\\ Joy Of Design

Bringing the conceptual ideal into the stage of fabrication. Explore into the world between the build and design.

MALAYSIAN

\\ Career Objective

jeffsohhx@gmail.com

https://issuu.com/jeffsoh /docs/final_port_a4

To be part of a passionate and inspiring team that allow me to grow and explore new and interesting concept in a design field that see the challenges of the future as an opportunities for something better.

\\ Experience

Mar - Aug 2019

Sep - Feb 201

Freelancing

Jul - Sep 2017

Freelancing

Aug - Sep 2017

Research

Assistant

Jan - Mar 2014

Intern

Jan - Mar 2013

Draftperson

Hassell , Brisbane Studio

Alexander Knox

- Grasshopper modelling

Blight Blight Blight Architecture Firm

- Digital Modeler with Rhino and Grasshopper software - Renderings

Rmit Fabrication Pod II

- Assembly of cells

B.Y.G Architecture Firm

- Prepare CAD drawings for shopping malls

- Early conceptual designs for highrise apartment and shoplots

- Measured and prepare drawings for Indian Temple documentation

Penang Ng Clan Temple Measured Drawings

- Measured and collect building dimension

- Prepare CAD drawings for documentation

2015 - 2017

Postgraduate

2012 - 2014

Undergraduate

\\ Skillset

Grasshopper

Rhino 3d Model

Auto CAD

Revit

Photoshop

Enscape

\\ Language

English

Mandarin

Bahasa Malaysia

Master in Design Innovation & Technology Rmit

Featured Project By IDDA (OKTA) https://www.idda.com.au/case-study-rmitstudents-master-full-scale-digital-fabrication

Bachelor of Science (Honour) (Architecture)

Taylor Lakeside University

INTERMEDIATE

Illustrator

InDesign

Revit

Reaper

Arduino

AfterEffect

DESIGN BRIEF //

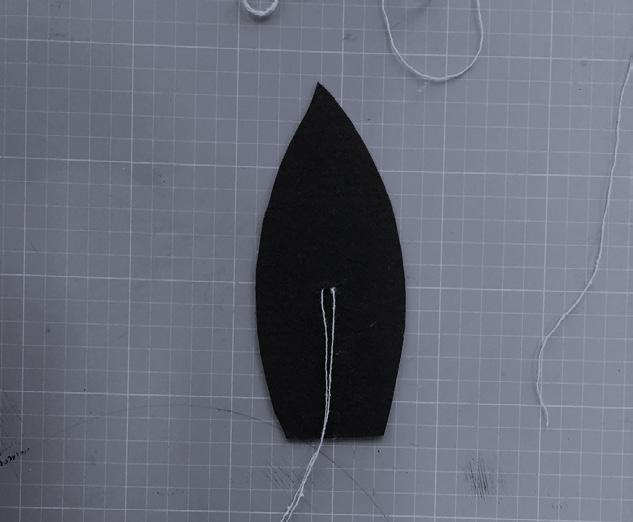

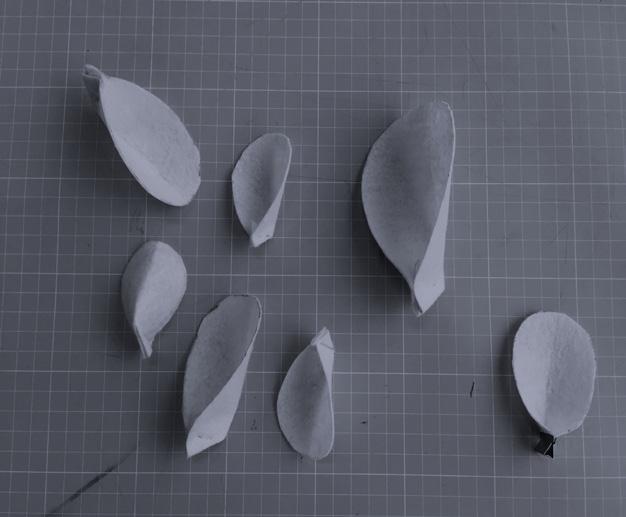

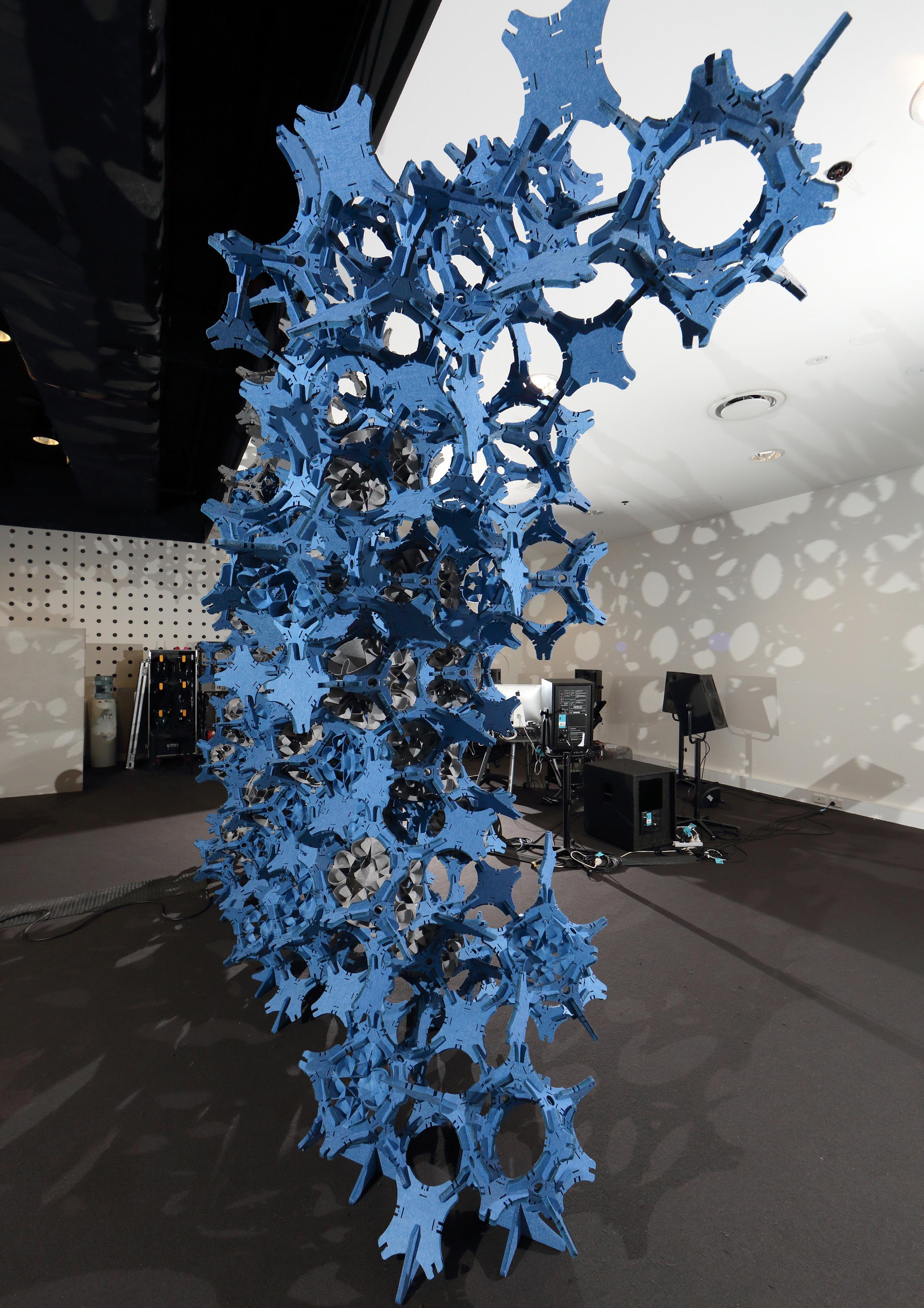

This project engage with digital fabrication and advance manufacturing techniques in order to fabricate , assemble and eventually create an architectural design. The aim of the project is to integrate new material systems and build a full-scale installation that divides the SPATIAL INFORMATION ARCHITECTURE LABORATORY (SIAL) sound studio. This studio will be limited mostly to echo panel material that made out of 100% PET (Polyethylene Terepthalate).

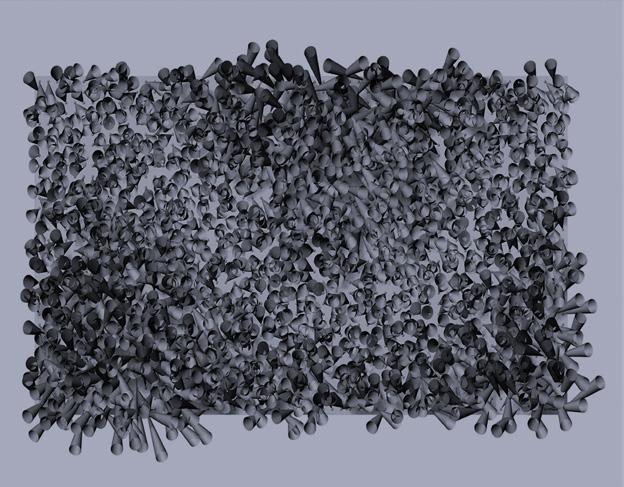

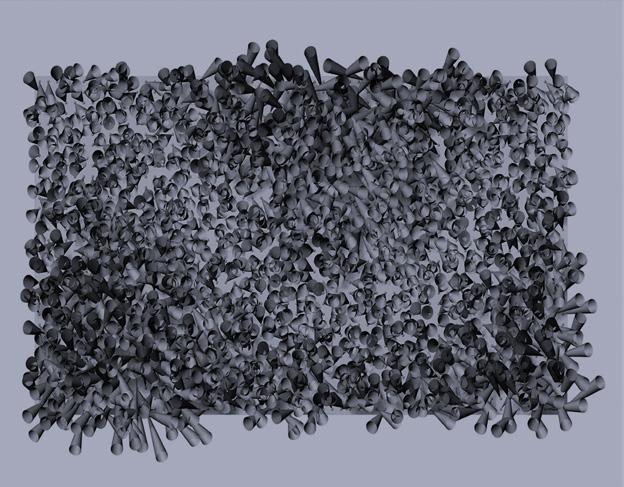

EXPLORATION //

Different type of individual modules are used to created an imitation of flowerlike-patterns in the early stages of the exploration.

CHOSEN MODULES

The three joint modules were used as the final iteration for further exploration in complex form making.

Three different underlined geometry was created from the chosen joint system. JOINT //

5 + , 9 3 0 5 , UNDERLINE

DESIGN BRIEF //

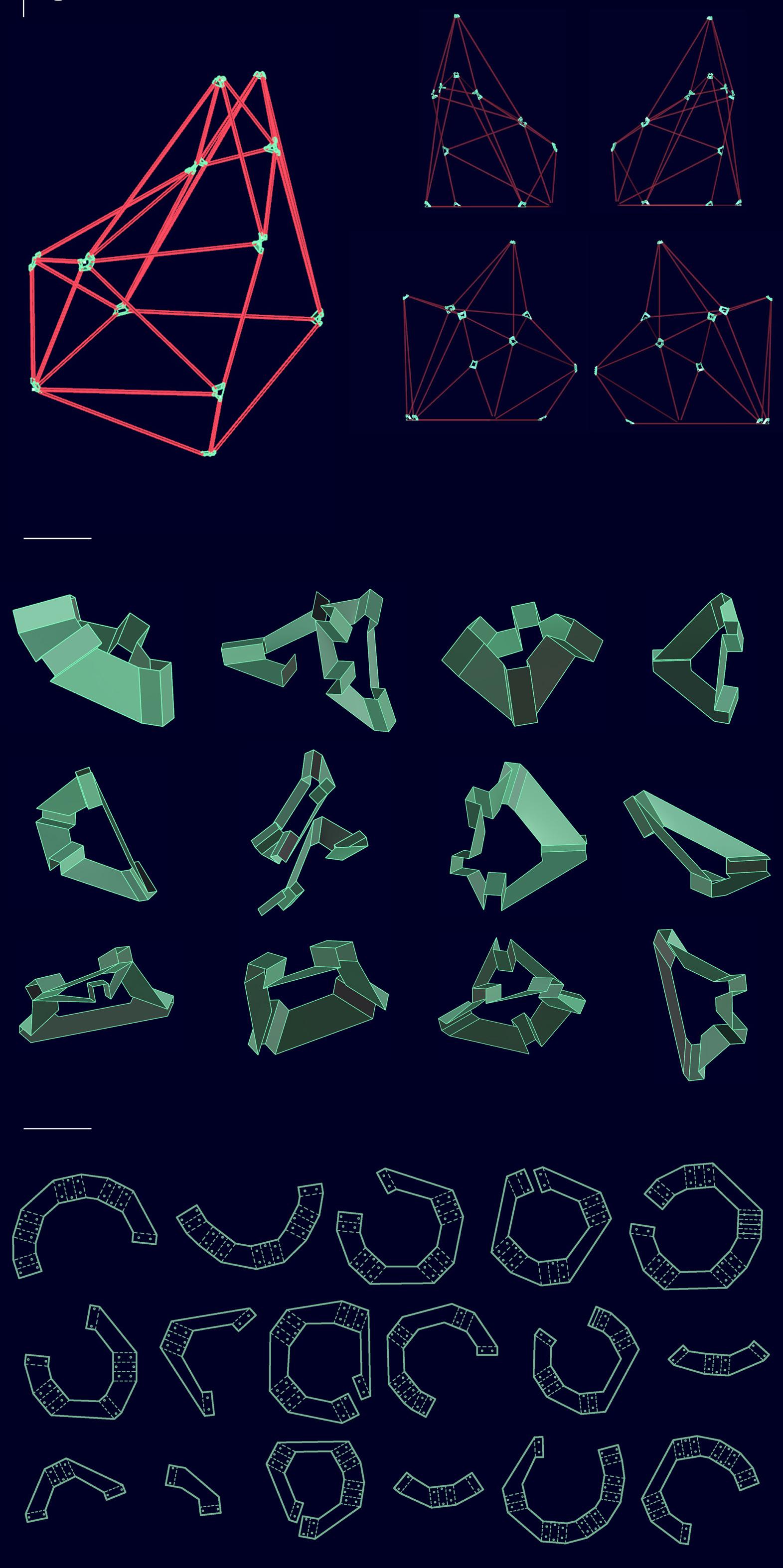

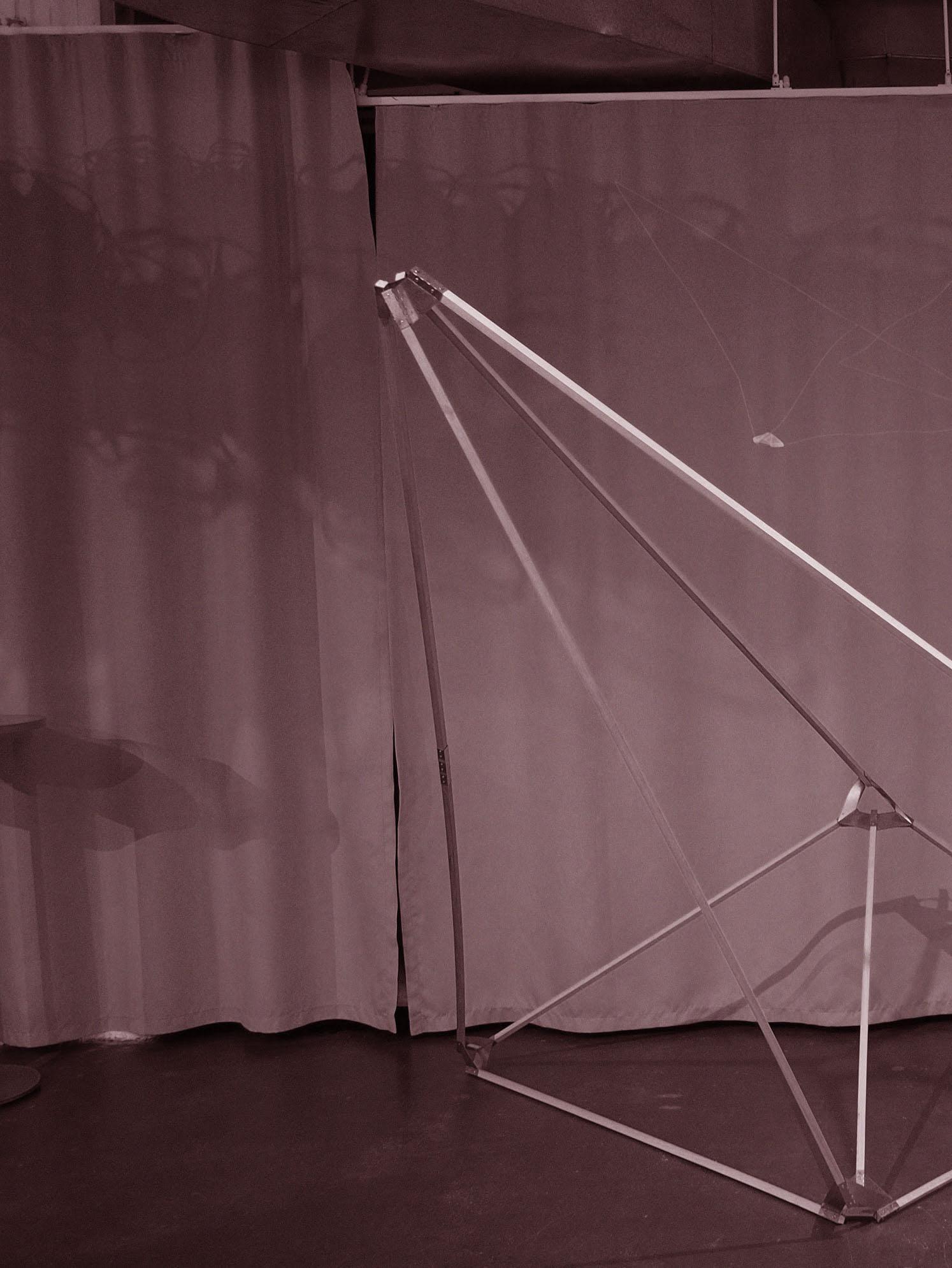

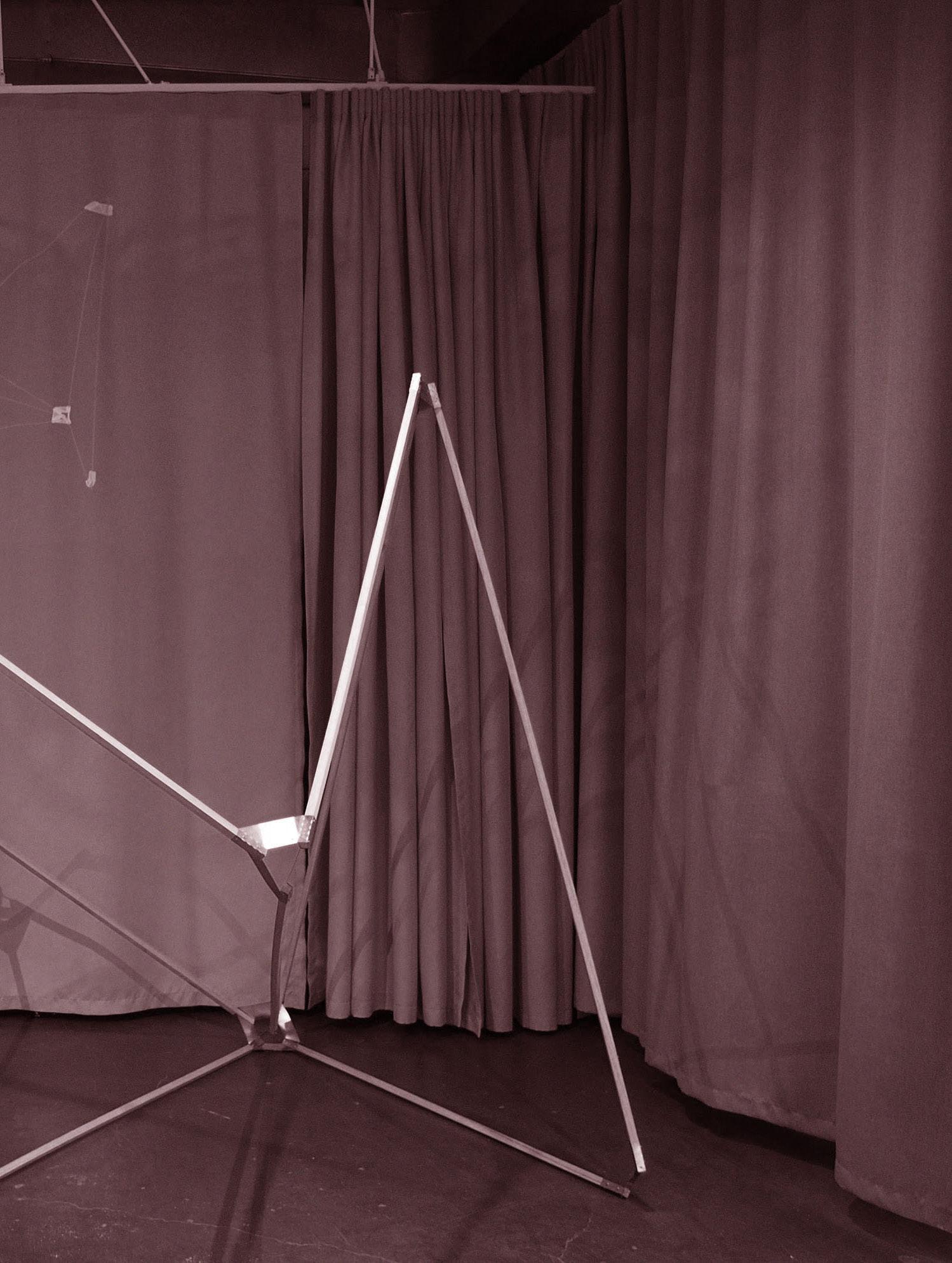

The Adaptivism project explored approaches to a flexible building system that allows the creation of a vast array of expressive architecture forms. The project focused on the development of a design methodology that employed the functions of the rhino and grasshopper software packages. The use of these programs enabled a consideration of the bringing together of ideas around digital fabrication and prefabricated building elements.

The resulting building system provides an interface for architects and designers to generate complex spatial and structural geometries in which the joint configuration is instantly calculated and translated into unfolded component patterns for steel fabrication. The system generates exact dimensions for the timber strut lengths and laser cutting patterns for the galvanised steel joining system. Ultimately the design of the system exposes the potentials that lie within the adaption of parametric software to the realm of lightweight prefabricated structures.

Final iteration is a flexible node system that allows the steel sheet to be wrap around the wooden members. Giving it a nice single enclosure on the connection point.

Each cut file are unique and served a specific joint for a different combination of angles.

STRUCTURAL STAGE

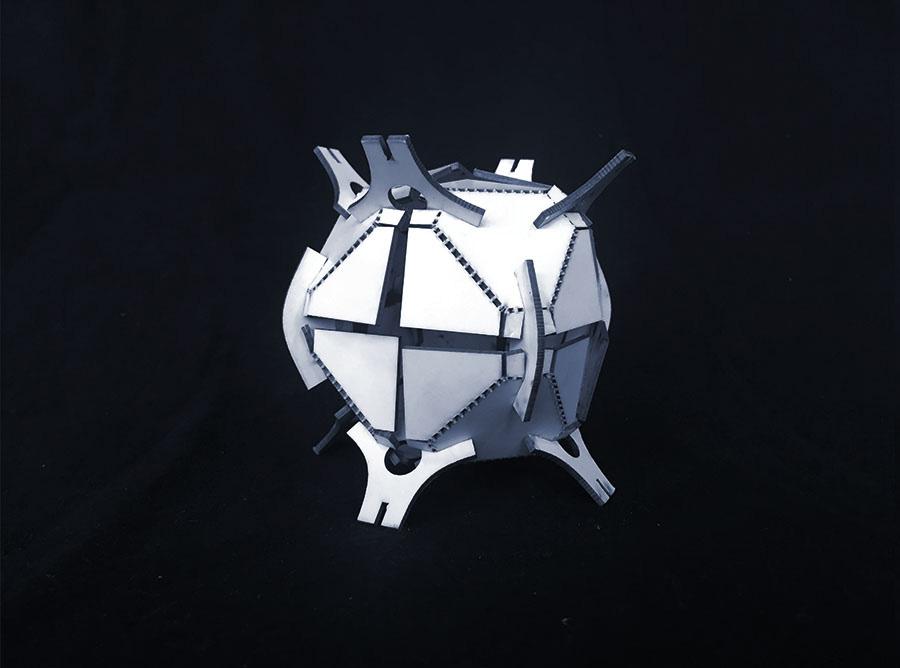

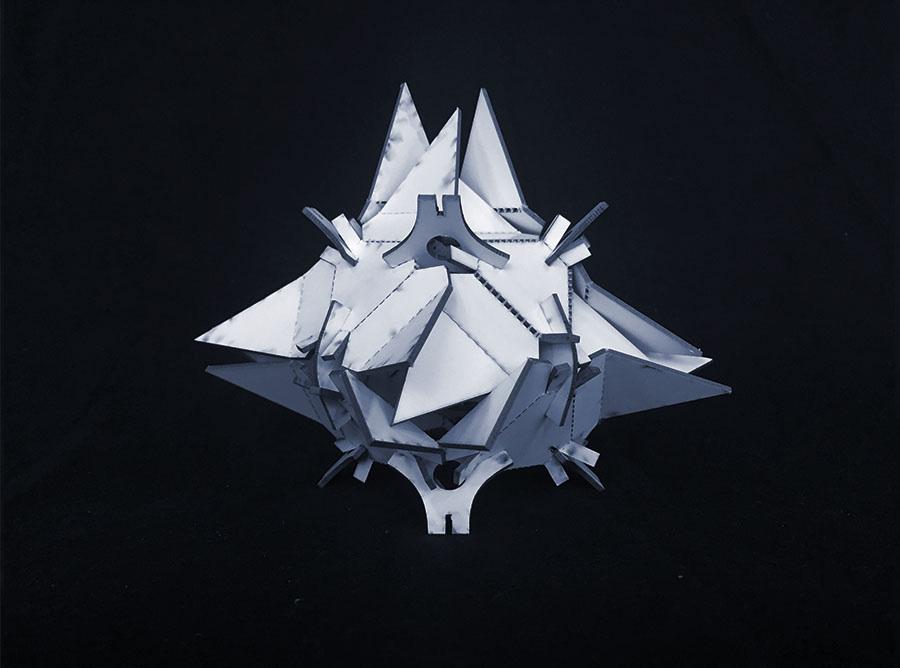

DESIGN BRIEF //

This is the second iteration of Fabrication Pod II where it aims to extend the research into the relationship between architecture and digital manufacturing. In this stage of the project , it aim to create a customisable and stackablecell components. In which, the used of lightweight structural framing system - custom cut sheet metal.

// Research Assistant for Chen Can Hui

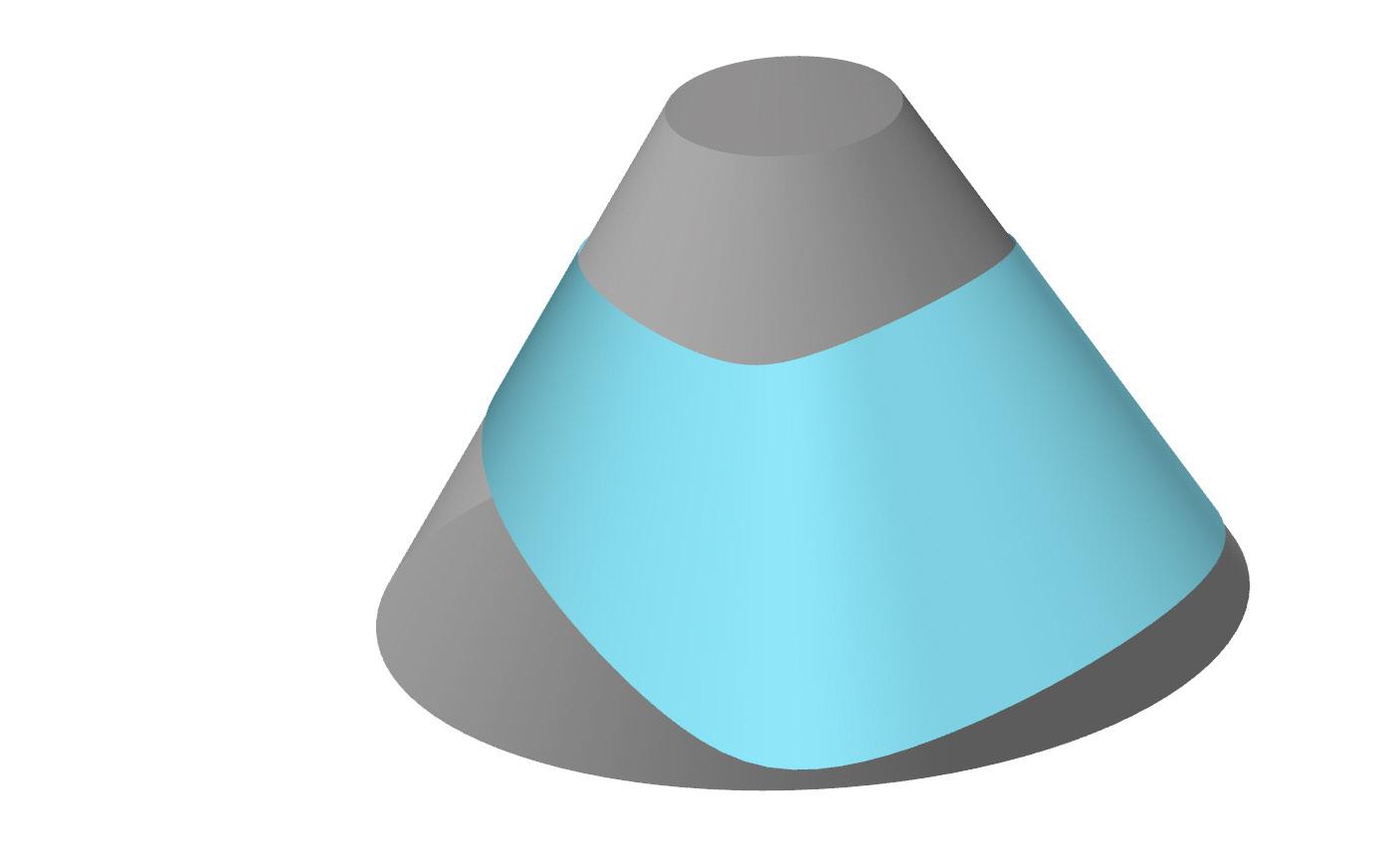

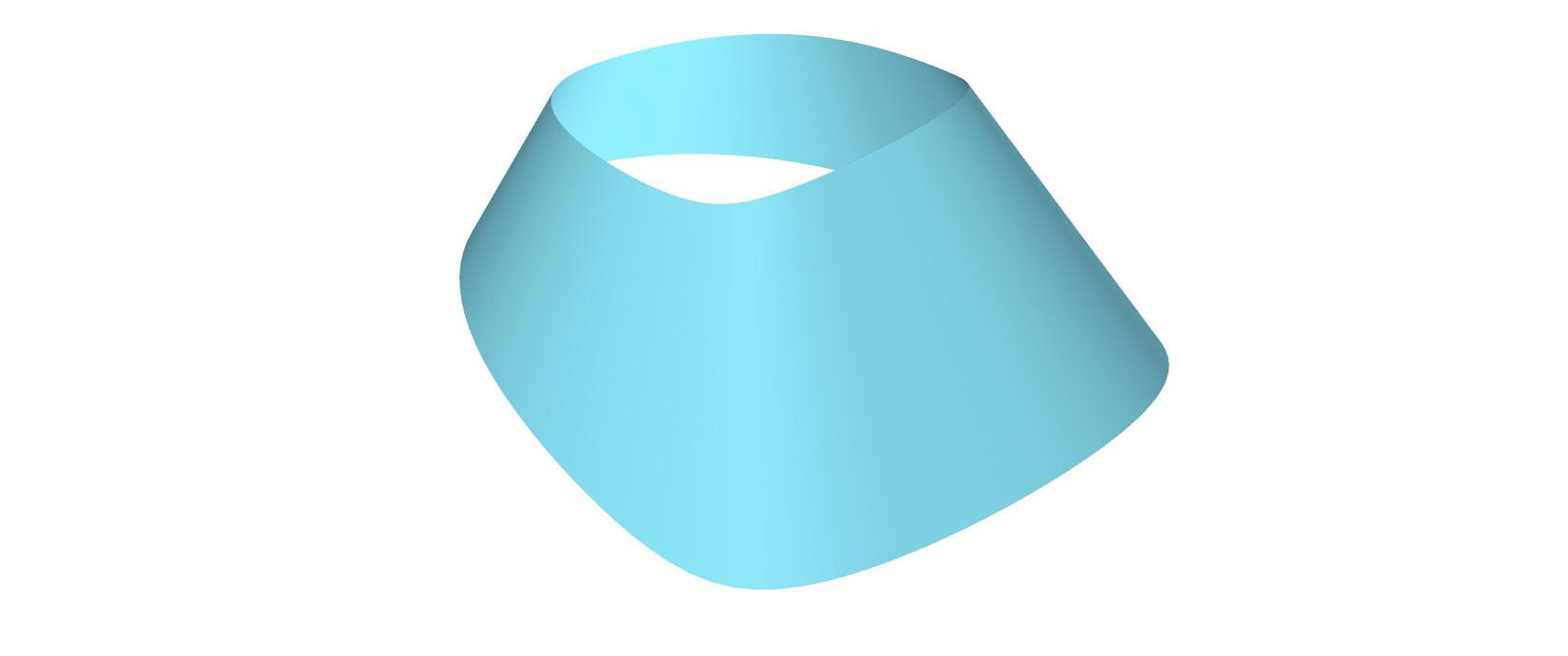

SKELETONS & CONES //

Sheet metal are laser cut and folded into the desirable cells while the plastic cone are cut by a 6 axis cnc that fit perfectly into the specific cells.

In the left pic shows only 2 parts of the cell wall that have been build.

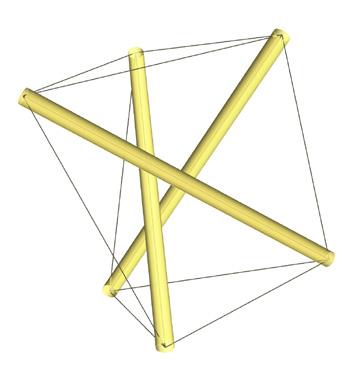

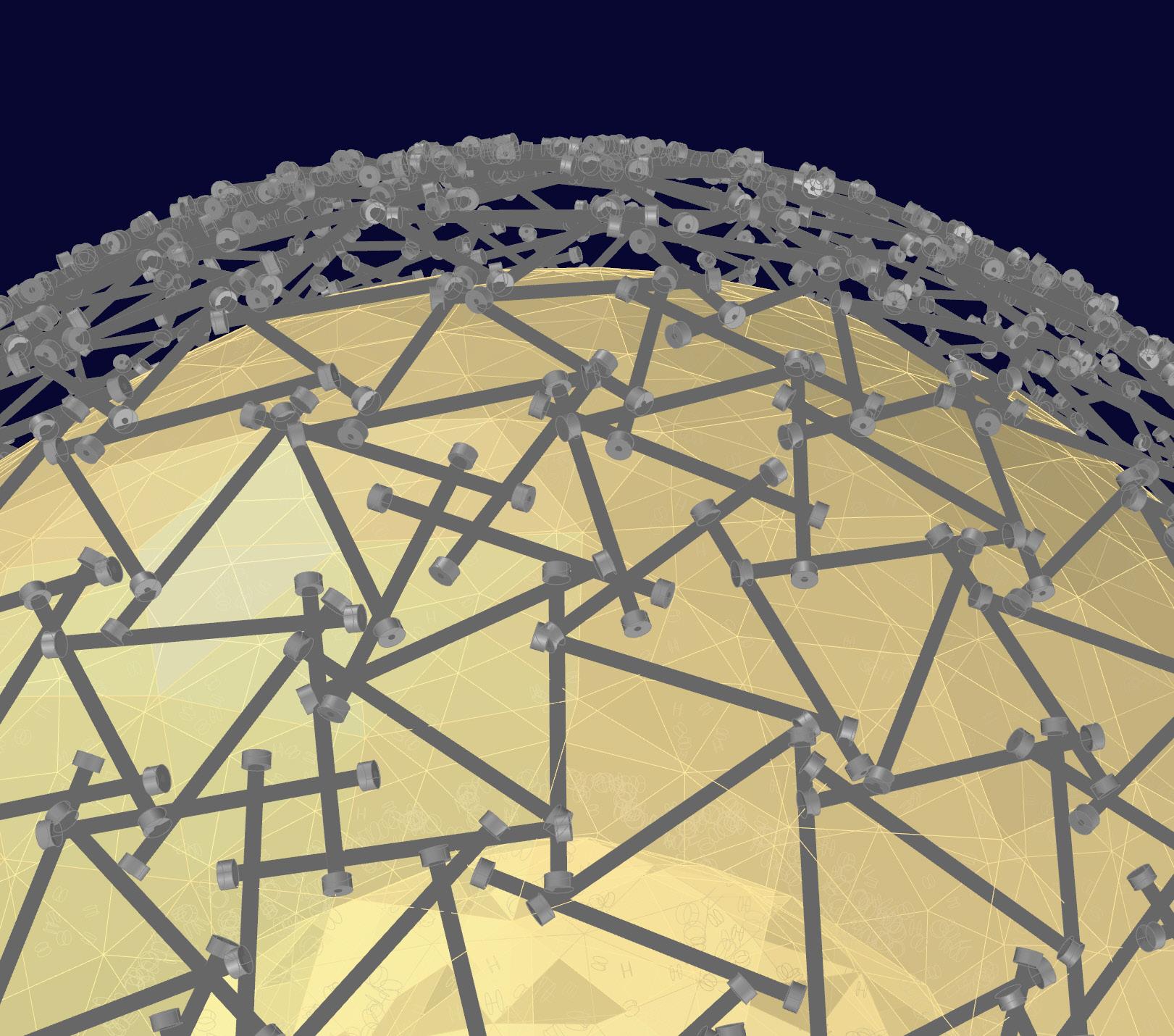

TENSIGRITY

DESIGN BRIEF //

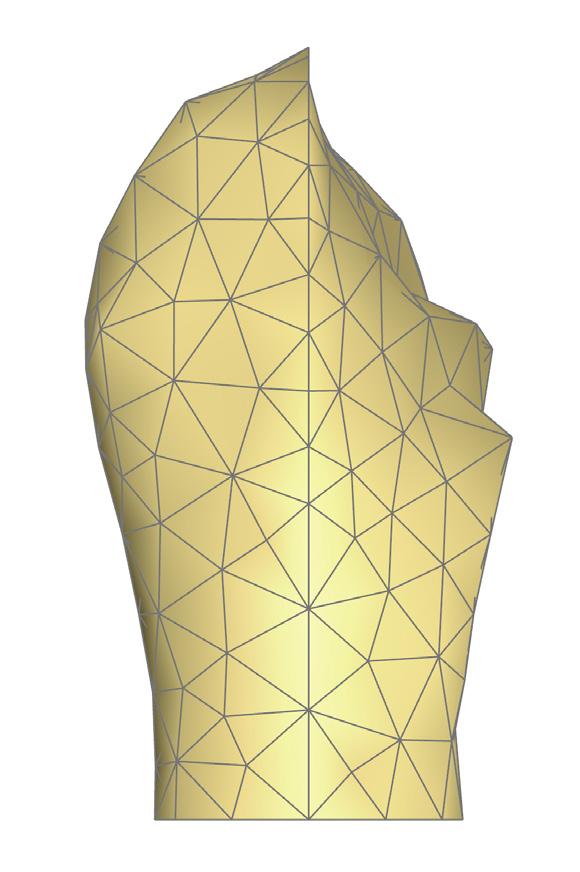

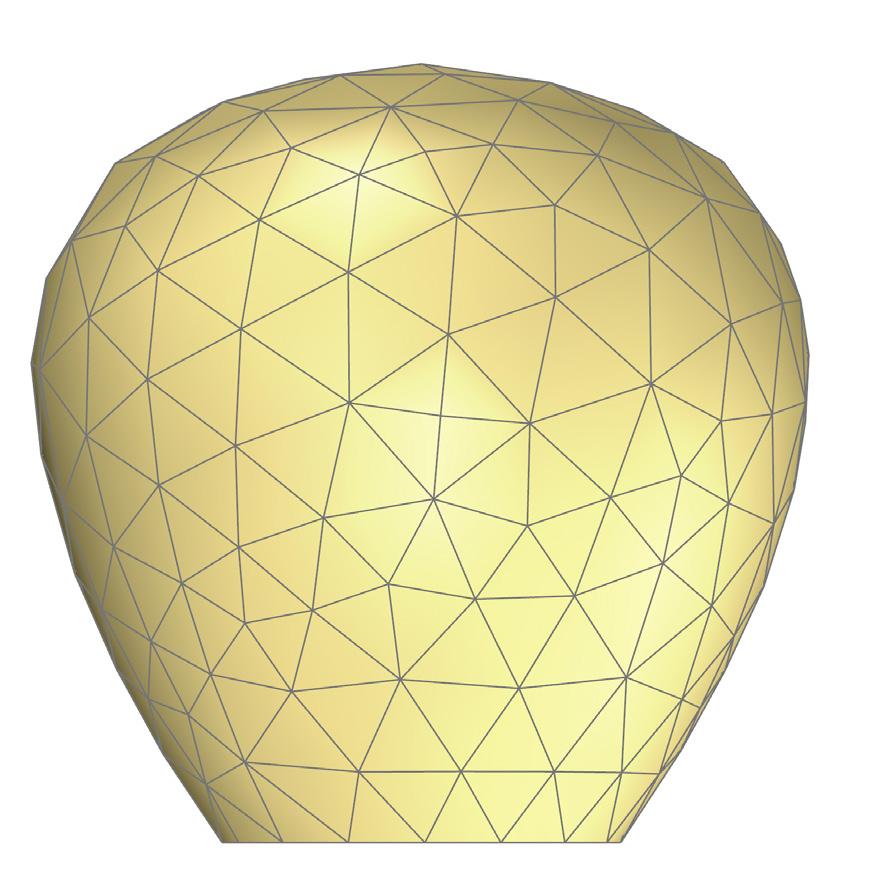

This project look into the posibility of creating lightbulb shapes sculptures by using reciprocal or tensigrity structural system. The goal of the project was to create a grasshopper script that allow 3500 number of metal bolts with each being 500mm in length to be joint into a tensigrity sculpture base on the form intended.

// Blight Blight Blight

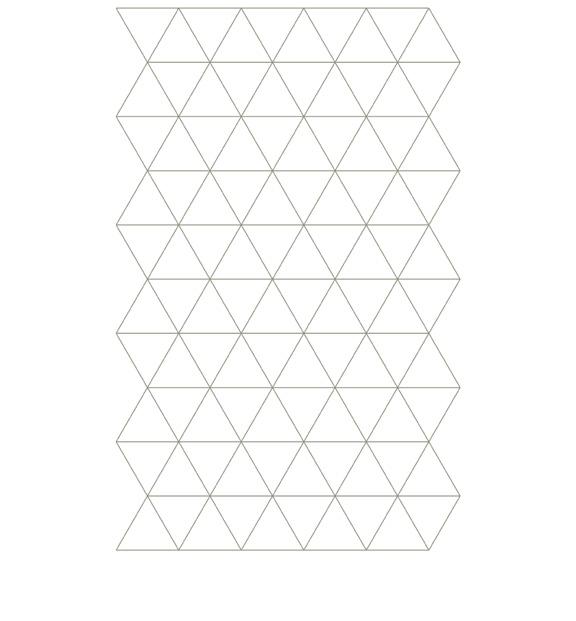

UNDERLINED GRID//

UNDERLINED GRID//

RECIPROCAL GRID//

STRUCTURE ON FORM //

CONNECTIONS//

Tensile cables are connected onto each bolt at the end of each sides with a specific nodes that are gonna be used . ( Diagram are just a reference to indicate the connection point between the cable and the bolts ).

ST KILDA 478

DESIGN BRIEF //

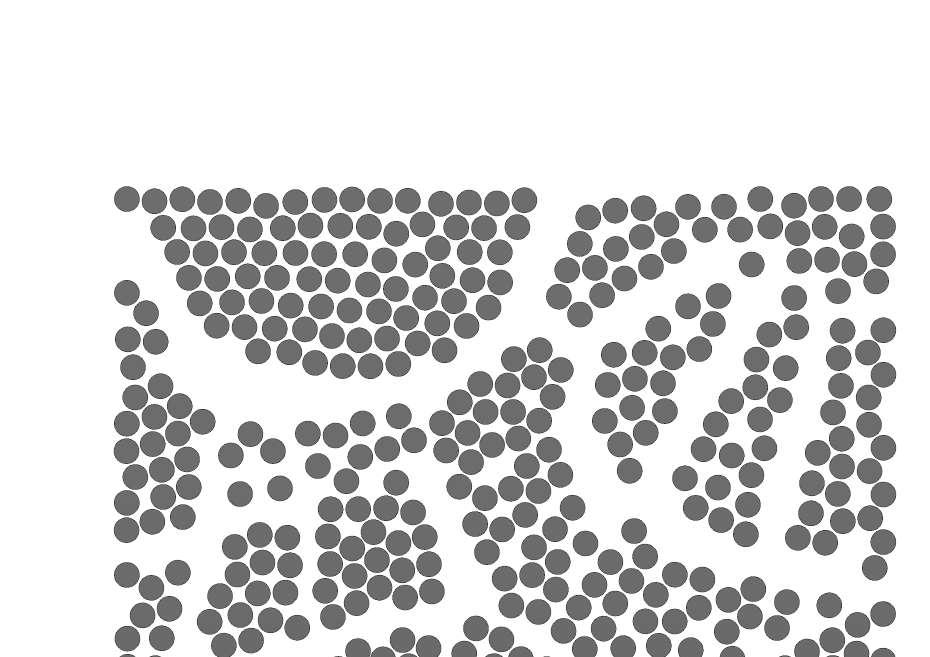

// Design By Alexander KnoxThis project work on projecting a specific deisgn pattern onto one of St Kilda 478 building facade. The facade design consist of 3 overlaying patterns coexist together. Starting from a basic old melboune urban map which was then convert into woven abstract and eventually into circles to create the peforations on the facade.

TRANSLATION \\

The map is further translate into laceabstract patterns..

" Peforation Size

Approx 20mm+ " 3mm Thickness

" Peforation Size 11mm rad

" Peforation Size

Approx 40mm+ " 4mm Thickness

" Peforation Size

Approx 80mm+ " 5mm Thickness PATTERN ITERATION//

" Peforation Size 14mm rad