JESSICA HALDANE

CARPE(NTRY) WOODCRAFT SCHOOL +

CARPE(NTRY) DIEM + PROCESSING CENTRE

“AT

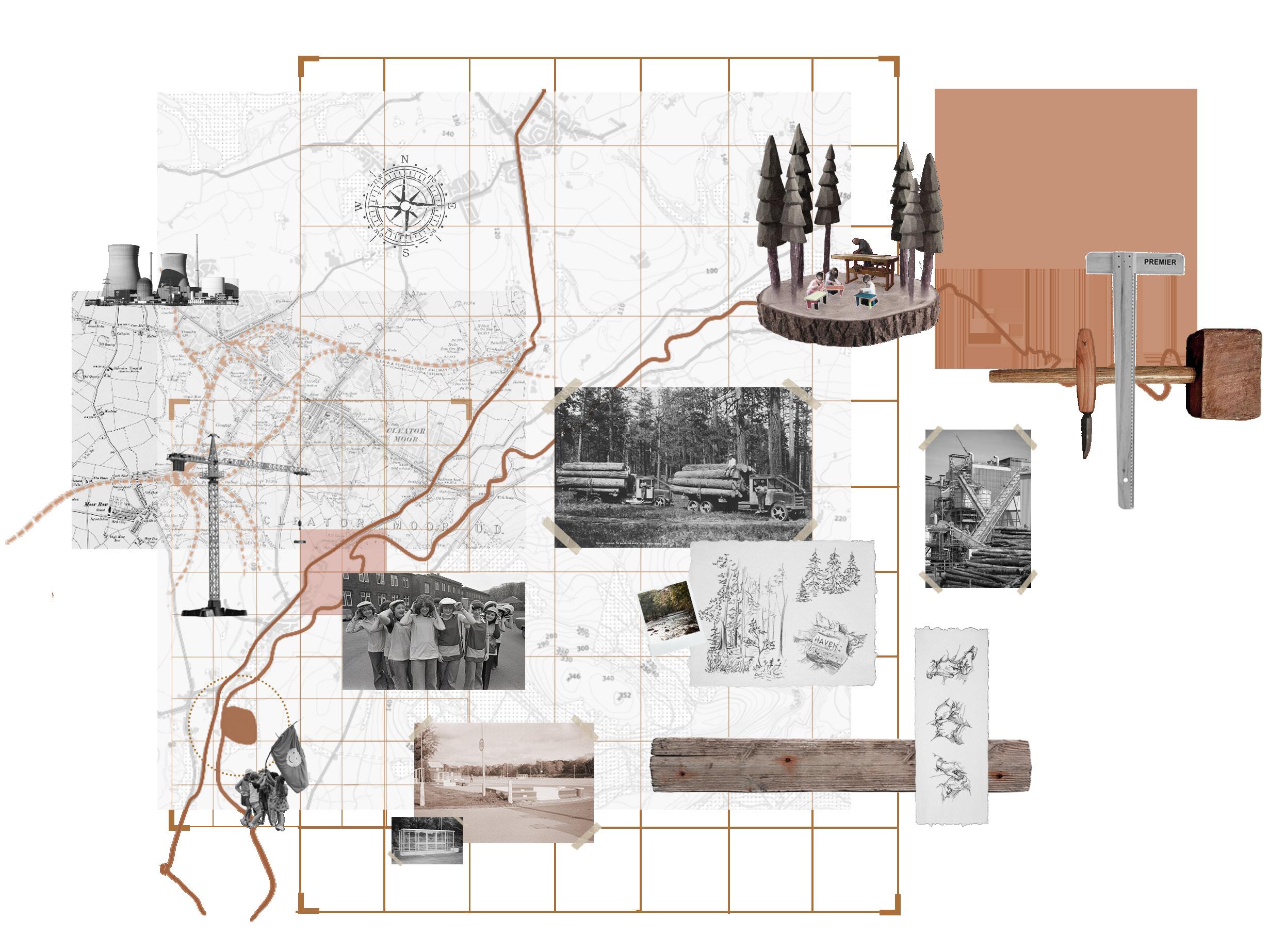

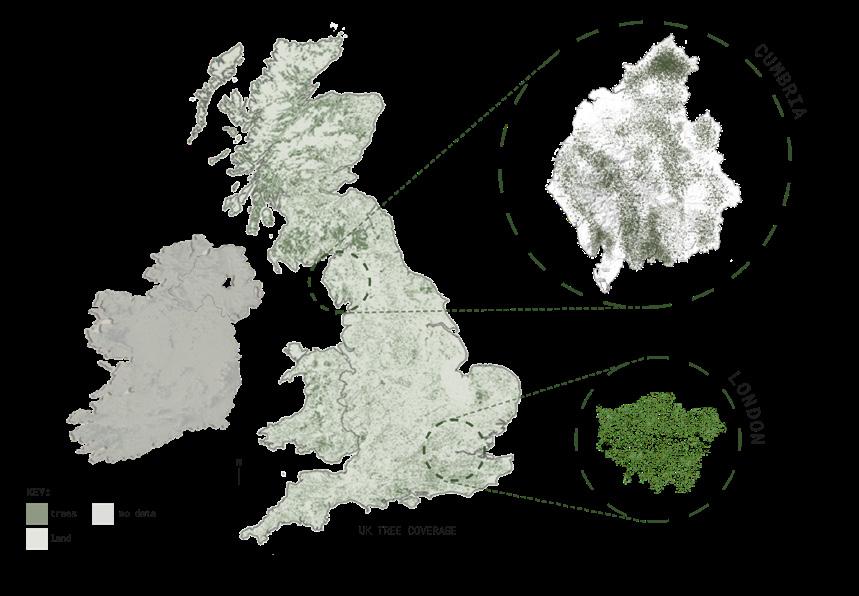

Beyond the idyllic and romanticised Lake District, the western borough of Copeland largely depends on nuclear industry for economic survival and finds itself intertwined with shortcomings in skills, education and mental health. The abandoned Kangol Factory in Cleator reflects these issues alongside stark realities of the wider territory such as Cumbria’s dwindling forests.

Carpe(ntry) Diem aims to heal Copeland through on site maximisation of forest potential with the implementation of an aforestation and rewilding scheme alongside Slöjd (woodcraft) education - slöjd meaning ‘handicraft’ in swedish and encompassing the link found between manual dexterity and cognitive development. This is particularly effective at reducing anxiety in users of high stress environments.

Users here are encouraged to ‘seize the day’ through a series of immersive workshops and nature walks, promoting human-nature symbiosis and acting as a cultural injection that acknowledges Cumbria’s rich industrial past in forestry and timber whilst looking towards an ecological future.

This scheme employs passive environmental principles and a localised circular economy - a notion that is enforced with external sourcing of wood material, for construction and programmed activities, from existing nearby sawmill schemes and high use of recycled material. The trees sourced via local sawmills were utilised to their full potential - from the bark to the resin. This circular sentiment is further sustained with on-site modular biofuel facilities, exchanging the waste from the locally provided material for mutually beneficial biomass-born energy.

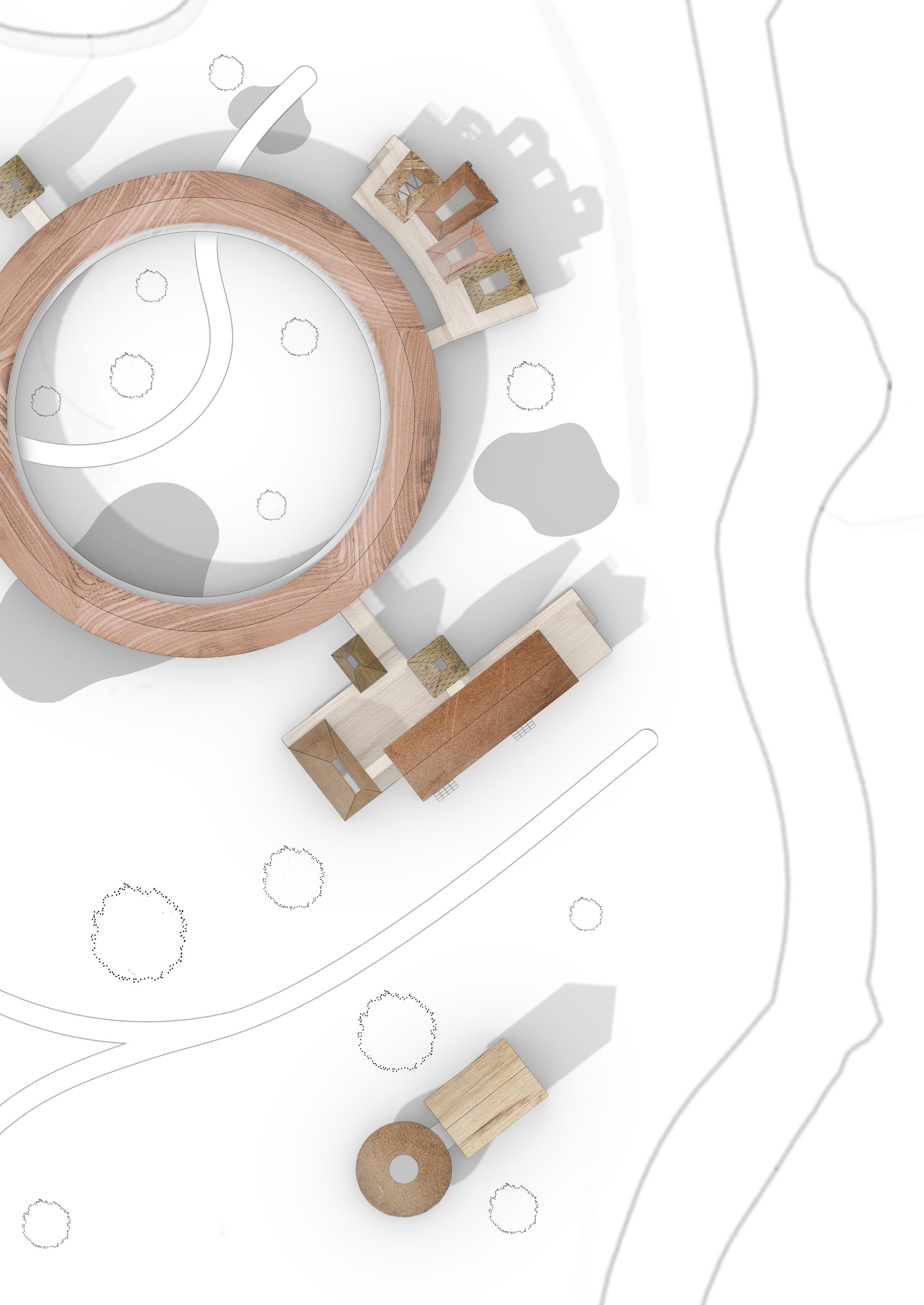

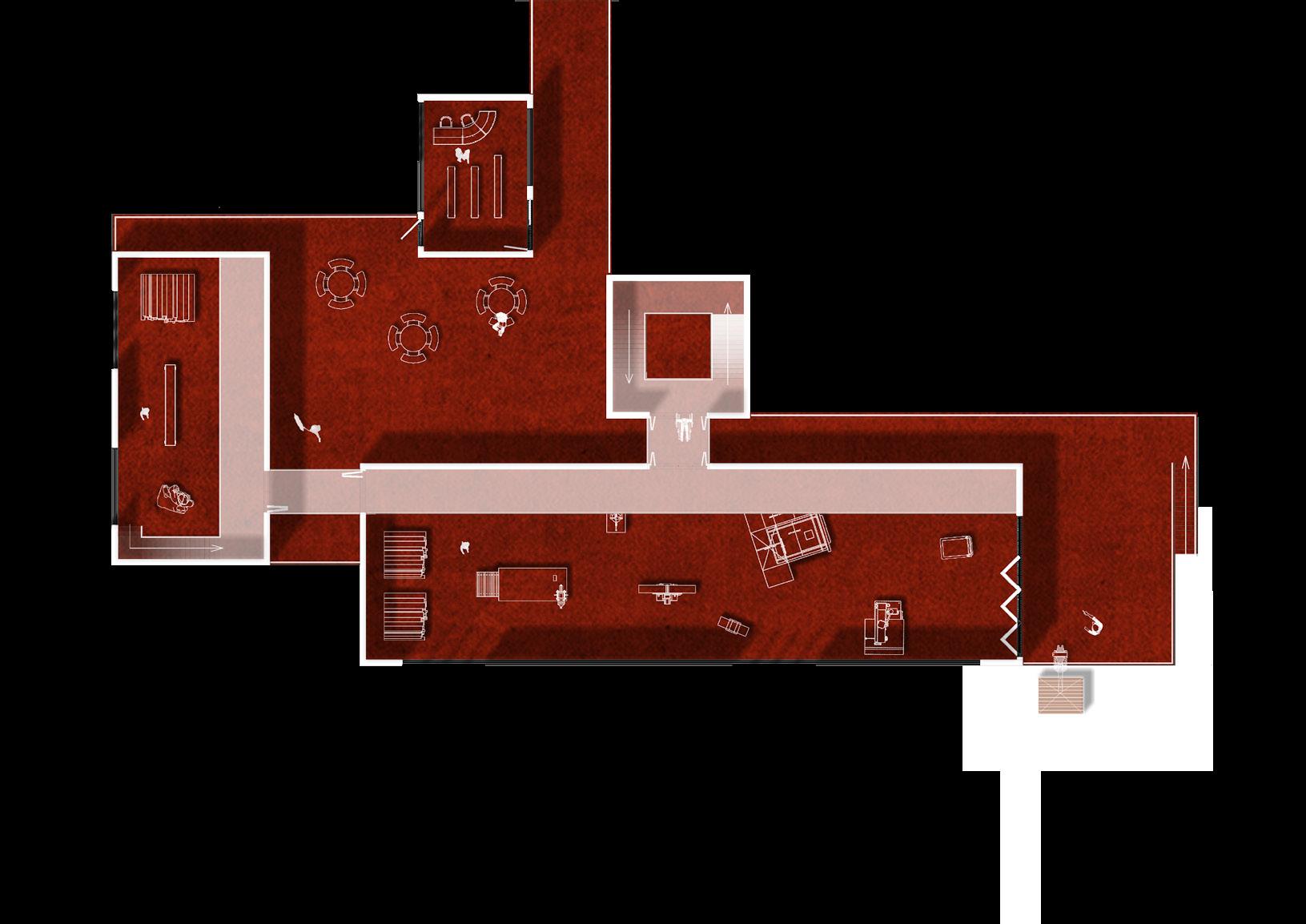

1

2 transport hub

3 wood processing facility

4 exhibition of recycled material

5 stairs/lift

6 reception

7 nature viewing orbit

8 woodcraft and forestry school 9 stairs/lift from ground level

1:200

ROOF oak shingles

criss crossed timber battens

membrane seal

SIPs (structural insulated panels): OSB + polyurethane

douglas fir finish

STRUCTURE

glulam timber trusses on timber columns

steel cables acting as tie rods stabilise the trusses

screw plates connect joints

WALLS oak strips

criss crossed timber battens

membrane seal

SIPs

douglas fir finish

FLOOR

screed

cordek foam + underfloor services

sealing layer

fiber cement board

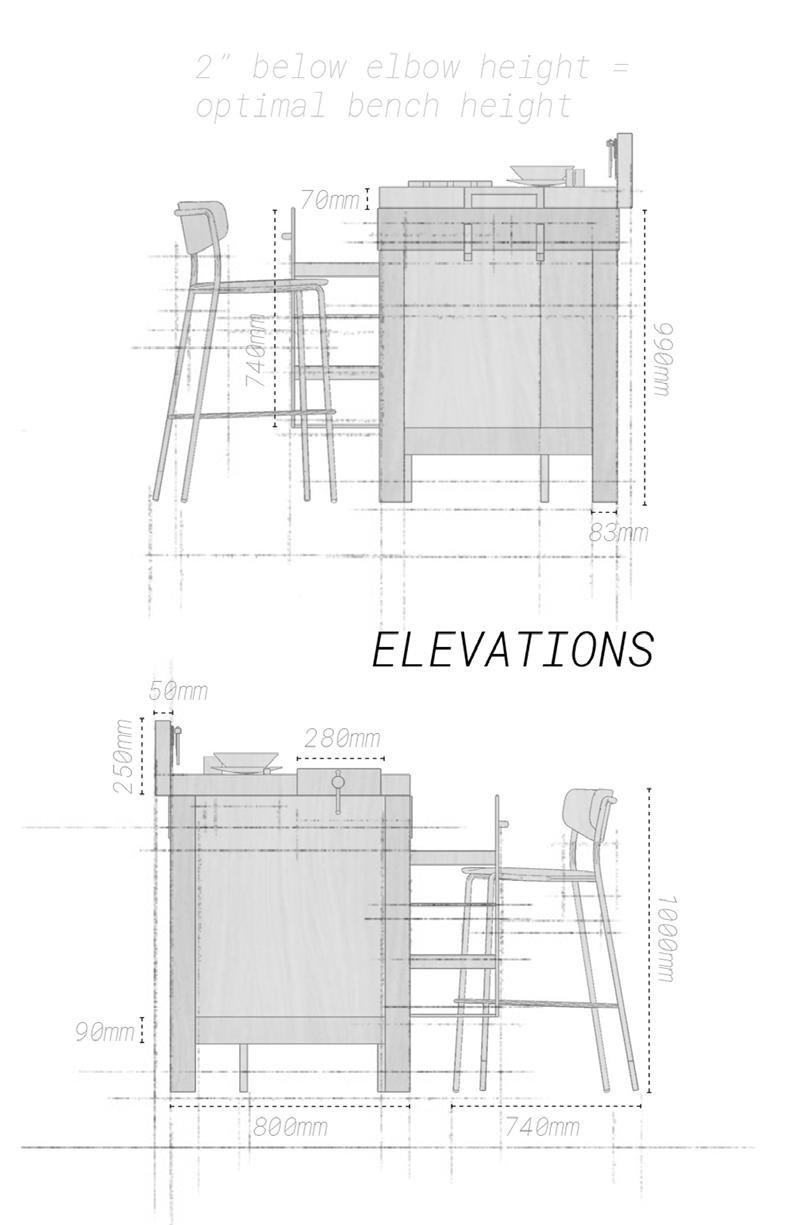

1:10 PERSONAL WORKBENCH MODEL // DESIGNED FOR OPTIMAL USE + MADE ENTIRELY OF WOODSHOP OFFCUTS (REPRESENTATIVE OF MY CIRCULAR SCHEME)

RECYCLED INTO CHIPBOARD OR USED AS BIOMASS FOR FUEL

DUST COLLECTION SYSTEM | HAND DRAWN ARRANGEMENT

THANK YOU FOR YOUR CONSIDERATION :)