The technicians at MCR safety have developed a range of hand and eye protection to combat hazards faced by workers in the Construction Industry. Here we’re presenting a brief overview of just a few of those products and their specific features and benefits.

Graphene Fibre is the next generation in cut-resistant fibre technology. This new carbonaceous material demonstrates extreme strength yet is lightweight and versatile enough to be used for specialist hand protection.

MCR Safety has introduced CT1071, a new Cut Level ‘E’ safety glove using the Graphene Fibre yarn. It offers a choice of different coatings designed for different tasks and working environments.

The glove has a 15-gauge shell specifically designed to take advantage of the ultra-lightweight nature of the new fibre. It’s a Cut Level ‘E’ yet you’ll find it’s 25% lighter than similar gloves offering this level of extreme protection. The fine construction means it’s supremely comfortable and easy to wear.

As the yarn isn’t blended with any harsh fibres, the high-level cut protection is maintained throughout the life of the glove. No fibre breakage means high durability, high comfort and no skin irritation. The silk-like ‘second skin’ shell follows the contours of your hand and as an additional benefit, it has the ability to draw moisture away from your skin keeping your hands cool and dry all day long.

CT1071NM has a diaphanous Nitrile Micro-Foam coating so you’ll enjoy enhanced grip, even in oily conditions. It’s robust with an extremely high level of durability yet it’s incredibly fine so it won’t impair the lightweight nature of the shell. The coating is also slightly textured to further improve gripping power.

Working outside in the cooler months is very tough on hands. Most sites are open to the elements so cold temperatures, rain and high winds are a constant cause of discomfort. Even if you’re working indoors, it’s still damp and draughty as there’s unlikely to be any heating. It’s important to look after your hands and shield them from these unpleasant factors.

MCR Safety has a number of winter lined gloves in the range, HydraTherm is the most recent addition and it’s ideal for the Construction Industry.

Its a double dipped latex glove designed for cold, damp environments. The double layer of latex provides powerful grip with water repellent properties. It’s soft, flexible and comfortable with good dexterity.

The first smooth layer of latex provides full coverage and this is the moisture barrier. The second layer covers the palm and fingers and has a sandy texture to deliver superior wet and dry grip.

It’s a durable glove that keeps hands warm and dry for indoor or outdoor work. It’s also sanitised to protect against bacteria and reduce odour.

Learn more about HydraTherm

Many tasks in the Construction Industry involve handling of abrasive or sharp materials that come into contact with the arm. It’s important that the correct arm protection is provided for operatives to ensure maximum safety.

There are a number of products available in the MCR Safety range, SL1067NO is a new addition, providing both cut and heat protection.

CT1071PU has Polyurethane coating which is especially form-fitting to enable dexterity, flexibility and great hand agility. It also has a degree of resistant to oils and solvents and will protect against abrasive activities. This coating is designed to enhance durability, improve grip and dexterity so intricate tasks can be performed accurately without removing the glove.

There are no harsh fibres, the glove is sanitised for hygiene and also comes complete with a reinforced area between thumb and forefinger for additional protection.

Learn more about Graphene Fibre Technology.

We Protect People.

This high visibility orange sleeve feels soft against the skin. It’s made using MCR Safety’s latest fibre technology designed for reliable cut protection teamed with comfort and flexibility. The knitted construction allows for great breathability and the adjustable fastening at the top of the arm ensures the optimum fit regardless of bicep dimensions.

It has great protective credentials achieving cut level ‘D’ in the EN388 test and EN407 level 1 contact heat resistance up to 100°C.

Learn more about SL1067NO or view all hand & arm protection.

Lacuna provides extreme cut protection and carries the prestigious Tornado Gloves branding. It’s the latest addition to the Tornado range developed by the technicians at MCR Safety.

This fantastic glove is a cut level 'F' which assures maximum cut-resistance. It’s constructed using a revolutionary new yarn formulation that incorporates high-tensile steel.

The technically blended yarn uses HPPE fibre with high-tensile steel forming a core running through the centre of each strand. The strength comes purely from the partnership of HPPE and steel with absolutely no need for glass fibre which can often cause skin irritation.

It’s flexible, comfortable and dexterous, ideal protection for challenging industrial environments, construction sites and manual handling tasks involving sharp, jagged objects.

The robust glove shell has been developed with three different coating options to cope with different environments and working conditions.

Construction industry eye hazards and many and varied. Flying debris is unavoidable from masonry drilling, angle-grinding or sawing wood. Eye protection is essential, it must be comfortable, wearable and it can also be stylish...

Sennen has wide panoramic coverage, with a one-piece polycarbonate lens and a close ergonomic fit. Soft TPR temples are designed for all-day comfort.

Marazion is a premium sports style eye protector, ideal for work or leisure. The low-profile, streamline design is incredibly lightweight at just 25g. Once again, TPR fittings ensure great comfort and a secure fit.

MCR Safety has a huge range of protective eyewear, goggles and face coverings that you an view on their website. They constantly update their range with the latest protective technology and also to keep in line current eyewear trends.

It’s so convenient when your prescription glasses can also be safety glasses! MCR Safety has a wide selection of prescription safety eyewear all manufactured in their own UK based optical lab. It’s CE and UKCA certified to EN166 plus it carries the British kitemark.

If you’re managing PPE for a team, you can also enjoy a corporate online ordering and management system called EyeTicket

From left to right, the grey palmed glove has Polyurethane coating with a ‘second-skin’ feel. It‘s incredibly dexterous, designed for precision handling tasks in high-risk environments where cut hazards are present. It has extra reinforcement between thumb and forefinger for added protection in that very vulnerable area of the hand.

Learn more about Lacuna CT1073PU

The black palmed glove has a Nitrile Sandy coating for incredible grip, it’s even been described as ‘vice-like’. The sandy surface texture is extremely dependable, especially in oily conditions. As the coating is black in colour, it’s practical for use in workplaces where oil and grime are commonplace.

Learn more about Lacuna CT1073NS

The distinctive blue palmed glove has a Latex coating, designed for powerful grip in damp or wet conditions. It has a crinkled finish that works in a similar way to the natural grip of human skin. It’s also highly efficient in dry environments so the glove is transferable from one work area to another.

Learn more about Lacuna CT1073SL

All three coatings are water repellent and each glove is fully sanitised for hand hygiene.

Learn more about EN388 testing for Cut Resistant Gloves

Latest additions to the range include Logan, with wide lens coverage for panoramic view and maximum protection. And Nevis, which hugs your face with its wrap-around arms and velvety TPR fittings.

It’s wise to wear hand protection at all times, even for every-day tasks. Contour Avenger is a General Handling Hero!

Wear it like a second-skin; work fast and efficiently, maybe even forget it’s on your hand. Enjoy freedom of movement and amazing dexterity yet know you’re protected from the minor knocks and scrapes that happen everyday!

The soft Nitrile coating helps you grip in wet, dry and oily conditions. It’s comfortable for all-day wear and you can switch easily from one task to another without removing the glove. Learn more about Contour Avenger

ecodan.me.uk/rduf3

As a market leader in low carbon heating systems, we help housing developers comply with the changes to Part L of the Building Regulations by specifying Ecodan Air Source Heat Pumps for new build homes.

Our dedicated website pages provide you with support at every one of the seven steps of the RIBA Plan of Work.

ecodan.me.uk/rdum

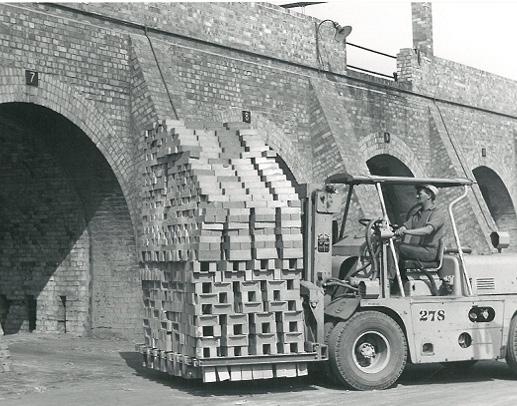

At its Annual Long Service Awards ceremony, held at St. Ermin’s Hotel in London, leading building products manufacturer Forterra celebrated Peterborough employee Keith Coulson, who represents the third-generation of Coulsons to have worked for the company.

Keith began his career in 1972, but has memories of the old brickyard from the age of five.

“We lived in a company house right opposite the brickyard. My father worked there and me and my brother would often play nearby. I even helped hand-set some of the bricks when I was a youngster.

“In fact, my mother also worked in the canteen at Kings Dyke for a while, so it’s always felt like a family company for us.”

When he left school at age 15, Keith started work as a messenger boy. Keith would cycle a 14-mile round trip from his home in Whittlesey to Peterborough each day, delivering messages from yard to yard.

“My grandad, George, had worked as a burner at King’s Dyke and he encouraged my own father to join the company shortly after leaving school. When I left school, my father encouraged me to do the same thing, and it felt like the best thing to do!”

After 12 months of this he became a Works Office relief, which involved him in various administrative tasks at a time when these were still more or less done manually. This was a role he held for the next 11 years across all the Peterborough area offices.

In 1984 Keith moved to the Kings Dyke factory to become a Production Auxiliary, where he developed and expanded his knowledge, learning all the jobs needed for production.

“For a time I worked at Kings Dyke alongside my father and my brother, Roy ‘Chipper’ Coulson, who himself has racked up 46 years at

the company. I enjoyed working with the both of them; it really added to the sense of camaraderie that was at Kings Dyke”

Between 1990 and 2002

Keith remained at Kings Dyke working as a Hand-Setter, building the units of bricks ready to be fired in the kilns.

“I really appreciated the incredible feeling of community there. The area manager would often pop down to the old brickyard and walk around, speaking to each of us, all of whom he knew by name.

“There was a clubhouse at Kings Dyke which everyone would gather in at the end of the day. We’d join darts teams and compete against other clubhouses every now and then – it was a really wonderful time.”

From 2002-2022, Keith has worked at Kings Dyke as a Wicket Man, responsible for the dismantling, erecting and maintenance of the ‘wickets’ or kiln doors, a role which he enjoys immensely.

In an even more impressive development, as of 2022 Keith’s son, Robert, has joined the company, marking four generations of Coulsons at Forterra.

“I’m proud to have worked for the same company for my entire life,” says Keith. “I’ve always been made to feel like a valued member of the team and have always greatly enjoyed the variety of roles I’ve held in the business.

“My wife Anita, whose own father worked at the company, has herself

often worked several cleaning jobs at Kings Dyke. We really have a lot of our family history bound up with the brickyard!”

David Jackson, Production Shift Manager at Forterra, says, “Keith is a very respected and valued member of the team who is always happy to carry out tasks when asked and always gives his best. We’re really proud to have had four generations of a family working here. Our community values and our employees are at the heart of the business, and Keith is a testament to that. I hope to keep him a little longer yet!”

For more information on Forterra, visit www.forterra.co.uk.

First impressions count – including digital ones – which is why AliMet Fabrications has launched a new website to better represent its extensive services as it celebrates its third anniversary.

The company, which specialises in the fabrication of commercial aluminium doors, windows, shopfronts and screen-work along with pressed metal services, has evolved since its first website was created for its 2019 launch.

The new site - www.alimet.co.uk - has an ultramodern design, improved navigation/user journey, and better categorisation of services. It includes a downloads section for customers to obtain technical drawings and data, product brochures and compliance certification. A news section has also been added for company updates and case studies.

Said Steve Marshall, Managing Director of AliMet Fabrications: “We felt it was time for AliMet Fabrications to present a fresh face to the world. The former iteration of the website was put in place when AliMet’s

management team acquired the assets of Midland Glass Solutions. Three years on, the company has evolved, our customer base is better established and the range of products and services that we offer has been extended.

“We have a much clearer idea of our markets and growth trajectory and wanted our online presence to represent this while providing a technical infrastructure to support future developments.”

The company, which is based in Bridgnorth, Shropshire, introduced four key appointments during 2022 and also became a member of the Automatic Door Suppliers Association (ADSA).

For more information about AliMet Fabrications’ services, email: sales@alimet.co.uk or call: 01746 761474.

Effective garment waterproofing is a hallmark of Snickers

Workwear’s winter clothing.

Whichever Snickers Workwear Jacket you choose, you can count on real comfort and protection from rain and foul weather.

Stay dry, warm and comfortable by choosing from a range of water-repellent jackets with welded seams that will keep you dry in light showers and deliver great breathability to ventilate your body when you’re active on site.

But if you need 100% waterproofness for long periods, check out the GORE-TEX® jackets. These highly technical garments are waterproof to keep you dry, windproof to keep you warm, and breathable to keep you comfortable all day long

There’s a host of AllroundWork and FlexiWork jacket styles and extensive size options available for tradesmen and women, so you can layer your working clothes properly to ensure that your energy and performance levels are as weatherproofed as you need to be.

For more information on Snickers Workwear’s Winter Working Clothes, call the Hultafors Group UK Helpline on 01484 854788, checkout the website at www.snickersworkwear.co.uk or email sales@hultaforsgroup.co.uk

It has used products from many of its suppliers and customers for the project including new windows, fire doors, electricals, plumbing, furniture, decoration, carpeting and signage, along with some of its own ironmongery products.

The refurb in the second change project to take place at Strand Hardware in recent months and follows a review and upgrade of its warehousing processes undertaken with WMG (Warwick Manufacturing Group).

It has resulted in a more modern, open plan work space for its expanding team – encouraging greater team synergy and literally breaking down walls to silo working which had been enforced by the old layout.

Strand has occupied the premises on the Premier Business Park, in Walsall, since the company was founded more than 30 years

ago and according to Managing Director Steve Marshall a little modernisation has been beneficial.

“Although Strand’s offices were perfectly functional, they were looking a little dated and our work with WMG gave us the impetus to extend our programme of improvements. Not only will it enhance working conditions for the Strand Hardware team but also convey a better image of who we are and what we are about to visiting business associates.

“Efficiency has underpinned all our recent changes. This includes energy efficiency and eco-saving measures such as the introduction of natural ventilation, insulation and energy-saving devices,” he said.

Shared facilities including board room, kitchen and bathrooms have been included in the make-over and equipment upgraded. Staff have also benefitted from ergonomically designed furniture and layout.

Its reception has been reconfigured to make it lighter and more airy. It also features digital displays to welcome visitors and showcase Strand’s extensive product range.

A key driver in the process has been digitisation – reducing paperbased processes and transferring its traditional filing system to a cloud based environment.

The company is planning an open day for company contacts and has invited Mayor of Walsall to oversee a rededication ceremony.

For more information on Strand Hardware products contact: info@strandhardware.co.uk or call: 01922 639111.

Strand Hardware has given its company headquarters a radical make over –improving its energy efficiency, work space and creating a welcoming new hi-tech reception.

Award-winning British comic book artist and illustrator Charlie Adlard is enjoying a new lease of life in a new home featuring a building material that is seriously old!

Charlie has been a “veteran” of the comic industry for more than 25 years and recently finished a 15year spell working on The Walking Dead series which was adapted for television by US network AMC in 2010. Charlie himself appeared in the pilot as a zombie extra!

Now free to pick and choose his own projects, including life drawing sessions and single illustrations for music, films and other media, Charlie is working from his new home on the banks of the River Severn in his hometown of Shrewsbury, Shropshire.

The house, which was designed as one of a pair by AHR Architecture, uses Welsh Slate products on various aspects – as vertical cladding on elevational features including a “chimney” on the house, and for hard landscaping, as walling and copings to terraces and walls in the landscaped gardens.

The architectural and landscaping products manufactured by Welsh Slate at its main Penrhyn quarry near Bangor are produced from a material that is 500 million years old, but at Charlie’s three-storey, split-level house, it has been used to complement the contemporary aesthetics of the building.

The cladding is from Welsh Slate’s Penrhyn Heather range, in a Honed finish, while the pillared walling is from the same Penrhyn quarry with a textured finish and the same Honed finish also features on the copings.

Charlie said he specified the Welsh Slate products for a variety of reasons. One was sustainability (the garden features an extensive

photovoltaic array), the other sentimentality!

“The house, as much as possible, is hopefully as environmentally friendly as we could make it, so a natural product like Welsh slate works with that remit. We also wanted to use as much locally sourced product as possible.

He also explained that his family has a strong connection to North Wales. His wife is Welsh - her family come from Bangor and Angleseyso to them it made sense to source

local materials from that area to complement their house design. They had always known about Welsh Slate, having visited the area many times, and eventually having a holiday home in Beaumaris that virtually looks across the Menai Strait to the quarry.

Charlie added: “The use of the Welsh Slate products has been mainly decorative, and they have made a striking natural addition to the modern look of the building. It’s the first time we have used Welsh Slate and we love it!”

The prosecution came after a photograph caught the moment a pair of workmen stood in the bucket of a telehandler to fit a stone into the top of a new home in Littleborough, Greater Manchester. It was one of a number of health and safety failings found during construction work at The Villas development on Starring Road in Littleborough.

Health & Safety Executive (HSE) inspectors visited the housing development on 7th July 2021 and issued Hoyle Developments Limited, the site’s principal contractor, with a prohibition notice for inadequate scaffolding and improvement notices for a lack of welfare facilities and insecure fencing.

HSE inspectors had visited the same housing development site four times between November 2018 and August 2021. Repeated breaches were found including a lack of sufficient welfare,

unsuitable controls for work at height and inadequate protection from silica dust exposure. Hoyle Developments was served with multiple notifications of contraventions, prohibition notices and improvement notices.

The HSE described the image as showing ‘a digger’. From the photo published it looks more like a telehandler, which makes it no less of an offence but it is at least a machine designed for lifting, rather than digging.

Hoyle Developments Limited, of Edenfield Road, Rochdale pleaded guilty to breaching Section 3 (1) of the Health and Safety at Work etc. Act 1974. The company was fined £120,000 and ordered to pay £3,165.15 in costs at Manchester Magistrates’ Court on 25th January 2023.

HSE inspector Mike Lisle said: “This proactive prosecution demonstrates that HSE will not hesitate to take proactive enforcement action against those that continuously fall below the required standards and demonstrate persistent poor health and safety. Health and safety should be an integral part of any business, not an afterthought, and having a clear health and safety policy and construction phase plan in place, before work commences, can assist with ensuring this.”

Wates Group has stepped outside of the construction industry to find its new chief executive Eoghan O’Lionaird.

O’Lionaird, 56, will join Wates later this month from his previous role as chief executive at Stock Market-listed marine services company James Fisher and Sons. He spent three years at James Fisher headquartered in Barrowin-Furness, Cumbria. Before that worked as group director at global instrumentation and software provider Spectris.

Cork-born O’Lionaird will be based in Wates’ headquarters in Leatherhead, Surrey.

He will take over from interim chief executive Philip Wainwright who has been in the post since the summer last year when previous Wates chief executive David Allen stepped down with immediate effect after running the family-owned building contractor for the last four years.

Wates Chairman, Sir James Wates, said: “Eoghan is a globally accomplished, motivational leader with an impressive track record in industry and we’re very pleased to be welcoming him to Wates.”

O’Lionaird said: “What marks Wates out from the competition is how it has rallied its people around a purpose greater than profit alone.

“This is clear from its commitment to making the built environment more sustainable. I’m looking forward to contributing to the Group’s strategy and marshalling the resources needed to achieve its ambitions.

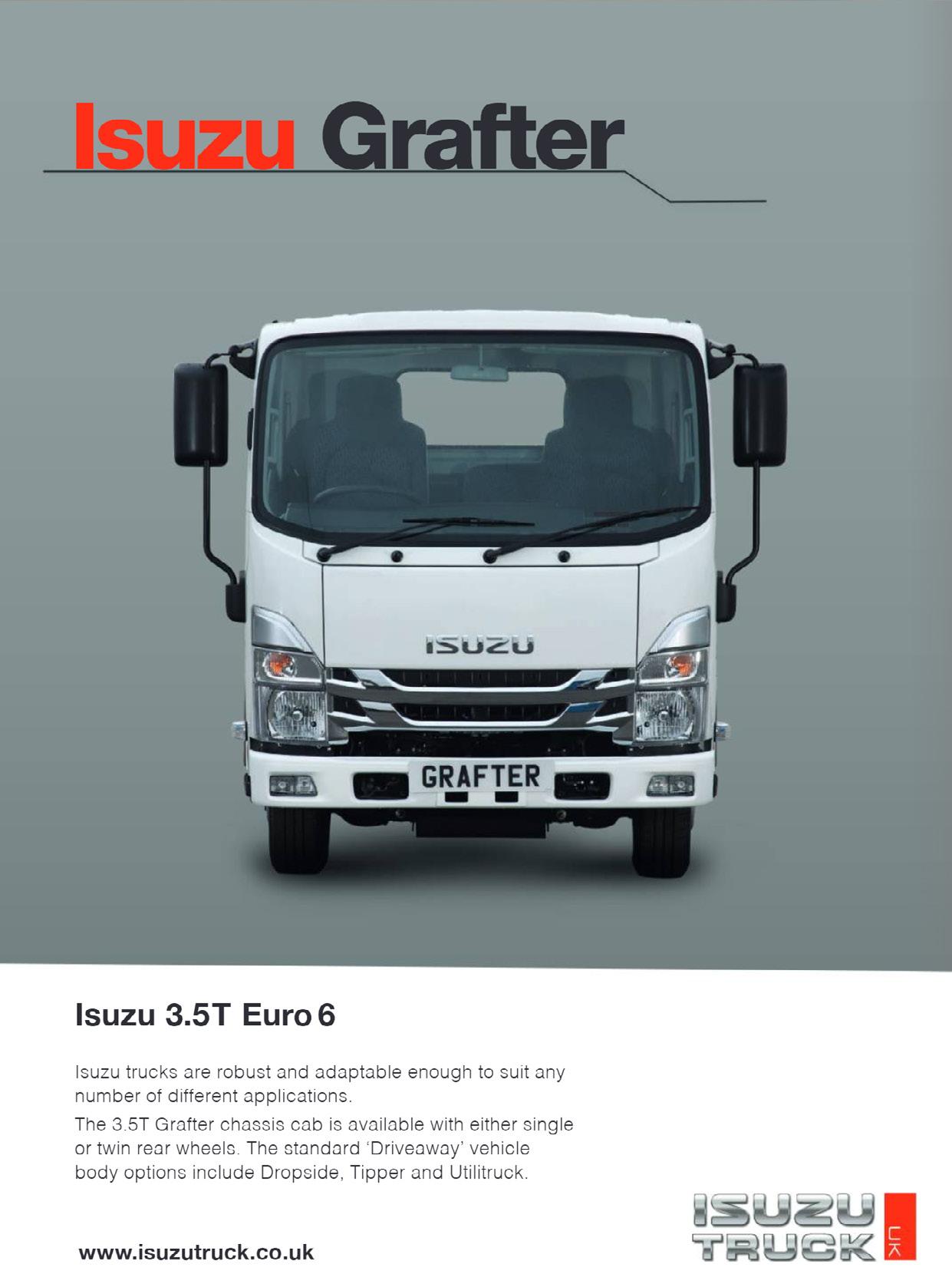

Isuzu trucks are robust and adaptable enough to suit any number of different applications.

The 3.5T Grafter chassis cab is available with either single or twin rear wheels. The standard ‘Driveaway’ vehicle body options include Dropside, Tipper and Utilitruck.

www.isuzutruck.co.uk

Dawsongroup, which leases street cleaning machinery to local authorities, will have 10 JCB Pothole Pro machines on delivery of its latest order, having bought its first five last October.

“We were so impressed with the JCB Pothole Pro that we have ordered an additional five machines which will double the size of our fleet within a fivemonth period,” said Dawsongroup managing director Glen Carruthers. “Every day we are talking to our customers asking them how to improve the way they do things and the Pothole Pro fits perfectly into that profile. The JCB Pothole Pro eradicates potholes easily with one machine in a more efficient, cost effective and safer way than more traditional methods.”

The Pothole Pro was launched in January 2021 as an adapted Hydradig wheeled excavator, with tools for cutting and cleaning around potholes. It includes a hydraulic cropping tool, which the previous JCB Pothole Master, a modified 3CX backhoe loader, does not.

Laing O’Rourke’s plant division, Select, has teamed up with Hong Kong-based Ampd Energy to trial the Enertainer, a plug and play device designed for the electrification of construction.

The Enertainer (…energy… container…) is powering three tower cranes at Olympia rather than traditional 500kVA diesel generators, thus reducing emissions on site.

According to the companies involved, the Enertainer is the first energy storage system in the UK able to power such large construction equipment. Select is now offering the Enertainer to customers across the rest of the UK.

AMPD Energy chief executive and founder Brandon Ng said: “This is a fantastic opportunity for us to demonstrate the Enertainer’s compelling environmental and commercial impacts, right here in London.

“We’re excited by the platform’s ability to transform construction and are proud to be partnering with industry leaders like Select and Laing O’Rourke, as we continue our journey towards making this a reality. We look forward to building on this first deployment over the course of 2023, powering cleaner, cheaper construction in the UK and across the world.”

Ian Fleming, Select Site Services product leader at Olympia Redevelopment, said: “The Ampd Enertainer is a game changer for site electrics and its infrastructure. Not only does it enable us to

power the crane on a small grid connection, but the innovative design allows us to feed it with small power cables and charge it when site demand for power is low. It has the capacity to run additional equipment so we are looking at other applications for it already.”

While Laing O’Rourke and Select are the first UK customer for the Enertainer, it has already been used in Hong Kong, Singapore and Australia by the likes of Gammon, Lendlease and Multiplex.

While Ampd Energy says that the Enertainer can power any type of electrical equipment, it is most effective when powering high power equipment with intermittent loads, such as cranes and hoists.

It is recharged by plugging in to the mains. If your site happens to be off grid, you can charge it using a diesel generator. While that may seem to defeat the whole point of switching to electricity, Ampd says that there would still be “significant” carbon and cost savings compared to a diesel generator attached directly to the equipment.

Volvo Cars is teaming up with Northvolt to build a manufacturing plant for vehicle batteries in Gothenburg, Sweden. Construction of the new battery plant will start in 2023 and it is scheduled to begin operations in 2025.

The new plant will produce battery cells specifically developed for use in next-generation pure electric Volvo and Polestar cars. It is set to create up to 3,000 jobs and will complement a planned R&D centre that that the Volvo and Northvolt announced in December as part of an investment of approximately SEK30bn.

Volvo Cars said that the new plant and close ties with Northvolt will significantly strengthen its electrification strategy as it aims to produce and sell only fully electric cars by 2030.

The plant will have a potential annual cell production capacity of up to 50 gigawatt hours (GWh), which would supply batteries for approximately half a million cars per year.

Volvo Cars said that the location of the plant in Torslanda, Gothenburg, offers benefits such as a direct route into its largest car plant, access to infrastructure and a strong pipeline of renewable energy supply and relevant job skills. It is also close to both Volvo Cars’ and Northvolt’s R&D units.

“Our battery cell partnership with Northvolt is key to our strategic ambitions in electrification,” said Håkan Samuelsson, Volvo Cars chief executive. “We are committed to becoming a leader in the premium electric car segment and selling only pure electric vehicles by 2030.”

“Establishing this gigafactory in Gothenburg is a decisive move, both to continue to transform one of the most dynamic automotive regions in the world, and to become the leading global supplier of sustainable batteries”, said Peter Carlsson, cofounder and CEO of Northvolt.

Laing O’Rourke has been using Chinese ‘smart batteries’ to power cranes London’s Olympia Redevelopment for the past six weeks.

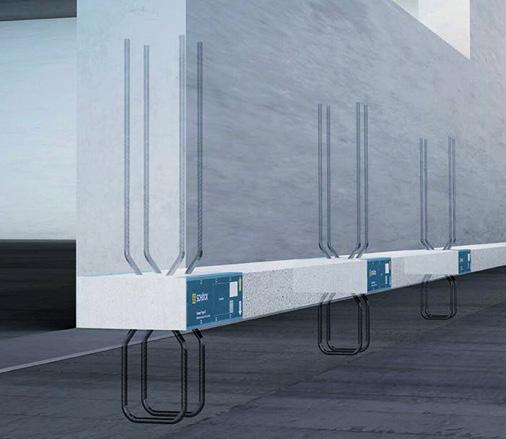

Field House is a substantial and stunning new private home set in the Cotswolds The client brief was for a ‘modern country house’ and the scheme offers a 21st century vision of a traditional country house and its landscape. The avoidance of thermal bridging at various points in the design detailing was extremely important and the Schöck Isokorb, along with the new Schöck Sconnex product, are incorporated to provide the necessary insulation solutions.

The Field House scheme is located on grassland used for animal stabling and creates a unique, site specific dwelling. Special consent was sought through the National Planning Policy Framework, which allows certain new homes to be built in the countryside and, as in this case, Areas of Outstanding National Beauty. Historically country houses tended to impose themselves on the landscape, but Field House is sensitively designed, becoming part of the landscape, rather than an imposition on it. In addition to integrating with the landscaping, other traditional themes that have been reinterpreted as part of the modern design proposals are the arrival forecourt; the gate house; the principal courtyard and the stepped garden terraces. Also, what in an earlier century would have been gardens or an idealised landscape, the design here forms a real environment providing habitats for wildlife, especially endangered species, to flourish. The main living space of the house contains a feature rammed earth wall that supports the concrete roof terrace structure above. The external walls of the house are constructed from rammed concrete, a dry concrete mix that is compacted between shutters. Sustainability was important and the engineers worked closely with the architect to reduce the embodied carbon in the house by refining the carbon heavy parts of the structure. For example by adding in an additional column to reduce the floor slab thickness by 100mm; and specifying a concrete mix that reduced the embodied carbon.

Special consideration had to be given to the avoidance of thermal bridging, particularly with the parapets and columns. The architecture and structure of Field House are closely integrated and as a result there was a high degree of collaboration between Bath and London based Integral Engineering Design and South Wales based Loyn+Co Architects. James Stroud, a director at Loyn+Co comments: “Minimising the risk of thermal bridging at critical connectivity areas throughout was an important consideration. We had no doubts that the Schöck product solutions used would exceed the performance requirements. As a result we incorporated the Isokorb XT type A as parapet thermal breaks and the Sconnex type W where columns needed to be thermally broken”

Parapets allow conductive materials to transfer energy through the thermal barrier and are therefore just as prone to the problems of thermal bridging as balconies. In the majority of cases, the conventional method of insulating parapets is to wrap the perimeter of the wall with an insulation barrier. However, the Schöck Isokorb XT type A offers an altogether more thermally efficient and costeffective alternative. It permits a more sophisticated

construction opportunity for greater freedom of design, allows flexible distance between elements according to load requirements, is extremely durable and impermeable to water – so no maintenance is required. The 120 mm insulation thickness of the XT type A significantly reduces heat loss, also the product is assessed as a ‘Certified Passive House Component’, provides BBA Certification, LABC Registration and NHBC approval – while meeting full compliance with the relevant UK building regulations.

The recently introduced Schöck Sconnex type W minimises the thermal bridge between the exterior wall insulation and the insulation above the floor slab. Around 40% of all thermal bridges in a building are caused by walls and supports, which in turn are responsible for about 10% of heating energy losses. The Schöck solution offers an application-friendly, high-quality solution. Heating costs are lower, a pleasant room climate is created and the linear thermal transmittance (Psi) of the connected reinforced concrete wall is reduced by up to 90 percent. This outstanding insulation performance is combined with an excellent load-bearing capacity, which transmits very high pressure, tensile and shear forces in the longitudinal and transverse direction. This is made possible by the use of a pressure buffer consisting of ultrahigh performance fibre reinforced concrete, which achieves compressive strength in excess of 175 N/mm2 – but with extremely good flexural strength as well. There is also a significant cost reduction involved when compared to installing insulation beneath the floor slab.

For full information on the entire range of Schöck structural building components contact the company on 01865 290 890; or visit the website at www.schoeck.com

By eliminating traditional cable hung on/off floats and utilising the pumps own proven rigid float arms with their large triangular low-level floats, pump control is simplified and improved. This design is far less prone to debris interfering with the float movement hence the stop/start of the pump is always more reliable.

Utilizing this float arm design also means that the invert levels in to the DrainKing are now lowered considerably making positioning of the unit much more flexible. It is now easier to fit the specified pipe gradient into the tank. Previously the minimum invert level was 260mm, now, with the Jung Pumpen UK6 pumps fitted, it can be as low as 120mm.

The New DrainKing, duty/standby wastewater pumping system, incorporating Jung Pumpen pumps, from Berkshire based Pump Technology Ltd., now features more flexible installation and more reliable operation with even easier maintenance.

The DrainKing comes supplied with its own pump station control panel. This cycles the duty pump, activates the standby pump and alarm.

In practice the control panel selects a duty pump and cycles it after every 4 hours of total operation. In the unlikely event of blockage, or pump failure, a finger float mounted on the side of the tank will detect a high wastewater level and activate an audio and visual alarm on the panel. The panel then selects the standby pump, its float arm already raised for switching on and pumping.

The panel shows pump status for both pumps. In the event of a power failure the alarm is powered by a rechargeable battery. The panel

has three volt-free contacts for connection to a Pump Technology Ltd remote alarm and/or to a BMS system.

These three volt-free alarms aid BMS logic when features such as solenoid shut off valves are incorporated into the appliance/drainage system.

The DrainKing can be fitted with a range of Jung Pumpen pumps, both single and 3phase.

With the US 103 E installed pumping capacity is over 12m head. With the 730HES or 1030HES pumps the DrainKing is also suitable for pumping hot wastewater continuously up to 90°C. Because of this special feature, this product is ideal for commercial kitchens, laundries, and commercial buildings.

The experienced application team at Pump Technology Ltd, based in Berkshire, provide specification and sizing support for consultants and installers alike. Speed of response is one of the company’s watchwords. Callers can speak to an engineer who can discuss their site and pumping application straight away, providing confidence to progress the project with the correct pumping system specification.

The New DrainKing tank and pumps are all held in stock and can be dispatched the same day.

Pump Technology Ltd is authorised by Jung Pumpen GmbH as a distributor and stockist for their pumping equipment, responsible for specification, supply and support and is the largest supplier of Jung Pumpen equipment in the UK.

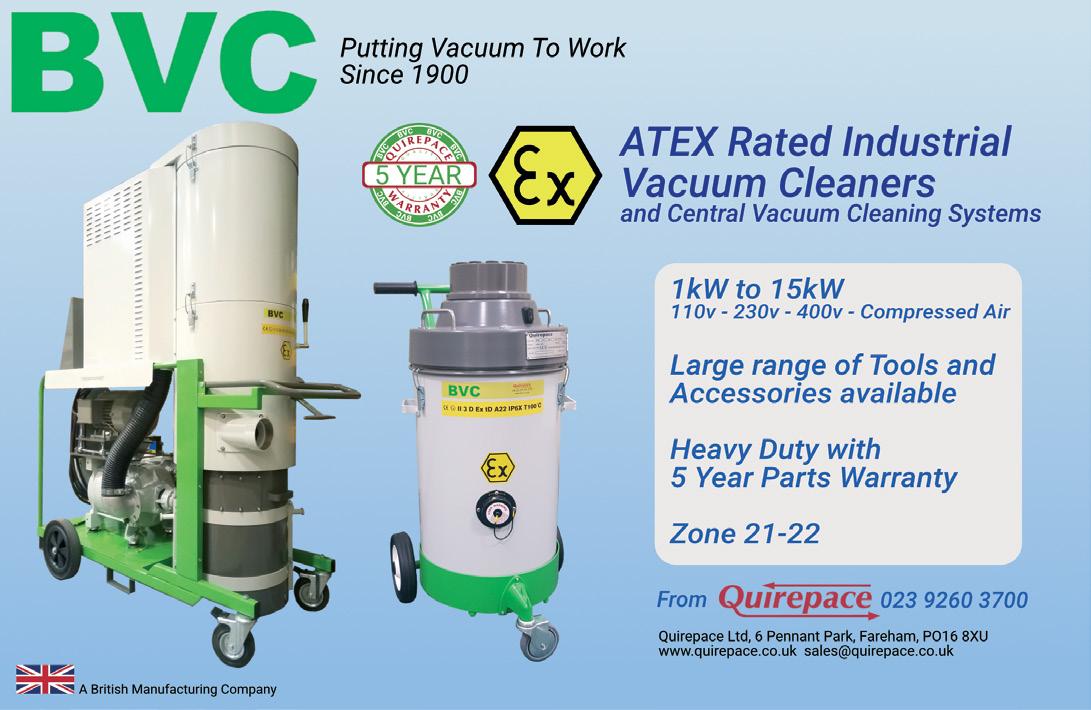

On 25 and 26 January, the BSS Conference took place at Wembley Stadium in London. This year, the theme was ‘Sustainability’ and BSS suppliers had the chance to exhibit and present seminar sessions to BSS staff and customers.

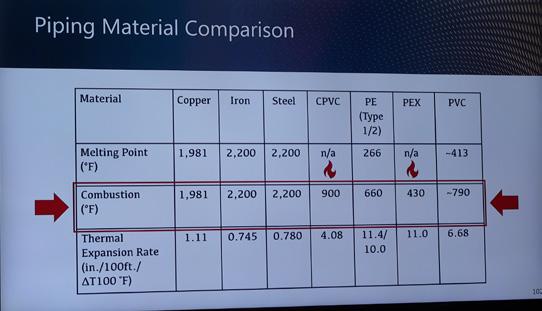

BSS Industrial is a specialist distributor of heating, ventilation, pipeline and mechanical services. It stocks a multitude of products and materials, including copper tube from both founding members of the Copper Sustainability Partnership (CuSP), Lawton Tubes and Mueller Europe. CuSP attended the conference, taking a stand in the exhibition marketplace as well as presenting a seminar session on the sustainability and safety credentials of copper. Here, Andrew Surtees, co-founder of CuSP, explores his top takeaways from the event and reflects on the key themes discussed.

With copper being a 100% recyclable, sustainable material, the theme of the conference was a perfect fit for CuSP. Unlike plastic and synthetic materials, copper can be reused and recycled infinitely without losing any of its properties – copper used once will be identical to that used 1,000 or even a million times.

According to the US Geological Survey, there are approximately 5.6 billion metric tonnes of

copper, which is more than sufficient to surpass both current and future demand. What’s more, the Copper Alliance states that, to date, at least 65% of all copper mined remains in circulation and around half of Europe’s copper demand is currently being met by recycled materials.

Plastic, on the other hand, does not tell the same sustainability story. In the past two years, construction industry plastic waste has increased by over 45%, with 40% of the plastics used by the industry sent to landfill. Despite plastic piping being marketed as recyclable, the reality is that most plastic pipe is not recycled.

This is evidenced by CORDIS research, which states that conventional non-recyclable pipes for heating plumbing systems are manufactured from non-recyclable cross linked PEX. They are also made of PEX/AL which comprises a layer of aluminium sandwiched between two PEX layers. Recent Copper Alliance research also evidences how copper tubes are the greener choice for cutting greenhouse gas emissions and mitigating climate change. A Life Cycle Assessment was conducted of copper, plastic multilayer pipes (PEX/ AL) and plastic cross-linked polyethylene (PEX) and the Global Warming Potential indicator showed that the PEX/AL and PEX systems impacted global warming 18% more than the copper pipe system.

Another key theme that CuSP focused on at the conference was fire safety and how copper offers greater safety in a building fire compared to plastic. Copper is well known for its thermal resilience and has an ability to withstand fluctuating temperatures. As a result, it won’t melt, burn or give off toxic fumes in a building fire.

However, the evidence of the dangers of plastic in building fires is simply shocking. With a combustion point of between 430°F and 900°F, depending on the type of material, plastic will melt in building fires and as it burns, it will release poisonous chemicals into the air. Copper, on the other hand, has a combustion point of 1,981°F, so is a much safer alternative.

A study conducted in 2019 (Releases of Fire-Derived Contaminants from Polymer Pipes Made of Polyvinyl Chloride) found that PVC pipes release carcinogenic toxins such as methylene chloride, allyl chloride and vinyl chloride when burnt. With this in mind, it’s no wonder that cancer rates within the firefighting profession have slowly risen since the 1950’s, coinciding with the time when plastic use in the construction industry and domestic settings started to grow.

We have also recently heard the tragic news that up to a dozen firefighters who tackled the blaze at Grenfell Tower have been diagnosed with terminal cancer. With polyethylene plastic being a main component of the cladding, there is no surprise that this is the case.

One thing that stood out at the conference was the amount of companies who were simply brushing over the sustainability issues of their products by using distraction techniques.

Whether it was focusing on their small range of metal products and including no mention of their plastic range, using games or giveaways (made of plastic!) as a distraction technique or simply not mentioning sustainability on their stand at all, it was interesting to see how some un-sustainable products were being marketed at a sustainability conference.

As the climate emergency worsens, events like this are so important to raise awareness about how the construction industry can improve its sustainability. However, it seems as though companies attending such events need to examine their ‘sustainable’ credentials before deciding to exhibit, to avoid greenwashing and avoidance of the problem.

The time has come for us to properly prioritise sustainability in the industry and copper is the perfect, professional solution.

To find out more about the sustainable credentials of copper and how you can play a part in the sustainability journey, visit www.cuspuk.com.

Three times faster to install, and easy to cut and bend by hand, TracPipe has been the market-leading product for over 20 years…

TracPipe is a BSI Kitemarked stainless steel semi-rigid gas piping system used on commercial and residential projects for LPG or natural gas from the meter to the appliance. TracPipe was launched in the UK market in 2000 and has been the leading product in the country since then.

This gas piping system is typically three times faster to install compared with traditional rigid steel or copper pipe installation. TracPipe has become recognised as the perfect alternative to rigid pipework installed between the meter and a fixed appliance, as it is easy to cut and bend by hand, and requires no soldering, welding or special tools.

TracPipe is supplied in sizes from DN12 to DN50 with lengths of up to 90m as standard with longer lengths available as special

orders. TracPipe Kits are available in sizes DN15, DN22, DN28 and DN32 in 5, 10 and 15-metre lengths.

TracPipe can be directly buried in the ground or non-structural screed and used externally above ground without the need for additional mechanical and corrosion protection. The product offers a two-hour fire rating when installed in continuous lengths (no joints) and can be routed within fire-protected shafts, corridors, and lobbies. The outer cover of TracPipe also has a class-leading Euroclass Reaction to Fire rating of B-s1 d0.

TracPipeCC is the original TracPipe revamped with a second polyethene outer cover over the length of the product. This system was designed to be installed in unventilated voids by adding a secondary containment sleeve.

Omegaflex conducted thorough research to design and develop this innovative product and ensure it met all necessary safety and installation requirements. This involved a robust internal testing regime to ensure the secondary outer cover performed as a ventilated duct in all aspects of installations likely to be encountered.

TracPipeCC remains the only product of this type that has been successfully independently assessed by two of the UK’s leading test authorities.

The product is available in sizes DN15 to DN50 and is supplied on reels of varying standard lengths, with longer lengths available as special orders.

T: +44 (0)1295 676 670

E: eurosales@omegaflex.net

www.omegaflex.co.uk

plumbing is the most common type of DIY work that forces people to eventually call in the experts, adding between £100-£500 on top of the original price of the job.

That’s according to new research from Toolstation, which surveyed both tradespeople and the general population. 68% said that they have attempted to fix something at home before hiring a professional, costing them between £100-£500 onto a job’s price to make it right.

Toolstation then spoke to plumbing, gas, and heating experts for advice on what shouldn’t be tried at home and why.

The leading motivation to try a job yourself before calling a professional is to cut costs (70% of the general population said this) and a further 74% of tradespeople also agreed.

The most common botched jobs in plumbing are:

Jamie, owner of Billabong Plumbing & Gas Services, says: “When money is tight, people will often resort to attempting plumbing jobs themselves to save money, but it can end up costing them more in the long run.”

“They then have to pay for my time to correct the problem, replacement parts and the cost to repair the damage, which is a lot more expensive than paying me to do the job in the first place.”

Jamie also said: “The most common jobs people attempt include fitting their own radiators, plumbing in taps, and installing electric showers. But when these jobs go wrong it often results in leaks and water damage, which is when I get a panicked call from a customer asking for help.”

Lorenzo, a heating engineer, states: “I am often called by people who have had a go at plumbing in a toilet in a downstairs loo. I think because it is seen as a small job and there are lots of YouTube tutorials, people feel confident having a go. The issues usually arise if they haven’t got the correct tools or an understanding of how a toilet functions.”

A spokesperson from Toolstation explains: “If you’ve spent £100 on new taps and make a mistake fitting them yourself, you’re going to have to pay around another £110-£130 for a professional to fix the problem, and that’s if the issue is just with the taps. Attempting to fix it yourself could mean doubling the cost compared to if you just called a plumber in the first place.”

Although people are trying to cut costs at home, having to call out a professional to fix a botched job could end up costing more. In fact, four in ten trade experts expect a botched job to add between £100£500 on top of the original price of the job.

Other findings from the study include: 30% of our trade experts stated that they fix mistakes at least monthly, sometimes even more frequently. 6% reported having to fix botch jobs at least once a week.

Experts warn against jobs involving water, electric and gas the most –these can lead to the most damage if done wrong. Half of trade experts turn down botched jobs due to the state of the job at hand. 7 in 10 worry that other unexpected problems will arise.

Waddesdon Manor is home to the Rothschild Collections of paintings, sculpture and decorative arts, and was built by Baron Ferdinand de Rothschild between 1874 and 1885.

Opened to the public in 1959, Waddesdon Manor is managed by the Rothschild Foundation, a family charitable trust, on behalf of the National Trust, who took over ownership in 1957.

They needed an access control system that could not only secure storerooms and valuable artwork and assets, but also keep members of the public away from restricted areas.

Keys in the existing locking system were badly worn, and the security and facilities management wanted to upgrade to a proven state of the art solution that provided control of key management and more information such as audit trails.

Mid-Beds Locksmiths Ltd - who have been responsible for the heritage and modern locks and ironmongery at the site for over 20 years - and the security team at Waddesdon conducted a survey of the site to identify the locks that most urgently needed replacing in stage one of the upgrade.

Mid-Beds Locksmiths Ltd suggested the eCLIQ solution from Abloy would be the ideal retrofit option. The security team were aware of Abloy’s strong reputation in the security industry as a trusted brand, with many Abloy products fitted in heritage sites and museums across the UK. As Abloy is known for its premium high quality high security products, this would also fulfil insurance criteria.

By switching to eCLIQ, staff would retain their own key with individual permissions, rather than having to share keys from the previous mechanical master key system. This meant Waddesdon could implement a fully traceable electromechanical key hierarchy system, with each department given different access rights based on their requirements. What’s more, the solution required no wiring, making the installation simple and maintaining the original appearance.

Abloy and Mid-Beds Locksmiths Ltd specified a new bespoke solution, issuing around 20 keys and 35 cylinders for stage one, with a view to expanding the system with further upgrades in the future.

The eCLIQ cylinders are suitable for doors of any thickness, making them the ideal solution for heritage doors as there are no cables or drilling required, plus the cylinders do not damage the original lock. Ornate cylinders were specified where required, fitting in with the building’s aesthetics and maintaining the appearance of historic locks.

The Waddesdon security team explained: “The eCLIQ system is the perfect solution for the heritage sector, as it allows access control in a historic property where you normally wouldn’t be able to get it without considerable impact on infrastructure.

“All of our access is now controlled by the admin onsite, and no one can give the wrong access to the wrong person – it just can’t happen. It’s a busy environment so this has saved significant admin time handing out keys.

“Instead of having to collect a bunch of 30 keys, staff have just one. Now people come to work in the morning, enter their key and are automatically given their access rights for 24 hours.

“Permissions are deleted after a period of time, so we don’t need to worry about lost or stolen keys. If someone lost a key previously, we would have to change 50-60 locks, but that’s not an issue anymore. Plus, the system offers tracking and audit trails for us to keep an eye on who is accessing which areas and when.

“We can change batteries so they won’t wear out, which offers another cost saving, and the locks are more robust for multiple use, so I’m confident it’ll be a more flexible and beneficial system long term.”

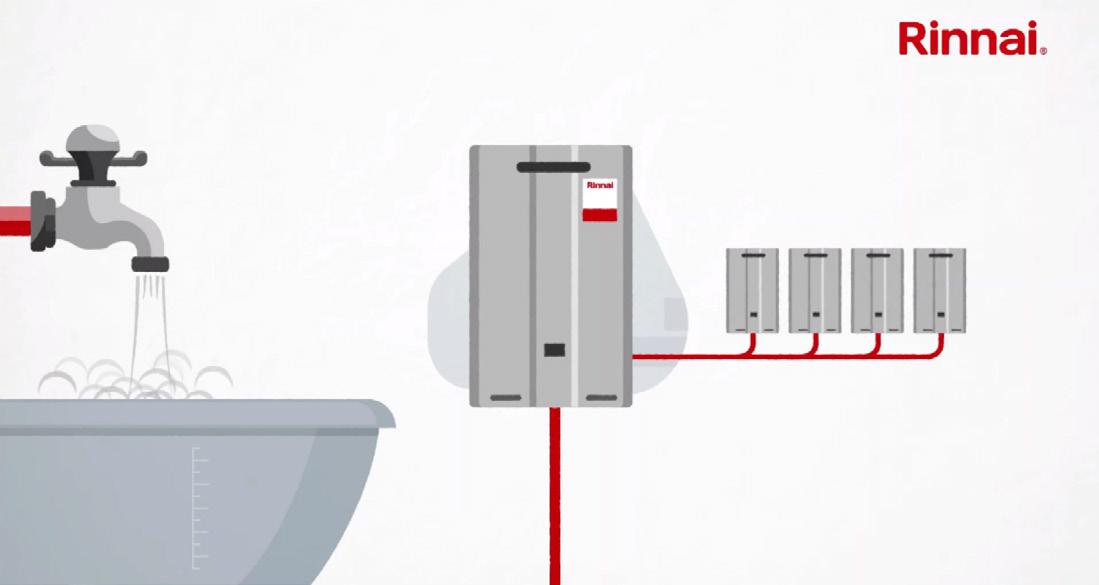

The Rinnai Infinity 11i (H541 x W373 x D173) 17i (H541 x W373 x D173) and 17e are ideally suited to any and all domestic properties or small businesses that need instant, economic and temperature-controlled volumes of hot water. The temperature range for all three models is between 37-65 degrees centigrade making them ideal for comfortable ablutions and heavy-duty high volume commercial cleaning for instance in restaurants where high temperature can cut through oil and grease.

The Rinnai Infinity 11i (11i Litres per minute) and 17i (17i litres per minute) are hydrogen ready at 20% hydrogen-methane blending and is Ultra Low-NOx surpassing ECO-DESIGN requirements. This model is internally wall mounted and is easily & quickly installed due to its light weight (14kg) and simple wiring.

Rinnai’s Infinity 11i and 17i include inbuild frost protection and push fit flue system. The system operates on demand with direct electronic ignition, ensuring that the continuous flow water heater only fires when hot water is needed, providing temperature accurate hot water instantly. In comparison traditional water storage systems will keep a body of water heated for when it is needed resulting in unnecessary energy usage and cost.

Rinnai’s H3 range of products which stands for Hydrogen / BioLPG ready, Hybrid Heat pumps and Solar Thermal and finally a wide range of LOW GWP heat pumps, includes the Infinity hydrogen blend ready and BioLPG ready continuous flow water heaters which are stacked with a multitude of features that ensure long life, robust & durable use, customer satisfaction and product efficiency.

Rinnai Infinity 11i and 17i models can be delivered to site in Hydrogen Blends ready natural gas, LPG and BioLPG variations ensuring that the units can cater towards hardto-reach industries and off-grid properties.

The final model in this range is the Infinity 17e external continuous flow water heater, the externally mounted 17i internal model in terms of flow rate and diminutive, lightweight design. External water heaters give the added benefit of relatively unconstrained installation caused by flue citing issues. The external variants are used widely in agriculture, glamping pods and leisure settings.

Rinnai’s Infinity models are designed to reduce energy usage and all related costs throughout a product’s working lifecycle. The products are designed to enhance efficient performance, product durability and reduce costs across all aspects of purchase and product labour.

Rinnai’s product and service offering is based on H3Hydrogen, Heating and Heat Pumps - which allows any site in either residential or commercial sites to maximise the energy efficiency and performance in striving for NetZero and Decarbonisation. Additionally, Rinnai is developing and introducing electrical formats to all existing product ranges within the next few months. Rinnai’s new “H3” range of products includes a wide selection of commercial heat pumps as well as hydrogen blends-ready and hybrid hot water heating systems.

Rinnai is a world leading manufacturer of hot water heaters and produces over two million units a year. The company operates on each of the five continents and the brand has gained an established reputation for high performance, robust cost efficiency and extended working lives.

Rinnai’s commercial and domestic hot water products offer a limitless supply of instantaneous temperature controlled hot water and all units are designed to align with present and future energy sources and accept either natural gas or hydrogen gas blends. Rinnai units are also suited for off-grid customers who require LPG and BioLPG or rDME.

Rinnai units are UKCA certified, A-rated water efficiency, accessed through multiple fuel options and are available for purchase 24/7, 365 days a year. Any unit can be delivered to any UK site within 24 hours. System design services are available if needed and cost comparison services are accessible to all customers who require further cost detail.

Rinnai’s Innovation Manifesto clearly outlines the path to carbon neutrality and maintains a pledge to fully decarbonize company operations by 2050. Rinnai will further support the global clean energy transition by introducing a wide variety of domestic heating options across multiple energy vectors.

Rinnai is committed to decarbonisation. Rinnai’s water heating products are all hydrogen-blends ready NOW including the world’s first 100% hydrogen powered water heater. Rinnai products also accept BioLPG capable of delivering NetZero carbon emissions. Rinnai offer comprehensive training courses and technical support in all aspects of the water heating industry. More information can be found on Rinnai’s website and its “Help Me Choose” webpage.

Experts together: Ideal Heating & ACV exhibit at Specifi events across the UK

Ideal Heating – Commercial Products is pleased to announce it is once again exhibiting at Specifi Mechanical Services events throughout 2023, alongside hot water generation and heating company ACV UK, as part of their Experts Together campaign; both companies are part of Groupe Atlantic.

Aimed at specifiers in the construction sector, the Specifi events provide a more relaxed, informal alternative to major exhibitions. They are designed for networking and professional development through the sharing of information.

Ideal Heating is exhibiting at eight Specifi Mechanical Services events, which are being held in Birmingham, Bristol, Edinburgh, Glasgow, Leeds, London and Manchester.

Ideal Heating’s experienced Specification Managers will be on hand to advise visitors on the latest cost-effective means of decarbonising commercial heating in light of the Part L uplift to Building Regulations for non-

domestic buildings, which came into effect in June 2022, targeting an average decrease of 27% in CO₂. They will be explaining how the building services and low carbon technologies that can help achieve this, with a focus on the benefits of heat pumps.

Ideal Heating’s new ECOMOD range of commercial monobloc air source heat pumps will be a key focus at the Specifi events. These heat pumps offer highly efficient COP performance with low environmental impact, thanks to the use of R32 refrigerant. The ECOMOD range of units are available in a choice of six outputs ranging from 14kW through to 70kW. Built with larger buildings in mind they can be cascaded up to seven units - from an external controller - for a performance output of up to 490kW.

Ideal Heating is pleased to be sharing its stand space at Specifi with ACV UK. Some of ACV’s most popular products include the WaterMaster Evo gas fired stainless steel condensing water heater with tank-in-tank technology; the SMART ME range of cylinders which can be installed with renewable energy products such as heat pumps; and a range of floor standing combined heating and hot water electric units and wall hung heating only electric boilers.

Ideal Heating will also be highlighting its free training courses and CIBSE accredited CPD seminars at Specifi, which have proven very popular amongst specifiers keen to gain a greater understanding of the different commercial boiler heat exchanger materials and the stages of plant room surveying. All training can be customised and is provided in Ideal’s state-of the-art Training Centres of Excellence located in Hull and Leeds.

For more information on the location and times of Specifi events, plus to register for free attendance, go to www.specifi.co.uk.

For more information on Ideal Heating –Commercial Products, visit: www.idealcommercialheating.co.uk and for ACV go to www.acv.com/gb

To align with net zero by 2050 there is an urgent requirement to decarbonise UK heating systems, with many leaning on the promise of increasing heat pump installation.

Whilst a positive initiative, data from the Heating and Hotwater Industry Council (HHIC) suggests the actual workforce requirement to attain 600,000 new installations per year could heavily outweigh current estimates, by as much as 200%.

The widely promoted 50,000 installers required to meet the government’s ambitious annual heat pump installation target of 600,000 may be three times lower than the number required, research has revealed.

Developing from discussions within the HHIC Systems Group, chaired by Steve Keeton, the organisation has conducted extensive investigations of working practices through the membership. It has revealed a figure of circa 150,000 workers is required to meet the

government’s target if today’s working model is followed.

Not only does this finding triple current predictions, it also reveals the need for 100,000 new entrants to the industry – a figure almost equivalent to the entire current Gas Safe Register.

Commenting on these findings, Steve Keeton says: “The industry is at a pivotal point, with an ageing workforce and exacerbated demand for modernised skillsets we really must look to new entrants as fundamental in providing the solution. The government must push harder than ever to engage and incentivise existing heating engineers to build skills in renewable technologies. In addition, it must attract more new people to enter the industry and appeal to the younger generation to proactively include low-carbon technologies in their portfolio. It is the cornerstone we need in order to achieve our nation’s emissions goals.”

Specialist Vital Energi has been awarded the latest major work package on the new Lombard Square development in Plumstead.

Berkeley and Peabody are transforming 17 acres of unused land in South East London which were once home to Arsenal Football Club.

Vital Energi has bagged the £13m design and build contract for the site’s Energy Centre and ground source heat pumps across all eight blocks containing 1,750 apartments.

The ground source heat pumps will extract water from aquifers

below the surface via 140m deep boreholes.

All risers and laterals will be installed within each block and Vital Energi will complete the design and build of the buried district heating network.

Rob Callaghan, Managing Director of Vital Energi’s London & Southern division, said: “We are looking forward to working on the design and build project in collaboration with Berkeley and Peabody, to

build a more sustainable and green community, whilst helping them to reach their net zero target by 2030.”

Karl Whiteman, Divisional Managing Director for Berkeley East Thames, said: “Together with our partner Peabody, we believe Lombard Square will be a real driver of change for Plumstead and Thamesmead.

“In addition to delivering new homes, it will offer employment retail and leisure opportunities alongside a new stunning biodiverse park that can be enjoyed by the whole community – –something we hope everyone will be proud of and benefit from.”

Vital Energi will start on site in August.

DEWALT, a Stanley Black & Decker (NYSE: SWK) brand and leader in total jobsite solutions, today announced the new 20V MAX* XR® 1/4 in. 3-Speed Impact Driver (DCF845) that boasts 30% more torque** and is designed for tough fastening jobs on the worksite. Delivering 1825 in-lbs of max torque and 3,400 RPM (no-load) through a brushless motor, the 20V MAX* XR® 1/4 in. 3-Speed Impact Driver is ideal for applications that demand power and efficiency. In addition to providing power, the 3 speed modes, variable speed trigger, forward/reverse switch, and

ergonomic grip help put the user in control when completing applications in various materials. With the on-tool 3-LED work light, users can illuminate dimly lit workspaces for enhanced visibility.

The 20V MAX* XR® 1/4 in. 3-Speed Impact Driver is available now as a bare unit (tool only, DCF845B) and in several kitted options (DCF845P1, DCF845P2, DCF845D1E1) where DEWALT products are sold.

To learn more about DEWALT tools, please visit: dewalt.com.

Snickers Workwear’s Protective Wear range is the betterinformed choice for professionals who demand quality, sustainable products that match protection standards for hazardous environments and foul weather.*

Snickers Workwear delivers a comprehensive selection of ergonomically designed Base, Mid- and Top-layer working clothes and accessories that also include Work Gloves, Kneepads and specialist ProtecWork clothing.

They are all certified as appropriate for different risks

at work to ensure the comfort, health and workforce-wellbeing all day, every day.

This extensive range also includes Hi-Vis clothing that provides protection against dangers such as Electric Arc, Heat and Flame, Chemicals and bad weather in high-risk environments.

So, whatever the hazard at work, Snickers Workwear’s Protective Wear collection - complimented by Solid Gear and Toe Guard safety footwear - can provide sustainable certified PPE solutions for maximum effective protection whatever the risks on site.

March 2023

Health & Safety Update focuses on the importance of safety within occupational and domestic environments – ensuring pro-activity rather than reactivity. We change attitudes towards Health & Safety measures, teaching our associates how to implement guidelines, prevent negligence, prevent injury and preventing the worst case scenario.

www.healthandsafetyupdate.co.uk

Peter Dumigan is managing director of the Hultafors Group UK, owners of Snickers Workwear and its ProtecWork range of Protective Wear. He writes:

Whilst it’s an employer’s legal responsibility to ensure that staff have the right level of protection and training against risks on site. Employees have a personal responsibility to be aware of risks and potential injuries to ensure adequate protection for themselves, their safety and wellbeing.

Depending on the job task to be performed, PPE for electricians generally includes safety glasses, face shields, hard hats, safety shoes, insulating (rubber) gloves and flame-resistant clothing.

In terms of clothing, there’s a big difference between conventional Workwear and specialist Protective Wear. Over the years, workwear has evolved to make your working day more comfortable and efficient, with built-in functionality for tools and fixings, as well as protection against cold, rain and the effects of warm weather.

Protective Wear, which can have one or more CE (European Conformity) marks, has been designed and developed to protect the wearer from serious risks such as heat, flames, electric arcs and hazardous chemicals. In effect, clothing that can mean the difference between life and death for the wearer.

In order to meet the protective requirements of a specific risk area, protective wear is divided into three categories - the higher the category number, the higher the level of protection.

Category I covers exposure to minimal risks, and for this category there are CE standards such as EN 343 (rain protection) and EN 14058 (cold protection).

Category II includes exposure to medium risks, for instance EN 20471 for high visibility clothing.

Category III covers exposure to serious risks, which include major hazards such as electric arcs and molten metal splashes or liquid chemicals.

To be able to properly identify what protection you need, you have to know what risks you, your employees or your workmates face.

Never assume that a Category I garment will protect against the more serious hazards and risks defined in Category III. It wont and you’ll be putting yourself at serious risk if you think it will.

That means understanding the hazards and risks of a specific electrician’s working environment or knowing the risk level before you start work and therefore wear appropriate clothing and PPE accessories.

That risk assessment and therefore the determination of the calorie levels required in the clothing needed has to be carried out by the company buying the clothing. Importantly, each working situation will have its own required minimum protection depending on the risk situation.

How do I know the protection level of my outfit?

It all starts with having working clothes with the appropriate CE mark for the specific risk environment.

In work locations that involve a risk of electric arcing, you must also ensure your clothing offers a level of protection that corresponds to the risk level – Category III.

You do this by adding up the total number of Calories of all the layers of your outfit and it’s important to remember that high-risk

environments require that all the clothes you wear, including underwear and base layers provide protection against heat and flames.

What is a Calorie in the context of PPE?

In PPE terms, Calories are used to define the protection level of a fabric an item of clothing or the system of materials/garments.

When an electric arc is triggered, different types of energy and risk factors are created, such as arc power, arc energy and incident energy, all of which are measured in Calories. This is why calories per square centimetre (cal/cm2) has become the unit used to measure a fabric’s or garment’s level of protection.

What sort of electric arc risks do electricians have to deal with?

Arcs due to electrical faults can cause severe injuries and damage such as thermal injury, serious burns, electric shock, noise, UV emissions, pressure and shrapnel, as well as toxic exposure and the impact of physical and mental shock.

What sort of burn injuries can occur?

A burn to the skin or other tissue caused by heat or hot substances in a solid, liquid or gaseous state. They can cause tissue damage to various degrees, depending on the nature, intensity and duration of the damage. Burns are classified into four types:

A First-degree burn results in damage to the epidermis (outermost layer of the skin), which normally heals in a couple of days.

A Second-degree burn damages the dermis (thick layer of living tissue below the epidermis),

usually causing skin blisters and major inflammation.

A Third-degree burn causes total damage to skin/tissue and is characterised by hard, white skin resembling parchment. In a full-thickness skin injury, sensory receptors in the tissue are damaged, meaning no pain will be felt in the damaged area.

A Fourth-degree burn extends through the entire skin into underlying fat, muscle and bone and, as a result, the skin is black and charred with dead tissue.

The injury area is defined as the TBSA (Total Burn Surface Area) percentage, which expresses the size of the burn as a percentage of

total body area. For instance an arm is approximately 9%, and a leg 18%.

“Based on independent tests and reports coupled with our years of experience, we recommend that you should never wear garments that offer total protection of less than 11 calories/cm2 if you are going to work in or near a high-risk environment”, says Peter Dumigan.

“This calorie level does not in any way provide total protection, far from it, but should be seen as a minimum level. Different jobs require

different levels of protection, and the higher the calorie level your clothes (or outfit) have, the better protection you get. Be sure you know the risk level before you enter a specific risk environment, and wear appropriate clothing”

“One of the best ways to improve your level of protection is to wear layers – base-, mid- and top-layers. A fundamental requirement is of course that all the garments are certified and flame retardant’ says Peter. The main benefit of wearing layers is that the air gap formed between different garments provides increased protection. There is no general rating for how much increased protection the air gap between layers provides. However, we have conducted a number of tests that show that the air gap increases protection by more than 5 cal/cm2

The calorie level of the extra protection depends on a variety of factors, such as fabric structure, thickness and construction – and for a precise value, combined tests on each layer must be performed. “What we know for certain”, says Peter, “is that wearing multiple layers improves the protection rating. It’s therefore best to think of the air gap between each layer as extra protection that improves your chances of avoiding burns in the event of an accident”

Working in high-risk environments involves, as the name implies, high-risk levels.

Arcs due to electrical faults can cause severe injuries and damage. So it’s vital that you choose the right protective wear to ensure your safety and well-being on site.

Tilsatec as a business is on a journey, one that’s never finished. Working towards positive change across manufacturing, logistics, energy consumption, recycling and raw materials to deliver high performance hand protection which enables customer to reduce their carbon footprint and take energy intensive products out of the supply chain.

EnVision is the umbrella under which our sustainability program sits, and it’s underpinned by our 3 key pillars; People. Planet. Protection.

The EnVision glove range has been designed to provide end users with a credible, viable eco-

friendly alternative to their current hand protection that doesn’t mean compromising on protection, comfort or significantly higher prices.

55-6725 cut level F glove with microfoam palm coating is made with 68% recycled and bio-based yarns. Tilsatec are one of only a handful of manufacturers to use Bio-Based Dyneema the first ever bio-based ultra-high molecular weight polyethylene fibre, reducing reliance on fossil fuel-based resources.

To arrange a site survey and try the phenomenal range for yourself contact info@tilsatec.com or tel: 01924 231681.

At its Annual Long Service Awards ceremony, held at St. Ermin’s Hotel in London, leading building products manufacturer Forterra celebrated Peterborough employee Keith Coulson, who represents the thirdgeneration of Coulsons to have worked for the company.

Keith began his career in 1972, but has memories of the old brickyard from the age of five.

“We lived in a company house right opposite the brickyard. My father worked there and me and my brother would often play nearby. I even helped hand-set some of the bricks when I was a youngster.

“In fact, my mother also worked in the canteen at Kings Dyke for a while, so it’s always felt like a family company for us.”

When he left school at age 15, Keith started work as a messenger boy. Keith would cycle a 14-mile round trip from his home in Whittlesey to Peterborough each day, delivering messages from yard to yard.

“My grandad, George, had worked as a burner at King’s Dyke and he encouraged my own father to join the company shortly after leaving school. When I left school, my father encouraged me to do the same thing, and it felt like the best thing to do!”

After 12 months of this he became a Works Office relief, which involved him in various administrative tasks at a time when these were still more or less done manually. This was a role he held for the next 11 years across all the Peterborough area offices.

In 1984 Keith moved to the Kings Dyke factory to become a Production Auxiliary, where he developed and expanded his knowledge, learning all the jobs needed for production.

“For a time I worked at Kings Dyke alongside my father and my brother, Roy ‘Chipper’ Coulson, who himself has racked up 46 years at the company.

I enjoyed working with the both of them; it really added to the sense of camaraderie that was at Kings Dyke”

Between 1990 and 2002 Keith remained at Kings Dyke working as a Hand-Setter, building the units of bricks ready to be fired in the kilns.

“I really appreciated the incredible feeling of community there. The area manager would often pop down to the old brickyard and walk around, speaking to each of us, all of whom he knew by name.

“There was a clubhouse at Kings Dyke which everyone would gather in at the end of the day. We’d join darts teams and compete against other clubhouses every now and then – it was a really wonderful time.”

From 2002-2022, Keith has worked at Kings Dyke as a Wicket Man, responsible for the dismantling, erecting and maintenance of the ‘wickets’ or kiln doors, a role which he enjoys immensely.

In an even more impressive development, as of 2022 Keith’s son, Robert, has joined the company, marking four generations of Coulsons at Forterra.

“I’m proud to have worked for the same company for my entire life,” says Keith. “I’ve always been made to feel like a valued member of the team and have always greatly enjoyed the variety of roles I’ve held in the business.

“My wife Anita, whose own father worked at the company,

has herself often worked several cleaning jobs at Kings Dyke. We really have a lot of our family history bound up with the brickyard!”

David Jackson, Production Shift Manager at Forterra, says, “Keith is a very respected and valued member of the team who is always happy to carry out tasks when asked and always gives his best. We’re really proud to have had four generations of a family working here. Our community values and our employees are at the heart of the business, and Keith is a testament to that. I hope to keep him a little longer yet!”

For more information on Forterra, visit www.forterra.co.uk.