www.sandwichandfoodtogonews.co.uk

We champion sustainable sourcing, explore new materials to reduce plastics, and develop recyclable and compostable solutions. All whilst working to responsible business practices and implementing our net zero programme.

visit website

ISSUE 210 MAR/APR 2024

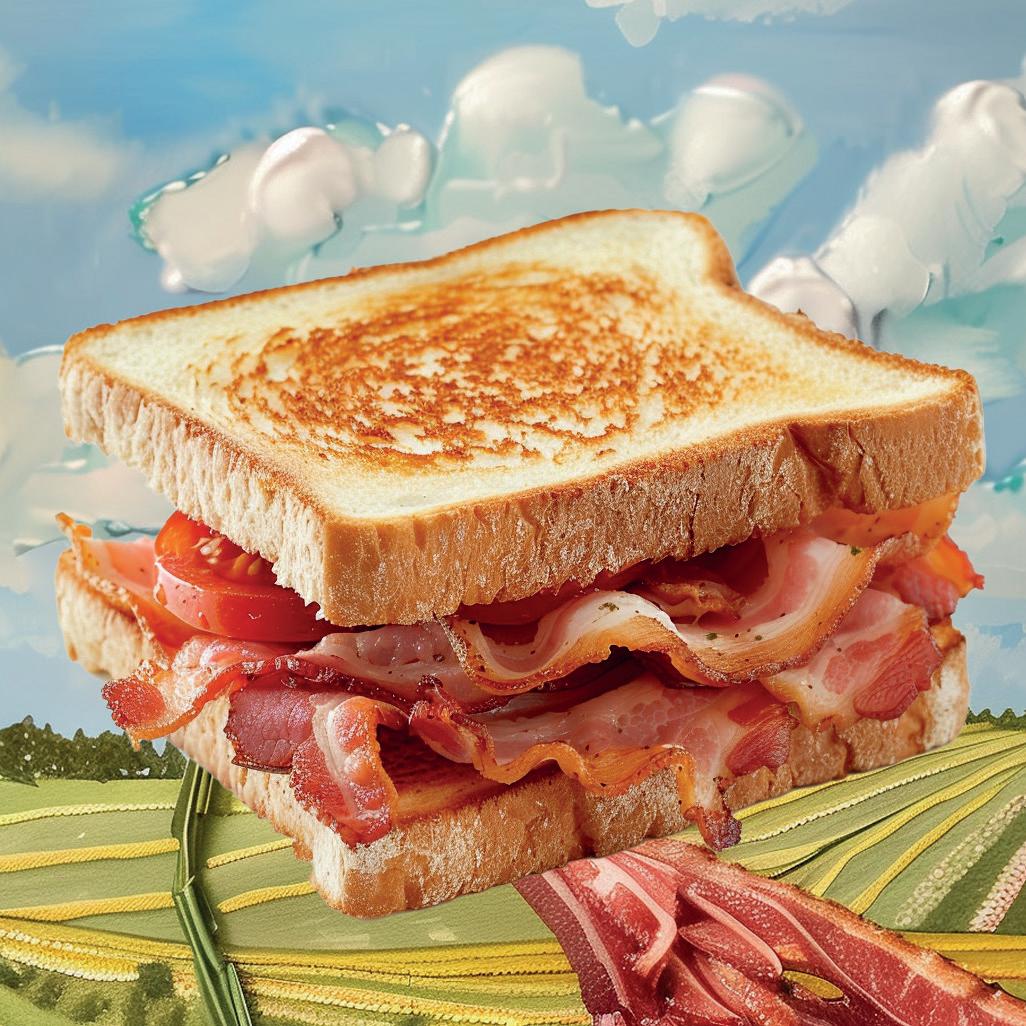

EAT HAPPY EAT GRUMPY Tel: 01992 307 627 www.thegrumpypigs.co.uk visit our website to see our full range ……Or the sweet smell of bacon Is that spring inthe air? ……Or the sweet smell of bacon Is that spring inthe air?

CONT ENTS

The packaging sector continues to thrive, with new products and innovation centre-stage. Our 30-page special re ects this – and it was a pleasure talking to those businesses making a signi cant impact not just in the UK, but globally.

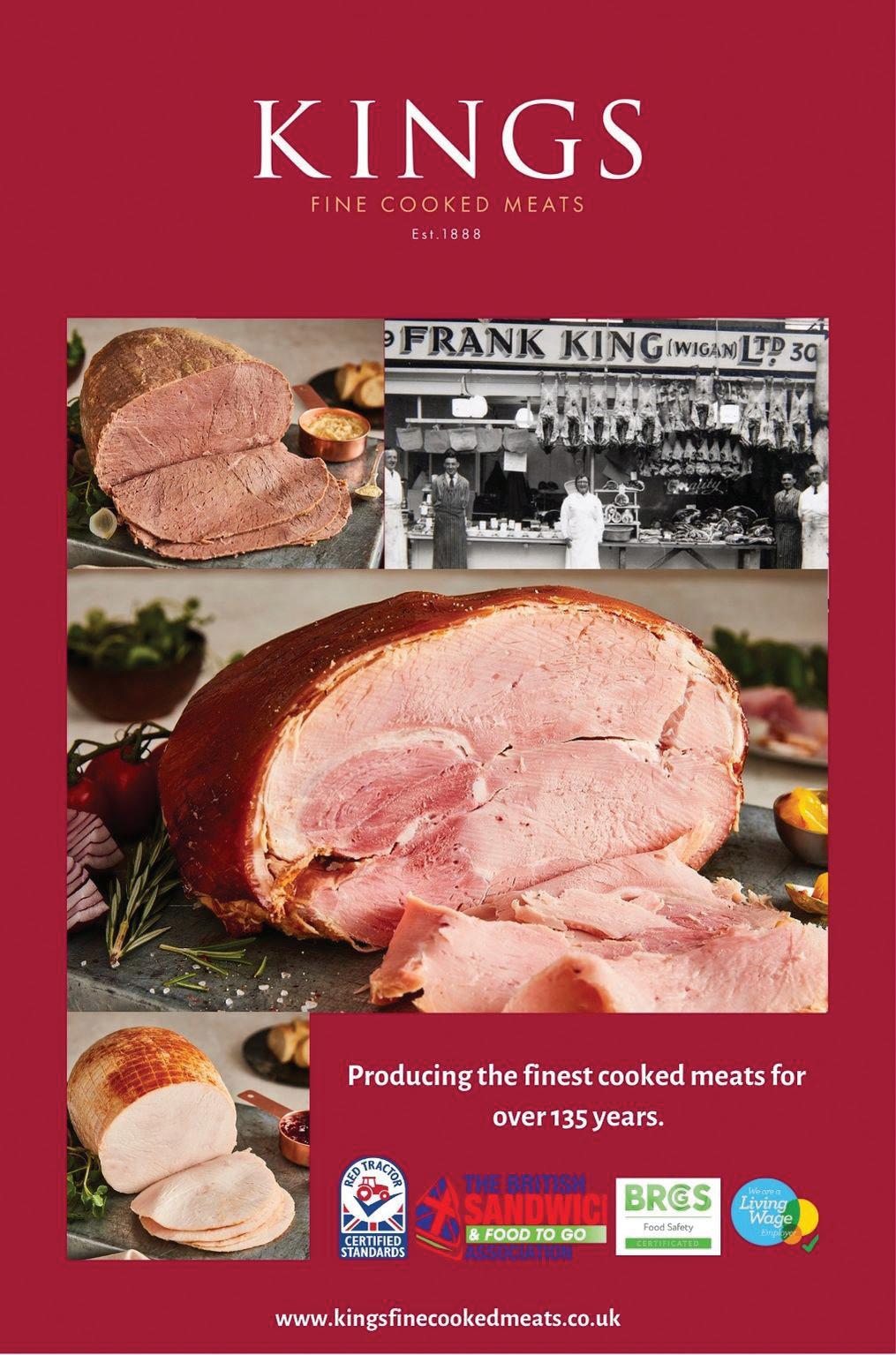

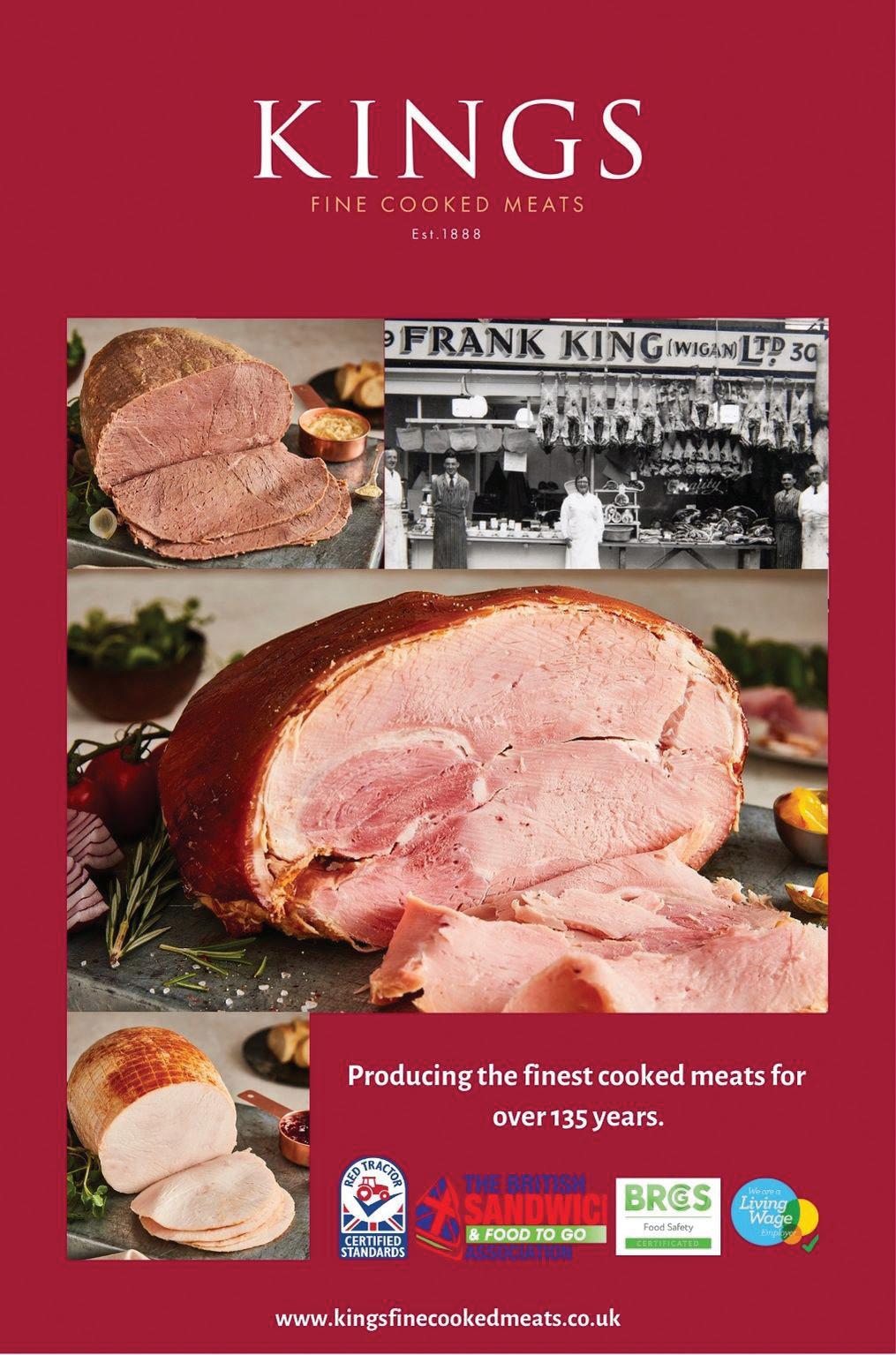

Our meats special examines exciting trends, providing in-depth analysis to help all operators. While the countdown continues to the biggest night in our industry – the Sammies awards. It’s 9 May, just in case it wasn’t in your diary! Cheers!

Editor Alex Bell, Tel: 01291 636349, email: alex@jandmgroup.co.uk

Advertising Paul Steer, Tel: 01291 636342, email: paul@jandmgroup.co.uk

Production Gareth Symonds, Tel: 01291 636339, email: gareth@jandmgroup.co.uk

Subscriptions and Customer Service

Tel: 01291 636338, email: subscriptions@sandwichandfoodtogonews.co.uk

Editorial Address Sandwich & Food To Go News, Engine Rooms, Station Road, Chepstow NP16 5PB www.sandwichandfoodtogonews.co.uk

In association with The British Sandwich & Food To Go Association.

PHONE +44 (0) 1291 636338

FAX +44 (0) 1291 630402

WEB www.sandwich.org.uk

EMAIL info@sandwich.org.uk

Paper used in the production of this publication is sourced from sustainable managed forests.

Opinions expressed in this magazine are those of the contributors and not necessarily those of J&M Group Ltd or this magazine. No responsibility is accepted for the opinions of contributors. This magazine is published by J&M Group Ltd. and supports the British Sandwich & Food to Go Association. It is circulated to managers, executives, buyers, retailers and traders in the sandwich industry. © 2024 J&M Group Ltd

NEWS

Pages 04-13. News round-up

PREVIEW

Page 14-16. Food, Drink & Hospitality Week

THE BRITISH SANDWICH & FOOD TO GO ASSOCIATION

Page 18-23. The Sammies 2024

PACKAGING SPECIAL

Page 24-53. BioPak / Woodly / Planglow / Vegware / Colpac / ProAmpac / eGreen / H-Pack / Coveris / Conglom / Bridge Cheese / Celebration / Faerch

MEAT PRODUCTS FOCUS

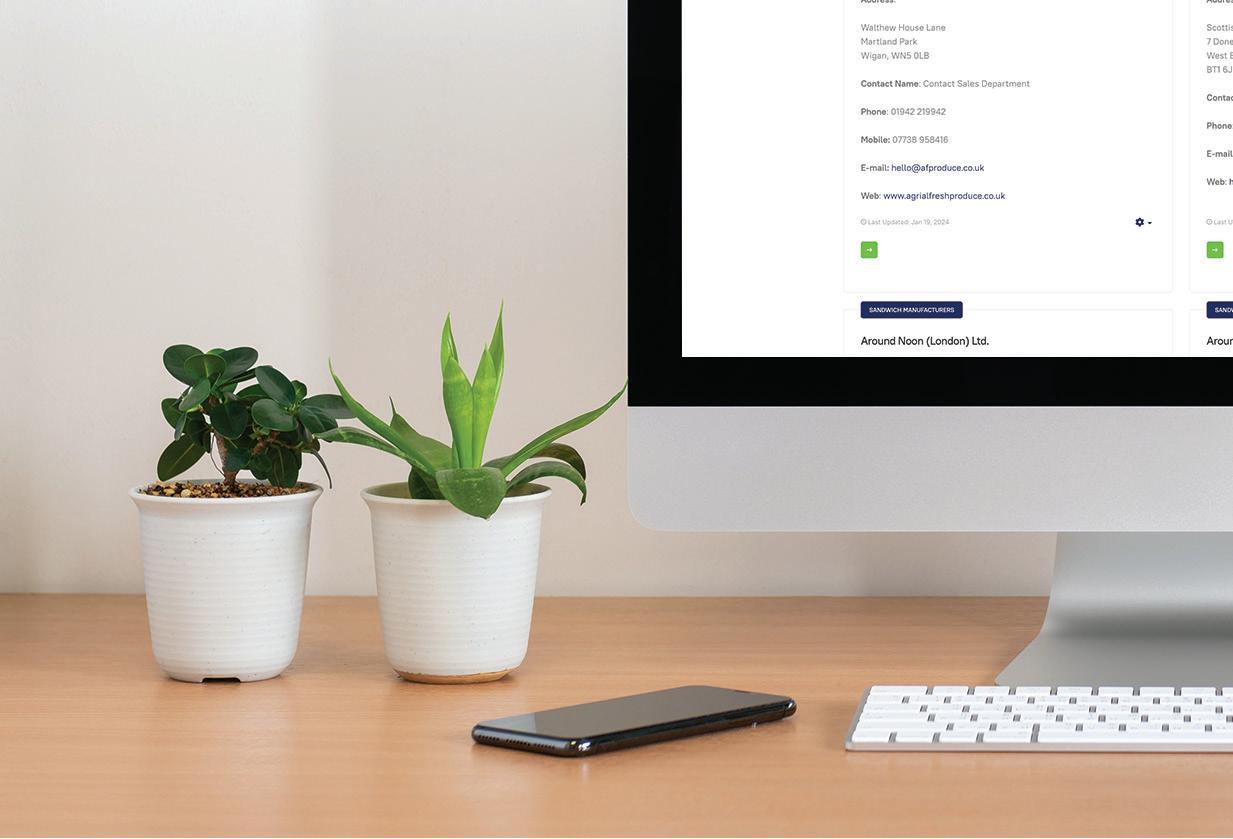

Page 54-67. AHDB / H. Smith / Grumpy Pigs / MB Chicken / Dawn Farm Foods / Sam Browne Foods

FTG TRENDS

Pages 68-69. Santa Maria Foodservice

ARTICLE

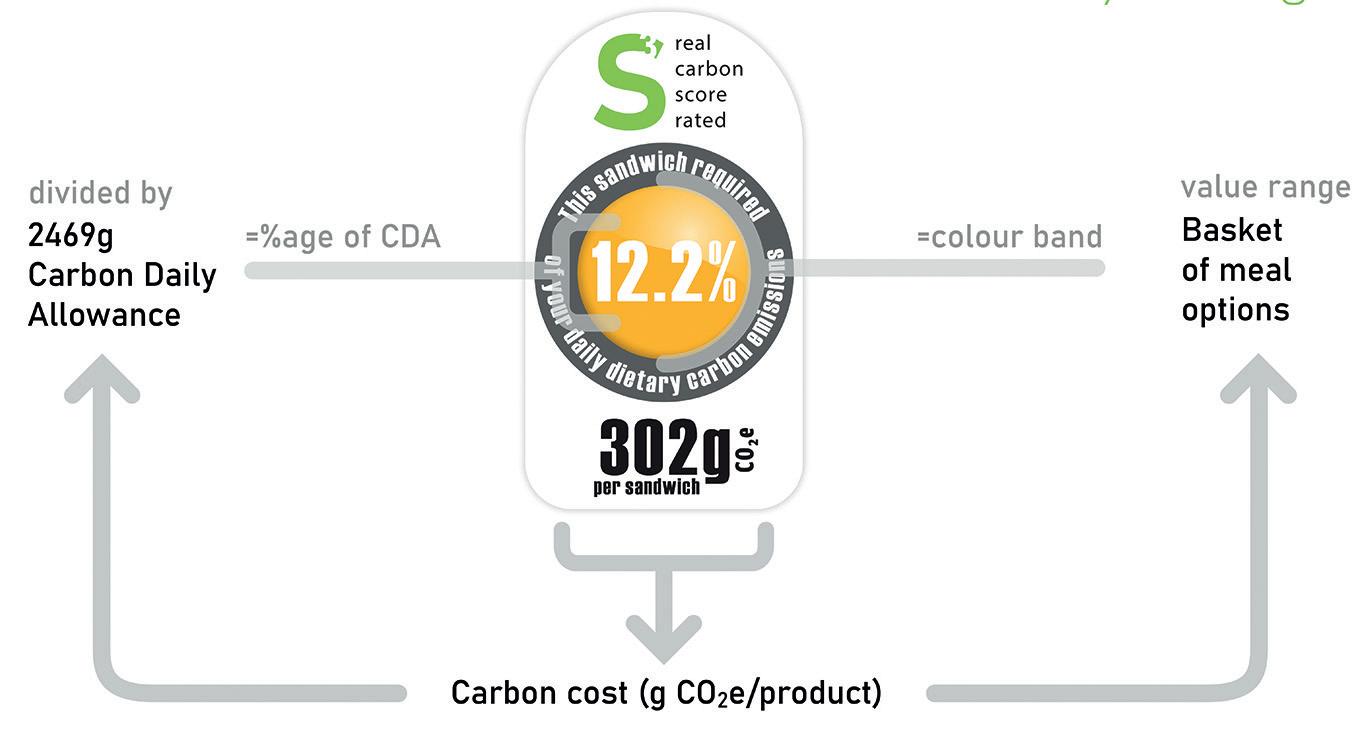

Pages 70-71. Cutting the carbon cost –Raynor Foods eco-labelling

REGULARS

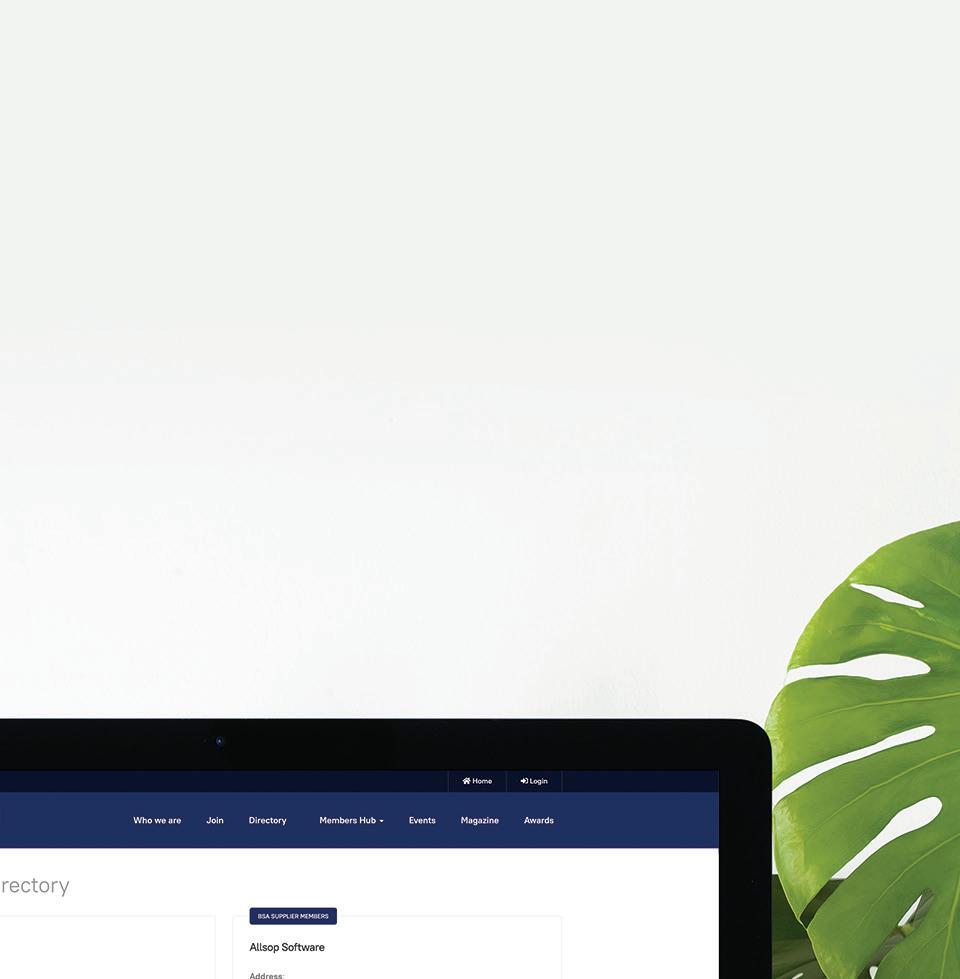

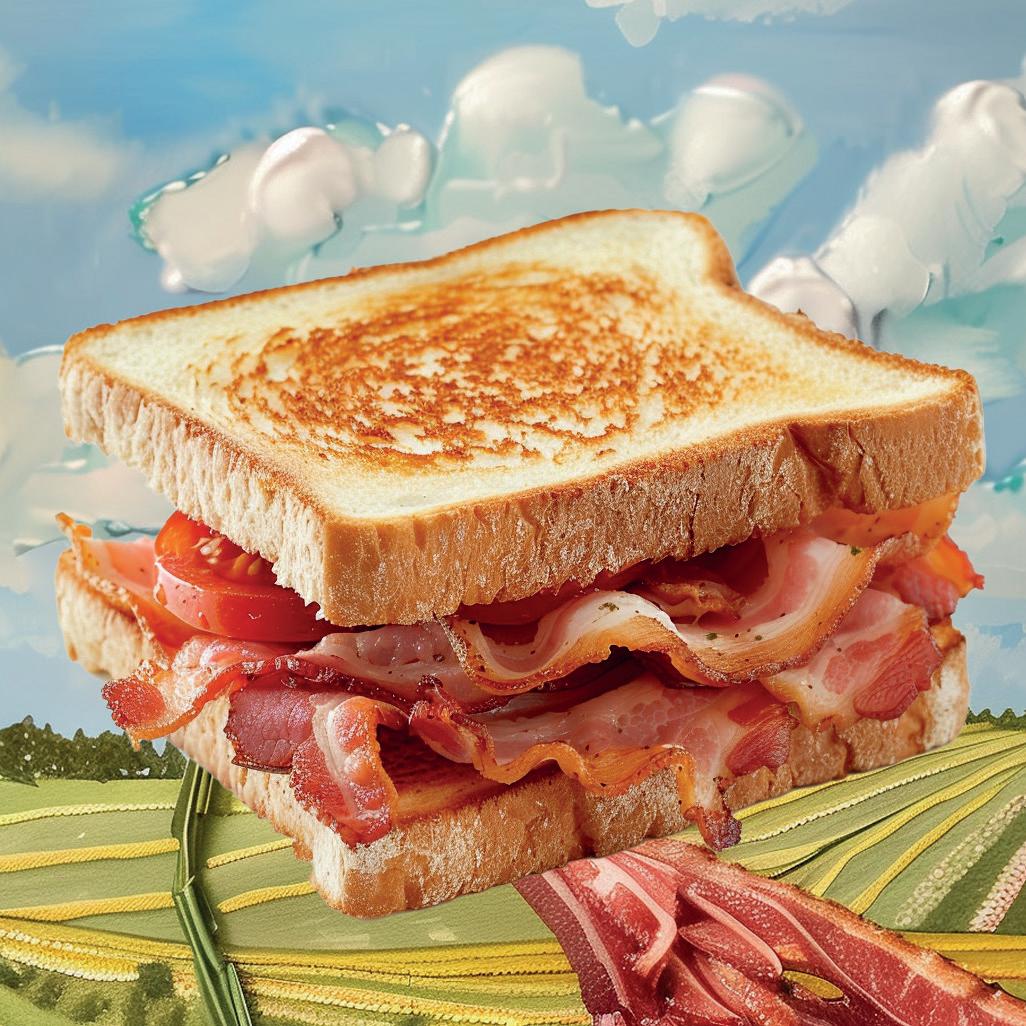

Page 73. BSA new member

Page 74. New products

Page 75. BSA listing index

www.sandwich.org.uk I 3

Sandwiches, wraps, rolls and much more handcrafted fresh everyday using the finest ingredients. An extensive range for both retail and hospitality. Delivered nationwide. Call the team on 020 3058 1245 or email sales@aroundnoon.com to find out more. Handmade with pride WWW.SOHOSANDWICH.CO.UK

______________ _____________ ________ ________ _________________________________________

Welcome

NEWS

Welcome forecasts for the sector, a high-profile café partnership is announced, plus the Food to Go Conference 2024 unveils its latest speaker line-up.

Hospitality Passport can ‘revolutionise’ recruitment

At a Workforce and Skills event, UKHospitality has unveiled further detail of the Hospitality Skills Passport, enabling new employees to demonstrate completion of the universal entry standard. This will give employers confidence that they are competent across a wide variety of necessary skills.

It can be used at every level of the sector, from starters to experienced staff, and will further professionalise training and development in hospitality. The concept has been tested, in partnership with the Department for Work and Pensions, through five pilot schemes across England and Wales.

The four-week programmes are aimed at providing jobs in hospitality for the unemployed, offering work experience, compliance and customer service training, and a guaranteed opportunity to interview at the end of the course, where they also receive their Hospitality Skills Passport.

The success rate has been significant, with the pilot schemes seeing an 85% completion rate and 80% of those completing the course now employed in hospitality.

For the schemes and passport to be rolled out further, UKHospitality is asking for funding from the Adult Education Budget to be allocated to employment programmes such as this.

Kate Nicholls, chief executive of UKHospitality, said: “Hospitality’s

variety is undoubtedly one of its strengths, but when it comes to entering the sector to work, it can be one of its greatest challenges.

“There are multiple routes into hospitality and with more than 200 different qualifications on offer, getting started can be confusing and deter potential entrants. That’s why a universal entry standard has never been more important.

“The new Hospitality Skills Passport initiative that we’ve developed, which is backed by the sector and being piloted by government, does just that and can revolutionise the way we recruit, induct and develop people.

“Through the evolution of this passport, by offering one place where people can store and track their

qualifications, we can improve the lives of employers and employees. It will streamline onboarding, identify training needs and help develop skills quicker than ever before.

“I’m delighted we’ve been able to share more details about how the passport would work and its staggering success helping people back into work, as part of the pilot schemes to test the concept.

“We now need to roll this out on a wider scale. That inevitably requires funding and we’re encouraging the government to offer greater flexibility by allowing Adult Education Budget funds to be used for this type of employment programme, given the clear benefits it can offer the sector and the economy.”

4 I www.sandwichandfoodtogonews.co.uk

Stunning figures for bread market

Retailers and operators have an opportunity to tap into the £1.2bn rise in the UK bread market over the next two years, according to a new report from bakery supplier Délifrance.

The Prove It: Breaking Bread report predicts the UK’s £7.8bn bread market will grow by 15% to £9 billion by 2026.

It states that businesses can take a slice of this growth by embracing evolving trends such as:

● Specialty and world breads

● Products using clean-label and regeneratively farmed ingredients

● Bread that offers health benefits or caters to specialist diets

● The impact of smaller bakeries on the wider market

● Consumers’ response to the cost of living crisis.

These topics and many more are examined in the report, which has been compiled following a survey of 1000 UK adults who regularly eat bread, in and out of home.

It also makes use of Délifrance’s internal market estimates and

insight, external market data and the experience of Harris & Hayes, one of the UK’s most trusted food consultants and future forecasters.

“Our latest Prove It the trends shaping the category, from the continued growth of sourdough to the opportunities across the globe,” said Délifrance marketing director, Stéphanie Brillouet.

report looks at examine differs

“We also take a deep dive into consumer attitudes to bread and examine what drives purchasing decisions, how consumption differs in and out of home, and the impact of environmental and economic concerns.”

Among the findings are how well bread is weathering the economic crisis. With it seen as offering excellent value for money, more than a quarter of consumers cite a drop in their household budget as a reason for increasing in-home consumption of bread.

And despite the pressure on spending, quality remains key. More

Pret A Manger has launched a freshly baked Fruit Scone. Initially in around 70 shops across the UK – including Harrogate, Orpington and Canterbury – Pret is planning to roll out the service to more shops later this year.

Initially made available in time for Mother’s Day, Pret’s new Fruit Scone is loaded with sultanas, with the optional accompaniment of Rodda’s Classic Cornish Clotted Cream and a mini jar of Bonne Maman Strawberry Conserve.

As part of Pret’s commitment to reducing food waste, the dough is cut into hexagons during the sconemaking process, ensuring minimal waste and maximum taste.

The scones are then glazed with free-range whole egg to give a distinctive shine, promising a crisp,

golden crust and delicate rise.

Katherine Bagshawe, UK food & coffee director at Pret, said: “We’re excited to launch Pret’s Fruit Scone, crafted with love, baked to perfection and served with a Pret smile.

than half of consumers (52%) say they base where they buy bread

than half of consumers (52%) say on the quality of products sold.

Additionally, these consumers are most likely to shop at independent bakeries and supermarket ISBs.

“It’s an exciting time for the bakery category,” said Harris & Hayes. “Shoppers are responding well to innovation, with regional specialties, snacking and occasion-led bakery representing a significant growth opportunity. Retailers and operators will benefit from offering considered ranges that cater to a plethora of differing needs and budgets.”

Fresh fruit scone on menu for Pret

“Made using high-quality ingredients and developed to have the perfect amount of crumble, the fruity sultana scones are a perfect afternoon tea treat. We felt it was the right time to bring back scones as we continue to expand our range for our shops outside of the city.”

Pret continues to evolve its counter menu and add in new products to cater to more customers.

Over the past few years, Pret has accelerated its regional expansion with franchise partners into areas outside London, including recent

openings in Bishop’s Stortford, Colchester and Worthing.

At the heart of Pret’s transformation has been a significant shift in the way the business serves customers, providing freshly made food and organic coffee through new digital and retail channels. Club Pret subscribers get 20% off the scones as part of their usual 20% discount on everything sold in-shop and up to five baristamade drinks per day.

www.sandwich.org.uk I 5

New café culture for Costa and Sainsbury’s

Costa Coffee, the Nation’s Favourite Coffee Shop*, and Sainsbury’s have announced a new café experience across the UK. It represents an expansion for Costa Coffee, as it unveils initial plans to open 11 stores within Sainsbury’s supermarkets throughout 2024.

The collaboration caters to the evolving preferences of supermarket customers. With an investment exceeding £3 million, the stores will boast a modern and inviting design.

The agreement is also set to create over 100 jobs. With training opportunities available for team members, the next generation of expert Costa Coffee Baristas will soon be in place in Sainsbury’s supermarkets.

Nick Ridley, property director at Costa Coffee, said: “We are excited to join forces with Sainsbury’s, bringing our much-loved Costa Coffee experiences to shoppers nationwide. We’re proud that we will soon be able to make a difference to customers looking to catch up with friends and family over lunch or enjoy a beloved Costa coffee after their weekly shop.”

It is the latest step in a strong relationship between the two companies. Alongside its Ready to Drink and At Home

ranges, Costa Coffee already has over 1000 Costa Express machines in Sainsbury’s stores and petrol stations, selling 10 million cups of coffee in 2023 alone.

Richard Crampton, Sainsbury’s director of fresh food, said: “We know that customers like the convenience of being able to stop for a drink, snack or sit-down lunch while shopping, and we think that Costa Coffee stores will offer a fantastic opportunity to do this within Sainsbury’s supermarkets. That’s why we’re delighted to be building on our existing collaboration with Costa Coffee to roll out this fantastic new option for customers over the next year and we’re looking forward to hearing what they think.”

Sainsbury’s Farlington Superstore in Portsmouth is home to the supermarket’s inaugural Costa Coffee store, which opened its doors in February 2024, creating nine new job roles.

*Allegra Strategies, 2023

Uncover a Williams Refrigeration Gem

With the release of the latest versions of its Gem Multideck range, Williams Refrigeration is highlighting the advances it has made in the range of customisation options that allow operators to perfect the look of their display.

Williams Multidecks are designed to maximise available display area and performance while delivering cost savings through energy efficient operation. This is achieved by combining technical know-how with a keen understanding of what makes a great looking display. The Multideck’s operating temperature range is from +3°C to +5°C – ideal for chilled grab-and-go foods.

The Gem range can be customised to suit a range of applications. Options include additional LED strip lights, inset within the ticket holders, which enhance the

display while using little energy and generating minimal heat. There are also night blinds, security shutters, front doors (sliding or hinged), rear loading doors for easy restocking, impulse snack selection baskets for added merchandising potential, food tray slides, glass shelves and mirrored panels, all of which can be specified to customer requirements. There’s also the option of remote refrigeration and the ability to multiplex units.

Williams Multidecks can be customised to match existing décor. A wide selection of colour combinations is possible, and the Gem Multideck range is compatible with Williams’ Chameleon vinyl wrapping system – which means the specifier can create a merchandiser that can look like it’s a piece of art, or made of bricks, or wooden for example.

Energy efficiency is crucial, with rising costs and a focus on environmental sustainability. The Gems use natural hydrocarbon refrigerant which reduces energy consumption thanks to its thermodynamic properties, with low GWP (Global Warming Potential) and zero ODP (Ozone Depletion Potential).

While the latest open-fronted models from Williams use a variety of clever features to minimise power consumption, units with doors can deliver further improvements.

Visit williams-refrigeration.co.uk.

NEWS

Fri-Jado get Space Saver lift-off

The all-new Space Saver from Fri-Jado is the world’s first rotisserie with a heated self-service display cabinet, helping to simplify any hot food offering.

Versatility and flexibility are central to the Space Saver, with the rotisserie giving operators the opportunity to expand menus beyond traditional options. It can be used for a diverse range of dishes, including alterative roasted meats such as pork joints, as well as vegetarian and even dessert options.

The Space Saver combines the latest roasting and holding technology in one compact unit. With key functions in a single footprint of just 1m2, it maximises floor space and simplifies in-store operation.

The unit also features exceptional thermal performance and incorporates ‘Hot Blanket Technology’, delivering up to 50% energy savings versus previous units, as well as precision temperature control variable by shelf, to ensure food is held at the best temperature for longer. LED lighting showcases the contents.

Alternatively, the Space Saver Premium features all the above industry-leading functionality but adds the TDR 5 S auto-clean rotisserie unit. This includes an integrated drain pump and grease tray alongside all necessary internal connections and piping, as well as the ability to restock the unit from the rear (exclusive to the Space Saver Premium). Rear load capacity improves restocking and unit management, as well as helping create seamless inoperation performance and ensures nothing disrupts the visual showpiece of the hot food being roasted and held.

For added convenience, the unit doesn’t require a wastewater connection and can be easily drained into an optional wastewater trolley. All cleaning can be pre-programmed to take place overnight, minimising downtime.

Developed in line with user feedback and with simple, intuitive controls, the rotisserie units can be operated by any member of the team using pre-set programmes. The design features double-pane glass on each side for maximum visibility and heat retention.

Gary Thacker, Fri-Jado sales director, said: “Consumers eat with their eyes more and more these days. From Instagram food influencers to TikTok trends, at Fri-Jado we know that food needs to be the core focus of everything we do. The new Space Saver unit truly maximises all these values in a single compact unit – creating genuine in-store theatre, encouraging aromas and helping boost sales.

“Our team has also worked tirelessly to ensure that these are some of our more energy-efficient appliances ever, recirculating the existing hot air to ensure much reduced

energy consumption, helping reduce costs and minimising the operator’s environmental impact. The Space Saver range is a feat of innovative engineering delivering the opportunity to any store or outlet nationwide to offer fresh and delicious rotisserie cuisine with simplicity, convenience and performance.”

For more details, visit frijado.com.

www.sandwich.org.uk I 7 220 0 20 F M C G F O O D D R I N K

Strong sales numbers for Coffee#1

Coffee#1 has announced continued strong trading for the first half of the financial year (Jun-Nov 2023), with sales of £29.5 million, representing total growth of 18.8%.

Coffee#1’s like-for-like sales performance for the same period remained robust at 8%, underpinned by sustained customer growth of 1.2%.

Founded in 2001 and now operating across Wales, the Southwest, the South Coast and parts of the Midlands, Coffee#1 also opened four stores during the same period, taking the estate to118, making it the fourth-largest coffee shop brand in the UK. Sites in Godalming and Chesterfield expanded its operating footprint, while openings in Yate and Cwmbran strengthened the existing operating area.

At the start of the second half of the financial year, Coffee#1 experienced particularly strong Christmas trading. It had record sales levels peaking at £1.37m during the week of 18 Dec, with nearly 300,000 customers. The store opening programme has also continued, with Derby in December and Fleet in January, and four further openings forecast this financial year, creating 35 new jobs.

The brand now operates 118 stores with over 1000 employees and a customer base that regularly exceeds 250,000 people per week. Despite inflationary pressures, the business remains committed to job creation and store growth with stores

"I've been delighted to see the recovery of the business."

in Westbourne and Loughborough currently under construction.

Coffee#1 also relaunched the store manager development programme during the first half of the year, with 25 existing assistant managers joining, with eight succeeding into their first management roles with the company.

Coffee#1 managing director, Bruce Newman, said: “Once again, we are indebted to our store and support teams. They have put in the hard work required to deliver excellent results. It takes first-class service and great teamwork, along with an outstanding menu, for our customers

New appointments at Fairfields Farm

UK crisp producer, Fairfields Farm, has announced the appointment of David Nairn as non-executive director. Having formerly served as managing director of Burts Snacks, Nairn will be supporting the executive team. This news aligns with Fairfields Farm’s growth ambitions, which saw business turnover grow by 56% between 2022 and 2023.

Nairn said: “I have been working in the snack category for a long time and certainly admired Fairfields Farm from afar. It’s a good, solid business with an exciting strategy and strong core values. I look forward to helping the business reach new heights.”

Tash Jones will join the board having been promoted from head of marketing & NPD to commercial director. In her new role, Jones will oversee sales and marketing.

With previous experience at Kettle Chips, Jones first joined the Fairfields Farm team in April 2021. “I’ve been a fan of the brand and business for the longest time, so it’s an absolute honour to be given the opportunity to lead a talented sales and marketing team and continue our work of providing a fantastic service to customers,” said Jones.

Co-founder, Robert Strathern, added: “I’d like to welcome David to

to want to come back time and time again. It’s been fantastic to witness that happening and see so many employees progressing their careers.”

Coffee#1 also reported annual results for the last financial year, ending May 2023 (FY23). Sales increased to £53.8m, a rise of 22%, with EBITDA of £7.0m. FY23 also saw strong store growth with 11 added to the estate, creating 110 jobs.

Coffee#1 expanded its presence in the delivery market, adding Uber Eats to an established partnership with Just Eat. Delivery was available from a total of 83 stores of the 112 trading at the end of the financial year.

Iced coffee is continuing to establish itself as a growth driver. Sales of cold coffee grew to four times the size of pre-Covid levels. Concurrently, Coffee#1’s food categories performed well, with sales growth of 17.5% and more customers ‘attaching’ a food item to a drink sale than in any prior year.

Newman continued: “I have been delighted to see the recovery of the business after the pandemic, with new programmes of learning & development landing and the resurgence of energy and culture which is so important to our brand.”

the team, and I’m confident that his considerable experience and expertise will help us to achieve our growth goals here at Fairfields Farm.

“I equally would like to congratulate Tash. The board has big ideas and plans, and Tash has already proven herself to be an asset. She will play a key role in helping us develop the business, particularly at a time when we are accelerating at a rapid pace.”

NEWS 8 I www.sandwichandfoodtogonews.co.uk

Sell more. Waste less.

Unleash your hot food-to-go menu with Flexeserve.

Offer your customers a wider range of hot food-to-go only with our unique technology.

Hold your products at optimum quality for longer, saving costs and reducing waste.

Minimise demand on busy kitchens whilst consistently delivering high-quality meals that your customers.

Now you can control your estate with cloud connectivity, ensuring total operational efficiency like never before.

Scan here to connect with our hot food experts.

NEWS www.sandwich.org.uk I 9

New Food to Go Award Sponsor

2024

Nutrition Progress Update makes debut for KFC

KFC UK&I has unveiled its first ever Nutrition Progress Update, which tracks the progress it has made on nutrition across its menu, aiming to increase transparency for consumers and the wider industry.

It sets out key steps KFC has taken on its nutrition journey. Progress includes reformulating KFC fries, which removed around 13 billion calories a year, and removing fullsugar Pepsi from its menu in England, which amounted to the removal of around eight billion calories a year. KFC has also been building out its range of 500 kcal or less options with Riceboxes, Salads and Twister Wraps.

Last year, KFC joined with youth activist movement Bite Back, whose Food Systems Accelerator Programme sees young people partnered with industry to identify, develop and deliver solutions on how to make healthy food more desirable, accessible and affordable. Through this, KFC UK&I has started its first set of behavioural intervention trials, designed to help understand what encourages customers towards healthier options, specifically at lunch.

This first Progress Update marks a key step in KFC’s ambition to be open and honest about its nutritional journey, recognising the role that KFC has to play in helping more people have access to nutritious food.

KFC has worked with partners to develop a number of 2025 ambitions. These include:

● Increase the number of non-HFSS items to 70% of the total menu through a combination of product innovation and reformulation of current items.

● Develop a sales-based target for the amount of HFSS and nonHFSS menu items sold, working alongside external partners to shape the metrics.

● Increase the percentage of menu items that meet PHE nutrient guidelines by 10%.

● Provide food education programmes in five cities for 500 young people through the KFC Youth Foundation.

Meg Farren, general manager, KFC, said: “We know it’s our great quality, finger lickin’ chicken that means people love KFC, but we also recognise that we have an important role to play in helping more people have access to nutritious food. We have made a start, but the fact of the matter is we’re not yet where we want to be on nutrition. That’s why we’ve decided to disclose our progress

and plans through our new annual Nutrition Progress Updates.

“While we’ll never stop providing fried chicken across menus, behind the scenes we’re continuing work on making sure any trip to KFC offers great quality, fresh, nutritious options, at great value for customers. By being open and transparent about the action we are taking, we hope we can bring others on this journey with us.”

Professor Richard Crisp said: “Making balanced, healthy choices around what we eat is something to which we all aspire. Intervention trials that measure the efficacy of different behavioural nudges are critical –they allow us to make data-driven decisions about which approaches work well, or not so well, in any given context. KFC understands this, and their science informed/data driven approach to this endeavour will help them fine-tune the way in which they present their healthier options through multiple channels, and in so doing, enable, enhance and empower their customers’ decision-making.”

Ambitions for 2025 that KFC UK&I is setting out have been developed in partnership with academics, nutritional experts and campaign groups. KFC will be comparing its menu items against the UK Nutrient Profiling Model 2004/2005, which is used by the government, to categorise nutritional value and define foods that are HFSS.

Four pillars have been identified that have the most impact on the nutritional value of its offer: menu innovation, reformulation, partnerships and nutritional information.

NEWS 10 I www.sandwichandfoodtogonews.co.uk

H-Pack Packaging has launched a ‘Great Taste’ range, aimed at the higher end of the fish and chip takeaway market.

The new line of packaging includes a series of small, medium, and large paper boxes and small and large paper bags – all boasting the same vibrant and eye-catching design.

With the complete range providing an opportunity for sellers to supply a more considered, identifiable offering, that appears unique to the individual food to go outlet, ‘Great Taste’ gives packaging a badge of quality that guarantees your food offering will stand out.

www.sandwich.org.uk I 11 For further information on our ‘Great Taste’ range Call: 01978 855 595 sales@h-packglobal.com www.h-packglobal.com

For the discerning customer…

Do your fish ‘n’ chips have

Taste?

Great

The Great Taste trades under H-Pack

Optimism high for FTG: Lumina

Fresh insights from Lumina Intelligence reveal a bright picture for FTG, with an increased focus on healthier options.

The UK FTG market is forecast to grow +3.5% to a value of £23 billion in 2024F, outpacing pre-pandemic value by +9.3%. This is ahead of the total eating out market and inflation, indicating growth from stronger volumes following a weaker 2023.

Strong net space growth (0.7% to 152,783 outlets) is forecast, driven by

the expansion of a variety of formats and locations, including travel hub, drive-thru and kiosk-style services.

Market growth was +8% in 2023, although cost of living pressures did have an effect. Penetration recovery from 2021-2023 was stronger in the total eating out market versus FTG.

FTG has been restricted by a slow return to travel, strike action and continued hybrid working, with financial strain prompting changes in spending habits. The most notable impact has been lower income families dropping out of lunch occasions, with declines in share focused on Wednesdays and Thursdays.

Convenience store grab and go has achieved FTG growth versus preCovid, driven by investment in ranges and value. Value growth is expected to have been +17.4% from 2019-2024F. The introduction of tiered meal deal ranges has allowed grocery operators

to avoid hiking costs of meal deals, while introducing more premium and foodservice-standard ranges.

Demands for nuanced health and premium quality are driving development. Most new products surveyed were aligned with healthier eating, carrying price points of +£4. Vegan, high protein and high fibre all gained share year-on-year. Gut health and immune system-boosting products were new to ranges in 2024.

Easing economic tailwinds, boosted tourism/travel and record employment is expected to result in a market value of £25 billion in 2027F. Average earnings outpacing inflation, with interest rate reductions, are forecast to bolster spending power. Greater emergence of nutrient dense, high quality and specialised options, with continued outlet expansion, should drive FTG market growth of +£2bn from 2024F-2027F.

All systems growth for Greggs

Greggs’ preliminary results for the 52 weeks ended 30 December 2023 reveal market share at an all-time high.

Total sales were up 19.6% on 2022, with like-for-like (LFL) sales in company-managed shops up 13.7% year-on-year.

The share of FTG breakfast visits increased to 19.6%, taking Greggs to number one in the market.

Underlying profit before tax, excluding exceptional income, was up 13.1% to £167.7 million (2022: £148.3m) for the UK’s leading food to go brand (YouGov’s Brand Index).

There were a record 220 new shop openings in 2023 and 75 closures, growing the estate to 2473 shops. Expanded partnerships with retailers included Primark, Tesco and Sainsbury’s, while London presence was extended –including new shops in Canary Wharf and Waterloo railway stations and Gatwick Airport. With a target of 160 net openings in 2024, there is a significant opportunity for more than 3000 shops over the longer term.

The evening is proving the fastest-growing day part, with 8.7% of company-managed shop sales in H2. Existing ranges proving most popular include the hot chicken goujons, potato wedges and pizzas. In terms of digital channels, delivery reach has been extended, with availability on Just Eat (1340 shops) and Uber Eats (930 shops) platforms. – sales up 23.6% in 2023. The Greggs app was scanned in 12.5% of shop transactions.

Greggs has also started 2024 positively, with LFL sales up 8.2% in the first nine weeks. Chief executive, Roisin Currie, said: “I am so proud of how our teams have risen to the challenge of serving more customers through more channels. They made sure that we kept pace with increased demand, as we delivered on our strategic growth plan. We are very much on track to deliver our bold five-year growth plan to double sales by 2026 and have significantly more than 3000 shops in the UK over the longer term.”

NEWS

Food to Go Conference 2024speakers & programme update

First speakers have been announced for the latest addition to the sandwich industry calendar, the Food to Go Conference 2024.

Organised with the support of the British Sandwich & Food to Go Association, the inaugural event is taking place on Thursday, 27 June 2024, at London venue One Birdcage Walk. Delegates can expect to enjoy presentations from leading industry heavyweights covering crucial topics affecting the sector. These include:

The ever-changing FTG market:

● Simon Stenning, strategy advisor and futurist

● Nicola Knight, Institute of Grocery Distribution

● Gavin Rothwell, Food Future Insights.

Working towards a sustainable future:

● Andy Cato/George Lamb, Wildfarmed

● Fran Haydock, Greencore

● Joanne Elsdon/Paul Rhodes, Greggs.

Facing up to the challenges of delivery – with industry expert, Peter Backman.

The case for switching away from bar codes – with GS1's Camilla Young.

DISCUSSION

Each themed session will conclude with a discussion forum, where speakers will be able to explore some of the points they have raised.

SPONSORSHIP

If you are interested in supporting the Food to Go Conference 2024 as a sponsor, get in touch with Sandra Bennett on 01291 636348 or by email to sandra@jandmgroup.co.uk.

In the meantime, keep an eye on the events page of the BSA website at sandwich.org.uk/events.

Discovery Day gives bakeries a taste of Food Works

A Discovery Day held at North Somerset’s The Food WorksSW proved a big hit with bakery businesses looking to find out about the innovation centre’s specialist kitchens and state-of-the-art facilities, while hearing from guest speakers.

Over 50 people attended the free event, which included a session aimed at bakery products. Guest speaker Chris Giddings, commercial director of Cakesmiths, shared industry insights and advice. In addition, Butcombe Brewery’s development chef, Jasper Prickett, spoke about how the hospitality business benefits from hiring out the bakery and commercial kitchens at The Food WorksSW.

The session included a kitchen

demonstration from the centre’s in-house technical experts, Zoe Plant and Rachel Goff, who showcased the specialist equipment and highlighted the technical advice they offer the sector. One-to-one business support with Simon Gregory, senior strategy and commercial manager at the Food and Drink Forum, was also available to visiting business owners.

Giddings said: “When Cakesmiths was smaller, we'd have loved a facility like this. It would have provided the perfect place to develop our cakes, particularly because we didn’t have a big new product development team. I’ve no doubt the support of The Food WorksSW would have allowed us to create great products.”

Jasper Prickett is a regular at Food WorksSW. He brings chefs from Butcombe’s collection of pubs and inns to the centre for training and to develop menus. He said: “One of the main reasons I hire the facilities here is so that I don’t get

in the way of our chefs in their busy working pub kitchens. Unlike other brands, we don’t have a dedicated development kitchen, so Food Works solves our problem.”

Zoe Plant, innovation and new product development manager at The Food WorksSW added: “It’s been fantastic to meet so many new businesses and show them what we can offer. The response to our Discovery Day has been extremely positive and we’re very grateful to all our guest speakers.”

Since its opening in October 2021, The Food Works has helped over 200 businesses. New products such as gelato, water kefir, vegan cheese, chilli sauces, high-protein cookies and frozen ready meals are just some of the products that have been developed in its kitchens.

Five product development kitchens are available for flexible short-term contract hire – prices start from just £100 per day (inc VAT).

For more info, visit foodworks-sw.co.uk.

www.sandwich.org.uk I 13

The place to be…

COME ONE, COME ALL

Food & Drink Expo is a festival of grocery, foodservice, manufacturing and speciality retail, offering food to go operators unique insight into the sector across three days.

When doors open (29 Apr-1 May, NEC Birmingham), the show will provide visitors with the most direct route to the UK food & drink market, bringing together the very best in product innovation, business advice and operational insight.

With over 1200 exhibitors confirmed, visitors can expect an unparalleled range of products and services, as big name exhibitors, small scale innovators and technical solutions fill the show floor. Exciting product launches come from:

● La Lorraine Bakery (Stand Z241), whose Topped Flatbreads come in four flavours and allow operators to offer warm premium snacks in just 7-9 minutes.

● One Good Thing (Stand V219) who offer wrapper-free snack and protein bars with a 100% natural edible coating.

● Novameat (FF210), offering a range of meat-free products including Deli Nova-t*rkey, which is ideal as a deli meat in a sandwich but can also be served hot for a bacon-like experience.

● Westfalia Fruit (X238), whose Smashed Avocado is never frozen and has a category leading shelflife thanks to an innovative high pressure processing system.

● devOATed (DD229), showcasing the UK’s first rich and indulgent oatshakes, made using 100% British oats.

After their inaugural success in 2023, two exclusive zones are set to return to Food & Drink Expo for 2024. Healthy & Natural zone will include a range of healthy, wellness and natural products encompassing free-from, vegetarian,

www.sandwich.org.uk I 15 YOUR EDGE IN PAYMENT & BUSINESS MANAGEMENT powered by ces software sales@3rtelecom.co.uk 01992 574 650 www.3rtelecom.co.uk *T&Cs Apply. Rates are subject to change. - Durable touch screen EPoS with optional extras - Bespoke screen customisation, the way you want it - Integrated with contactless payment and mobile top-up - Standalone debit/ credit card payment facility available - Support for hardware/ software/ back-up available - UK based customer support, 24/7 365 days - Finance options available (subject to credit approval) BEST RATES GUARANTEE 0.290% Per Transaction* From 0.699% Per Transaction* From

low-calorie and organic items, to name just a few.

Exhibiting in this zone are suppliers including Clearspring (S259), whose humble beginnings of Japanese miso soup haven’t stopped them becoming pioneers of authentic specialities with over 300 organic products today. And Truede & Peng (V278), who offer authentic Turkish snacks, including a range of roasted chickpeas.

Plant-Based Zone will also be making a comeback, with everyone’s

favourite vegan and plantbased exhibitors showcasing the future of this ever-growing sector. Those exhibiting include Buttermilk (CC231), Glebe Farm Foods (CC228) and Suma Wholefoods (CC210), whose products include Suma Vegan Chick’n Soup.

TALKING HEADS

On The Grocer Stage, a variety of expert panels will call on some of the industry’s biggest names for their take on the sector’s most pressing challenges. Key highlights of the schedule’s programme include:

● Staff wellbeing: Creating an inclusive culture that allows colleagues to thrive, Monday 29 April, 11.15am.

● Food to go: The trends to watch out for in 2024, Monday 29 April, 1.45pm.

● Diversity and inclusion: How far have we come and where do we

need to get to?, Tuesday 30 April, 10.30am.

● Social Media Food & Drink Trends –What’s Hot Now, Tuesday 30 April, 2.45pm.

● The Marketplace Model: Making it work for Everyone, Wednesday 1 May, 11.15am.

● Cassandra Stavrou: Healthy snacking PROPERly, Wednesday 1 May, 12pm.

● Price, promotions and NPD: The impact on convenience, Wednesday 1 May, 1.45pm.

Andrew Reed, managing director –wine & exhibitions, William Reed, said: “The food to go market is a significant player in the wider industry that Food & Drink Expo celebrates so well. The show has product innovation and specialist advice at its very heart and can offer industry leaders three days of insight which simply cannot be found elsewhere.”

For the full list of products on show and to register for your free pass now, visit foodanddrinkexpo.co.uk

NEWS 16 I www.sandwichandfoodtogonews.co.uk

Insight. Networking. Innovation.

Food & Drink Expo returns to the NEC, Birmingham from the 29 April - 01 May 2024 alongside Farm Shop & Deli Show, National Convenience Show, The Forecourt Show and The Restaurant Show.

• Sample and source the latest offerings

• Learn the latest trends and insights

• Make valuable contacts

To advertise please call Paul Steer on 01291 636342 I 17

This is a trade event. No under 18s will be admitted. Find out more and register free at: foodanddrinkexpo.co.uk

DOORS

29 APRIL - 01 MAY 2024 NEC BIRMINGHAM 24 NEC BIRMINGHAM

OPEN NEXT MONTH

SANDWICH & FOOD TO GO INDUSTRY AWARDS

The awards judging process is well underway and the shortlist for each award catgeory can be found on the awards website at www.thesammies.co.uk.

En Route Retailer Award

Focusing on travel. From forecourts and motorway services to airports, railway platforms and bus stations, this award recognises the work these businesses are doing to develop and drive this sector.

Convenience Retailer Award

This award will recognise the work being done by the convenience retailers to develop the sandwich and food to go market in the high street.

MultipleAwardRetailer

This award recognises those retailers who have done the most to develop their business over the last year.

Sandwich Industry Award

Presented to a business or individual who the BSA Management Committee consider deserves recognition for the work they have done to advance the UK sandwich and food to go markets.

New Sandwich Award

Open to any sandwich (not a range), this award rewards innovation within the sandwich market, in both the hot and cold sectors

HealthyAwardEating

This award recognises the work being done to provide consumers with new, interesting and innovative healthy eating products.

New Product Award

Ingredient

This award recognises development and innovation by suppliers and focuses on new ingredients.

Environmental & Sustainability Award

This award is designed to recognise the work being done at all levels of the industry to reduce the sectorʼs impact on the environment and improve sustainability.

Marketing Award

This award is presented to a sandwich or food to go retailer, manufacturer or supplier who has initiated a successful and innovative marketing campaign to achieve strategic goals.

Business Development Award

New Product Award

Packaging & Equipment

This award recognises development and innovation by suppliers and focuses on new packaging and equipment.

This award recognises business developments that have helped progress the industry.

RetailerIndependentAward Café Retailer Award

. This award shines a spotlight on the independent retailers which so often lead the way in new trends and tastes.

This award will recognise the work being done by the café retailers to develop either the high street or in-store market.

Manufacturer Award

This award recognises the overall contribution made by manufacturers to elevate and grow the industry.

New Food to Go Award

This award recognises development and innovation in the food to go market by manufacturers and foodservice businesses.

Chain Retailer Award

This award recognises the work being done by the chain retailers in developing the market in the high street

SAMMIES AWARDS DINNER THURSDAY, 9 MAY 2024

Hosted by celebrity chef Theo Randall, comedian Charlie Baker and with dancing through to the wee small hours courtesy of “DJ to the Stars” Tony Perry.

JOIN US FOR

AT THE ROYAL LANCASTER, LONDON BOOK NOW WWW.THESAMMIES.CO.UK

THE

SPONSORED BY

SAMMIES AWARDS DAYTIME PROGRAMME

If youʼre attending the Sammies Awards Dinner, why not make time to join us at the Royal Lancaster, London for our daytime programme of events?

The live finals of the Sandwich & Food to Go Designer competition provide a fantastic opportunity to gain insight into the creative process of the industryʼs culinary superstars.

There will also be a presentation from Hywel Davies, strategic insight director at Kantar. He oversees the management of the Kantar Out of Home panel which measures how we purchase and consume food and non-alcoholic drink when outside of the home.

Hywell will look at the changing face of the food to go market, review the past 12 months and deliver a vision of what has and will change in the market.

Anyone from the industry is welcome to attend. To secure your place, contact Sandra Bennett at the BSA by email to sandra@sandwich.org.uk or call 01291 636348. OF THE YEAR 2024

SANDWICH & FOOD TO GO

AND FINALLY...

Following three hotly contested regional semi-finals in early March, the successful finalists in this yearʼs competition have been revealed.

Each contestant will prepare and present their creation to the judges and an excited audience at the live finals on 9 May 2024.

SANDWICH & FOOD

TO GO

OF THE YEAR

2024

We welcome back celebrity chef Theo Randall who joins us as the head judge. Under his watchful eye, the judging panel will consider taste, presentation, texture, commercial viability and innovative use of the sponsor products as they choose the category winners and decide who will be awarded the title of Sandwich & Food to Go Designer of the Year.

FUTURA FOODS GORGONZOLA PICCANTE CATEGORY

Kirsty Fitzpatrick, Deli Lites Honey, Iʼm Feeling Blue

Chrissie Attewell, Samworth Brothers Thereʼs Always Next Thyme

James Burgess, Fresh Cut Foods Salt Beef & Gorgonzola Waldorf

Stephen Jordan-Bird, Samworth Brothers Gorgon-rola-Zola

Kirsty Fonseca, Greencore Gorgonzola with Parma Ham

JDM FOOD GROUP FREE FROM CATEGORY

Kirsty Fitzpatrick, Deli Lites Banging Chicken

Kirsty Fonseca, Greencore Nut Free Satay Burrito

Kat Padgett, Around Noon Beets & Greens

James Burgess, Fresh Cut Foods Pulled Spiced Lamb Turkish Flatbread

Edvinas Smgelskis, Samworth Brothers Satay Prawn in the Sea Shell

H. SMITH FOOD GROUP

DELIGHTFUL BREADED CHICKEN CATEGORY

Kirsty Fitzpatrick, Deli Lites

Second to Naan

Phil Thompson, Sandwich King

Tipsy Chicken Banhi Mi

Charlotte Palmer, Greencore Japanese Fried Chicken Wrap

Kirsty Fonseca, Greencore Katsu Bao Bun

Dai Llewellyn, The Co-op Crispy Bombay Sando

MONA DAIRY GOUDA CATEGORY

Kirsty Donaldson, Deli Lites

Too Gouda to be True

Harry Dempster, Samworth Brothers

The Gouda, the Bad and the Ugly

Barney Luxmoore, Jabberwocky Goudagette

Ivor Peters, Urban Rajah

Mumbai Garam Toastie

Stephen Jordan-Bird, Samworth Brothers

Mona Cheesa

COTTAGE DELIGHT CHUTNEY & CURD CATEGORY

Kirsty Donaldson, Deli Lites

It Takes Two to Mango

Harry Dempster, Samworth Brothers

The Italian Cobb

Lee Williamson, Gosh Foods

Toasted Club with Torchon Ham

Kieran McGivern, Around Noon

York Shire Ya Know Yer Self

James Burgess, Fresh Cut Foods

California Prawn Roll

Sustainable success

It’s been a stellar year so far for the innovative team at BioPak. Technical director, Sam Walker, tells us more.

With 18 years in the sector, BioPak understands the sandwich and FTG market better than most. What are you most excited about?

Our focus lies not only on new fitfor-purpose packaging solutions – we are also investing heavily in research, development and testing of innovative materials to shape the future. Particularly interesting are advancements in linings, with aqueous dispersion coating disrupting

the market in a big way in recent years.

BioPak’s aqueous-lined cups are already part of our core range, and when paired with our plantfibre lids, customers have a full home compostable (NF-T51-800) solution. The exciting news is that we are looking at a new coating technology called PHA. PHAs, or polyhydroxyalkanoates, are bioderived polymers produced via industrial microbial fermentation of carbon-based feedstocks – a process more similar to brewing than the chemical synthesis used to produce most biopolymers. PHA bioplastic is one of the most promising technologies, deemed to be compostable and marine degradable. What this space!

We are also still seeing strong growth in pulp and fibre-based packaging. Our ability to print on these materials is attractive to brands. The added sustainability narrative

of utilising waste fibre in production gives them the edge over other formats. However, PFAS in packaging has been making headlines. At BioPak, a large portion of our products have no intentionally added PFAS, and we are working to completely remove them from our full range in 2024.

How do you navigate complicated packaging legislation?

Staying informed is paramount, plus industry and legislative participation. The landscape is indeed complex, with the recent implementation of singleuse plastics bans (both in the UK and EU, each with its own nuances), alongside impending Extended Producer Responsibility (EPR) and Simpler Recycling regulations.

24 I www.sandwichandfoodtogonews.co.uk

At BioPak, we’ve always prided ourselves on due diligence and compliance. We’ve built specialised teams across all our territories (UK, Australia, NZ, Singapore and Hong Kong) to stay abreast of regional legislation. Despite differences across the globe, many rules still operate within similar parameters, providing a foundation for compliance efforts.

Our deep understanding of the evolving regulatory framework gives BioPak’s customers not only confidence in our product, but they often use us as advisors to shape their own sustainability journey. For example, some clients operate across multiple regions and strive for a uniform approach. Achieving a one-size-fits-all solution isn’t always feasible and often requires compromise. This underscores the importance of continued flexibility and collaboration.

Congratulations on the Innovation Award 2024 at the Food Manufacture Excellence Awards.

Thank you – it was truly an honour. Our success lies in a unique capability to handle every aspect of the process in-house, coupled with extensive expertise at each stage. Over our nine-year partnership with Deliveroo, we’ve gained unparalleled knowledge in the meal delivery sector, from understanding challenges associated with different cuisines to identifying the most suitable materials and solutions to address them

We provide clients with a free packaging assessment, evaluating pain points and opportunities. They receive a personalised report, inclusive of a full operational review, packaging recommendations, fitfor-purpose NPDs, in-store trial and implementation road map.

There are dedicated design, production, quality, marketing and logistics teams, all seamlessly integrated to provide that comprehensive end-to-end solution. This holistic approach sets us apart in the competitive marketplace.

Tell us more about your business relationship with Mexican restaurant brand, Wahaca. We are proud to have a customer like Wahaca, and I believe it’s the result of who we are. Wahaca is the leading sustainable restaurant, and we are the leaders in sustainable packaging, so it was only natural we found each other! Together, we developed a certified home compostable, plant-fibre printed taco solution – the first of its kind on the UK market.

We have comprehensive data available for our entire range to illustrate the tangible benefits of using BioPak. Our approach goes beyond mere eco-consciousness. We provide quantitative evidence to support the positive impact of proposed solutions, whether through weight reduction, utilising more sustainable materials or a combination of both. By sharing the data behind the changes, brands can effectively convey the rationale to customers, fostering understanding and buy-in. Sustainability is an ongoing process, so transparent communication of progress, underpinned by evidence, is essential for engagement. And it helps to combat greenwashing and comply with legislation.

There is also growing interest from traditional distributors, driven by demand and regulatory changes. As consultants, we guide them through the complexities of both.

What can the UK learn from your global approach to relationships?

That we are all in it together, while collaboration is essential for effective

PACKAGING

adaptation and problem-solving in the rapidly evolving market. We can address most challenges by pooling our knowledge and resources from the BioPak regional teams, while integrating invaluable first-hand and on-ground experience from global and local clients.

This commitment not only sets us apart but also fosters vital relationships. By prioritising partnerships and shared insights, we uncover solutions and opportunities that may otherwise go unnoticed.

Can you expand on your key sandwich and FTG relationships?

The FTG landscape has been challenging. While some operators have thrived, others have faced significant setbacks. However, we’re

PACKAGING

now witnessing signs of recovery, with steady growth. The larger players seem to be faring the best, capitalising on their scale and resources to navigate challenges more effectively. Unfortunately, smaller to mid-sized operators are feeling the pinch, grappling with inflation, while struggling to negotiate favourable pricing due to limited buying power.

Despite this, there’s a notable shift towards paper and fibre-based among FTG brands. This reflects a broader commitment to reducing plastic consumption and embracing sustainability. Brands are allocating resources to facilitate these changes.

Apart from NPDs and innovative tech, what else is driving growth?

BioPak was founded in 2006 before there was an appetite or any real movement towards sustainable solutions. Our goal from the start was to disrupt the foodservice packaging industry and change consumer behaviour. To continue our mission, mergers and acquisitions are a growth driver. We have just launched BioPak in Hong Kong, a timely expansion ahead of single-use plastic bans coming into effect in April 2024.

The next frontier is reusable solutions, with the goal of converting disposable packaging users to

reusables. BioPak is looking to meaningfully introduce reusables to our markets, with convenient infrastructure. Our track record shows that we can change behaviour, disrupt industry and influence policies.

What are the major compostable packaging challenges for companies?

The biggest is a lack of composting infrastructure coupled with the singleminded push for recycling. Companies need to take responsibility for product end-of-life. We believe compostable packaging is the best solution to address plastic waste and pollution generated by the foodservice industry.

Unfortunately, only 9% of all plastic waste ever produced in the world has been recycled. It’s estimated that the UK produces 1.85 billion pieces of plastic per week – of which only 12% is likely to be recycled! Food & drink packaging made up an overwhelming majority (83%) of the waste generated during the count. Once soiled and contaminated with residue, recyclable plastic food containers can’t be recycled – they go straight to landfill or incinerators. Unfortunately, contamination can compromise a whole container of perfectly good recyclable material.

Compostable packaging addresses this challenge, while also helping

divert food waste from incineration. To manage the end-of-life for our packaging, we have set up Compost Connect – a not-for-profit platform committed to education, lifting composting rates, and connecting foodservice businesses to commercial organic waste pick-up services. Businesses can go online at compostconnect.org/uk/ and search their postcode to find out if commercial organics collection is in their area.

A major problem is greenwashing – think packaging, beauty and fashion. This is when organisations make their products, services or practices seem far more environmentally friendly than what they actually are. For example, they can use loose claims and buzzwords like ‘green’ and ‘eco-friendly’ without any verified supporting evidence or certifications. These claims are often exaggerated, aspirational or downright untrue. This makes it difficult for customers and consumers to make environmentally conscious decisions.

Certifications create transparency. Packaging must undergo a stringent compostability test by a verified third-party provider like DIN CERTCO or TUV to receive a compostable certification. Customers should look for two types of compostable standards: Home Compostable (NF T51-800) and Industrially Compostable (EN 13432).

The certification logo on the packaging must display three elements: certification logo, the type of certification and the company license number. If one of these is missing, it’s most likely not certified.

Unfortunately, not many people recognise and understand these logos, making it easy for companies to take advantage. The legislation, however, is catching up. The European Union proposed the Green Claims Directive and the UK’s Competition and Markets Authority (CMA) enacted legislation to curb greenwashing last year. This is exciting news and a step in the right direction for our industry.

26 I www.sandwichandfoodtogonews.co.uk

Make the Switch to BioPak Plant Based Packaging

BioPak products are made from rapidly renewable, plant-based materials, designed for the circular economy. 5% of profits are donated to positive change.

www.biopak.com/uk

Top of the tree

From

near-infrared spectroscopy

to breathability, Woodly’s quest to accelerate change is gaining momentum.

PUTTING THE CONSUMER FIRST

Material innovation and extensive recycling sounds like a relatively simple mantra to solving the packaging and waste conundrum. And it’s one that Woodly has adopted, with its new type of plastic based on wood. Coming from softwood cellulose, it mimics the best qualities of traditional fossil-based plastics. A straightforward approach to what is becoming an increasingly complicated mine eld for foodservice operators.

“From what I’ve observed, plantbased products are more popular than ever,” said Woodly vice president of sales and marketing, Christoph Schiller. “There is also a strong focus on sustainably sourced materials. Consumers are increasingly aware and seeking more than just the number of calories on packaging. Healthy and environmentally friendly food is crucial when making everyday

choices, and one doesn’t necessarily have to break the bank any more.”

However, that doesn’t make the path to sustainability any easier for the foodservice sector.

“Legislation is not only complex but also rapidly changing, leading to confusion among customers, who often don’t know what to expect,” continued Schiller. “This slows down long-term planning and decision-making. We strive to support them as much as possible.

“Despite the complexity, there are trends to be observed, such as a shift away from biodegradability and compostability. While these concepts may seem appealing, they proved impractical in real life. For instance, imagine buying a sandwich wrapped in compostable material. It is unlikely that you’ll carry around an empty package for the entire day, until you can compost it at home.

28 I www.sandwichandfoodtogonews.co.uk

Compostable materials also require industrial facilities.

“There is a focus on materials that can be recycled. Many people are unaware that in the recycling process, lightweight packaging is typically sorted out in one of the rst stages and directed to a waste-to-energy stream. Therefore, if customers are seeking truly sustainable materials, they should consider the total life cycle of the product.

“Here is where Woodly can help. One of the key challenges we face is whether Woodly, as a bio-based material, can be recycled in standard household waste streams. Many recyclers typically avoid biomaterials due to concerns about contamination in their sorting processes. We have had pilot testing, where Woodly can be detected with NIR (near-infrared spectroscopy) and separated from the plastic waste stream. And this

year, we have partnered with OPRL – the not-for-pro t, independent experts in packaging recyclability.”

PROBLEM SOLVING

As the deferred Extended Producer Responsibility (EPR) scheme illustrates, negotiating a path through everchanging government legislation is certainly not easy.

“I think some ideas have been good, but there is currently too much uncertainty and ad hoc actions in the approach. I am a strong advocate for reusability. Whenever possible, we

should avoid single-use packaging, that’s clear. Or at least ensure that the packaging is recyclable. However, it must be implemented in a smart way.

“For example, the concept of the 30% recycled content target is a good idea, but realistically there isn’t enough material on the market that is both post-recycled and food contact approved. As a result, many resort to using industrial PCR, which is questionable.

www.sandwich.org.uk I 29

PACKAGING

“In the continuous effort to create environmentally friendly legislation, we may have lost sight of the ultimate goal: saving the planet. In my opinion, a full science-based, life-cycle assessment should be implemented to evaluate different materials. While advocating for the reduction of plastic usage is important, it’s essential to consider whether a blanket ban is the optimal solution in all cases. Plastic serves a vital role in sectors like FTG by safeguarding food, prolonging shelf life and significantly reducing waste.

“Fresh food wrapped in traditional plastic fights against its barrier, so moisture condenses inside the packaging. Water drops on the roll or baguette, which eventually becomes soggy. Products lose customer appeal, and even if they are still within their best-before date, remain unsold.

“Woodly solves this problem. Its controlled breathability allows water to evaporate from inside the packaging, keeping the product not only visually appealing, but fresher for longer. In the case of pastries, like croissants, Woodly operates in the opposite

"Plastic serves a vital role in sectors like FTG by safeguarding food, prolonging shelf life and reducing waste."

manner, protecting the product from absorbing moisture from the outside, helping it to remain fresh.

“We have conducted numerous tests with customers – they all confirm the efficacy of Woodly in reducing food waste and associated costs.”

CLEAR OBJECTIVES

The past few months have been quite a journey for Woodly. Having debuted in the UK with a somewhat slim contacts book, it now has a strong relationship with Seal Packaging.

“We like to think of them as our wings and wheels in the UK,” continued Schiller. “They have been

companions from the very beginning, and we deeply value this relationship.

“Along the way, I have had help from many companies, including Bunzl and Accrued Plastic. Most importantly, I am proud of our first customers who chose to trust us here. Our objectives are clear: create a material as functional as traditional plastic while making a positive impact on the food waste problem.

“Credibility is our greatest asset – this is how we earned trust in the Nordic countries. We are in people’s businesses and view every project as a mutual journey for everyone to enjoy.

“I am also in the process of recruiting our first UK team member, scheduled to commence at the onset of the second quarter. This year began early for me, as on 2 January I was on a plane to the UK, and the intensity has remained the same ever since.

“We are exhibiting at the Food and Drink Expo in Birmingham and again at lunch! in London. We’re engaged in numerous commercial conversations and trials, and while it is a very intense time for Woodly, I love it!”

30 I www.sandwichandfoodtogonews.co.uk

PACKAGING

To advertise please call Paul Steer on 01291 636342 I 31 FROM SINGLE PACK MANUAL TO HIGH SPEED LINEAR AUTOMATIC MACHINES SOKEN ENGINEERING IS PART OF THEJENTON GROUP QUALITY HEAT SEALING MACHINES FOR SANDWICH, WRAP, SALAD AND READY MEAL PACKS • Increases shelf life (for up to 3 days) • Less food waste • Greener packaging options • Food-to-Go and Convenience packs • Medical, Pharma, Parts Here at Soken Engineering we have 20 years experience, including worldwide sales. Our innovative UK built all electric machines range from low-cost entry level to high throughput production line models. SEAL PACK SELL www.sokenengineering.com +44 (0)1256 892 194

The perfect Plan

Thinking ahead is crucial when it comes to sustainability goals – and Planglow is often ahead of the curve.

POINT OF DIFFERENCE

Founded in the 1980s, Planglow started out as a provider of catering labels and revolutionary software, LabelLogic – one of the first programmes of its ilk. It was in 2002 that it launched dedicated software to support food providers looking to create nutrition labels. Planglow was also ahead of the grab-and-go packaging curve, with a sandwich box and disposable coffee cup in 2005. It’s an award-winning business that continues to thrive in a hugely competitive sector.

“Offering an off-theshelf brand has always been our strength and differentiates us from commodity packaging,” said Planglow marketing director, Rachael Sawtell. “We also try to ensure products can be disposed of in as many waste streams as possible. For example, we swapped cups and pots from PLA lined to aqueous lined, opening up recycling (as well as home and industrial composting) waste streams to customers.”

Packaging strategies need to form part of sustainability reporting, with Planglow having strict directives and ambitions in place.

“Over the past year, we have undergone a robust review of suppliers, making revisions as necessary. This ensures stronger relationships and optimum compatibility with evolving business requirements.

“In terms of our customer base, we continue to build upon connections with businesses of all sizes – from independent cafés to contract caterers. We have also set up integrations between the key recipe management software providers and our labelling software (LabelLogic Live) to ensure seamless data integration and compliance with latest legislation.”

THE WAY AHEAD

A recent six-week trial in Medway by The Compostable Coalition UK reported a five-fold increase in consumers disposing of compostable packaging in food waste bins, when residents were educated with clear communication and labelling. Around 120 households received goods including confectionery, fresh produce and shopping bags from the likes of Co-Op, Ocado and Lipton Teas.

“We would very much like to see compostable packaging accepted in food waste bins,” continued Sawtell. “This successful trial in Kent

Our temperature controlled food delivery vehicles are designed to display and vend your pre-made Hot and Cold food. Delivering direct creates you a captive audience, offering customers the ultimate in convenience and service. Call us today and take the first step towards increasing your sales.

· Our mobile “shops” have no rent or rates to pay and operate with one staff member.

· Our trucks are chosen by all the major names in mobile catering for their build quality and reliability.

· Flexible finance packages available.

· Fully accredited by the BSA

· Whole vehicle type approved

· A very profitable addition to any food business.

· Established since 1973

www.sandwich.org.uk I 33

for delivered food has never been greater !

Demand

Here’s the solution, mobile catering!

www.jiffytrucks.co.uk

over 40 years experience in mobile retail Jiffy are the name you can trust, our success relies upon your success. Call us now to arrange a demonstration, or visit us at the factory and meet the team.

01274 596000

for new revenue streams? Supply your products with the original Jiffy truck. Now available with a finance balloon, allowing low monthly payments, with enough equity for a new van every 4 years.

With

Tel

sales@jiffytrucks.co.uk Looking

PACKAGING

proved the model works when the infrastructure is there to support it. Packaging contaminated with food waste can’t be recycled. Meanwhile, compostable packaging actually improves the breakdown of food waste by introducing more oxygen and improving the structure of the compost or other by-products such as soil conditioner. Therefore, a nationwide shift towards compostables feels like a no-brainer.”

But it’s not just the purchasing public that needs to consider all options – it’s an opportunity for the whole foodservice sector.

“Since the pandemic, we’ve seen a clear shift in the grab-and-go market towards hot foods. From 2022-2023, over a fifth (22%) of consumers were opting for hot FTG. This is a 12.5%

increase on 2019, when around just one in eight (13%) selected hot foods instead of ambient and chilled options. Over the same period, sales of the sandwich plummeted. Although 2023 showed signs of recovery, as even heavily paired back, prepackaged high-street ranges began to show signs of life as they branched out once more beyond core fillings.”

Planglow has an exciting concept in development for grab-and-go, which it will begin to roll out later this year. It has also just launched two unique labelling products – overprintable eight per sheet dissolver labels and deli ticket sheets (also eight per sheet):

● Dissolver Labels all come out in the wash. No scrubbing or peeling required, thanks to a fast-dissolving material which leaves you with residue-free containers – even in cold water – minimising clean-up times and bacteria. Developed for reusable takeout packaging, plates and back-of-house catering containers, overprint using the Planglow food labelling app and any standard inkjet or laser printer. Sold in packs of 100 sheets, they have a working temperature range of -40°C to 100°C. Performance should always be tested in actual application conditions.

● Developed exclusively for Planglow, the time and labour saving eightper-sheet Deli Tickets are unique to the market. Providing clear product information at salad bars, deli counters and shelf edges, simply print and peel pre-cut tickets from their sheet and you’re ready to go.

“Overprint in LabelLogic Live adding calorie/nutritional information, reference intakes, allergen and Natasha’s Law, ingredients, carbon data and more, as these generously sized products will accommodate as much information as you require,” said Sawtell. “You can even brand with your own logo and messaging.

“Made in the UK, our semi-gloss Deli Tickets are sold in packs of 100 sheets and feature a ‘no stick’ adhesive, with the laminate made using FSC-certified paper – suitable for laser printers only.”

And while current economic challenges are inescapable, the Planglow approach is pragmatic: “Regrettably, like many businesses, our biggest current pressure point is our overseas supply chain. As a result, shipping costs are escalating. However, our procurement team works hard to manage and maintain current pricing, without passing on to our customers,” concluded Sawtell.

34 I www.sandwichandfoodtogonews.co.uk

www.sandwich.org.uk I 35

Compostable packaging: a vital solution

Vegware is at the forefront of foodservice recycling – and the business has invaluable advice around end-of-life innovation.

BIG PICTURE

The future of sustainable packaging is no longer solely about packaging, but end-of-life solutions. The way we approach both needs to be holistic. We must think beyond function, considering its implications and what we have at our disposal.

In a foodservice context, residue complicates dry mixed recycling. A decade of conversations with waste professionals tells us that foodcontaminated packaging is very unlikely to be recycled.

Many look for a silver bullet when it comes to the sustainable hinterland. The critical thing with all packaging options – recyclable, compostable or reusable – is understanding the right applications. All will prove to be useful in the future of sustainable packaging. The task is knowing how to maximise the potential of each tool.

Vegware was founded in 2006 to advocate for plant-based and compostable packaging, highlighting its potential in diverting waste from landfill or incineration. Compostable packaging can help businesses looking to find circular solutions.

GROWING INFRASTRUCTURE

We have taken on the mantle in providing end-of-life solutions for products. Our in-house team of four waste management consultants have been working with the sector since 2011. Their progress has been instrumental in setting up compostable packaging collections. Businesses can now access regular collections in over 40 of the UK’s largest towns and cities. We help some clients set up dedicated collections, use UK-wide post-back services or invest in on-site composting units.

As well as working with the waste sector, Vegware runs its own collections in Central Belt Scotland called Close the Loop. In 2023, we took 10,000 wheelie bins of used Vegware and food waste to industrial composting.

In just over a decade, we have proven how compostables can work and advocated for a rethink in approach. There is public support for this too. A YouGov survey of UK adults showed that 89% supported councils being required to collect all recyclable or compostable packaging from households.

PACKAGING

"With single-use plastics bans in the UK and EU, compostable materials are being seen as an alternative."

A primary criticism of compostable packaging is lack of infrastructure – but there are more UK facilities accepting Vegware’s compostable packaging than there are facilities to recycle paper cups. It’s the collection infrastructure which needs to develop – as we have been doing since 2011 by growing business collections. And with single-use plastics bans in the UK and EU, compostable materials are being seen as an alternative.

We are very proud of what we

have achieved in just over a decade, but we know there is a lot still to do. Legislative changes and an increase in popularity present an opportunity to re-evaluate how we see compostable materials and waste more generally.

LOOKING FORWARD

With infrastructure in mind, we’ve expanded our range of products certified for home composting.

This year, we added to our Vegware Nourish moulded fibre – a range of takeaway boxes and tableware with no added PFAS, all certified for home or industrial composting.

Also in 2024, the relaunch of our Green Tree range included paper cups certified for home composting, followed by soup containers and more.

We are working on two fronts, bringing end-of-life solutions to consumers. Advancing our range of home compostable products and continually advocating for improved composting infrastructure.

www.sandwich.org.uk I 37 Est’d 1938 WELCOME TO GAGGIA GAGGIA MILANO THE ART OF PERFECTION gaggiamilanoprofessional Gaggia Professional gaggiaprofessional 01902 355 000

Total Package

Developing products while supporting and advising around new legislation is the Colpac methodology – and it’s working well.

COMMON THEMES

Off-the-shelf paperboard food packaging is not only better for the planet, but is flexible, comes in a variety of sizes and can comfortably hold hot, cold, wet or dry foods. It’s even spreading to airlines, as it’s recyclable, compostable, delivered nested, with custom prints available. Colpac is at the very heart of this

burgeoning sector – with major ambitions for the year ahead.

“Building on the success of our UK manufactured multi-food pots, we are looking to extend these lines to give customers even more choice,” said Colpac head of marketing and product, Kate Berry.

“Ranges like Stagione® will also evolve throughout 2024. These align with recycling guidelines and support sustainable sourcing due to the use of FSC® certified materials. (Colpac’s FSC® license code is CO41147).

“We will continue to champion lightweighting and encourage the use of innovative materials to reduce plastic, a common theme throughout all product development. We also identify innovations to

support trends around hot food to go, premiumisation and one touch.”

FINDING A PATH

Unpacking government legislation is not easy. With the UK generating around 11.6 million tonnes of packaging waste annually, it’s a matter of high priority. Westminster has set a commitment to recycle 65% of municipal waste by 2025 and eliminate avoidable waste by 2050. They’re ambitious targets, so operators have to be agile in this space.

“Engaging with legislative stakeholders is the only way to keep up to date with regulatory updates,” continued Berry. “At Colpac, we are proud to be members of industry, technical and stakeholder groups where we advocate for change. By contributing and understanding policy developments, we can actively advise customers and ensure they stay ahead of the curve.

“Our advice is to work with businesses like ours that actively

38 I www.sandwichandfoodtogonews.co.uk

engage in supporting legislation development, and those that validate their claims through industry bodies. Businesses should look for the highest food safety standards, such as our BRCGS AA+ certification, and to those investing in proving their claims, such as our net-zero target validation from the Science Based Targets initiative.

Key for Colpac is collaboration on bespoke packaging solutions. It works to understand customer requirements, developing pack configurations and designs that showcase products and brand values, ultimately helping clients sell more food. With flexible production and a highly skilled team, its UK-based factory presents the ability to work with short development timelines.