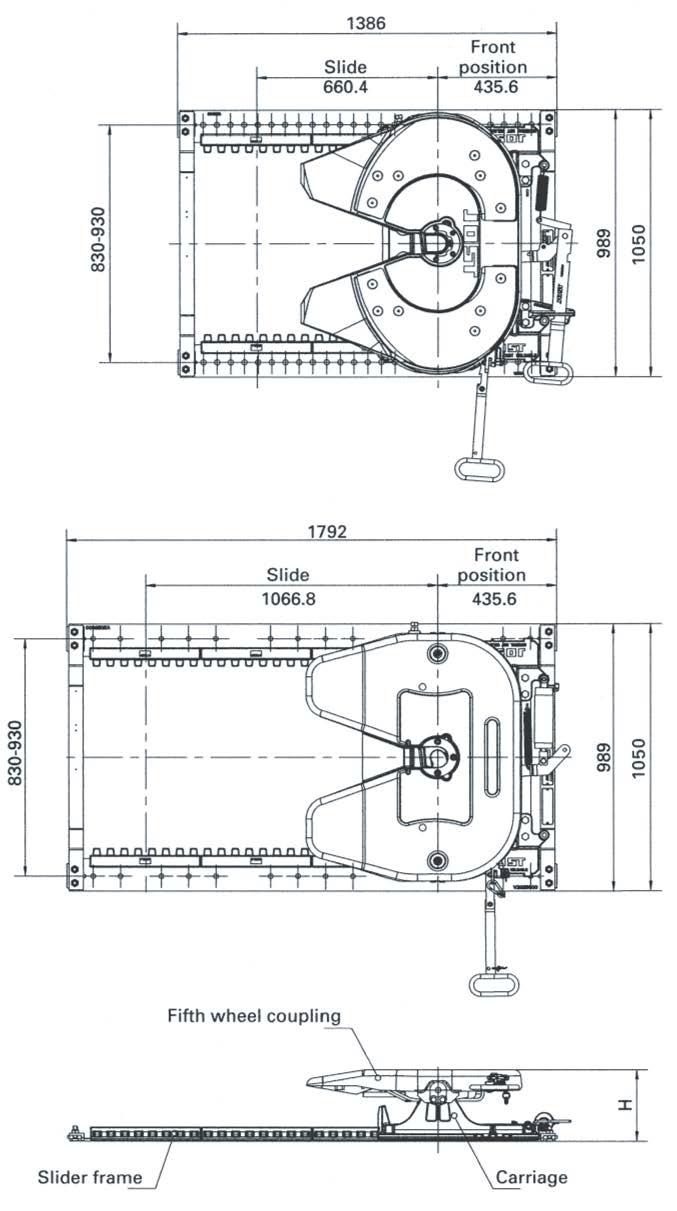

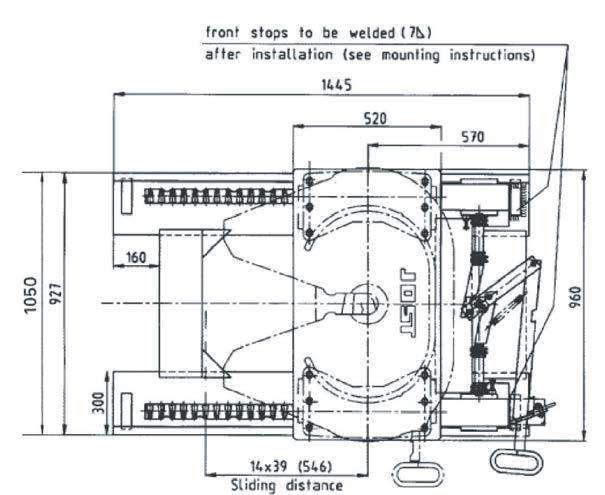

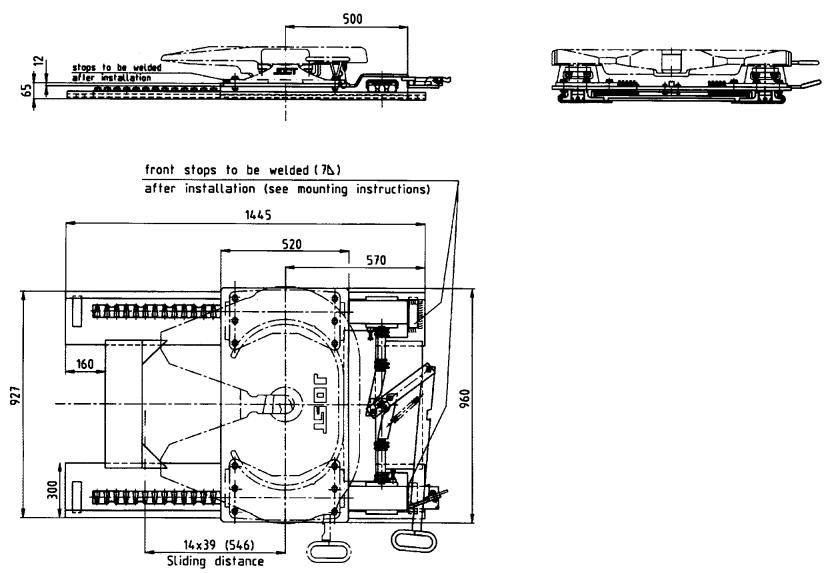

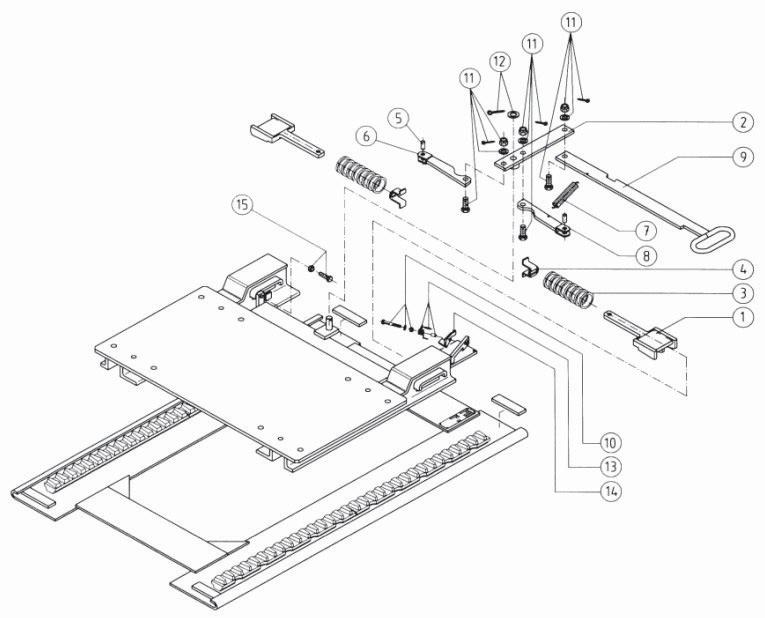

Maintenance-free sliding blocks

Stainless steel and other corrosion-resistant materials.

Guide rails ensure precise, smooth lateral movement

Maintenance-free protection of pneumatic and power cables

Coupling and uncoupling without the need to raise or lower the unit

• Fast and easy attachment and disconnection of pneumatic and power cables.

• Access from side of vehicle to alleviate OH & S issues

• Easy Connect is universal and directly fits most trailer models

• Prevents damage to spiral connections (suzies, see illustration below)

Easy connect system provides for lateral movement when negotiating bends. This prevents stress and excessive strain on the spiral connections (suzies).

Part No: SKE0105000000

3½" and 2"

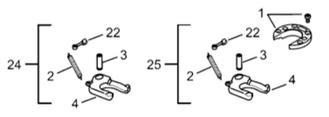

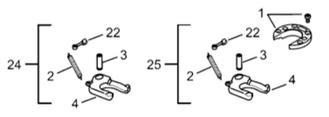

locked with spring hook inserted set for coupling

hole to use when locking open the operating handling when exchanging lock jaw

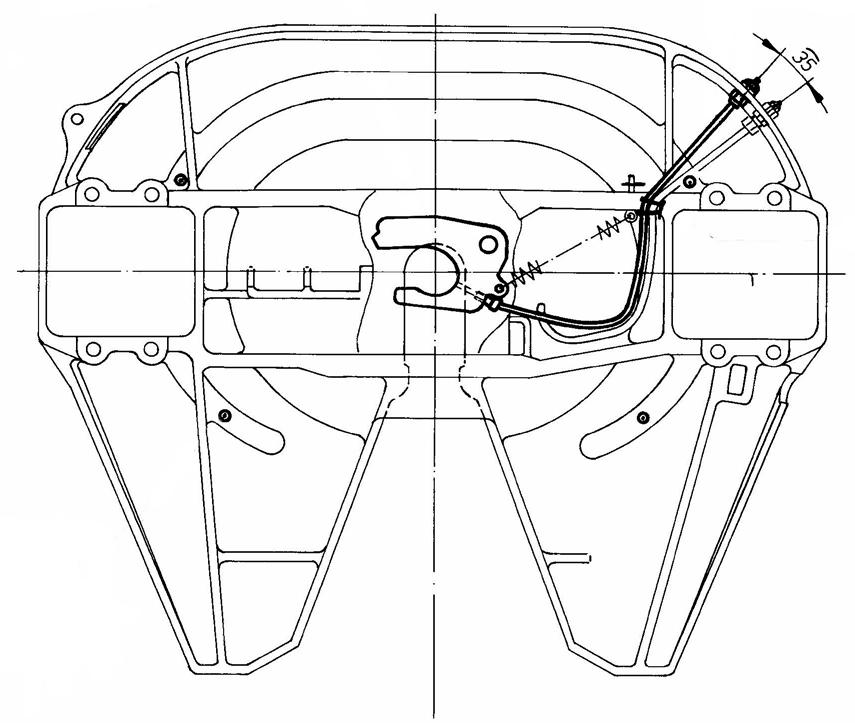

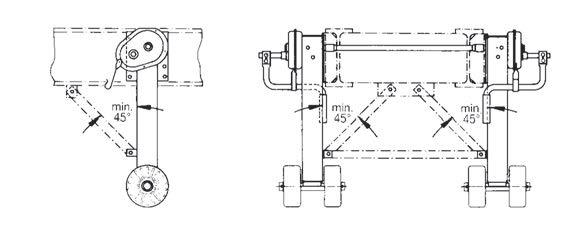

JSK38G cardan mounting

• wear resistant bushes

• lateral movement up to a max. of 7° for off road operation.

• lateral movement can be limited to approx. 0° for highway operation.

JSK38C, JSK39C, JSK38DV Rubber mounting

• shock absorbing by large rubber pads slack and maintenance free

• Oil and grease resistant

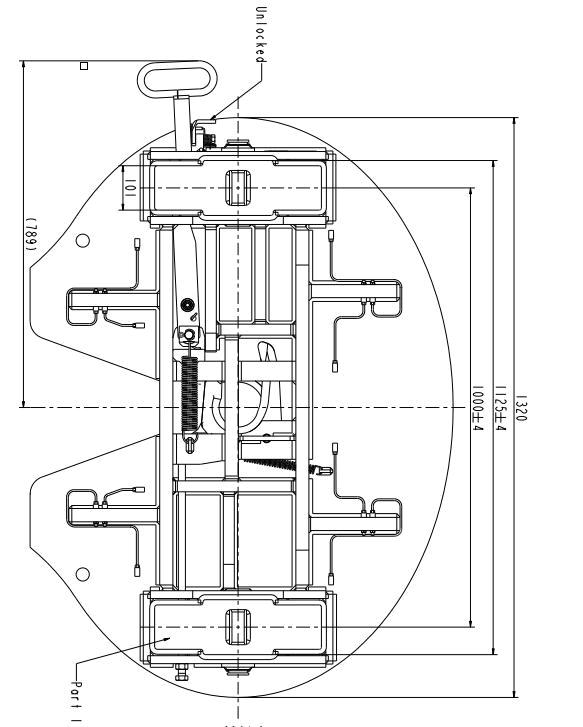

Operating instructions

The outfit should be parked on a flat and even road surface.

Coupling-up:

1. The fifth wheel must be in the reset position, i.e. the end of the operating handle standing out approx. 300 mm otherwise: Raise secondary safety latch’ (A) and move handle forward to unlock (B). Pull handle to end position (C).

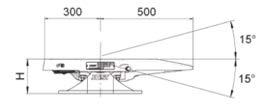

2. Skid plate of semi trailer should be approx. 50 mm lower than the top of the fifth wheel.

IMPORTANT: Loss of pressure in the air suspension of the trailer can alter the height of the king pin.

3 Reverse tractor - the mechanism locks automatically.

4 Check that the skid plate is resting on the fifth wheel plate with no gap between the two.

5 Ensure secondary safety latch is engaged.

IMPORTANT: The secondary safety latch in the secured position ensures the locking mechanism is closed. If secondary safety latch is in raised position, the coupling-up procedure must be repeated.

Un-coupling:

1. Raise secondary safety latch (A). Move handle forward to unlock (B). Pull handle to end position (C)

2 Drive tractor away. The fifth wheel mechanism will automatically assume the coupling-up position (D)

Lateral movement on type JSK38G

The lateral movement should only be engaged for off-road use. On the road, and especially at higher speeds, it must be blocked for safety reasons.

To set the lateral movement: For normal road Use: