Whether it’s TV docos on the spending habits of meal deal addicts or Denise van Outen chomping on supermarket Chocolate Croissant Cups, the topic of food to go is everywhere. In-store bakeries, indulgent o erings, value for money in di cult times… all topics undergoing lively debate!

So, it’s only tting that we devote 20 pages to the future of FTG. We spoke to key players, touching on packaging challenges, machinery, product innovation and some of the most gorgeous salad bowl o erings on the planet.

As you can see, we’re at a monster 72 pages – which can only be achieved with the help of our members, subscribers, contributors and advertisers, plus a superb in-house team of Gareth Symonds and Paul Steer. Thanks to them all!

Editor Alex Bell, Tel: 01291 636349, email: alex@jandmgroup.co.uk

Advertising Paul Steer, Tel: 01291 636342, email: paul@jandmgroup.co.uk

Production Gareth Symonds, Tel: 01291 636339, email: gareth@jandmgroup.co.uk

Subscriptions and Customer Service Tel: 01291 636338, email: subscriptions@sandwichandfoodtogonews.co.uk

Editorial Address Sandwich & Food To Go News, Engine Rooms, Station Road, Chepstow NP16 5PB www.sandwichandfoodtogonews.co.uk

In association with The British Sandwich & Food To Go Association.

PHONE +44 (0) 1291 636338

FAX +44 (0) 1291 630402

WEB www.sandwich.org.uk

EMAIL info@sandwich.org.uk

Paper used in the production of this publication is sourced from sustainable managed forests.

NEWS

04-10 Round-up of the latest stories

REVIEW

12-14 Brighton rocked – Foodservice Packaging Association Awards

THE BRITISH SANDWICH & FOOD TO GO ASSOCIATION

18-22 The Sammies 2025

FTG FUTURE

24-45 Colpac / Simply Lunch / Millitec / Sabert / Santa Maria (Paulig PRO) / WorldBake / atis

FILLINGS

46-56 Deli Fillers / Paci c West / Leathams / Florette / Beacon Foods

BREAKFAST

58-65 La Lorraine Bakery Group / Fosters Bakery / Jason’s Sourdough & Pidy

REGULARS

66 Classi eds

67-70 Index / Manufacturers & distributors

A delicious selection of products including familiar favourites across multiple categories. Our Twelve range stands out with great flavour profiles and a strong shelf presence.

Bridor, the French bakery manufacturer, is launching the Croissant Revolution guide, highlighting the sizeable sales opportunity croissants o er the hospitality sector at all times of day, backed by new consumer research.

strongly in uences their overall perception of an establishment.

While breakfast is the most popular consumption occasion according to 83%, a notable number of consumers choose it as an afternoon snack or accompaniment to a co ee break.

The UK’s love a air with the croissant is evident, as the guide reveals that 93% of buyers eat them at least once a week. Over half (55%) of Brits eat them up to twice a week, and nearly one-quarter (23%) enjoy three to four times a week. The ndings are the result of a recent UK survey conducted by the company*.

Croissants are the rst choice for 95% of consumers when buying a pastry and 88% state that the quality

Utilising Bridor’s 30 years of bakery know-how, the guide shares valuable insights to provide operators with the information they need to boost croissant sales throughout the day. With 93% of consumers looking for an original taste, Bridor is encouraging operators to take advantage of the pastry’s versatility and upsell with a variety of savoury llings or sweet toppings.

Erwan Inizan, Northern Europe sales director at Bridor, said: “We’ve been baking croissants for over 30 years and they still have so much to o er. We truly believe a ‘Croissant Revolution’ is underway and our new guide shares valuable consumer insight. Of course, a great-tasting and visually enticing croissant is fundamental to any Viennese pastry

o ering. Once in place, we rmly believe that hotels, cafés and bakeries can join the croissant revolution and see the bene ts of o ering a mix of sweet and savoury options.

“In addition to classic o erings, we know that consumers are interested in trying out the latest avour trends and innovative ingredients. Operators should be creative with striking toppings and novel llings with bespoke pastries throughout the day. Repeat footfall as a result of a robust pastry o ering can reap strong sales.”

Find the guide at: content.bridor.com/ Bridor_Croissant-Revolution.

*All data from UK Bridor study, 800 buyers of croissants at least once a week – Jan 2025.

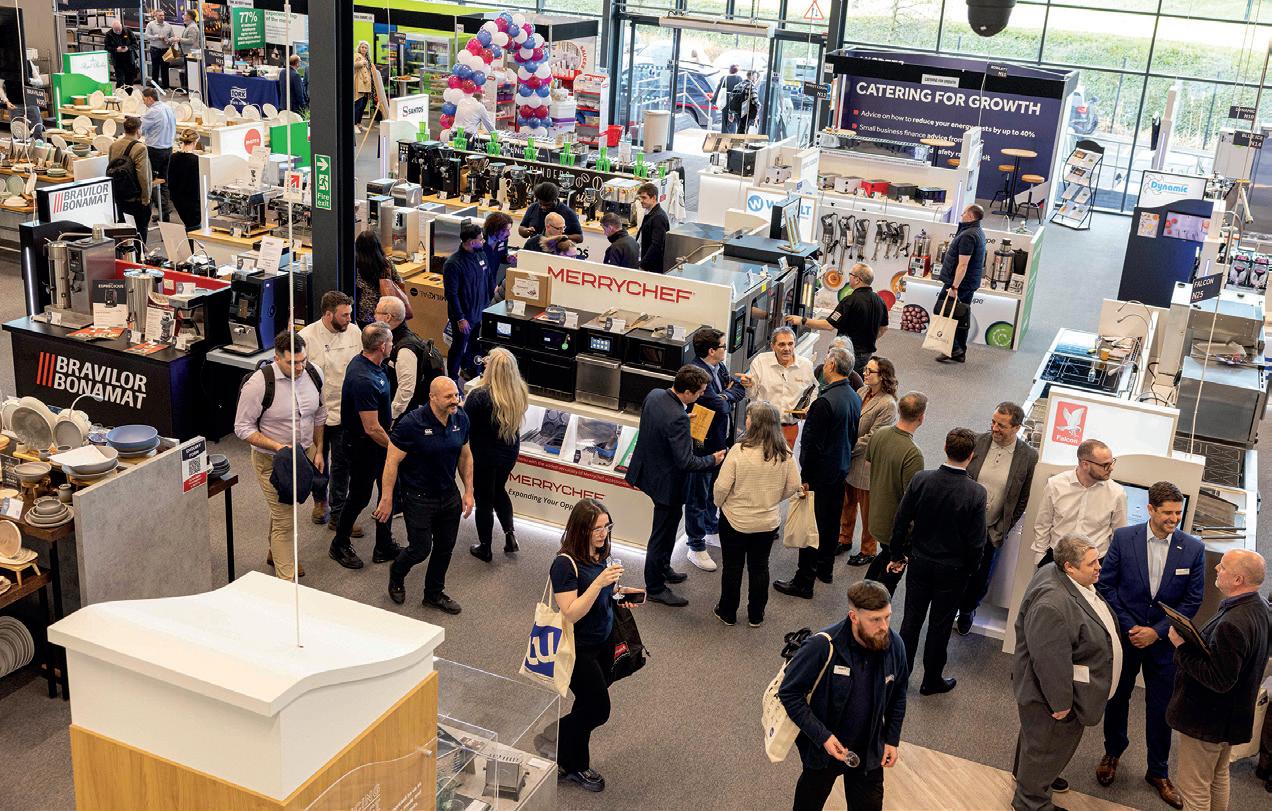

Two days, 94 stands and over 150 brands, Nisbets Live 2025 was back for its fourth and most successful year yet. Running from 26-27 March at the National Catering Equipment Centre in Bristol, Nisbets Live 2025 o ered exclusive show discounts, live demonstrations, free expert advice and an opportunity to discover the latest commercial cooking equipment.

With registration up by over 23% and footfall seeing nearly 30% growth, this event was bigger and better than ever – 55 key accounts chains were in attendance.

New for 2025 was the Digital Kitchen Cook LIVE and Catering for Growth. Nisbets Executive Chef, Chris John, showed spectators how to make the most of the latest equipment, with a variety of leading brands on display.

Richard Ebbs, head of product sales e ectiveness, Nisbets UK, said: “Our success is testament to the hard work and dedication of all departments. It is fantastic to see it come together and showcase Nisbets at its best.”

The Nisbets Second Annual Sustainability Award

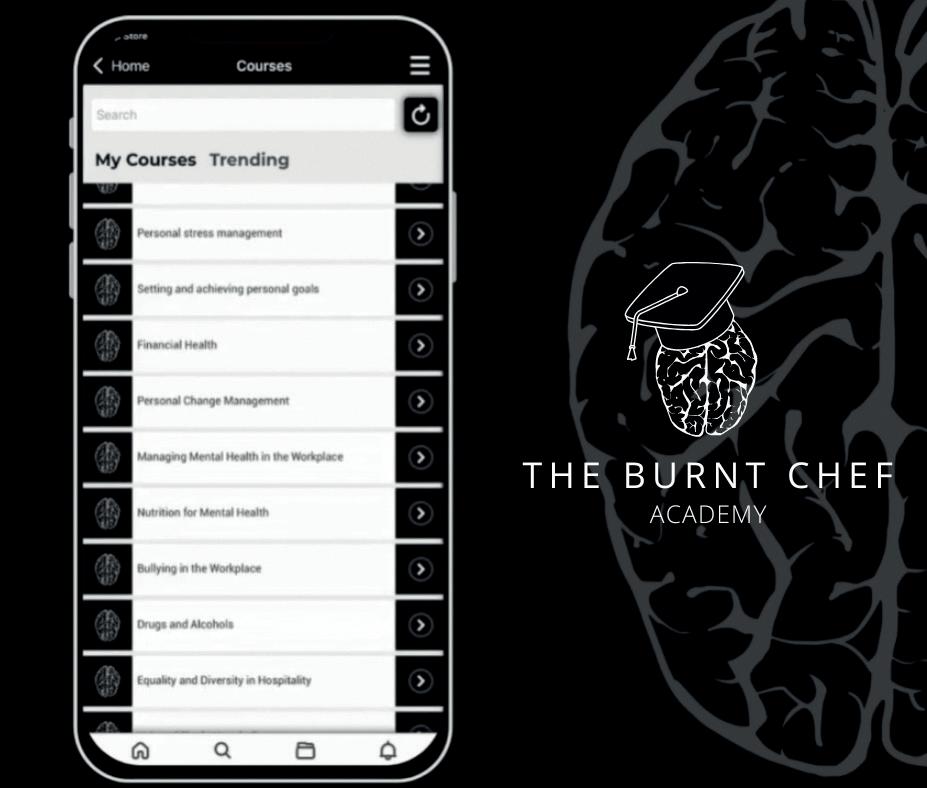

Following the successful launch of a mental health initiative that provides free-to-use modules to colleges, The Burnt Chef Project has announced four additional modules to the series. Thanks to donations from the virtual fundraiser held last year, the Bourdain Challenge and other global fundraising e orts, The Burnt Chef Project has been able to not only allocate funds to this initiative but continue to expand.

Designed for colleges teaching the hospitality professionals of tomorrow, the modules have been speci cally designed to build the resilience and perseverance of students. Helping form e ective coping skills for young people who are nding their way into the world of work, the modules o er content which complements topics from their courses.

Covering topics including discrimination and equality, budgeting, tax and pensions, recognising stress, planning and time

received nearly three times as many entries as last year, re ecting the growing prominence of the issue within the industry, as well as the continuous commitment of Nisbets.

Mark Conron, Nisbets global head of customer communications, said: “As a leader in sustainability, we are immensely pleased with the signi cant strides taken in our own e orts to be more eco-friendly. We have removed over 40 tonnes of plastic from product packaging in two years and aim to remove an additional 20 tonnes for 2025. With sustainability central to everything we do, we are thrilled to o er this award to recognise the e orts of others.”

For 2025, the Sustainability Award went to Santos for its exceptional improvements in a variety of areas, particularly their moulded cellulose packaging and reduced energy use during manufacturing, with an emphasis on products that are ‘built to last’.

management, gambling, drugs and alcohol and mental health stigma, they are written in bite-sized sections, making them easy to absorb and learn around a formal college course.

Modules available include:

● Drugs & Alcohol

● Equality and Diversity in the Hospitality Industry

● Why Mental Health Matters

● Why Sleep Matters

● Financial Health

Each module delivers an overview of the relevant topic, delving into key issues and de ning the signs and symptoms of mental health-related stress associated with it.

Kris Hall, founder and CEO of The Burnt Chef Project, said: “Our aim is to support the next generation of hospitality professionals, by helping them enter the industry with greater resilience. The college modules allow future talent of our industry to better cope with everyday stresses, while being equipped with the knowledge

and a deeper understanding of several crucial life skills.”

Free to students across the globe, colleges simply need to contact The Burnt Chef Project through the website to create a bespoke portal. From there, educational establishments can invite students to join, accessing content and hundreds of useful tips and tools in the process.

Visit theburntchefproject.com.

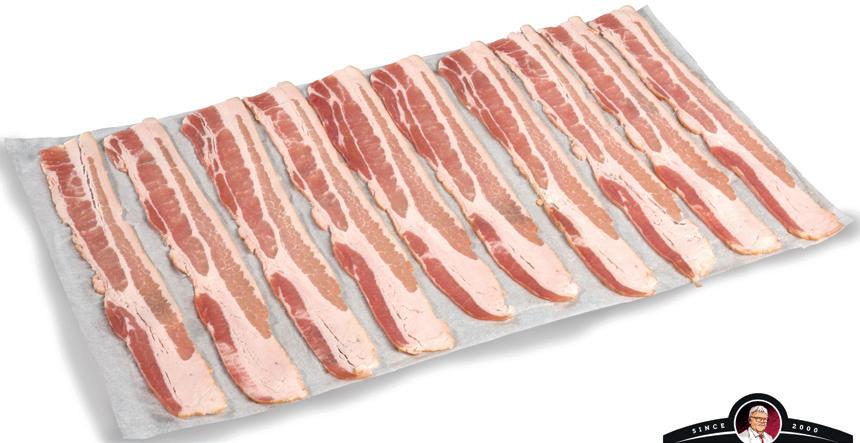

Ready to eat

Convenient to use

Natural beechwood smoked bacon rashers

•Succulent and ready to eat

•No additives

•EU-27 origin

•Diced / strips / slice / whole fillet

•Versatile

•Great tasting

•Crunchy

•The ideal ingredient

Coated breast fillet products

•Crunchy coatings with tender chicken

•Cookin 5 range

•Be-spoke product design service

•EU-27 origin

•Limited handling

•Natural beechwood smoke

•Convenient, cook it your way

•Great tasting

•Ready to eat

•Convenient

•Thinly sliced

•The perfect breakfast rasher

With over 50 years experience in mobile retail Jiffy are the name you can trust, our success relies upon your success. Call us now to arrange a demo Tel 01274 596000 sales@jiffytrucks.co.uk Looking for new revenue streams? Supply your products with the original Jiffy truck. Now available with a finance balloon, allowing low monthly payments, with enough equity for a new van every 4 years.

Our temperature controlled food delivery vehicles are designed to display and vend your pre-made Hot and Cold food. Delivering direct creates you a captive audience, offering customers the ultimate in convenience and service. Call us today and take the first step towards increasing your sales.

· Our mobile “shops” have no rent or rates to pay and operate with one staff member.

· Our trucks are chosen by all the major names in mobile catering for their build quality and reliability.

· Flexible finance packages available.

· Fully accredited by the BSA

· Whole vehicle type approved

· A very profitable addition to any food business.

· Established 1974

An array of innovative operators were recognised at the annual Foodservice Packaging Association (FPA) Awards, which never fail to disappoint.

It was that time of year again, as the cream of the industry came together on 13 March to celebrate the Foodservice Packaging Association (FPA) Awards.

Hosted by comedian Tom Allen and attended by over 400 members and guests, The Grand, Brighton, was a suitably glamorous venue for a day and night of recognition.

“The FPA Awards recognise the hard work and innovation of individuals and businesses, each setting an example for the packaging sector,” said FPA interim executive chair, Anna Turner. “The winners are a shining example of how packaging businesses can respond to immense challenges faced by the sector and come out on top.

“Many congratulations to all this year’s winners and finalists, and our thanks to our sponsors for the support they provide, which helped us to raise the bar for attendees yet again this year.”

In the Rising Star category, Maria Clark, sustainability manager at Booker, took home the prize.

“The quality of the entries this year was exceptionally high, but Maria stood out as the worthy winner,” said Turner. “During her time at Booker she has developed the company’s

sustainability goals significantly and worked hard to change the mindset of the company’s stakeholders.

“Winning the Rising Star Award also entitles Maria to an automatic place at Sheffield Hallam University to study the four-year Packaging Professional Integrated Degree and Apprenticeship course. The programme is part-time and offers a mix of online and in-person study. To support Maria when she is on campus the FPA is delighted to confirm the association will be making a financial contribution towards her travel costs and accommodation.”

Clark joined Booker in June 2022 as sustainability manager, responsible for the planet agenda – including sustainable packaging. And she quickly recognised challenges around catering disposables. Clark worked closely with a variety of teams to assess environmental impact and validate claims. She supported the development of a range of packaging that not only met rigorous design standards but also communicated material types – enabling customers to make informed purchasing decisions.

For a full winner’s list, visit fpa-awards.org.uk.

Ware there’s a will…

Vegware won the FPA Corporate Social Responsibility award for the Vegware Community Fund. The unique approach, providing monthly grants of £20-200 to nonprofit organisations and charities, addresses a critical gap in funding, offering support for essential running costs. This enables these organisations to focus on their vital work, free from a constant burden of financial insecurity.

Beyond mere financial assistance, Vegware cultivates a robust support system. By offering a platform for promotion through their blog and social media channels, they amplify the reach and impact of their recipients’ initiatives. This symbiotic relationship, where recipients in turn share details of Vegware’s support, creates a sense of community and mutual appreciation.

The company’s active engagement extends beyond monetary contributions. The Vegware Giving scheme, which allows employees a paid day annually for volunteering, demonstrates a hands-on approach to community support. Partnering with The Yard, a long-term Community Fund recipient, exemplifies this commitment. The team’s tidying, repainting and preparing the facility for reopening highlights Vegware’s dedication.

The impact of the Community Fund is also evident in the success of the Green Schools Project, which has reached over 20,000 students, empowering them to take climate action. Similarly, the Three Hares Woodland – a communityled initiative focused on biodiversity and education – has thrived with the Fund’s support. These examples showcase the tangible outcomes of Vegware’s investment in community-driven sustainability.

Looking forward, Vegware aims to expand the Community Fund’s reach globally, aligning with its own growing distribution. By strengthening ties with recipients through enhanced communication and staff engagement, Vegware is solidifying its role as a catalyst for positive change in communities worldwide.

EasySlice Deli Egg is the perfect egg – flavour and texture as a freshly boiled egg and comes pre-sliced. Our frozen long eggs are time-saving – no boiling or peeling required – and provide uniform slices with no waste. The long eggs are delivered frozen and are pre-sliced. Each long egg measures 19 centimeters and are sliced into 42 pieces – perfect for sandwiches or open-faced sandwiches.

However, the long egg is one of the crown jewels at the Danish egg company, Danæg. This year the company celebrates its 130th year birthday with a relaunch of an improved version of the long egg, EasySlice Deli Egg.

Back in the 1970’s the Danish egg company, Danæg, developed the long egg. The recipe behind was a long-shaped version of a boiled egg, including a creamy hardboiled yolk running through it, which guaranteed the perfect egg slice every time.

40 years later the long egg has gone through an improvement that clearly shows and tastes and has been relaunched by the name, EasySlice Deli Egg.

One EasySlice Deli Egg is the equivalent to around six boiled eggs, measuring 19 centimetres. It can be cut into 42 slices. The product is delivered frozen and ready to use and is available either pre-cut or in whole cylinder-shaped rolls.

But what is the secret to creating this 19-centimetre-long masterpiece?

“No, Danish hens do not lay 19-centimetre eggs,” Mr. Peter T. Munch, Export Director in Danæg explains, with a smile. “The EasySlice is something that we produce in one of our Danish factories, in Roskilde, about half an hour’s drive from Copenhagen.”

“We have special machines which separate six eggs whites and yolks and make a long egg from the boiled whites. A hole is made in the middle, which the yolks go in, then it’s all boiled and frozen and is then ready to use. And there is no food waste, because every slice of the EasySlice looks perfect – yolk in the middle surrounded by whites. There are also significant hygiene benefits for our customers, as using a EasySlice means there are no raw eggs in the professional kitchen space.”

The product offers all the flavour and texture of a freshly boiled egg, but it is easier and more efficient to slice. The long shape makes it convenient and perfect for use in the preparation of salads or sandwiches where the perfect egg slice makes a notable difference in both taste and presentation.

In 2025 Danæg is celebrating its 130th year birthday. The Danish egg company was founded back in 1895 with a vision to provide high quality eggs to the world. The vision is the same 130 years later along with a unique talent for innovation.

“We provide eggs and egg products to a wide range of customers,” says Mr. Munch. “From cantinas to gastronomy, from airline catering to convenience stores, from bakeries to the food industry, just to name a few. We are driven by the desire to make the job easier for professional chefs, bakers and confectioners in busy catering centres or at the detail-oriented Michelin restaurant.”

The Sammies are made possible by the generous support of our fantastic sponsors.

New for 2025, Flexeserve and ProAmpac are joining forces for our exciting hot-hold food to go category.

Korean Savoury Wa e and Chilli Chicken Bites with a Whipped Honey Butter Sauce by Hayley Alouini from Greencore

Steak and Ale Toastie with a Godminster Cheddar Rarebit by Richard De'Ath from Greencore

Chilli Con Carne Wrap by Kerrie-Ann Parker-Thompson from On a Roll Sandwich Company

Braised Oxtail French Dip by Nyani Lebrasse from Around Noon

Horny Cone by Edvinas Smigelskis from Samworth Brothers

Futura Foods are the UK's Mediterranean dairy specialists, supplying premium and innovative products for over 25 years.

Honey Harissa Chicken with Labneh Mezza by Hayley Alouini from Greencore

Roasted Beetroot and Preserved Lemon Labneh Mezzaluna by Robert Lawton from Leathams Ltd.

Middle-Eastern Labneh-Lamb Wrap by Georgina Magowan from Freshcut Foods

Sunset Labneh Flatbread by Katherine Robertson from Greencore

Labneh Power Pot by Fran Crute from The FSC Group

H. Smith Food Group is a leading independent supplier in the UK's foodservice, manufacturing and food to go sectors.

Bu alo Slider by Harry Dempster from Samworth Brothers

Blue Samurai Sandwich by Ildiko Magyari from G C Crosby

Mumbai Toastie by Ben Bradley from On a Roll Sandwich Company

Hot Honey Korean Chicken Baozi Buns by Oliver Bloxham from The FSC Group

Cluckin Banh-Tastic by Matt Brooker from Simply Lunch

Kings Fine Cooked Meats are one of the nation's favourite cooked and sliced meat manufacturers.

The Hawaiian Ham’Wich by Georgina Magowan from Freshcut Foods

Hoggin' The Mojo! by Donna Mcguire from Deli Lites

The Ryes Of Ham by Mel Walmsley from Lakes Sandwiches Ltd

Eat. Beach. Sleep. Repeat. by Kieran McGivern from Around Noon

Croque-Keoni-mana by Alice Staines from Raynor Foods

The Roberts family knows a thing or two about baking, with 130 years and four generations of skills and passion.

Steak My Tru e by Matthew Brennan from Samworth Brothers

‘Pork Pie Toastie’ by Chrissie Attwell from Samworth Brothers

Got This in the Spice Bag by Kieran McGivern from Around Noon

Firecracker Scotch Egg Sarnie by Emma Corkish from The FSC Group

Katsu Krunwich by Fran Crute from The FSC Group

Sodiaal is one of the leading dairy cooperatives in France, producing P.D.O cheeses, Brittany butter, UHT milk and cream.

Anvil Special 24.3 (+Raclette Halo) by Barny Luxmoore from The Jabberwocky

Marmite Cheesy Roast Beef Crumpet by Abigail Pearce from Greencore

K-Pop Comte Street by Ivor Peters from Urban Rajah

#Notaphillycheese by Stephen Jordan-Bird from Samworth Brothers

Cosy Croll by Edvinas Smigelskis from Samworth Brothers

Sauces, condiments, relishes & chutneys

NPD, global trends, healthy options

FOCUS

Environmental Packaging, labelling, thought leadership, waste disposal

PREVIEW

lunch! The National FTG, Retail & Coffee Shop Event – part one

As a major industry voice, Colpac is at the forefront of understanding packaging requirements and how operators need to respond. We spoke with ESG director, Talia Goldman.

The future of FTG is being impacted by EPR. How is Colpac addressing this?

Packaging Extended Producer Responsibility (pEPR) is a significant opportunity for us to work towards a circular packaging industry. As with most major shifts in policy, there is a lot of complexity and uncertainty for operators in understanding their obligations under pEPR.

We are working closely with our customers, including operators of all sizes, and wider industry, to interpret the legislation. We are also identifying product information and supply chain details necessary to collaborate on pEPR, and to act on the information that they will need to report on going forward. Our commitment to working through intricacies of policy, alongside

industry collaboration, is central to supporting operators. For example, I represent UK manufacturers in the PackUK (pEPR scheme administrator) interim steering group, and we are a founding member of the Alliance for Fibre-based Packaging, for which I am also a co-chair. Participation in these key groups, as well as others, cements us at the heart of reform and we are excited to be a guiding light through this change in support of circularity.

What are the common challenges you are seeing?

Primarily, trying to understand what compliance obligations are under pEPR and how this will impact businesses. We are working directly with customers to help

them appreciate the relevance and importance of pEPR and the opportunities it can bring. Then we assist with identifying their reporting and financial obligations, in line with the guidance laid out by PackUK, the Environment Agency, trade associations, compliance schemes and other industry bodies.

I was part of the launch of PackUK at Packaging Innovations in February, and it was quite surprising to see how many organisations had not yet understood the purpose of the regulation and what they needed to do to comply. I was pleased to take part in a panel discussion with Defra Minister Mary Creagh and other representatives to answer questions from audience members. Since

then, we have provided even more detailed support to customers on understanding their pEPR obligations.

Going forward, we will focus on developing packaging solutions to help reduce pEPR fees and ensure that we continue to balance functionality with long-term sustainability.

What are the key relationships that keep you at the cutting edge?

Supply chain collaboration and global partnerships with trade bodies are critical. Being a member of the PackUK interim Steering Group and a co-founder and co-chair of the newly founded Alliance for Fibre-based Packaging has established strong partnerships. This has enabled us to provide two-way support for industry and customers, diving into the details of policy and using our expertise and experience in manufacturing to shape the governance and development of reforms such as pEPR.

We also work with other trade bodies. Being members of the Foodservice Packaging Association (FPA) and British Printing Industries Federation (BPIF), while participating in groups such as BPIF’s Policy & Public Affairs Committee, gives us access to cross-industry insight and collaboration. We are also members of Sedex, a critical project in risk management for many operators that we work with, as this helps us reinforce

guiding principles around supply chain transparency and social responsibility.

How are you adapting to the everchanging world of packaging?

We drive the evolution of technology and design every day, as we continuously improve and invest in packaging – from construction to design, materials, operational processes and machinery.

We have recently worked with customers to further improve the recyclability of wrap packs and platter bases. We did this through replacing a plastic laminate with direct food contact inks, the first projects of this kind in foodservice. It was thrilling to help them towards the goal of

eliminating unnecessary plastic and increasing recyclability. We also significantly reduced their projected pEPR unit costs. These were exciting projects to deliver because they demonstrate the true aim of pEPR, while bringing sustainability benefits and cost savings for our customers.

Where do you see opportunities for growth in FTG?

The enormity of the FTG landscape and evolution of trends creates a constant supply and demand for materials, technology and design, drawing in influences from all over the world. Consumers want new FTG packaging concepts and it’s our job to help deliver in the most appropriate formats, ultimately selling more food.

The packaging sector is under pressure to be sustainable but is incredibly resilient. Would you agree? Yes! We are about to enter a period of immense change, with pEPR, PPWR, EUDR and other emerging legislation, as well as the need to make progress on requirements such as net-zero. This comes with opportunities to improve sustainability. The best way to maximise benefits is to focus on significantly improving supply chain collaboration, working with customers and competitors alike, to develop an effective circular packaging industry that is sustainable long term.

Colpac has announced the new iteration of its kraft baguette box, redesigned to deliver maximised visibility, cost savings and efficiency.

With continued evolution of the artisan bakery trend1 and 76% of consumers being very quality led when making food-to-go choices2, larger bread formats are becoming a popular method of presenting gourmet sandwiches. Perfectly suited to artisanal cafes and delis, higherend contract caterers and sandwich manufacturers, Colpac’s updated baguette box meets the evolving needs of today’s FTG market.

With increased visibility, the new box better showcases food products through an over-edge window. This helps customers to display fresh baguettes at their best, enticing consumers to purchase.

back-of-house or at made-to-order counters. The packs can be formed and filled more easily, with a crash lock base at one end and simple tuck closure at the other, helping businesses to reduce fill time.

Time is everything in fast-paced foodservice environments, with catering teams preparing for busy lunchtimes. Colpac’s new baguette boxes are quick to construct, streamlining the packing process

"We understand the pressures foodservice businesses face to balance sustainability, efficiency and cost."

The box is more cost-effective than its previous version, without compromising on quality. Further savings can be made with regards to Extended Producer Responsibility (EPR). Colpac’s team lightweighted the box by creating a refreshed design

which utilises less material, allowing for more units per tonne. For customers looking to optimise transportation and storage, the new boxes are also delivered flat, enabling larger case counts and increased pallet quantities.

“We understand the pressures foodservice businesses face to balance sustainability, efficiency and cost,” said Andrew Grimbaldeston, managing director at Colpac. “Our new kraft baguette box offers customers a value-added solution with lower operational demands and increased EPR efficiency, all at a lower cost.”

Manufactured from FSC-certified paperboard, at Colpac’s UK factory, the boxes have the assurance of utilising sustainably sourced materials. The paperboard also contains recycled material and is widely recyclable within the UK’s recycling system, meaning this packaging is categorised as ‘green’ in the UK’s new Recyclability Assessment Methodology (RAM).

1 Caterer.com [Rise of artisan breads]. 2 Lumina Intelligence FTG Mkt Rep 25.

Jack Page, business development director at Simply Lunch, shares their latest industry insights, sustainability goals and the company’s long-term vision for the future.

At Simply Lunch, we’re always striving to push the boundaries of food to go and deliver exceptional, high-quality products tailored to modern consumer needs. Our latest innovation, the MADE range – set to launch in mid-May – is testament to this commitment.

It’s an exciting step forward for Simply Lunch. We’re bringing customers hand-crafted, made-inhouse products designed to cater for all-day dining occasions, dietary preferences and evolving consumer expectations.

Additionally, Simply Lunch is launching the Cookhouse, a new initiative that will allow us to cook our own pasta, grains and vegetables in-house. This gives us greater control over freshness, quality and consistency, while also allowing us to develop recipes. By having this capability, we can better meet consumer demand for fresh, wholesome and well-balanced meals.

ensuring recyclability at every step.

The range consists of 30+ products, featuring premium bread carriers such as focaccias, bagels, pretzel rolls, classic farmhouse sandwiches, wraps and Wildfarmed ciabattas – perfect for customers who value quality and authenticity in their FTG choices.

What makes MADE truly special is our ability to bespoke-brand products. For partners with sufficient volume, we can apply a customer’s logo on top, elevating the overall experience, adding a unique touch to every bite.

With sustainability at the forefront of industry discussions, Simply Lunch is making significant strides in transparency and responsible manufacturing.

All MADE range products will include carbon ratings, enhancing visibility for consumers who want to make informed choices. We’ve already pioneered this approach in our Plant Powered range, and it’s a natural progression to expand this across our broader offering.

Furthermore, the packaging is designed with sustainability in mind, adhering to OPRL compliance and

Simply Lunch is addressing the increasing scrutiny on carbon footprint in food manufacturing and packaging through a comprehensive sustainability strategy. The approach includes reducing direct and indirect emissions by tracking and minimising Scope 1, 2, and 3 emissions, with a notable reduction of 10.12% per million products produced over the past three years.

The company is committed to offering recyclable options and has plans for a brand refresh in 2025 to further reduce or eliminate excess packaging. Partnerships with companies like Wildfarmed and Daily Dose Juices emphasise the use of regenerative and waste-reducing practices. Additionally, Simply Lunch is implementing a digitalisation strategy to streamline operations, reduce waste and enhance efficiency – all while working towards achieving B Corp certification to validate and guide sustainability efforts.

It’s crucial that we continue to innovate, not just with our products

but also in our approach to reducing environmental impact. This holistic overview ensures we meet customer needs while driving real change.

The FTG sector is evolving rapidly, with consumer preferences shifting towards healthier, functional foods.

Protein and fibre are huge focus areas. Consumers are making more deliberate spending choices, seeking out meals that offer nutritional benefits while maintaining convenience. And data-led product development has become a core part of the Simply Lunch approach.

We’re analysing consumer buying patterns and industry reports to shape our innovation pipeline. Recent insights show a significant increase in demand for high-protein, high-fibre meals, with some studies indicating a double-digit growth in

these categories over the past year.

We’re also seeing an increased appetite for globally inspired flavours, with Mediterranean, Middle Eastern and Korean-inspired options gaining traction.

Customers want variety, boldness and better-foryou options that don’t compromise on taste. Convenience remains key but with an expectation of higher quality and responsible sourcing.

Meanwhile, Simply Lunch continues to grow through strategic collaborations, including a recent launch with British Airways – marking a significant milestone.

We’ve also recently launched with some very well-known big brands, which is an incredibly exciting step in our expansion – and our own-label business is experiencing tremendous growth. While we can’t reveal everything just yet, we’re exploring new ingredient-based partnerships and strengthening relationships with community charities. This is integral to our values and long-term vision.

Hospitality and foodservice are grappling with significant financial speed-bumps, including rising National Insurance Contributions (NIC) and increasing pressures across the supply chain. Simply Lunch recognises that these financial challenges make it incredibly difficult to avoid passing some costs onto consumers. However, it is committed

to mitigating the impact as much as possible, having implemented numerous initiatives. These include energy-saving projects which support both carbon emission reduction goals and help control operational costs.

It’s a tough landscape, and while we’re doing everything we can, some increases are inevitable. We remain committed to delivering value without compromising on quality, but the industry as a whole is having to make tough decisions.

Despite our best efforts, Simply Lunch cannot control the pricing strategies of their customers, and some cost increases may inevitably be passed onto consumers. Nonetheless, we remain dedicated to finding innovative solutions to minimise these impacts and continue providing highquality, sustainable products.

And with the upcoming MADE range, continued expansion in premium partnerships and a deep commitment to responsible business practices, the future is bright.

We’re always looking for ways to enhance our offering, meet evolving consumer needs and contribute positively to the industry. There’s a lot more to come from Simply Lunch.

The UK food to go sector is experiencing significant growth. Alongside popular options like sandwiches and wraps, pasta is becoming an increasingly big player. The broader market, which includes various pasta-based dishes, is also on the rise, with an expected annual growth rate of 3.62% from 2024 to 20291. Fresh, convenient meals like pasta salads have key role in reshaping the outlook for the industry.

Pasta salads are popular for several reasons. They are refreshing, convenient and offer a satisfying mix of flavours and textures. Many consumers perceive them as a lighter meal option, perfect for school or work, enjoying at a picnic or as a side dish.

However, meeting this growing demand presents challenges, particularly ensuring consistent portion sizes while maintaining quality. A key pasta salad feature is diversity of texture. Served chilled, they offer a delightful contrast between soft pasta

Millitec is renowned for innovative depositing technologies, especially adept at handling salads and pasta. Here’s their take on large-scale production priorities.

and fresh, crunchy ingredients like bell peppers, red onions, cucumbers, cherry tomatoes and zucchini.

Gary Crickmore, project manager at Millitec, explained the importance of appearance and portion control: “Customers expect these pasta salads to look and taste great straight from the shelves. They need to look fresh, natural and unprocessed. Ensuring a consistent and appealing appearance is key to satisfaction.”

In large-scale production, consistency isn’t just about visual appeal. Over- or under-portioning can affect nutritional labelling, trust and regulatory compliance.

“It’s not just about the look – it’s about maintaining food integrity,” continued Crickmore. “For example, the balance of ingredients and sauces is essential. You need to ensure that each serving is within the expected weight and nutritional values.”

In addition to portioning challenges, sustainability remains a major concern. Consumers want eco-friendly options, pushing manufacturers to reduce energy consumption and minimise waste.

How do we face these challenges? Millitec has developed innovative solutions to improve portion control, energy efficiency and sustainability in food production.

The Hygienic Pasta Depositor (HPD) is designed to handle a variety of delicate ingredients, including pasta, sauces, rice, peas, corns, carrots, noodles, shrimp and more. Its versatility makes it ideal for portioning foods with diverse ingredients, while ensuring all delicate components are handled gently, preventing damage and preserving both texture and visual appeal.

The HPD features a twinhead system, depositing up to 60 packs per minute, 30

per head, providing a fast and efficient solution for highvolume production lines. But efficiency alone is not enough; accuracy is just as important. Julija Kazakeviciute, design manager at Millitec, said: “Depending on the product’s density and volume, we can calculate the mass required and design different inserts for the depositing weight.”

With adjustable depositing ranging from 1.0g to 2.0g, depending on the ingredients, this level of precision allows manufacturers to efficiently deposit small amounts of pasta salad into small pots on conveyor lines, significantly minimising food waste.

What sets Millitec apart is its dressing and ingredient balance function, ensuring an even distribution, preventing overdressing while maintaining flavour consistency. This is particularly important in pasta salads, where an excess can impact texture and shelf life.

“The depositor utilises a Sauce and Dressing Capture

system which maintains the Back-of-pack (BOP) analysis and recipe balance, ensuring the correct amount of sauce is applied to each portion and enhancing production consistency,” continued Crickmore.

Beyond precision, the HPD is designed for energy efficiency. Traditional pneumatic systems are often energy-intensive and costly to maintain. By integrating electric actuators, Millitec has significantly reduced energy consumption and maintenance costs.

“Switching to electric actuators significantly lowers energy usage and maintenance expenses, making the process sustainable and cost-effective for manufacturers,” said Crickmore.

Food safety is of huge importance in production. Inadequate equipment cleaning can lead to crosscontamination, recalls and financial losses.

The HPD has hygiene in mind, constructed using food-grade materials and featuring an easy-to-strip-down design. The entire cleaning and reassembly process can be completed by a single operator, requiring minimal tools, reducing downtime.

"Switching to electric actuators significantly lowers energy usage and maintenance expenses."

And as FTG continues to evolve, innovation will be key to staying competitive. The HPD is just one example of how advanced technology is addressing industry challenges related to consistency, speed and sustainability. By adopting innovative depositing technology, manufacturers can reduce waste, improve efficiency and streamline production –while staying ahead in a rapidly evolving market.

1latest.atlanteuk.co.uk/the-fresh-pasta-market-in-the-ukwhats-cooking?

In an example of added-value engineering, Sabert Corporation Europe has enhanced an existing packaging solution for Pret A Manger, with a bespoke insert to allow the secure delivery of eight granola pots.

“We wanted to improve the customer experience for our breakfast granola pots,” said Simon Oxley, global head of packaging at Pret A Manger. “We’ve worked with Sabert for many years and they were quick to engineer a solution which improved the offering, while still using the original packaging format.

“Sustainability is important to Pret, so we’re also delighted that the entire packaging solution is fully recyclable and made from Forest Stewardship Council (FSC®) certified paperboard.”

at Sabert Corporation Europe. “It is conveniently packed in cases of 50pcs to maximise storage space in-store.

“The key outcome is a positive impact on Pret delivery sales during the breakfast period and increased usage of the delivery box, which we were already supplying.”

“The insert is the perfect solution, while also being simple to use and cost-effective,” said Jack Richardson, senior national account manager

“We have over 40 years’ experience in providing innovative, sustainable, value-added packaging to the highest standards, supported by outstanding customer service,” said Alex Noake, senior vice president and managing director of Sabert Corporation Europe.

“Reinventing food packaging to nourish and protect our world – ‘We make food look great’ – has evolved to become more than a tagline.

“Sabert has always been a trailblazer in foodservice

packaging and the company’s innovation is widely recognised.

“The Snap2Go range – a fully recyclable solution for chilled meals and food-to-go outlets – won the New Product category at the British Sandwich & Food to Go Industry Awards, The Sammies. Meanwhile, Tray2Go – a fully recyclable solution for sushi, other chilled FTG, confectionery and bakery products – earned the National Gold Award in the Paper & Packaging Innovation category at the Green Apple Awards for Environmental Best Practice.

“With our award-winning products and bespoke solutions, we continue to offer clients the best guarantees of quality, safety and service – making Sabert the ‘go to’ for every operator’s sustainable 2Go foodservice packaging solutions,” said Noake.

For more info, check out sabert.eu/uk/.

How Coveris are putting growing food-to-go brands on shelf faster, more distinctively, and more sustainably.

As the UK’s largest fibre-based food-to-go packaging manufacturer, responsible for putting over 1.15 billion recyclable packs on the shelf every year, it’s clear that Coveris are a critical component in the lunchtime supply-chain.

Having led the UK food-to-go packaging market for over 15 years, the business continues to go from strength to strength, having recently announced a £5M investment into its Cambridgeshire-based ‘super-site’ to support growing demand.

With the UK food-to-go market expected to increase in value by almost 40% by 2028 (IGD), Coveris are now reaching out to support new, developing brands and manufacturers to launch and

grow within the sector.

Delivering more than just packaging, Coveris’ secret weapon in this space lies in its end-to-end partnership model, seamlessly supporting brands across sustainability-led design, innovation, artwork, technical expertise, strategic machinery/OEM partnerships and print. Add in rapid lead times, vertically integrated processes, scalable production and operational efficiencies, and the result is a partnership built for performance and progress.

Providing a total packaging solutions approach, the manufacturer also offers the industry’s largest range of food-to-go products, spanning more than 30 lines, including its award-winning RecylaLite sandwich and

wrap range, innovative formats for sushi, hot-to-go and salads, including bowls, trays, labels, lidding and films.

Coveris’ Food-on-the-move Sales Director, Paul Robertson, takes a look at some of the recent work that they have been doing to support growing brands across the sector:

Elevating brands through better packaging

“Our recent collaboration with plantbased food-to-go brand, Pollen + Grace, is a really great example of how we have supported a purposeled business to communicate and enhance its value through responsible, differentiated packaging.

CONTACT

Paul Robertson

Coveris FOTM Sales Director

“Fresh, natural and vibrant were some of the key requirements for delivery and in addition to material selection, we worked closely with Pollen + Grace to optimise design for print to ensure brand positioning. Through this collaboration, the products look consistently fantastic on-shelf and communicate product value invitingly and effectively to consumers.”

Rosanna McCallum, Pollen + Grace’s Head of Operations, commented, “We’ve spent years perfecting our salads, and we’re delighted to now be able to deliver against a long running promise of ours: to use new recyclable

packaging together with recycled content, building a circular economy for our packaging. It’s been a pleasure collaborating with the Coveris team, who helped us get this important packaging project over the line against tight time constraints.”

Adding to Coveris’ brand support offer is its Rivendell graphics business, working hand-in-hand with the creative Pack Positive® Centre to deliver integrated, design-to-print solutions. As the UK’s largest and most sustainable flexographic platemaking facility, print and colour expertise is combined with packaging design, development, trialling, validation, and artwork, all under one roof to offer major speed, cost and quality efficiencies for Coveris’ clients.

Sustainability by design Sustainability is no longer a choice but a fundamental requirement for packaging and the wider supplychain. What has come from this is both a demand for more recyclable solutions that maintain cost and

functionality, as well as a need to navigate burdensome and complex legislation – particularly for smaller scale manufacturers.

As part of our leading No Waste agenda, we are continually striving to offer the lightest, most recyclable products in the market, as well as providing expert sustainability advice to enable our customers to make more responsible choices that are safe, compliant and cost-effective under new EPR guidelines.

In a recent project with manufacturer Around Noon, we optimised their sandwich packs for EPR compliance, achieving a 40% film weight saving through Coveris’ vertically integrated film science and manufacturing expertise. This shift upgraded the packs from a fibrecomposite red to green status under the new RAM tool, resulting in a more responsible solution that maintains product freshness and quality.

Our ability to deliver all three, without compromising on quality, cost and innovation is what sets us apart.

In the future, Coveris will be looking to enhance its sustainable offering further through an exclusive consumer behaviour forum to delve deeper into the customer relationship with packaging, providing expert insight and development into the next generation of sustainable food-to-go solutions.

Service that matters Service can be an overused word but for Coveris, it’s the foundation of everything we do. In the fastmoving world of food-to-go, agility, reliability and consistency aren’t just nice to have, they’re essential.

As true specialists in food-togo packaging, we work in close partnership with our customers to deliver smarter solutions. Combining collaborative innovation, forecasting and launch support with streamlined artwork, print and stock processes results in faster, more efficient, reduced waste supply that is scalable.

As one of the UK’s largest independent food-to-go manufacturers, Tiffin Sandwiches have been working with Coveris to drive greater on-shelf impact across a complex and agile supplychain. Managing two redesigns in six months to support enhanced product segmentation and colour differentiation, Coveris’ rapid service delivery around print management and speed-to-market were critical to ensuring demand was met to maintain that every single second of every single day, someone is consuming one of their products. Also shifting to a lighter sandwich pack as part of this process, a 20% weight saving with sustainable impact and EPR cost saving have been delivered.

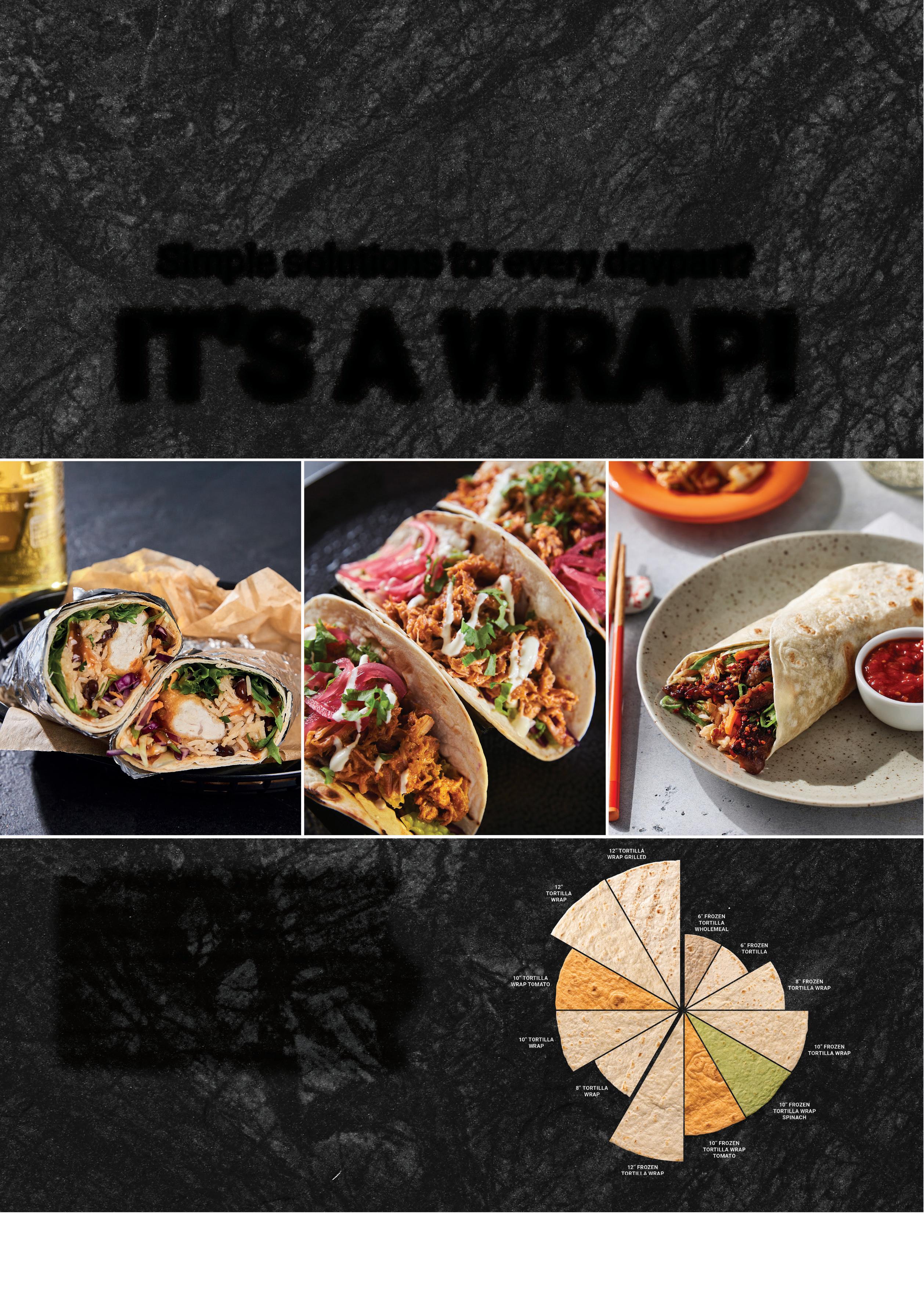

Barnaby MacAdam, development chef at Santa Maria Foodservice (Paulig PRO), on trends, NPD and cost-effective indulgence.

What’s new on your product horizon?

We’re constantly pushing the boundaries of innovation. The second half of the year is especially exciting, as we get ready to launch a new range to help operators elevate their offerings. Our focus continues to be unlocking a world of flavour, providing chefs and foodservice professionals with the tools they need to create bold, globally inspired dishes.

food has evolved from a niche offering to a mainstream trend. Dishes like Korean BBQ tacos, birria quesadillas and loaded fries tap into the desire for indulgence.

We embrace this movement by fusing global influences. Whether it’s hand-held bites, spice-packed tacos, loaded fries or creative burgers, street food is more than just a meal – it’s an experience.

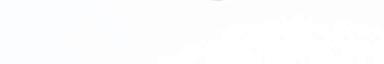

The thriving UK FTG market is expected to reach a value of £24bn in 20251. So, at Santa Maria we’re introducing seasonings, spices, sauces and tortilla innovations, catering to trends such as premium street food, fusion and plantbased options. These additions aim to bring convenience without compromise, enabling operators to deliver exciting, high-quality meals at speed.

We have drawn from global inspiration, while our improved tortillas enhance texture and taste and align with salt-level guidelines. With consumers increasingly looking for more adventurous and convenient eating experiences, there is huge potential.

What does street food look like to your business?

It has never been more relevant, representing boldness, cultural diversity and ultimate convenience. With 90% of consumers open to trying international flavours2, street

And it’s on the rise because of convenience – a major factor in consumers’ decision-making when choosing where and what to eat3 – as well as creativity and cultural connection. Whether it’s plant-based innovations like jackfruit burritos or bold takes on classic comfort foods, they crave the familiar and exciting. The UK’s growing demand for affordable, quick, quality food alternatives to mainstream restaurants has further fuelled the trend. Social media has also played a huge role in the popularity of food trucks and pop-ups, with viral and eye-catching dishes drawing customers eager to try something new.

Tacos remain a classic, with exciting global twists like Korean BBQ, Thai-spiced jackfruit and birria quesadillas. Our Santa Maria Chicken Taco L.A Style is a fusion of bold Korean flavours and Californian freshness. It features grilled chicken thighs marinated in our smoky Santa Maria BBQ Sauce Korean Style, paired with crisp cabbage, crunchy julienned carrots and pickled cucumber. A rich sesame dressing adds depth, while our warm Santa Maria Soft Tortilla ties everything together. Topped with fresh spring onions and toasted sesame seeds, these tacos offer a delicious balance of sweet, savoury and umami.

Comfort food is also thriving, with loaded fries, cheesy tater tots and truffle-infused sweet potato fries. Take our Santa Maria Dirty as Cluck Fries ‘Loaded’ recipe – chicken tenders are cooked as usual, then tossed in our Steakhouse BBQ Rub. They’re served on top of fries with Santa Maria Chipotle Sauce drizzled over the top, finished with fresh herbs. For a vegan alternative, try our Kickin’ Kerala Fries, seasoned with our authentic Kerala Spice Mix, topped with shredded onion bhajis and drizzled with a lemon curry mayo and sweet mango chutney. Finished with a dollop of mint yoghurt and a sprinkle of fresh coriander, these loaded fries offer a harmonious blend of spicy, tangy and sweet.

From pretzel-inspired carriers to ‘thaw & serve’ concepts, WorldBake’s frozen offering is bang on trend.

If you visit the worldbake.com website, you’re immediately transported to a utopia of premium baked goods. There is imagery of waffles and eggs perfectly benedicted, alongside a sprinkling of raspberries and a halfdrunk coffee. You could be in a luxury hotel on Lake Como or preparing for a day on the slopes in Austria!

It’s an apt representation of WorldBake Ltd’s extensive portfolio, supplying frozen baked goods to the UK and Ireland since 2008.

“Innovation is at the heart of what we do, and we’re constantly looking to source and provide new bakery products, all produced in GFSIaccredited factories,” said sales & marketing executive, Lucy Rogers.

“Our bespoke development allows

offerings

us to create unique offerings tailored to evolving consumer trends. Right now, we’re particularly excited about our new Pretzel Bites, which have been a huge hit!”

And when it comes to FTG, WorldBake sees huge opportunities.

● Booming pretzel market –experiencing double-digit growth,

reflecting increased demand.

● Indulgence meets convenience –frozen and ready-to-bake options are becoming more popular, as consumers enjoy authentic products from across the globe.

● FTG expansion – a more diverse range of products to meet different taste preferences.

● Plant-based evolution – while plant-based options remain popular, we’re noticing a shift away from ultra-processed foods to simpler, more natural ingredients.

● Sustainability matters – consumers and businesses alike are focusing on eco-friendly packaging and responsible sourcing.

As summer looms into view, this obviously affects menu choices and business strategies, with more of a drift towards lighter, portable baked goods that are ideal for outdoor dining and events.

“We adapt our promotions to align with seasonal trends,” continued Rogers. “BBQ season is a big driver, with our Pretzel Burger Buns and Pretzel Hotdog Rolls all top sellers.

“Staying ahead of the competition is about focusing on three key pillars: quality, innovation and customer service. By combining traditional European baking expertise with modern innovations and global

sourcing, we provide distinctive, highquality products that stand out in the market. Our ability to anticipate trends and deliver on expectations keeps us at the forefront of the industry.

“When it comes to relationships, they are built on trust, quality and consistency. We work closely with partners to ensure they receive premium products that meet their exact needs. And we’re keen to collaborate with more businesses that share our passion, expanding our reach within the sector.”

Frozen bakery is undeniably gaining in popularity, for several key reasons, according to Rogers.

“Convenience, as they offer easy storage, reduced waste and streamlined operations. And quality preservation means freshness, flavour and texture are locked in, ensuring consistency. And WorldBake’s ‘Bakeoff ’ and ‘Thaw & Serve’ options provide versatility and flexibility.

“As demand for quality, convenient baked goods grows, frozen bakery is an essential solution for many.”

From chopped romaine to chilli lime cashews and shallots, the atis ingredients menu is a treasure trove of nutrition – and a new store opening shows the recipe is working perfectly.

Having just opened its newest flagship store in the heart of London’s Covent Garden, atis is a sustainable, plant-focused salad and plate concept on the up. It marks the brand’s 10th location in London and its first opening of 2025, with more expansion plans in the pipeline.

Since launching by Old Street in October 2019, atis has delivered signature build-your-own bowls, nourishing plates and plant-forward dishes. As part of the new spring menu, it introduced the Covent Garden Goddess (£10) – an exclusive special edition featuring kale & cabbage, chopped romaine, broccoli, cucumber, pink slaw, crumbled feta, avocado, omega seeds and an apple cider vinaigrette.

Co-founder, Eleanor Warder, said: “We are so excited. This new location marks an important step in our journey, bringing our fresh, sustainable and delicious food to an even wider community, while creating a vibrant and welcoming space for all.”

Warder and husband Phil Honer were inspired to open atis by their time living in the US, where they observed the success of health-focused, fast-casual concepts like Sweetgreen. Recognising a gap in the London market, they set out to create a space for delicious plant-powered food, while embodying values of sustainability and community.

With a significant consumer shift towards nutritious and flexitarian eating, alongside quality ingredients and transparency in sourcing, the timing has been perfect. But it’s the customisation aspect that’s currently enlivening FTG.

“In terms of the evolution of palates in the UK, it’s been exciting to see how open people are to bold, globally inspired flavours,” continued Warder. “There’s an appreciation for fresh, vibrant ingredients, and people are becoming adventurous with things like fermented foods, umami-rich dressings and diverse grains and proteins. It’s a great time to be in the food industry, and we love being part of this shift towards mindful, flavour-forward eating.”

Ingredient excellence is at the heart of the atis ethos, ensuring every element of the bowls is vibrant and responsibly sourced.

“We collaborate with a range of specialist suppliers to bring bold flavours to our menu. This includes artisanal dressings, unique grains and plant-based proteins. Sustainability is a major focus, and we partner with suppliers who are committed to reducing food and packaging waste. We also strive to use compostable or recyclable materials across our operations.

“The goal is to expand our network, collaborating with brands that are forward-thinking and align with our vision.”

The business also wants to expand its presence in London and beyond, wherever there is demand.

And the Covent Garden store reflects their signature modern aesthetic, designed in collaboration with Daytrip Studio, who said: “It brings atis’ vibrant, fresh and healthy offer to one of London’s most dynamic neighbourhoods.

Situated on a prominent corner plot within a newly renovated brutalist landmark designed by noted architect Richard Siefert, of Centre Point fame, the space is bright and inviting, featuring clean lines, minimalist furniture and a playful arrangement of glossy yellow tiles.

“The facade’s tall windows create opportunities for branding and a unique view into the store from behind

the serving line. Indoor and outdoor seating, with added planting, allows customers to enjoy Covent Garden.”

The store offers delivery via Deliveroo, with operating hours aligned with opening times. Click and collect services are also available, along with atis kiosks and catering.

NEW

Sorriso® Pink Sliced Sweet and Sour Onions

Perfect for elevating pizzas, sandwiches, burritos, panini, burgers, salads, quiches, cold pla ers, etc. New

BBQ pulled jackfruit

BBQ pulled bamboo

BBQ pulled

There’s a clear message emanating from manufacturer Deli Fillers, whether it’s quality vegan, traditional or innovative flavours on the menu.

LET’S TWIST AGAIN

Welcome to the world of Deli Fillers, as the business embarks on developing new relationships in foodservice. Focused on quality, unmatched variety and responsible craftsmanship, a production facility also delivers ownbrand and white-label options.

“We offer a range of classic premium fillings and plant-based alternatives but it’s our vegan range that really excites us,” said founder and CEO, Emily Cardy. “Our focus is on flavour-packed twists on traditional favourites, bringing comfort and nostalgia to the plant-based world.

“People don’t just want vegan – they want familiar classics, made without animal products. That’s why we developed plant-based versions of deli staples, from creamy coronation veg to a rich, savoury vegan ‘tuna’ mix.”

Buzzwords right now include ‘healthy indulgence’, with more people returning to the office and treating themselves during the week.

“Nutrition is just as important as taste,” continued Cardy. “Our fillings are designed to be as satisfying as

their non-vegan counterparts, packed with natural protein sources like chickpeas, beans and lentils to help keep customers fuller for longer. We’re always ensuring our products are as nourishing as they are delicious.”

Deli Fillers works with wholesale, foodservice and retail partners to create ready-to-go vegan fillings and bespoke NPD. The goal is to make switching to plant-based options effortless – whether customers are fully vegan or looking for an alternative.

“As a female-led business, we take a hands-on, adaptable approach, always pushing plant-based innovation. We’re also halal suitable and aiming for certification within the year. Vegan food should be as satisfying and full of flavour as traditional counterparts, and we’re here to prove it.”

LOBSTER, ANYONE?

A somewhat random feature on msn.com recently claimed to reveal the top 20 sandwich fillings. Unsurprisingly, cheese was number one – but examples included Camembert, creamy mozzarella and spicy pepper Jack. Other choices were

beef brisket, falafel and lobster!

“The fillings sector is evolving fast. In 2025, the focus is on big flavours and better nutrition, with protein a major driver. While demand for plantbased proteins like chickpeas, lentils and beans is growing, there’s a strong market for non-plant-based options.

“Health is playing a bigger role but without sacrificing comfort. Consumers want better-for-you sandwiches that still feel indulgent, hence the rise in functional ingredients like gut-friendly ferments, high-fibre bases and omegarich seeds. Also, protein-packed deli fillers are giving customers the best of both worlds.

“Inclusivity is another key trend. The demand for halal-certified and allergen-friendly options is on the up, and businesses are looking for suppliers who can offer these without compromise. We’re making sure our range is as accessible as it is delicious, with something for every customer.”

Unsurprisingly, this incorporates taking ingredients and provenance seriously. “For us, it’s all about quality, traceability and sustainability, without compromising on affordability.

“We work closely with trusted, accredited suppliers to ensure every ingredient meets strict quality and safety standards. Whether it’s chickpeas for our vegan coronation mix, high-protein dairy for creamy deli fillings or responsibly sourced poultry, our supply chain is transparent, ethical and built on long-term relationships.

“Food safety is non-negotiable, so we’ve invested in enhanced listeria testing across our range. We go beyond basic requirements to ensure rigorous microbiological safety, giving our customers extra peace of mind when it comes to ready-to-eat fillings.”

The Deli Fillers NPD team is very much hands-on, refining recipes. The focus is on clean-label ingredients using protein sources. This lends itself to the sustainability model, minimising waste, improving packaging and sourcing locally where possible.

Deli Fillers has grown substantially because of its strong relationships across foodservice, retail and contract catering, with like-minded businesses that share its commitments.

“There is a focus on wholesale distribution, ensuring products are widely available. By aligning with major partners and contract caterers, we can bring our vegan deli staples to more UK operators.

“Vegan and healthier options are a huge part of our business, reflecting how people eat today. More consumers are dipping in and out of plant-based eating. It’s not just dedicated vegans – it’s

flexitarians, those with dietary needs, and even meat-eaters seeking better alternatives. That’s why we create vegan versions of traditional favourites – familiar, satisfying and flavour-packed, so they don’t feel like a compromise. Our range is accessible, affordable and easy to incorporate into everyday menus.”

Securing an exclusive white-label contract with a large NHS supplier illustrates how those principles are resonating. “To build on our progress, we’re bringing in a business development representative to expand our reach into foodservice, wholesalers and buying groups. We haven’t found the perfect person yet but we’re sure it won’t be long!

“We are in a strong position to grow across multiple sectors – and we love a challenge! If any brands or foodservice operators want customised filling solutions, from vegan to high-protein or something completely new, we’d love to chat,” concluded Cardy.

Meet our game-changing vegan deli llers – perfect for sandwiches, wraps, and deli counters. Made in-house with great ingredients, they deliver the taste and texture of traditional llings, without the dairy or sh.

● Vegan tuna mayo – creamy, avourful, and totally sh-free

● Vegan cheese & onion – classic avour, plant-based twist

● Vegan coronation roasted veg – A staple for every sandwich

● Ready-to-use – saves time and e ort and ensures the perfect avour, every time

● Perfect for cafés, sandwich shops & foodto-go brands

We caught up with Pacific West MD, Martin Finegan, who filled us in on how its seafood range is gaining serious momentum in FTG.

Let’s talk sandwich premiumisation. What does that look like to you and how are you capitalising?

For Pacific West, premiumisation in the UK is about elevating the humble sandwich into a more exciting and satisfying meal experience. It’s about moving beyond standard fillings and focusing on quality, flavour and innovation that resonates with the discerning consumer.

To us, a premium sandwich starts with high-grade ingredients that deliver exceptional taste and texture. In our world, this means sourcing quality seafood and developing unique coatings and flavour profiles that can transform a simple sandwich into something special. Think beyond basic tuna mayo – consider sustainably sourced smoked salmon with vibrant dill and lemon, or perhaps a crispy coated prawn with spicy sriracha mayo.

Crucially, premiumisation also considers the operator’s perspective. Our products are designed to be consistent and easy to handle, ensuring that even with the fast pace of the UK food-to-go market, they can confidently deliver the best possible sandwich every time. This reliability is key to building trust and encouraging repeat purchases at an exceptional price point.

Ultimately, a premium sandwich needs to offer the end consumer a noticeable step up in quality and taste. It’s about creating a moment of enjoyment that justifies the higher cost and encourages them to choose that option over a standard one. This could be through exciting flavour combinations, interesting textures or the perception of a more gourmet or indulgent filling.

Flavours and the quality of produce are everything. How do you keep standards high?

We’ve been manufacturing seafood for over 25 years and have a reputation for delivering market-challenging products, with a focus on coatings and flavour.

Our NPD team thrives on challenges to improve range and capabilities. Combine this with the future investment commitments and we are confident that Pacific West is a

long-term partner for the FTG sector. As a manufacturer, we have the ability to work with producers to develop the flavour profiles that they want, or we can offer a wide range of value-added seafood from our new Fully Cooked range, including Lemon Sourdough Crumbed Fish Goujons, Crispy Fish Bites and more.

It’s an incredibly competitive sector. What trends are you seeing and are you excited about what’s next?

The FTG sector is rapidly evolving and is an exciting space. A recent Lumina report* revealed that 76% of consumers are ‘very quality led’, with 11% choosing a venue based on quality of ingredients. This is an everyday expectation, leading to the elevation of classics, including sandwiches.

The report also shares an example of premiumisation by Café Mondo in Peckham, London, where the most popular menu choice is a fish finger sandwich, which retails at £12 –it’s regularly selling out and prompting long queues.

They deliver a nostalgic experience and have been popular in the hospitality sector for some time. However, the Pacific West Fully Cooked range offers products that can help any operator, even with the most challenging kitchen, to deliver their own fish finger sandwiches. And with three different flavour profiles of fully cooked fish goujons, we see this an exciting opportunity for multi-site operators to create true NPD.

Partnership wise, who are you working with in FTG – and what are your ambitions in terms of future relationships?

Pacific West is poised to revolutionise UK FTG with exciting developments in our Fully Cooked range, set to hit high streets nationwide. We are proud to be first to market with a product specifically designed for efficient manufacturer prep and distribution throughout the supply chain. Our ambition is to collaborate with forward-thinking manufacturers and operators. Seafood is an underrepresented protein, and with the demand for flexitarian and pescatarian options, the moment to innovate is now.

*Lumina Intelligence UK Food to Go Market Report, Mar 25.

more traditional Creole flavours, with their Hot Don Po’ boy filled with ‘nduja, finocchiona, pickled chilli, mozzarella, tomato sauce and hot red pesto’.

Paul Lackie, head of food at Leathams, oversees NPD for the suppliers who specialise in bringing authentic and innovative foods from around the world to the UK. “Diners today are more discerning. They can taste the difference between authentic and imitation. But they’re also adventurous, so FTG vendors shouldn’t be afraid to try merging influences from around the world in this way.”

Speaking of pizzas, there has been an increase in pizza-style sandwiches in FTG, exemplified by the Co-op’s Irresistible range launch, including a margherita-inspired pizza wrap, sold with an industry first-to-market tomato marinara dip for dunking on the go! Other trends include Italianinspired fillings like Salsiccia Piccante or traditional Italian flavour profiles such as Prosciutto Crudo, Italian tomatoes and pesto, sliced mozzarella and a touch of spice.

“Consumers have a taste for sweet heat and are adding it to homecooked dishes, as well as ordering from out-of-home menus,” continued Lackie. “The Roquito® Candied Jalapeños and Roquito® Hot Honey are an easy way to add a burst of

sweetness with a good kick of spice to any filling or topping, and to leverage trends within pizza for FTG.” Another notable addition to the Co-op Irresistible range is the Hand Finished Ham Hock and Hot Honey sandwich, which the retailer notes was inspired by a trip to New York City, showing a tangible application of hot honey that doesn’t cause the bread to disintegrate.

The age-old dilemma for sandwiches, especially as fillings move to incorporate more sauce and wetter elements, is how to ensure the bread holds its structure without falling apart in your hands. Particularly for FTG, this challenge is accentuated for pre-packed items that need to stand the test of time.

“It’s about making smart choices with your fillings,” said Lackie. “For example, switching sliced tomatoes for a lower moisture product such as the SunBlush® Slow Roasted Tomato Bruschetta or SunBlush® Tomato Tapenade ensures intense tomato flavour, without the soggy bread!”

This is also a considered method of ensuring consistency in every bite (instead of half of your tomato slice being pulled out of the sandwich on the first mouthful), and also offers other benefits, such as a lower moisture level and more intensified flavour profile versus a fresh tomato bruschetta or slice.

We’ve seen a huge rise in decadent sandwiches taking foodservice by storm, and operators like Sandwich Sandwich going from strength to strength with their seemingly unstoppable, overly filled masterpieces. But while this trend is a big hit with consumers, replicating it for FTG poses its own challenges.

Overloading sandwiches isn’t as achievable for pre-packed solutions, particularly with sauces and wet elements, but Lackie thinks certain ingredients can give the illusion of this fullness at a manageable cost.

“Mortadella is the perfect sandwich meat to help operators realise a very full product without exceeding a realistic price point for the consumer. Ingredients like Charcuti® Mortadella are authentically produced, tap into Italian cuisine trends that aren’t going anywhere anytime soon, and are a more economic option than other cured Italian fillings. This means you can load up a generous serve, which presents visually as value for money for the consumer,” concluded Lackie.

To find out more about Leathams, email customerservice@leathams.co.uk.

Agrial is a farmer-owned cooperative, made up of an extensive network of 12,000-plus passionate farmers, with over 5500 hectares of fields and 829 hectares of greenhouse tunnels.

“That scale allows us to remain competitive and ensure customers not only receive great value but also a consistent supply of quality ingredients all year round. Florette

Foodservice benefits from a core uniformed range, which prevents further complexity across our operation, ensuring we don’t incur additional costs in the supply chain.”

And in terms of staying ahead of the competition, logistics are a key advantage for Florette.

“One of the biggest developments affecting the sector is supply issues caused by changes to the climate and the repercussions of ongoing world conflicts.

“But Florette Foodservice has a dedicated farm in Colchester, perfectly placed to grow salad throughout the peak summer season. This UK operation means our products have fewer miles to travel, extending shelf life, freshness and taste. The range is then packed within a dedicated and specialised UK

operation, which again strengthens supply chain resiliency and quality.

“Our bespoke foodservice range includes washed and ready-to-eat products to provide convenient solutions for chefs that improve efficiency in the kitchen.”

Florette has been supplying major UK QSR operators for many years, both direct and via other food manufacturers within sandwiches and prepared meal formats.

“The extremely high technical and food safety requirements our customers set mean we work very closely with them across several tiers to ensure we consistently meet the highest product specifications. This level of collaboration requires significant investment across our supply chain, including our people, which allows us to build strong relationships with customers across all sectors,” concluded Jones.

florettesalad.co.uk/ecovadis-2024/.

Discover more Urschel cutting solutions at urschel.com.

www.urschel.com

Successful operations depend on Urschel for cutting edge solutions. Rely on Urschel for rugged, high-powered machinery to maximize capacity and cost-savings. Precision cuts, sanitary stainlesssteel design, backed by service and support for the long life of your machine.

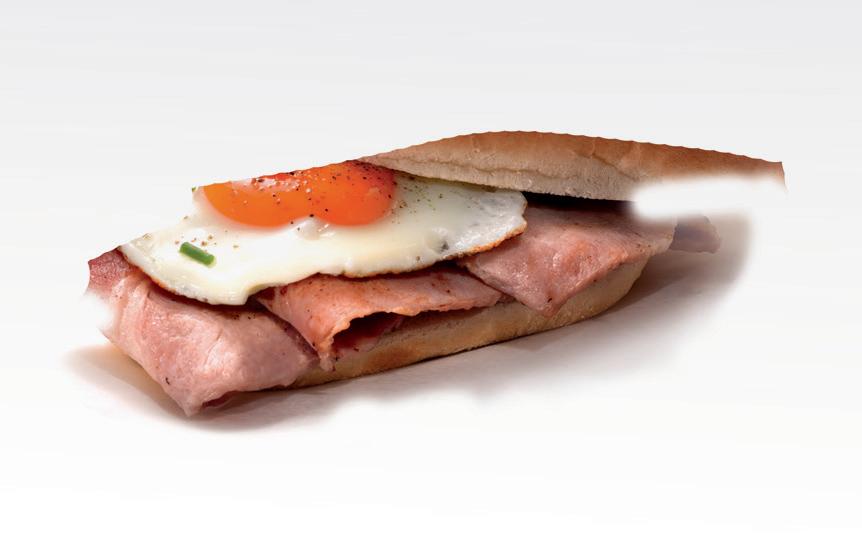

Great British Bacon.

Fully Cooked and Ready to Eat, saving Time, Labour and Energy.

READY TO ORDER I READY TO EAT

ProAmpac’s RecycAll all-paper range is a groundbreaking advancement in sustainable food-to-go packaging, designed to reduce environmental impact while maintaining product protection, visibility, and branding appeal. This fully recyclable, all-fiber solution eliminates traditional plastic film, making it easy for consumers to recycle within standard paper streams.

Visit us at ProAmpac.com to learn more about our sustainability initiatives.

fermented sprouted rye grain and linseeds add a sweet and healthy touch, giving each roll that premium, authentic feel. The end result is ultimate freshness and quality – pair with fish and seafood, including smoked salmon and cream cheese.

Conscious consumption is also worth keeping an eye on, as consumers opt for more plant-based, healthier options. Panesco’s Pave Gard Chasse Pre-Sliced bread, for instance, is filled with total goodness. Served well as a sandwich with sundried tomato tapenade, fresh goat’s cheese and marinated grilled aubergines, it’s packed with texture.

Panesco’s Croissant curved has been a top seller for years. Ideal for breakfast, this premium option works as a sandwich bun or garnished with sweet or savoury fillings.

The Croissant Double Colour Choco Filled also ticks the indulgence box. This layered, double-coloured butter croissant, created by two flavours of laminated yeast dough (natural and cocoa) infused with a rich choco filling, is perfect for chocolate lovers. Suitable for breakfast, coffee and teatime, as well as an in-between sweet, this ready-to-bake product’s use of butter and its hint of sourdough results in a rich, tantalising flavour.

Consumers are also expecting simplicity, transparency and traceability, with a need to know where and how products are made, raised and grown. They want clean, easily understandable labels and foods to be made with the most functional and natural ingredients possible.

How important is sustainability? It’s at the forefront of everything we do. Just last year, LLBG released

its annual global sustainability report, unveiling the company’s achievements and ongoing initiatives.

Entitled Rising Responsibly, it was based on 3Ps – product, planet and people – along with 10 companywide projects to help deliver our ambitions. These are responsible sourcing, sustainable innovation, purposeled brands, reporting & carbon roadmap, energy transition & reduction, wheat & regenerative agriculture, circular packaging, zero food waste, community and happy employees.

How does your business approach change as the warmer summer months arrive?

Going forward, LLBG is focusing on improving its reporting and data strategy through its use of Corporate Sustainability Reporting Directive (CSRD), driving energy efficiency, implementing a zero-accident workplace and reducing waste levels.

As our ambitions grow, I can see how we can have a larger and wider impact on our climate, soil, water and health of our consumers. We want to continue to build on this, helping to bake a better world together.