Langley Training Services (LTS) – a new social enterprise within the Langley Group – has been endorsed by the UK Government as a training provider.

LTS delivers specialist apprenticeship training schemes directly to equip young roofers with future-proofed skills as the construction industry embraces the challenge of providing a more sustainable future.

The Level 2 Roofing apprenticeship, initially based out of Langley’s headquarters and training centre facility in Daventry is eligible for government funding. It follows the social enterprise successfully registering as an approved apprenticeship training provider (RoATP) with the Education and Skills Funding Agency (ESFA).

LTS is open to support eligible applicants aged 16 and above, with successful applicants travelling across the UK to gain hands-on, practical training. Those enrolled will likely include new trainees working under an employer who requires formalised core skills and knowledge for competence and progression in the workplace. The apprentices will focus on waterproofing skills, with future apprenticeships planned to support green infrastructure.

The creation of apprenticeship schemes is in line with the broader organisation’s Social Value strategy and core values of SPIRE (Safety, Purpose, Innovation, Responsibility, Expertise) to provide people with the skills required for the industry whilst bettering themselves. In establishing the social enterprise,

Langley bolsters its reputation nationally for creating solid foundations for the next generation through professional qualifications and an overall approach led by quality and standards.

Increased funding from the government has arisen as a result of a recent analysis which has shown that for Net Zero housing targets to be met in the South East of England alone, more than 46,000 new skilled workers are needed. It also follows the NFRC reporting that over half of roofing and cladding contractors found it harder to recruit suitable labour in the third quarter of 2022.

Neel Bidessie, Director of Social Value and People Development, said: “Training is an integral part of the Langley culture. Through our history to date, we’ve earned an industry-renowned reputation for the delivery of high-quality services to support our partners, clients and broader supply chain and this new apprenticeship provision is no different – Langley Training Services is here to support internal employees, existing industry employees, passionate school and college leavers, individuals, and third sector organisations in equal measure.

“Ultimately, this provision leverages Langley’s capacity to improve people’s lives by opening the door to a world of opportunity in a rewarding career path. We’re confident this apprenticeship facility will deliver for the individuals and businesses involved, as well as play an important role in plugging the national skills gap in support of the government’s levelling up agenda.”

Langley Training Services is now open to applications, with the next cohort set to commence training this spring. With limited spaces available, applicants are encouraged to apply as soon as possible.

To find out more about the Langley Group, visit: www.langley.co.uk/training

The world of Roofing and Construction is changing. Experience is vital, but the industry is moving towards qualification requirements to improve industry standards.

Our NVQ qualifications don’t require downtime. They are carried out on-site during the working day and are fully funded or co-funded for eligible candidates until July 2023.

What we offer:

Langley Training Services (LTS) deliver the following National Vocational Qualifications (NVQs).

• NOCN Cskills Awards Level 2 NVQ Diploma in Waterproof Membrane Roofing Systems (Construction) - Reinforced

Bitumen Membrane Roofing

• NOCN Cskills Awards Level 2 NVQ Diploma in Waterproof

Membrane Roofing Systems (Construction) – Liquid Applied Membrane Roofing Systems

• NOCN Level 3 NVQ Site Inspection

Who is it for:

• NVQ Level 2 RBM & Liquid is relevant to installers and will help them to gain the appropriate CSCS Card.

• NVQ Level 3 Site Inspections is relevant to operational managers, Site Managers, Projects Managers, Surveyors and Contracts Managers.

Why are these qualifications important:

NVQs are widely recognised and valued by employers. They can enhance an individual’s career prospects, demonstrate their expertise and increase their earning potential.

Qualifying your workforce and reducing the skills gap broadens your Social Value offering benefiting you, your clients and the whole construction industry.

Our courses are delivered flexibly and once we have assessed your eligibility can be fully or part funded until July 2023.

For more information or to book LANGLEY TRAINING SERVICES 01327 704778

training@langley.co.uk

langley.co.uk/training

Most contractors are familiar with the concept of floor mounted lifting stations and below ground pumping stations, but may not always be sure which is best for an application. So here is some useful information from David Johnson, Business Development Manager of Aldermaston Based Pump Technology Ltd, to help.

Considerations that effect a pumping solution choice might include - how far, how high and how much to pump, as well as tank holding capacity in the event of a loss of mains electricity for example.

Other factors can include - site layout (is there adjacent land available to carry out civil works to submerge a tank), water table, the need to excavate a basement floor etc.

Floor Mounted Lifting Stations: Generally, these are positioned in a basement or plant room and used to pump wastewater and sewage from individual sections of the building, such as changing rooms for example, to a nearby outside public sewer.

Whilst contractors are familiar with the common sizes of the Jung Pumpen lifting stations such as the EffluMaxi / Compli 400 or the 1010, the larger EfluMaxi Compli pumping systems like the 1500 and 2500 might be new to them. The tanks on these models have a storage capacity up to 500 Litres and two tanks can be manifold together to double this.

a below ground pumping station, pumping all waste from the building. They offer the waste volume storage and pumping capabilities associated with discharging wastewater and sewage over relatively long distances to the public sewer This is particularly beneficial when Civil works for a below ground pumping station would be difficult due to lack of outside space or the cost of excavating a basement.

The large EffluMaxi Compli pumping systems can be floor mounted within a basement or plant room. They also have the advantage of the pumps being mounted external to the tank. This “drywell” configuration provides its own advantages. For example, inspection and maintenance savings. With the pumps on the outside of the tank they can be easily isolated and removed for maintenance if required. They are obviously cleaner to handle and the health and safety risks, associated with working over deep pits or confined spaces, are eliminated.

To support Engineers with sizing of either the floor mounted EffluMaxi / Compli or their below ground PumpMatic pumping stations, Pump Technology Ltd has its own in-house qualified pump consultant, Steve Murphy.

Steve will work with engineers to discuss the application, site and future maintenance requirements. He will then size either (or both) options to allow contractors to select the system best suited to a particular installation.

The combination of application, type of building use, quantity of waste fluid to be pumped and site layout will generally lead the selection process to a clear conclusion between floor mounted or below ground.

Pump Technology Ltd’s below ground “PumpMatic” pumping stations are manufactured in house by a Pump Technology Ltd. group company. This enables the company to ensure that the specification, build and on-time delivery of these units is assured.

The below ground pumping station collects all wastewater and sewage that has come from the building and needs pumping to a public sewer connection point. These tanks are usually sited outside the building and have to be buried underground. When compared with a floor mounted lifting station there is a greater choice of tank sizes and pumps available and the product cost less, but when the full civil works is considered and the, potentially, more costly maintenance, the lifting station can prove more suitable.

A wide range of standard modular tanks or custom tanks to suit almost every site elevations and inlet or inlets positions can all be factory rigged.

An extensive selection of submersible pumps from leading European manufacturers are available, including vortex or cutter designs.

Pump Technology Ltd, is currently celebrating its 30th Year specialising in wastewater and sewage pumping solutions. As the largest Jung Pumpen GmbH, authorised distributor and stockist in the UK, they have extensive and in-depth knowledge of the Jung Pumpen product range which is second-to-none.

The Remember Me memorial portico at St Paul’s Cathedral is a physical memorial to all those that died as a result of the Covid-19 pandemic. Entered via the cathedral’s North Transept entrance it is home to the online book of remembrance.

Designed by Caroe Architecture with Connolly Wellingham, the portico is a beautiful, elliptical structure crafted in the UK and featuring several GEZE doors.

As a visitor enters the cathedral from the North Transept they pass through a pair of swing doors powered by GEZE Powerturn automatic swing door operators. These doors take the visitor into the memorial and were chosen as they can open large or heavy doors and offer the flexibility of allowing the doors to be used both manually and automatically due to GEZE’s Smart swing function.

Above the doors, etched in to the structure in gold are the words ‘ Remembering all who died as a result of the coronavirus pandemic’.

Once inside the portico, visitors can view the online Remember Me memorial, search for and view the tribute to their loved one, light a candle and take a moment to pause and reflect in this tranquil space. The online book is open to all people, whatever their faith or none.

From the memorial portico the main entrance into the cathedral is through GEZE’s TSA 325 NT,

a manual revolving door with 4 leaves. The revolving door was chosen as it minimises air flow into the cathedral as only one quadrant is open at a time.

To ensure access for all a GEZE Slimdrive SCR curved automatic sliding doors was installed opposite the revolving door enabling those who are less able, or people with children in buggies, can still visit the memorial and access the cathedral. The Slimdrive SCR is controlled by wave sensors to ensure the doors only open when requested. This is part of the portico’s design to minimise air flow.

Across all the glass in the doors are beautiful phrases such as ‘we will always remember’ and ‘never forget’.

The Remember Me memorial portico is a poignant tribute to those who died as a result of the Covid-19 pandemic and is the most significant change to St Paul’s Cathedral in 300 years.

Following the public response to the online memorial, and in partnership with the Daily Mail, over £2million was raised to give the Remember Me memorial a physical home within the Cathedral. Said GEZE’s National Specification Manager, Richard RichardsonDerry, ‘We were honoured to play a part in the construction of the Remember Me memorial. The combined challenges of minimising air flow, ensuring equal access and creating a beautiful structure to recognise those lives lost has been successfully achieved’.

Additional information:

For more information about GEZE UK’s comprehensive range of automatic and manual door closers call 01543 443000 or visit www.geze.co.uk

ecodan.me.uk/rduf3

As a market leader in low carbon heating systems, we help housing developers comply with the changes to Part L of the Building Regulations by specifying Ecodan Air Source Heat Pumps for new build homes.

Our dedicated website pages provide you with support at every one of the seven steps of the RIBA Plan of Work.

ecodan.me.uk/rdum

The original and still the best, Magicman supply on-site sustainable repair and refurbishment technicians who deliver on time, every time. Fully certified with every commercial accreditation. Comprehensively insured, monitored and audited. Available nationwide. Is it any wonder that over 300 companies and organisations trust and rely on us?

Gilberts Blackpool is continuing its pioneering reputation at the original outlet for one of the UK’s fastest-growing coffee brands.

Black Sheep Coffee, with its strapline of ‘leaving the herd behind’, it is leading the field in expansion, opening 30 stores in 2022, with a focus on speciality coffee and customer service. Founded less than a decade ago, the brand already has 40 outlets across the UK, including at the iconic, once-derelict Grade II* Battersea Power Station.

The chain’s owner Group Metropolitan has turned to Gilberts to create a discreet means of balancing adequate ventilation for the Battersea outlet’s kitchen without impacting on customers’ ability to relax and enjoy a coffee al fresco in the outside seating area.

A floor-mounted screen of 12no. AP50 acoustic panels enclosed behind a bank of 12 no. WGF38 factory-built flanged louvres minimises noise whilst directing the extract air (and associated odours from the kitchen) upwards away from guests and surrounding residents.

To accommodate the architecture of the external façade, the compact bank graduates from 1.5m to 2m along its 10.4m length, providing 50% free ventilation with noise modulation.

Group Metropolitan Contracts Manager Karolis Vigelis commented, “The design of the Battersea Power Station outlet’s exterior meant that although the concept was comparatively simple, getting the design right, to make it effective yet as discreet as possible, was more complex. The end result shows how it pays to think outside the box, not follow the herd!”

The WG38 is the smallest profile available in Gilberts’ louvre

product range, developed over the years to provide a comprehensive package to keep pace with the evolution of building design and structural interfaces. It includes standard, high performance, site assembled and acoustic louvres, available in a range of ratings for weight, ventilation, weather, insects and even bird ingress. Even fixings can often be tailored to individual site preferences.

Innovatively, with its in-house design expertise, Gilberts has the capability to create bespoke configurations which can be both CFD modelled, and tested within its own laboratory to give customers complete ‘fit for purpose’ peace of mind.

Gilberts also offers a comprehensive range of PPC,PVF and PVF2 coatings across its louvres, available in any RAL colour, applied to louvres of almost any size.

Founded six decades ago, and still family-owned, Gilberts is the UK’s leading independent air movement engineer. It is unique in its ability to design, manufacture and test all products- including bespoke fabrications- in-house, to the extent it even designs and manufactures its own tools at its 140,000 sq ft head office and production facility.

Breedon Group plc (Breedon or the Group), a leading vertically-integrated construction materials group in Great Britain and Ireland, today announces the launch of its 2023 apprenticeship programme that will see 70 new apprentices join the Group in September this year.

Applications for the 2023 intake are now open and this year’s apprentices are invited to apply for roles across many different disciplines at various sites across England, Scotland and Wales, including:

• Mechanical and Electrical Maintenance Technicians

• Lab technicians

• HGV Service and Maintenance Technician

• Quantity Surveyors

• Surfacing Operatives

• Plant Maintenance

• Customer Services

• Machinery Operatives

• Operations Management

• Project Engineers

Those interested in building their future at Breedon need no prior experience or qualifications if they are applying for a Level 2, Intermediate Apprenticeship. However, applicants looking to apply for Levels 3 or higher will need specific qualifications:

• Level 3 Advanced Apprenticeships require 5 GCSEs

• Levels 4, 5, 6 or Higher/Degree Apprenticeships require A levels or a BTEC

Jorden, a Mobile Plant Operative based in Longwater, East Anglia, said: “I didn’t need any previous experience within the field and have

been given all the help and support that I need to do well within my role. I had reached the age where I no longer wanted just a job but a career, and I really feel that I have found that within Breedon. Now I am working in this industry, I can’t imagine wanting to do anything else.”

Successful applicants will be paid from day one and will have the opportunity to build a career, having gained industry experience at the largest independent construction materials group in the UK.

Those interested in applying for the programme should visit our website to apply

The application window will be open for one month, meaning all applications must be submitted by 5 May 2023. A full timeline

for the application process and onboarding programme for the successful applicants can be found on Breedon’s website here

Caroline Roberts, Group People Director at Breedon commented: “Breedon is a wonderful place to build a career, and this year’s programme will see our new class of apprentices begin varied and dynamic careers at sites across England, Scotland and Wales.

“We are always looking for talented, ambitious young people to join our team and make Breedon an even greater place to work. .Our purpose is to make a material difference to the lives of all of our colleagues, as well as to our customers and local communities. That’s why I am delighted to be launching this year’s apprenticeship programme.”

The Chartered Institute of Building (CIOB) is launching a range of resources designed to help construction clients achieve better project outcomes and create more value.

The Chartered Institute of Building (CIOB) is launching a range of resources designed to help construction clients achieve better project outcomes and create more value.

Central to the resources for clients include a new best practice guide for professional clients: Leading Projects in the Built Environment, which is available to download free of charge.

Aimed at those who are new to the process, the new Client Guide is designed to help professional clients get the building blocks right from the start. It explains how projects are generally structured and managed, and what to look out for along the way. Drawing on CIOB members’ experience and expertise, it highlights the things clients can do to benefit their project. Although it is aimed primarily at clients running larger projects/programmes, the principles apply to all clients regardless of project size.

Alongside the new Client Guide, the initial resources include online training courses and signposting to third-party support, as well as a set of top tips FAQs for homeowners. Over time, the CIOB envisages a global, one stop shop for all those in need of advice on how to make their construction project a success. There will be best practice case studies and knowledge sharing podcasts and resources available for contractors, who themselves become clients when they subcontract work.

Linda Stevens, Head of Client Development at CIOB, said: “Being a client is not easy. Regardless of the type of project, they are responsible for co-ordinating a complex web of resources, in some cases relying on many specialist consultants. Our aim is to capture and share learnings to encourage greater collaboration and good decision making, highlight known pitfalls and help minimise waste. Ultimately, we want to help clients achieve better project outcomes for them, the environment and society at large.”

Jon Enever, Chief Client Officer at Gleeds, and a member of the CIOB’s Client Steering Group said: “It’s not uncommon for clients, particularly for end user clients, to have no training and little or no prior experience of the construction process. For example, a headteacher overseeing the building of new classroom block, a medical practice manager commissioning an extension to new waiting room, a voluntary group leading on the renovation of a community centre and, of course, an individual planning a loft conversion or a kitchen extension at home.

“In many cases the client will be trying to co-ordinate their project alongside their day jobs, so having support and guidance from a trusted body, such as CIOB, which can potentially highlight best practice, should ultimately help them achieve a quality outcome, better value for their investment and peace of mind during the process.”

To access CIOB’s client resources visit the dedicated webpage.

The UK’s leading heating and hot water manufacturer, Worcester Bosch, are delighted to announce the launch of its new Savvy Series to support installers in guiding homeowners through the various options and advantages around future green home heating technologies.

With the cost of living a huge ongoing topic impacting the lifestyles of millions of UK homeowners, the new content series is part of an extensive push by Worcester Bosch to deliver quality and impactful energy saving tips to homeowners to help curb the cost of household spend and energy usage. It will also provide much needed guidance for consumers to empower them when it comes to choosing future greener heating systems for their homes.

The Savvy Series will be fronted by TV presenter and consumer champion Angellica Bell, with each video revealing new tips on how homeowners can either save money in the face of skyrocketing household bills or gain a better understanding of greener heating options for their home.

The series also simplifies greener home heating, giving the viewer a better understanding of the future technology that may be available to them. The home heating solutions covered include hydrogen, heat pumps and hybrid systems.

The below topics are available on the Worcester Bosch YouTube channel and its website.

• Being the boss of your home heating and saving on energy bills

• Getting to grips with hybrids

• Hearing about heat pumps

• The benefits of home air conditioning

• Hello to hydrogen

Savvy Series presenter Angellica Bell said: “Many of us don’t realise just how energy-intensive our homes can be, and as a result, how much it can chip away at our finances. By making a few quick changes to the way we set-up our homes, it can really make a huge difference. I hope the Savvy Series helps homeowners make savings on their energy bills as well as guide them to making greener heating choices.”

Martyn Bridges, Director of Technical Services at Worcester Bosch, said: “The cost-of-living crisis shows no signs of stopping, leaving millions of us with rising household bills – and with that, mounting pressures enforcing us to consider cut-backs in all parts of our lives to cope.

“We’re delighted to have Angellica as the face of our Savvy Series. Her involvement will help us reach more homeowners with both energysaving tips and the right guidance to help them transition to the greener heating future.”

Richard Lloyd, a Cannock-based installer, said: “Future home heating solutions – what they are, and how they can help – is something customers often ask us about. The landscape is complex for those unfamiliar with the various options, and it can be quite scary to get your head around.

“This series will really support the industry in communicating to customers in new, engaging and simplistic terms not only what the different types of technologies are, but how customers can benefit from each one. This’ll be a great tool we can reference in our customer communications.”

To find out more about Worcester Bosch’s new Savvy Series, please visit their website here.

Fronted by TV presenter and consumer champion Angellica Bell, the content series is designed to provide guidance to homeowners on greener home heating options

Despite the pandemic, house prices grew steadily over the last few years. Yet as inflation surged to a 41 year high of 11% in late 2022, and The Bank of England base rate followed suit to reach 4.5% by March 2023, house prices have fallen. Higher inflation tends to result in slower house price growth and it can make it harder to secure a mortgage. Average house prices currently sit at £296,000, which is less than this time last year.

The cost per square meter of floorspace across the country varies wildly. In 2020 Which? reported that the North East of England offered the most affordable prices at £1,568 per square meter. The East of England was the third most expensive at £3,435 per m2, whilst the South East was over £4,000 per m2 and Greater London was the most expensive at £6,219 per m2 Since then, prices have increased with latest estimates suggesting that average prices across London are £7,000 per m2

In the most affluent boroughs of London such as Kensington and Chelsea where average house prices top £1.4m, just one square meter of floorspace is worth an eye-watering £28,500. Even in Camden (with average house prices of around £800,000) it is £16,000 per m2. To make things worse in London, the comparatively small abodes offer an average internal space of just 93m2 – which means that space really is at a premium not only in terms of cost but also availability.

Pocket doors slide into a cavity, or pocket in the wall. The door panel is top-hung from a track that allows the door to slide from side to side.

ECLISSE systems are made from galvanised steel and aluminium. They have been comprehensively tested for reliability and robustness making them suitable for use anywhere in the home including the bathroom.

ECLISSE offer pocket systems to suit 10 standard UK door sizes, the three standard Irish standard door sizes, plus bespoke sizes. They can be used with your choice of timber doors as well as with a wide range of fully tempered frameless glass doors, to add a touch of elegance.

ECLISSE pocket door systems are an excellent way to create more usable space that would otherwise be taken up by the arc of the door, as well as the wall space behind. As well as enhancing the flow of the property

this freeing up of otherwise unusable space also offers opportunities for freestanding shelving or artwork. Without a door encroaching into the room, you will also be able to move furniture closer to the edges – creating more usable space in the centre which will make the room feel more spacious.

The functional nature, but creative designs, of pocket doors also makes them an excellent choice for smaller rooms such as utility rooms, ensuites or washrooms –for which you might also choose a glazed door to allow in extra light and add a touch of elegance. Additionally, anyone that works from home might consider using a pocket door to partition off a workstation or home office allowing them to create a sense of division between workspace and personal space.

Telescopic pocket doors, can be used for wider openings, and are a great way to make more inventive use of open plan space allowing areas to be divided off when required such as between a lounge and a dining room, or to partition off a room when guests are in the home allowing for personal space.

Apartments and luxury flats can be very restricted in size making it vital that every square meter is utilised to its maximum potential. By installing pocket doors instead of traditional hinged doors 8% of usable space can be gained in a 100m2 layout. In Kensington and Chelsea that equates to a whopping £228,000, whilst even in North East England where property prices are cheapest it still adds up to a very bankable £12,544 – a fantastic return on the comparatively small investment of installing pocket doors.

To find out how you can make the most of your space and add refinement by using ECLISSE pocket door systems, plus how to correctly size and install them, call now to speak to one of our friendly product experts in our UK-based Customer Service Team.

0333 5770828

info@eclisse.co.uk

www.eclisse.co.uk

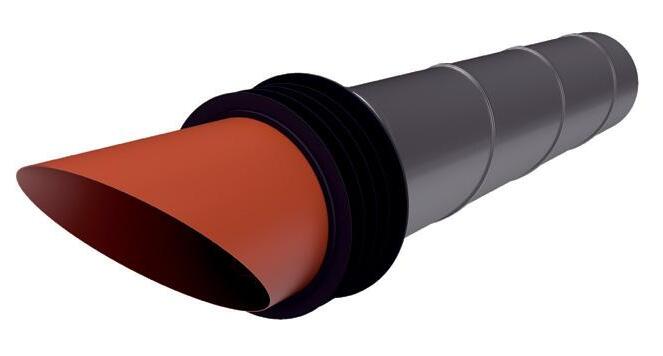

Titon has extended the market leading Titon FireSafe® range by introducing the new non-combustible Titon FireSafe® 100mm Push Through Pull Kit that is ideal for Social Housing, new build, and refurb residential applications.

The Titon FireSafe® 100mm Push Through Pull Kit is a fire rated terminal and ducting kit that has been designed specifically for applications that need to meet be non-combustible, as set out in Approved Document B (fire safety) Volume 1: Dwellings, 2019 edition.

Titon FireSafe® 100mm Push Through Pull Kit is performance tested to BS EN13141-2:2010 and corrosion salt sprayed BS EN ISO 9227:2012. Constructed from 0.6mm electrogalvanized sheet steel (A1) and polyester powder coated (terminal only) to classification A2-s1, d0.

The Titon FireSafe® 100mm Push Through Pull Kit has been developed to work with Titon’s energy efficient constant flow Titon Ultimate® dMEV, which has been tested in accordance with the latest SAP10 dMEV (Consp10) test standard introduced

on 15th June 2022. The Titon FireSafe® 100mm Push Through Pull Kit is also compatible with the vast majority of 100mm fans on the market.

The new Titon FireSafe® 100mm Push Through Pull Kit is easy to install and cut down to a desired length, it’s perfect for onsite installation when current systems need to be changed or new ones need to be installed.

Speaking about the introduction Roy Byom, Titon’s Social Housing Manager stated, ‘This product will enable installers with achieving a fire rated through the wall duct application, from ground floor to properties at higher levels’

The new product comes in Terracotta and White, with special paint finishes available on request, depending on the quantity required.

Titon has extended its market leading Titon FireSafe® range by adding the new Titon FireSafe® 100mm Push Through Wall Kit, a superior circular fire safe terminal that assists in removing the dangers offered by plastic grilles and ducting in mechanical ventilation systems.

The Titon FireSafe® 100mm Push Through Wall Kit offers low resistance to airflow, but high resistance to fire as set out in Approved Document B (fire safety) volume 1: Dwellings, 2019 edition. Ideal for residential new build, refurbishment and social housing applications where mould and condensation cause a major problem.

Ð Easy to install and can be cut to desired length on site

Ð Performance tested to BS EN13141-2:2010

Ð Designed for installation with Titon Ultimate® dMEV

Ð Material 0.6mm electrogalvanized sheet steel, fire class A1 ‘no contribution to fire’

Ð Terminal polyester powder coating meeting EN13501-1 classification A2-s1,d0

Ð Corrosion resistance - salt spray tested to BS EN ISO 9227:2012

With as many as 40,000 stitches, and up to 64 pieces of fabric in a single pair of Snickers Workwear trousers, it’s little wonder they’re built to last and the preferred choice of discerning tradesmen and women.

Ergonomically designed for maximum comfort, freedom of movement and functionality, there’s over 80 different styles and 71 different sizes in the Snickers Workwear Trouser system. So you will always find a pair to suit you. The men’s and women’s Trousers range includes full stretch slim fit styles plus street-smart regular and looser fits throughout the full LiteWork, FlexiWork, RUFFwork and AllroundWork trouser families.

With at least 16 pocket compartments integral to every pair complimented by a choice of 8 different Kneepads, Snickers Workwear knows that your work trousers have to do a lot of things. Keep you comfortable, carry

your essentials, and protect your knees and legs from debris and hazards in the workplace.

So, whatever your trade, wherever you’re working and whatever your sustainability preferences are, you can be sure there is a pair of Snickers Workwear Trousers to suit you.

Getting more information on the Snickers Workwear clothing range is easy. You can call the Helpline on 01484 854788; check out www.snickersworkwear.co.uk and download a digital catalogue or email sales@hultaforsgroup.co.uk

BSH012 BR

• Lace Boot with built-in EN/UKCA standard ankle protection

• Waterproof

• Non-metallic

• Brown cowhide leather upper

• Anti-scuff toe protection

• Sizes 6/40 - 13/47

• Suggested sector use: Agriculture, Construction, Engineering, Manufacturing, Maintenance, Trades, Utilities

SAFETY SPEC

• S3 HRO AN SRC

• Composite toecap

• Non-metallic anti-penetration Nail Stop midsole

• Antistatic

• Ankle Impact Protection

• Slip resistant - max test

• Heat (300ºC/60 secs) and Oil Resistant Non-marking Rubber Outsole

Go to www.buckbootz.com.

For more product and stocking information call 01382 82 82 00 or email info@buckbootz.com

Approved Supplier Member of

It can be difficult to communicate health and safety accessibly. Scientific research can seem dry or remote, whilst over-emphasising danger is counterproductive. So when we devised our ROPE theory, we opted to focus on both narrative and relatable examples – underpinned by hard science. So what is ROPE?

ROPE breaks down into four interconnected aspects: Rest, Observation, Planning and Empowerment. But to explain these, we reached initially not for stories of workplace failure, but human heroism; in particular, the ascent of Everest.

Paul Verrico has recently launched a new theory he and his team have been working on across the IOSH network. Called ROPE, it rests on medical research around Rest, Observation, Planning and Empowerment

In 1952, Sir Edmund Hillary and Tenzing Norgay were the first climbers confirmed to have reached Everest’s summit. Hillary recorded: “After an hour’s steady going we reached the foot of the most formidable-looking problem on the ridge – a rock step some 40ft high” –now known as the Hillary Step.

A 40ft near-vertical rock face, at around 29,000 feet. This is known as the hardest part of the Nepalside ascent and last real challenge. With a 10,000ft drop to one side and an 8,000ft drop on the other it is no picnic, but the climb is not rated as technically difficult. In fact, under the popular Yosemite system, it is only rated Class 4 –“simple climbing with exposure – a rope is often used.”

Hillary wrote: “The rock itself, smooth and almost holdless, might have been an interesting Sunday afternoon problem for a group of expert rock climbers in the Lake District, but here it was a barrier beyond our feeble strength to overcome… Despite the considerable effort involved, my progress although slow was steady, and as Tenzing paid out the rope I inched my way upwards until I could finally reach over the top of the rock and drag myself out of the crack on to a wide ledge… As I heaved hard on the rope Tenzing wriggled his way up the crack and finally collapsed exhausted at the top like a giant fish when it has just been hauled from the sea after a terrific struggle’ (Hillary and Hunt, 1953).”

In Into Thin Air Jon Krakauer wrote about the fateful 1996 Everest ascent which killed six, including guide Rob Hall. He said: “people’s perceptions of their own abilities are amazingly far off the mark…one teammate, for example, was reduced to a helpless, infantile state by his infirmities and needed extensive help to make it down to the South Col. And yet he doesn’t seem to remember this; his view is that he was just fine, that he didn’t need any help.”

Few experiences are as extreme as climbing Everest, but parallels can be drawn with everyday working life. One demonstration of the dangers of fatigue is the case of Michael Eyres in the UK (EWCA, 2007).

Eyres was paralysed in a road accident, on a day when he’d started working at 3.30am. He drove 111 miles to fit a kitchen with a colleague. At 2.30pm they were called to another job 122 miles away. Driving back to the office that evening 20-year-old Eyres fell asleep at the wheel and crashed. Lord Justice Ward, at the Court of Appeal, ruled that he was ‘in that predicament because his employers had put him there’.

Van Dongen et al (2003) published research on ‘the cumulative cost of additional wakefulness: doseresponse effects on neurobehavioral

functions and sleep physiology from chronic sleep restriction and total sleep deprivation’.

They found even moderate sleep loss seriously impairs functions in the otherwise healthy. Worse, subjects were unaware of increasing cognitive defects – in other words, when we are sleep-deprived we don’t notice the effects.

Fatigue prevents us performing safely – and, like Hillary’s climb, otherwise-simple tasks become near-impossible.

Altitude sickness is an emergency demanding immediate descent and medical attention. But climbing downhill is actually harder than going up. Likewise, employees may show signs of ‘altitude sickness’ when under too much stress – and may need help ‘down the mountain’, eg reducing responsibilities. But this can be hard if they fear losing status. Yet it may be vital for their safety –and others’.

During the pandemic, a foodproduction company promoted an experienced operator. But with colleagues shielding she was also working overtime. She had received all relevant safety training and was rated excellent – but management didn’t check in on her. One shift she didn’t properly supervise equipment and a junior colleagues was seriously injured. Her lapse was down to stress; the company hadn’t monitored her overtime and she’d burned out. Continuous observation could have prevented this.

Rob Hall made a fatal mistake in the 1996 Everest ascent. He had previously watched another party turn back, and told Krakauer: “To turn around that close to the summit… that showed incredibly good judgement on young Göran’s [Kropp]

part. I’m impressed – considerably more impressed, actually, than if he’d continued climbing and made the top.” Kropp had risk-assessed the danger, and “stopped work”.

But Hall’s team failed to stick to the agreed plan of a “turnaround time” of 2pm. Some didn’t reach the summit until after 4, and the results were catastrophic.

It is important to understand that people often make seeminglyrational decisions because the situation appears controlled. But if environmental change is slow, they may not notice or react appropriately.

Proper planning should therefore anticipate environmental change, using forward-looking data. Purely reactive risk-management can itself expose employees to risk.

As Krakauer began his descent he spotted wispy clouds around other mountain peaks. A teammate who was also a pilot later told him these were often “crowns of robust thunderheads” – but this potentially life-saving information was never

shared further. Team members were not empowered to give informed views.

Our theory draws from Conklin and Hollnagel, - “if Planning involves ensuring that workers have the ability ‘to be able to do work in a varying and unpredictable world’ (Conklin, 2017) or ‘having the capacity to make things go well’ (Hollnagel, 2014) then Empowerment is about giving local teams the ability to speak up and act in accordance with their training, rather than sticking by rote to policies that were made off-site for work as an imagined task rather than for work as done.”

Empowerment culture is critical. Leaders must encourage open discussion, and encourage workers to constructively question processes – this can help reduce incidents and increase productivity.

Sir Edmund Hillary conquered the ferocious conditions on Everest by modelling safety behaviours from which we can all learn. A rope is part of the fundamental equipment for successful climbers. Likewise, we believe ROPE is a key strategy for senior managers and safety practitioners to navigate the high altitude of the workplace safely.

DEWALT, a Stanley Black & Decker (NYSE: SWK) brand and leader in total jobsite solutions, today announced a new 20V MAX* Brushless 1/2 in. Drill/Driver (DCD793) and Hammer Drill (DCD798). Engineered for optimal speed, control and precision in a multitude of jobsite applications, the drills each feature a two-speed transmission, a variable speed trigger and a 1/2-in. metal ratcheting chuck.

Designed with an efficient brushless motor and 2 in. shorter in length** (compared to the DCD771) at 6.38 inches, the 20V MAX* Brushless 1/2 in. Drill/Driver delivers up to 16% more power*** (compared to

the DCD771) and can be used for a variety of applications. The 20V MAX* Brushless 1/2 in. Hammer Drill features an integrated hammer mode function and is 1 in. shorter in length† at only 6.93 in. (tool head length only). This hammer drill quickly drills into materials, including wood, masonry and metal, with up to 28,050 bpm in hammer mode for masonry drilling. Each tool produces 404 unit watts out of power†† with up to 1,650 RPM (noload) and features an on-tool LED.

The 20V MAX* Brushless 1/2 in. Drill/Driver and 20V MAX* Brushless 1/2 in. Hammer Drill will be available in March as bare tools and in kitted options. The kitted options will include a DCB203 battery and charger (for the bare tool options, the battery and charger will be sold separately).

To learn more about these DEWALT products, please visit: www.dewalt.com.

* Maximum initial battery voltage (measured without a workload) is 20 volts. Nominal voltage is 18.

**The DCD793 is over 2 in. shorter in length compared to DCD771, tool head length only.

***The DEWALT DCD793 with a DEWALT DCB203 battery (sold separately) provides up to 16% More Power vs. DEWALT DCD771 with a DEWALT DCB203 battery (sold separately).

† DCD798 is over 1 in. shorter in length compared to DCD778, tool head length only.

†† Based on using DCB203 battery

DEWALT, a Stanley Black & Decker (NYSE: SWK) brand and leader in total jobsite solutions announced its new DEWALT 20V MAX* Compact Press Tool (DCE210) and several new jaw and ring press attachments for plumbers, pipefitters, and HVACR technicians. The new press tool provides broad press versatility in a compact design that allows for trouble-free pressing in small spaces. “This new tool represents the next generation of pressing technology from DEWALT,” said Justin Burke, Product Manager, Stanley Black & Decker. “DEWALT is maximizing installation capabilities with a compact press platform so tradespeople can complete jobs with minimal tools at a level of quality and performance expected from professionals.”

In addition to the compact press tool itself – which boasts a compact one-handed design, press tracking software, and TOOL CONNECT™ software – the attachments for pressing pipes larger than 1-1/4 in. expands the tool’s capabilities even further making it a valuable asset for the tradesperson.

Featuring a lightweight inline design, the press tool is ideal for work in overhead and one-handed press applications. Onboard design features include a 180-degree rotating head allowing for optimal pressing angles, an LED light, Crimp Connect® software

to generate data from successful press cycles, as well as TOOL CONNECT™ software to easily connect to your tool via the TOOL CONNECT™ platform.

The DCE210D2K kit will include 1/2 in. – 1-1/4 in. Compact CTS (copper tube size) jaws for connecting copper and stainless-steel CTS piping systems. In addition to the 20V MAX* Compact Press Tool and CTS jaws, DEWALT will offer additional press jaws, rings, and an actuator for IPS (iron pipe size) carbon steel pipe, larger CTS pipe, and an ACR press system (sold separately).

Each ring and jaw is manufactured to achieve optimal distribution of force while maintaining a high level of durability throughout the life of the product. A gray galvanized coating finish helps prevent rust buildup and corrosion.

Look for more information regarding the DEWALT 20V MAX* Compact Press Tool this summer.

To learn more about DEWALT products, please visit: dewalt.com

* Maximum initial battery voltage (measured without a workload) is 20 volts. Nominal voltage is 18.

New press tool tackles several pressing applications across materials, all in a compact design for work in tight spaces

M12 FUEL™ is engineered for the most demanding tradesmen in the world.

M12 FUEL™ delivers unrivaled performance in a compact structure and features three MILWAUKEE® exclusive innovations – the POWERSTATE™ Brushless Motor, REDLITHIUM™ Battery Pack and REDLINK PLUS™ Intelligence Hardware and Software – that deliver unmatched power, run-time and durability.

Simply put, M12 FUEL™ is best-in-class, full-circle technology that drives, protects and powers your cordless tools beyond the rest.

TM

MORE POWER LONGER MOTOR LIFE

MORE RUN-TIME

1

POWERSTATE BRUSHLESS MOTOR

■ MILWAUKEE Built Brushless Motor

■ Outperforms All Leading Competitors

■ Up to 10X Longer Motor Life

2 REDLINK PLUS ™ INTELLIGENCE

■ Most Advanced Electronic System on the Market for Maximum Performance

■ Total System Communication with Overload Protection Increases Tool Life

■ Built-In Fuel Gauge Displays Remaining Charge

3

REDLITHIUM™

CP2.0 & XC4.0

BATTERY PACKS

■ Up to 2X More Run-Time

■ Up to 20% More Power

■ Over 2X More Recharges than Leading Competitors

■ Operates Below -18°C / 0°F

PORTABLE PRODUCTIVITY TRADE FOCUSED SYSTEM WIDE

FEIN, the leading power tools and accessories manufacturer, has announced a new grinding product range, revealing new safety and performance features to meet the latest user needs.

Following the launch, power tool operators working across disciplines will be able to choose from the extended range of over 40 grinding tools, with corded and cordless options available. The range has been developed as a result of first-hand industry feedback, to provide a product suitable for every application, for example, angle grinding, die grinding and stainless-steel processing.

The portfolio includes the launch of the CG 15 compact angle grinder - the first of its class to feature a fully encapsulated, brushless FEIN PowerDrive motor. The tool’s powerful, yet efficient, 1500W motor and superior power-to-weight ratio allow user to operate with superior efficiency and endurance. Furthermore, the angle grinder has been designed with cost and longevity considerations in mind, it requires fewer wearing parts, has longer service intervals and incurs lower maintenance costs throughout its life.

The CG 15 grinder also offers users extensive protection through a variety of safety features which were driven by user feedback, including restart protection, kick back check, jam monitoring and an efficient brake which brings the tool to a stop in less than 2 seconds.

Safety remains an important topic in the industry, with grinding tools classified by RoSPA (The Royal Society for the Prevention of Accidents) as one of the most dangerous tools, with 5,400 injuries recorded annually. FEIN’s Protago high-safety angle grinder, featured in the grinding tool range, was created in collaboration to set new safety standards in the industry. Bouygues, the construction giant, had previously banned the use of compact angle grinders following a serious accident, however, together

with FEIN, the teams developed the Protago with safety features that almost fully eliminate the serious risks associated with improper operation.

The Protago, in addition to 9 other tools in this launch, is now available on the 18v AMPShare battery platform, powered by Bosch. The multi-brand shared system allows users to power over 200 different tools from over 30 brands with just one AMPShare battery, eliminating the costly requirement to purchase a specific battery type per tool.

Speaking on the grinder range extension, Andy Mills, managing director at FEIN UK shared: “Our grinder portfolio was developed as

a result of our application-based approach at FEIN, which means that we are out in the industry meeting users to gain a detailed understanding of their working environments and the challenges they are facing to ensure that our products are meeting their needs. By continuing this approach with our grinding tools and this development, we are really proud to be offering users the right product for every application.”

“This grinding tool launch will also see an additional 10 FEIN products becoming available on AMPShare. We are really excited to see our customers responses to this development because we know how the shared battery system makes

their lives easier and enables them the freedom to pick the best tool for the job – and we will be continuing to make our products available on AMPShare throughout the year.”

FEIN has a rich history in providing application-based solutions for end-users across metalworking sectors. With over 150 years’ experience in manufacturing power tools, FEIN is research and innovation-led, continuing to meet the industry’s needs with new product features year after year.

To find out more about the FEIN’s range of grinding tools, visit fein.com/en_uk/.

In the fight against the plastics greenwash across the industry, housing and care provider, GreenSquareAccord, has successfully completed the build of virtually plastic free homes. The project demonstrated the ‘art of the possible’ in living plastic free and provided learnings to inspire future developments.

The first of its kind in Europe, the CHARM (Circular Housing Asset Renovation & Management) project saw the construction of a block of 12 one-bedroom flats in a former factory car park in Redditch. Owned and built by GreenSquareAccord and developed through collaboration with Redditch Borough Council, the ground-breaking property is part of the CHARM partnership, made up of representatives from four European countries: the UK, France, Belgium and the Netherlands. Now complete, the apartments are managed by Redditch Cooperative Homes.

The homes incorporated 125 tonnes of recycled materials into the construction of the block, saving these materials from being landfilled. Alongside wide recycling use, another key element to the sustainable construction project included reducing the amount of materials used in the build.

What many of us don’t realise, is just how much plastic usage goes into building a house or developing a property. Thanks to the resourceful planning, the CHARM development saves 65 tonnes per dwelling of material use.

Whilst it is impossible to achieve a fully plastic free construction project in this current climate, the CHARM property used 85% less plastic in its construction compared to usual projects of its size.

Due to the innovative materials used, and labour involved, the costs of the

development were significantly higher than those of a ‘standard’ development. However, we have no choice but to continue to innovate construction materials and methods to advance progress in the sector, in turn, making developments of this kind more affordable over the long term.

By making many thoughtful substitutions away from plastic, the CHARM project has set the standard for future construction projects.

The shell of the property was built from timber panels from GreenSquareAccord’s award-winning, low carbon manufacturing facility, LoCaL Homes.

The pipes in the development, that would traditionally be made of plastic, were replaced with copper and provide all twelve flats with water. Each boiler has also been fitted with copper pipes to heat the flats. Copper has also been used for the electrical wiring in the dozen flats, showcasing its wide versatility.

As one of the most sustainable materials in construction, copper is infinitely recyclable, meaning it can be used over and over without any loss in performance or properties. In fact, at least 65% of all copper mined remains in circulation - and around half of Europe’s copper demand is currently being met by other recycled materials.

Instead of plastic cladding, the CHARM properties feature cementitious board. The board contains minimal traces of plastic as a binding agent, unfortunately exemplifying the impossibility of an entirely plastic free project. Despite originally intending to install timber as a cladding material,

The UK construction industry’s harmful impact on the environment is well documented, with plastics and synthetic materials at the forefront of the damage.

planners elected cementitious board instead in order to make the building as fire safe as possible.

Plastic need was also eliminated in the bathroom, being replaced by ceramics, while timber was used to create kitchen units. Where plastic is typically present in window frames, the CHARM project installed aluminium instead.

Other swaps in the build to reduce synthetic materials include mineral insulated copper cable in the internal electrical power circuits, foam glass floor insulation, flooring using sisal and linoleum, and copper pipework with welded joints.

Throughout the period of the development construction, some surprising materials were found to contain plastic. These included paint, sealant, and insulation, meaning alternative options had to be sourced. Developers identified plastic free paints using natural ingredients like graphene and lime paint.

The CHARM team had to make some other compromises in the material

choices. For example, plastic intumescent strips had to be installed to ensure fire safety. What’s more, utility companies offer standard meters without a plastic free option. Despite these setbacks, the project still managed to save 65 tonnes of material per residence.

The CHARM project not only created 12 affordable homes for members of the community, but it also reduced the environmental impact of the construction.

Setting a new standard and ‘art of the possible’ example of sustainability for the construction sector is critical given the industry’s role in plastic pollution.

In the UK, the construction industry accounts for 19% of all plastic waste across the UK, which is the equivalent to approximately 50,000 tonnes, or five times the weight of the Eiffel Tower.

Of the 50,000 tonnes, it’s estimated that 20,000 tonnes are sent straight to landfill to be incinerated, releasing toxic fumes and carbon emissions.

Could developments like the CHARM project indicate the future of construction? The answer is simple, yes. Reducing plastic waste by the mass is of critical importance and the CHARM project is paving the way for future construction projects.

After being recognised for its potential, the project received £1.2m EU funding from the Interreg NorthWest Europe funding partnership, opening the way for future projects and development.

Now, the United Nations are aiming to sign an agreement which would see the elimination of plastic pollution with legally binding enforcement. Under this directive, it’s likely projects such as CHARM virtually plastic free homes, would become increasingly more present in our modern world.

Reducing plastic and synthetic materials in building projects and replacing them with more sustainable options, such as copper, is the only future of the construction industry.

To find out more about sustainability in the built environment and how copper can support a plastic free future, please visit: www.cuspuk.com

Increasing environmental responsibilities and sustainability targets are driving the construction industries ongoing needs for cost effective, easy to use solutions for dealing with wastewater onsite. Sites need quick replies, concise information, simple transactions and deliveries without hassle. For the past 9 years Kelly Tanks has enjoyed providing all of these whilst building a large customer base, expanding their team and facilities, and responding to customer demand with innovative new products year on year.

KEY BENEFITS YOU CAN EXPECT FROM KELLY TANKS EQUIPMENT:

• Designed to meet the rigours of the construction industry

• Fast and Simple to Set up

• Small Footprint equipment available

• Units can be linked to handle range of flows, pumps sizes & particle characteristics

• Easy to Maintain and Monitor equipment

• Reduce off-site disposal costs

• Reduce risk of pollution

• Easy to use equipment

Mark, Kelly and team KT provide a selection of Water Treatment and Concrete Washout Solutions for hire or purchase. Their popularity and proven track record is a result of providing the kit you need, in the manner you want, at a price you’re happy with. Match this with their eager to please attitudes and above and beyond aftercare and its easy to see why their customers keep returning.

Various concrete washout solutions, to allow concrete trucks and equipment to be washed off safely onsite, including closed loop washwater recycling, washwater filtration sacks, pH correction, robust washout trays and skip washouts.

Self contained units or full systems to separate and treat wastewater and Water Quality Monitoring Systems including Settlement

& lamella Tanks, flocculation and pH adjustment dosing, pH/TSS/ Turbidity remote monitoring, auto de-sludging.

Water Treatment Solutions for high alkaline hydrodemolition waste, used to retain solids and automatically correct pH.

Automated daily prevention for concrete drum build-up. Using recycled or fresh water the highly efficient electric driven pump combined with the water jets at the tip of the boom remove the days build up before it hardens. DrumBlaster Build-up Control Technology incorporates an extendable boom with a rotating head allowing the mixer drum to remain stationary.

Tailor made solutions to suit all applications. Whether an idea or

a full plan, we can accommodate. We can also tweak our existing products and/or have them sprayed in your corporate colours.

Complete onsite Water Management. Consultancy, Testing, Supply, Install and Maintenance.

Kelly Tanks take pride in the quality of their products and have a classy approach to customer service making them a real pleasure to deal with. If you weren’t able to experience their hospitality for yourself at Hillhead this year, you can catch them again at the Contamination Expo, Birmingham NEC in September. If you need anything in the meantime give them a call on 01889 508944, email info@kellytanks.co.uk or check out their website www.kellytanks.co.uk.

More than 2,000 lots, ranging from small tools up to mid-size excavators, will go under the hammer at Lambourn Business Park on the 19th and 20th April.

The inventory includes 150 excavators (predominantly Kubota) and 124 site dumpers as well as tractors, loaders, telehandlers, fork lifts, asphalt equipment, compactors/rollers, generators and buckets/attachments.

The auction is being managed by Euro Auctions, whose sales

manager David Betts said: “It is not often an inventory like this comes to market. The business has looked after its inventory very, very well. There are some very attractive late, low hours machines on offer and I think bidding will be strong.”

Owner/director Jonathan Stevens said: “Since 1997 the unique ethos of this business has been to provide all the plant and tool hire needs in one place – from small drills to 14-tonne excavators. We have worked in partnership with our customers, no

matter how big or small, and they have relied on us to get what they need with the minimum of hassle. We have used auctions to regularly dispose of stock and update our fleet to provide the latest in mini diggers, excavators, dumpers, telehandlers and consistently refresh all our listed product range. We’re very familiar with auctions and know it’s the best way to sell this volume of stock and get the best return, hence we are disposing of our current stock in this manner.”

Autonomous Solutions, Inc. (ASI), a leading provider of industrial ground vehicle automation, has announced its vision for its subsidiary ASI Construction, which aims to provide autonomous solutions that empower end users to become the leading producers in their respective applications. As a response to market demands, ASI’s primary focus is end users with production operations who can leverage ASI’s market-leading Mobius® software.

ASI is currently seeking customers who are ready to scale autonomy in their construction loading and haulage applications. The company aims to deliver high-quality autonomous installations that enable customers to transform their production operations and unlock their full potential, similar to the unprecedented success ASI has proven with its customer, Roy Hill, in the mining industry. The company is committed to this vision and is open to investment partners who are passionate about making positive change in the construction industry through developing the most innovative technology offerings.

“At ASI, we believe that our autonomous solutions are the key to unlocking the future of production; it’s a journey of transformation worth taking,” said Bret Turpin, Product Manager of ASI Construction. “That’s why we’re partnering with end users to make our vision a reality, and we’re excited to help them become the leading producers in their industries.”

ASI’s autonomous solutions have already proven their worth in the mining industry, and the company is eager to replicate this success in the construction industry. The company’s innovative solutions can help end users optimize their production processes, reduce operating costs, and enhance safety, while providing real-time data to support better operational decision-making.

For more information on ASI’s autonomous solutions, please visit its website go.asirobots.com/en/revolutionize-construction or contact its team directly.

“It is important for us to continuing advancing our company over the years, and we’re pleased to have had Lloyds Bank by our side since 2012 to support our progress. We are looking forward to the new developments that the updated machine will bring with it.”

Danial Helsby, Relationship Manager for Lloyds Bank, said: “We are proud to be supporting Cohesion Piling with their endeavour to increase the reliability and efficiency of their work, thereby maintaining higher turnover rates.”

Gregg Menzies, Associate Director, Asset Finance for Lloyds Bank, said: “At Lloyds Bank we are keen to support the CapEx plans of North West businesses via a full range of asset funding options and the construction industry continues to be a strong sector for us.

Cohesion Piling, established in 2012, specialises in piled foundation and underpinning work across both the public and private sectors. The business installs concrete or steel piling to support structures around the UK ranging from standard housing and cinemas to tower blocks and office developments.

Lloyds Bank has a long-standing relationship with the company, having supported them with an overdraft facility when they were first putting together a business plan in 2012, and has been working with them ever since.

The business has grown since then and has seen a steady increase in demand for its services postpandemic. The hire purchase funding from Lloyds Bank of £500,000 has allowed Cohesion Piling to invest in new machinery, which will increase efficiency and reliability allowing it to grow the business even further.

The durability of the new CFA Piling Machine makes it more effective, and it also boasts a bigger rig which allows the piles to get in quicker, making the system more economical. The machine is currently being debuted in Blackpool for four weeks before moving on to its next site.

Next year, Cohesion Piling is looking to develop further by replacing and adding to their fleet of four. This includes machinery for new, lower carbon products, eliminating steel reinforcement and minimising site waste. They are also keen to grow in size and are partnering with Manchester Building College to recruit graduates for work experience.

Gary Kime, manager at Cohesion Piling said: “Cohesion Piling is currently experiencing high demand, and we are excited to continue growing as an organisation and be able to serve our customers with increased proficiency.

“We recognise how important it is to be by the side of businesses during this time, and Cohesion Piling is a standout example of a company whose asset funding needs we have long supported. We are pleased to see the company grow over the years, and look forward to seeing what they do next.”

A Rochdale-based piling company is set to increase its efficiency and reliability thanks to a half a million pound investment in new machinery supported by Lloyds Bank.

Tradesmen across the UK are being encouraged to get hands on to ‘check their tools’ are in good working order by leading builder’s merchants MKM to mark April’s Testicular Cancer Awareness Month.

Following on from the successful launch of their ‘Check Your Tools’ campaign last year, MKM has once again partnered with charity The OddBalls Foundation to increase awareness and knowledge around testicular self-examination, while raising funds and helping to break down barriers to encourage more open conversations amongst men.

This marks the second year of the partnership between MKM and The OddBalls Foundation, with charity representatives set to host selfexamination workshops at several of the builders merchant’s 100 plus branches across the UK.

Testicular cancer is the most commonly occurring cancer in men aged 15-49, with 2,300 new cases diagnosed annually. Despite being one of the most treatable forms of cancer in men if caught early enough, the illness still claims an average of 60 lives in the UK each year.

Nicola Ollett, Head of Marketing at MKM, said: “As April marks Testicular Cancer Awareness Month, we are encouraging our branches and customers to grab the opportunity to do some good and potentially save some lives along the way.

“One of the biggest issues surrounding self-examination is a lack of knowledge as to what to look out for, but a self-exam only takes a minute and being familiar with the look, feel and shape of your testicles can help you spot any abnormalities early.

“Testicular cancer is highly treatable if caught early enough, so regular self-examination really does make all the difference.

“Last year’s campaign was a huge success, with Branch Directors and customers

sharing positive feedback on The OddBalls Foundation workshops – this year we are looking to provide even greater support for our customers and the work of the The OddBalls Foundation.

“It’s all about communication and knowledge – some of our customers might turn a shade of red in the face when we tell them how important it is to check their tools but this is a message we are 100% behind and we won’t shy away from a potentially awkward conversation if it means we are raising awareness.”

The OddBalls Foundation was founded in 2015 and educates people on the basics of Testicular Cancer, encouraging regular self-checking to promote early diagnosis; ultimately, saving lives.

Kieran Kelly, Foundation Manager at The OddBalls Foundation, said: “Working with MKM last year was fantastic in terms of spreading the word of how important self-examination can be.

“Aside from being proactive and positive with their support, their social values align with ours and we are really excited to launch Check Your Tools for 2023.”

At the end of February, Prime Minister Rishi Sunak announced ‘The Windsor Framework: A new way forward’ as a EU trade deal breakthrough, brokered with French President Macron.

As is usual with such announcements, the details are to follow shortly. On the face of it, it’s a big, good news story for the UK and Northern Ireland (NI) and it got a cautious but positive reception in GB, and in Dublin, and a mixed reception from politicians in NI.

On the 22nd March the agreement passed its first reading in Parliament, unhindered by what turned out to be limited opposition from a section of the Tory party led by former Prime Ministers Boris Johnson and Liz Truss.

But, on the basis of what they’d read and heard, how did those directly affected, builders’ merchants in Northern Ireland see it?

To find out, MRA Research added four questions to its Builders’ Merchants Monthly Omnibus Survey on the 1st and 2nd March, immediately after the Northern Ireland Protocol & Windsor Framework was announced on 27th February.

A representative sample of 44 NI builders’ merchants were asked their views on the agreement, which has been presented by the government as a ‘new way forward for a prosperous, stable future for Northern Ireland.’

Asked how positive they were about the deal from what they’d heard so far, over half (52%) were in favour of it. Just over one in 10 (11%) of responses were negative, but more than a third (37%) were neither for nor against.

Asked how confident they felt that the Windsor Framework would provide the stability and certainty business was seeking, one in two merchants

were confident that would be the case. But one in six were not at all confident. And more than half felt the agreement would leave their business better placed to deal with the economic challenges that lie ahead. But, 46% felt there would be no difference.

Half the merchants interviewed thought the EU trade deal was likely to stimulate growth in construction.

When asked about their overall response to the agreement, 54% of merchants were in favour of it.

MRA Research also asked Builders Merchant Building Index (BMBI) Experts for their thoughts on the deal. The BMBI is a monthly index of builders’ merchant sales, and the most reliable, up-to-date measure of Repair, Maintenance, and Improvement (RMI) activity in the UK.

Mathew Whitehouse, Marketing Director at Bostik and BMBI’s Expert for Adhesives & Sealants, said: “The Windsor Framework is not quite as we were pre-Brexit, but the idea of a dedicated channel for goods only heading to NI makes absolute sense, making it so much easier and quicker with the removal of the administrative burden currently in place. Sense at last prevails, assuming it’s ratified by MPs and the devolved government in Belfast.”

BMBI’s Expert for Fasteners & Fixings, Ian Doherty, Chief Executive at Hexstone, and the Owlett-Jaton brand, disagreed: “Although we have not seen the detail of how exactly processes will change, I believe the Windsor Framework will have little impact on fastener and fixings sales to NI. The major disruption to this trade was caused by the imposition by the EU of Anti-Dumping Duties (ADD) on Chinese manufactured products.

On a scale of 1 to 10 where 1 is very negative and 10 very positive, how psotivie are you about what you have heard so far about the deal?

Scale:

1 (Very Negative) to 4

5 to 6

7 to 10 (Very Positive)

Base: 44 MRA Research 2023

“I would expect that these duties will be unchanged by the Windsor Framework and that products will still be deemed to be at risk of moving into the Republic of Ireland and therefore will be red channel.”

Kevin Morgan, Group Commercial Director of The Crystal Group and BMBI’s Expert for PVC-U Windows & Doors, said: “The new proposals solve the issue of the protocol and will reduce problematic checks and controls - for us and our industry this potentially unlocks more supplier opportunities in Northern Ireland – noticeably for Crystal-Direct it has opportunities through its bigger retail partnerships who operate in the whole of the UK with the same unified prices.”

Some BMBI Experts are waiting to see the detail of the deal before commenting while others are not greatly involved in the NI market.

Transport for London has signed up house builder Barratt London as its joint venture partner to deliver a 900-flats scheme alongside Tube train tracks at Bollo Lane in Acton.

Under the deal Britain’s biggest house builder will also be in line to deliver other scheme on TfL land around the capital.

The site in Bollo Lane received the planning go-ahead back in January 2021 and will provide 50 per cent affordable housing.

The development will be delivered in three phases with the first phase comprising 195 build to rent homes, the second phase delivering around 450 homes and a third phase delivering around 250 homes.

Further land to the north in Acton, which could be incorporated into the partnership, could deliver a new facility for the London Transport Museum together with a further 800 homes.

As well as delivering new homes and public realm improvements, both TfL and Barratt London will seek to deliver new educational and job opportunities for those considering a career in the construction industry, including for those who live locally, through apprenticeships and training programmes.

Gary Ennis, Regional Managing Director of Barratt London & Southern Regions, said: “We are proud to be continuing our partnership with Transport for London following the success of our joint venture at Blackhorse View, Walthamstow and the start of construction of our site at Wembley Park.”

The partnership forms part of TfL’s wider development activity that

is being taken forward through its wholly owned commercial property company, TTLP, which –alongside new commercial office developments – will see thousands of new homes built on its land across the capital.

TTLP currently has more than 3,750 homes under construction and more than 350 already completed.

May 2023

Health & Safety Update focuses on the importance of safety within occupational and domestic environments – ensuring pro-activity rather than reactivity. We change attitudes towards Health & Safety measures, teaching our associates how to implement guidelines, prevent negligence, prevent injury and preventing the worst case scenario.

www.healthandsafetyupdate.co.uk

About 110 building inspectors and 111 fire-protection officers will be recruited and trained over the next three years, the Department for Levelling Up, Housing and Communities (DLUHC) said.

The move is part of a government effort to boost standards under the post-Grenfell Building Safety Act, which came into force last year.

Since the Grenfell Tower tragedy in 2017, there has been a shortage of building inspectors and fire-safety experts. In 2020, a committee of MPs warned that cladding remediation work was at risk due to a lack of fire-safety experts.

Specialists have been in high demand as developers, builders, freeholders and insurers have sought to understand whether their buildings are safe following widespread fears over combustible cladding and poor construction work, as well as shifting building-safety requirements.

Under the new package, £16.5m will go to Local Authority Building Control (LABC), the not-for-profit body that represents local authority building-control teams in England and Wales, and £26m to England’s Fire and Rescue Services and the National Fire Chiefs Council.

Lorna Stimpson, LABC’s chief executive, said: “Buildingcontrol surveyors are a scarce commodity and so it’s important that we start to invest in this previously underfunded but vital public service role.”

The new building-control inspectors, fire inspectors and fire engineers will work as “local partner regulators” to the Building Safety Regulator (BSR), which was established last year as part of the post-Grenfell measures. The BSR operates within the Health and Safety Executive (HSE).

DLUHC said the new recruits would oversee the “safety and standards of the design, construction and management of higher-risk buildings, as well as strengthening the sector as a whole”.

Lee Rowley, minister for building safety, said: “This taxpayer funding will give additional resource to local regulators, who will support the work of the regulator in making buildings safer.”

Peter Baker, chief inspector of buildings at the HSE, added: “I welcome the work to quickly increase capability and capacity so our regulatory partners can deliver their important roles.”

Latest official figures show that of the 464 high-rise blocks with Grenfell-style aluminium composite material (ACM) cladding, 357 have had remediation work fully completed.

In addition, hundreds of other buildings with dangerous non-ACM cladding, or fire-safety defects, are being worked on, as the building safety crisis drags on.

Now supplying Germany’s leading safety eyewear from INFIELD®

Non prescription safety glasses include:

Traditional eyewear with integrated eye shields

Plastic & metal frames

Contemporary wraparound eyeshields

Over-spectacle & visitor safety spectacles

Full view safety goggles

Face protection visors

Compliant to EN166 safety standards

Prescription eyewear voucher includes:

A full eye & eyesight test

Visual acuity reporting

Single vision or multifocal lenses

Choice of lens including CR39, polycarbonate, and Trivex

A post-Covid, post-Brexit 2022 saw a realignment for many organisations of their purpose and core values, as well as their working practices. Individuals in the workplace are re-assessing work-life balance, and those entering the workforce have different expectations of the contribution and value placed upon their time. This includes how training and development is undertaken and how it will be woven into a meaningful and rewarding career path.