JOE RUSSELL

Selected works produced at the Bartlett School of Architecture, UCL

GRADUATE APPLICATION

Selected works produced at the Bartlett School of Architecture, UCL

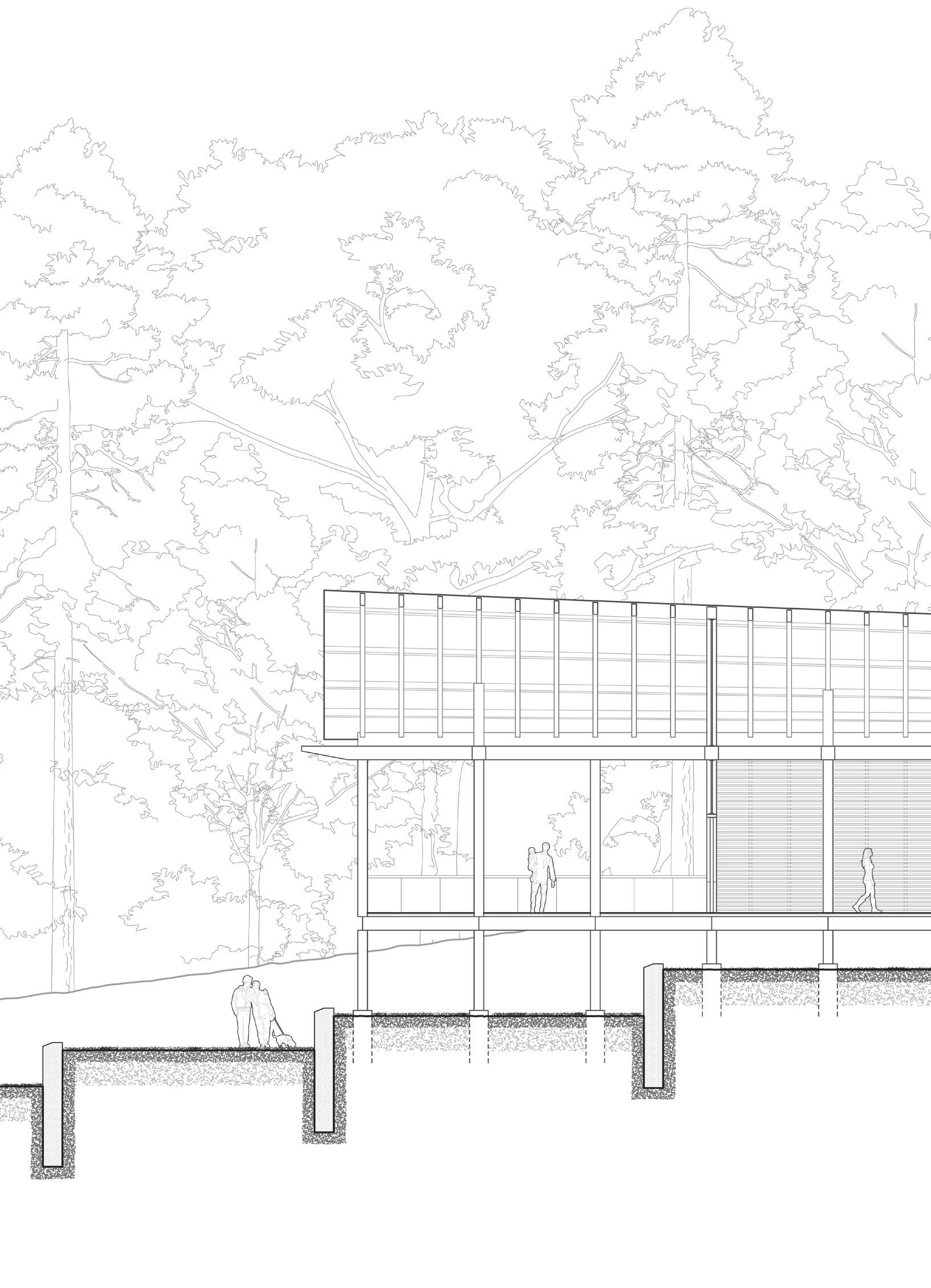

Individual Building Project, 2022

BSc Architecture, Bartlett School of Architecture

Tutors: Professor Murray Fraser and Michiko Sumi

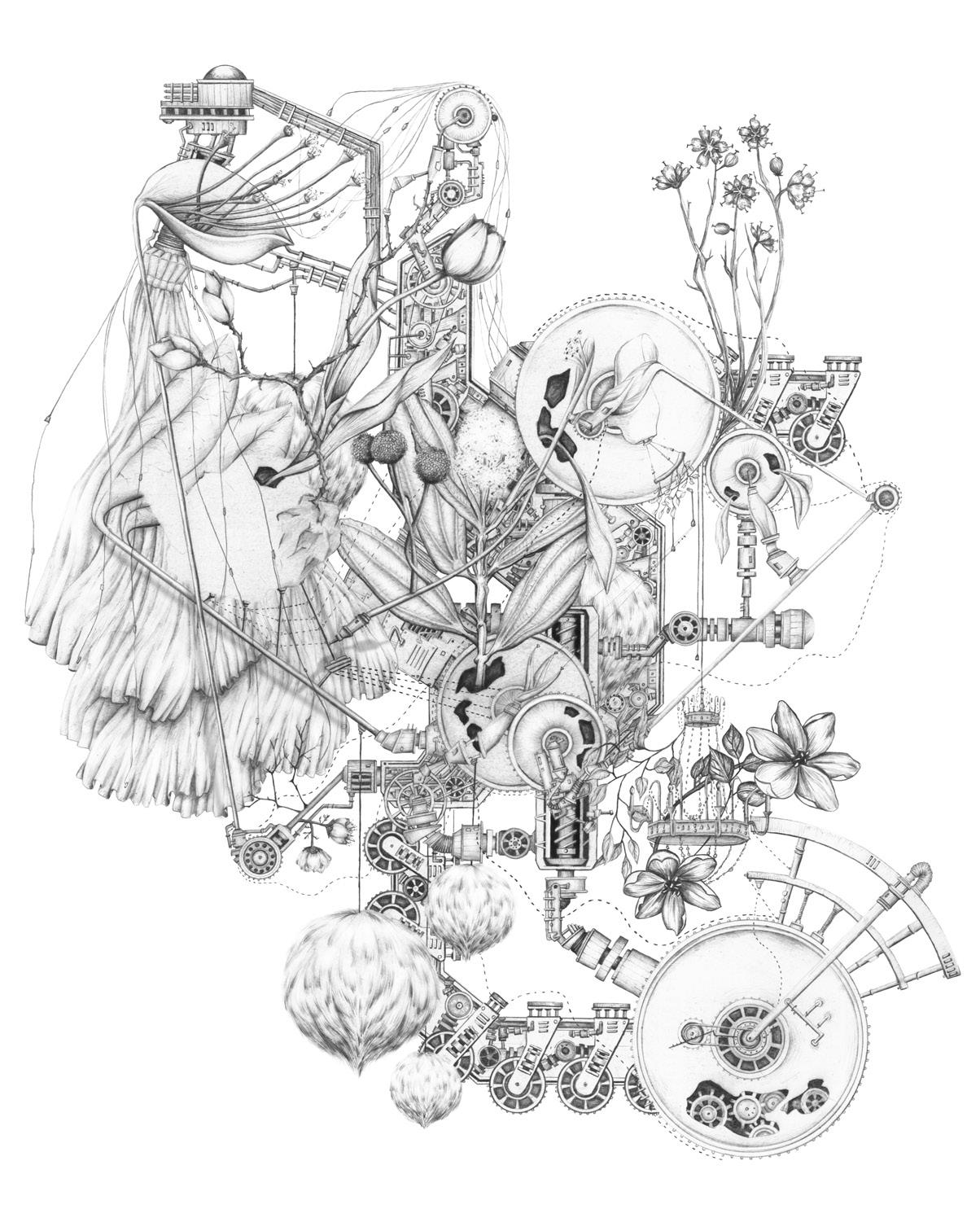

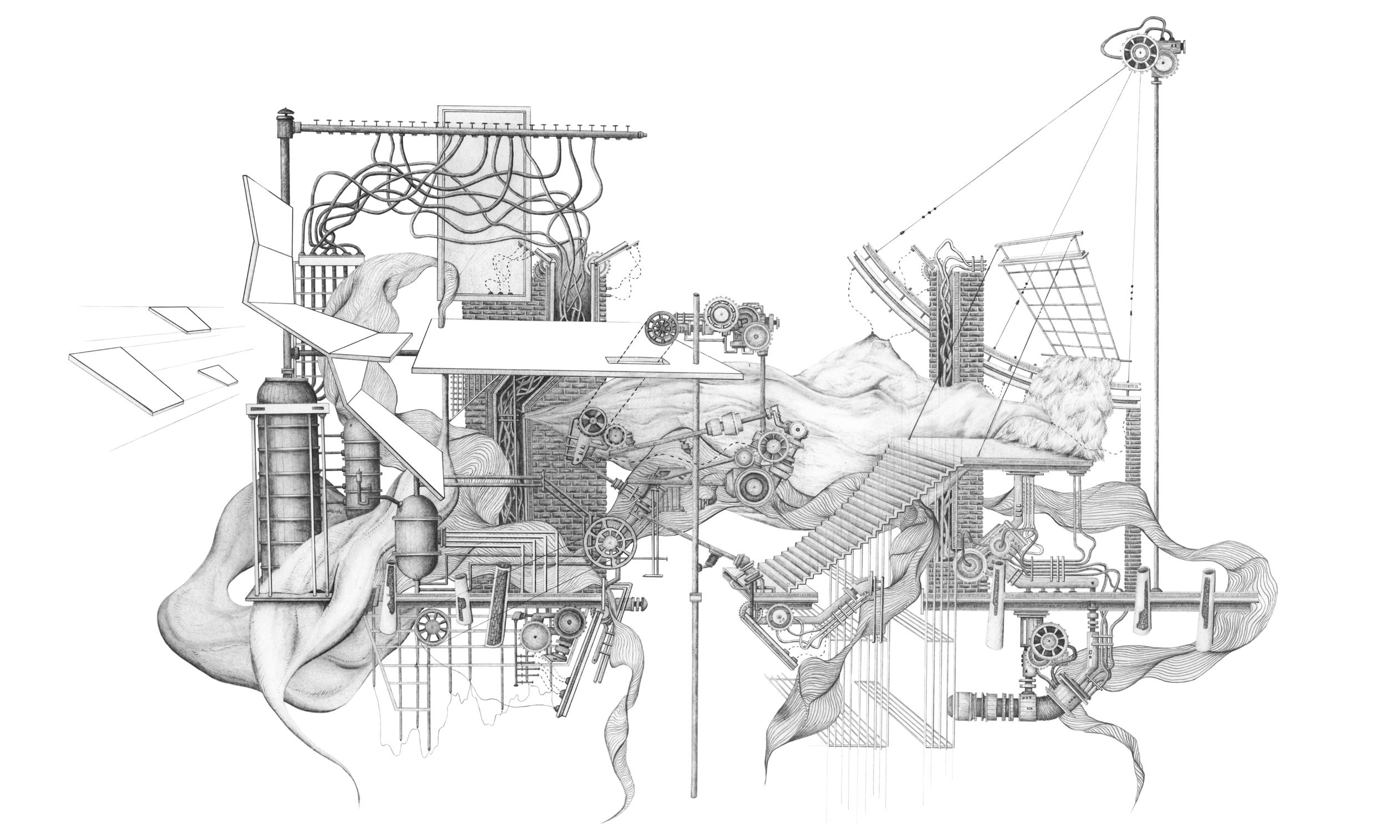

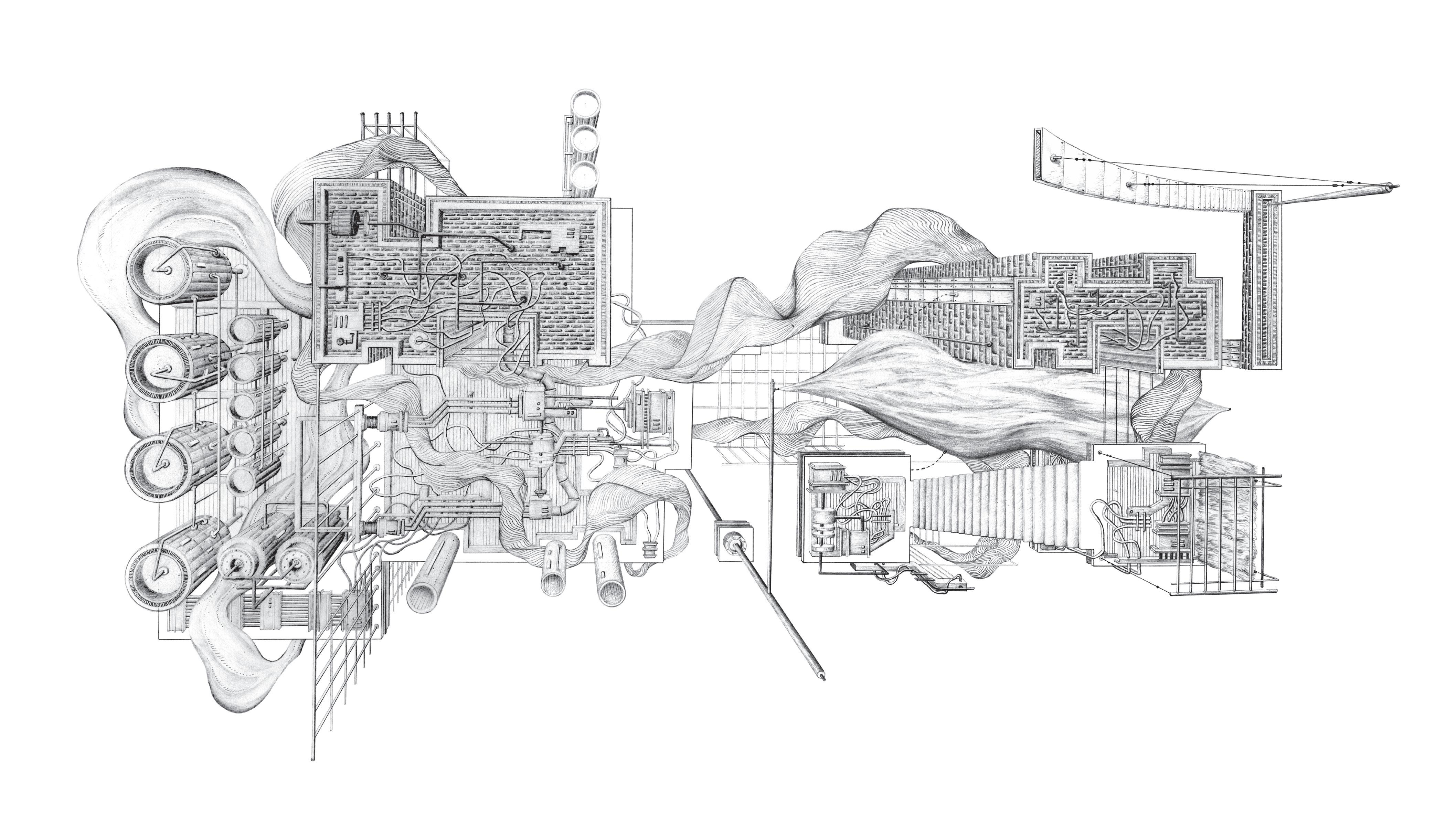

Individual Design Project, 2021

BSc Architecture, Bartlett School of Architecture

Tutors: Professor Murray Fraser and Michiko Sumi

Individual Building Project, 2021

BSc Architecture, Bartlett School of Architecture

Tutors: Pascal Bronner and Thomas Hillier

Individual Design Project, 2020

BSc Architecture, Bartlett School of Architecture

Tutors: Pascal Bronner and Thomas Hillier

AJ Student Prize Winner 2022

Bartlett Medal Winner 2022

RIBA President’s Medal Nominee 2022

1st Class Honours

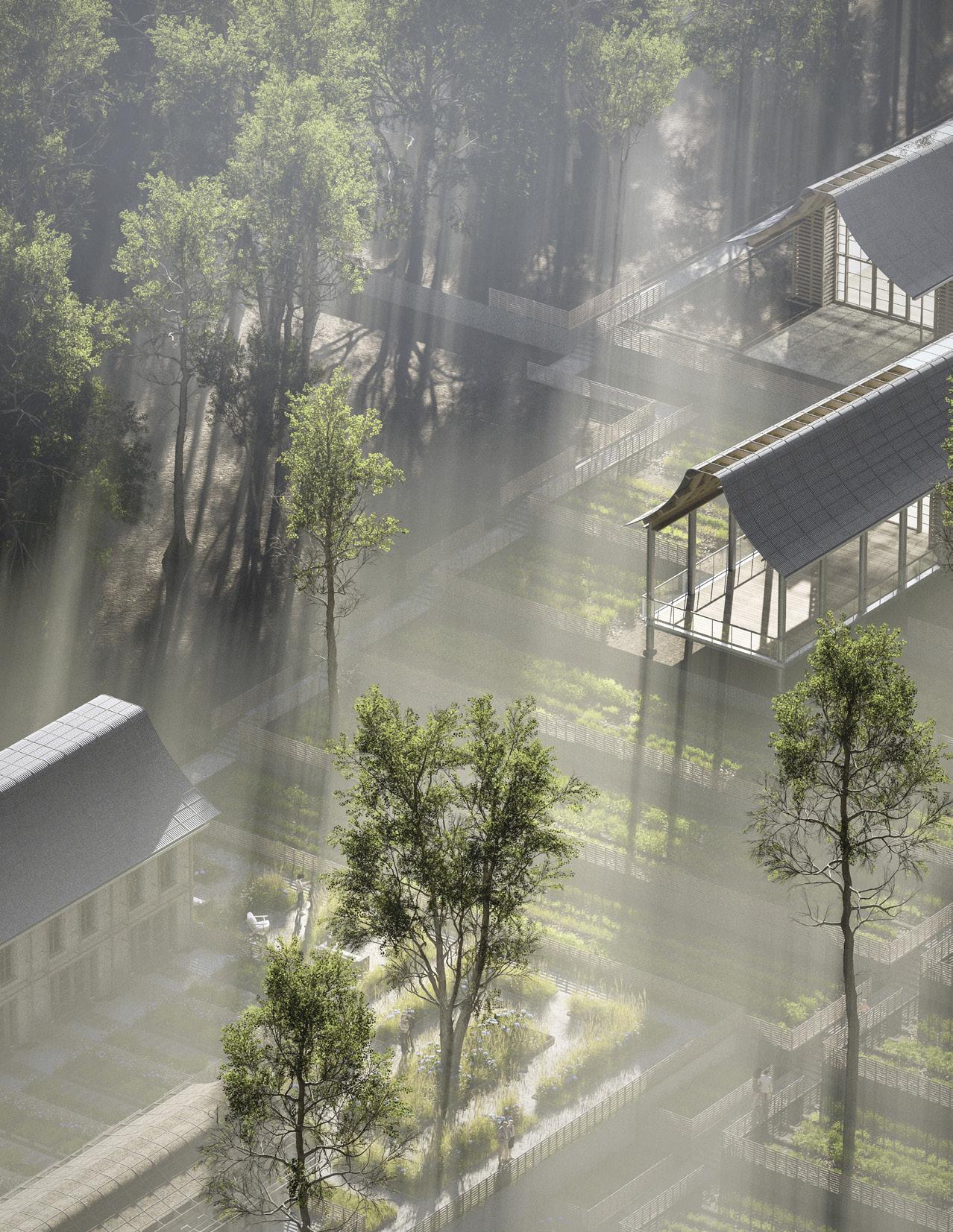

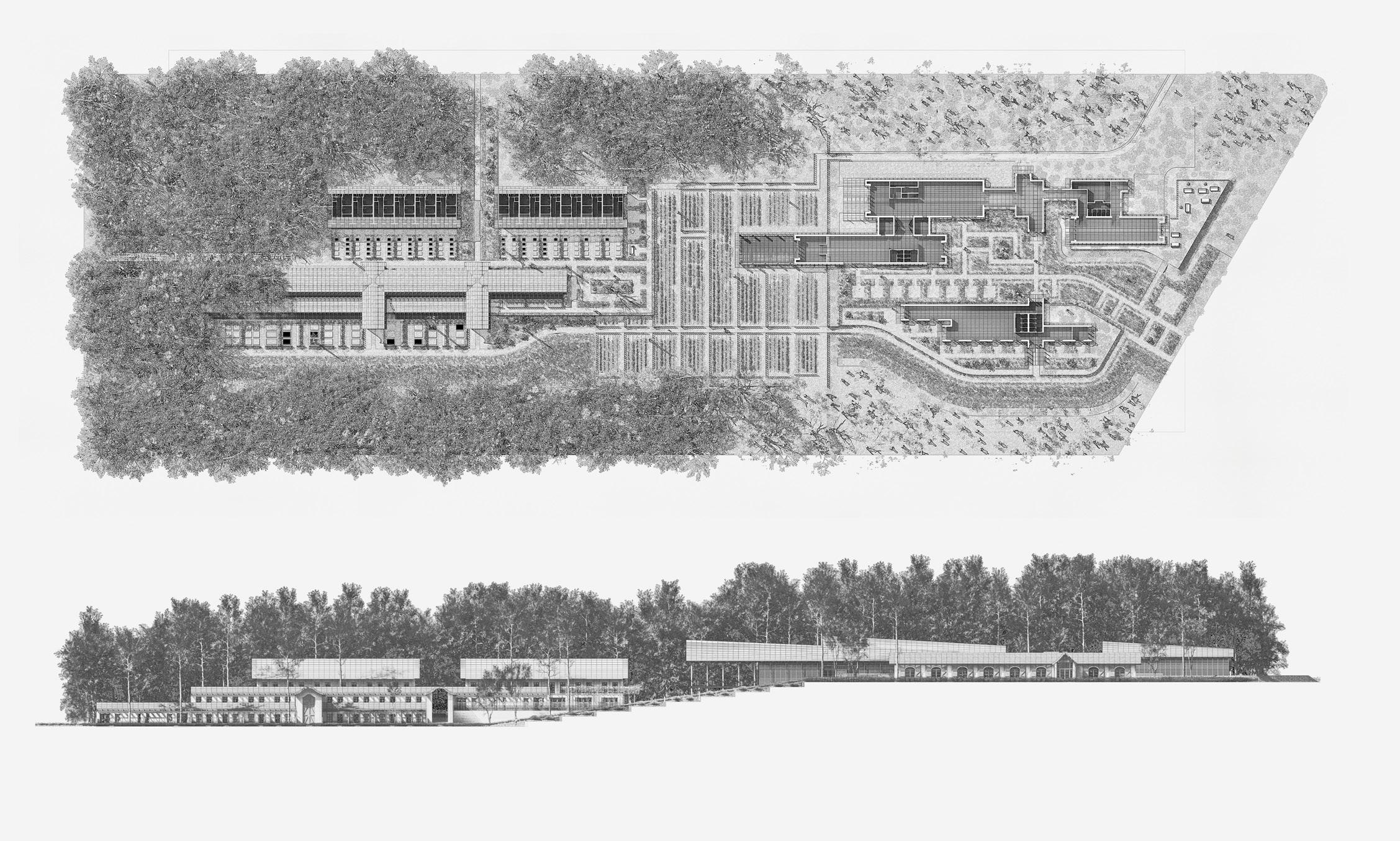

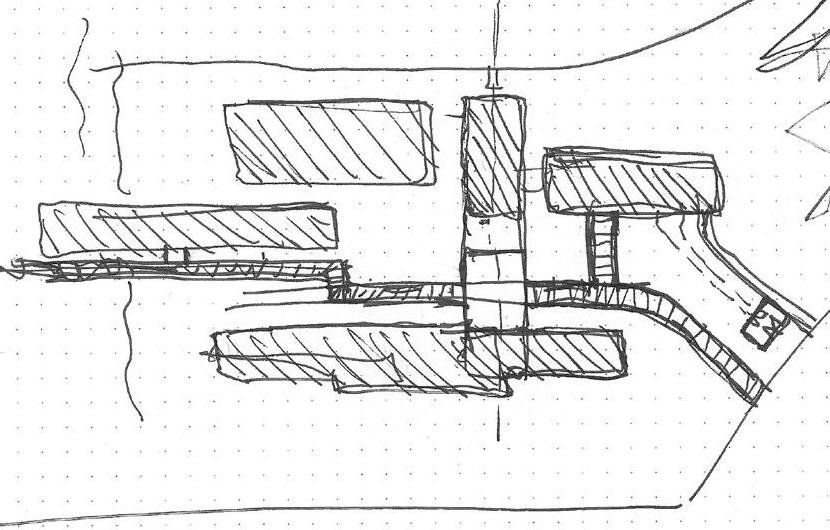

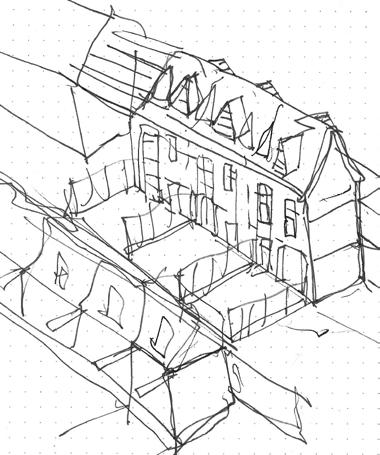

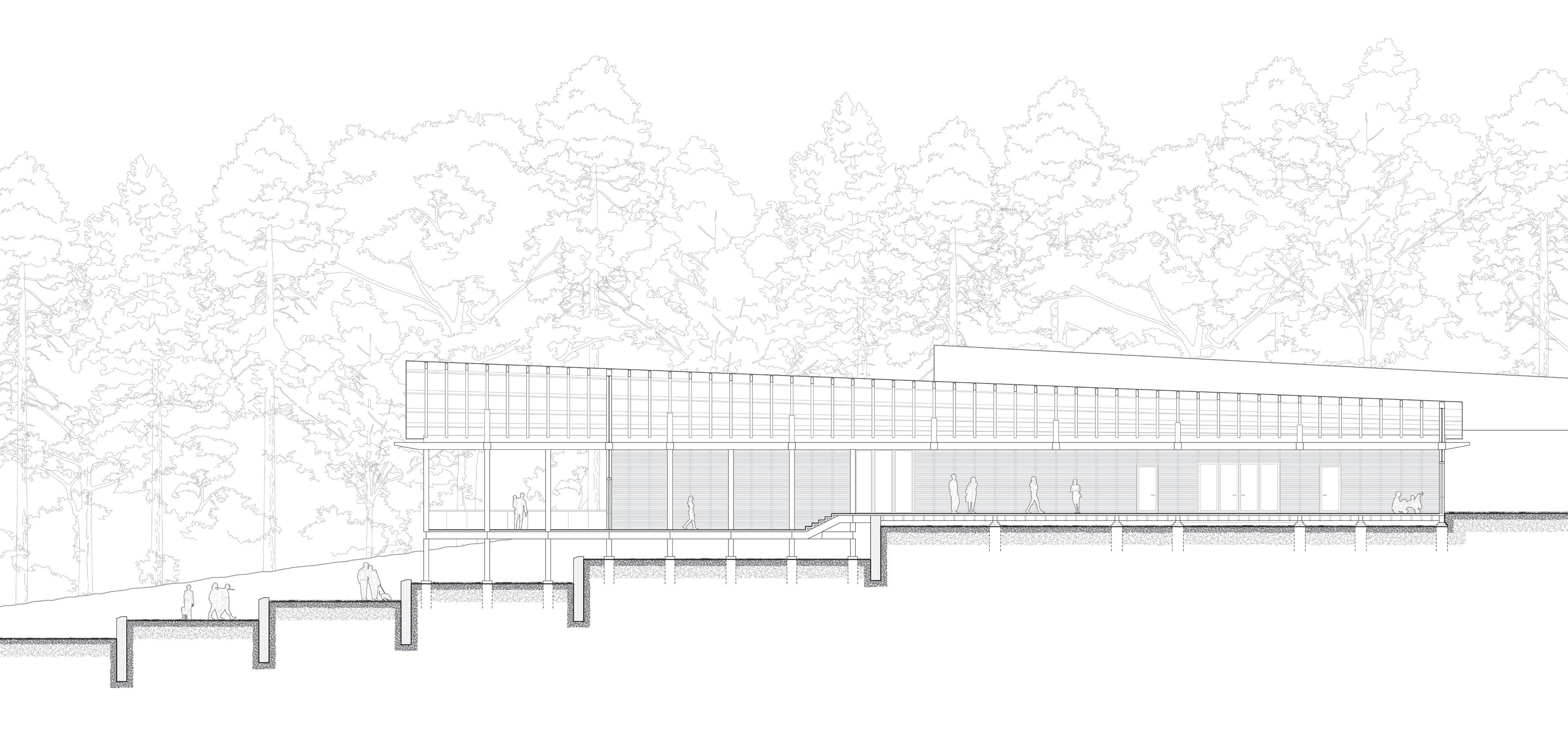

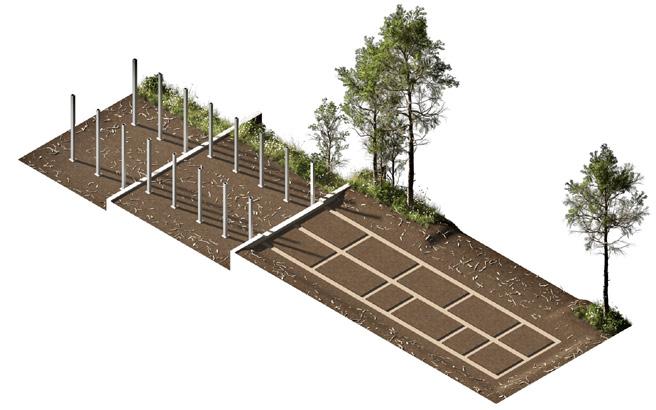

This project responds to the UK’s increasingly severe housing crisis by proposing a housing/community scheme as a precedent for socially and ecologically sustainable future developments within the Metropolitan Green Belt (MGB).

The Green Belt Act of 1938 constituted the first formal planning legislation to define the open space surrounding Greater London as protected land. Initially proposed to give access to the countryside, the MGB later became a physical constraint to the growth of London. The current policy is set out within the National Planning Policy Framework which states ‘the fundamental aim of Green Belt Policy is to prevent urban sprawl by keeping land permanently open.’

for MGB expansion in the 1950s, said that Green Belt land did not have to be ‘green’ or even particularly attractive, as its purpose was to stop urban development. Therefore, the ‘actual use or enjoyment of the Green Belt is clearly seen as an incidental benefit’ of the policy rather than its intended goal .

A 21st-Century Metropolitan Green Belt written by Dr Alan Mace of the London School of Economics, critiques current Green Belt policy and instead proposes urban planning solutions for sustainable future development within the MGB. This project – titled ‘Tightening the Green Belt: Oakwood Mews, Enfield’ – takes on these ideas and adapts them at the scale of an architectural scheme that relies upon locally sourced natural/recycled materials.

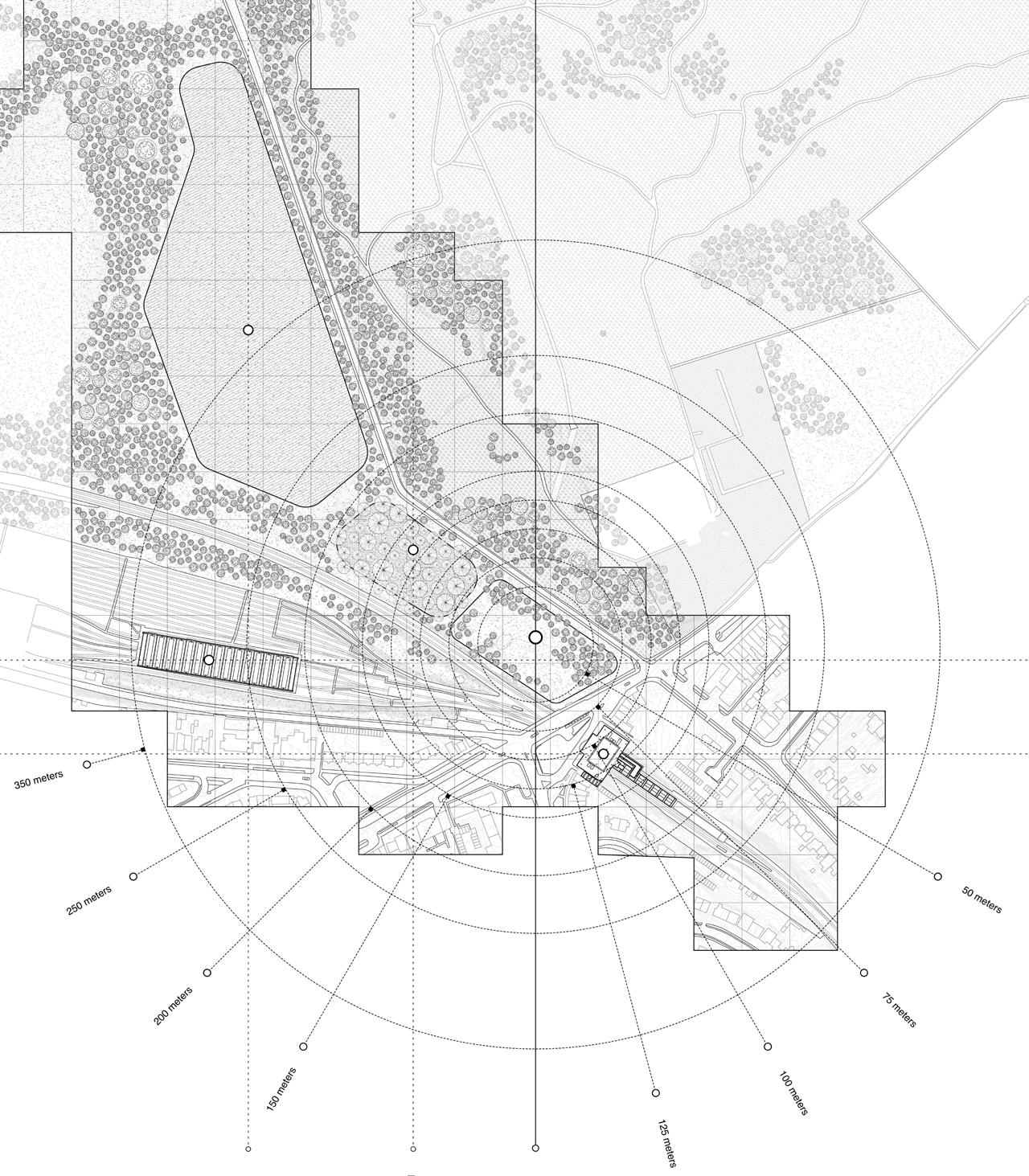

Finding a site was dictated by the parameters set out within Dr Mace’s A 21st Century Metropolitan Green Belt. I focused on Enfield in the North London area to conduct a ‘mini-expedition’ to find a site that would meet the requirements set out for the project.

The site eventually chosen was the land opposite Oakwood underground station near the northern end of the Piccadilly Line. The station was designed by renowned modernist architect Charles Holden, who designed a number of muchpraised stations along the Piccadilly Line. Oakwood is the penultimate stop, and being so close to this station means that there will be very easy public access for residents and visitors to my new housing/ community scheme.

The land ultimately provided the best opportunity to produce architectural design that most thoughtfully responded to the parameters proposed by Dr Mace for sustainable development:

“Development within the MGB should:

I. Limit environmental losses

II. Benefit existing residents

III. Limit private car usage

IV. Be close to public transport links”

The site stretches for approximately 200 meters in length and 50 meters in width. The topography of the site slopes down notably on its northern boundary, away from the road that passes in front of the underground station.

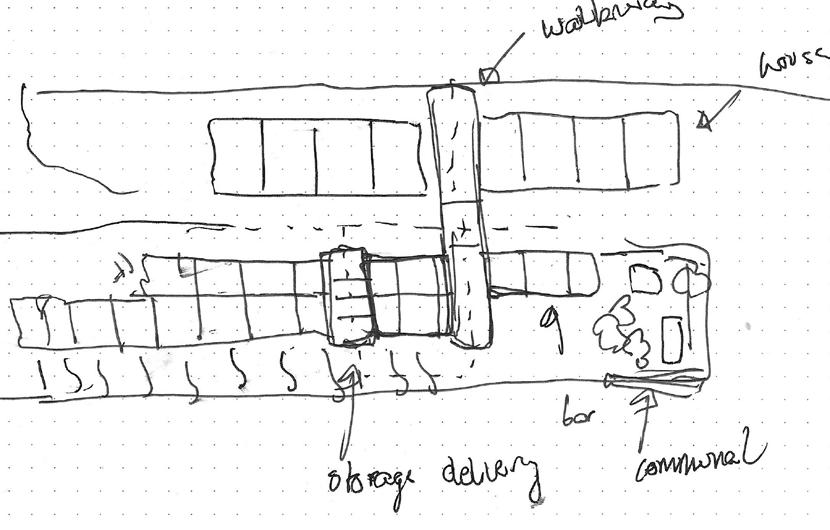

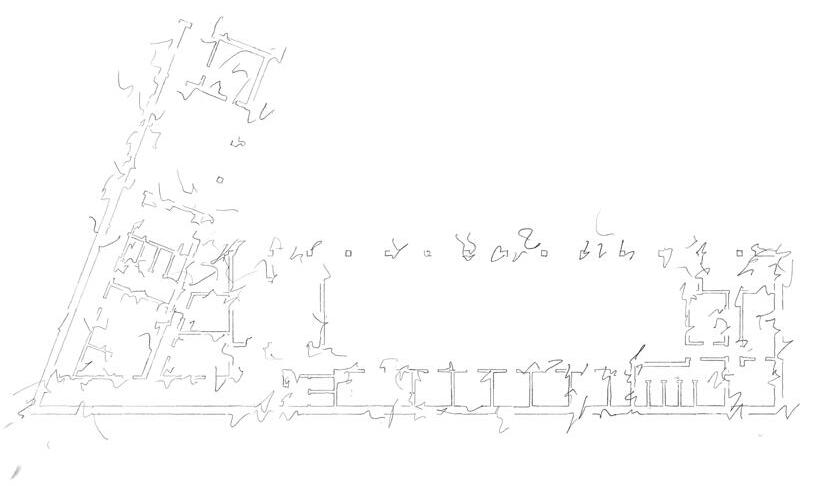

1. Two bedroom houses

2. Storage and delivery shed

3. Two bedroom houses II

4. Three bedroom houses

5. Stairs to upper level

6. One bedroom house

7. Three bedroom houses II

8. Cantilevered balcony

9. Lower level workspace

10. Multipurpose space

11. Toilets

12. Storage facility

.13. Main hall

14. Open plan nursery

15. Nursery toilets

16. Main lobby

17. Kitchen and storage

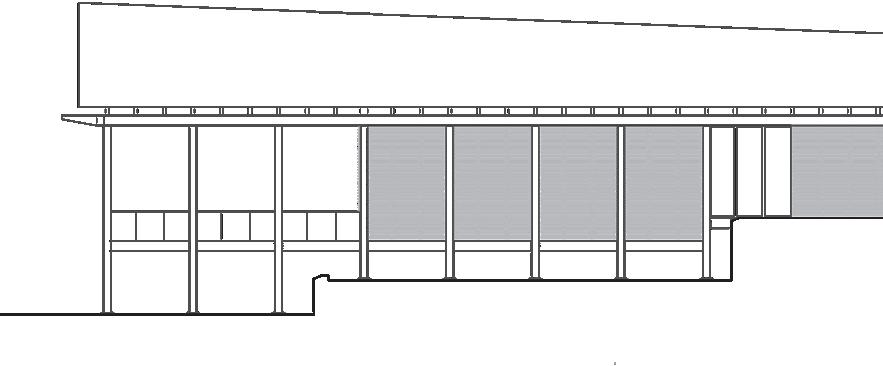

18. Cafe

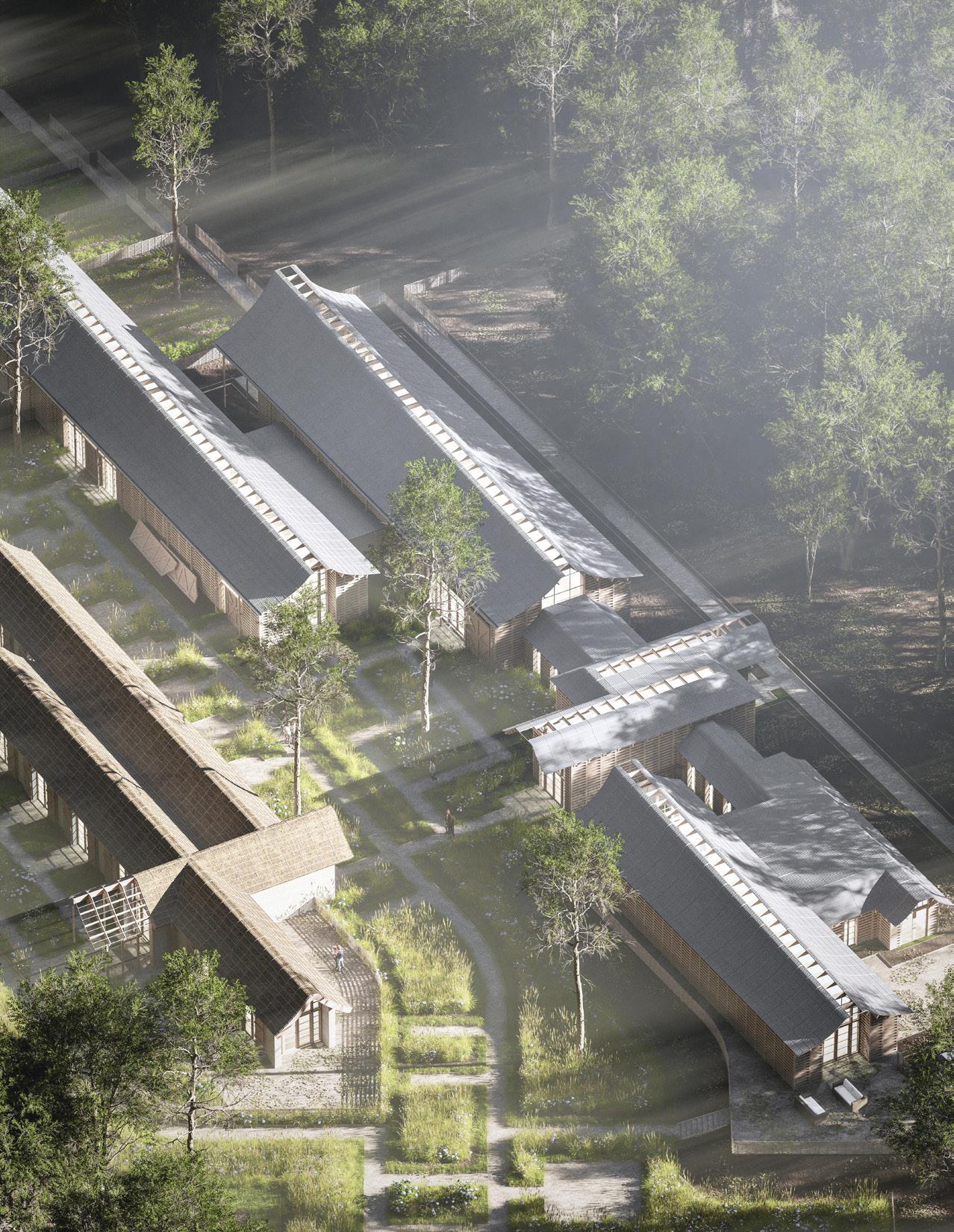

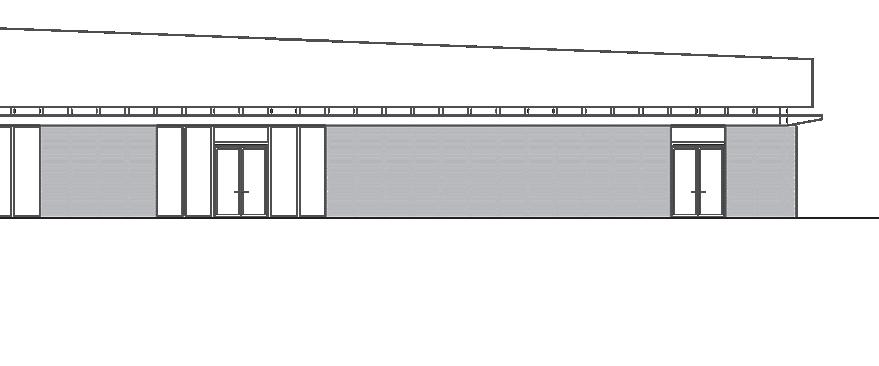

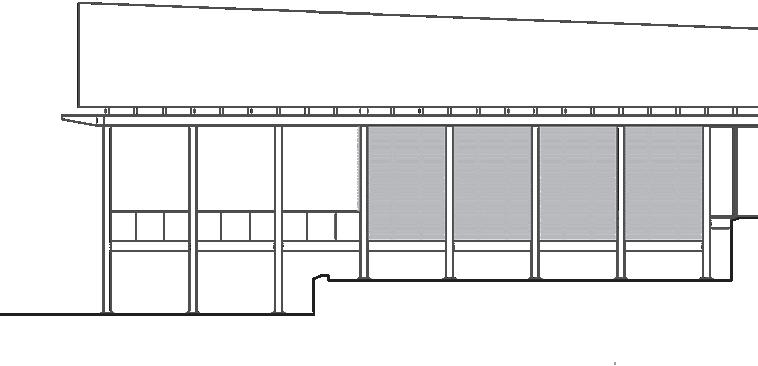

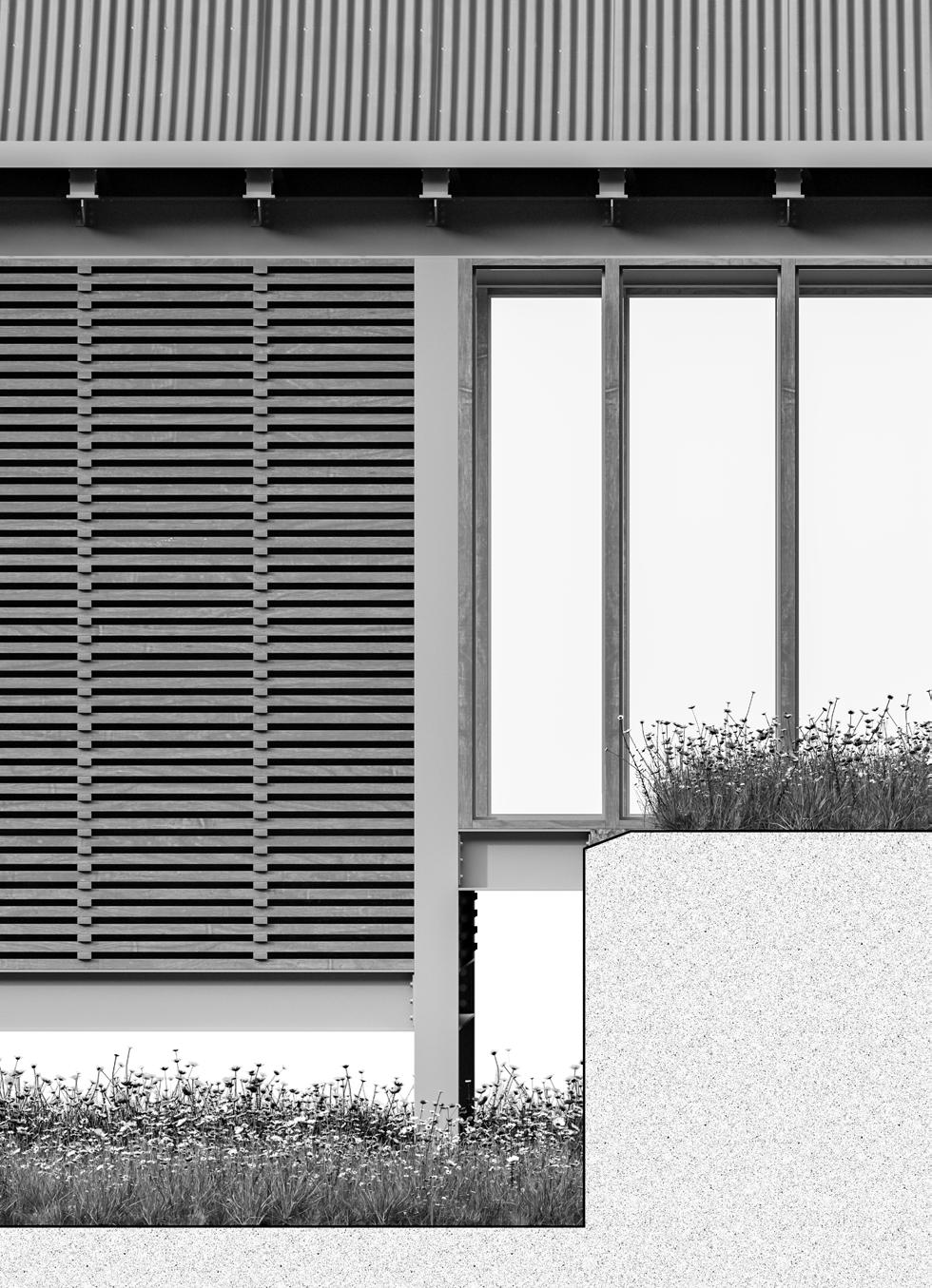

The community center is located at the south end of the site where the land meets Bramley Road. Included within the larger built body (clad in stacked timber beams and roofed with reclaimed corrugated steel sheeting) is a cafe, workspace, hall, kitchen and lobby. The spaces are designed to be purposefully open with minimal interior walls. This allows for the building to easily adapt to the differing needs of a range of occupiers.

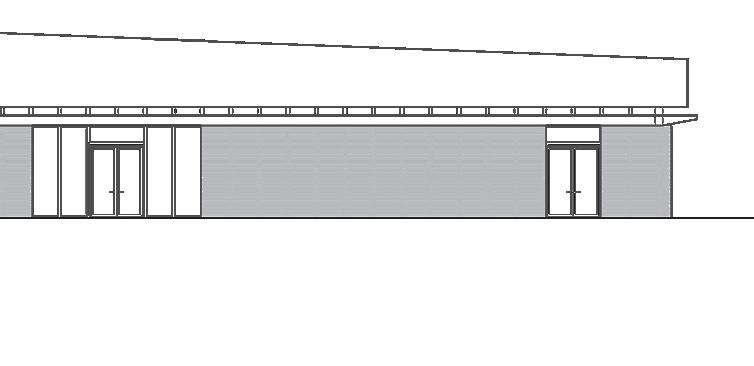

Opposite the main center is the nursery, equipped with white-washed, reclaimed brick walls and thatched roofing. The nursery is also very open plan which allows

the space to become an extension of the main center during out-of-school hours (such as evenings and weekends).

These public-serving components are deliberately oversized in comparison to the number of housing units within the scheme. This is to cater to both new residents and existing local residents.

The housing consists of a range of semidetached and terraced one-bedroom, two-bedroom and three-bedroom homes. The proposal is medium-density, with each property having its own small private garden. All residents have access to the large public gardens designed to enhance community engagement.

The three-bedroom houses are fitted with reclaimed corrugated steel sheet roofing, while the one and two-bedroom homes have natural thatched roofing.

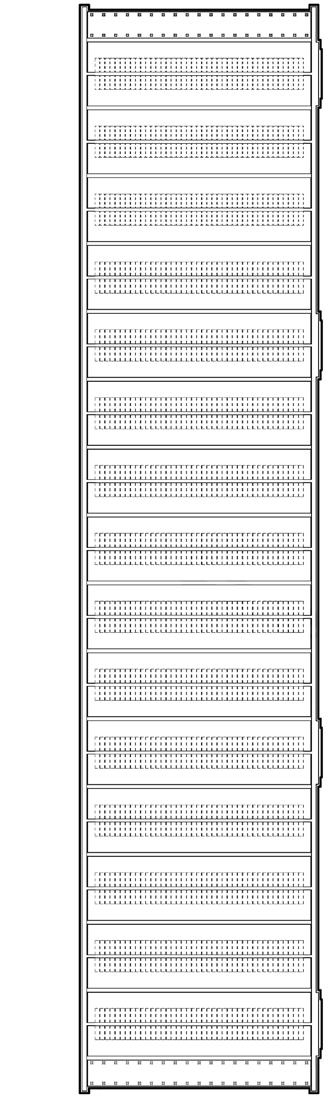

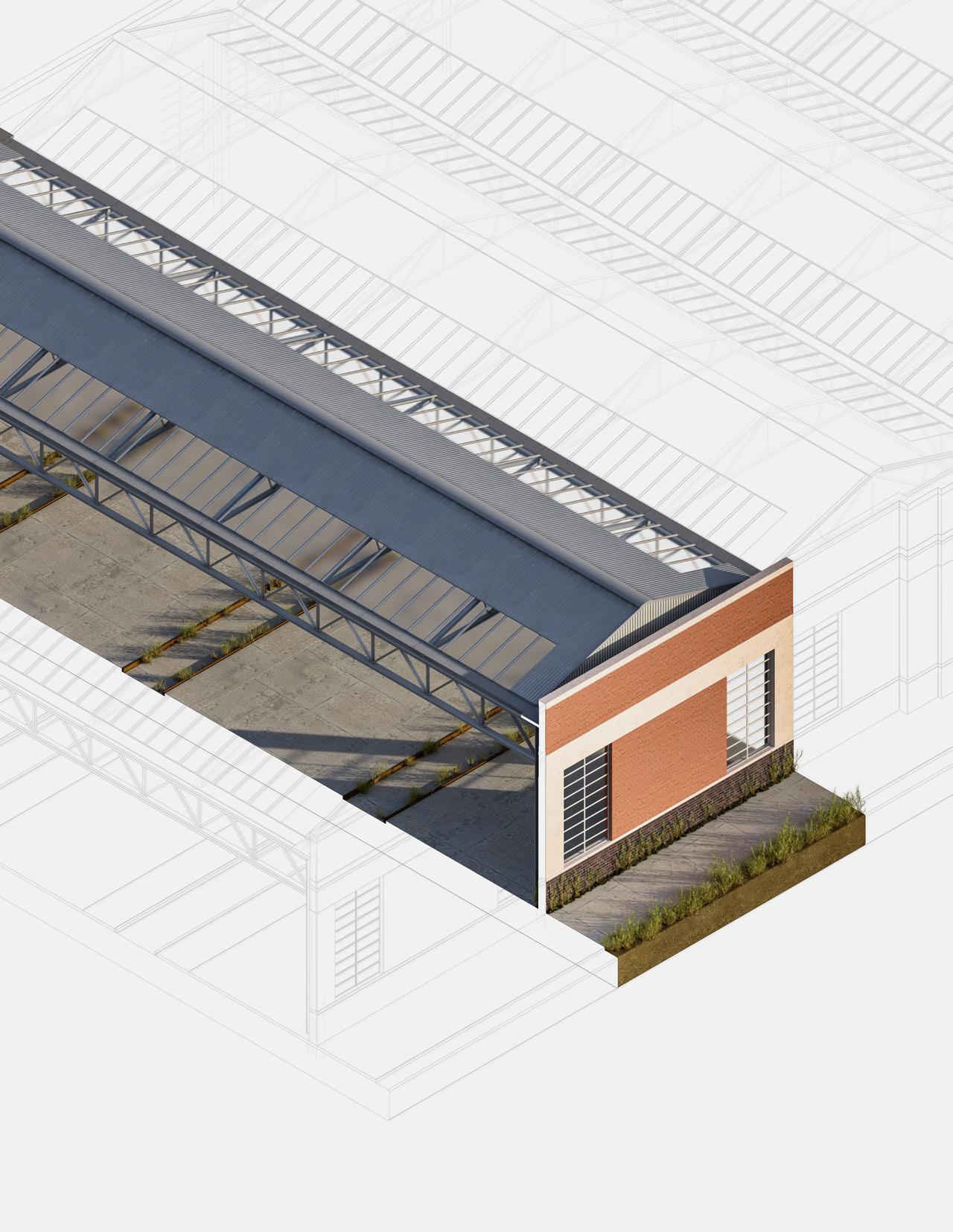

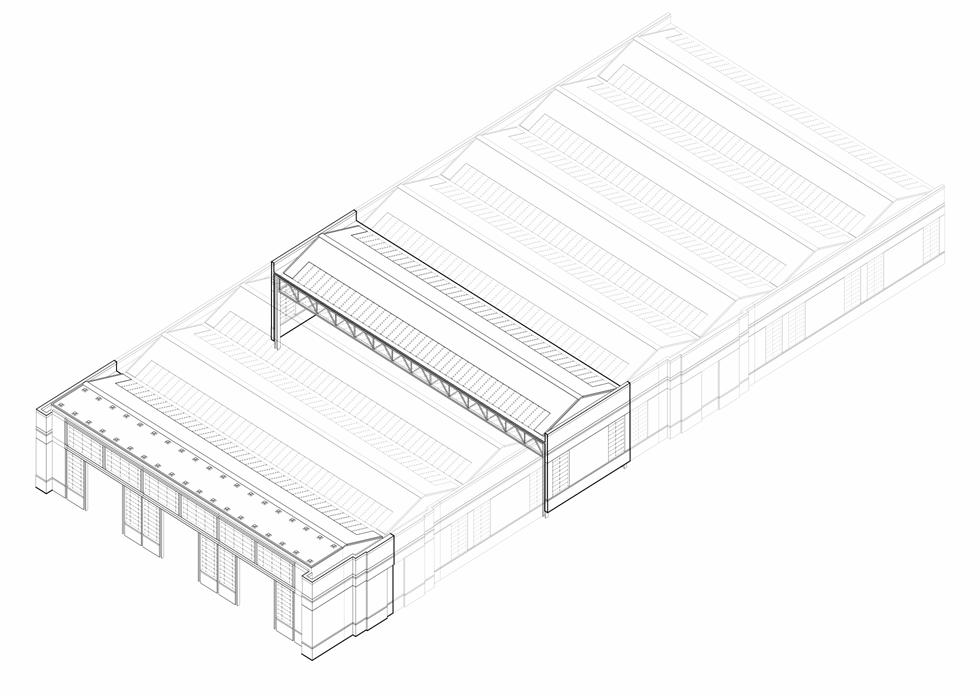

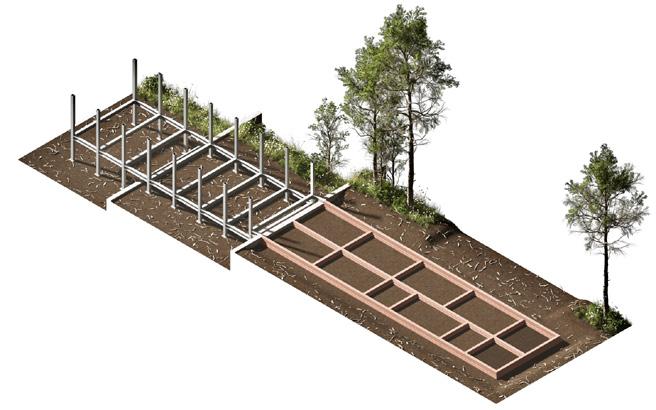

In anticipation of a new fleet of underground trains being introduced to the Piccadilly Line in 2025, Transport for London (TfL) is undertaking major upgrades to the line’s maintenance depots. The upgrade will involve the complete demolition of its current Cockfosters depot.

My project therefore responds to this demolition by placing itself within this process of depot deconstruction. In doing so, my scheme gains an array of recycled building materials and prevents several hundred tonnes of embodied carbon from being dumped in landfill sites around London.

In addition to salvaging the Cockfosters depot materials, My proposal is also to source local naturally occurring materials that can be sustainably harvested (i.e. timber from the plentiful pine/fir woodlands and straw bales grown on adjacent farmland). The combining of harvested material with recycled material presents an opportunity to develop an architectural design that tackles the restrictiveness of the reused component catalog balanced with the expansiveness of new building materials.

The drawing that I made of the existing site to the left outlines the location of horticultural land (straw bale), coniferous woodland (pine/fir trees), the Cockfosters depot and my chosen site in the center.

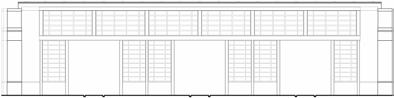

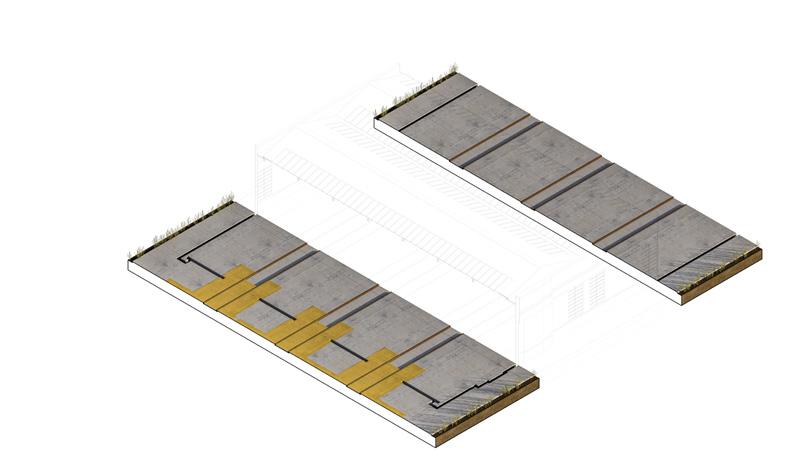

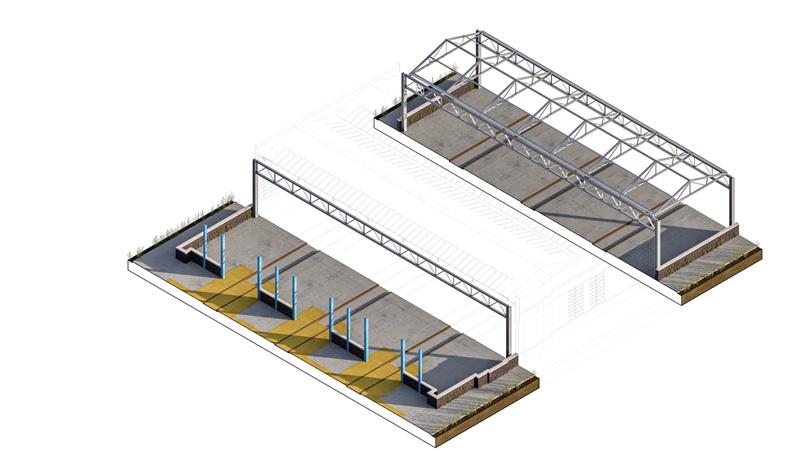

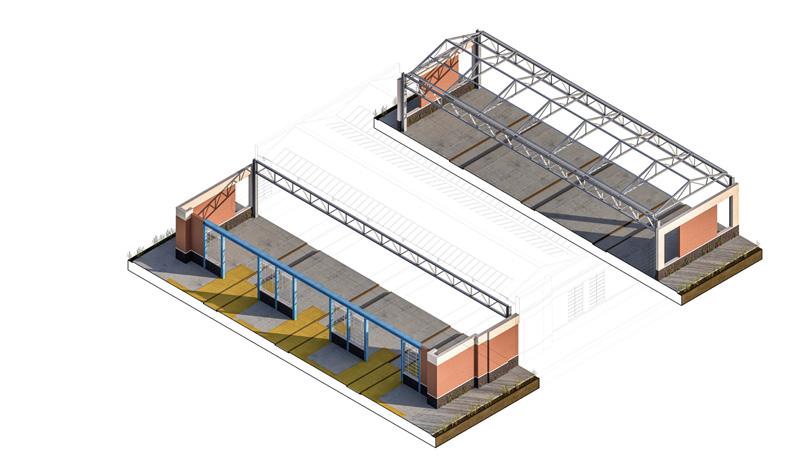

At the first stage of assessing what recycled materials would be available for reuse in my project, I carried out a detailed survey of the existing Cockfosters depot as the plans and sections were not publicly available. I then drew up the most accurate 3D model of the building so that I could calculate precisely which materials would become available and how much embodied carbon could be salvaged/saved from landfill.

NOTE: There are 2 sets of ‘A’ and 14 sets of ‘B’. The values on the following page give embodied carbon values for the entire depot. The visuals are not representative.

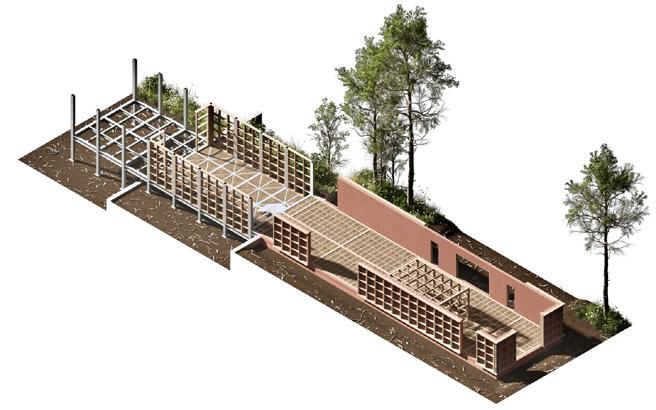

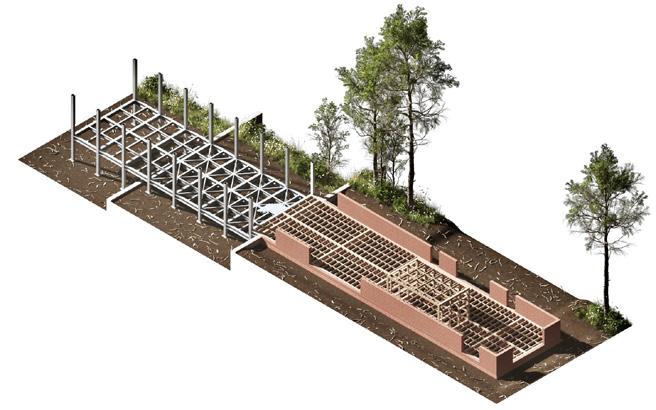

STAGE 0

Embodied carbon salvaged: 0 kgCO2e

Material types: n/a

Embodied carbon salvaged total: 0 tCO2e

STAGE 1

Embodied carbon salvaged:

27785.9 kgCO2e

Material types: Glass, Steel

Embodied carbon total: 27.8 tCO2e

STAGE 2

Embodied carbon salvaged:

69521.2 kgCO2e

Material types:

Concrete, Brick, Steel, Glass

Embodied carbon total: 97.3 tCO2e

STAGE 3

Embodied carbon salvaged: 121139.6 kgCO2e

Material types: Concrete, Brick, Steel, Glass

Embodied carbon total: 218.4 tCO2e

STAGE 4

Embodied carbon salvaged: 142985.2 kgCO2e

Material types: Brick, Steel

Embodied carbon total: 361.4 tCO2e

STAGE 5

Embodied carbon salvaged: 363071.6 kgCO2e

Material types: Brick, Steel

Embodied carbon total: 724.5 tCO2e

Component - B

Concrete - 0.930 m3

Mass of concrete = 2300kg/m3 x 0.930m3 = 2139.0kg

Concrete carbon coefficient = 0.143

Embodied carbon = 30.6 kgCO2e

Total (x14) = 428.4 kgCO2e

Brick 5.597 m3

Mass of Bricks = 1600kg/m3 x 5.597m3 = 8955.2kg

Brick carbon coefficient = 0.23

Embodied carbon = 2059.7 kgCO2e

Total (x14) = 28835.8 kgCO2e

Glass 0.163 m3

Mass of glass = 2500kg/m3 x 0.163m3 = 407.5kg

Glass carbon coefficient = 0.86

Embodied carbon = 350.5 kgCO2e

Total (x14) = 4907.0 kgCO2e

STAGE 3

Component - A

Concrete - 4.727 m3

Mass of concrete = 2300kg/m3 x 4.727 m3 = 10,872.1kg

Concrete carbon coefficient = 0.143

Embodied carbon = 1554.7 kgCO2e

Total (x2) = 3109.4 kgCO2e

Brick 19.783 m3

Mass of Bricks = 1600kg/m3 x 19.783m3 = 31652.1kg

Brick carbon coefficient = 0.23

Embodied carbon = 7280.0 kgCO2e

Total (x2) = 14560.0 kgCO2e

Steel beam - 0.756m3

Mass of steel = 7850kg/m3 x 0.756m3 = 5934.6kg

British steel EPD carbon coefficient = 2.45

Embodied carbon = 14539.8 kgCO2e

Total (x2) = 29079.6 kgCO2e

Glass 0.254 m3

Mass of glass = 2500kg/m3 x 0.254m3 = 635.0kg

Glass carbon coefficient = 0.86

Embodied carbon = 546.1 kgCO2e

Total (x2) = 1092.2 kgCO2e

Component - B

14,649.6kg

Brick carbon coefficient = 0.23

Embodied carbon = 3369.4 kgCO2e

Total (x14) = 47171.6 kgCO2e

STAGE 4

Component A

Steel beam - 0.433 m3

Mass of steel = 7850kg/m3 x 0.433m3 = 3399.1kg

British steel EPD carbon coefficient = 2.45

Embodied carbon = 8327.8 kgCO2e

Total (x2) = 16655.6 kgCO2e

Brick - 2.991 m3

Mass of Bricks = 1600kg/m3 x 2.991m3 = 4785.6kg

Brick carbon coefficient = 0.23

Embodied carbon = 1100.7 kgCO2e

Total (x2) = 2201.4 kgCO2e

Component B

Steel beam - 0.461 m3

Mass of steel = 7850kg/m3 x 0.461m3 = 3618.9kg

British steel EPD carbon coefficient = 2.45

Embodied carbon = 8866.3 kgCO2e

Total (x14) = 124128.2 kgCO2e

STAGE 5

Component A

Steel - 0.569m3

Mass of steel = 7850kg/m3 x 0.569m3 = 4466.7kg

British steel EPD carbon coefficient = 2.45

Embodied carbon = 10943.4 kgCO2e

Total (x2) = 21886.8 kgCO2e

Brick - 7.327 m3

Mass of Bricks = 1600kg/m3 x 7.327m3 = 11723.2kg

Brick carbon coefficient = 0.23

Embodied carbon = 2696.3 kgCO2e

Total (x2) = 5392.6 kgCO2e

Component B

Steel -1.138m3

Mass of steel = 7850kg/m3 x 1.138m3 = 8933.3kg

British steel EPD carbon coefficient = 2.45

2.45

Embodied carbon = 12655.0 kgCO2e

Total (x2) = 25310.0 kgCO2e

Glass - 0.353 m3

Mass of glass = 2500kg/m3 x 0.353m3 = 882.5kg

Glass carbon coefficient = 0.86

Embodied carbon = 759.0 kgCO2e

Total (x2) = 1518.0 kgCO2e

Concrete - 5.674 m3

Mass of concrete = 2300kg/m3 x 5.674m3 = 13050.2kg

Concrete carbon coefficient = 0.143

Embodied carbon = 1866.2 kgCO2e

Total (x14) = 26126.8 kgCO2e

Brick 9.156 m3

Mass of Bricks = 1600kg/m3 x 9.156m3 =

Embodied carbon = 21886.8 kgCO2e

Total (x14) = 306415.2 kgCO2e

Brick - 5.667m3

Mass of Bricks = 1600kg/m3 x 5.667m3 = 9067.2kg

Brick carbon coefficient = 0.23

Embodied carbon = 2085.5 kgCO2e

Total (x14) = 29197.0 kgCO2e

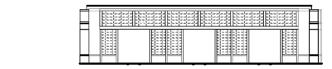

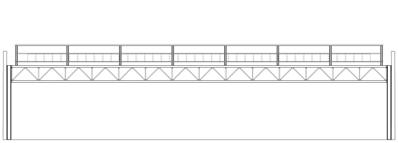

Close up view of depot front elevation (component A)

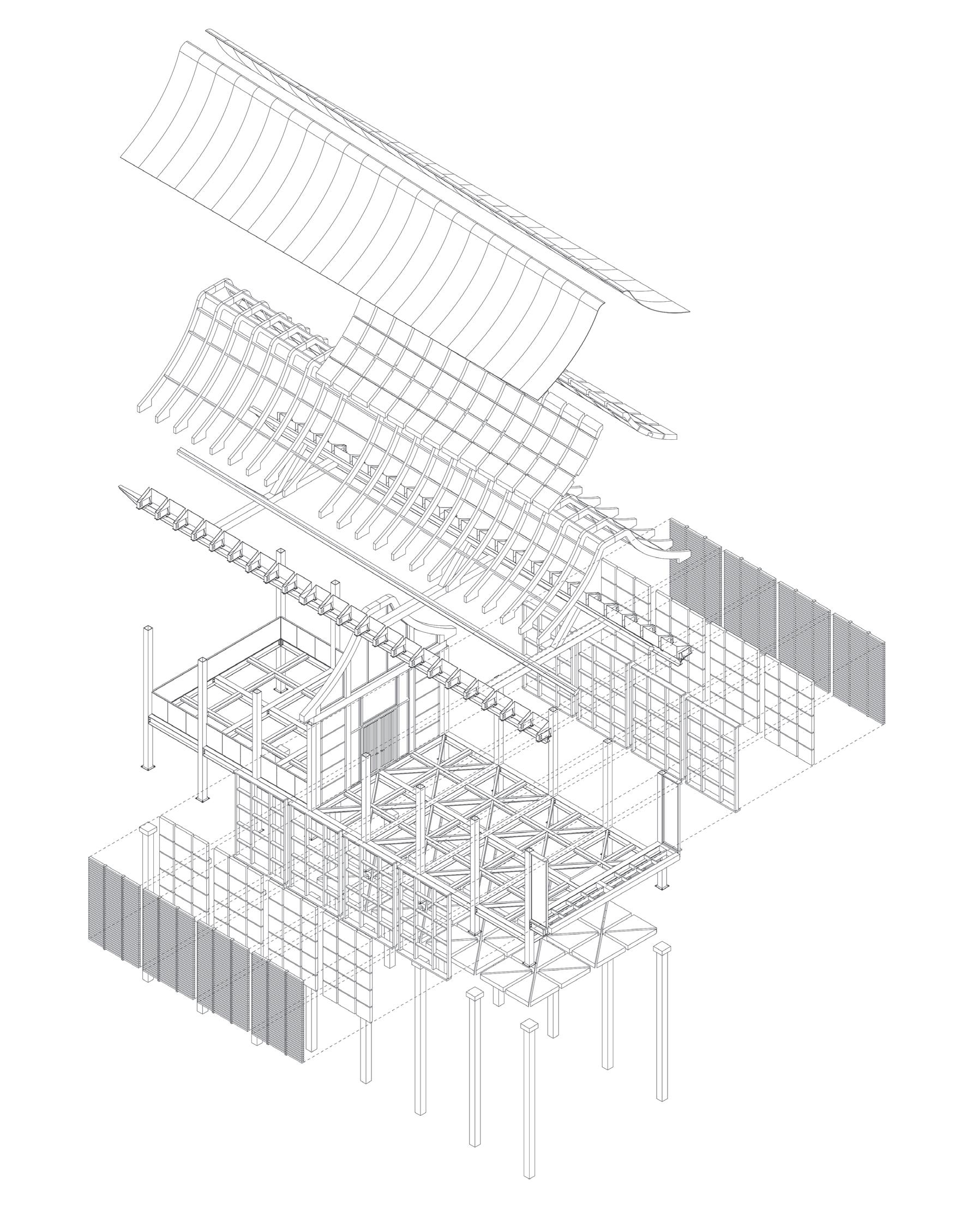

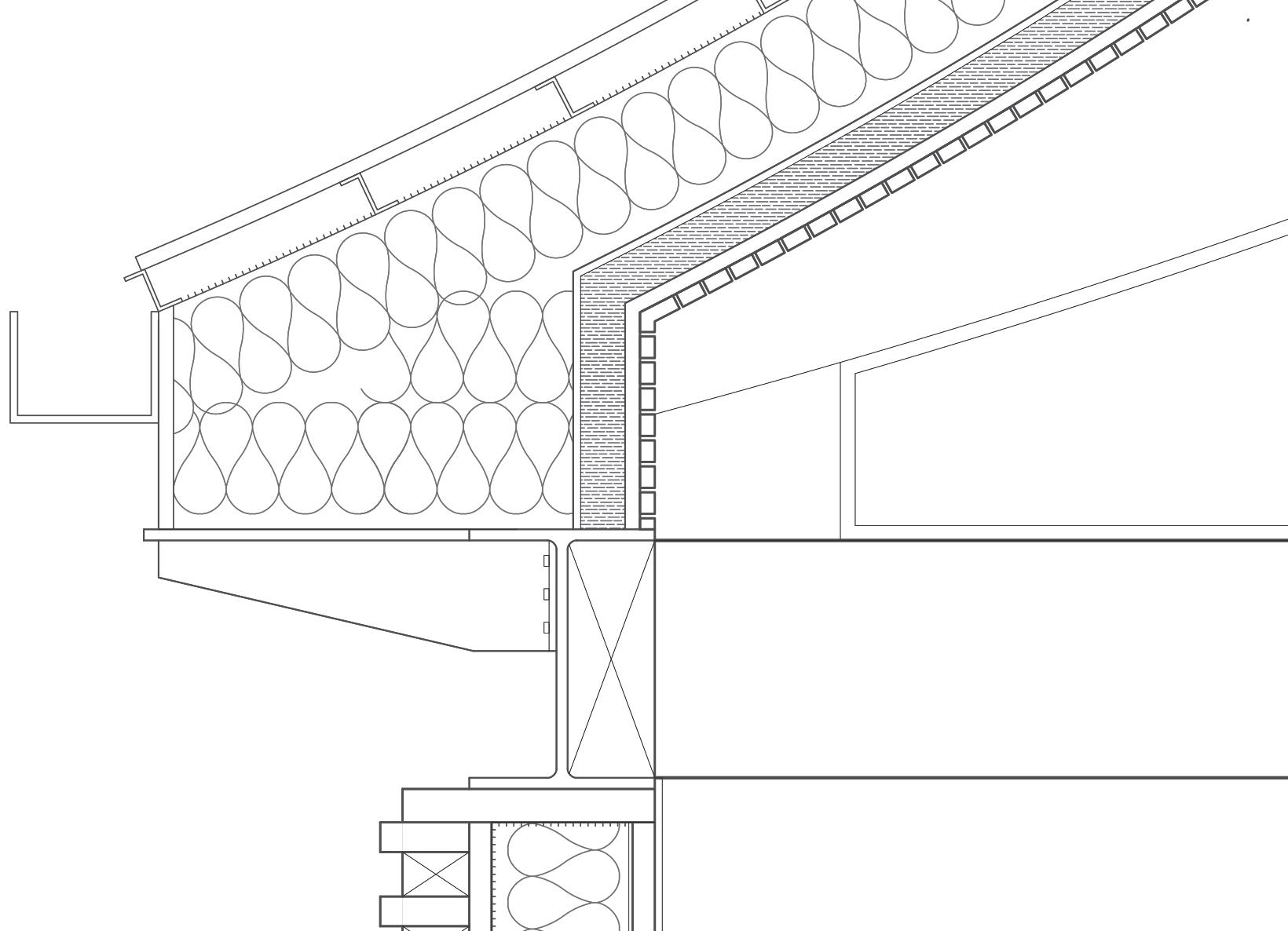

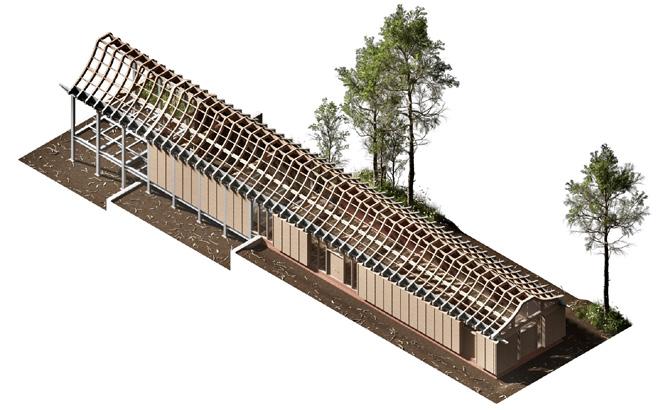

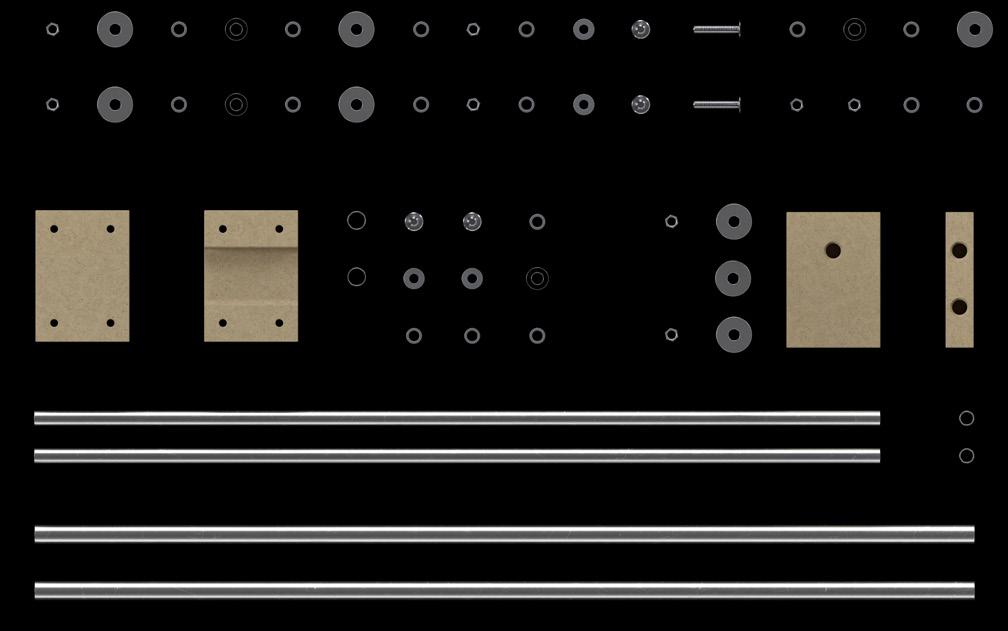

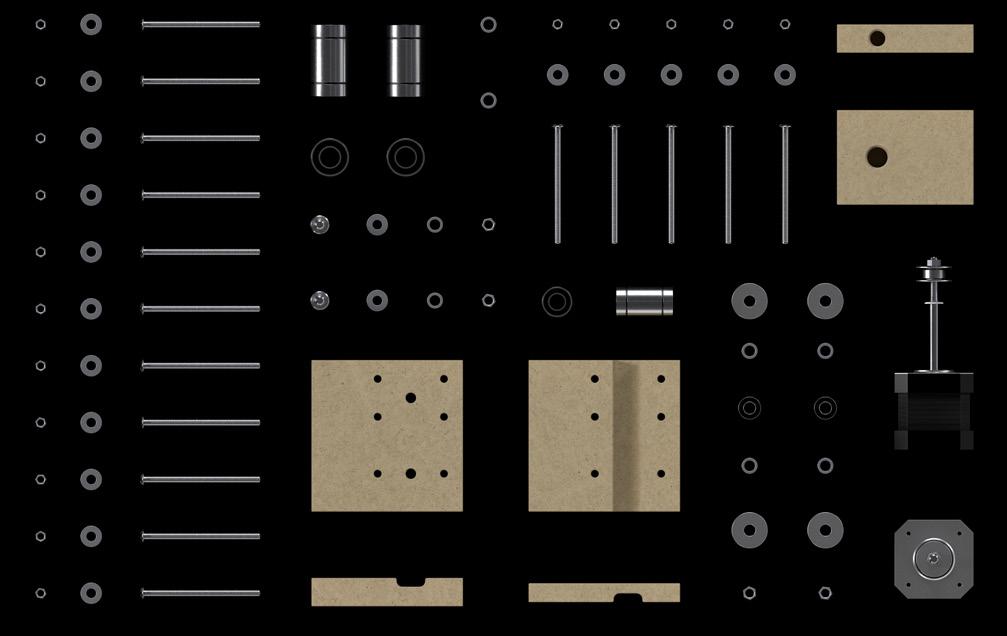

Throughout the design development process a series of section-cut models were used to refine the proposal, exploring how the recycled/harvested materials could be combined elegantly and productively.

The models visualise the architectural qualities of key spaces such as the housing types (single storey - 1 bedroom house, double storey - 2 bedroom house and double storey - 3 bedroom house).

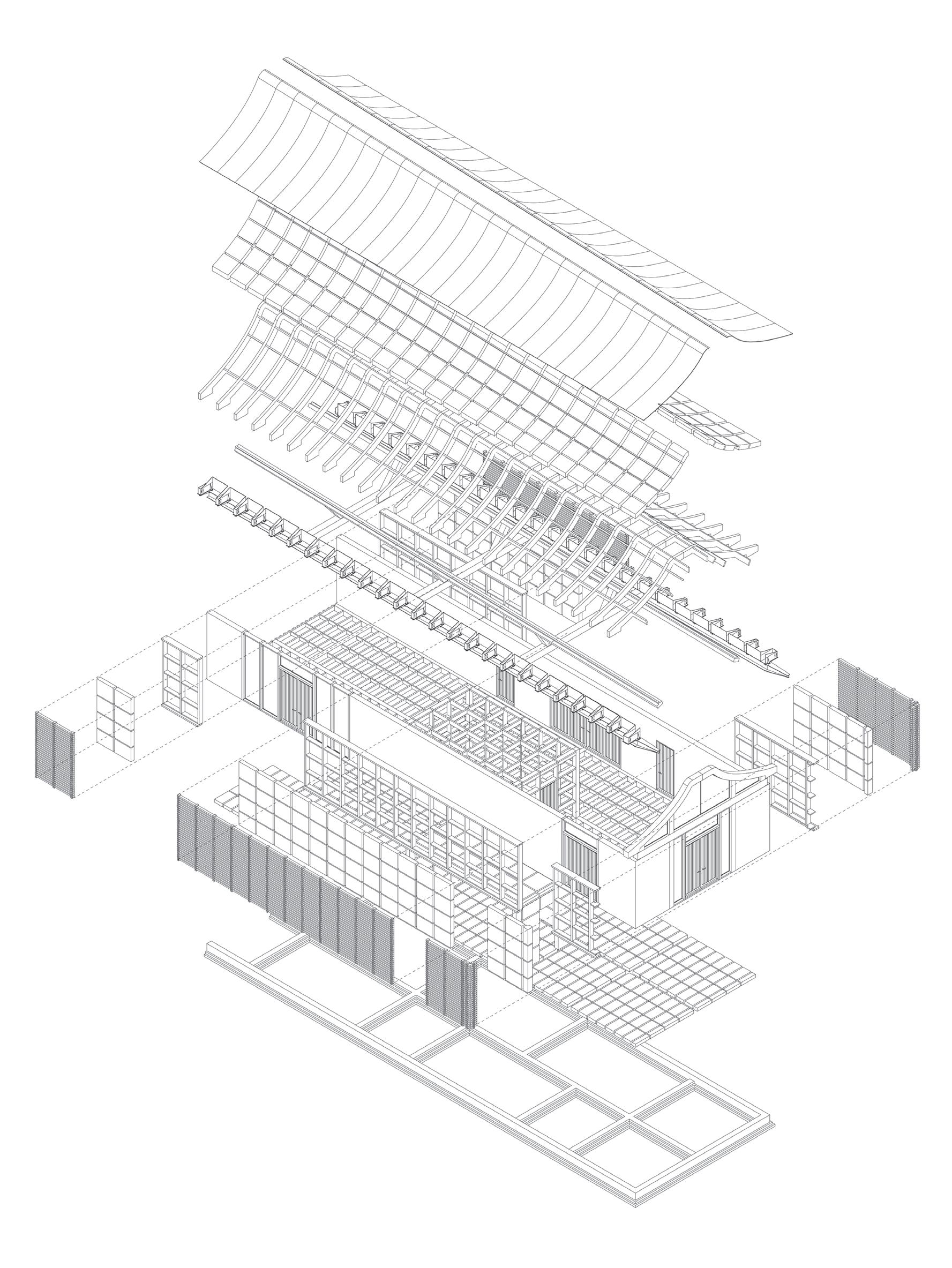

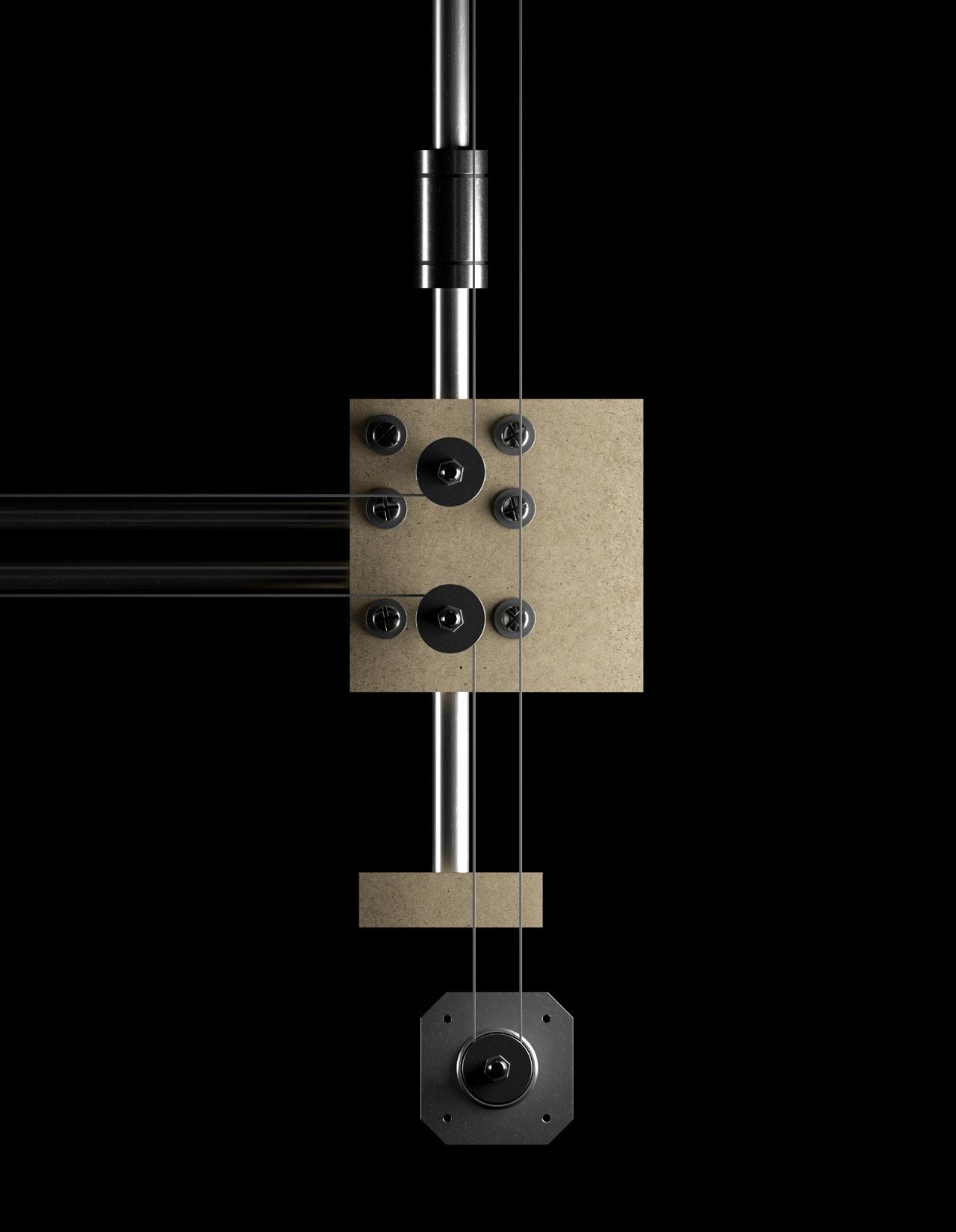

1. Reclaimed corrugated steel sheet roofing

2. Steam bent curved timber beam rafters

3. Rewelded steel support for roof beams

4. Steel beam framework

5. Wall insulation / straw bale

6. Exterior timber cladding / facade

7. Roof insulation / straw bale

8. Timber frame to hold insulation

9. Floor insulation

10. Reclaimed H-Beams as pile foundations

1. Roof insulation / straw bale

2. Rewelded steel support for roof beams

3. Reclaimed brick walls

4. Timber frame to hold insulation

5. Exterior timber cladding / facade

6. Wall insulation / straw bale

7. Reclaimed corrugated steel sheet roofing

8. Steam bent curved timber beam rafters

9. Primary roof support beams

10. Front entrance

11. Floor insulation

12. Brick footings

STAGE 1 - H-PILES

Net embodied carbon: -67.9 tCO2e

Saved from landfill:

67911.9 kgCO2e

Harvested material:

0 kgCO2e

STAGE 2 - RAMMED EARTH

Net embodied carbon: -85.4 tCO2e

Saved from landfill:

29502.7 kgCO2e

Harvested material:

11978.8 kgCO2e

STAGE 3 - PRIMARY FRAME

Net embodied carbon:

-118.7 tCO2e

Saved from landfill:

33266.2 kgCO2e

Harvested material: 0 kgCO2e

STAGE 4 - SECONDARY FRAME

Net embodied carbon: -150.0 tCO2e

Saved from landfill: 32265.8 kgCO2e

Harvested material:

1033.4 kgCO2e

STAGE 5 - INSULATION

Net embodied carbon: -156.4 tCO2e

Saved from landfill: 7246.7 kgCO2e

Harvested material: 785.6 kgCO2e

STAGE 6 - TERTIARY FRAME

Net embodied carbon: -155.8 tCO2e

Saved from landfill: 0 kgCO2e

Harvested material: 619.8 kgC02e

STAGE 7 - INSULATION

Net embodied carbon: -156.6 tCO2e

Saved from landfill:

1412.6 kgCO2e

Harvested material:

657.9 kgCO2e

STAGE 8 - ROOF SUPPORT

Net embodied carbon: -206.4 tCO2e

Saved from landfill:

51280.1 kgCO2e

Harvested material:

1479.0 kgCO2e

STAGE 9 - ROOF SUPPORT

Net embodied carbon: -205.7 tCO2e

Saved from landfill: 0 kgCO2e

Harvested material:

733.9 kgCO2e

STAGE 10 - RAFTERS

Net embodied carbon: -203.5 tCO2e

Saved from landfill: 0 kgCO2e

Harvested material: 2166.1 kgCO2e

STAGE 11 - INSULATION

Net embodied carbon: -202.7 tCO2e

Saved from landfill: 0 kgCO2e

Harvested material: 808.2 kgCO2e

STAGE 12 - CLADDING

Net embodied carbon: -209.9 tCO2e

Saved from landfill: 7156.0 kgCO2e

Harvested material: 0 kgCO2e

STAGE 1

Type - Reclaimed

Concrete - 3.456 m3

Mass of concrete = 2300kg/m3 x 3.456 m3 =

7948.8 kg

Concrete carbon coefficient = 0.143

Embodied carbon = 1136.7 kgCO2e

Steel - 3.472 m3

Mass of Steel = 7850kg/m3 x 3.472 m3 =

27255.2 kg

British steel EPD carbon coefficient = 2.45

Embodied carbon = 66775.2 kgCO2e

STAGE 2

Type - Reclaimed

Steel - 1.534 m3

Mass of Steel = 7850kg/m3 x 1.534 m3 =

12041.9 kg

British steel EPD carbon coefficient = 2.45

Embodied carbon = 29502.7 kgCO2e

Type - Harvested

Stabilised rammed earth - 129.641 m3

Mass of rammed earth = 1540kg/m3 x m3 =

199647.1 kg

Cement Stabilised Soil Carbon Coefficient =

0.060

Embodied carbon = 11978.8 kgCO2e

STAGE 3

Type - Reclaimed

Brick - 22.143 m3

Mass of Bricks = 1600kg/m3 x m3 = 35428.8 kg

Brick carbon coefficient = 0.23

Embodied carbon = 8148.6 kgCO2e

Steel - 1.306 m3

Mass of Steel = 7850kg/m3 x m3 = 10252.1 kg

British steel EPD carbon coefficient = 2.45

Embodied carbon = 25117.6 kgCO2e

STAGE 4

Type - Reclaimed

Brick - 18.379 m3

Mass of Bricks = 1600kg/m3 x m3 = 29406.4 kg

Brick carbon coefficient = 0.23

Embodied carbon = 6763.5 kgCO2e

Steel - 1.326 m3

Mass of Steel = 7850kg/m3 x m3 = 10409.1 kg

British steel EPD carbon coefficient = 2.45

Embodied carbon = 25502.3 kgCO2e

Type - Harvested

Timber - 10.742 m3

Mass of Timber = 370kg/m3 x m3 = 3974.5 kg

Timber carbon coefficient = 0.26

Embodied carbon = 1033.4 kgCO2e

STAGE 5

Type - Reclaimed

Brick 19.692 m3

Mass of Bricks = 1600kg/m3 x m3 = 31507.2 kg

Brick carbon coefficient = 0.23

Embodied carbon = 7246.7 kgCO2e

Type - Harvested

Straw Bale - 35.726 m3

Total lifespan carbon emission = 14.12 kgCO2e/ m3

Embodied carbon = 504.5 kgCO2e

Timber - 2.922 m3

Mass of Timber = 370kg/m3 x m3 = 1081.1 kg

Timber carbon coefficient = 0.26

Embodied carbon = 281.1 kgCO2e

STAGE 6

Type - Harvested

Timber - 6.443 m3

Mass of Timber = 370kg/m3 x m3 = 2383.9 kg

Timber carbon coefficient = 0.26

Embodied carbon = 619.8 kgCO2e

STAGE 7

Type - Reclaimed

Glass 0.657 m3

Mass of glass = 2500kg/m3 x m3 = 1642.5 kg

Glass carbon coefficient = 0.86

Embodied carbon = 1412.6 kgCO2e

Type - Harvested

Straw Bale - 46.592 m3

Total lifespan carbon emission = 14.12 kgCO2e/ m3

Embodied carbon = 657.9 kgCO2e

STAGE 8

Type - Reclaimed

Steel - 2.630 m3

Mass of Steel = 7850kg/m3 x m3 = 20645.5 kg

British steel EPD carbon coefficient = 2.45

Embodied carbon = 50581.5 kgCO2e

Glass - 0.285 m3

Mass of glass = 2500kg/m3 x m3 = 812.3 kg

Glass carbon coefficient = 0.86

Embodied carbon = 698.6 kgCO2e

Type - Harvested

Timber 15.374 m3

Mass of Timber = 370kg/m3 x m3 = 5688.4 kg

Timber carbon coefficient = 0.26

Embodied carbon = 1479.0 kgCO2e

STAGE 9

Type - Harvested

Timber 7.629 m3

Mass of Timber = 370kg/m3 x m3 = 2822.7 kg

Timber carbon coefficient = 0.26

Embodied carbon = 733.9 kgCO2e

STAGE 10

Type - Harvested

Timber 22.517 m3

Mass of Timber = 370kg/m3 x m3 = 8331.3 kg

Timber carbon coefficient = 0.26

Embodied carbon = 2166.1 kgCO2e

STAGE 11

Type - Harvested

Straw Bale 57.235 m3

Total lifespan carbon emission = 14.12 kgCO2e/

m3

Embodied carbon = 808.2 kgCO2e

STAGE 12

Type - Reclaimed

Steel sheet 0.268 m3

Mass of sheet = 7850kg/m3 x m3 = 2103.8 kg

British steel EPD carbon coefficient = 2.45

Embodied carbon = 5154.3 kgCO2e

Glass - 0.931 m3

Mass of glass = 2500kg/m3 x m3 = 2327.5 kg

Glass carbon coefficient = 0.86

Embodied carbon = 2001.7 kgCO2e

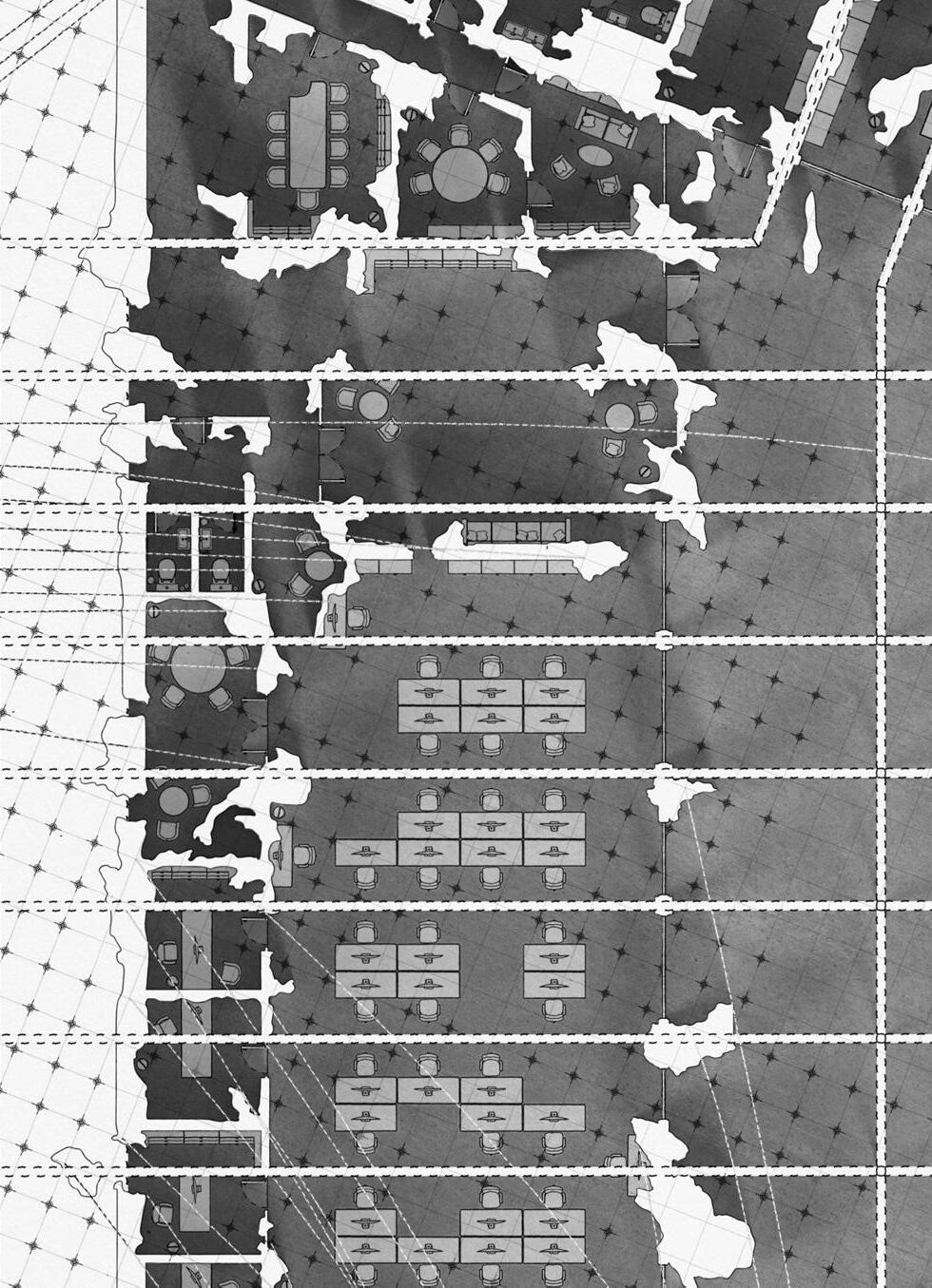

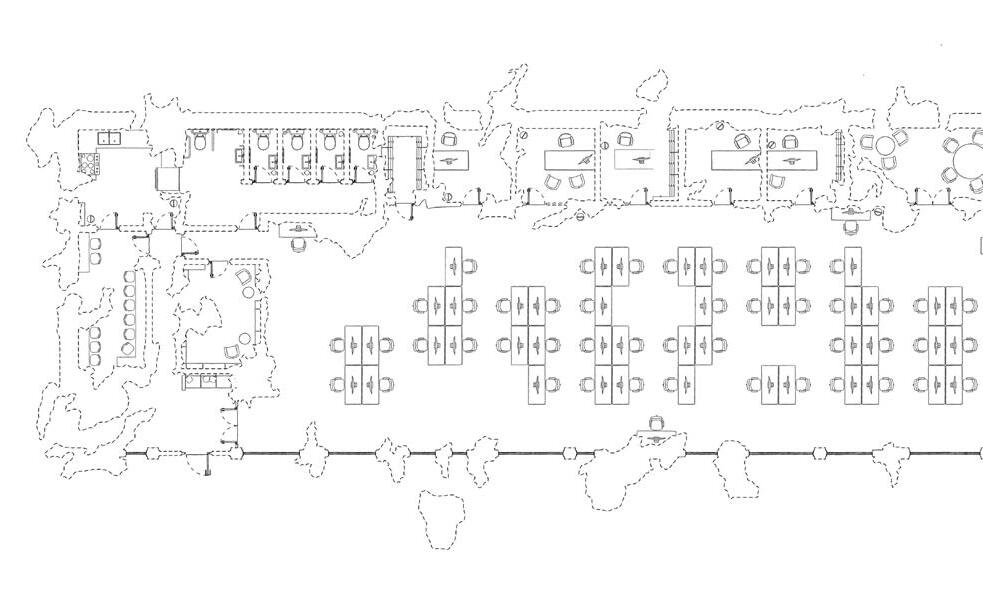

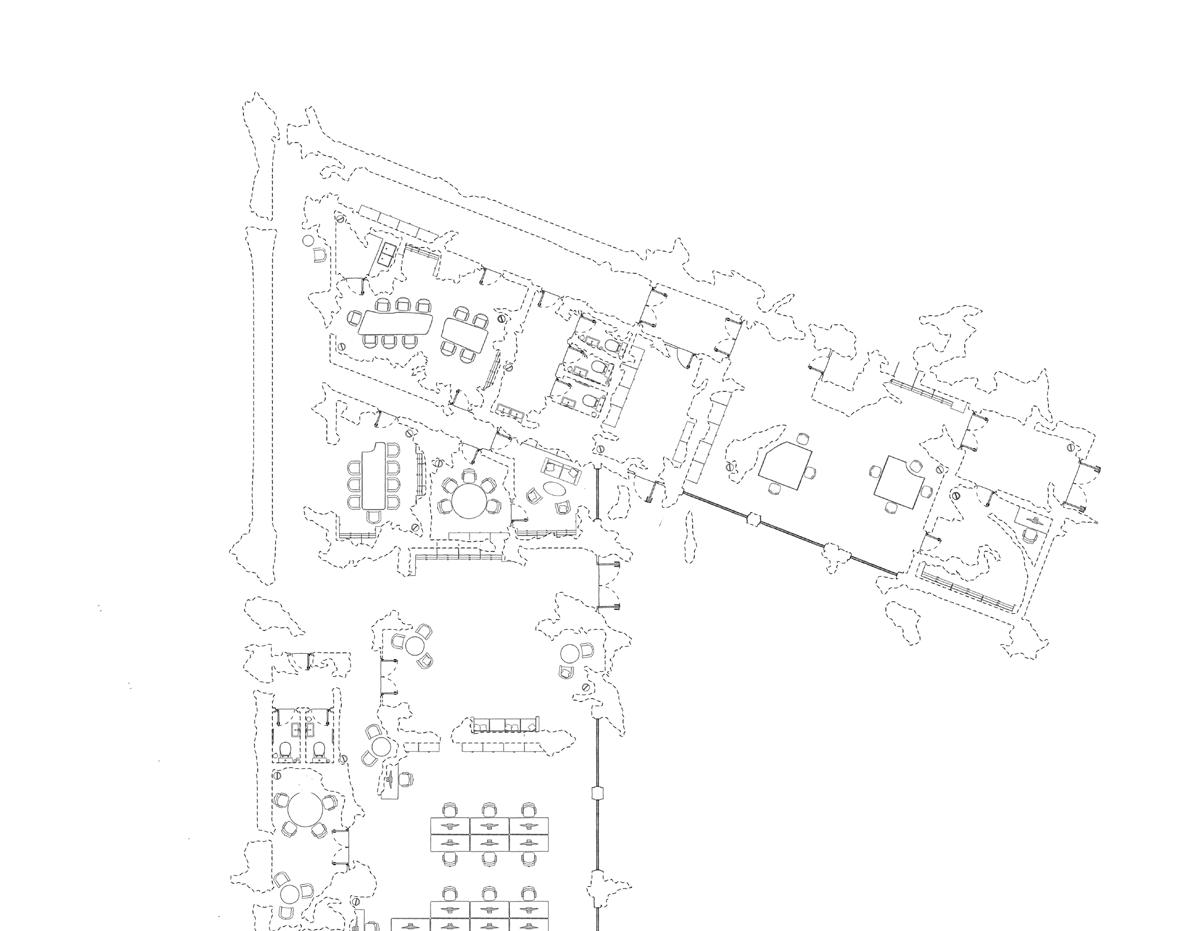

This project investigates the state of the architectural industry in terms of practice and labor. It addresses key issues such as underpayment and overwork, and argues that these are caused by companies putting financial gains before the treatment of, and working conditions for, employees. As such, the project concludes that this prioritization is a result of modern-day, capital-driven efficiency.

This modern-day efficiency first came to fruition during the industrial revolution, when production methods were mechanized and mass scaled. Arkwright’s spinning frame is a prime example of improved manufacturing efficiency during this period. However, it also highlights several of the problems caused by streamlined mass production such as child labor, deplorable working conditions, and severe underpayment. In recognizing this, the project communicates an unfavorable view toward striving for efficiency.

The project then investigates the efficiency of architectural labor and designer workflow. It assesses the certainty of

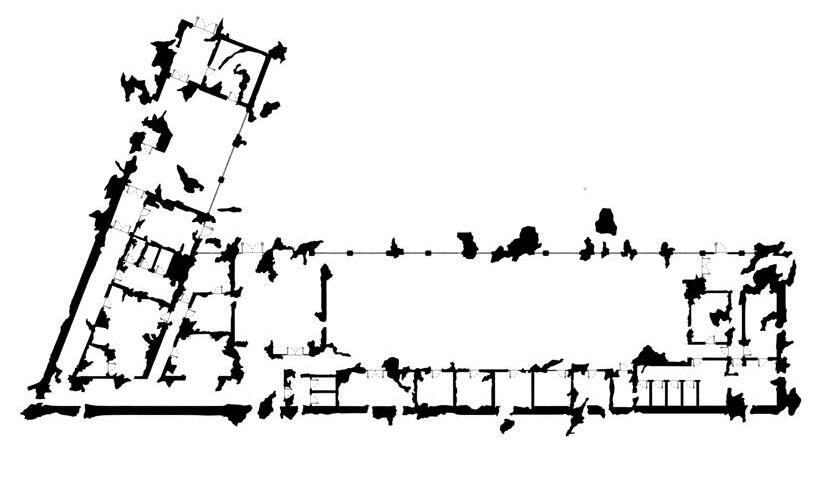

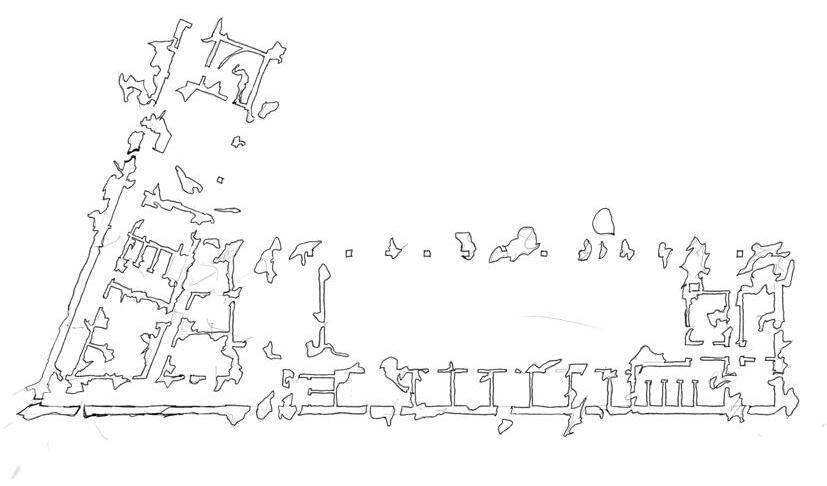

errors in hand drawing - a task that can never be completely efficient - and by using this concept as a foundation, argues that designers are innately inefficient. From here, I design an ‘inefficient’ drawing machine that bases its algorithm on human error probabilities to mimic human inefficiency in drawing production. I produce a typical office floor plan and incorporate the inefficient drawing machine into the design process to investigate how mistakes and ‘inefficiencies’ can create new uses for spaces.

Ultimately, the project proposes that architects should rethink the current emphasis on production efficiency as the principal dictator of how we design and inhabit space. Instead, we should incorporate mistakes and chances into our designs. This alternative design process could make architecture more in touch with human’s intrinsic inefficiency through the random errors and ‘inefficiencies’ it creates.

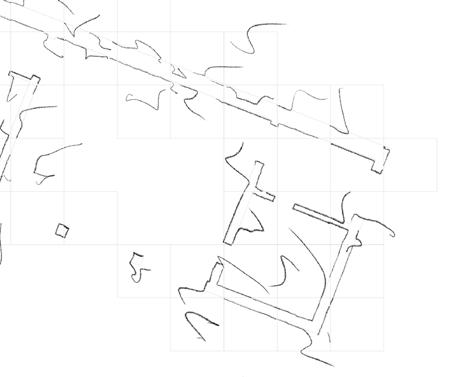

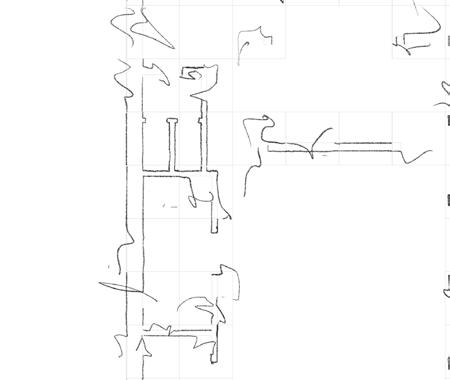

Raw output with initial errors from the drawing machine

Redrawing the plan - my intervention - in order to create closed wall forms

Refined vector-based composition - digital intervention - for 3D modelling

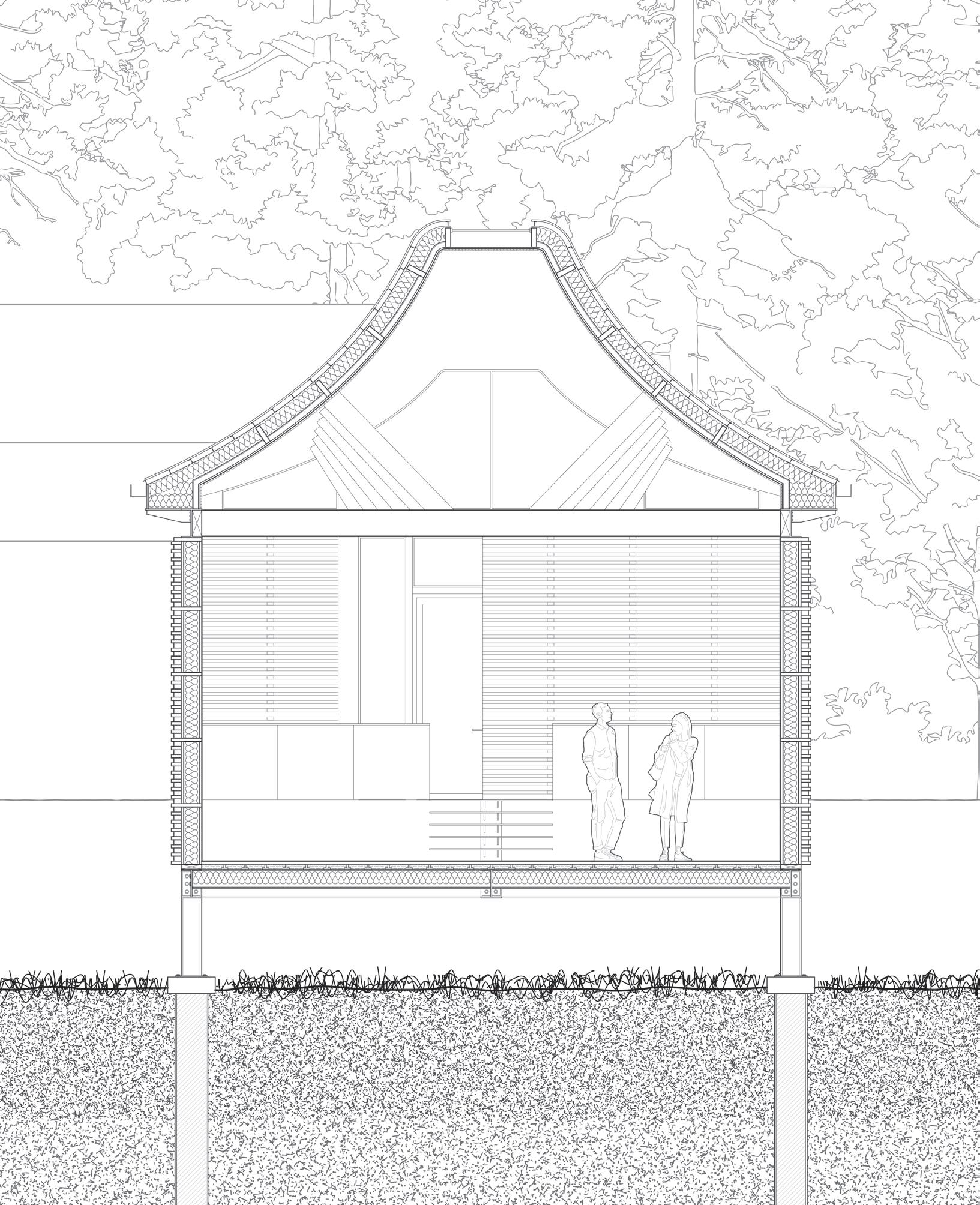

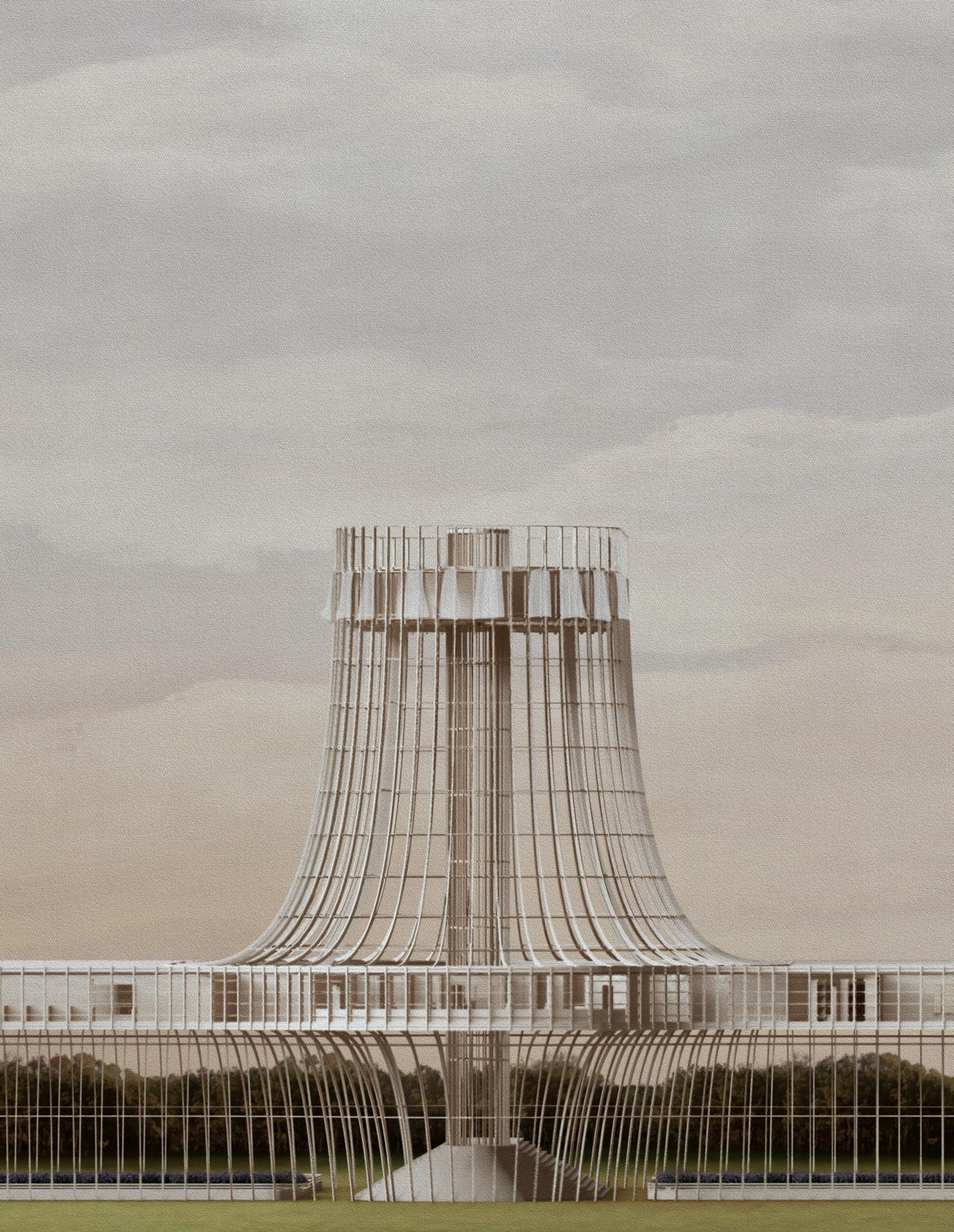

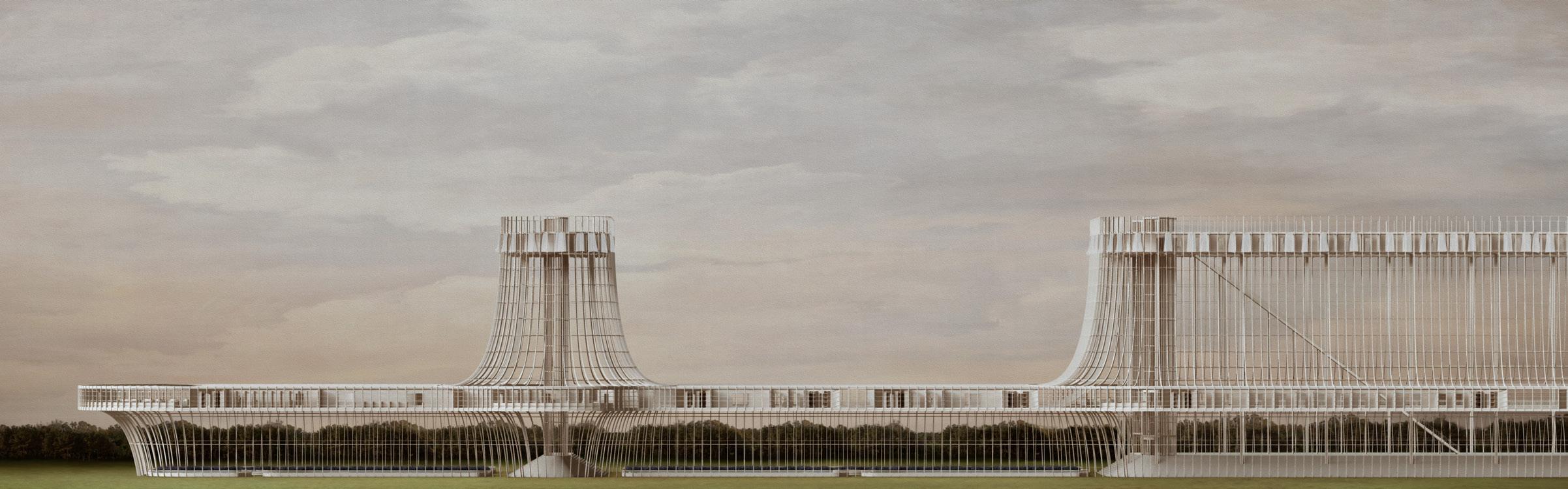

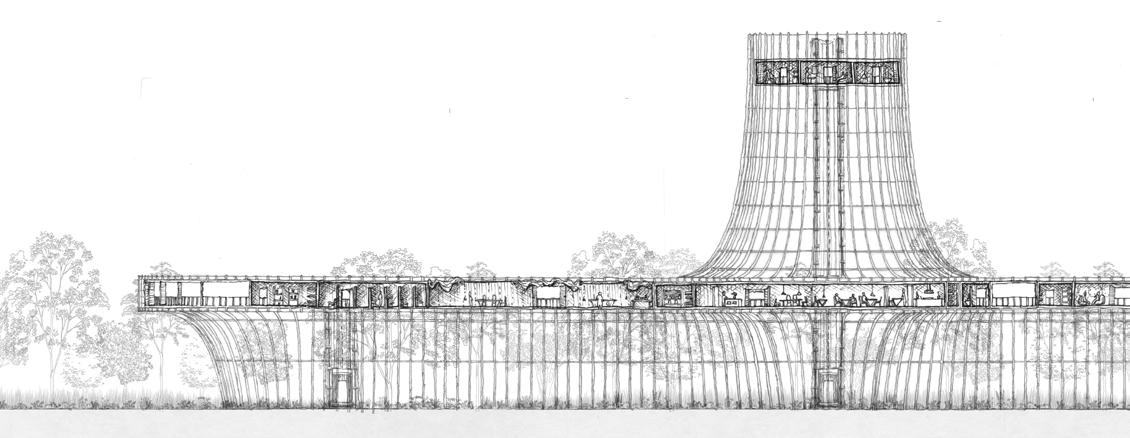

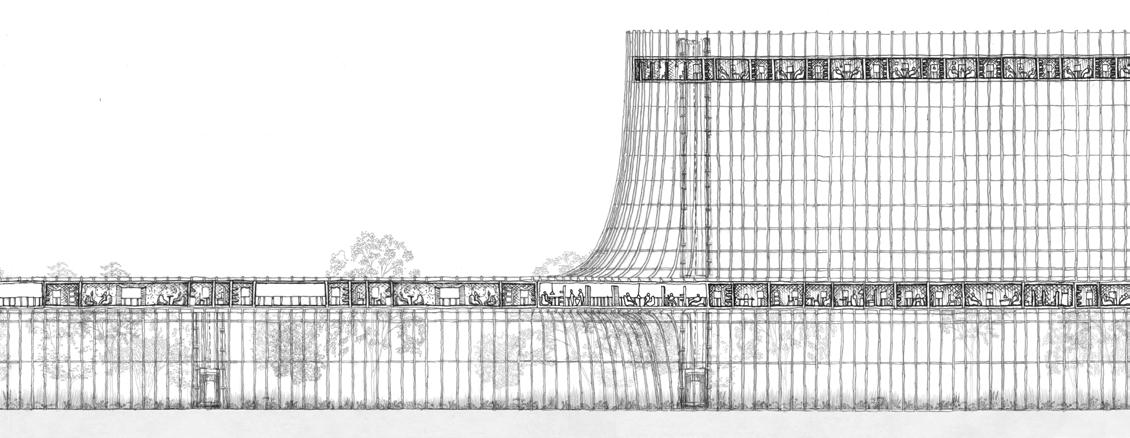

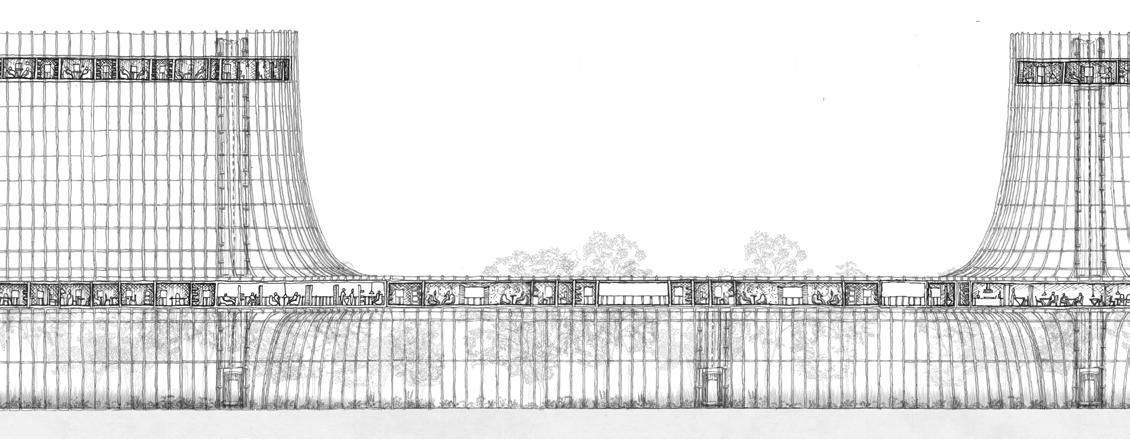

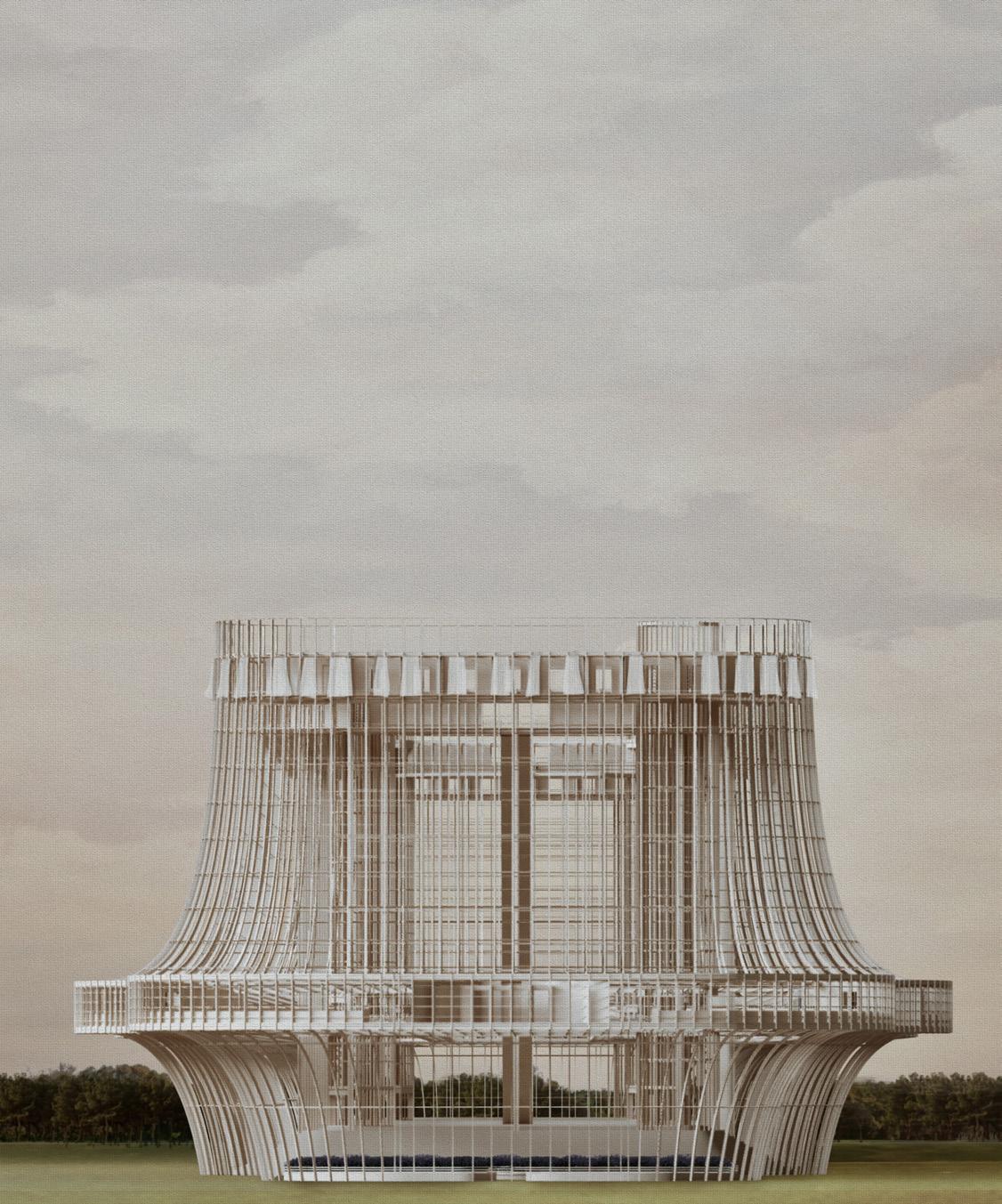

The project proposes a mental health revolution through an examination of the long-term effects of the Covid-19 pandemic on public mental health. Inspired by the Great Exhibition of 1851, a celebration of industry that was emblematic of the nineteenth century’s economic and technological advancements, this project aims to communicate a celebration of openness toward mental health. Thus, a celebration representative of the societal needs of the 21st century.

Located within the same footprint of Hyde Park as the original Great Exhibition, a monumental in scale, yet delicate, latticelike structure hangs above a sculpted landscape. The building performs as a clinic and public space, illustrating the themes of transparency and openness through both its framework and function. The structure aims to be a celebration of acceptance; a physical beacon of hope to the millions suffering in silence from mental illness every year.

This project is a short speculative investigation into how memories change and evolve over time. The project starts with reflecting on my memories of a trip to Camden Passage, an area in Islington, London, known for its antique shops and cafes. Using hand drawing as a chosen medium, the project investigates how my memories change and shift as new

experiences and memories are added as the project timeline progresses. The evolution of what is included in the drawings speaks to the changing nature of memory and how it shapes our understanding of the past. Overall, ‘A Memory Machine’ is a highly personal examination of memory’s complex and fluid nature.