MBA NORTH SAFETY AWARDS 08 NEW LAYERS OF STRUCTURAL VALUE 44 PYLON SPIRES OF MSIKABA BRIDGE 33

JULY 2023 | No 1172

Address: Unit 21, Hunky Dory Business Park, 9 Goedehoop Avenue (M57), Olifantsfontein Telephone: (012) 670 9083 E-mail: info@twinstar.co.za It’s always the last piece in a puzzle that goes missing! That’s ‘cause we’ve got it! YOUR PRECAST CONCRETE SPECIALIST PRODUCTS Storm Water Electrical Markers Water Reticulation Outdoor & Building Polymer Products Mining Solutions Kerb Inlet & Road Products Custom Products SERVICES Moulds Drawings IM/08/2022 TWINSTAR PRECAST solves those difficult, one-off jobs that make civil engineering & construction challenging.

South African Builder is the official journal of Master Builders South Africa, established in 1923. The opinions expressed by contributors are not necessarily those of Master Builders South Africa. SA Builder is a registered trademark of Master Builders South Africa. Any use of this trademark without the express and written approval of Master Builders South Africa is prohibited. No material contained herein may be reproduced in whole or in part without the prior written permission of the publisher. SA Builder © 2023. All rights reserved.

CONTENTS AND CREDITS

PUBLISHER

Isikhova Media (Pty) Ltd

10th Floor, Metal Box, 25 Owl Street, Milpark, Johannesburg, South Africa

Tel: +27 11 883 4627

www.sabuilder.co.za /www.isikhova.co.za

CONTRIBUTIONS

Master Builders South Africa

Tel: +27 11 205 9000

E-mail: editor@sabuilder.co.za

www.masterbuilders.org.za

Free download available on: www.sabuilder.co.za

Twitter: @Builders_SA | Facebook: @SouthAfricanBuilder

FEATURES

25 Major mixed-use developments from TUHF

28 Don’t fly blind when investing in renewables for buildings

31 Expanding the Eastgate Shopping Centre’s solar capacity

PROJECTS

33 Spires shoot skywards as Msikaba Bridge advances

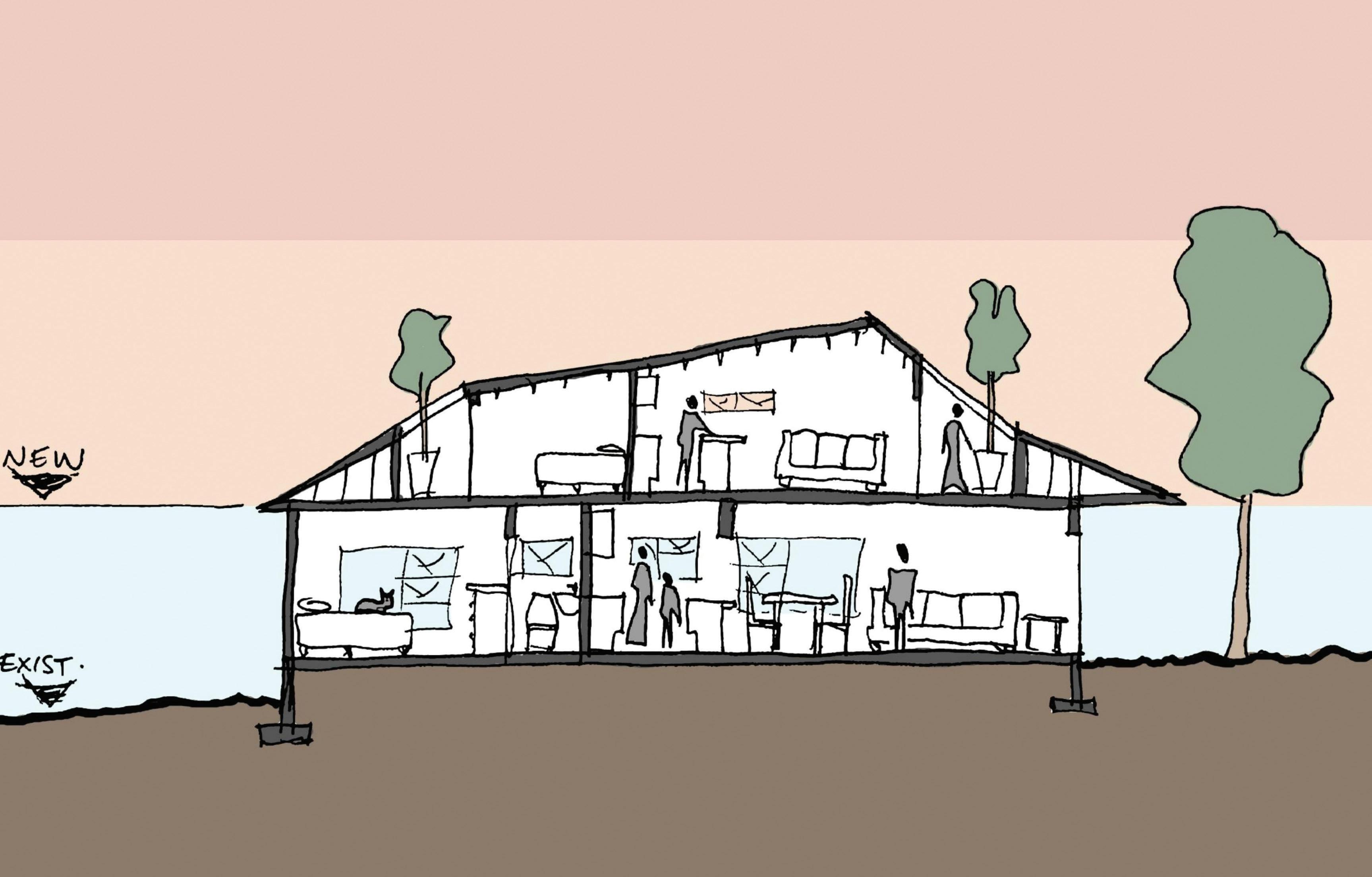

36 Pioneering a precast luxury home in SA

BUILDING BUSINESS

38 Construction industry, currency risk and streamlined payments

PRODUCTS

42 Portable power and security solutions

GLOBAL VIEW

44 Palimpsest: layering (sub)urban fabric

INNOVATION

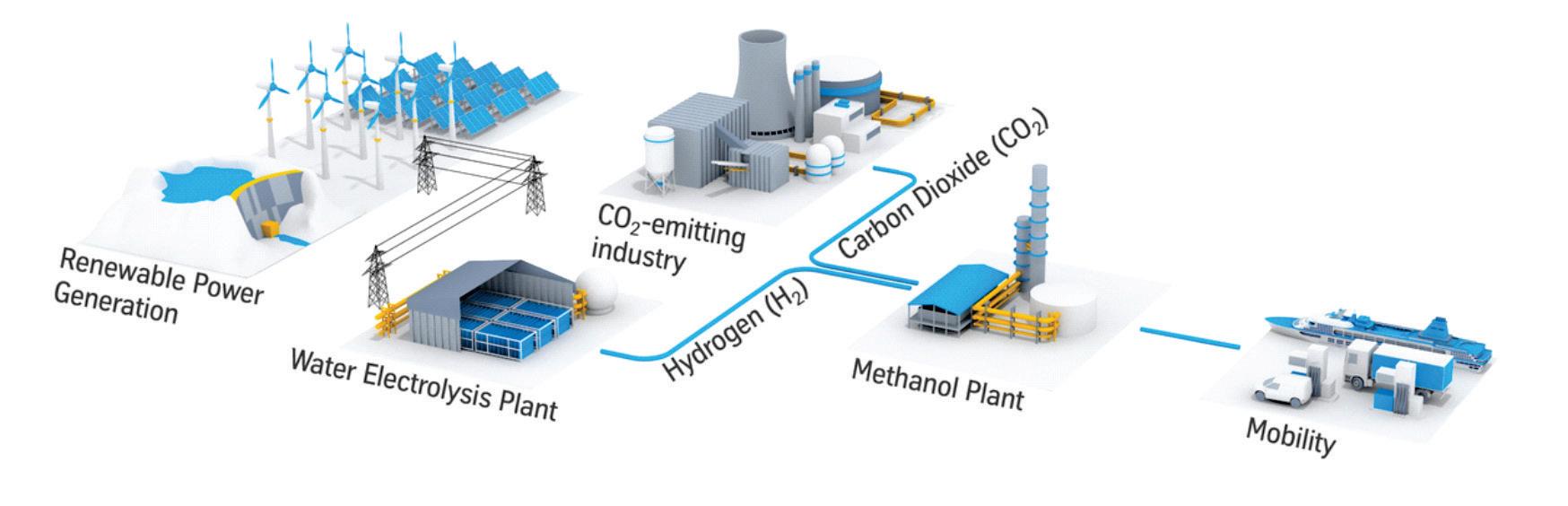

46 Zero-carbon energy carrier

CAPTAINS OF CONSTRUCTION

47 Meet Landseer Collen

Editor: Nicholas McDiarmid

E-mail: nicholas@isikhova.co.za

Director: brand strategy: Jenny Justus

Tel: 083 450 6052

E-mail: jenny@isikhova.co.za

Managing director: Imraan Mahomed

E-mail: imraan@isikhova.co.za

Creative director: Joanne Brook

E-mail: joanne@isikhova.co.za

Proud Media Partner

Operations director: Thuli Majola

E-mail: thuli@isikhova.co.za

Copy editor: Anne Phillips

Advertising sales: Tel: +27 11 883 4627 Mobile: 072 383 3203/083 450 6052

savvy thinkers smart doers together people

02 Message from the editor 02 From the president’s desk COVER STORY 04 Sustainability is not about targets, but commitment MBA NEWS 06 MBA development trust bursaries –creating the next generation 08 Master Builders North annual health and safety results 10 Managing scaffolding on site 12 Project management: The art of shaping success (part 2) INDUSTRY NEWS 14 Modena receives international award 15 The trend towards larger power plant solutions 16 When aesthetics meet quality 17 Engineering the next generation 18 Innovative access doors for dewatering pumps 20 How WEG VSD technology can help deal with load-shedding ASSOCIATION NEWS 22 The plumbing industry’s impact on cholera

JULY 2023 SOUTH AFRICAN BUILDER 01

CONTENTS

10 34 26

42

WINTER STRATEGIES

I am personally a fan of winter, but am all too aware of its impact on builders and our industry as a whole. It is really worth figuring out effective and easyto-implement strategies to mitigate the season’s inevitable issues.

First, take care of your people. Winter is no joke for our real heroes: those labouring at the coalface. From transport to clothing, childcare and nutrition, we must do more to acknowledge the cost implications for workers, especially this year. Basic living costs have been subject to chronic pricegouging. As we all know, so-called inflation is a tough sell when our major corporate earnings have indecent profiteering. Prices need to be brought back in line, but right now, your workers are feeling the stress in unimaginable ways. This is essential firstly for humanitarian reasons, but also because project

delays, downtime due to illness and managing the chaos this causes for managers are all major costscavengers.

SIMPLE SOLUTIONS

Ensure that every worker has warm clothing and a decent coat. Take a trip to a thrift store and you will be amazed at how little it costs to keep your workers warm and safe.

Make sure every worker is supported in getting themselves and their children to healthcare providers; again, a pack of generic vitamin C and D costs little and does a huge amount.

While we come up with ways to knock the greed out of our system and restore the kind of capitalism that really responds to competition, let us keep our sites competitive and functioning by using compassion and simple smarts.

Nicholas McDiarmid, Editor: SA Builder

FROM THE PRESIDENT’S DESK

As we approach the MBSA Annual Congress, scheduled for 8 September 2023, the urge to evaluate the state of South Africa’s construction industry is impossible to resist.

Global and national economic pressures continue to affect the industry and it is alarming that governance at local, provincial and national levels is being hampered by “special-interest groups” – meaning that the interests of the few often trample the national interest. That being the case, our industry's output will take another two years just to regain pre-pandemic levels. The good news is that recovery is underway.

BUILDING INCLUSIVE SOLUTIONS

The MBSA Annual Congress is a unique forum that sees emerging business-owners on an equal footing with leaders from government, established corporates and financial institutions, addressing crucial issues and creating real opportunities for the entire building and construction industry in the country.

Approximately 350 delegates are expected at this year’s event: leaders and owners of established and emerging businesses in the industry, senior government officials, representatives from national and local government, financial institutions, suppliers in the construction industry and many more. Register now!

SOUTH AFRICAN BUILDER JULY 2023 02 EDITOR'S NOTE

LOW MAINTENANCE

NEVER PAINT

WEATHERPROOF

FADE PROOF

SOLAR COMPATIBLE

HARVEY

SUSTAINABILITY IS NOT ABOUT TARGETS, BUT COMMITMENT

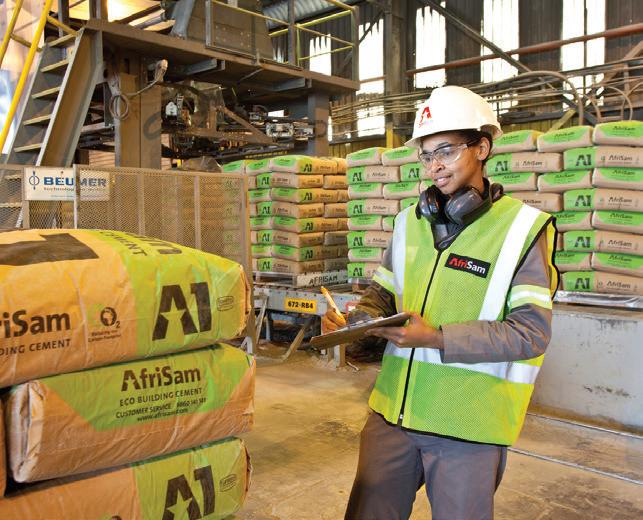

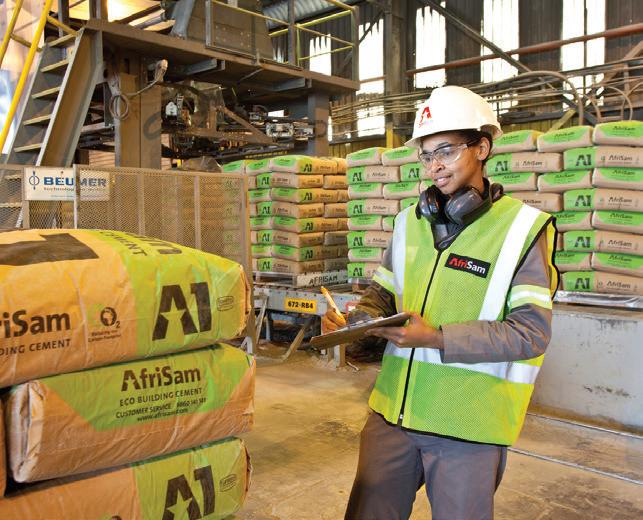

Despite the difficult conditions in the construction sector, AfriSam remains committed to its sustainability journey, which delivers responsible solutions to customers while ensuring worldclass quality and results.

AfriSam is one of the leading innovators in the field of cementitious extenders, for example, which reduce the carbon footprint of cement and concrete, while complying with technical specifications. The company’s cement manufacturing processes are among the most energyefficient in the sector, which also lowers carbon emissions. The mining of the raw materials for cement production is carried out in a similarly responsible manner, with environmental rehabilitation conducted to the highest standard.

“Thanks to our sustainability roadmap, when customers procure our products, they can rest assured that we’ve prioritised the environmental impact in our supply chain,” says AfriSam cementitious executive Hannes Meyer. “This supports their own sustainability efforts, improving the environmental performance of the construction industry as a whole.”

CONSERVATION, MITIGATION, OPTIMISATION – PROCESSES AND PRODUCT

“Water management is vital throughout our operations and water conservation is a stringent component of our mining and manufacturing processes,” says Meyer. “Our ready-mix operations recycle water extensively and this informs our efforts to promote biodiversity in the natural environment.”

This approach is becoming more important to contractors, especially as developers and endcustomers move toward green building strategies and targets. AfriSam gives its customers the opportunity to support a more sustainable future for the sector by choosing construction materials that embody this commitment.

“There seems to be a considerable amount of ‘greenwashing’ from construction material suppliers,” says Meyer. “They create an impression of a sustainable approach, in the complete absence of any credible evidence.”

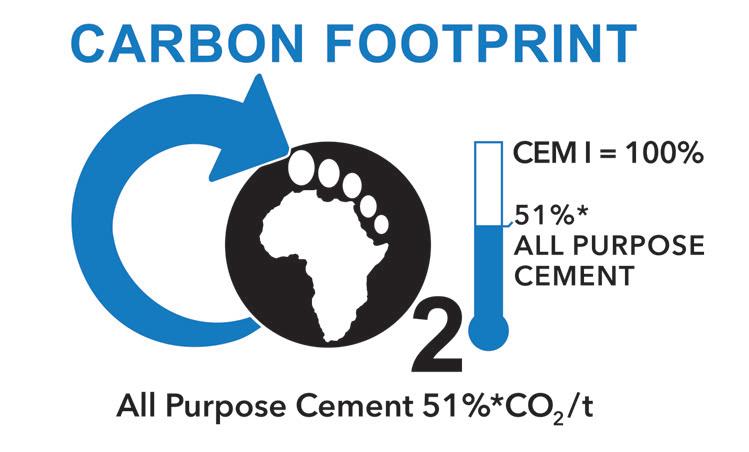

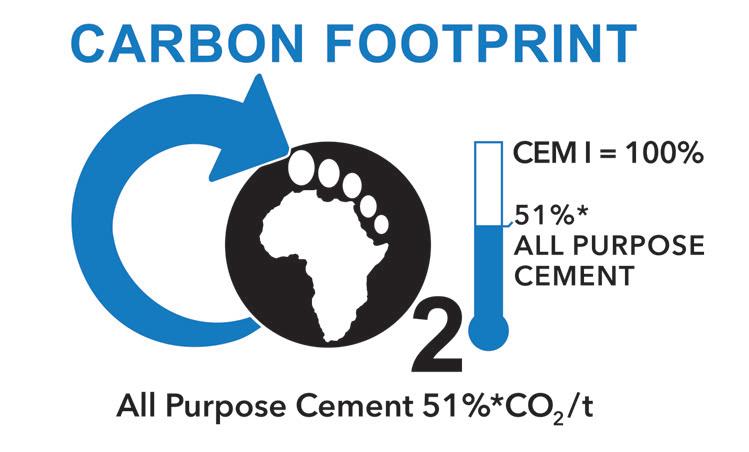

Meyer highlights that AfriSam has been pursuing its sustainability mission since the early 1990s and has taken a long-term view of continuously improving its performance. In 2009, AfriSam was the first to introduce a carbon dioxide (CO2 ) rating system, which indicates the carbon footprint of each of its cement products relative to Ordinary Portland Cement. This was followed by the launch of Eco Building Cement in May 2010 as the lowest-carbonfootprint product.

SOUTH AFRICAN BUILDER JULY 2023 04 COVER STORY

(Above): The company’s manufacturing processes are among the most energy-efficient in the sector.

“What’s significant in our approach is that we not only set targets and goals for ourselves, but are practical about what’s achievable,” adds Meyer. “Now we’re looking towards what we can achieve by 2030, basing our expectations on what we’ve accomplished in the past.”

Since 1990, AfriSam has been able to reduce the volume of carbon dioxide emissions per ton of cementitious material by 33%. As arguably the world’s first construction material supplier to carbon-footprint all its production operations, the company enables customers to measure and document this data in their environmental reporting.

“This makes an important practical contribution to contractors’ efforts to align with the sustainability goals of architects, developers and end-customers,” explains Meyer. “It’s gradually becoming expected of contractors to have not only a sustainability policy, but the ability to report accurately on their carbon footprint. This will be for their own reporting, but also for their customers to account for the impacts in their supply chains.”

AfriSam process engineer Marieta Buckle agrees that it is easy to set carbon-zero targets, but more difficult to reach them, especially in a carbon-intensive industry like cement manufacturing.

“Applying a carbon capture utilisation and storage strategy would probably more than double the cost of cement in the market,” she explains. “This, in turn, would have a direct impact on the cost of

building homes and infrastructure in the country – which is clearly not an acceptable outcome, given the needs of the public.”

Buckle points to the deception of using these targets for marketing purposes in the absence of necessary technological developments. It is more realistic to consider the practicalities of a “just transition” in the South African context.

“As a developing country, we’re looking at a future that will demand the construction of millions of houses – structures that require considerable quantities of cement,” she says. “The way we pursue our just transition must take into account the affordability of these homes for the vast majority of citizens.”

With all its innovation, research and development, AfriSam has therefore been cautious in the way it sets and publicises its sustainability targets. Having considered a wide variety of options available, it has implemented a number of strategies which will have the least cost impact on customers and the market.

“These improve on the carbon footprint of our products, for instance, while remaining competitive in the market,” says Buckle. “This is vital for the commercial sustainability of our business, as we must ensure the security of our employees and customers while also entrenching our presence here for future generations. In this sense, we take a holistic view of sustainability.”

AFRISAM –THE CONTRACTORS' PARTNER

“Our leading-edge product offering of credible, verifiable carbon reductions is highly valuable in and of itself. AfriSam is the partner of choice for contractors committed to a sustainable future. For contractors with a strategic vision to lead their business to the top of the new carbon economy, AfriSam is more than just a partner: it’s a catalyst for opportunities of incalculable value,” says Buckle.

JULY 2023 SOUTH AFRICAN BUILDER 05 COVER STORY

MBA DEVELOPMENT TRUST BURSARIES –CREATING THE NEXT GENERATION

In an effort to promote careers in the built industry, MBA Western Cape (MBAWC) offers bursaries to no fewer than 20 students a year towards their studies through the MBA Development Trust Bursary. This funding is aimed at helping the “missing middle”, who are categorised as those who do not qualify for funding from the National Student Financial Aid Scheme (NSFAS), but whose parents cannot afford to pay for their education.

ORIENTATION 2023

The 2023 academic year has been no different. We received over 50 applications for this bursary and it was a marathon exercise finalising the final 23 students who MBAWC will be funding this year. At the end of the selection process, we hosted an orientation session for the bursary recipients where a conducive environment was created for the students to network. The bursary programme attracts students from all levels –from matriculants fresh out of high school to post-graduate students who might already be working within the industry.

At the orientation session, Roekeya Bardien, MBAWC’s executive director, went through what our expectations are of these students. Chief among these is that we expect them to be active citizens and not use the education funded by the construction

industry in the Cape Peninsula to contribute towards an economy elsewhere. This is particularly important, given that there is so much ambition among young students to work abroad.

training

In the last part of the orientation, the students were encouraged to set clear goals for themselves using methodologies such as vision boarding.

INDUSTRY INTERACTION

We look forward to having more sessions with these students ,where they will have the opportunity to interact with other industry role-players who are currently being moulded by MBAWC through our occupational health and safety programme, as well as those on our apprentice programme. Our goal is to be at the forefront of creating a cadre of young people who will take the construction industry to greater heights and make it a fashionable career choice.

SOUTH AFRICAN BUILDER JULY 2023 06 MBA NEWS

(Left): From construction planning to project design, South Africa's tax regime offers a broad framework for construction R&D.

to keep

Visit MBA Western Cape at: www.mbawc.org.za

abreast of our regional

initiatives and industry development initiatives.

(Left): With the speed of innovation and access to integrated intelligence and robotics, a new age of R&D is upon us.

WE ADD MUCH MORE

VALUE

Our specialists are standing by to assist you with design, specifications, detailed drawings, and certifications

We’ll also do a rational design to help your plans comply with Sans 10400 XA. Our after-sales service extends to on-site, trade and technical assistance, from placing the order – to installation.

Call 086 110 2425 now. We’d be happy to assist with your next project.

www.summitxps.co.za

R-VALUES THAN JUST GOOD

MASTER BUILDERS NORTH ANNUAL HEALTH AND SAFETY RESULTS

The Master Builders Association (MBA) North region has announced the winners of its prestigious 2023 Annual Regional Safety Competition, which advocates and recognises best practice in construction site safety.

The awards form part of broader efforts by MBA North and sponsor Federated Employers Mutual Assurance Company (RF) (FEM) to improve safety in the construction industry and provide a platform for companies to benchmark their health and safety (H&S) management systems and implementation against other companies in the region and nationally.

VALUE AND NUMBER OF PROJECTS UP

The 2023 competition attracted entries from 78 projects, 29 principal and sub-contractors that entered the competition, including a joint venture between WBHO Construction

and Trencon Construction. There were five withdrawals and three disqualifications from the competition. Entries were up by nine from 69 projects in 2022, representing a total project value of approximately R10,6 billion.

The audits for the projects commenced in March 2023 with Enza Construction for the Dainfern Square site. They continued for 10 weeks, with the final day in May with Bantry Construction Services for the Krone warehouse and office building. This year the competition attracted 10 new companies: Barrow Construction, BCMA Construction, Tractionel Enterprise, Tshwane Fire Sprinklers, HVAC Installations, Warb Plumbing, Pre-Form, Zadok Holdings, Presto Electrical and Gauteng Piling.

TOP WINNERS

The competition’s top winner was undoubtedly WBHO Construction, which took first and second place

SOUTH AFRICAN BUILDER JULY 2023 08 MBA NEWS

in categories I, H and G and won the coveted R750 million+ category for its SA Reserve Bank project. It was followed by Enza Construction, which won category F (R100 million-R250 million) for the Africa Data Centre. 2022 new entrant Viva Projects JHB won category E (R40 million-R100 million) for the Bok student accommodation site.

Tri-Star Construction followed, winning in categories C (less than R15 million) for the Wits Hillman House and D (R15 million-R40 million) for Riverside View Ext 69.

Tiber Construction won in category A – Plant & Yard – for the Village Yard.

These winners were announced on 1 June 2023. The projects

will now go through to the MBA’s National Safety Awards, the results of which will be announced at the annual congress on 8 September. The association extends its thanks to all the members that entered the competition and showed their commitment to the health and safety of their employees on sites.

ALL SAFETY CHAMPIONS

The difference between first, second and third place is often minimal. Every member which entered is an H&S champion. The quality of the H&S systems of winning companies is extremely high. The association is committed to growing the competition and entering more sub-contractors in 2024.

ABOUT MBA NORTH

MBA North is the amalgamation of the former MBAs of Johannesburg (founded in 1894) and Pretoria (founded in 1903). The organisations merged to form the Gauteng MBA in 1996 and was renamed MBA North, representing four regions: Gauteng, North West, Mpumalanga and Limpopo.

It is a chapter of MBA SA. Based in Halfway House, MBA North represents the interests of employers in the building and allied trade industries in the abovementioned four regions. It aims to serve its members by facilitating best practices within its membership and the building industry as a whole.

MBA NEWS

MANAGING SCAFFOLDING ON SITE

By Deon Bester, MBA Western Cape

There are a few fundamental items that must be addressed when erecting and using scaffolding on site. We can divide these fundamentals into four parts, namely: pre-erection, during erection, use of scaffold and inspections.

PRE-ERECTION

In terms of the SANS Code 10085, “The Design, Erection, Use and Inspection of Access Scaffolding”, the supervisor of scaffolding needs to perform the following duties prior to the erection of the scaffolding on the site:

• Confirm the type of scaffold that needs to be built with the person requiring it.

• Establish the type of scaffold to be used.

• Identify the location of the scaffold.

• Establish for how long the scaffold will be used.

• Establish the classification of the scaffolding.

• Establish the number of working platforms and the total number of platforms to be provided.

• Establish the scaffold ties and any other factors affecting the stability of the scaffolding.

• Establish the volume of material to be supplied and whether the material will be re-used on the site.

• Identify the access positions for ladders or staircases.

• Identify the arrangements for the safety of the scaffold and the required inspections during its use.

These duties are expanded upon further in the code under section 14.

DURING ERECTION

All scaffolding must be erected by competent scaffold erectors who are trained according to the requirements of the SANS code in section 16.

Scaffolding must be erected under the supervision of both a team leader and a competent person.

SOUTH AFRICAN BUILDER JULY 2023 10 MBA NEWS

“ALL SCAFFOLDING MUST BE ERECTED BY COMPETENT SCAFFOLD ERECTORS WHO ARE TRAINED ACCORDING TO THE REQUIREMENTS OF THE SANS CODE IN SECTION 16.”

(Right): Contractors must ensure that they remain in control of all scaffold structures on site.

The scaffold must be inspected and handed over to the user. This must be recorded and those records must be kept on site.

In terms of the construction regulations section 16, a supervisor must be appointed to supervise the erection of the scaffold. His/ Her duties are different from those of the supervisor referred to in the SANS code.

USE OF THE SCAFFOLDING

The user of a scaffold remains responsible for the continued safety of its structure. The user must ensure that the scaffold is not overloaded, that adequate ties and bracing are in place and that the working platforms are in the correct position and are complete with toe-boards and guardrails.

Further, the user must ensure that safe and convenient access ladders are provided and that scaffolding is tagged as either “Safe for use” or “Unsafe for use”. There also needs to be a system in place to ensure co-operation between all users of the scaffold so that it remains safe.

INSPECTION

Scaffolding must be inspected, as noted below, by a person competent in such inspections:

• It must be inspected by a scaffold supervisor prior to use.

• It must be inspected prior to handover.

• It must be inspected at least weekly.

• It must be inspected after inclement weather.

• It must be inspected after any mishap resulting in jarring, tilting or overloading.

• It must be inspected after any alteration and before dismantling.

The result of these inspections must be kept in a register on site. It is important to note that all scaffold structures must be clearly identified on the register to ensure traceability of the structure on site.

The management of scaffolding on sites will always remain a challenge, mainly because most scaffolding services numerous trades during its lifespan.

KEEPING CONTROL OF THE SCAFFOLDING STRUCTURE

One of the most important, yet challenging issues regarding scaffolding is the alteration of its structure by workers, as well as its abuse by them. Contractors must ensure that they remain in control of all scaffold structures on site and not leave it up to the contractor who built them.

The SANS code is very clear that the user remains responsible for the scaffold once it has been handed over for use.

SANS 10085 is regarded as a regulation, as it has been incorporated into section 44 of the Act. A copy of the standard regulations must, therefore, be available on site.

Please consult the standard regulations for information or contact the MBAWC for any further information and guidance.

JULY 2023 SOUTH AFRICAN BUILDER 11 MBA NEWS

(Above): One of the most important, yet challenging issues around scaffolding is the alteration of scaffold structures by workers.

(Below): It is important to note that all scaffold structures must be clearly identified on the register to ensure traceability of the structure on site.

PROJECT MANAGEMENT:

THE ART OF SHAPING SUCCESS (PART 2)

By Bilaal Dawood, head of membership services: MBA KZN

In part 2 of this feature, of which part 1 appeared in SA Builder’s June 2023 edition, scope creep and productivity delays are explored further.

Scope creep is the result of changes or additions to a project’s scope requirements due to poor communication, unclear requirements or shifting priorities on the project which result in cost and schedule overruns. Change

orders or variation orders, on the other hand, are formal changes to the contract such as alterations to design, specifications or materials.

Effective contract management requires that these are closely monitored and the correct

processes in terms of the contract are followed to address them and the cost and time impact that accompany them. Failure to properly deal with these will, in some instances, result in parties being time-barred from claiming

SOUTH AFRICAN BUILDER JULY 2023 12 MBA NEWS

a very

and

of it happens on site.

“EFFECTIVE CONTRACT MANAGEMENT REQUIRES IDENTIFYING AND ADDRESSING RED FLAGS EARLY ON, MITIGATING THEIR IMPACT ON THE PROJECT AND DEALING WITH THEM IN TERMS OF THE CONTRACT, WHERE REQUIRED.”

(Below): Contract management is

active pursuit

much

these, thus losing entitlement or ending up in disputes.

PRODUCTIVITY ISSUES AND DELAYS

These affect the cost and time of a project. Contract management professionals should be equipped to identify the root cause of these issues and implement strategies to mitigate them. Delays need to be identified as early as possible and addressed in a timely manner. In terms of the common law, the party suffering damage is expected to take steps to mitigate their damage. Therefore, in instances of delay, the party suffering the delay must take steps to mitigate the impact of the delay.

It is recommended that the sitefacing construction manager or foreman be provided with a delay register to record all delays. These delays are then communicated to the responsible contract management professional

to evaluate on a weekly basis. Thereafter, the impact of the delays is assessed and timeous notification and claim must be complied with.

IGNORING RED FLAGS

Ignoring red flags on a construction project can have severe consequences. Red flags are warning signs that indicate potential problems or risks in the project. Failing to address these warning signs promptly and following the terms of the contract, where required, can lead to project delays, cost overruns and even legal disputes. Ignoring red flags can also damage reputations, lead to loss of business and harm relationships with clients and stakeholders.

Effective contract management requires identifying and addressing red flags early on, mitigating their impact on the project and dealing with them in terms of the contract, where required. This involves establishing clear communication channels, monitoring project progress and implementing appropriate risk management strategies. Ignoring red flags in contract management is not an option.

While a contract is an effective and imperative tool to identify the black and white rights and duties of the parties, it is also essential to consider the softer elements of stakeholder and relationship management in executing a contract. Often there is hesitation to implement a contractual right or duty and give notice to the other party due to fear of reprisal or dissatisfaction from a client or stakeholder, which is often to the detriment of the party entitled to raise it. A better methodology to adopt is to diplomatically and clearly communicate with the client and stakeholder and attempt to resolve the issues. This protects you if there is a dispute where a paper trail is needed.

Please contact the association should you require any further assistance in this regard.

JULY 2023 SOUTH AFRICAN BUILDER 13 MBA NEWS

(Above): Effective contracts require input from all involved in a project from its inception.

(Below): The agreements that make up a construction contract might begin with a handshake, but implementation must be exacting, as every detail is a potential problem.

MODENA RECEIVES INTERNATIONAL AWARD

Modena Design Centres was awarded the prestigious KnowledgePoint Fusion 360 award for Education 2023 at the International Autodesk Learning Partner Summit held in Istanbul, Turkey, from 24-25 May.

“We’re extremely proud and honoured to have received this accolade for our unwavering dedication to flying the Autodesk Education flag. With a passion for education, our team has tirelessly driven the Autodesk Education offering, leaving no stone unturned. We’ll continue to pursue our mission of providing quality training across all facets of education in South Africa,” says Heather McDade, MD of Modena Durban.

“Over the years, we’ve conducted workshops and provided faculty training at renowned universities like the Mangosuthu University of Technology and the University of KwaZulu-Natal, engaging with mechanical engineering, civil engineering and architecture departments. Through the use of powerful software such as Fusion, Revit, Civil 3D and Inventor, we’ve empowered educators and students alike.”

In the past year, Modena Design Centres has successfully trained 45 engineering and graphic design educators for the education department. This has led to an ongoing collaboration with the department on a national plan, solidifying the company’s commitment to education on a larger scale.

Additionally, Modena Design Centres has conducted 12 workshops, equipping 25 students with valuable skills on Autodesk Fusion 360. The company prioritises the development of young minds, offering school holiday training programmes as an elective for high school pupils.

Moreover its dedication extends beyond universities and schools. Modena has actively supported and participated in the Autodesk First Steps in Your Career Programme, assisting numerous students and

institutions in registering for their Autodesk Education software and engaging with the education community. It is the only Autodesk Platinum Partner in Africa, as well as being an authorised Autodesk training centre, software and services provider.

The company also expands access to a broad portfolio of design technology, programs and communities, empowering students to solve design and engineering challenges.

SOUTH AFRICAN BUILDER JULY 2023 14 INDUSTRY NEWS

Reliable and consistent power supply is critical to economic growth in Africa, leading more companies to install ever-larger power systems. Zest WEG notes that it is seeing more demand for generating plants with capacity of 10MW and more. A popular option among many customers has been Zest WEG’s modular solutions in this power range.

Whether companies need power to survive load-shedding or to raise their production output, the trend is for these power-generating systems to get bigger.

According to Bernard Mitton, business development consultant at Zest WEG, it is becoming more common for customers to request proposals for power solutions that exceed 10MW. In SA, this is mainly a response to rising levels of loadshedding. In other parts of Africa, says Mitton, it is economic growth that drives demand.

“For many companies wanting to grow their output, it’s vital to have a continuous and reliable power supply,” he says. “In recent years, Zest WEG has been designing and installing more of these large power plants for customers across the continent.”

It is Zest WEG’s depth of inhouse engineering expertise and technical capability that earns it these contracts, he explains. From

THE TREND TOWARDS LARGER POWER PLANT SOLUTIONS

generators installed within a containerised solution or a dedicated power plant room. They can generate power at 400V, to be stepped up by transformer up to 11kV, or power can be generated directly with an alternator output up to 11kV.

the generator sets themselves to the transformers, switchgear and containers, the company can provide customers with a full turnkey solution.

“We often propose a modular system that allows the customer to execute their project in phases,” he says. “They can begin with the most cost-effective solution and then expand the plant as the power demand grows.”

In one of these 10MW systems, there are usually eight to 10

“For a typical 10MW power plant, we connect the generators to a common switchboard up to a maximum of 2kV to distribute power to the various on-site loads,” says Mitton. “The switchboard solution can be installed in a container, an e-house or a plant room.”

The generating units are customengineered, built and fully tested in Zest WEG’s Cape Town generator facility. Testing includes a step-load test and the synchronisation of generators to each other – verifying all setpoints, engine performance and efficiency indicators.

JULY 2023 SOUTH AFRICAN BUILDER 15 INDUSTRY NEWS

(Below right): Bernard Mitton, business development consultant at Zest WEG.

(Right): Generators ready to be installed within a custom-engineered container solution.

(Above): A generator installed in a 12m-high cube container.

WHEN AESTHETICS MEET QUALITY

Factors that contribute to the success of new or re-purposed commercial and residential developments include the sourcing of quality products that offer lower long-term maintenance costing and superior aesthetics for the development upon completion. It is these factors that Technicrete, part of the IS Group, brings to site through its wide range of sustainable brick and paving solutions.

The development of the trendy and upmarket Glen Starling Estate in Kempton Park, east of Johannesburg, which comprises 405 multi-storey units, communal and swimming pool facilities, as well as parking, required paving and kerbing that would offer reliability and longevity due to the anticipated high vehicle and foot traffic throughout the complex.

LONGER LIFE

Technicrete sales consultant Thabani Mtolo says the kerbing and paving solutions supplied to the estate were chosen for the specific benefits they offered

to the required applications. “Residential roadways and parking developments need a concrete product solution that provides enhanced longevity, while providing the required aesthetics for an upmarket housing scheme that also offers communal leisure areas,” he explains.

“We’re always pleased to collaborate with Pentacon Civils, with which we’ve established a good relationship. We understand the time constraints to which it sometimes works and so far, we’ve met its requirements satisfactorily.

INTEGRAL FINISHES

“Technicrete’s 60m grey zig-zag interlocking pavers were the perfect choice for this project due to their unparalled longevity and the fact that they can easily withstand a high level of traffic. The big bonus of these interlocking pavers is the pleasing finish they contributed to the development. Figure 7 1 000m semi-mountable kerbs were applied throughout the estate roadways, again perfectly

suited for use and durable enough to withstand the odd pavement mount by vehicles,” says Mtolo.

“For ease of identification, it was decided to use a two-tone format for the parking areas. Technicrete’s 50m Terracotta BondBrick traditional paver was applied to highlight the parking bay surface, while the 50m slatecoloured Double Bond, with its cobbled effect, was used for parking demarcation lines. Both these products were specifically designed for parking and driveway applications and offer durability, while still being an economical purchase,” he adds.

Technicrete supplied 8 290m2 of the zig-zag grey interlocking pavers, 8 250m2 of terracotta Bond Brick, 657m2 of slate-coloured Bond Slate and 2 000m of Figure 7 kerbs.

The company is renowned for its vast range of building, infrastructure and mining concrete solutions for both the residential and commercial sectors.

SOUTH AFRICAN BUILDER JULY 2023 16 INDUSTRY NEWS

ENGINEERING THE NEXT GENERATION

A lot can be learnt about an organisation where leaders grow other leaders and are willing to engage, encourage and invest in those who want to make a positive impact and contribution. This is the view of Shamenthree Naidoo, learning experience leader at Zutari, whose team has successfully pioneered the Adaptive Leader Programme (ALP) at the leading consulting engineering and infrastructure advisory firm.

The first cohort of ALP candidates kicked off the 18-month programme in August 2021, with the last webinars and in-person sessions concluding in April this year. High-potential candidates were identified and then shortlisted, after which the final list of 23 was announced.

ADAPTIVE LEADERSHIP

“Our aim was to develop adaptive leaders equipped to embrace change, navigate ambiguity and complexity, and harness an increasingly diverse workforce across a networked organisation,” explains Naidoo. The programme was delivered across a blended approach of face-to-face, virtual and remote learning, including both team and individual assignments and assessments. It was co-created with Zutari leaders and in collaboration with a number of renowned global and local leadership development institutions, service providers and external facilitators.

“The ALP aimed to attract future leaders with an owner mindset, a passion for inclusive leadership, building Zutari’s culture and a keen interest in developing an agile leadership approach,” says Blanché Hanstein-Kaber, country manager: Namibia. Candidates from South Africa, the rest of the continent and even as far afield as the Middle East met up at the Zutari head office in Centurion through various stages of the programme.

PUSHING THE LIMITS

Ushantha O’Donnell, a commercial lead at Zutari who empowers engineers to lead projects by troubleshooting complex contractual issues and resolving any disputes (typically between contractors and clients), is a successful ALP graduate. “It’s been an important rung in my career ladder, not just within the organisation, but also in terms of my personal development. It was an intense experience that drew us out of our comfort zones, pushed us to new levels, tested our limits and gave us the tools to become thought leaders,” she says.

“Zutari is a large, living entity. For most of our careers, we’ve been concerned with only the one function in which we operate. Now we can look at the organisation in its entirety and how it functions holistically and perpetuates itself. The programme’s taken away that microscopic lens and given us a macroscopic overview. It’s fostered our trust in the organisation as individuals, knowing that we’re part of something greater. It’s been an incredible journey.”

ALWAYS DEVELOPING, NEVER DEVELOPED

“Leadership development will never be an isolated event, but rather a journey of meaningful connection, deep conversations, rigorous debate and realistic business challenges peppered with fun and much larger-thanlife personalities, as well as an attitude of making a difference for the greater good of the business,” says Naidoo.

JULY 2023 SOUTH AFRICAN BUILDER 17 INDUSTRY NEWS

(Above, from left): Ushantha O’Donnell, commercial lead, Zutari; Shamenthree Naidoo, learning experience leader, Zutari and Blanché Hanstein-Kaber, country manager: Namibia, Zutari.

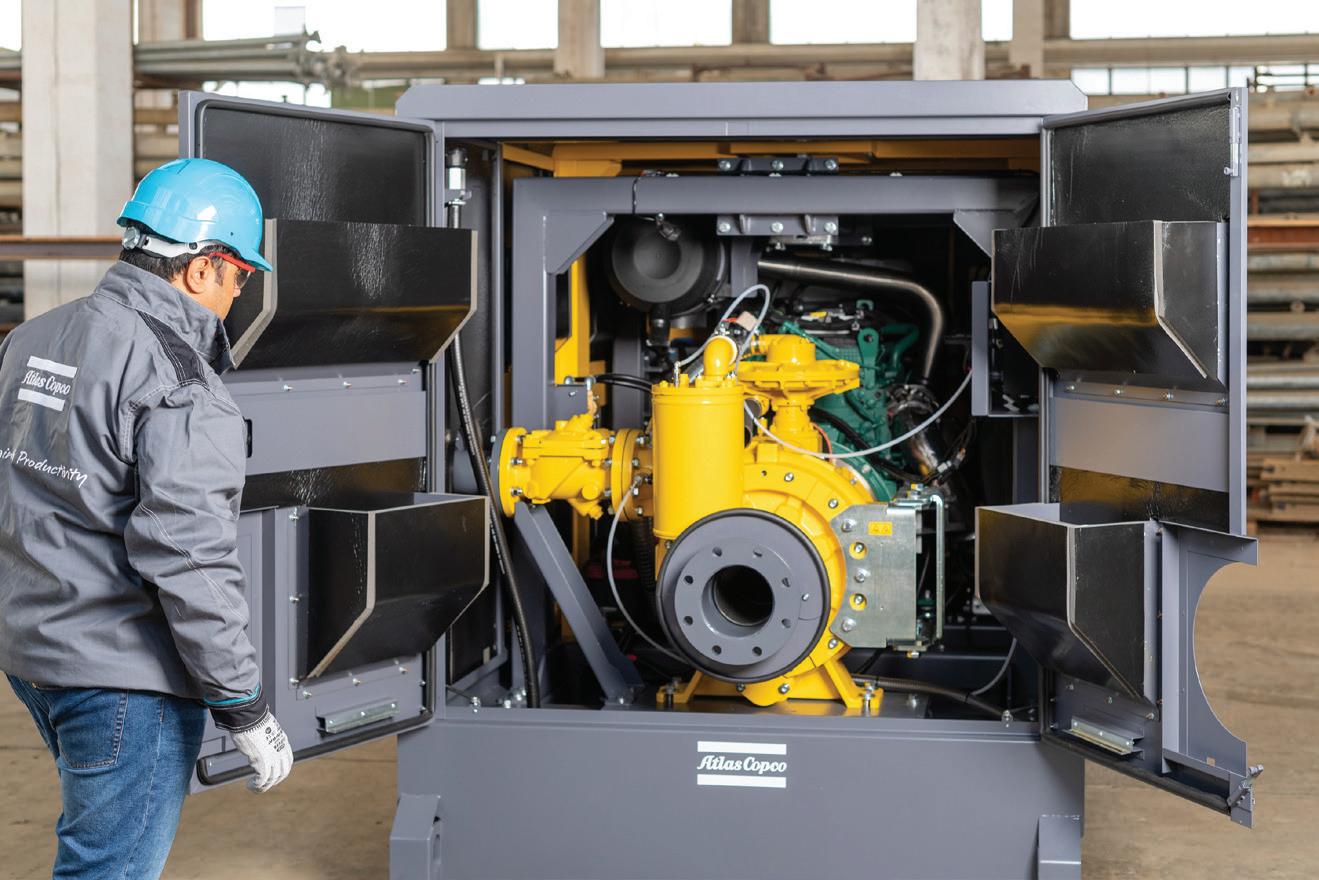

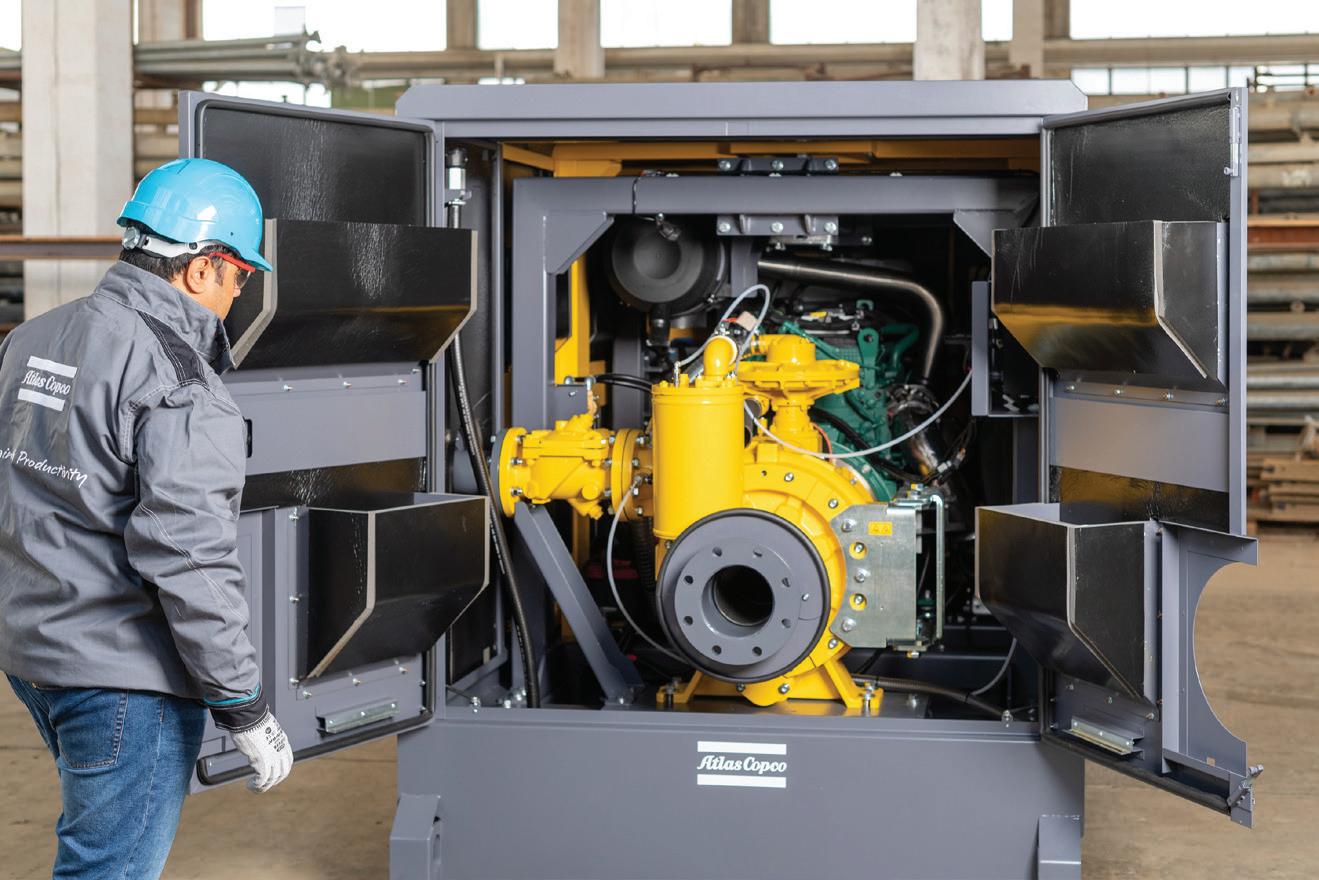

A simple, but brilliant innovation has given Atlas Copco dieseldriven dewatering pump sets –distributed locally by dewatering specialist IPR – the edge over their competitors. With a patented hinged door now a standard feature of Atlas Copco’s PAS and PAC ranges of pumps, a technician can gain access to pump internals within three minutes, with no assistance or specialised lifting equipment.

WHAT HEAVY LIFTING?

A patented hinged door on Atlas Copco’s diesel-driven dewatering pump sets saves users time and trouble, ensuring that there is no longer any excuse to avoid regular inspection and maintenance.

INNOVATIVE ACCESS DOORS FOR DEWATERING PUMPS

“The hinged-door concept has meant a massive improvement in ease of maintenance for users of these end-suction dewatering units,” says Steve du Toit, IPR product manager for Atlas Copco. “It reduces the downtime required for inspection and servicing of Atlas Copco’s PAS and PAC pumps, as it requires none of the traditional equipment that was normally involved in safely lifting and moving large pump covers.”

An individual technician can now conduct inspections and main -

tenance on their own – a job that previously required a team with appropriate heavy lifting equipment to open and handle the end-suction cover. Depending on the size of the pump, it also required certain certified rigging equipment and a mobile crane or forklift.

“With the hinged door, you need none of these items,” explains Du Toit. “The technician simply

SOUTH AFRICAN BUILDER JULY 2023 18 INDUSTRY NEWS

(Above): With a patented hinged door now a standard feature of Atlas Copco’s PAS and PAC ranges of pumps, a technician can gain access to pump internals within three minutes.

loosens the bolts on the cover and swings it open on the hinge, gaining access to the impeller within as little as three minutes.”

SAFETY ADVANTAGE

This makes the feature very useful in applications varying from mining to agriculture. In mining, he says, the strict safety compliance requirements make it essential to use the proper lifting equipment for heavy pump end-suction covers. Where pumps are used in the agricultural context, it is often difficult to get the required lifting equipment into the remote locations where pumps may be operating.

“Quick and easy access to the wear plates, the impeller and the mechanical seal is particularly important in applications where the pump’s expected to run continuously and mustn’t be stopped for any length of time,” says Du Toit. “The patented hinged door drastically reduces the inspection time so that it can be returned to work much more quickly.”

MARKET WELCOME

South Africa’s market response to date has been enthusiastic, he adds. Perhaps the greatest

contribution of the hinged door innovation is that it allows users to check and service pumps regularly, whereas it was previously such an arduous task that it was often simply avoided.

“Of course, this regular maintenance has a positive long-term impact on the pump’s performance, reliability and lifespan,” he says. “By

facilitating frequent inspections, the hinged door can also benefit the user by lowering their total cost of ownership because they don’t have to replace pumps prematurely.”

“AN INDIVIDUAL TECHNICIAN CAN NOW CONDUCT INSPECTIONS AND MAINTENANCE ON THEIR OWN.”

JULY 2023 SOUTH AFRICAN BUILDER 19 INDUSTRY NEWS

(Above): A patented hinged door on Atlas Copco’s diesel-driven dewatering pump sets saves users time and trouble.

(Below, from left): The simple, but brilliant hinged door concept has meant a massive improvement in ease of maintenance for users of these endsuction dewatering units. By facilitating frequent inspections, the hinged door can also benefit the user by lowering their total cost of ownership, since they do not need to replace pumps prematurely.

HOW WEG VSD TECHNOLOGY CAN HELP DEAL WITH LOAD-SHEDDING

There is barely a South African industry sector that does not rely heavily on electric motors and is deeply affected by load-shedding. Zest WEG’s Pieter de Villiers explains how variable speed drives (VSDs) can be used to bridge the gap between grid electricity supply and back-up power during load-shedding.

“Any industrial operation that relies on electric motors will face severe challenges to its continuous workflow when load-shedding strikes,” says De Villiers, the Gqeberha branch manager for Zest WEG. “Much of the disruption is related to the process of starting machinery up again after a power loss, which must often be conducted as a series of sequential actions that an operator has to oversee and implement.”

AUTOMATED START-UP SEQUENCES

What many motor users are not aware of is the usefulness of WEG VSDs in automating and controlling this start-up, explains De Villiers. WEG VSDs can be programmed to initiate a sequence of actions so that this does not have to be done manually by the operator. A simple example is when water is being pumped through pipelines which drain out during load-shedding. In most cases, the pumps cannot sim-

ply be started up again at full speed in a “dry” condition without the risk of cavitation and other damage.

“In cases like this, the WEG VSD can be programmed to start the pump at a lower speed until the pipeline’s full of water, after which it can resume full pumping duties,” he says. “Similarly, it’s important for a

NO TRIPPING OUT

He stresses that the full range of WEG VSDs has built-in PLC capability, allowing the drives to be programmed in this way without the need for PLCs to be added to the system. Another function of VSDs that makes them valuable assets in times of load-shedding is preventing equipment from tripping out. This can happen when there is too much “dead time” between grid power turning off and a back-up generator kicking in.

“A common way that the VSD stays live during this dead time is through the stored energy in its capacitors, allowing it to then re-accelerate the motor when the generator kicks in,” explains De Villiers. “It’s also possible to set up the drive to utilise the inertia from the load and therefore power from the motor itself, essentially using the motor briefly as a generator to keep the VSD alive.”

HYBRID SOLUTIONS

siren to be sounded on a mining operation before a conveyor system’s re-activated after the start of load-shedding for safety reasons. The WEG VSD can also be programmed to automate the re-start process and it initiates the siren to warn staff that the conveyor will be running again.”

WEG VSDs also play a useful role when energy-users want to harness renewable energy sources such as solar power. In a hybrid power system where a motor is connected to both the grid and to solar panels, a VSD can utilise the best source to feed the motor. If there is sufficient sunlight, the system will detect the power flowing in from the panels and optimise that power source.

SOUTH AFRICAN BUILDER JULY 2023 20 INDUSTRY NEWS

(Above, from top): A range of WEG VSDs that can prevent equipment from tripping out during loadshedding and a range of WEG VSDs that have built-in PLC capability.

(Above): Pieter de Villiers, Gqeberha branch manager for Zest WEG.

True beauty doesn’t fade with time.

Hydro aluminium garage doors are lightweight, corrosion-resistant and extremely durable, which makes them perfect for coastal areas. They’re also easy to clean and maintain. Available as single or double doors in four attractive colours, Hydro aluminium doors will enhance the kerb appeal of any home. For more info, visit hydrodoors.co.za or call 086 110 2425.

THE PLUMBING INDUSTRY’S IMPACT ON CHOLERA

With the recent outbreak of cholera in several regions of South Africa, awareness of water-borne diseases affecting both urban and rural populations is growing.

The tragic losses of lives have seen the media and most authorities focusing on the important issues of wastewater treatment and the standard of potable water in protecting public health. However, the state of the plumbing industry is no less important and must be included in this national discussion.

Plumbing is crucial to every component of a nation’s critical water infrastructure. From building dams and bulk water supply lines to water treatment plants and wastewater treatment works, plumbing is fundamental.

UNQUALIFIED PLUMBERS A GREATER HEALTH RISK THAN UNQUALIFIED DOCTORS

A potable water treatment plant becomes useless if contamination or major leaks occur prior to reticulation. Wastewater treatment plants become pointless if the bulk delivery of sewerage is regularly interrupted and risk significant damage if poorly installed systems cannot cope with large volumes of rainwater, leading to huge spillages of raw sewage.

Our vital water and wastewater systems must be installed, connected and repaired in very specific ways, using the correct materials to function properly. Qualified plumbers are highly specialised professionals. The

damage to our water networks and the risks to public health posed by unqualified ones can literally be lethal. Available research reveals dangerous levels of noncompliance and a proliferation of unqualified, self-described “plumbers”.

According to the Water Research Commission, in 2006 as much as 60% of all plumbing materials being sold in SA did not comply with legal requirements. Anecdotal evidence suggests that the situation has worsened since then.

THE TOP ISSUES

• Unqualified workmen: Trade & Industrial Policy Strategies conducted research in 2018 which found that of the 126 000 people who identified

their job titles as “plumber”, only an estimated 15 000 were actually qualified.

• Informal operators edging out formal enterprises: In 2019, PEM Consulting found that the plumbing industry was characterised by far more informal than formal activity, with the number of formal enterprises declining every year and the number of informal operators increasing. Most informal enterprises fly, which gives them a competitive advantage, as their costs and commitments to their staff and clients are low.

• In successive surveys by the Institute of Plumbing South Africa (IOPSA) from 2018-2022, the single biggest factor affecting plumbers’ ability to succeed was the activities of informal, unqualified “plumbers”.

• Non-compliant plumbing installations dominate urban homes: Other research by IOPSA found that most municipalities did not have adequate water service by-laws and were unable to adequately control plumbing work being conducted in their jurisdictions. In related research, IOPSA found that as many as 70% of homes in urban areas had noncompliant plumbing installations.

To say that the situation is dire would be a gross understatement. It is little wonder that SA finds itself in the midst of a growing water, sanitation and health crisis.

SOUTH AFRICAN BUILDER JULY 2023 22 ASSOCIATION NEWS

(Above): For plumbing systems to work properly, they must be installed, connected and repaired in particular ways, using the correct materials.

FINDING SOLUTIONS IN THE ABSENCE OF POLITICAL WILL

Unfortunately, the answer to this problem is not straightforward. On the legislative side, various regulations and standards are being worked on. Sadly, however, most of these have been stuck in bureaucratic limbo for years, with little political will driving their completion and implementation. The power to enforce both current and future legislation lies firmly in the hands of local government. As most South Africans know, the majority of municipalities are facing very serious challenges. With the exception of a handful of metros, it is highly doubtful that municipalities have the funds, technical capacity or political impetus to reverse the situation.

A COLLECTIVE SOLUTION

IOPSA, the Plumbing Industry Registration Board (PIRB), SA Women in Plumbing, the Plumbers’ Business Forum and the Building Construction &

Allied Workers’ Union (BCAWU) have come together to present a plan which would assist greatly. Collectively, these organisations represent the vast majority of formal businesses and workers in the plumbing industry. The idea would require qualified plumbers to register with the PIRB and would include the issuing of a

certificate of compliance for all plumbing work.

Regular proactive auditing needs to be conducted on plumbers’ work, ensuring compliance, safety, ethics and recourse for the public. Far from impinging on local authorities’ powers, this system would go a long way towards helping them enforce regulations and protect vital infrastructure and public health. The system has been in operation on a voluntary basis for more than a decade and is working extremely well. Thousands of qualified plumbers are already registered and are subjecting themselves to oversight in the best interests of the industry and public health and safety. What is needed now is the support of government and the broader public.

If urgent action is not taken very soon, we could see the collapse of a critical trade in SA and the risk of further deadly diseases such as cholera. We need to do something now.

ASSOCIATION NEWS

ELTON'S READY MIX CONCRETE 04 BIG 5 CONSTRUCT SOUTHERN AFRICA 22 INTEGRATED IT DEVELOPMENT 44 JUNE 2023 No 1171 Contact Thuli to book your space 011 883 4627 / thuli@isikhova.co.za

“ WASTEWATER TREATMENT PLANTS BECOME POINTLESS IF THE BULK DELIVERY OF SEWERAGE IS REGULARLY INTERRUPTED AND RISK SIGNIFICANT DAMAGE IF POORLY INSTALLED SYSTEMS CANNOT COPE WITH LARGE VOLUMES OF RAINWATER, LEADING TO HUGE SPILLAGES OF RAW SEWAGE.”

Harvey Roofing Products, a division of the Macsteel Group, is the market leader in steel roofing tiles and accessories. Established in 1967, the company provides high-quality products and exceptional services, evolving into one of the most attractive and sturdiest products on the market.

DURABLE STONE-COAT RANGE

Making a huge impact on appearance and longevity, Harvey Roofing uses crushed rocks to coat its stone-coat range. With its superior ability to withstand harsh weather conditions such as the glaring sun, gale-force winds, rain and hail, Harvey has you covered.

BENEFITS OVER TRADITIONAL ROOF TILES

• Eye-catching aesthetics.

• Remarkable strength.

• Weatherproof.

• Highly resistant to ultraviolet rays and extreme weather conditions.

• Minimal maintenance.

• Low lifetime cost.

• Re-roofing solution.

• 20-year warranty.

NEW PRODUCTS ON THE MARKET

As a complement to its flagship stone-coated product, Harvey Thatch Tiles, the company has launched its Greystone and Midnight Black ranges. These superior roof tiles never require painting, as their natural stone coating is fade-resistant and durable, delivering a natural appearance.

For a trustworthy, durable and well-established tile option, look no further than Harvey Tiles.

YOUR QUALITY ROOFING INNOVATORS

Be aware of imitations. If it doesn’t say Harvey Tile, it isn’t a Harvey Tile.

MARKET-LEADING ROOFING TILES AND ACCESSORIES

SOUTH AFRICAN BUILDER JULY 2023 24

For more information,

Tel: +27 11 741 5600 • E-mail: info@hrp.co.za • Website: www.harveyroofingproducts.co.za

SPONSORED ARTICLE

contact Harvey Roofing:

MAJOR MIXED-USE DEVELOPMENTS FROM TUHF

While many construction projects backed by TUHF entail funding a development entrepreneur for a small to medium construction project, that is not always the case. The partnership between TUHF and Concor Construction for funding two and possibly more developments in the Conradie Park precinct in the Western Cape is a fine example of this.

Together, the companies are bringing to life two developments in the broader Conradie Park precinct, billed as one of the Western Cape government’s seven game-changer projects and part of the provincial strategy to redress spatial apartheid planning.

Mark Schonrock, development executive at Concor Construction, explains that the company has an extensive record of developing large-scale developments in South

Kings Blockhouse and Silvermine: TUHF and Concor Construction go big in mixed-use commercial residential developments, opening the doors for alternative workplace models

Africa and has had its eye on constructing a mega-development in the Western Cape for some time. When the vacant land parcel, which the province had been seeking to unlock for about a decade, came on the market five years ago, Concor successfully secured the winning bid.

CONRADIE PARK

The result today is the establishment of Conradie Park, a residentially led mixed-use development encompassing social housing, FLISP housing, open-market residential apartments, commercial and retail developments and even a crèche that currently caters for

65 children, plus two affordable private schools.

Schonrock explains that TUHF is currently providing development finance supporting the establishment of two of these residential blocks – Kings Blockhouse and Silvermine – which are both four-storey apartment blocks for sale to the open market, with 149 apartments and 80 apartments respectively.

When complete in November 2023, Kings Blockhouse will offer

(Below): Conradie Park aerial view.

FEATURE

55 bachelor units (29m²), 57 onebedrooms (42m²) and 37 twobedrooms (55m²). The smaller of the two developments, Silvermine, which is due for completion in August 2023, will boast 31 studio apartments, 45 one-bedrooms and four two-bedrooms, ranging from 29-41m² and 41-53m² respectively.

Together, the buildings will deliver 229 new residential units to families and young professionals in the Conradie Park precinct, with apartments in both blocks being close to 100% sold at present. As will be the case throughout the precinct, there will be fibre wifi available throughout, as well as access to a laundry, a school and a 22 000m² park where visitors and residents can run or walk their dogs. There will also be other services, such as a hairdressing salon and convenience shopping centre.

SUSTAINABILITY

In terms of sustainability, all units have low-flow taps and doubleflush toilets, while lighting is catered for through energyefficient LED technology. In the likely event of power outages, there are generators to power the larger blocks and UPSs for the smaller ones. However, a solar panel solution will be implemented into the buildings further into the Conradie Park development through Concor Construction’s renewable energies division.

Schonrock stresses that since Conradie Park is envisaged as being a multi-functional precinct,

“SINCE CONRADIE PARK IS ENVISAGED AS BEING A MULTIFUNCTIONAL PRECINCT, OPEN TO ALL, THE ALREADY COMPLETED BLOCKS – AS WELL AS KINGS BLOCKHOUSE, SILVERMINE AND FUTURE DEVELOPMENTS – WILL NOT BE RUN IN THE SAME WAY AS EXCLUSIVE GATED COMMUNITIES, FROM WHICH THE CITY OF CAPE TOWN IS MOVING AWAY.”

open to all, the already completed blocks – as well as Kings Blockhouse, Silvermine and future developments – will not be run in the same way as exclusive gated communities, from which the City

of Cape Town is moving away. Rather, security will be achieved through passive monitoring, licence plate recognition cameras and security guards at the precinct’s three access points.

SOUTH AFRICAN BUILDER JULY 2023 26

FEATURE

(Right and below): Conradie Park Kings Blockhouse.

“We kept strategic ground-floor locations for specific retail offerings, so at night when residents are in their units, those retailers will bring in street activity, which builds a sense of security as well,” he adds. With a development of this magnitude, the challenges are equally as broad. In particular, unlocking the potential of Conradie Park (and of any building projects done within the precinct) has required a significant capital outlay to address traffic access, water supply, sewer and bulk electrical reticulation.

SURROUNDING INFRASTRUCTURE UPGRADE

“Before we started on the site, we did a massive bulk infrastructure upgrade to all the surrounding roads. We built new pedestrian bridges and upgraded all the traffic intersections in the area to prepare for the future residential, commercial and retail elements. That was always a concern of the surrounding communities,” explains Schonrock.

Given that when complete, Conradie Park is slated to accommodate around 3 500 permanent residents, traffic from their home to the CBD, work and Cape Town surrounds has been carefully considered in the development rezoning process.

However, Schonrock stresses that that should not be a problem, as Mutual Station is just 400m away and caters to both the northern and the central line. There is also easy access to taxis that leave from the station, along with Golden Arrow buses. Furthermore, Concor Construction is currently in discussions with MyCiti to bring one of its feeder routes closer to the development as soon as possible.

CREATING A COMMUNITY

One of the most noteworthy features of the new developments is not wholly quantifiable, but is no less valuable. Due to the collaboration between TUHF, Concor Construction, the Western Cape provincial government and

national government, a budding community is already beginning to emerge on what was previously an under-utilised, vacant tract of land.

“It’s truly remarkable for TUHF to be involved in a project of this nature in a year when we’re celebrating 20 years of seeing potential where others don’t. The Conradie Park precinct development is a typical example of yet another successful public-private partnership that demonstrates how the private sector can collaborate with developers and government in redeveloping large tracts of land, thereby increasing revenues for the fiscus and stimulating local economic development. The precinct’s testament to the way affordable housing has evolved and we’re proud to be collaborating with Concor on this exciting journey,” says Velda Derrocks, regional manager for the Cape region.

JULY 2023 SOUTH AFRICAN BUILDER 27 FEATURE

(Below): Conradie Park aerial view.

DON’T FLY BLIND WHEN INVESTING IN RENEWABLES FOR BUILDINGS

By Mark Freeman, offer manager, digital buildings: Anglophone Africa at Schneider Electric

The proverbial race is on; organisations are scrambling to get one step ahead of the country’s volatile energy provision by implementing interventions such as solar arrays that will lessen the load and stress and stabilise supply.

It is admirable, but jumping headlong into these projects will see some companies flying too

close to the sun (no pun intended). Before implementing any form of alternative energy resources, companies must gain deep insight into their buildings’ energy consumption and then make educated decisions.

Establishing a society where energy-efficiency remains top of mind is a prevalent and persistent message, and one of the first steps is buildings. Digitisation and visualisation remain two of the key pillars that allow building-owners

SOUTH AFRICAN BUILDER JULY 2023 28 FEATURE

(Below): Energy management systems include complex renewable generation technologies and large-scale battery-type energy storage devices.

“TOGETHER, BMS AND EMS ARE CRITICAL TOOLS IN ENABLING ORGANISATIONS NOT ONLY TO DEFINITIVELY DEVELOP THEIR NEXT INVESTMENT IN SOLAR, FOR EXAMPLE, BUT ALSO TO GAIN VALUABLE INSIGHT INTO HOW THE BUILDING IN ITS CURRENT FORM IS PERFORMING.”

and managers to effectively manage energy consumption.

THE VALUE OF BUILDING MANAGEMENT AND ENERGY MANAGEMENT SYSTEMS

Understanding the importance of building management systems (BMS) and energy management systems (EMS) is critical if organisations want to take the next step in establishing a distributed energy posture (DER) that will not only stabilise energy supply, but also future-proof a significant investment.

The job of a BMS is primarily to manage and control the building systems, especially HVAC, lighting, access control, etc, whereas an EMS provides energy, demand and power quality monitoring.

It is the EMS which can facilitate effective energy visualisation and analytics, providing dashboards and trends for energy consumption at equipment, system, building, campus and portfolio levels which can be used effectively for decision-making.

Together, BMS and EMS are critical tools in enabling organisations not only to definitively develop their next investment in solar, for example, but also to gain valuable insight into how the building in its current form is performing.

LEARNING THE ENERGY BEHAVIOURS

This is an important element that provides organisations with important information about where the building is consuming too much energy and how this, with incremental changes, can be rectified.

For example, HVAC systems use significant amounts of energy to operate. Here, by using the BMS, organisations can customise their HVAC operations to run at certain hours in certain areas of the building. This will not only result in significant savings, but also ensure that the building remains comfortable.

Moreover, by using both BMS and EMS, organisations can accurately assess what their investment will be in renewables, ensuring that they neither over- nor underprovide what the facility requires to run optimally.

OPTIMAL ENERGY USE

Importantly, the BMS also ensures that when buildings move over the

DERs, the facility is managed in a manner that maximises the various resources available at certain times of the day, thus ensuring that organisations get the most out of their investment.

In tandem with an EMS, buildings can run at optimised energyefficiency and also make automated, incremental changes when it is a cloudy day, for example, and the solar array is less effective. Here, the EMS will switch over to the grid more regularly than usual to ensure battery storage is adequately replenished when load-shedding occurs.

Only fools rush in, goes the saying – and particularly so when it comes to implementing renewables. Organisations must ensure that they have the right tools not only to assess and optimise their current posture, but also to optimise their investment for years to come.

JULY 2023 SOUTH AFRICAN BUILDER 29 FEATURE

(Left and below): Building management systems can include smart parking installations all the way to advanced building information modelling technologies, using artificial intelligence and realtime sensors in constant response to usage and event challenges.

TWINSTAR PRECAST: CONCRETE SOLUTIONS FOR ELECTRICAL INSTALLATIONS

South Africa’s highly compromised electricity supply has created a demand for portable and fixed generators and other hybrid solutions to keep our businesses afloat.

Twinstar’s reputation as a master of bespoke precast manufacturing is evidenced by the diversity of its clients, as well as its reputation for standardised bulk products: manhole covers, stormwater grates, transformer boxes and more.

It makes sense to turn to Twinstar when planning the installation of your company’s off-grid energy solution, from generators of all sizes to any associated structures your installation might require.

ELECTRICAL STRUCTURES FOR ALL ENTERPRISES

Twinstar Precast manufactures a wide range of plinths for electrical reticulation and other electrical installations. Of great importance to businesses today, it is expert at casting plinths for generators and other electrical equipment.

Standard mini-sub and kiosk plinths are a solid and trusted Twinstar product line, but the company is equally at home

casting non-standard plinths to suit any other kiosk or mini-sub.

Apart from plinths, Twinstar also supplies cable covers slabs (also known as trench covers or cable protection slabs). Cable markers are available as well, while electrical joint boxes and distribution boxes are likewise among its range of electrical products.

In addition, a kiosk protection box is available which is used by local municipalities to protect prepaid meter boxes from vandalism and theft.

CABLE COVER SLABS

Cable cover slabs are available in standard Eskom sizes. Any other size is available on request. All cable cover slabs are cast with chamfered edges to minimise chips on sharp edges.

CUSTOM-MADE ENCLOSURES

Custom-made enclosures are available to protect pre-paid electricity cabins or any other cabin at high risk of tampering and theft.

PRECAST POLYMER

Polymer concrete products contain

no metal components, thus eliminating the risk of theft.

Logos and identification marks or letters can be added to polymer products for easy identification of services (eg “GAS” or “FIBRE”) and can also be used to identify the owner of the specific service.

MARKETS AND RANGE

“We make our own moulds and have one truck with an excellent crane that enables us to deliver large concrete products in segments, to the great advantage of our clients. By keeping weight within the regulated range, we save clients thousands of rands in transport costs. We guide the placement and fitting of the product and will be on site, if necessary,” says the company.

All practical aspects are considered to ensure that the product meets the client’s particular requirements.

Twinstars manufacturing facility is situated in Olifantsfontein, Gauteng and delivers to anywhere in SA. Its crane-mounted trucks can offload products directly on site and can also help place slabs during installation.

SPONSORED FEATURE SOUTH AFRICAN BUILDER JULY 2023 30

EXPANDING

EASTGATE SHOPPING CENTRE’S

SOLAR CAPACITY

With its depth of expertise in the renewable energy sector, leading South African contractor Concor is tackling an exciting solar power expansion for Liberty Two Degrees at its popular Eastgate Shopping Centre in Johannesburg. In addition to ensuring quality and safety in construction, Concor will also be phasing its workflow to minimise disruption to the centre’s tenants and shoppers.

RENEWABLE ENERGY

As South African businesses embrace the power of renewable energy, leading black-owned contractor Concor is busy on another solar project that will contribute to a more sustainable future.

The project will add another 5,74MW (4,75MWac) to the already existing 1MW solar power plant at the Eastgate Shopping Centre. This project aligns with Liberty 2 Degrees’ execution of its netzero 2030 targets, reducing energy reliance from the grid in line with its focus on creating Good and Smart Spaces. According to Martin Muller, contract manager at Con -

cor, this second-phase project will comprise approximately 550 tons of structural steel roof constructed on concrete plinths on the upper parking area of the centre.

STRUCTURED RENEWABLES

Concor has executed similar projects in both the retail and commercial office environment, as well as contributing significantly to pioneering wind energy projects around the

country. This latest PV project commenced in February 2023 and is scheduled for completion by the end of January 2024.

“We’ll be constructing concrete columns and steelwork to hold the photovoltaic panels on the upper parking level, over an area of 31 000m²,” says Muller. “The panels will also create shade for shoppers parking on this level.”

MITIGATING SHOPPER DISRUPTION

The project requires the existing column heads that support the

JULY 2023 SOUTH AFRICAN BUILDER 31 FEATURE

(Above): Leading South African contractor Concor is tackling an exciting solar power expansion for Liberty Two Degrees at its popular Eastgate Shopping Centre in Johannesburg.

“CONCOR HAS EXECUTED SIMILAR PROJECTS IN BOTH THE RETAIL AND COMMERCIAL OFFICE ENVIRONMENT, AS WELL AS CONTRIBUTING SIGNIFICANTLY TO PIONEERING WIND ENERGY PROJECTS AROUND THE COUNTRY.”

parking deck to be exposed, he explains. This will allow Concor to drill and dowel into the column heads, so that starter bars can be inserted for the stub columns to be poured – ensuring that the loads are spread onto the main columns below. Special attention is being focused on mitigating any disruption to the shopping centre’s tenants and shoppers.

“A full mitigation kit will also be applied to keep water out during construction and minimise any impact on the live shopping area below,” he says.

The concrete stub columns, most of which will be 2m high, will be constructed from 30MPa

ready-mix concrete. To enhance sustainability, this Green Starrated concrete will use 30% fly-ash to reduce the concrete’s embodied energy. The steelwork in the project will consume some 600 tons of structural steel.

“CONCOR’S

TEAM WILL CO-ORDINATE EIGHT SUBCONTRACTORS ON SITE, WHERE THE WORKFORCE WILL NUMBER ABOUT 40 AT THE PROJECT PEAK.”

Concor’s experienced management team will coordinate eight sub-contractors on site, where the workforce will number about 40 at the project peak. Workflow will also be carefully planned around critical periods, so that the year’s busy shopping times are not unduly affected.

SOUTH AFRICAN BUILDER JULY 2023 32 FEATURE

(Above): Specialised concrete columns are used to carry the load of the PV panel structures.

(Above): Careful planning during upgrades is essential to mitigate interruptions and inconveniences to shoppers and traders alike.

EXPERIENCED MANAGEMENT

SPIRES SHOOT SKYWARDS AS MSIKABA BRIDGE ADVANCES

The pylon spires of South Africa’s Msikaba Bridge mega-project are on their way up, soon to tower almost 130m high on either side of the near-200m-deep river gorge.

For Laurence Savage, Concor’s project director on this contract, this momentous phase will reveal the sheer grace of the bridge design and the awesome scale of the development. The bridge forms part of the N2 Wild Coast project of the SA National Roads Agency Ltd (SANRAL) and is being constructed by the CME JV, a partnership between Concor and MECSA, both 100% blackowned Grade 9CE South African construction companies.

ICONIC STRUCTURES

Currently being slip-formed from the bifurcated legs of the pylons, each of the spires extends 95m

from the bifurcation to the top of each pylon – taking the height of the bridge pylons to 128m.

“The inverted Y-shape of the concrete pylons is strikingly elegant and will become a hallmark of this iconic structure, diverging from the foundation legs up towards the bifurcation and symmetrically converging to the top of the spire,” says Savage. “This is the largest cable-stayed bridge to be built in SA and probably one of the most complex engineering bridge projects yet executed in Africa.”

In this design, each pylon rests on two inclined legs that meet 21m from the start of the bifurcation, which extends a full 11m. At 32m, the first section of the spire – starting with a diameter of 6m – is uninterrupted for 55,7m and comprises 14 slipform lifts. Then begins the inclusion of 17 anchor inserts over the next 35m of the spire, which reaches a height of

JULY 2023 SOUTH AFRICAN BUILDER 33

PROJECT

(Left): Like the legs of the bridge pylon, the reinforced concrete spire is hollow to reduce weight and is formed in a tubular design, improving its strength-to-weight ratio.

(Above): Each spire will extend 95m from the bifurcation to the top of each pylon.

PROJECT

124m and will have converged to a 4m diameter. These anchor inserts accommodate the 17 cables that run from the anchor blocks located behind each pylon to the spire and then down to the 580m-long bridge deck.

ADVANCED JACKING SYSTEM

“To accomplish the lifts, we’re using a jacking system for the formwork shutters, with eight jacks around the circumference of the spire,” explains Savage. “Each lift is 3,6m conducted at intervals of about two weeks per lift and we’re making steady progress, with quality and safety being paramount.”

SPECIALISED STAIR SYSTEM

The work is accessed using a specialised stair system, with one set of access stairs from ground level to the top of the bifurcation and a second stairwell to follow the shutter system up the spire. The formwork system comprises three decks that trail below each other;

the interlinked decks lift together as the shutters are jacked up.

“The depth of the gorge – at around 197m – means that no work on the bridge deck itself can be done from ground level,” says Savage. “Everything has to be done suspended from these two pylons, one on the south side of

“DESPITE THE HIGH-RISK SITE, WHICH HAS INCLUDED EXCAVATIONS OF UP TO 17M FOR THE PYLON ANCHORS, THE SITE TEAM RECENTLY ACHIEVED 3,5 MILLION LOST TIME INJURY-FREE HOURS.”

the gorge and the other on the north side of the river.”

Like the leg of the bridge pylon, the reinforced concrete spire – with walls 1m thick – is hollow to reduce weight and is formed in a tubular design that significantly improves its strength-to-weight ratio. The reinforcing bar used in the spire includes 12-16mm bar as lacing, with primary bars of 30mm and 40mm bar employed in high densities to carry the significant loads.

SOUTH AFRICAN BUILDER JULY 2023 34

(Below): With construction of the pylon spires underway at the Msikaba Bridge project, the scale of the development is apparent.

(Above): The pylon lifts are accomplished using a jacking system for the formwork shutters, with eight jacks around the circumference of the spire.

“Once the stays and bridge are in place, the load on each pylon will amount to about 7 000 tons,” adds Savage. The pylons are well advanced, with about half of the planned concrete volumes already poured by the top of bifurcation. After the last anchor insert, a 4m parapet will be constructed around the very top of the pylon spire. Access to the inside of the pylon will be restricted to engineering inspections and maintenance.

PRECISION, PRECISION, PRECISION

“Indicative of the precision engineering being employed on this project is the number of activities that must take place at the same time – in a confined area,” explains Savage. “By the time we’ve completed the fifth anchor insert, for instance, we’ll have begun the launching of the first deck segment, followed shortly by the second and third ones. While these activities are taking place, the spire and inserts will continue to be erected and cast.”

He emphasises the intense focus on safety that has characterised the project, in line with Concor’s zero-harm policy and protocols. Despite the high-risk site, which has included excavations of up to 17m for the pylon anchors, the site team recently achieved 3,5 million lost time injury-free hours. Preparation for working at heights is a particular priority, with specialised training mandatory for these activities.

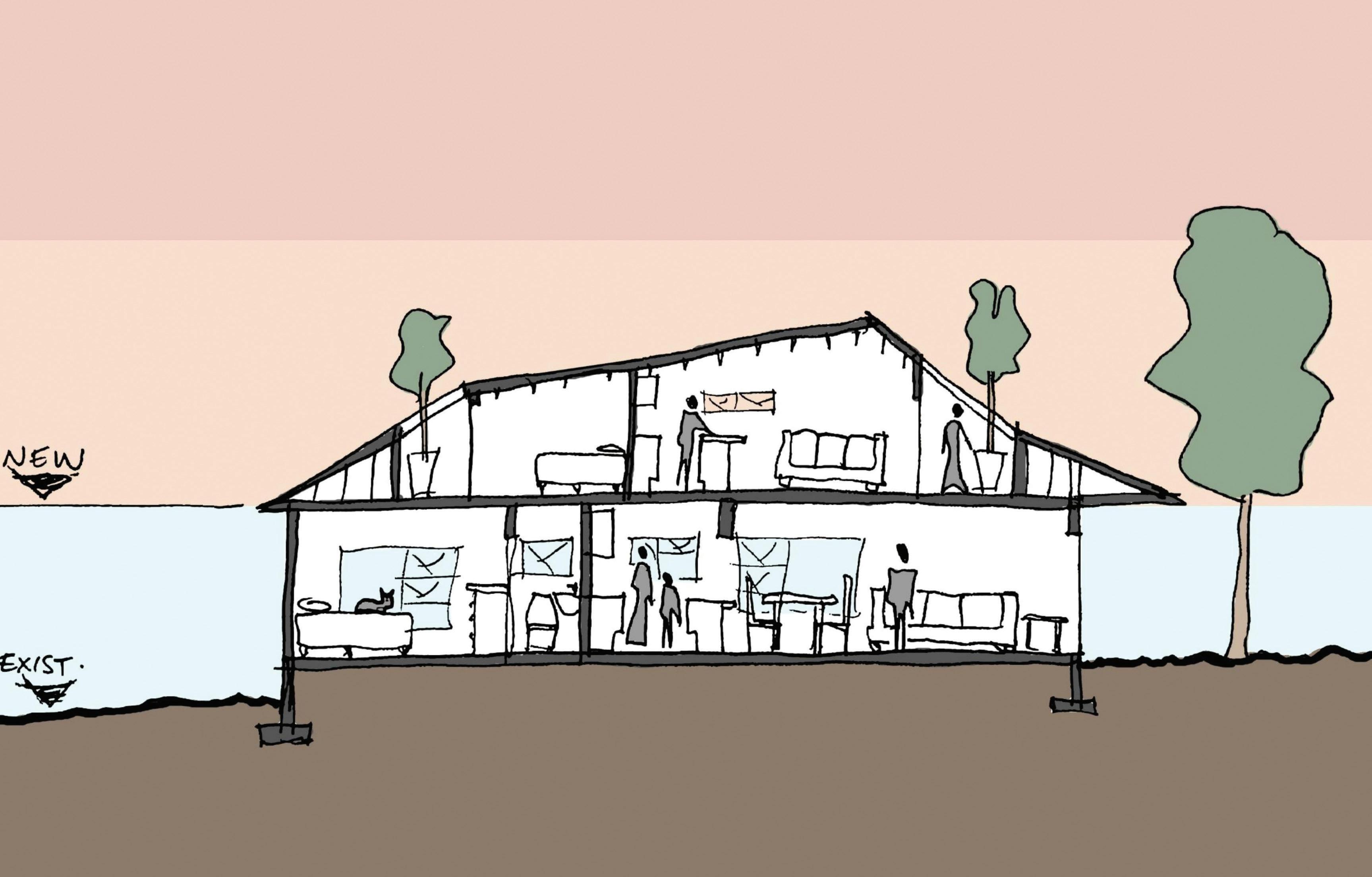

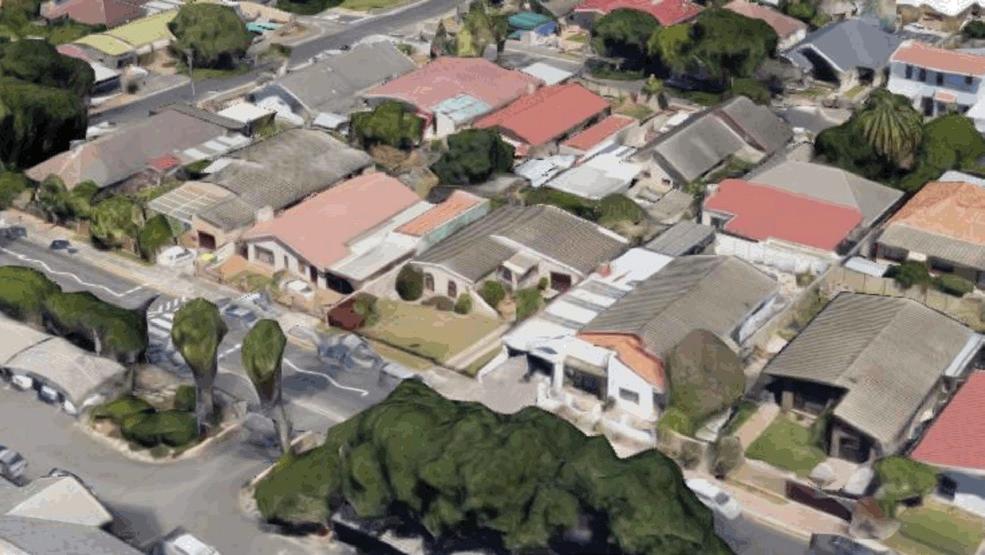

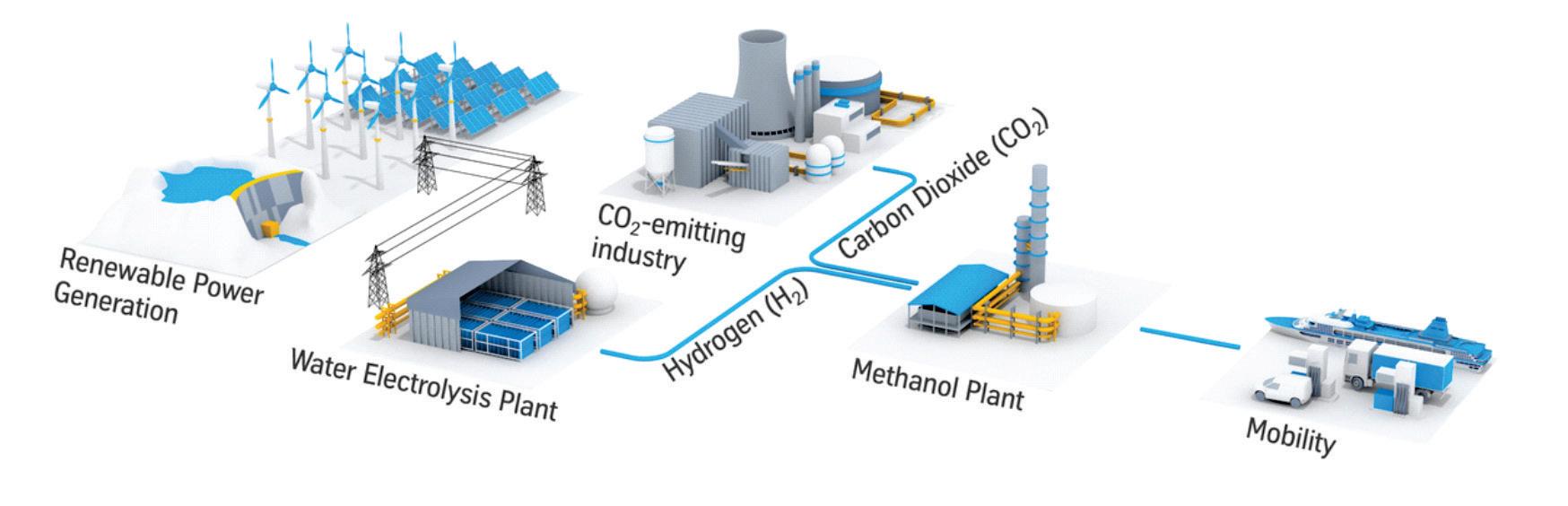

“This is all part of a training regime around safety, where we’re continuously conducting risk