Case study: Mater

Case study: Nordisk Film Shortcut

Photo: Mater

Transforming film production Nordisk Film Shortcut’s ground-breaking LED stage greatly reduces the carbon footprint of any production. Contributor

The global entertainment industry has witnessed a growing demand for

– Nordisk Film Shortcut

sustainable and eco-friendly practices to reduce its environmental impact. Traditional film production involves extensive travel, on-location shoots, and large-scale set constructions, leading to significant carbon emissions. Shortcut LED stage is a 100% solar powered 360˚ LED stage in which you can film photorealistic locations from all over the world, greatly reducing the carbon footprint of any production.

Using innovation to make new materials

As the Shortcut Stage is 100% powered by solar power, it actively participates in the shift to reduce the carbon footprint, contributing to a greener and more sustainable entertainment industry.

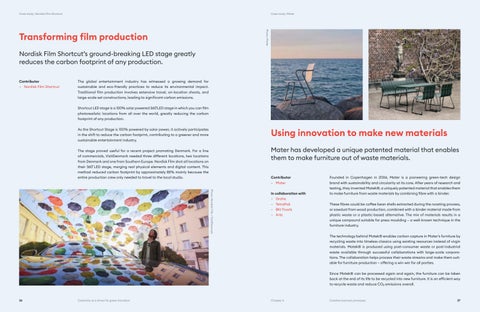

Mater has developed a unique patented material that enables them to make furniture out of waste materials.

The stage proved useful for a recent project promoting Denmark. For a line of commercials, VisitDenmark needed three different locations, two locations from Denmark and one from Southern Europe. Nordisk Film shot all locations on their 360˚ LED stage, merging real physical elements and digital content. This method reduced carbon footprint by approximately 85% mainly because the entire production crew only needed to travel to the local studio.

Contributor – Mater Photo: Nordisk Film / VisitDenmark

In collaboration with – Grohe – TetraPak – BKI Foods – Arla

Founded in Copenhagen in 2006, Mater is a pioneering green-tech design brand with sustainability and circularity at its core. After years of research and testing, they invented Matek®, a uniquely patented material that enables them to make furniture from waste materials by combining fibre with a binder. These fibres could be coffee bean shells extracted during the roasting process, or sawdust from wood production, combined with a binder material made from plastic waste or a plastic-based alternative. The mix of materials results in a unique compound suitable for press moulding – a well-known technique in the furniture industry. The technology behind Matek® enables carbon capture in Mater’s furniture by recycling waste into timeless classics using existing resources instead of virgin materials. Matek® is produced using post-consumer waste or post-industrial waste available through successful collaborations with large-scale corporations. The collaboration helps process their waste streams and make them suitable for furniture production – offering a win-win for all parties. Since Matek® can be processed again and again, the furniture can be taken back at the end of its life to be recycled into new furniture. It is an efficient way to recycle waste and reduce CO2 emissions overall.

36

Creativity as a driver for green transition

Chapter 4

Creative business processes

37