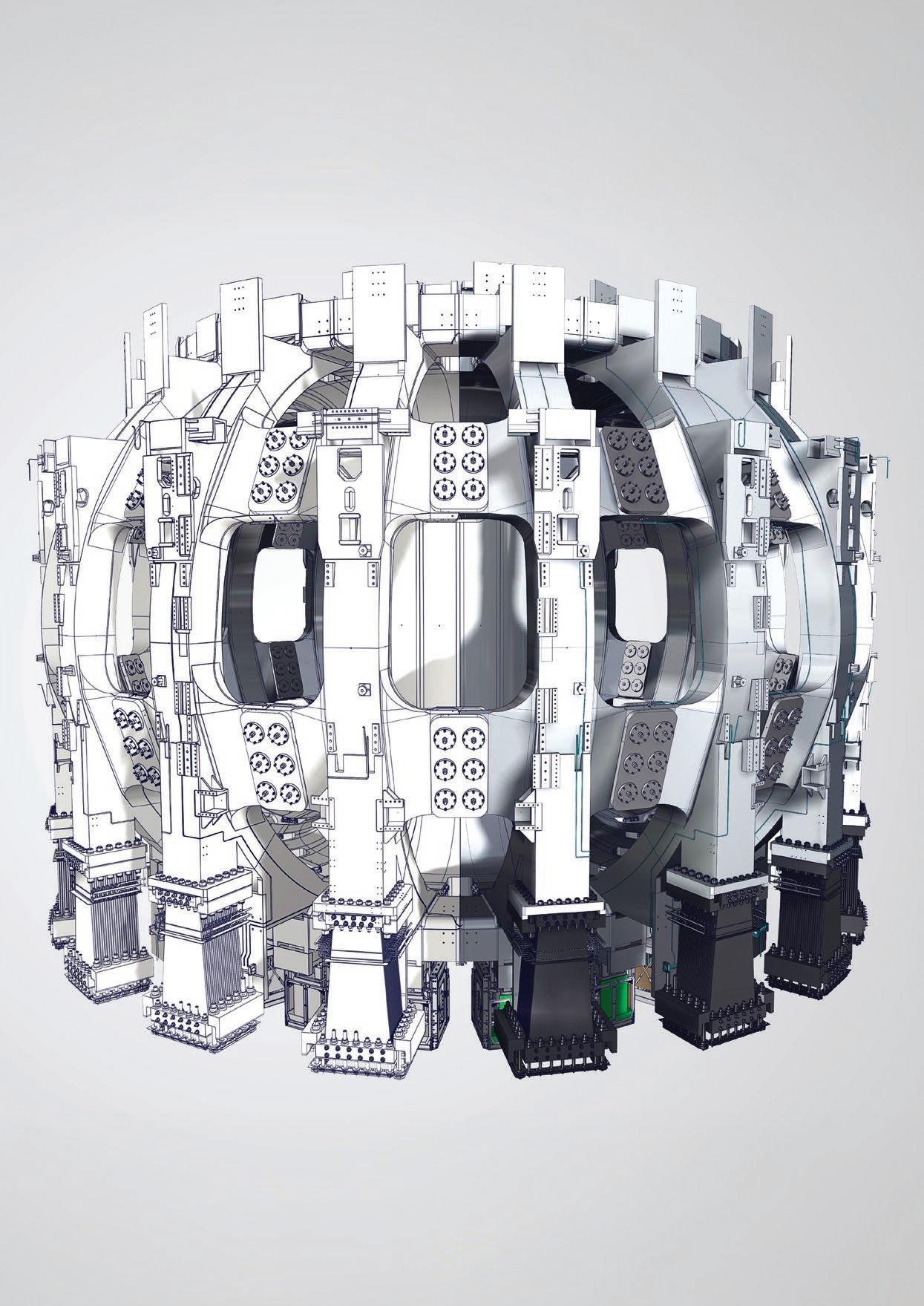

The ITER tokamak is a large-scale experimental reactor under construction that aims to achieve a self-sustaining burning plasma at industrial scale. It will achieve a power gain of Q≥10, meaning it will produce significantly more fusion power than the energy input required to heat the plasma. This demonstration of high-gain, long-duration plasma performance in a tokamak configuration will benchmark much of the physics and engineering needed to build commercial fusion power plants.

Fusion energy is the power generated by fusing (joining) two light atomic nuclei into a heavier nucleus—a process that releases a tremendous amount of energy. Fusion is a strong candidate for contributing future baseload energy to the world energy supply.

Another important long-term contribution of ITER is the role it has played to expand industrial capabilities and build the industrial knowledge that will be critical for the fusion economy of the future. For companies to supply ITER with superconducting magnets, cryogenic systems, vacuum technologies, high-precision machining, robotics, and diagnostics has required the development, qualification, and coordination of a vast network of industrial partners on three continents. Through ITER, dozens of firms have gained expertise in producing components for fusion environments, often to unprecedented technical specifications.

An “international project that aims to demonstrate the scientific and technological feasibility of fusion energy for peaceful purposes, an essential feature of which would be achieving sustained fusion power generation.” (From Article 2 of the ITER Agreement)

ITER’s programmatic goal, signifying that fusion output of at least 500 MW is produced in the machine from 50 MW of injected heating power.

PROJECT MEMBERS

The People’s Republic of China, the European Atomic Energy Community (Euratom), the Republic of India, Japan, the Republic of Korea, the Russian Federation, and the United States of America are the seven signatories to the ITER Agreement.

THE ITER AGREEMENT

Signed by all Members in November 2006, the ITER Agreement establishes the ITER Organization and defines the joint implementation of the ITER project.

ITER ORGANIZATION

Established to construct, operate, exploit and de-activate the ITER facilities in accordance with project objectives; encourage the exploitation of the ITER facilities by the laboratories, other institutions and personnel participating in fusion energy research and development programs of the Members; and promote public understanding and acceptance of fusion energy (Article 3). The ITER Organization is licensed as a nuclear operator under French law.

ITER COUNCIL

The governing body of the ITER Organization. The Council is responsible for the promotion and overall direction of the ITER Organization and has the authority to appoint the Director-General; to approve the total budget for various phases of the project, the annual updates of the Project Plan and Resource Estimates and (correspondingly,) the annual budget of the ITER Organization; and to decide on the participation of additional states or organizations in the project. (Article 6)

DOMESTIC AGENCIES

Each Member has created a Domestic Agency to fulfil its procurement responsibilities to ITER. These agencies employ their own staff, have their own budget, and contract directly with industry.

STAC

The Science and Technology Advisory Committee (STAC) advises the ITER Council on science and technology issues that arise during the course of ITER construction and operation.

MAC

The Management Advisory Committee (MAC) advises the ITER Council on management and administrative issues arising during the implementation of the ITER Project.

FAB

The Financial Audit Board (FAB) undertakes the audit of the annual accounts of the ITER Organization. (Article 17)

MANAGEMENT ASSESSOR

A Management Assessor is appointed every two years by the ITER Council to assess the management of the ITER Organization activities. (Article 18)

I want to congratulate the ITER Organization for its successful project execution this year in accordance with Baseline 2024 and express my appreciation for the hard work of the staff of the ITER Organization and Domestic Agencies under the leadership of the Director-General.

The updated baseline proposal presented in June 2024 to the ITER Council, which prioritizes the start of substantial research operation, was the object of careful review and discussion by the ITER Members. During the Council’s meeting in November, Members endorsed its overall approach, considering that it was a robust and well-considered guide for the implementation of the project. Project performance is now tracking well against the Baseline 2024; moving forward, monthly key performance indicators and bi-monthly reports to the ITER Council provide the ITER Members with the tools they need to monitor performance closely.

The Council also welcomes the on-schedule repairs to the thermal shield and the vacuum vessel sectors that permitted sector module assembly to restart in the third quarter of 2024; since then, two completed modules have been lowered into the tokamak pit. The arrival of three vacuum vessel sectors—two from Europe (October 2024 and May 2025) and the final one from Korea (November 2024)—are key milestones that increase confidence in the project’s ability to deliver.

The superconducting magnet procurement program, one of ITER’s longest and most demanding, is drawing to a close as the delivery of the final central solenoid and correction coil magnets is expected before the end of 2025. The fabrication of other major components and systems— such as the divertor, blanket, heating and vacuum systems—is advancing well. On site at ITER in southern France, an increasing number of plant systems are in the testing and commissioning phase. In 2024, helium was compressed for the first time in the cryoplant, the first cooling towers spun their giant fans, and the first CODAC command was issued from the main ITER control room.

The ITER Council is also encouraged by the progress made in deploying a matrix organization that optimizes the human resources of the ITER Organization across functions and business units—part of a suite of improvements to organizational methods, processes and structures that were initiated in 2023 and that are contributing to improved project performance. The continued strengthening of the Organization’s interactions with the French Nuclear Safety Authority is also commendable, as frequent and transparent communication will be key in the years ahead to progressing through the different stages of ITER licensing.

I want to conclude by emphasizing the vital role ITER plays in advancing fusion energy. Knowledge and experience have been accumulating since the earliest design and engineering efforts for ITER. Capturing and disseminating this legacy will help advance future generations of nuclear fusion devices and people. The ITER Council supports practical and appropriate mechanisms for sharing ITER knowledge with private sector fusion companies within the confines of the intellectual property provisions of the ITER Agreement.

MASSIMO GARRIBBA

Luxembourg September 2025

At the start of the 36th Meeting of the ITER Council in June 2025, I accompanied the Heads of Delegation to the Tokamak Complex where they were able to view an exceptional sight: two sector modules installed side by side inside the cylindrical volume of the assembly pit. It was an important moment signifying how—after a period of reorganization, re-baselining and recovery—the project is now moving forward with agility based on the schedule we have established in Baseline 2024.

In the case of the sector modules, the teams were even a little ahead of schedule. In addition to assembling each module in approximately one-third the time of the initial exercise in 2021-2022, the work was completed several weeks ahead of the date planned in our new schedule. To me, this indicates that we have built a solid, achievable baseline for the project that is grounded in conservative assumptions and reliable technical data and that incorporates the lessons learned since the start of our machine assembly project. Following the endorsement of the Baseline 2024 approach by the ITER Council in November 2024, we aligned the level-one ITER Research Plan with the machine configuration of the new Baseline and will work to further refine and elaborate our scientific blueprint in the months ahead.

Major machine components and systems reached ITER in 2024—among them the first European vacuum vessel sector (#5), the fourth and final Korean vacuum vessel sector (#1), the last of six poloidal field coils (PF3), radiofrequency gyrotrons, power supply components, correction coils, and the last structural elements for the central solenoid tower. When the final central solenoid module reaches ITER later this year the project will have completed the procurement of all major magnets—a welcome conclusion to many decades of development, testing and fabrication. Repairs to the vacuum vessel and thermal shield are progressing well and the tools in the Assembly Hall—including two upending cradles, twin sector sub-assembly tools and the overhead cranes— are in constant use. Plant assembly is accelerating and important test benches, including those for magnet cold testing and cryopump pre-testing, are coming online.

It has always been my view that empowering the right people in the right positions results in them managing risks, finding efficiencies, and ultimately reducing schedule and cost through well-considered actions. This has been the goal of the re-organization that we undertook shortly after my arrival as Director-General in late 2022, and on 1 January 2025 the new matrixed structure was fully implemented. We also made significant improvements to project management systems in 2024 and introduced the regular reporting of key performance indicators and a migration to a cloud-based scheduling tool that will facilitate schedule integration. The global management of engineering data is also improving, as data silos are reduced and the organization and control over the full lifecycle of the ITER machine is strengthened. In parallel, we are exploring the potential of artificial intelligence (AI) in our engineering, administrative, and management domains to enhance efficiency still further.

Finally, we continue to position the ITER Organization as a resource for private sector fusion initiatives, as we open some of our in-house simulation tools, share documents through our Private Sector Fusion Engagement help desk (with appropriate constraints for protecting intellectual property), and formalize other means of interaction such as technical visits by private sector fusion companies. We are consolidating the lessons learned during ITER’s design, manufacturing and assembly phases into the ITER Design Handbook, of which Volume 1 will be issued later this year. In a similar vein, we are driving a new initiative to harmonize engineering standards for tokamak components based on ITER’s industrial and regulatory experience. I see these knowledge-sharing initiatives as important outputs from the ITER project, benefitting the fusion community today and contributing to the development of fusion energy more generally.

In a year that was characterized by significant achievement I would like to conclude by saying how proud I am of the ITER Organization and Domestic Agency teams, without whose dedication the progress detailed in this report would not have been possible

PIETRO BARABASCHI St. Paul-lez-Durance

August 2025

INTELLECTUAL PROPERTY DECLARATIONS*

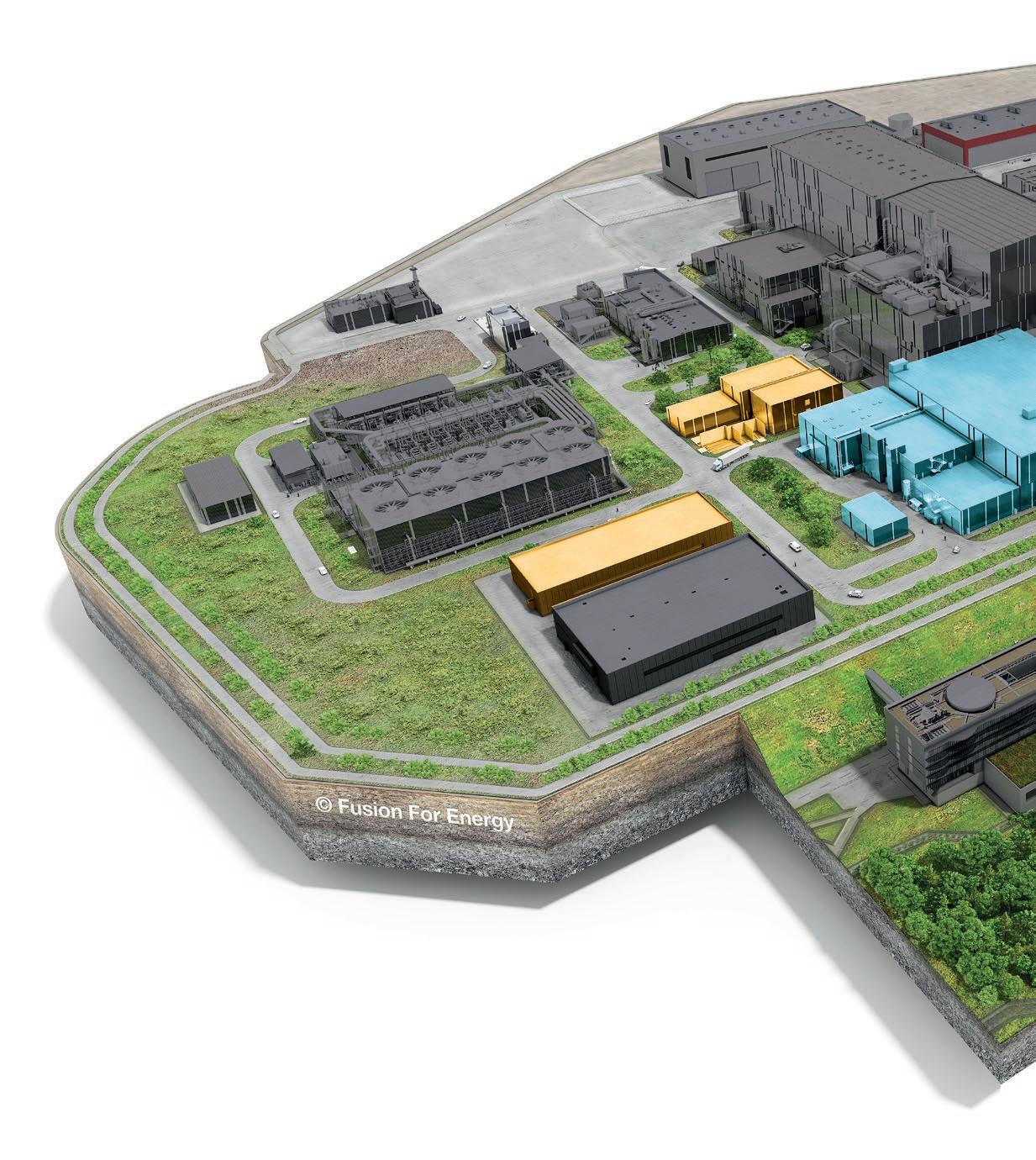

Civil structures and building services are constructed by the European Domestic Agency, Fusion for Energy, in conjunction with its Architect Engineer b.NEXT. Each area or building is handed over to the ITER Organization at an agreed level-of-completion milestone. Overall platform coordination is managed by the ITER Organization.

Buildings in place

Buildings in progress

Buildings to come

TOKAMAK COMPLEX

• Piping installed for fuelling and cooling water systems

• Assembly completed for all drain tanks

• Fibre optic cables, network cubicles installed for diagnostics

• Penetrations backfilled

• Tritium Building: civil works completed, painting completed

• C2 crane removed after 10 years of service

ASSEMBLY HALL

• Floor plates installed for second upending tool

CRYOPLANT

• Buildings and cryobridge transferred to the ITER Organization

• Start of liquid helium production

• Cryobridge installation activities continue

• Cryopump test facility installed

MAGNET POWER CONVERSION

• Static magnetic field test facility installed

• Busbar bridges and cladding completed

MAINTENANCE TEST FACILITY

(FORMER CRYOSTAT WORKSHOP)

• Repair of sector #8 ongoing

• Pre-assembly activities on sectors #5 and #1

• Staging area for thermal shield panels

• Building extension planned

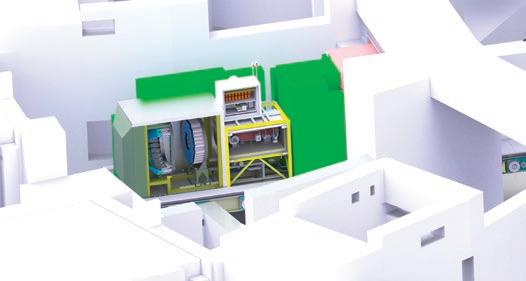

RADIOFREQUENCY HEATING

• Building transferred to the ITER Organization

• Installation of control cubicles and gyrotron supports

• Commissioning of first power supplies ongoing

• Two new heating and current drive buildings in design

STORAGE

SITE SERVICES BUILDING

• Distributing cooling water and compressed air

COOLING TOWER ZONE

• Heat rejection system in routine operation

ELECTRICAL SWITCHYARD

• First energization of reactive power compensation system

WINDING FACILITY

• Coil activities end in April; equipment removed

• Final handover to the ITER Organization

• Progressive installation of magnet cold test facility

• Progressive installation of port plug test facility

• Hosting some thermal shield repair

CONTROL BUILDING

• First command issued from main control room

• Installation of I&C cubicles ongoing

• Installation of building services ongoing

NEUTRAL BEAM POWER SUPPLY

• Buildings erected, cladding completed

• “Ready for Equipment” conditions met

• First equipment delivered

EMERGENCY POWER SUPPLY

• Construction underway; main civil works completed

BUILDINGS TO COME

HOT CELL COMPLEX

NEW HEATING BUILDINGS (other side of Assembly Hall)

Careful planning and preparation in 2023 for the remediation of key machine elements allowed the ITER Construction Project and its industrial partners to implement the repair program with focus and efficiency in 2024. Vacuum vessel sector and thermal shield repair began early in the year, and by September the first sector—with its geometry restored to nominal—was ready to resume sector module assembly activities, followed closely by a second three months later. With the coincident return of the first refurbished sets of thermal shield panels to ITER, the specialized tools hosting the sectors in the Assembly Hall could return to their original purpose— creating the nine vacuum vessel sub-assemblies that will be inserted one after the other in the tokamak pit to form the torus-shaped plasma chamber. After two years of delay due to defect remediation, vacuum vessel assembly is back on track.

REPAIRS – The teams worked on repairing three vacuum vessel sectors in 2024—two positioned vertically in Assembly Hall tooling (sectors #7 and #6) and a third positioned horizontally in the former Cryostat Workshop (sector #8). The sequence of activities was identical in each case—grinding down areas of the bevel joint regions that had excess material, using manual and automatic metal build-up techniques to restore the areas with insufficient material, and finally machining the joint surfaces to reach nominal dimensions. Sectors #7 and #6 were completed in the second half of the year; sector #8 will require more time because it is the most affected by dimensional non-conformities and it will also have to undergo an extra handling operation— rotation—to expose its second side for repair. Vacuum vessel thermal shield repair and remanufacturing also proceeded

The first megawatt compressors of the ITER cryoplant are functioning.

according to schedule, with priority given to the sets that were required first for the restart of sector sub-assembly. All elements of the support thermal shield were repaired on site and reinstalled. For the lower cryostat thermal shield, which must be repaired in the tokamak pit, a contract will be signed in 2025.

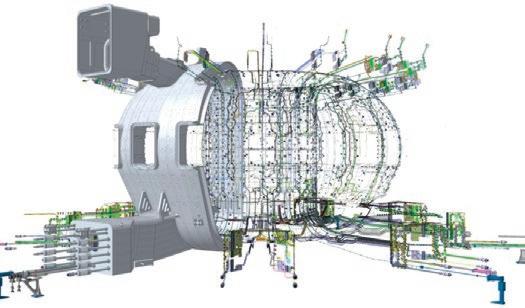

RE-START OF SECTOR SUB-ASSEMBLY – By the end of the year, all repair-related scaffolding had been removed from the vacuum vessel sectors in tooling and the teams were back to building “sector modules” by assembling each vacuum vessel sector with its thermal shield and two toroidal field coils. Once completed, these 1,380-tonne assemblies will be lifted into the tokamak pit; when all nine have been installed, the welding of the ITER vacuum vessel can commence. These strategic “building blocks” of the ITER machine are on the critical path. The ITER Organization and its industrial partners are counting on lessons learned during the creation of the first module in 2022 (which had to be disassembled later for repair) as well as a streamlined work organization, improved methods and procedures, and better tool performance to significantly reduce the time required for finalization. A second upending tool expected in 2025 will also facilitate the logistics of sector sub-assembly.

VACUUM VESSEL WELDING STRATEGY – Welding the vacuum vessel is among the most complex and critical stages of tokamak assembly. To address the challenges involved— particularly welding shrinkage—the ITER Organization has collaborated with experienced industrial partners to develop a refined strategy. Instead of the previous “triplet” approach, where sectors were welded in groups of three, the new plan adopts a quasi-simultaneous welding sequence across all nine ▲

sectors. This method ensures a more balanced distribution of stress and minimizes deformation. As strong mechanical clamps hold the sectors together as a single torus, welding will proceed on three field joints spaced 120 degrees apart. When the first set of welds are completed the robots will shift 40 degrees, and then again 40 degrees to complete the welds at one level before moving to the next. In mechanical tests this strategy was shown to minimize and balance welding shrinkage; it is also expected to save time. The strategy will be presented to a special session of the Management Advisory Committee in 2025 before the in-pit welding contract is awarded.

ASSEMBLY AND COMMISSIONING – Component installation in the Tokamak Complex continues to progress steadily as cryolines, pipe bundles, busbars, fibre optics, cables and I&C cubicles and equipment are positioned with precision by the teams. A new augmented reality application on phones and tablets is allowing

engineers and technicians to verify during walkthroughs if a plant component has been properly installed. The ITER plant systems that have already come online such as steady-state electrical distribution, heat removal with cooling water, chilled water, demineralized water, and compressed air are actively supporting plant commissioning in other areas. Test activities on the reactive power compensation system, now completed, led to the production of the first live data to the real-time network in 2024. Liquid helium was produced for the first time in the cryoplant, leading to visible vapour above the ITER cooling towers as water circulated to cool the compressors. Operators began the commissioning of the first electron cyclotron power supplies in the Radiofrequency Building; equipment was also installed for the first gyrotron wave-generating devices. The energization of part of the pulsed-power electrical network was supported by two 400kV lines connected to the French grid. Finally, in a decisive commissioning milestone, the first CODAC command was issued from the main ITER control room in December, opening a valve in one of the cooling loops of the reactive power compensation installation. An increase in plant commissioning activities has also resulted in the introduction of around-the-clock shift operation managers to ensure that operational areas of the plant are functioning normally and to intervene in the case of off-normal events.

MAJOR

– In a major milestone for the project, Europe delivered its first vacuum vessel sector (#5) in October; one other is expected from Europe next year and three in 2026 to complete deliveries. Korea delivered its final sector (#1) in November. Procurement has ended for two of the three main ITER magnet systems: toroidal field coils (last coil delivered in 2023) and poloidal field coils (last coil delivered in 2024). Some of these magnets—at least one from every toroidal field coil supplier and the smallest poloidal field coil—will be tested beginning late 2025 at their operational temperature of 4 K in ITER’s magnet cold test facility, under construction now. All magnet support elements have been finalized and delivered, and the last vacuum vessel gravity supports arrived late in the year. Five of the eight ITER torus and cryostat cryopumps have been received and a test installation in the cryoplant is ready to put them through a range of cryogenic processes. The last batch of cryolines, four gyrotron sets, all top correction coils and several large magnet feeder components also arrived onsite in 2024.

The last central solenoid modules are scheduled to arrive in 2025, and with those deliveries the procurement program for the largest and most integrated superconducting magnet system ever built will conclude. Five vacuum vessel sectors are now at ITER—including the first European-built sector—and the activities to build sector modules have started again in specialized tooling in the Assembly Hall following the repair of key components. Series manufacturing is underway for all elements of the ITER divertor, which is needed in the machine for the first phase of ITER operation, and procurement activities for the blanket first wall are transitioning to reflect the change of armour material from beryllium to tungsten decided by the ITER Organization. On all fronts, the project is converging toward a dense and tightly choreographed assembly phase that will culminate with cryostat closure in 2033.

Two vacuum vessel sectors were delivered in 2024, bringing the number of these key plasma-chamber components on site to five. With the delivery of sector #1 Korea has completed its full scope. Europe delivered its first sector (#5) in October and is on schedule to complete a second by early next year. All vacuum vessel sectors are expected on site in 2026 to meet machine assembly sequencing milestones. In 2024, a successful campaign to repair defective thermal shield piping and dimensional non-conformities on the sectors led to the restart of module assembly in September; sector #7 will be the first to be joined with its thermal shield and pair of toroidal field coils and inserted as a completed module into the tokamak pit next year. Contracts for the assembly of the vacuum vessel, including the quasi-simultaneous welding of all nine sectors to control distortions, have been concluded or are in planning with industrial partners.

Of the four major sections of the ITER cryostat supplied by India, two—the base and the lower cylinder—have already been installed in the tokamak pit. The remaining two sections—the upper cylinder and the top lid—are currently stored on the ITER platform under protective wrapping. Although the cryostat’s manufacturing was completed in 2022, several tasks remain. These include welding all sections together inside the pit and finalizing the fabrication of the torus cryopump housing (India) and rectangular bellows (ITER). Additionally, the cooling circuit on the cryostat thermal shield requires repair due to concerns about corrosion-induced cracking. For the already-installed lower cryostat thermal shield, these repairs will be carried out directly in the tokamak pit.

In a dedicated area of the Assembly Hall, ITER teams are assembling the 18-metre-tall central solenoid magnet that will be installed at the centre of the machine. The United States is responsible for delivering six modules plus a seventh as a spare, all wound from niobium-tin superconductor supplied by Japan. Four modules have been delivered and stacked; the fifth and sixth modules will reach ITER in 2025. All elements of the support structure have also been delivered by the United States—including tie structures, key blocks and specialized bolts.

Toroidal field coil procurement ended in late 2023 with the final deliveries of completed coils from Europe and Japan; acceptance testing for the last European coil was performed at ITER in 2024. With the restart of vacuum vessel sector sub-assembly, coil pairs are returning to the Assembly Hall where they are associated with the vacuum vessel sectors suspended vertically in tooling. A magnet cold test facility is planned as part of new riskmitigation strategies decided in conjunction with the updated ITER baseline (Baseline 2024). Several toroidal field coils—ideally at least one per Domestic Agency supplier—will be tested at the operating temperature of 4 K beginning in late 2025.

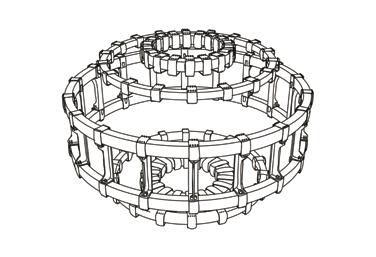

The decade-long effort to procure ITER’s poloidal field coil magnet system concluded in April with the delivery of PF3 by Europe. Between 2021 and 2024 Europe delivered five of the six ring-shaped coils required by ITER—including four manufactured in a production facility on the ITER site and a fifth produced in China—while Russia manufactured and delivered the sixth poloidal field coil (PF1). In a ceremony in June, Europe celebrated the wealth of accumulated knowledge that led to a 15-month gain in fabrication time between the first and last coils it produced. Two of the finalized coils have been installed at the bottom of the tokamak pit; the other four can only be inserted after the installation of all nine vacuum vessel sectors. All magnet supports for poloidal field coils have reached ITER from China.

The divertor must be ready for the Start of Research Operation (SRO)—the first experimental phase in Baseline 2024. In Europe, fabrication has been launched for all cassette bodies (the base structures that carry the plasma-facing targets), and an industrial partner has been named for the production of a second subset of inner vertical targets. In Japan, series manufacturing is underway for the first 18 outer vertical targets, and a prototype from the qualification phase has been sent to ITER for integration during divertor cassette assembly trials. Russia has completed high-heat-flux testing on the inner target test assembly at the ITER Divertor Test Facility and is making plans for outer vertical target testing; it has also manufactured and tested some plasma-facing elements of the divertor dome and completed all dome support structures.

Following the decision in 2023 to replace beryllium with tungsten as blanket firstwall armour material, the blanket team has developed a tungsten wall design that is configured for operational performance but also for minimal impact on ongoing first wall manufacturing processes in China, Europe and Russia. This design must go through the normal configuration approval process; in the interim, the Members involved with procurement are advancing R&D and qualification programs in close collaboration with the ITER Organization. For the blanket shield blocks, which are not affected by the change in the first wall, production continues in China and Korea. Overall, 60% of shield blocks have been manufactured and the first batch of 48 units has been shipped by China. The final design of the blanket remote handling system—which will enable the robotic exchange of blanket modules—is advancing in Japan.

> The first repaired panels of vacuum vessel thermal shield leave INOX-CVA India in February for shipment to ITER. The panels— which have new cooling circuits and polished, instead of silvercoated, surfaces—will be reassembled into the inboard and outboard thermal shield segments needed for vacuum vessel sector sub-assembly. [1]

> Europe is manufacturing power supply equipment for the neutral beam injection heating system. After successfully testing different elements on MITICA, a real-size prototype of ITER’s neutral beam injectors, contractors have begun manufacturing the production units for ITER. Already delivered on site are the acceleration grid power supplies and structural equipment for the high voltage deck and bushing assembly. © F4E [2]

> The design of ITER’s disruption mitigation system has been greenlit for manufacturing, after experts found no showstoppers during the final design review in March. The system, based on shattered pellet injection technology, will protect machine components in the case of a sudden loss of stored thermal and magnetic energy in the plasma.

> Researchers at the Max Planck Institute for Plasma Physics in Garching, Germany, have generated the ion current densities required for ITER neutral beam injection on the ELISE testbed—a negative ion source prototype that is half the size of ITER’s. This experimental first is good news for the development of reliable, high-performance heating neutral beam injectors for ITER.

> Once the nine sectors of the ITER vacuum vessel have been aligned and welded together, teams can start installing the captive components inside the vessel required for the first phase of ITER operation. Thousands of components must be installed, including diagnostic looms, cables, instrumentation, pellet and gas injection systems, in-vessel coils, blanket manifolds, blanket modules and the ITER divertor. At a workshop in February, experts reviewed the preparation and planning in place for the coordination and execution of this critical phase of ITER assembly. [3]

3 4

> China has sent the first 48 blanket shield blocks of 220 that it is producing (see photo). These actively cooled elements provide nuclear shielding for the vacuum vessel and coil systems as well as support for the blanket first wall panels. Shield block fabrication is also progressing in Korea. [4]

> The vacuum team is currently qualifying more than 70 different types of metal valves to ensure they remain secure in the case of an earthquake. The valves are submitted to highintensity simulations on shaker tables to guarantee they close or open correctly and continue to serve as a confinement barrier during a seismic event. 1 2

> ITER receives the first production cryopump in May, followed by four others during the year. Serial production of three other powerful torus and cryostat cryopumps is advancing at Research Instruments, Germany, on behalf of the European Domestic Agency, with all units expected onsite next year. [5]

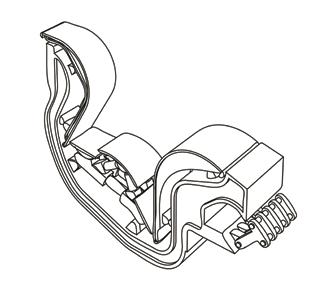

> As part of its in-kind contributions to the project, Russia is supplying switching equipment (see photo), busbars, energyabsorbing resistors and control racks for the power supply and protection of the ITER superconducting magnets. Thirteen truckloads of equipment reached ITER during the year. [6]

> A four-year program to manufacture and test a full-scale prototype of the divertor outer vertical target has successfully come to an end in Japan, with a first industrial supplier— Mitsubishi Heavy Industries—now qualified to begin the series fabrication of 18 units. Tendering for the next batch will begin in 2025. [7]

> Europe is procuring the mass-spectrometry technology that will allow experts to locate and analyze leaks in ITER’s vacuum boundaries by monitoring roughly 2,000 entry points in the cryostat, vacuum vessel, and neutral beam injectors. This year, the team completed the final design review of three out of eight sub-systems and is strain testing equipment.

> The first repaired elements of the vacuum vessel thermal shield reach ITER in March. During the repair process, the original silver coating and cooling circuit is removed, the panel surfaces are polished to mirror-like perfection (less than 80 microns rugosity), and new cooling pipes are welded. [8]

> The last poloidal field coil, PF3, leaves the European winding facility in April. The full set of six ring-shaped magnets has now been procured for ITER—one by Russia and five by Europe. Two of the coils are already in the tokamak pit; the rest will be lowered into place after the assembly and welding of the vacuum vessel. [9]

> As part of ongoing repair activities this year, small panels that erect a thermal barrier between the vacuum vessel and toroidal field coil gravity supports (the support thermal shield) were extracted from the machine assembly pit. Defective piping was removed, and the panels were machined to remove approximately 2 mm of surface material. New piping circuits are now being welded under the responsibility of the consortium responsible for machine assembly, CNPE, before the panels are re-installed in the pit. [10] 5 8 10 9 6 7

> Millions of watts of power will be injected into the ITER plasma through neutral particle injection. At the ITER Neutral Beam Test Facility in Italy, where this important external heating system is being tested in advance of operation, work is underway to assemble MITICA, a fullsize 1 MV heating neutral beam injector. Pictured is the electrostatic residual ion dump delivered by Europe in October. ©Consorzio RFX [11]

> Because the project is replacing beryllium with tungsten as the armour material for the first wall of the blanket, a new wallconditioning technique must be implemented to mitigate the risk of impurities contaminating the plasma. Called boronization, it requires new equipment and new networks that impact other systems and buildings. During a design integration review in February, requirements were defined and impacts assessed to ensure workability.

> The next five years are critical for delivering tritium plant subsystems. While the tokamak exhaust system, the tritium storage and delivery system, the air detritiation system, and the isotope separation and water detritiation systems are at different levels of maturity, all procuring Domestic Agencies are conducting gate reviews that will lead to the start of manufacturing. A Tritium Plant Summit in May at ITER was the opportunity to coordinate and share best practices.

> An expert panel formed in 2024 is looking at the set of diagnostics proposed in the updated baseline—in particular port-based diagnostics—to ensure that it is coherent with ITER’s research objectives. The panel is also revisiting the management model originally established to integrate and deliver port plugs in order to make recommendations for reducing schedule risks and containing costs.

> A newly unveiled industry wall at ITER recognizes the principal industrial contractors from around the world that are supplying components for the machine and plant systems. Some are global leaders and technological powerhouses; others, less known, possess specific savoir-faire. The wall traces the extensive fusion supply chain that the ITER project has created across three continents.[12]

> An international consortium is working to deliver an essential diagnostic system for ITER’s mission—the high-resolution neutron spectrometer. The system, which provides highprecision measurements of neutron spectra to support plasma performance and fusion research, is being developed through a collaborative effort between the ITER Organization, Uppsala University and Fagerström (Sweden), the Institute of Nuclear Physics (IFJ-PAN, Poland), and the National Research Council of Italy (CNR). [13]

> A second European contractor has been certified as part of a competitive contracting strategy to produce 13 divertor inner vertical targets after successfully manufacturing a full-scale prototype. Two contractors have now been selected to fabricate 13 units each; at the conclusion of this first phase, a call will be reopened for the fabrication of the remaining 32 units. ©Alsymex [14]

> Approximately 70% of the busbar lengths expected from Russia have been received at ITER and busbar installation on site has passed the halfway milestone. In 2024, two busbar bridges connecting the magnet power conversion buildings and the Tokamak Complex are declared “Ready for Equipment.”

> As part of commissioning activities underway in the ITER cryoplant, 12 out of the facility’s 18 megawatt-class compressors have been producing liquid helium at 4 K since September. Operating in conditions as near as possible to future reality helps to ensure that the highly complex machinery in the plant is performing as expected.

> Europe delivers vacuum vessel sector #5 in October after final in-factory inspection (left page, full photo). Four more sectors are expected before the end of 2026.

> A test facility at ITER will ensure that ITER’s torus and cryostat cryopumps, which are designed to operate at temperatures as low as 4.5 K and as high as 200 °C, will perform as expected. In June, the team installs a cryojumper—the line that connects the test bench to fluid distribution in the cryoplant—as part of preparations for commissioning. [15]

> The stainless-steel plugs sealing off each tokamak port opening are not only massive, they are also complex, carrying and protecting important payloads such as diagnostics and heating system elements that are critical to efficient operation. To ensure that each port plug performs as required, a stringent battery of environmental and functional tests is planned at ITER before installation. Russia has delivered part of the first test stand—a 20-tonne metal structure that will evenly distribute the test stand’s weight on the floor. [16]

16

> Europe has selected the supplier for the supply of six gyrotrons following the success of a development program that included the manufacturing of a pilot proof-of-concept pre-series unit. The contract covers manufacturing design, production, factory testing, including installation and site acceptance testing. Gyrotrons are the powerful wave generators for the electron cyclotron auxiliary heating system.

> The ITER remote handling and blanket projects are collaborating with an external contractor to develop suitable non-destructive testing techniques to inspect in-vessel pipe welds during the nuclear phase of operation. After evaluation, a promising technique has been identified and a bespoke probe manufactured for testing.

> The functional and safety requirements for the ITER Hot Cell have been refined to match Baseline 2024 and a pre-concept defined; going forward, the team will continue to develop the design with the support of industry. The Hot Cell facility will not be needed before the deuterium-tritium phase of operation.

> China shipped all six top correction coils to ITER this year; manufacturing and testing for the last set—side correction coils—will conclude in 2025. These small superconducting coils compensate for field errors caused by geometrical deviations due to manufacturing and assembly tolerances.

> In addition to the independent magnet modules of the central solenoid, the United States is delivering the elements of the “exoskeleton” that will hold the modules in place and resist the extreme force that will build up during operation. Contractors have manufactured more than 9,000 individual elements, including unique high-resistance bolts (see photo). All deliveries will be completed early next year. [17]

17 18

> Vacuum sector #1—the fourth and final sector manufactured by Korea—is delivered in November. Work continues to deliver the equatorial and lower ports and the other structures, like port extensions, that will create the junction between the vacuum vessel and the cryostat. [18]

> Diagnostic thermocouples are designed to measure and monitor the temperature and heat flux on the plasma-facing divertor targets. Four ITER units were installed on a divertor sector of the WEST tokamak and tested in situ in a campaign starting in February. All units functioned well and provided important data that will be used to plan for ITER operation.

> India has completed all cryoline-related deliveries to ITER and 90% of cryoline and warm line installation has been completed onsite. Five kilometres of cryolines are needed to deliver cryogenic cooling power to the main “clients” in the Tokamak Building—the ITER magnets (45%), the thermal shield (40%), and the cryopumps (15%). 15

Two documents outline how the ITER project plans to achieve its mission and goals—the ITER Baseline, which details the scope, schedule, cost and risk of the project, and the ITER Research Plan, which is the document that guides the commissioning and experimental exploitation of the ITER device once construction is complete. The documents are closely linked, meaning that changes to one must be reflected in the other.

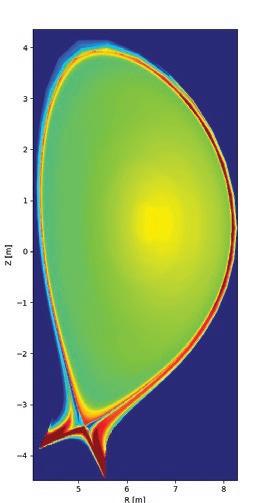

In the new project baseline, whose overall approach was endorsed by the ITER Council in November, ITER’s programmatic goals have not changed; however, there are substantial modifications to baseline systems and components as well as to installation sequences. The new high-level ITER Research Plan (Level 1) that was submitted to the ITER Council as part of baseline documentation reflects this new plant configuration, linking the hardware capabilities of the ITER facility to each stage of the Operation Phase and defining the main experimental approaches that will be followed to achieve the project’s goals. Elaborated by ITER Organization and Member experts, the plan lays out three main plasma operation phases—SRO (Start of Research Operation), DT-1 (first Deuterium-Tritum phase), and DT-2 (second Deuterium-Tritium phase). In annexes, it also includes research plans for the ITER Neutral Beam Test Facility and the Test Blanket Modules program.

Following endorsement by the Science and Technology Advisory Committee (STAC-30) in May, the high-level plan (Level 1) was widely shared in the fusion community at major 2024 conferences such as the 50th Conference of the European Physical Society Plasma Physics Division, the 33rd Symposium on Fusion Technology, the 66th Annual Meeting of the American Physical Society Plasma Physics Division, the 8th Asia-Pacific Conference on Plasma Physics, and at meetings of the International Tokamak Physics Activity (ITPA) Topical Groups and Coordination Committee. Feedback received on Level 1 will now be incorporated into the further refinement and elaboration of the blueprint down to Levels 2 and 3.

Level 2 describes the plans for scientific exploitation and their incidence on medium-level configuration details of the tokamak and its ancillary systems under configuration control— meaning that any modification to these details may require a project change request and that any impact on hardware must be evaluated by the ITER Organization in coordination with the Domestic Agencies. Level 3 addresses system configuration details whose modification would have no impact on configuration control.

ITER Organization and Member experts are closely looking at baseline-related design refinements of key systems—including diagnostics, heating and current drive, fuel cycle, and the blanket first wall—as they finalize the plan’s detailed objectives, experimental strategies and timelines for each experimental campaign. The final ITER Research Plan (down to Levels 2 and 3) will also make recommendations on the preparatory R&D required to support routine and reliable operation of the ITER tokamak in hydrogen, deuterium and deuterium-tritium plasma scenarios.

The resulting document, detailed down to Levels 2 and 3, will be reviewed by the ITER Science and Technology Advisory Committee at its meeting in May 2025 (STAC-32).

The new ITER Baseline and Research Plan were elaborated with the involvement of the ITER Member fusion community and will require its support to carry out.

One of the most challenging modifications of Baseline 2024 in terms of impact on the ITER Research Plan is the replacement of beryllium by tungsten as the plasma-facing material in the blanket first wall. A higher Z (tungsten) source means higher potential contamination of the plasma core and impact on the fusion power output; it can also be an obstacle to reliable plasma start-up which in most tokamaks, including ITER, is performed by growing the plasma in a configuration that directly contacts the main chamber walls. A plasma chemical vapour deposition process known as boronization, a wall-conditioning technique, has been introduced as part of the new baseline to improve plasma start-up with an all-tungsten wall.

In recent years, several medium-sized research tokamaks in ITER Member facilities—such as Alcator C-Mod, ASDEX Upgrade, WEST and EAST—have gathered important data by operating with majority-tungsten plasma-facing components, improving confidence that the ITER Organization plan to modify the ITER wall material is a manageable risk. The ITPA groups performed an independent evaluation and concluded that “there is no fundamental impediment” for achieving ITER’s programmatic goal of Q=10 with the change of first-wall material if the appropriate risk mitigation techniques are deployed. Nevertheless, some aspects require further experiments and modelling to be more confident that experiments in mediumsized tokamaks can be extrapolated to ITER.

Through the ITER Scientist Fellowship Network and the ITPA, the fusion community was mobilized in 2023 and entered full production mode in 2024 to address the open R&D issues related to the new ITER Baseline and Research Plan. As an example of recent progress in these R&D areas, the EAST, WEST and ASDEX Upgrade tokamaks carried out dedicated experiments in 2024 in coordination with the ITER Organization. In these experiments the advantages provided by central electron cyclotron heating in the initial phase of the discharge (limited on the first wall) were confirmed, the impact of boronization (or lack of) and of its uniformity on plasma start-up were assessed, and the compatibility of small ELM regimes (as required for high-Q operation in ITER) to sustain high plasma performance when operating with a tungsten wall was demonstrated. (Results from EAST are discussed in more detail in the next paragraph; those from ASDEX Upgrade and WEST will be reported at 2025 conferences.)

The first tokamak to contribute with new experimental results in 2024 was the EAST tokamak during a series of experiments organized by the EAST team in China, the ITER Organization Science Division, and members of the ASDEX Upgrade team. These experiments were executed in January, in time to incorporate the new data obtained into the new baseline proposal. The experiments were designed around three main priorities: the optimization and characterization of boronization, plasma start-up on tungsten surfaces, and the impact of boronization coating on plasma operation in high confinement mode (H-mode). While these issues had to some extent been addressed on ASDEX Upgrade and WEST, the new EAST experiments made a significant addition to the database.

Six boronization processes and over 400 tokamak pulses were executed during the campaign, providing a wealth of data. Valuable new information was obtained on boronization uniformity and process and on routine plasma start-up and stationary operation on a pure-tungsten, water-cooled outer limiter (including a record 17-second limiter discharge). A clear demonstration has also been obtained that good H-mode confinement can be obtained in both boronized and unboronized conditions in proximity to tungsten main chamber surfaces, provided edge localized magnetohydrodynamic (ELM) activity is kept to low levels. Since this is already a condition for the adequate lifetime of the ITER tungsten divertor targets, the EAST experiments provide yet more evidence of the importance of ELM control on a full-tungsten ITER.

To refine the assessments on which these conclusions are based requires dedicated experiments on present full-tungsten devices supported by modelling. This will allow the validation and refinement of the models used to predict ITER plasmas, thus increasing confidence in these predictions. A list of the highest priority topics for R&D related to the use of a tungsten wall in ITER will be described in the final version of the ITER Research Plan.

Reliable predictions of ITER plasmas—spanning the entire crosssection from the plasma core and scrape-off layer up to the material surface—are key to the achievement of ITER’s fusion power demonstration goals. These predictions are essential for defining and preparing plasma operational scenarios and analyzing plasma pulses that will be executed in ITER, as well as for evaluating the required control schemes through the simulations of measurements, actuators, and the associated plasma responses. Given the strong non-linear coupling of processes governing burning plasma behaviour, separate modelling of individual processes and/or plasma regions is not sufficient. A holistic, integrated approach is therefore mandatory.

Advanced predictive modelling of plasma operation scenarios requires validated physics models covering a wide range of physics fidelity—from fast empirical or surrogate models for control applications to high-fidelity physics models for detailed analysis. These validated models are integrated into robust modelling workflows designed to address specific use cases without loss of physics fidelity. Large-scale automated validation and uncertainty quantification (UQ) can significantly facilitate the validation of both stand-alone physics models and integrated modelling workflows, providing the ranges of validity and/or uncertainties. Recent advances in artificial intelligence (AI) can also contribute to the development of the surrogate models necessary to develop fast-plasma pulse design software and plasma control algorithms suitable for real-time application. A new Persistent Actor Framework (based upon the MUSCLE3 Multiscale Coupling Library and Environment) implemented

▲

This figure shows the normalized profile of plasma radiation (in logarithmic scale with respect to its average value) across the cross-section of an ITER deuterium-tritium (DT) high-Q plasma modelled with JINTRAC. The asymmetry of the radiation profile in the core is caused by the centrifugal effect of rotation on the density of tungsten in the plasma for the expected Mach number of ~ 0.15 in ITER.

within ITER’s Integrated Modelling & Analysis Suite (IMAS) is enabling cosimulations across different software environments. All these advanced developments not only support ITER integrated modelling priorities, but also those of existing and future devices.

The ITER Organization and Member communities are working closely together on a coordinated program of model validation, coupled with presentday experiments and all phases of the ITER Research Plan in order to resolve the open issues that have already been identified and maintain a predictive capability for later phases and future fusion devices.

The third meeting of Advances in Tokamak Integrated Modelling (ATIM) was hosted at ITER in 2024, jointly organized by EUROfusion’s TSVV11 (Theory, Simulation, Validation and Verification) task and the Dutch eScience Centre (Large-scale Validation and Uncertainty Quantification).

In 2025, the ITER International School will focus on the topic of integrated modelling and the validation necessary on existing facilities to prepare for ITER operation and support ITER’s scientific exploitation.

D / SCIENTIFIC DATA CENTRE COMES ON LINE

ITER’s Scientific Data and Computing Centre will come online in 2025 after six years of design and construction. Equipment formerly housed in temporary locations will be relocated to the new 250 m² space in the basement of ITER Headquarters, which houses 46 high-density racks constituting both the ITER high-performance computer (HPC) and the storage and communication systems used to manage all project data.

The ITER HPC is composed of multiple clusters designed to handle computationally intensive jobs such as Monte Carlo simulations, plasma physics simulations, and neutronics and fluid dynamics calculations. The Scientific Data and Computing Centre also fulfills one of the high-level requirements for the ITER project, which is to store, secure, process and distribute the vast amount of data produced throughout its lifetime.

The main ITER control room, where operations will be monitored and analyzed, will have 10 days of data on hand for very fast access and analysis, whereas the Data Centre will act as the vault. All data from ITER operation will be streamed there and kept in an online state throughout the lifetime of the project to allow ITER Organization and ITER Member scientists to perform analysis across the different experimental phases.

The Data Centre will be connected to a backup and distribution centre in Marseille using dedicated, and redundant, high-speed fibre optics. Data storage and management will start in 2025 when the Centre begins receiving data from various ITER plant systems.

A multiyear effort to reshape the IT architecture for the management of project engineering data is well underway. The progressive decommissioning of some project management software in favor of a smaller subset directly connected to a central hub—the ITER Collaborative Platform (ICP)—is helping to remove data silos and improve workflow efficiency and access.

In-house experts have also introduced artificial intelligence (AI) to improve ITER systems engineering processes. The first use case deployed was facilitating information retrieval from the ITER Document Management (IDM) system—ITER’s historic document repository that hosts over 1.5 million documents.

The new set of tools uses AI to summarize each document within the IDM system and the results are used to index all information in a vector database. The team developed an application that uses natural language processing to send queries to the vector database and return one or more responses using a popular technique called retrieval-augmented generation (RAG). Instead of just matching keywords like traditional search engines, it allows users to ask questions and find semantically meaningful information. Users can ask questions in all the languages supported by OpenAI—including Mandarin, Korean, Japanese,

Russian and Hindi. But the answers are always in English to standardize the output and facilitate performance monitoring.

Since the first release in early 2024, the artificial intelligence assistant, called “Lucy,” continues to evolve. It is already at work understanding natural language and intent in order to provide users with the most relevant matches, and has been equipped with a special agent to decipher ITER acronyms and abbreviations. ITER experts are planning to integrate the chatbot into applications used by employees on a daily basis and to make it available to other fusion institutions that use the IDM system.

The ITER Organization has also introduced digital tools to bridge the gap between the physical and the virtual on the construction site. Through a collaboration between the Design Office and IT groups, a new solution allows any person at ITER to view the 3D design model of the ITER plant—from the highestlevel view of the entire site all the way down to a millimetre-level view of any component—and use it to compare the as-built to the as-designed.

Every week, output is extracted from all CAD tools—around 20 terabytes of data in over 100,000 files—and converted to a common format on a high-performance server. The resulting integrated model is only a few gigabytes and can be downloaded to a standard laptop or workstation and viewed through

Navisworks 3D Viewer. One of the reasons the integrated model can be made so much smaller is that it only needs to be viewable, not editable. The model can also be enriched with the engineering properties of components, for example their nominal dimensions and properties or their safety class, thanks to a connection between Navisworks and the ITER engineering database.

The integrated model that provides the as-designed view of ITER is also being enriched with as-built information through a laser scanning solution, Cintoo. A second application, Gamma AR, now allows engineers to walk through work areas and compare as-built work to the as-designed 3D models on their tablets and smartphones. With 3D models overlaid on reality, any issues become immediately apparent.

ITER installation and assembly supervisors on site are using these powerful new tools to verify conformity with design, spot deltas, identify and flag installation clashes, and visually plan installation sequences for critical and congested areas of the plant. Significant savings in both time and cost are expected.

FEBRUARY

> Rollout of new CARE corporate values (Collaboration, Accountability, Respect, Excellence)

APRIL

> Public Open Doors Day

MAY

> Inaugural Private/Public Fusion Workshop

> Work launched on the ITER Design Handbook

JUNE

> 34th Meeting of the ITER Council

> Celebration for the completion of European poloidal field coils

> ITER Robots competition, 13th edition

> Open Doors for ITER families

JULY

> Press conference at ITER Headquarters on the new ITER baseline

> Celebration for the completion of all toroidal field coils

AUGUST

> Laetitia Grammatico is appointed Head of the Administration Department

SEPTEMBER

> 4th Safety Day: “We are all accountable”

OCTOBER

> Launch of the new ITER website

> ITER’s document management system IDM turns 20

> DeLeah Lockridge takes up the position of Deputy Director General/Head of the Engineering Services Department

NOVEMBER

> 35th Meeting of the ITER Council

> Council endorses the overall approach proposed for Baseline 2024

> Deliveries celebrated: the first European and the last Korean vacuum vessel sectors

> Launch of the Private Sector Fusion Engagement Project (PSFE)

> Public Open Doors Day

> ITER is present at the United Nations Climate Change Conference (COP29) in Baku, Azerbaijan

DECEMBER

> First CODAC (Control, Data Access and Communication) command issued from the main ITER control room

> ITER International School #13 held in Nagoya, Japan

> Fifth annual ITER Awards

> 23,055 people visit ITER in 2024 (cumulative since 2007 = 239,891)

In 2024, the ITER Organization transitioned from a focus on preparing the new technical baseline and associated schedule to executing, monitoring and controlling work in order to keep to the Baseline 2024 work plan. Strong project performance was sustained over the 12 months of this report, with key indicators showing an execution rate for 2024 that surpassed all previous years. Organizational and project transformation, now in its second year, saw the continued rollout of a new matrixed structure, improved administrative efficiency, and enhanced project-wide integration—factors that are helping to accelerate the schedule and optimize costs. Constructive engagement with the French nuclear safety authority remained a priority, with particular emphasis this year on licensing issues related to vacuum vessel welding. The ITER Organization also broadened its strategic outreach in 2024 by establishing new channels to share knowledge with private sector fusion initiatives.

ITER PROJECT BASELINE – The initial presentation of the new project baseline to the 34th Meeting of the ITER Council in June was followed by a months-long review of the proposal by the ITER Members, including during special meetings of the ITER Council’s management and scientific advisory committees. Recommendations from the review process were incorporated into the baseline proposal presented to the 35th Council Meeting in November, where delegates from the seven ITER Members endorsed the overall framework of Baseline 2024, “without prejudice to the domestic process of approval.” This positive result concludes more than two years of coordination between the ITER Organization and the Domestic Agencies to update the scope, schedule, cost and risk assessment of the project. Baseline 2024 is now the reference document—the definitive blueprint against which all progress and performance will be measured moving forward.

The overarching objective of Baseline 2024 is to deliver scientific value as rapidly as possible, with a focus on achieving meaningful research outcomes. The core “mission elements” of the project remain unchanged: demonstrating the integration of systems needed for industrial-scale fusion operations, achieving a burning plasma with 500 MW of thermal fusion power for 50 MW of input heating power (Q≥10), sustaining 400-second pulses, and reaching thermal equilibria in plasma and structures. ITER’s first operational phase—Start of Research Operation— will feature hydrogen and deuterium-deuterium plasmas that culminate in the operation of the machine in long pulses at full magnetic energy and plasma current. In the new plan, the achievement of full magnetic energy in 2036 represents a delay of three years relative to the 2016 reference, while the start of the deuterium-tritium operation phase in 2039 represents a delay of four years.

To enhance schedule and cost control as the project works toward these milestones, key performance indicators such as schedule and cost performance indices, estimate to complete, and milestone trend analysis will be tracked monthly beginning in 2025. Changes to the machine assembly sequence have been introduced to improve efficiency and reduce risk. The machine assembly contracting strategy has also been revised where necessary, resulting in several new contracts being signed or planned over the course of the year. In addition, a new strategy for vacuum vessel welding (see pages 14-15) will be implemented through the signing of a major contract in 2025.

REGULATORY ENVIRONMENT – In the updated baseline, the licensing strategy is based on the progressive acquisition of knowledge. In parallel to the stepwise plan for operation is a stepwise approach to demonstrating nuclear safety, allowing the project to accumulate operational knowledge and experience. At each stage, the detail and scope of the nuclear safety case will match the project’s maturity and incorporate knowledge gained from prior experimental phases. During the first phases—SRO (Start of Research Operation, with deuteriumdeuterium plasmas only, and DT-1 (Deuterium-Tritium 1, with limited fluence—the nuclear safety stakes will be limited as the project acquires data on systems and components. A third operational phase, DT-2, will focus on the achievement of all scientific goals.

The ITER Organization continues to interact with the French nuclear safety authority ASN (Autorité de sûreté nucléaire) on this staged approach, and a calendar of regulatory filings has been established. The first of two submissions related to the assembly hold point was sent to ASN in December; an update of the Preliminary Safety Report (RPrS) is expected in 2027. Constructive exchanges are also ongoing related to size defect optimization and the conformity assessment for the vacuum vessel. Additionally, reorganization within the nuclear safety group at ITER is underway to improve the management of high-level nuclear safety requirements and strategies, including through project-wide training and independent monitoring and inspections.

REORGANIZATION – The full matrixed organizational structure has been rolled out in phases and will be fully adopted on 1 January 2025. It optimizes the ITER Organization workforce by structuring engineering resources according to the fields of expertise needed for the new baseline and by empowering project leaders and managers to take decisions and be accountable for the scope, schedule and cost in their operational units. Recruitment for the highest-level positions in the new organigramme concluded in 2024 with the appointment of the Head of Engineering Services. Work will continue next year to finalize the Engineering Services structure, appoint managers, and develop tools and procedures to streamline resource allocation and support line and matrix managers.

GLOBAL MANAGEMENT OF ENGINEERING DATA – Efforts to reduce the number of data silos within the project and drive access to engineering data through one portal continued in 2024. The main platform ICP (ITER Collaborative Platform) has been upgraded with cutting-edge technologies to facilitate the productive use of ITER’s extensive datasets. Data from numerous engineering platforms has been repatriated to ICP and other transfers will be carried out to create a unique data and document management system within the project. In 2024, augmented reality was introduced on the ITER worksite, facilitating spot checks on installed components and systems and the comparison of “as-built” to “as-designed” configurations. In parallel to the efforts to consolidate and improve the quality of engineering data, initiatives are underway to explore the potential of artificial intelligence in such diverse areas as administration, science, engineering and management.

PUBLIC/PRIVATE COLLABORATION – The ITER Organization held the first Public/Private Sector Fusion Workshop in May focusing on the status of private sector initiatives and the ways in which the ITER project can help. The workshop attracted 350 participants including representatives from 30 startups, as well as from research institutes and the broader fusion supply chain. Recognizing the value of private-public collaboration for all Members, the ITER Council is supporting ITER-led initiatives

to establish channels for sharing knowledge with private sector entities—including the formalization of technical visits, discussions between experts, open sourcing of some ITER science software, and a Private Sector Fusion Engagement (PSFE) help desk to oversee the sharing of ITER documents, with appropriate constraints for protecting intellectual property. A second workshop is planned in 2025.

STAFFING – In 2024, the ITER Organization continued to seek to improve ITER Member representation in the staff body, collecting feedback directly from underrepresented groups and Domestic Agencies to guide its efforts. It also pursued the implementation of a two-year action plan, initiated last year, aimed at preventing psychosocial risks among staff and introduced new corporate values. In a project first, the number of directly employed staff decreased by 0.9% to 1,092 people in 2024 (a net reduction of 10 staff members). With the staffing cap of 1,170 set by the ITER Council nearly attained, overall staff numbers are expected to remain relatively stable in the coming years. In addition to directly employed staff, contributions to the project were also made by 14 experts, 5 visiting researchers, 160 interns, 218 ITER Project Associates, and 21 post-doctoral fellows.

OCCUPATIONAL SAFETY – The positive trend in safety indicators continued in 2024, with all targets achieved and yearon-year decreases recorded in lost-time injuries, minor injuries and first-aid events. To continue to reduce the frequency of incidents related to strenuous activity, the ITER Organization actively encourages all contractors to train their employees to manipulate and lift heavy objects using appropriate movements and body posture. An analysis of construction site incidents over three years has led to the selection of nine key life-saving rules that will be the object of an educational campaign in 2025.

INTERNATIONAL COOPERATION – The ITER Organization maintains cooperation agreements with the laboratories and educational establishments of the ITER Members (see full list on pages 56-57) as well as international organizations and nonMember states.

(1) Includes 7 Monaco Postdoctoral Fellows and staff funded for work on the tokamak cooling water system (TCWS, 27), the vacuum auxiliary system (VAS, 2) and the safety control system for nuclear (SCS-N, 2).

(2) Includes 5 Monaco Postdoctoral Fellows and staff funded for work on the TCWS (25), VAS (2) and SCS-N (2).

(3) Includes 9 Postdoctoral Fellows (6 Monaco and 3 KO) and staff funded for work on the TCWS (19), VAS (2) and SCS-N (2).

(4) Includes 18 Postdoctoral Fellows (4 Monaco, 6 KO, 8 IO) and staff funded for work on the TCWS (15), VAS (2) and SCS-N (1).

(5) Includes 21 Postdoctoral Fellows (5 Monaco, 6 KO, 10 IO) and staff funded for work on the TCWS (12), VAS (1) and SCS-N (1).

* “Other” refers to staff members from Switzerland, Ukraine and, from 2023, the United Kingdom (following ITER Council consultation and approval).

* For the full names of units, see the Organization Chart on page 58.

the

CUMULATIVE IN-KIND CONTRIBUTIONS BY MEMBERS

Amounts in ITER Unit of Account (IUA)

R&D

MANUFACTURING MILESTONES

MAJOR CONTRACTS

ITER ORGANIZATION / DOMESTIC AGENCY MILESTONES

COMPLETED PACKAGE

The figures on the following pages are adjusted annually for changes in credit value due to Procurement Arrangement Refinements (PAR) and Additional Direct Investment (ADI) related to Project Change Requests. Please note that the 2024 figures supersede all previously published figures.

Packages allocated to the ITER Organization (some cryogenics, heating, tooling, tritium plant, and diagnostics) are not represented in these pages.

www.iterchina.cn

PROCUREMENT ARRANGEMENTS

Fourteen PAs signed since 2007 representing: 100% in number and 100% of the total value of CN-DA in-kind contributions. Over 93 design or fabrication contracts related to ITER procurement have been signed with laboratories and industry.

Chinese procurement highlights in 2024

MAGNET SYSTEMS

All conductor unit lengths delivered

All conductor unit lengths delivered

All magnet supports delivered

13 feeder components sent to IO, including 2 cryostat feedthroughs 2 units of auxiliary materials delivered CORRECTION COILS

All top correction coils (TCC) delivered to IO in 2024 FAT on first side correction coil (SCC) completed

CORRECTION COIL AND FEEDER CONDUCTORS

All correction coil and feeder conductors delivered POWER SYSTEMS

converters

First high-power energization achieved; commissioning activities continue at IO BLANKET

Task Agreement signed for launch of tungsten armour joint qualification program BLANKET SHIELD BLOCKS

First 48 shield block units delivered FUEL CYCLE

Gas valve box feasibility study carried out DIAGNOSTICS

PDR closure report for remaining neutron flux monitors approved

of ITER system procured by China

MRR 1-b for radial X-ray camera (RXC) mechanical components (excluding electrical feedthrough) approved MRR 3 for RXC I&C was approved

www.iter-india.org

PROCUREMENT ARRANGEMENTS

Fourteen PAs signed since 2007 representing: 100% in number and 100% of the total value of IN-DA in-kind contributions.

50 design or fabrication contracts related to ITER procurement have been signed with industry and R&D organizations.

Indian procurement highlights in 2024 CRYOSTAT

CRYOSTAT

Delivered all six units of torus cryopump housing (TCPH) to IO

Completed SAT of cryostat I&C cubicles (7 units)

Delivered cryostat optical sensors (displacement and accelerometers)

CRYOGENIC SYSTEMS

Lower pipe chase cryolines completed

All cryoline deliveries completed

Mechanical installation of cryolines and warmlines at IO is at 89%

First 3 auxiliary cold boxes (ACBs) positioned in Tokamak Building

Last 2 ACBs dispatched to IO after successful factory tests

FAT of warm panels for ACBs and thermal shield cold valve box (TCVB) completed

HEATING & CURRENT DRIVE SYSTEMS

DIAGNOSTIC NEUTRAL BEAM (DNB) POWER SUPPLY

Manufacturing of 200kW, 1MHz solid-state RF generator ongoing

DNB BEAM LINE

Integrated testing of beamline components successfully completed at Indian Test Facility

Beam source in advanced stage of manufacturing

MRR of DNB vessel completed

NBTF COMPONENTS (BEAM DUMP & 100 KV POWER SUPPLY)

All NBTF components completed

Support provided for SPIDER activities

ION CYCLOTRON RADIO FREQUENCY (RF) POWER SOURCES

Tender document for high-power amplifiers (120kW and 1500kW) revised to align with Baseline 2024 requirements

In-house-developed 10KW solid-state power amplifiers tested up to 7kW at ITER India laboratory ION CYCLOTRON RF POWER SUPPLY

Final design of power supply system completed

ELECTRON CYCLOTRON HIGH VOLTAGE POWER SUPPLY

Final design of power supply system completed

ELECTRON CYCLOTRON RF GYROTRON POWER SOURCES (2 GYROTRONS OUT OF 24)

1 MW gyrotron test stand operated continuously to verify reliability and ease of operation

Preparatory design activities for FDR in progress

COOLING WATER SYSTEMS

HEAT REJECTION, COMPONENT COOLING AND CHILLED WATER SYSTEMS

Heat rejection system cooling water is operational at IO

Prototyping and manufacturing contract placed for safety-important (SIC) butterfly valves

VACUUM VESSEL

IN-WALL SHIELDING (IWS) BLOCK ASSEMBLIES

All In-wall shielding block assemblies delivered DIAGNOSTICS DIAGNOSTICS

Electron cyclotron emission (ECE): Attenuation measurements of prototype transmission lines initiated using hot/cold sources and a Fourier-transform (FT) spectrometer

CXRS diagnostics: prototype misalignment compensator (MAC) fabrication ongoing; experiments on different shielding materials conducted to protect motors from magnetic field

X-ray crystal spectroscopy (XRCS)/Edge: Large-area hybrid pixel detector prototype set-up completed and performance tested

XRCS/Survey: Front-end sight tube delivered to IO; preliminary design of I&C conducted; prototype manufacturing activities progressing Upper port plug: port integration and design activities underway % of ITER system

www.fusion.qst.go.jp/ITER/english/iter.html

PROCUREMENT ARRANGEMENTS

Fifteen PAs signed since 2007 representing: 83% in number and 98% of the total value of JA-DA in-kind contributions.

More than 1,000 design or fabrication contracts related to ITER procurement have been signed with industry since 2007.

Japanese procurement highlights in 2024

MAGNET SYSTEMS

All conductor unit lengths delivered

of ITER system procured by Japan

(9 OUT OF 19)

All toroidal field coils delivered TOROIDAL FIELD MAGNET STRUCTURES

All toroidal field magnet structures delivered CENTRAL SOLENOID CONDUCTOR

All conductor unit lengths delivered HEATING & CURRENT DRIVE SYSTEMS HIGH VOLTAGE BUSHING (MITICA)

Procurement of high voltage bushing completed

VOLTAGE BUSHINGS

ITER Task Agreements are underway for FDR

(HNB2 ACCELERATOR)

High voltage test underway

FDR for DC generator (DCG) step-up transformers held

Manufacturing underway on DCG step-up transformers and insulating transformers

Final design and analysis for outdoor components underway for FDR ELECTRON CYCLOTRON RADIO FREQUENCY POWER SOURCES (8 GYROTRONS OUT OF 24)

All eight gyrotron systems delivered to IO ELECTRON CYCLOTRON EQUATORIAL LAUNCHER

Final design and analysis progressing for FDR

REMOTE HANDLING

BLANKET REMOTE HANDLING SYSTEM

JA-DA’s contribution to initial assembly agreed with IO

Final design continuing; prototype test for design verification ongoing DIVERTOR

Manufacturing of outer target prototypes completed

Half outer target prototype delivered to IO for assembly tests

Commissioning of hot helium leak test facility completed

Series manufacturing underway for outer targets #1-18; MRR for outer targets #7-18 completed

TRITIUM PLANT

ATMOSPHERE DETRITIATION SYSTEM

JA-DA/IO procurement activities proceeding

DIAGNOSTICS

DIAGNOSTICS

Microfission chamber: final design underway for feedthrough and connector/ex-vessel components and detectors

Edge Thomson scattering: resolving FDR chits for beam dump; final design of other components underway

Poloidal polarimeter: retroreflector in manufacturing; FDR closed for equatorial port #10; final design underway for other components

Infrared thermography: final design underway

Divertor impurity monitor: resolving PDR chits for upper port #1 and equatorial port #1 components, preliminary design underway for lower port #2 components

Lower port #2 integration: final design underway

https://www.iterkorea.org

PROCUREMENT ARRANGEMENTS

Eight PAs signed since 2007 representing: 89% in number and 95.5% of the total value of KO-DA in-kind contributions.

Over 300 design or fabrication contracts related to ITER procurement have been signed with universities, laboratories and industry since 2007.

Korean procurement highlights in 2024

VACUUM VESSEL

MAIN VESSEL (4 OF 9 SECTORS)

Procurement Arrangement scope completed (S#6 and S#7 delivered)

Delegation Agreement scope under direct IO contract completed (sectors #8 and #1)

Third vacuum vessel sector (#8) delivered in 2022

Fourth vacuum vessel sector (#1) delivered in 2024

EQUATORIAL PORTS AND LOWER PORTS

All nine sets of vacuum vessel gravity supports (VVGS) delivered

All VVGS threaded inserts delivered

Lower port extensions (#04, #06 and #18) delivered to the ITER site

Sealing flange contract signed

Activities progressing on remaining ports, super bolts and inserts, and sealing flange

BLANKET

Procurement of raw material—221 forging blocks and rolling plate—completed

Series production underway: 125 of 220 blocks completed

POWER SYSTEMS

AC/DC CONVERTERS

Toroidal field coil AC/DC converter transformer delivered to IO and installed

First legal inspection completed; preparing low-voltage test activities

MAGNET SYSTEMS

All conductor unit lengths delivered THERMAL SHIELD

VACUUM VESSEL THERMAL SHIELD AND CRYOSTAT THERMAL SHIELD

All of the main components of the thermal shields delivered

ASSEMBLY TOOLING

All machine assembly tools delivered

Storage and delivery system (SDS) preliminary design updates reviewed

Task Agreement on 5x-bed manufacturability progressing; SDS preliminary design document review completed

Preparation for SDS Procurement Arrangement underway

DIAGNOSTICS