Prototyping

Iterative Testing / Record of Process

Experiments

costs of running the building.

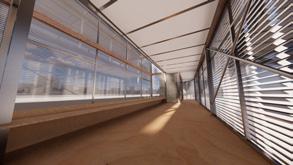

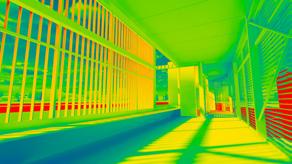

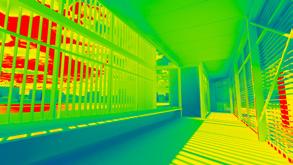

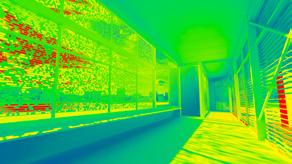

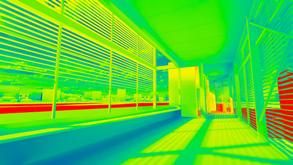

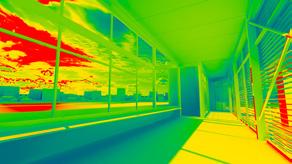

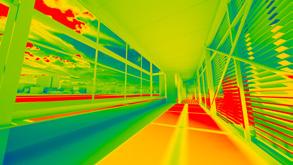

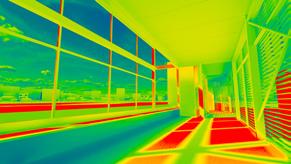

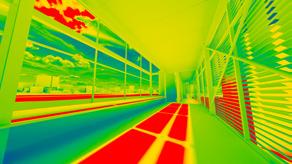

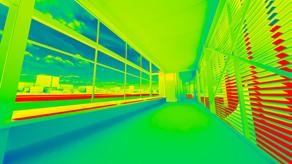

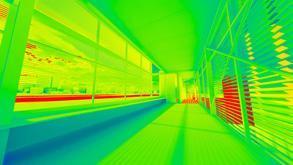

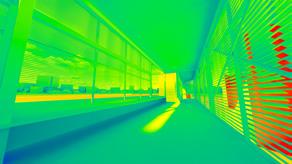

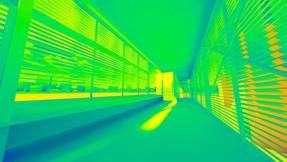

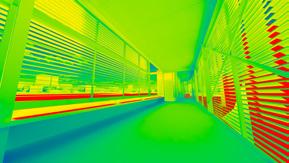

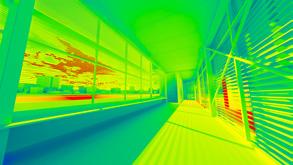

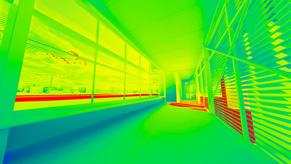

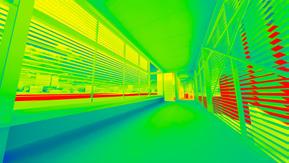

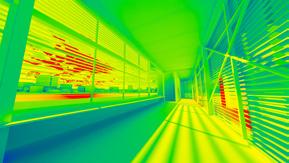

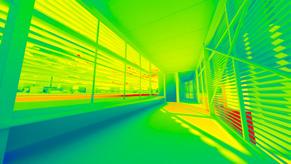

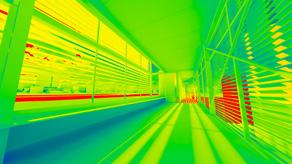

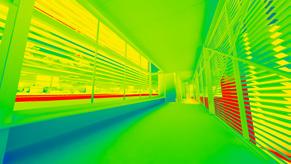

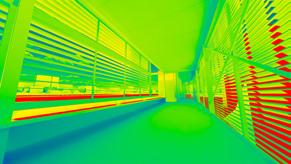

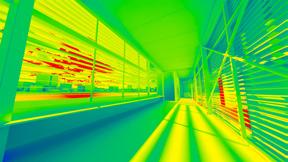

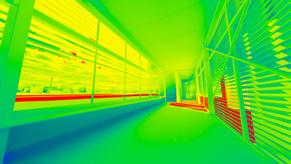

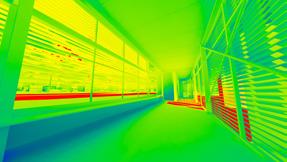

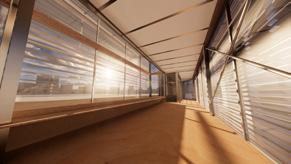

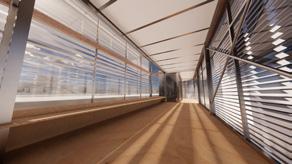

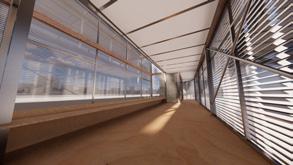

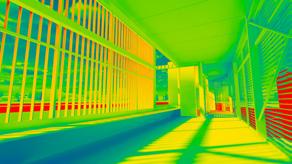

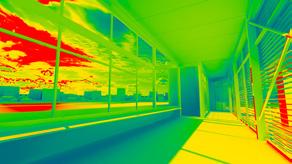

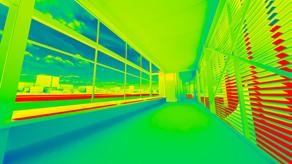

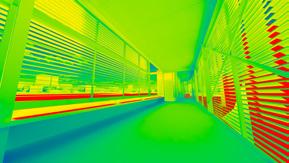

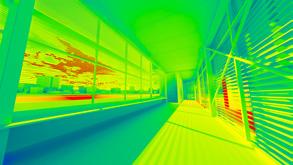

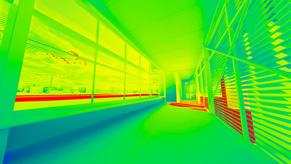

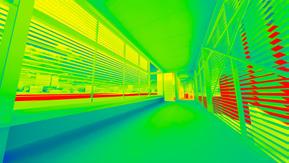

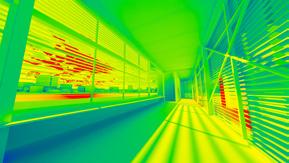

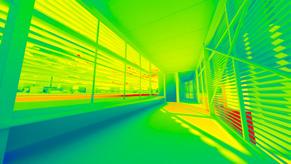

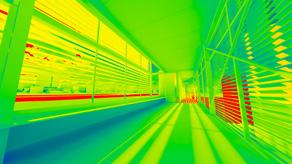

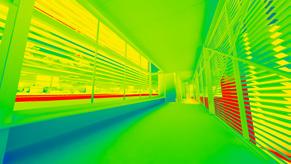

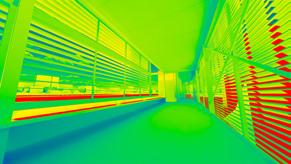

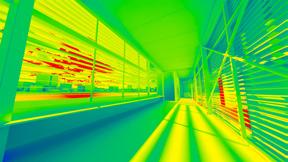

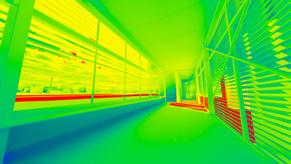

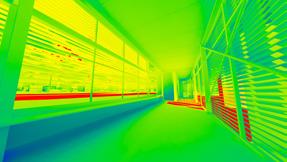

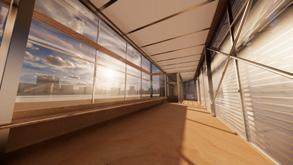

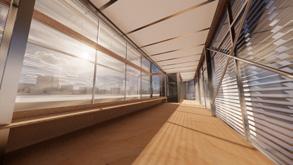

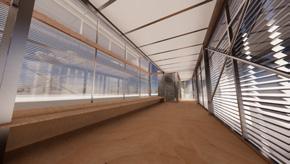

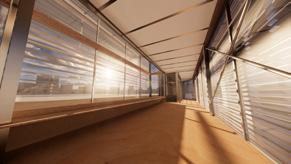

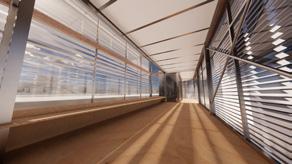

The graphics on the right side show the interior spaces. That view was chosen since the sunlight coming from the ra ments reaches the floor below. This is a reference for the outputs from testing the prototypes. The goal was to reduce the spaces that are coloured red and orange as they represent the excessive illuminance that is not desired. One constraint was programmatic - the visitors have to have the possibilty to see the outside. It was a significant ref erence during all the stages of testing represented by the overview graphic.

Firstly I conducted a quick survey of the types of facades was interested in. 3 types were selected: vertical strips, horizontal strips, and perforated panels (Initial Selections). The intention was to do a quick test and determine which type provides visibility and shading. After testing them I selected one type as the topic of prototyping and conducted specific tests appropriate to the chosen type (Prototyping). I tried to analyse important properties and relations in the chosen type and iterate by changing one specific parameter.

Prototyping

and not restricting visibility. That, however, is not true, as seen on the left side where the view is quite limited.

I opted for these days and times to test if in summer the space is shaded, and if in equinox the sunlight is blocked during the midday. did not investigate December since for most of the day it is dark and, in the case of horizontal strips that I decided to test, if during March the sun can go through the louvres, it can in winter as well.

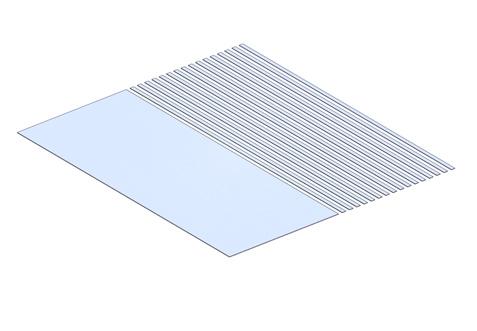

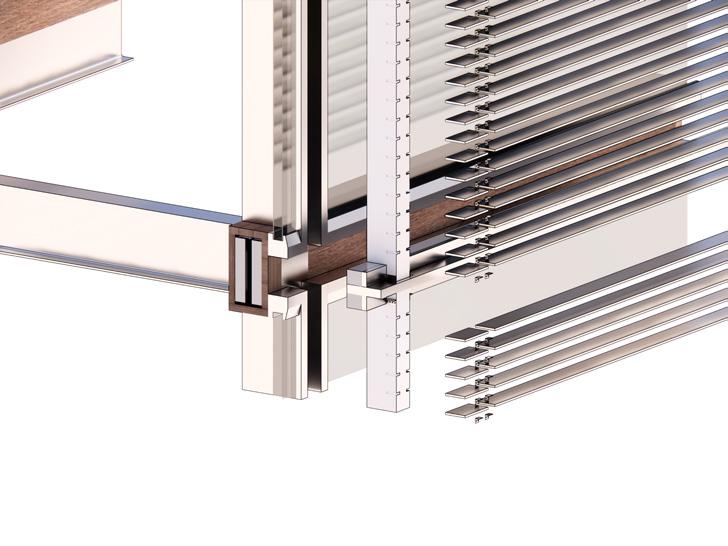

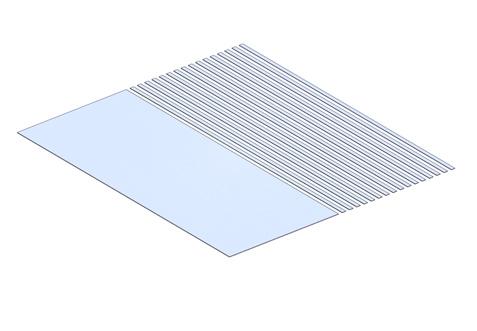

It is important to consider important variables in this louvre type: for the louvre system to work, a and b have to maintain specific lengths that are determined by d. a tan(d) = b So whenever a distance x is added to a, b has to change as well. Specifically: a + x → b + tan(d)x

The parameter chose to iterate was a. The reasons are that: a change in a is followed by a change in b and a change in the number of strips N; it was easier to construct a grasshopper algorithm where the control parameter is a. Iterations shows that the longer the number of the strips is smaller, so visibility and the relations above are maintained

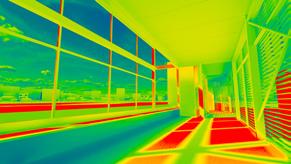

The red regions show where illuminance was higher in the reference pictures, showing a immediate improvement. The results are also better in comparison with the initial sleection tests. In the 20th March 2:00, 4:00, 5:00 yellow regions show the, as predicted.

The overview turned out to quite satisfactory where most of the outside is visible.

The degree d is determined by the altitude value of the given place. I opted for the altitude of the march equinox which is 36°; thus d = 36°. I treat the March equinox as a barrier between the colder period (i.e. with lower altitude) when the sun can go through the louvres and the warmer period (i.e. with higher altitude) that needs to be blocked.

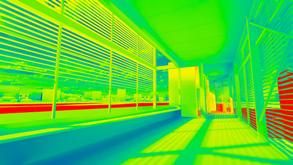

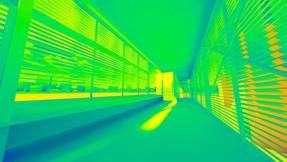

Each of the iterations showed an improvement. However, the 3rd iteration provided the best shading and maintain visibility of the outside. Other reasons are stated in the Constructability and the Life&Building Safetry reflections.

Perforated surfaces can provide an aesthetically interesting pattern that can lower the illuminance quite evenly along the whole floor. However, it does not allow residents to see the outside (the overview on the left side) and for the variants with more perforations, the shading effect disappears.

The illuminance analysis shows, however, that my initial intuitions were wrong. The illumination is similar to the vertical facade.

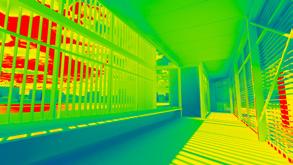

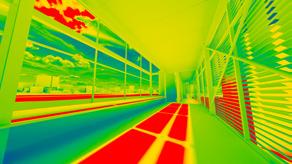

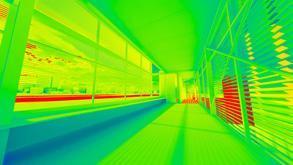

As above the pictures show a massive improvement to the top reference pictures. The shorted and placed more closely strips provide the same improvements and on the 20th March 2:00, 4:00, and 5:00 the regions show more green, indicating a better outcome

The overview turned shows that the visibility turned out to be similary satisfactory.

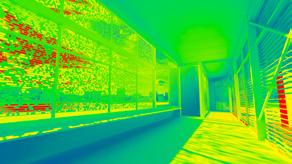

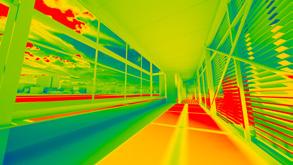

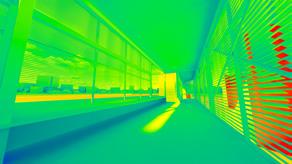

Horizontal louvres have is one of the typical approaches. They are especially beneficial when mounted onto the southern side of the building. The renders on the right side show how the illuminance. In comparison to the types above there are more green regions, which indicates the desired outcome.

Contrary to my intuition, the horizontal strips turned out to provide the highest degree of visibility.

I opted for the horizontal louvre system. There are theoretical reasons, i.e. the southward orientation, and experimanetal reasons i.e. the illuminance analysis, and the visibility factor, that point to this type as the most appropriate option.

Reflections on Constructability

As in the previous examples pictures on the right show improved outcomes. The regions on the 20th March at 4:00, and 5:00 seem to have a similar amount of green and yellow spaces as the iteration above; the 20th March at 2:00 gives indicates and difference with the iteration above with more green. Against my expectations of the worst visibility, the outcome is comparable to the previous iterations.

Reflections on Life and Building Safety

Thanks to aluminum as the material of choice, the struc ture itself is lighter and does not affect one heavily. However, the 3rd iteration also is advan tageous in this regard: the low er total area mentioned in the Constructability section indi cates a lower total weight than the previous iterations; The ef fects of wind on the

Iteration 1 Iteration 2 Iteration 3

Improved Indoor Air Quality

mounted onto

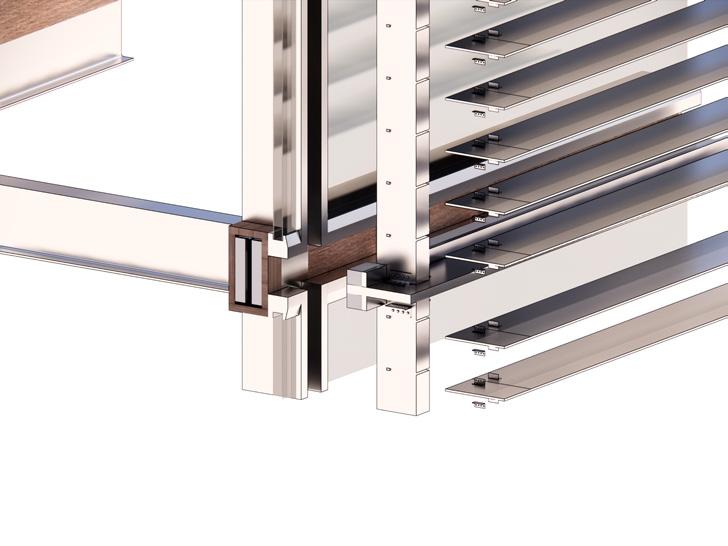

L-type brackets on both sides. each iteration uses different sizes of brackets, respectively to its size. Iteration

With a CNC machine, the strips for the louvre system can be easily manufactured from a simple aluminum plate without wasting any parts.

The facade can be designed modularly as not only the fragment is planned to receive the facade. this makes the assembly of the facade faster.

The small width of the strip allows for the facade cleaners to hang safely and clean the surfaces. The strips also can serve as an additional support for them.

The frame has cutouts where the strips are inserted and then screwed. The simplicity of construction allows for a simple and cheap renovation and removal of a damaged piece.

Aluminum is naturally resistant to weathering. It develops a natural oxide coating when exposed to the weather, which protects the degradation of the material and other layers of the building.

The facade not only blocks excessive sunlight without restricting visibility but also without blocking potential ventilation. The upper part of the glazed panels could be opened for the fresh air to flow into the space and ventilate it, improving the air condition inside the space

Passive Cooling

On warmer days, cooling is important for not only thermal comfort but also health. The shading provided by the facade helps to provide that with reducing reliance on the mechanical solutions.

Sunlight b Glazed Surface b a d d x tan(d)x Shaded p o d o S Glazed Surface 36° 55° SummerWinterSolstice EquinoxesSolstice 12° Natural Coating Moisture, Wind Moisture, Wind 12:00 10:00 March 20 July 21 2:00 4:00 5:00 12:00 March 20 July 21 16:00 12:00 March 20 July 21 16:00 12:00 March 20 July 21 16:00 12:00 10:00 March 20 July 21 2:00 4:00 5:00 12:00 10:00 March 20 July 21 2:00 4:00 5:00 12:00 10:00 March 20 July 21 14:00 16:00 17:00

Initial

Horizontal System Decision:

System Outcomes Outcomes Outcomes Perforated System Vertical System Iteration 3 Decision: Iteration 3 Iteration 1 Iteration 1 Iteration 2 Iteration 3 Iteration 2

Selection

Horizontal

Although the site is covered by the viaduct a lot of light could go through the upper levels The goal is to find a specific facade that limits the illumination, as it can result in excessive heat gain during sunny and warmer days. Taking into account the future rise of temperatures and that most energy is spent on mechanical cooling, a louvre system is needed. It will decrease operational Carbon and long-term economic

Overview Overview Overview Variables: a = 100mm → b = ~72.7mm N of strips: 50 N of strips: 18 N of strips: 11 Variables: a = 100mm → b = ~363mm Variables: a = 300mm → b = ~218mm

Costs Modularity Manufacturing Maintainability Removeability Light Load Resistance to Corrosion A

insulated infills is attached to the structure

the glazed panels. The

smallest

The

the

=

is the lowest for the 3rd iteration for a = 500, A = 500l * 11 = 5500l; for a = 300, A = 300l * 18 = 5400l; for a = 100, A = 100l * 50 = 5000l;

frame with

between

frame is

the structure with

3 is cheaper because of the

area:

total area of all

strips (A

alN, where l - length, which is the same for each iteration)

to the structure; The illuminance analysis above shows promising improvements. However, vertical strips are most appropriate for the west and east. Thus, checking other types is necessary. My initial thought was that the vertical louvres have the advantage of shading the area

longer is that they can wobble, causing small but still real damages

Overview Length of a Sunlight Angle

Technical Detail

Integrative Systems / Design Conclusions

Skin

The floor slabs retained the CLT slab. As stated on page 1, the aim was to use environmentally beneficial materials where possible. The CLT slabs and wooden covers are the results.

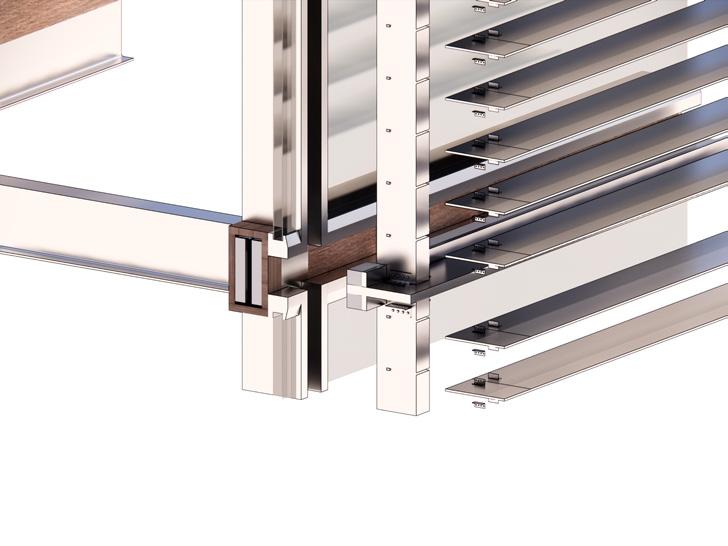

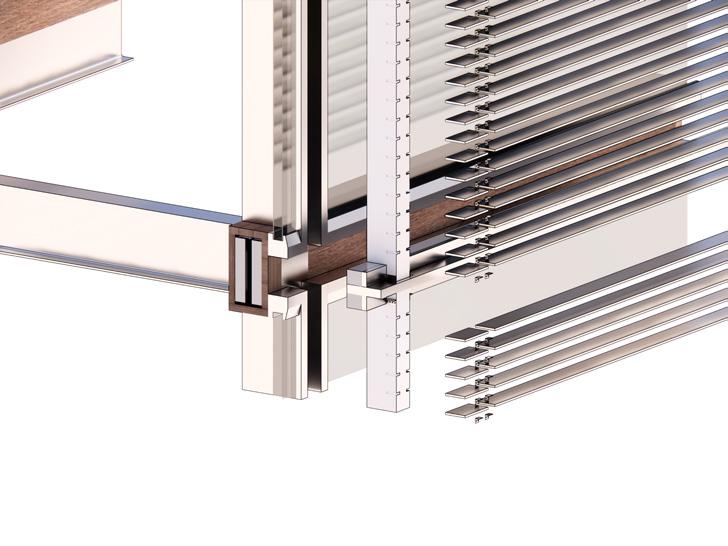

Facade

The final lovre system is iteration 1 with 100mm wide strips. To install these facade segments, a frame is inserted in between the window panels, so they are attached to the structure directly. the strips are partially inserted into the small cutouts in the vertical parts of the frame and partially screwed with the help of L-brackets. Thus the stability of the whole system is accomplished.

Inserting the frame and attaching it to the structure

Inserting strips into the frame

on the Technologies Position

As mentioned on the 1st page, the fragment responds to climate change via the choice of recyclable materials, using materials with low carbon footprint, e.g. CLT, where it is possible, and giving access to natural light

On the 2nd page, the iterations had strong connections to the climate response: In summer the energy costs are the highest for cooling, and with the prospect of the future warmer mean temperature a proper louvre system was needed to limit illuminance that, when considering a glazed and exposed to sun fragment, can lead to the excessive heat gain that can lead overreliance on mechanical solutions that increase operational carbon.

As stated on the 1st page, the fragments tackle the dilemma of building and life safety by choosing materials and elements, e.g. steel and CLT for structural reasons, and coating elements to decrease flammability. To tackle fire safety specifically, a shaft at the top of the gap was proposed that can be opened when smoke is detected

The louvre system itself enhances safety, especially life safety, by preventing excessive heat gains that can lead to thermal discomfort and even in extreme situations health risks.

The fragment, like the rest of the project, is intended to be constructed out of the commonly known and available in the economy. In the best possible option, they can be sourced locally from the C&D Recycling Facilities, thus lowering the costs and energy needed in the spheres of transport and production.

The louvre system was also intended to follow these strategies. The system is also easier to renovate, thanks to its simplicity. Additionally, Iterertion 3 has also an explicit cost advantage.

Net Zero Operational Carbon

Fine tune internal environment with efficient mechanical systems: An operable shaft automatically opens when smoke is detected. The operable panels can and, due to the gaps between them and the floor, have to be remotely operable.

• Provide responsive local controls: As mentioned above, smoke detectors open the shaft when smoke is detected. there is a possibility to install a system regulated by a thermostat or a more advanced system to regulate the air inflow through the operable panels.

Net Zero Embodied Carbon

• Prioritise ethical and responsible sourcing of all materials: materials can be sourced locally, which can result in a better understanding of the potential providers and if they produce their products ethically.

Minimise materials with high embodied energy impacts: The project was designed can be constructed fro the materials from providers so fo recyclable and reusable materials and elements.

Design building for disassembly and the circular economy: The assembly can be done with repurposed materials and elements as well as after disassembly the elements can be released back into the economy for future projects

Good Heath & Wellbeing

• Provide spaces with strong visual connection to outside: The constraint of maintaining the outside visible was determined by the desire to expose the viaduct and the space above the viaduct to the people inside.

Provide responsive local controls eg. opening windows, or local control: The fragment provides operable windows and the shaft that can be used for ventilation and in case of fire.

• Design spaces with good indoor air quality: The operable panels provide fresh air when needed.

• Design spaces to adaptive thermal comfort standards: The operable panels provide fresh air when needed louvre system and operable panels help in regulating thermal comfort.

Design spaces with good acoustic comfort: Aluminium as the material of choice for the facade louvre system is good in decreasing noise.

Design Insights

Before testing, I was most inclined towards the vertical option, and after choosing the horizontal system my intuition was leading me rather towards iteration 1. Iterating these prototypes allowed me to confront my mistaken perception of these options and by focusing on one specific parameter I could test and compare the iterations clearly and implications were varied, ranging from climate change, constructability, and building&life safty.

If there was more time, I would model a series of physical prototypes. More parameter could be tested to, e.g. the angle of the strips, the material they are made from. other types of facades, e,g, the vertical, could be tested rigorously. All of that could be explored in a potential further prototyping.

The state of change was important throughout the whole process: At the beginning, the fragment was designed in a way that promotes a circular economy and simple elements that can accelerate a state of change. The respect for the architectural artifacts on the side evinced through the visibility aspect. I tried to propose both a fragment on page 1 and a louver system on page 2 that provides visibility and acts as an architectural promenade.

Athough the fragemnt and ptrototyping has, in my opinion, succeded in the goal that put forward for myself, there a aspects of the fragment that could be critiqued: The choice of materials, ampunf glazing, the shape itself. The iterations as well could be criticised: The choice of louvre system, choice of the parameter a for testing, or the idea of glazing being covered by a louvre sytem could have some better alternative.

Iterations Programme Critique Further Developments RIBA Outcomes Climate Change Building & Life Safety Constructability Reflections

1 Ventilation/Fire Safety Shaft 2 12 2 2 2 8 8 8 4 6 3 Screed roof finish 9 10 8 Gutter 7 7 7 7 8 7 7 8 9 9 10 11 4 4 4 5 5 5 Annotation Structure: 1 - Steel Universal Beams 2 - Steel SHS Column Floor/Skin Buildup: 3 - CLT Slab 4 - Insulation • 5 - Wooden Covers 6 - Plasterboad Ceiling 7 - Double-glazed Panels 8 - Glazed Panels Aluminium Frame 9 - Aluminium Louvre System Strips 10 - Alumium Frame Holding Frame 11 - L-Brackets 12 - Indoor glazing - VPM - DPM