QUALITY CONCRETE IN ABUNDANCE – ON SITE, ON TIME, EVERY TIME 04 LABOUR IN REMOTE SITES 28 DECARBONISING YOUR BUSINESS 36

FEBRUARY 2023 | No 1167

Extensive range of spare parts to keep telehandlers going in construction and agriculture. ONE SCAN AWAY PARTS FOR TELEHANDLERS WWW.TVH.COM/EN-ZA/TELEHANDLER TVH PARTS SOUTH AFRICA (PTY) LTD • HEAD OFFICE JOHANNESBURG 90 Electron Avenue • Isando • Kempton Park 1600 • South Africa • GPS S -26.130318, E 28.214541 T +27 11 281 2700 • F +27 11 392 3599 / +27 11 974 9845 • sales.southafrica@tvh.com • www.tvh.com DURBAN 17 Kyalami Road Westmead Pinetown 3600 T +27 31 100 0760 F +27 31 700 6191 LICHTENBURG Shop 1 103 Scholtz Street Lichtenburg 2740 T +27 18 632 6192/6092 F +27 18 632 6108 PORT ELIZABETH 220 Commercial Road Sidwell Port Elizabeth 6001 T +27 41 453 1404/8 F +27 41 453 1409 RICHARDS BAY Unit 3 Ferro Park 1 Ferro Gang Road • Alton Richards Bay 3900 T +27 35 751 1001 F +27 86 530 3145 CAPE TOWN 4 Buchan Street Stikland Industrial Bellville, Cape Town T +27 21 988 2432 F +27 21 988 9127

South African Builder is the official journal of Master Builders South Africa, established in 1923. The opinions expressed by contributors are not necessarily those of Master Builders South Africa. SA Builder is a registered trademark of Master Builders South Africa. Any use of this trademark without the express and written approval of Master Builders South Africa is prohibited. No material contained herein may be reproduced in whole or in part without the prior written permission of the publisher. SA Builder © 2023. All rights reserved.

PUBLISHER Isikhova Media (Pty) Ltd

10th Floor, Metal Box, 25 Owl Street, Milpark, Johannesburg, South Africa

Tel: +27 11 883 4627

www.sabuilder.co.za /www.isikhova.co.za

CONTRIBUTIONS

Master Builders South Africa

Tel: +27 11 205 9000

E-mail: editor@sabuilder.co.za

www.masterbuilders.org.za

Free download available on: www.sabuilder.co.za

Twitter: @Builders_SA | Facebook: @SouthAfricanBuilder

CONTENTS AND CREDITS

FEATURES

26 Plan A: Powering dreams of modular homes

28 Construction labour in remote areas

31 SAICE’s Infrastructure Report Card

ASSOCIATIONS

34 ECA SA Presidential Awards

TECHNICAL

36 Concrete steps towards decarbonisation

BUILDER’S VIEW

38 Breathing new life into small towns

PRODUCTS

41 High-performance adhesives can assist with household savings

QUICKBUILD

42 Home-owners and solar panels: What you need to know

GLOBAL VIEW

44 Tearing it up as a global contractor

CAPTAINS OF CONSTRUCTION

47 Meet Joe Brinkmann

Editor-in-chief: Jason Aarons

E-mail: jason@isikhova.co.za

Editor: Nicholas McDiarmid

E-mail: nicholas@isikhova.co.za

Director: Brand Strategy: Jenny Justus

Tel: 083 450 6052

E-mail: jenny@isikhova.co.za

Managing Director: Imraan Mahomed

E-mail: imraan@isikhova.co.za

Creative Director: Joanne Brook

E-mail: joanne@isikhova.co.za

Operations Director: Thuli Majola

E-mail: thuli@isikhova.co.za

Copy Editor: Anne Phillips

Advertising sales: Tel: +27 11 883 4627 Mobile: 072 383 3203 / 083 450 6052

MESSAGE FROM THE EDITOR 02 A future of contradictions COVER STORY 04 SA Nuclear facility scales new heights in concrete mastery MBSA NEWS 08 Workplace, environment, health and hygiene 10 The importance of employment equity compliance INDUSTRY NEWS 12 Building quality, health, safety and environmental management cultures 14 Specialty chemical plant with 100% renewable power 16 SA cement and concrete industry faces huge challenges

Valuable legacy of concrete central to training programme 18 Greenovate Awards 2022

Quality of mortar mix in sustainability BUILDING BUSINESS

Digital systems in employee management

17

22

24

FEBRUARY 2023 SOUTH AFRICAN BUILDER 01

CONTENTS

28 08 44

42

savvy thinkers smart doers together people Proud Media Partner

A FUTURE OF CONTRADICTIONS

Last year, South Africa impressed the world by being the first developing country to present an innovative and viable comprehensive investment plan for the Just Energy Transition at COP27. This much-lauded paper was presented by André Ruyter, then CEO of Eskom, who has since stepped down, having been accused by Minister of Mineral Resources & Energy Gwede Mantashe of trying to overthrow the government.

Much like the well thought-out Strategic Infrastructure Projects which have still failed to materialise into jobs and economic benefits in our post-Covid-19 recovery, what looks great on paper is frequently contradicted by the actions of those in power. With Eskom starting this year with 11 generators breaking down and punishing load-shedding levels for the foreseeable future, we can look forward to living in a state of uncertain and conflicting opportunities and outcomes.

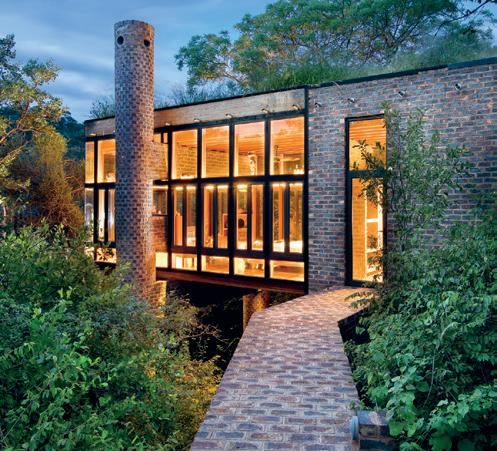

In the building industry, residential housing and mixed-use developments are seeing much of the action this year. The Department of Human Settlements says that progress is being made on the Mooikloof Mega-City development in Gauteng, with the first residential apartments in the project being ready for occupation in 2023.

The development has a total project value of over R84 billion and is one of the 62 Strategic Integrated Projects gazetted in 2020. It is being developed in phases, with the first phase focused on residential developments with a scope for up to 50 000 sectional title units. Once completed, the new city will also feature schools, shops and offices, all constructed in line with green building principles.

According to the department, the first phase of the project is well underway and 546 units are due for completion in September 2023. The mega-city is a public-private collaboration with developer Balwin Properties.

We also see the launch of SA’s first and only multisector residential investment and development

conference and exhibition in response to the country’s massive housing shortage and high urbanisation rate. It is estimated that 71% of South Africans will soon live in urban areas and with the housing shortage already at alarming rates, this is a guaranteed growth area.

THREATS IDENTIFIED

The sustainability of SA’s cement and concrete industry is a bellwether for construction as a whole. It faces significant threats, including economic decline, cheap imports, rising input costs and the crisis in the industry caused by the activities of the construction mafia and a lack of major projects.

The latter has been exacerbated by government’s planned massive expenditure on infrastructure to kick-start the economy post-Covid-19 largely failing to materialise, putting about 35 000 local jobs and billions of rands’ investments in the cement industry’s value chain in jeopardy. The significance of these issues has shaped the Master Builders Association SA’s strategy for 2023 and we will track progress on all these fronts.

GREEN FINANCING

Green financing is an area worth exploring for all involved in the business of building. Nedbank is looking at offering green bonds for residential homes, as well as commercial developers, and some of the other banks are following suit.

Green financing goes hand in hand with Excellence in Design for Greater Efficiencies certification. Residential buildings that attain this certification can qualify for financing through a green bond, which has a lower interest rate and is thus more affordable. This is becoming an attractive proposition for capturing a well-populated residential market.

In an uncertain environment, what is indeed certain is that construction and all its allied industries have a crucial role to play in rejuvenating SA’s economy and enabling its future. This, at least, is a supremely positive indicator for the year ahead.

Nicholas McDiarmid: editor

SOUTH AFRICAN BUILDER FEBRUARY 2023 02 EDITOR'S NOTE

Corner North Rand & Trichardt Road, Bartlett AH, Boksburg BOKSBURG Corner Fourways Boulevard & Roos Street Fourways FOURWAYS Corner Blackrock Street & Stoneridge Drive, Greenstone Park Ext 2, Edenvale GREENSTONE Corner Hendrik Potgieter & Cascades Road, Little Falls, Roodepoort LITTLE FALLS shop online at www.leroymerlin.co.za leroymerlinsa1 leroymerlin.southafrica leroymerlinsa Venezia satin 81480105 Palomino satin 81480106 Verona satin 81480099 Verona satin dark 81480100 Rhodium satin 81480101 Roma satin 81480103 Semi Face Bricks - R1449 per stack of 500 Bonding agent PLASTERGRIP 20l 81470303 R849 GET 5L FREE 81470303 Brickforce 2.8mm x 75mm x 20m NHBRC 81415462 Also available in 2.8mm x 150mm x 20m NHBRC 81415456 | R48.90 R48.90 Valid from 3 - 28 February 2023. Terms and conditions apply. We’ve got all the building materials you need to complete your contracting jobs without hassle. Cement KBC 32.5N 50kg 81412024 R86.99

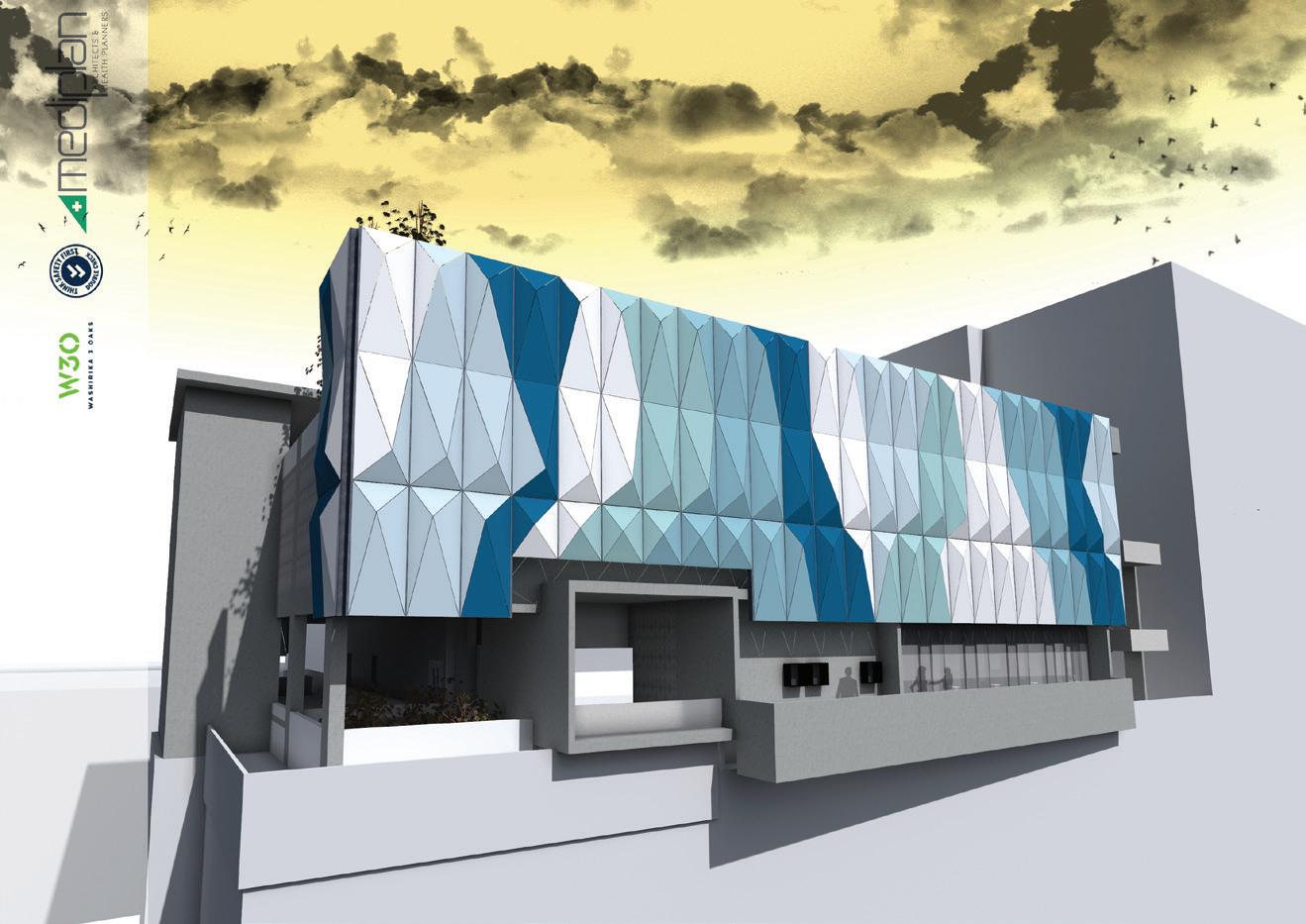

The intricate story behind the construction of Nuclear Medicine Research Infrastructure (NuMeRI) – a medical imaging facility dedicated to drug development and clinical research at the Steve Biko Academic Hospital in Tshwane, Gauteng – is characterised by supreme levels of professional and technical skills of which South Africa can be truly proud. This is vitally important at a time of deep national uncertainty – an inspiring reminder of our country’s reservoirs of expertise and experience that continue to surprise not only us, but the world.

The facility’s importance to research and development of nuclear technologies in medicine and bioscience is highly exponential, scaling up availability of radiation treatment provincially and nationally, while consolidating expertise and opening up a new world of initiatives for medical innovation in SA.

All structural concrete work was completed in December 2022, with full commissioning scheduled for mid-August this year. As an addition of a new radiotherapy bunker and linear accelerator machine to the existing oncology wing at the hospital, it will be equipped with a cyclotron, a GMP radio-pharmacy production facility and state-of-the-art pre-clinical imaging modalities. Construction began in 2020 in Tshwane with a budget of R300 million.

THE RIGHT TEAM

Being a nuclear facility, the project had a number of intrinsic requirements, primarily to be

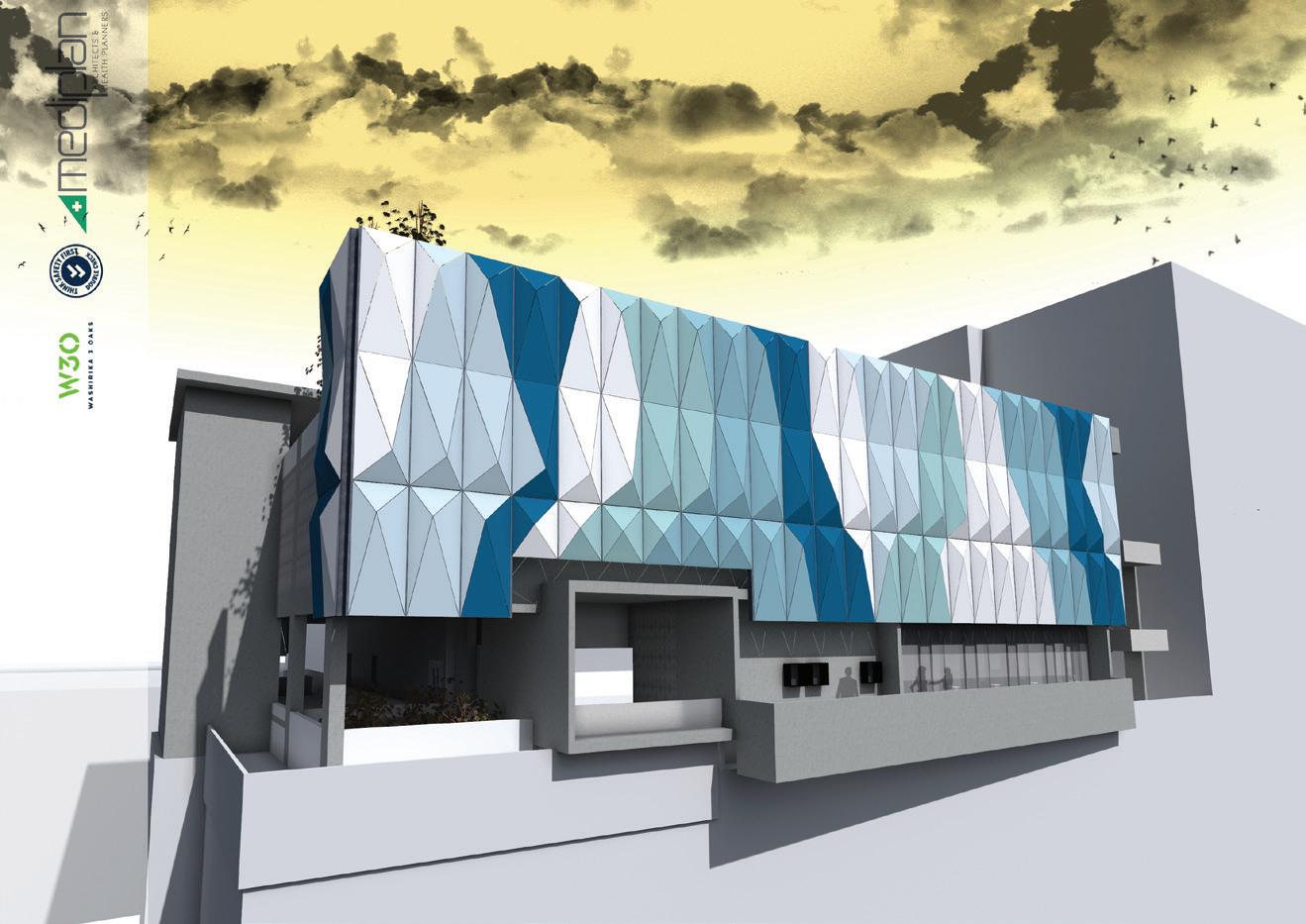

STEVE BIKO HOSPITAL’S

GROUNDBREAKING NUCLEAR FACILITY

New heights in construction collaboration

safe and to comply with the intricate regulations that govern SA’s nuclear industry. Washirika 3 Oaks (W3O) was appointed as the turnkey contractor for the project after a competitive bid process, and was joined by other leaders in their fields, including Mediplan Designs, a healthcare facility specialist architectural design practice with direct knowledge and experience acquired during

its work as lead architect on the Steve Biko Academic Hospital itself, as well as as one of the few practices in the country specialising in nuclear medicine and general healthcare. DLV Engineers brought its combined structural engineering expertise and considerable experience in concrete bunker engineering.

Key to the success of the building, which demands the complete

SOUTH AFRICAN BUILDER FEBRUARY 2023 04 SPONSORED EDITORIAL

containment of radiation, was the ability to deliver, pour and place the concrete, as per the structural engineer’s specifications. Quantum Concrete was appointed to source, mix, deliver and pour the concrete, while Formacon was appointed to do the formwork.

ROOFTOP NUCLEAR BUNKERS

One of the defining aspects of the two bunkers comprising the new NuMeRI facility is its unexpected rooftop position – an exception to the usual underground placement of nuclear bunkers.

Lead designer, LW van der Merwe of Mediplan Designs, explains how this unusual design came about.

“Being the architects of the original hospital, we had the original design on hand. We proposed using the roof of a four-floor wing because of the numerous proximal benefits to the facility’s functioning and because we knew it was structurally feasible.”

Originally designed to be 10 floors, the wing in question

could not be completed during the original build due to budget constraints. By that stage, the existing structure was capable of bearing a 10-story load. In essence, placing the two bunkers on top of the four storeys was predesigned. “This positioned the

new facility closer to the hospital’s nuclear medicine department, benefitting researchers, patients and m edical personnel,” says Van der Merwe.

This design made sense to the clients – who are the University of Pretoria and the Department of Health, under the name NuMeRI –as did working with the hospital’s original engineering firm, DLV Engineers. That said, even Jan Wesseloo, DLV Engineers’ senior structural engineer, was initially sceptical about the roof design, but the combined teams’ structural engineering expertise and prior experience with concrete bunker design soon allayed any doubts.

The building is split over three storeys, with animal testing, drug development and clinical trials on separate floors. Level four is an animal testing facility and is specifically for cancer treatment.

THE NUCLEUS OF THE PROJECT

The extreme toxicity of radiation means there can be no risk of leakage at all. While lead cladding is one way of achieving this, Wesseloo explains that the best solution was to use concrete: “The walls and floors had to be 2,5-3m wide respectively and completely devoid of even the smallest of cracks. This can only be achieved by eliminating shrinkage during the concrete’s curing process. Including a very high proportion of slag in the concrete mix-design prolongs the curing time to about three months.

“Because of the massive weight of these concrete structures, we

FEBRUARY 2023 SOUTH AFRICAN BUILDER 05 SPONSORED EDITORIAL

(Above): The unusual decision to build the facility on the rooftop level was informed by the architect's work on the original Steve Biko Academic Hospital.

(Above): The W3O team: Jacques Nel (Project Manager), Hans Bodemer (Commercial Director), Herman Labuschagne (Contracts Manager) and Danie Strooh (Construction Manager) pictured here at the NuMeRI bunker.

SPONSORED EDITORIAL

deployed a sophisticated beam system, capable of spreading the immense load,” Wesseloo points out. “Four beams, each 4,5m deep, span the perimeter, reinforced by two additional cross-beams.”

Working with DLV Engineers’ concrete specifications, sourcing the right concrete from Afrisam, co-ordinating the mix and its delivery from that company – and, of course, ensuring that all the formwork was correctly in place –came together on the days of the big pours.

ELIMINATING STRAIGHT LINES AND CRACKS

Lourens de Beer and Calvin Billett of Quantum Concrete were responsible for ensuring that the mix and transportation of the concrete were co-ordinated within a very tight schedule.

“The majority of SA’s fly-ash is unclassified, which makes sourcing it a challenge; the mix for this project is extremely exacting and

everything hinges on getting it right. It was really a case of co-ordinating the fly-ash within workable proximities of the project,” says De Beer.

“In conjunction with the consultants, a design strength of 30 megapascal [MPa] at 56 days was agreed upon for the bunkers, which had to be crackfree,”explains Billett. “The strength achieved with a concrete mix designed with 65% fly-ash is far greater in real terms, relative to the percentage difference in a mix of up to 50% fly-ash.” This non-proportional leap in strength achieved by the 65% fly-ash is considerably more profound than any of the strengthening agents and continues to gain in strength in perpetuity.

“It was this property of the mix that gave the project team its confidence in using such a high proportion of fly-ash,” notes Billett. “Other precautions in the concrete mix design included a low-demand

dolomitic aggregate and two Mapei admixtures.”

A buffer surcharge of high-quality ash was ordered in advance to ensure provision of the classified fly-ash. “The heat generated by cement is proportional to the volumes involved, which is why the sourcing of finer, more reactive classified ash was important,” explains Billett, “as was pouring the concrete early in the day, before the midday heat set in.”

“Getting this concrete mix perfect is at the heart of the construction process. Yes, the design of the structure is also pivotal to the containment of the radiation, but any loss in concrete quality on the day of the pour or any deviations from the anticipated curing process could mean either throwing the project off course, or even require tearing down an entire structure and building it from scratch,” says De Beer. The testing of the concrete on site and over the weeks of its curing were the true landmarks of the build’s success.

Results obtained: seven days –15MPa >> 28 days – 20MPa >> 56 days – over 30MPa (exceeding the required result) >> 56 days onwards – MPa increases ad infinitum

TRAPPING RADIATION WITH MAZES

Van der Merwe points out that each wall and the floor had to be single pours. In addition, the design of each connection point

SOUTH AFRICAN BUILDER FEBRUARY 2023 06

(Left): All ducts, airways, and HVAC conduits are designed and structured to ensure no radiation escapes.

followed a structure specified for the containment of the kind of radiation the facility deploys. “Another first for this project was designing for a cyclotron accelerator. In fact, we’ve worked with Yunus Manga of NuMeRI facilities for linear accelerators and the key challenge in the design for a cyclotron accelerator is that the radioactive beams go in all directions,” he says.

The design solution for this is the use of a maze-like structure for the joins and portals, such as entryways – and in this case, an access point designed in the roof for the installation of the cyclotron. “The design is Tetris-like and obstructs the trajectory of radiation in all directions. The roof aperture is designed in this way, as is the service door to the cyclotron,” explains Van der Merwe. The roof itself will be sealed with concrete once the cyclotron is installed.

COMMISSIONING

With one bunker dedicated to research and the other to manufacturing isotopes, both are now undergoing full fitment with HVAC, IT infrastructure and the installation of a massive door, procured from a specialist manufacturer in Turkey. This allows technicians to enter the cyclotron’s environment and perform the necessary services and corrections. The door runs on tracks and fits into the frame in the Tetrislike design mentioned by Van der Merwe.

The NuMeRI facility is one of a kind and is a model of expertise and world-class abilities in a structure of great complexity and importance. Its demonstration of remarkable capacity for construction excellence in SA takes our sector another step forward.

FEBRUARY 2023 SOUTH AFRICAN BUILDER 07 SPONSORED EDITORIAL

(Above): Gavin Morrow, Chief Executive Officer of W3O.

(Above): NuMeRI view from the North West.

“BEING A NUCLEAR FACILITY, THE PROJECT HAD A NUMBER OF INTRINSIC REQUIREMENTS, PRIMARILY TO BE SAFE AND TO COMPLY WITH THE INTRICATE REGULATIONS THAT GOVERN SA’S NUCLEAR INDUSTRY.”

WORKPLACE, ENVIRONMENT, HEALTH AND HYGIENE

By Neil Enslin, Head: Occupational Health & Safety, MBA KZN

Workplace facilities on a construction site should always be kept clean. It is a legal requirement to provide a workplace that has sufficient and hygienic toilets, showers, change rooms and eating areas. The work environment must also have adequate lighting and ventilation and workers must be protected from excessive noise and heat.

LIGHTING

Adequate lighting must be provided in dark areas such as stairwells and basements. In plant and storage yards, surveys

should be conducted to determine whether the light that is provided complies with the minimum requirements of the Occupational Health and Safety Act.

VENTILATION

Make sure that working areas are suitably ventilated. Extraction and exhaustion systems must be installed where needed in hazardous areas, such as those in which chemicals and adhesives are used, where welding is taking place, or where a petrol or diesel motor is running in a confined space or basement. The plant yard’s spray and sandblasting booth should be subjected to a

survey to determine whether the ventilation is adequate.

NOISE

Loud noise over long periods can lead to permanent hearing loss. It is therefore extremely important that all reasonable steps are taken to reduce noise levels at the source. Areas where noise levels exceed 85dB must be suitably identified with signage requiring persons to wear appropriate hearing protection. Workers must adhere to these warning signs at all times to avoid any chance of permanent hearing loss. It is also advisable to conduct noise surveys for the plant yard to

SOUTH AFRICAN BUILDER FEBRUARY 2023 08 MBA NEWS

ascertain the level of sound to which workers are exposed.

HEAT STRESS

In extreme climate conditions, it is essential to ensure that the correct measures are taken to prevent heat exhaustion in problematic areas such as steel deck workplaces and when the wet bulb globe temperature monitoring index reaches 30˚C. Cold drinking water must be readily available when extreme temperatures are experienced, as dehydration has serious consequences for workers’ health. They can become dehydrated without realising it, so it is very important to ensure that they drink adequate amounts of water during the course of the day.

ABLUTIONS

Construction sites must always have suitable ablution facilities available for workers and it is important that these be kept clean and functional.

The requirements regarding these facilities are:

• There must be one toilet provided for every 30 employees, with toilet paper available at all times.

• There must be one shower available for every 15 employees where they can use both hot and cold water. Clean towels and soap must also be available.

• Soap must be available for washing hands, as well as clean, dry towels or an air-drying machine for drying hands.

• Separate changing areas and facilities must be provided for females.

• There must also be adequate storage facilities provided in the change rooms.

• It is essential to keep all ablution facilities hygienic at all times.

EATING/COOKING FACILITIES

A suitable, separate, weatherprotected area must be designated as an eating area. This area must be separate from the changing area. Make sure that there is an adequate number of refuse bins with lids available in this area. Should food be prepared and cooked on site, it is advisable that the local health department approves the facilities.

POLLUTION OF ENVIRONMENT

A pollution policy which is signed by the CEO must be published on site. Ensure that there are adequate measures in place to control dust that is generated. A good practice is to water gravel roads on a daily basis. Ensure that

empty cement pockets, plastic wrappings, bags and packing material are accumulated and disposed of in the correct manner.

Ensure that oil, chemicals or fuels such as petrol and diesel are not disposed of in stormwater drains. Only dispose of such substances in the correct manner and obtain a certificate from the service provider which does this.

HAZARDOUS CHEMICALS

Hazardous substances being used on site, such as diesel, oil, cement, thinners, paint, acids and degreasers, must be identified and recorded. This record should be made available to employees. Hazardous substances must be stored safely, with segregation principles being applied at all times. Material safety data sheets indicating hazardous properties and emergency procedures to be followed in the event of an incident must be kept on file and readily available.

FEBRUARY 2023 SOUTH AFRICAN BUILDER 09 MBA NEWS

(Above and left): As we settle into 2023, take an inventory of your medical and first aid equipment, which can save lives.

THE IMPORTANCE OF EMPLOYMENT

EQUITY COMPLIANCE

By Dr Prishana Datadin, human resources manager: MBA KZN

The Employment Equity (EE) Act is a law that promotes equal opportunity and fair treatment in employment through the elimination of unfair discrimination. It also ensures that affirmative action is implemented and measured in order to redress the disadvantages in employment experienced by designated groups and to ensure that equitable representation is made in all occupational levels of the workforce.

Organisations that employ more than 50 employees and/or that have an annual turnover greater than the threshold specific to the industry/ sector are required to submit annual EE reports. These reports include the EEA2 and EEA4. Organisations

are further required to develop and implement EE plans in which numerical goals and sector targets must be set out. Non-compliance results in heavy fines.

A designated employer must prepare and implement an EE plan to achieve employment equity, which must:

• Contain objectives for each year of the plan.

• Include affirmative action measures.

• Stipulate numerical goals for achieving equitable representation.

• Specify numerical targets for each year of the plan.

• Include a timetable for each year.

• Incorporate internal monitoring and evaluation procedures, including internal dispute resolution mechanisms.

• Identify persons, including senior managers, to monitor and implement the plan.

THE BENEFITS OF EE PLANNING INCLUDE:

• Assisting the entity with succession planning.

• Assisting the entity to plan a more representative staff complement.

• Legislative compliance forecasts and meeting targets.

(Right): Equity is about more than balancing social reality – it is about creating stakeholders with a meaningful influence and a literal stake in the best outcomes for the business.

(Above): Employment equity creates a business able to serve and benefit from direct relationships across all communities. Equity is a national goal with deeply personal benefits.

SOUTH AFRICAN BUILDER FEBRUARY 2023 10 MBA NEWS

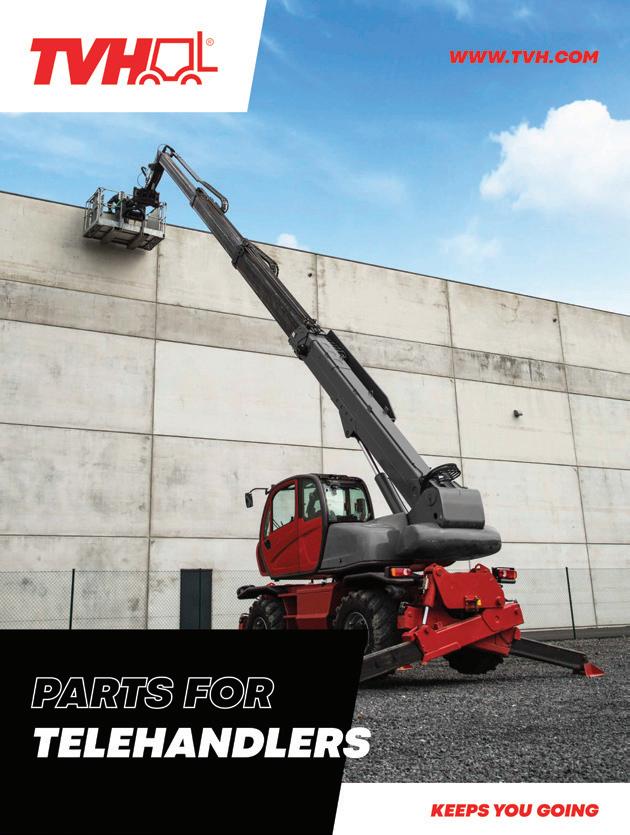

TELEHANDLERS’ VERSATILITY DRIVES VALUE IN MULTIPLE SECTORS

Telehandlers are versatile machines that can be equipped with various attachments. Well established in the construction sector for their value in functioning across multiple applications, they are providing the same benefits to the agricultural sector.

Irrespective of application, telehandlers require thorough maintenance regimes, as well as reliable suppliers of parts with the expertise and skills to provide the necessary technical support. THV embodies the ideal technical support partner, capable of ensuring the full lifetime value of your telehandler’s potential.

THV sources and maintains the full scope of quality parts across a telehandler’s life of service, with recognised expertise from industry leaders. Claudio Giordano is a perfect example.

A TRULY SPECIALISED EXPERT

Giordano joined TVH in 2016, bringing with him 10 years’ successful experience as a sales and marketing manager for a major telehandler brand. His experience with both the machines and their attachments made his specialised expertise a rare asset in his active role as THV’s market management specialist for telehandlers and as global product manager for CAM Attachments.

“In the past, telehandlers were mainly used in construction,” he explains. “However, that sector suffered major losses in 2008 and 2009 due to the global financial crisis, gutting budgets in most construction companies for any new capital equipment investment.

“Telehandler manufacturers started focusing on the agricultural sector instead. This wasn’t a far-fetched shift, since the adaptability of

telehandlers makes them practical and time-efficient for farming.”

CONSTRUCTION VS AGRICULTURE

“There are some differences between telehandlers for construction and those for agriculture, such as a difference in speed,” says Giordano. In agriculture, fields are less crowded and the distance to the farm can be great, so speed is crucial, with farming equipment often reaching speeds of 40-45km/h.

“More significant is the difference in the power of the thermal engine, which has an impact on the hydraulic power and pulling power of the machine,” he elaborates. “Because of the types of attachments used in agriculture, they need adequate hydraulic power at the head of the boom. And since they’re often used to tow heavy trailers, they also require a lot of pulling power.”

TVH, YOUR PARTNER FOR TELEHANDLER PARTS

“We have all the parts one could possibly need, including engine parts, transmission parts, electronic boards, hydraulic parts and tyres. If you’re not sure what part you require, our skilled employees can provide professional service and will help with all your technical questions,” he says.

FEBRUARY 2023 SOUTH AFRICAN BUILDER 11 ADVERTORIAL

“IT IS ESSENTIAL FOR SOLUTIONPROVIDERS TO DEVELOP A STRONG SKILL BASE BY FINDING THE RIGHT INDIVIDUALS TO TRAIN AND DEPLOY AS COMPETENT QHSE RESOURCES IN REMOTE AREAS.”

BUILDING QUALITY, HEALTH, SAFETY AND

ENVIRONMENTAL MANAGEMENT CULTURES

In the mining and industrial sector, progressive operations in remote locations across Africa rely on key partnerships to help them navigate and overcome numerous logical and practical obstacles. The remote site industry is one of the industries where a quality, health, safety and environment (QHSE) culture needs to be treated not as a simple compliance requirement, but as a reality which ensures environmental protection, as well as the safety of staff, clients, their employees and the communities in which they work.

Gift Mutonhere, the head of QHSE at the Allterrain Services (ATS) division of the Tsebo Group – which specialises in catering and facility management for many of Africa’s most remote industrial and mining sites – says: “It’s important that we hold ourselves accountable by implementing best practices according to the highest international standards.”

To him, health and safety are more than procedural exercises when it comes to operating in such environments. This is particularly

so in areas where the nearest town or medical facility could be hundreds of kilometres away and where a QHSE incident not only has major implications for precious human lives, but can also have devastating financial and downtime implications for site operations.

Companies need to look at the overall project objectives and targets to understand how a site-specific strategy can be developed to reach them. This could be anything from attaining ISO certification

SOUTH AFRICAN BUILDER FEBRUARY 2023 12 INDUSTRY NEWS

(Above): The complete environment of a construction site needs full attention in all aspects of quality, health and safety.

to increasing a client’s lost time injury-free hours. Achieving this requires taking a broad-ranging preventative approach to potential risks before developing a sitespecific QHSE system and working in tandem with the client so that QHSE becomes a lived reality for all members on the operation.

The ultimate goal for ATS is to achieve certification on applicable ISO standards. including food safety, quality, occupational health and safety, and environmental management systems. However, achieving this level of best practice excellence is not without its challenges.

“It means adopting an agile approach, a can-do attitude and a long-term view of QHSE. Dynamic activities that range from catering to soft and hard maintenance work, construction and facility development, overcoming resourcing issues for quality raw materials, produce, products and parts, and employing and training a professional team in skills-scarce areas are all part of the job,” explains Mutonhere.

It is essential for solution-providers to develop a strong skill base by finding the right individuals to train and deploy as competent QHSE resources in remote areas. Companies in this sector will also need to overcome the logistical challenge of getting items such as specialised kitchen equipment or safety, health, hygiene and sanitation consumables to site, often in countries where these resources are not readily available.

“Even things like acquiring highquality produce and protein can be a challenge. We have to consider the environment in which produce is farmed, processed, packaged and transported so that we don’t risk people contracting food-borne illnesses such as typhoid, hepatitis A and cholera, which are prevalent throughout Africa. We have to audit local suppliers and work with internal community liaison personnel to develop safe local supply chains,” says Mutonhere.

Apart from benefiting the operation, suppliers need to consider their impact on an

environmental level. This means minimising waste, recycling and, where possible, using cleaning chemicals and products which are not detrimental to the environment. Taking that one step further, it also means educating the local communities in best practices for the planet, as well as in health and safety at home.

Mining, oil and gas, or remote site operations do not exist in a vacuum – they form part of communities and need to play their part in ways that are both sustainable and responsible. This could take the form of community programmes to educate people in things like the importance of water-saving, hand-washing, and health and safety campaigns regarding prevalent diseases or community clean-ups and treeplanting initiatives.

“To be in this business, you have to be passionate about people. QHSE is about much more than ticking off a compliance checklist – it’s about building environments where people can thrive,” says Mutonhere.

FEBRUARY 2023 SOUTH AFRICAN BUILDER 13 INDUSTRY NEWS

(Above): The intersection of human and machine is the focal point of safety training, equipment competence and daily maintenance.

(Below): Engineering quality, health and safety into every project is the most life-saving, profitable step taken in a project.

(Above): Ongoing monitoring goes hand in hand with personnel compliance and daily vigilance.

(Right): Solar panels are successfully used in CorteCros® to supplement a building’s electricity. The total installed power of the panels is 12,00kWp. The total average annual production is approximately 20 000 kWh, while total average

Corrosion protection manufacturer CorteCros ®, daughter company of Cortec ® Corporation, is proud to announce that its manufacturing facility in Split, Croatia, is now almost fully solar-powered. The company installed new solar panels for energy production recently and is now generating electricity from them. Solar panels collect clean renewable energy from the sun and convert it into electrical energy which is used to power the CorteCros ® facility and logistics centre. Unfortunately, unstable geopolitical situations and high energy prices are problems all over the world. This is another reason for the company to utilise its own energy resources as much as possible.

The CorteCros® manufacturing facility and warehouse are located in Split, Dalmatia, a Croatian coastal region that offers maximum sun exposure. This provides an excellent opportunity to utilise energy from renewable resources such as the

SPECIALTY CHEMICAL PLANT WITH

100% RENEWABLE POWER

sun. All companies in the Cortec ® Corporation are environmentally responsible, utilising sustainable resources in product development and their operations wherever they can. CorteCros’s green transition to carbon-neutral plant and the adjustment to its own energy resources are of huge importance for the organisation as an environmentally conscious manufacturer. The CorteCros® logistics and distribution centre recently expanded its production facility and storage capacity. In fact, Split is now Europe’s main production and distribution point for Cortec ®’s chemical corrosion protection products.

SOUTH AFRICAN BUILDER FEBRUARY 2023 14 INDUSTRY NEWS

(Left): The Croatian coastal region of Dalmatia has almost 3 000 sunny hours per year. A development project. The CorteCros® logistics centre is in an excellent geostrategic location within the Split port authority of Croatia.

annual consumption is 19 554,24kWh.

In addition to manufacturing and testing, CorteCros ® provides integrated solutions and full technical support for Cortec’s products and services. A newly equipped ASTM- and ISO-certified laboratory is also located in the logistics centre in Split. All products are registered according to the REACH standard.

CorteCros ® also offers a wide range of biotechnology solutions from Cortec’s Canadian subsidiary, Bionetix ® International, which uses a variety of micro-organisms and nutrients to create biological products used in thousands of field applications worldwide.

By using a solar power system, CorteCros® is able to achieve

savings from energy costs as high as 97%. Solar panels provide a very practical way of producing electricity for many applications. This renewable energy system can provide power for upwards of three decades, if properly maintained.

Patented VpCI® Technologies licensed under Cortec® Corporation are some of the most widely used and renowned corrosion protection products in the world. The Cortec® Corporation has 10 locations around the globe, with headquarters in St Paul, Minnesota, USA. The company supplies three continents – Europe, Asia and North America – from its facilities in Croatia. Capacities there include EcoCortec’s anticorrosion films and a bioplastics

plant located in the east of the country, CorteCros’s logistics and production centre and sales offices in the capital, Zagreb.

The CorteCros® team worked extremely hard to achieve these important milestones for quality, environmental and credit management. Since global climate change is accelerating, it has become more important that we do whatever we can to reduce the pressure on our atmosphere from the emission of greenhouse gases. Solar panels have no moving parts, require little maintenance and last for decades. This green project is another in step in achieving Cortec’s goal of full commitment to sustainable corrosion protection technologies.

Need Quality Products Formulated For

When

INDUSTRY NEWS

You

Superior Results!

Bonding Agents

Chemical Anchors

Concrete Bonding

Concrete Crack Repairs

Concrete Release Agents

Concrete Repair Mortars

Curing Compounds

Epoxy Adhesives

Epoxy Grout

Joint Sealants

Non Shrink Grouts

Pre Cast Repairs

Water Proofing • Tel: + 27 11 822 2320 • Fax: + 27 11 822 2354 • e-mail: cindy@ashak.co.za 6755 A.Shak Constrctn SA Builder 1/2PG febr’23 ad

•

•

•

•

•

•

•

•

•

•

•

•

•

SA CEMENT AND CONCRETE INDUSTRY TACKLING HUGE CHALLENGES

The entire South African cement and concrete industry is threatened by multiple challenges of economic decline, the crisis in the construction industry, cheap imports and environment-related issues. Some 35 000 local jobs are on the line, together with billions of rands’ worth of investments in the sector’s long value chain.

Cement manufacturing emits significant quantities of greenhouse gases which impact SA’s decarbonisation commitments as it moves towards net zero, within the framework of the Just Energy Transition Investment Plan.

“As responsible stakeholders committed to playing our part in SA achieving its nationally determined commitments in terms of the UN Framework Convention on Climate Change, the local cement sector has committed itself to ‘Vision: Net Zero Carbon’ by 2050,” says Cement & Concrete SA CEO Bryan Perrie.

“This includes an undertaking to decarbonise in accordance with the 1,5˚C global temperature increase pathway in the Paris Agreement, which was reinforced at COP26 in Glasgow, Scotland, last year. The local cement and concrete sector has set key milestones

for 2030 in accordance with SA’s technical reporting guidelines and in line with the Inter-Governmental Panel on Climate Change reporting framework.”

The industry has been under huge pressure due to a toxic cocktail of factors. In addition to the general economic downturn and decline in investor confidence, the sector was hit hard by the Covid-19 pandemic lockdown. The construction industry is in crisis and is now confronted by the threat of construction mafias who have sprung up across the country.

The local cement production capacity is about 20 million tons, but the industry is currently producing just 12 million tons. More than one

million tons of cement imports –the equivalent of an entire cement plant – enter our market annually.

“With so much at stake, the sector’s in discussions with the SA International Trade Administration Commission and the Department of Trade, Industry and Competition to take positive action to prioritise its local cement industry,” says Perrie.

Newly-published government regulations do not require localisation of products such as cement and concrete, leaving this to individual departments and state-owned enterprises. “More is required to secure the sustainability of a sector impacted by both the global pandemic and a decade-long slowdown in SA’s planned infrastructure build-out,” adds Perrie.

SOUTH AFRICAN BUILDER FEBRUARY 2023 16 INDUSTRY NEWS

(Above): Brian Perrie, CEO of Cement & Concrete SA.

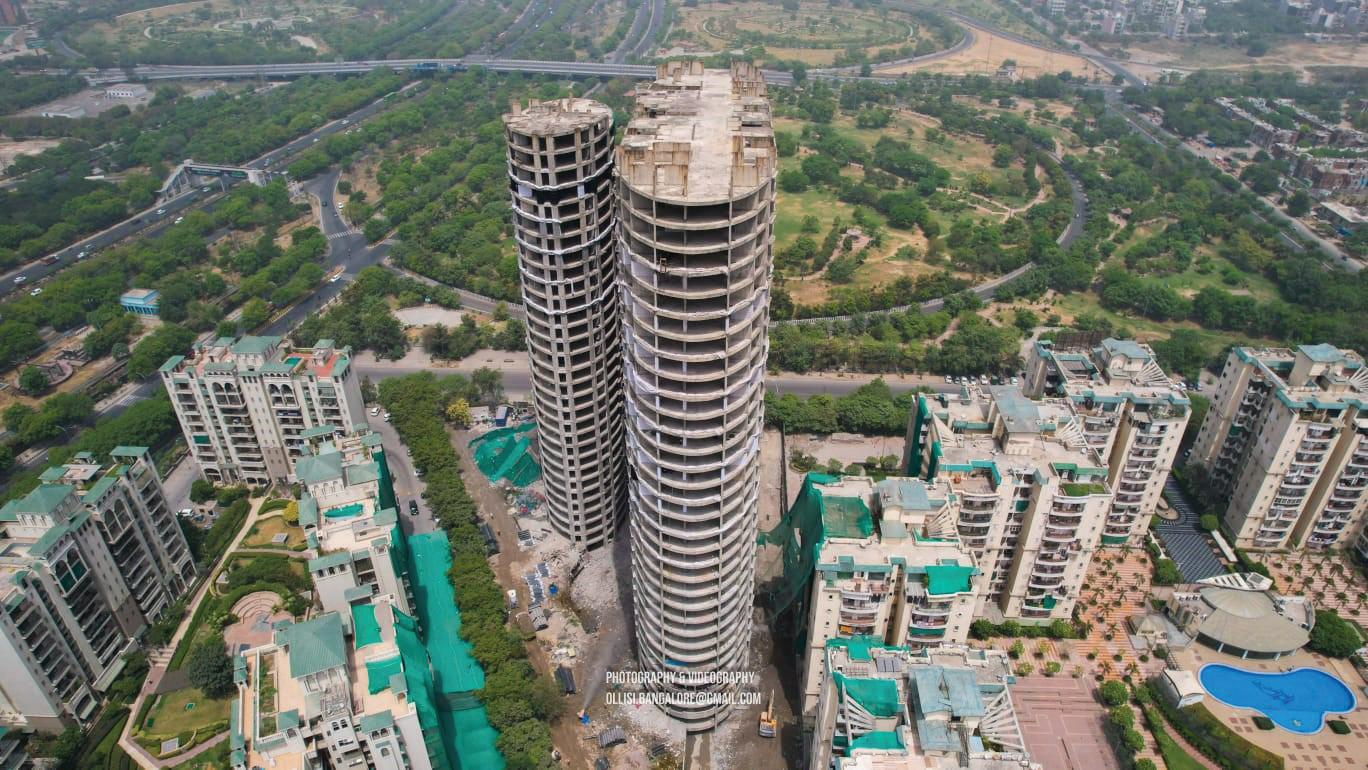

VALUABLE LEGACY OF CONCRETE CENTRAL TO 2023 TRAINING PROGRAMME

Sustainability best practice to ensure that the finished concrete product utilises resources as efficiently as possible is a common theme of Cement & Concrete SA’s School of Concrete Technology’s (SCT’s) courses for 2023.

In his foreword to the school’s training programme for next year, John Roxburgh, senior lecturer, says the SCT realises how critical it is to produce quality concrete which meets all strength and durability requirements. “Our variety of courses caters for different needs required by a broad spectrum of students,” he states. “Our slogan for the year is: ‘Not without concrete!’ It’s a theme that’s run through our lecture courses for many years, so for 2023, we’ve made it our official one.”

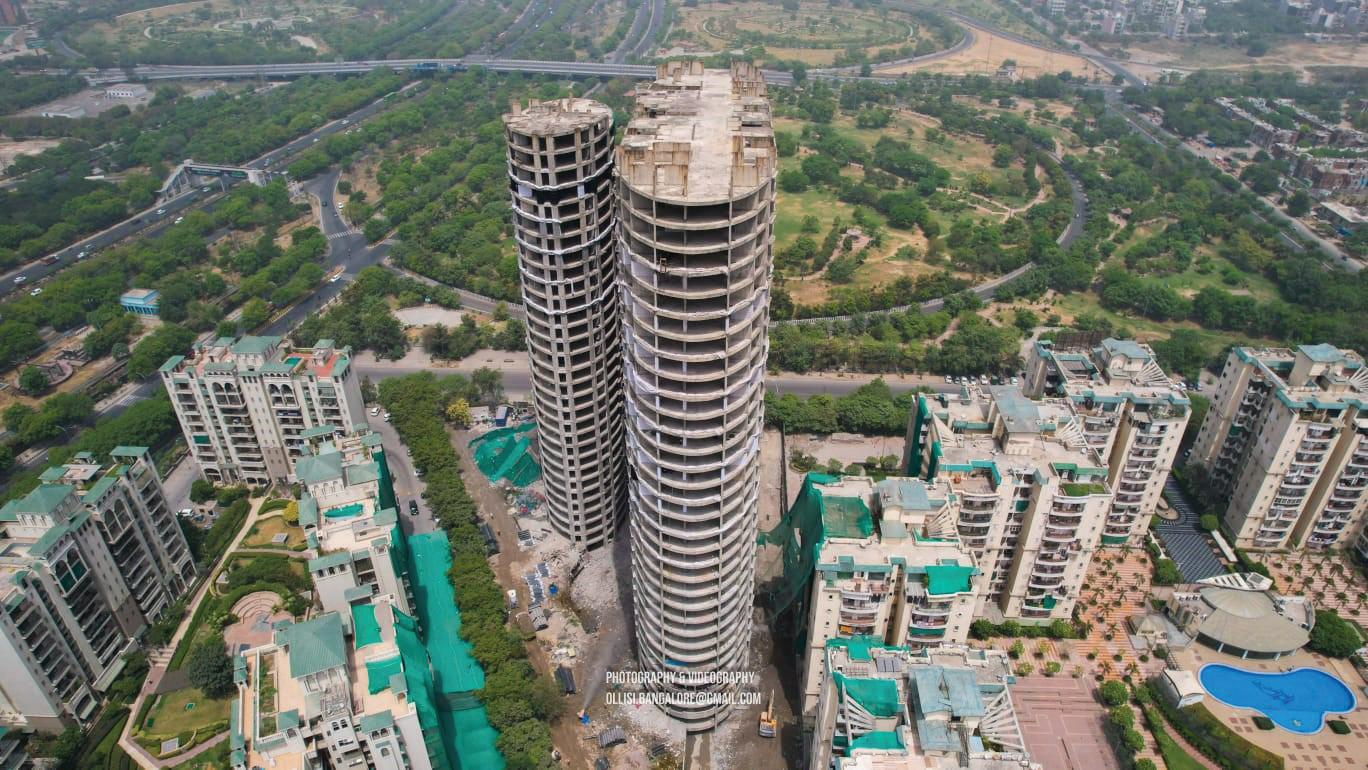

“NOT WITHOUT CONCRETE...”

The 2023 training programme endorses the slogan by featuring photos of images directly linked to concrete – such as the tallest building in the world, the Old Kingdom pyramids, and the longest bridge and longest tunnel in the world. Others are more abstract, such as the launching of the Saturn V rocket in the Apollo 11 mission, symbolic buildings of past empires and events, and huge stadia for world sporting events. “None of these would have been built or existed without concrete. All the images represent something big or amazing in the history of mankind. Our

civilisation’s been built off the back of concrete. It’s the often unfairly maligned, quiet, solid facilitator of all things we do in this world today,” adds Roxburgh.

As usual, the SCT curriculum for 2023 covers 10 standard courses ranging from basic topics such as the “Introduction to Concrete” to more specialised training on various topics. including “Concrete for Industrial Floors” and “Concrete Road Design and Construction”.

FROM STANDARD TO SPECIALISED

All the courses are presented live in Midrand, with some also scheduled for Durban and Cape Town. Furthermore, on an advanced level, the UK Institute of Concrete Technology’s two highly-respected courses – “Concrete Technology and Construction General Principles and Practical Application” and the pinnacle of concrete training, “Advanced Concrete Technology (ACT)” – will continue in 2023. Roxburgh says the ACT modularised self-study programme was successfully launched in 2022 and several delegates have already joined it.

Continuing professional development points are awarded for selected courses.

The SCT 2023 training programme can be downloaded from www.cemcon-sa.org.za or, for further information about the courses, tel: 011 315 0300.

INDUSTRY NEWS

(Above left): John Roxburgh, senior lecturer at Cement & Concrete SA's School of Concrete Technology.

GREENOVATE AWARDS 2022: THE WINNERS

The University of Cape Town (UCT) continued its dominance at the annual Growthpoint Properties (JSE: GRT) and Green Building Council of SA (GBCSA) Greenovate Awards 2022. Its students triumphed, taking the top spots in both the property and engineering categories of the awards, which encourage, enable and reward innovative solutions for a more sustainable built environment by young talent.

The sustainability ideas explored by local university students included using mushroom roots to create sustainable insulation material, adding artificial photosynthesis to the façades of buildings to power them, the way bringing nature into building designs positively impacts the study performance of

SOUTH AFRICAN BUILDER FEBRUARY 2023 18 INDUSTRY NEWS

(Above): The University of Cape Town’s Anna Pamela Reid took first place in the Greenovate Awards engineering stream for the submission Mycelium Bio-Composite as a Sustainable Insulation Solution

university students and investing in property for social impact.

UCT triumphed in the engineering category, which incorporates electrical, computer and electronic, civil and mechanical engineering. The first- and secondplace winners were both from that institution, while the third place went to a student from the University of Pretoria (UP).

The property category – which includes quantity surveying, construction management and property studies – was also won by UCT. The second and third places went to the University of the Witwatersrand (Wits).

For the first time this year, a new award was introduced, sponsored by International Finance Corporation (IFC) and linked to EDGE green building certification (an innovation of the IFC and a member of the World Bank Group). This award was won by students from Wits University.

The winners were announced at a gala dinner held at Katy’s Palace Bar in Kramerville, with its spectacular views of the Sandton Central skyline, an iconic South African built environment which also happens to have the highest concentration of certified green buildings in Africa.

Now in its eighth year, Greenovate launched in 2015 to seed an early passion for sustainable development in university students by focusing on property industry challenges and opportunities. The programme showcases up-andcoming talent, providing a plat-

form for the future leaders of the built industry.

In 2022, 21 students from five universities – Wits, UCT, UP, Nelson Mandela University and Stellenbosch University –entered the awards. The students researched existing challenges, proposed unique solutions to reallife problems and presented their ideas to industry decision-makers.

“This year’s forward-thinking projects are a window into the possibility of a better built environment,” says Grahame Cruickshanks, Growthpoint’s

head of sustainability and utilities. “They’re a starting point for meeting the significant need for research and development that offers implementable solutions for a sustainable built environment. Growthpoint is committed to becoming carbonneutral by 2050 and innovation in the green building and energy spaces is essential to achieve that goal. We’re proud to drive the Greenovate Awards and confident that, in the very capable hands of SA’s young talent, we’ll see better, sustainable and green buildings in future.”

Co-founder of the competition, the GBCSA, is entirely dedicated to shaping a green future and a built environment where people and the planet thrive. “The unlimited approach to life and ideas that we see reflected in

FEBRUARY 2023 SOUTH AFRICAN BUILDER 19 INDUSTRY NEWS

“GREENOVATE LAUNCHED IN 2015 TO SEED AN EARLY PASSION FOR SUSTAINABLE DEVELOPMENT IN UNIVERSITY STUDENTS BY FOCUSING ON PROPERTY INDUSTRY CHALLENGES AND OPPORTUNITIES.”

(Above): Mbali Mahlangeni and Toneka Pasiwe of UCT, first prize winners in the property stream, present a summary of their work, An Investigation into the Impact of the South African Private Sector Investing in Social Infrastructure as a Vehicle to Attain Their Environmental, Social and Governance (ESG) Goals, at the Greenovate Awards gala dinner.

the Greenovate Awards by our university students is amazing. It’s equally exciting to see the property industry coming together to support and create opportunities for our greenminded young talent. The result: a growing community of advocates for green building with a passion for creating a better world and a brighter, greener future,” says Lisa Reynolds, GBCSA’s CEO.

Prize money of R34 500 is awarded to the winning student/s in each category, while the runnerup receives R17 250, the thirdplace winner takes home R11 500 and the IFC prize-winner/s receive a laptop computer and EDGE Expert training with the GBCSA. All winners receive tickets to attend the GBCSA convention, where the top team in each category will present their projects on the innovation stage. Continuing to promote sustainable thinking and learning, the three top participants for each stream also win entry to a nationally recognised GBCSA Accredited Professional (AP) candidate course.

Students entering the Greenovate Awards gain rare access to mentorship and collaborative advantages. In preparation for the awards, they are given the opportunity, expertise and resources to develop their research into a real and workable product or service for the property industry. The awards’ mentorship programme and workshops with industry experts benefit the students immensely.

This year’s mentors for the property stream included Thashni Chetty of Turner & Townsend, Hlolo Manthose of WSP, Makhosazana Mthethwa of Solid Green Consulting, Mthobisi Masinga of the GBCSA, Jutta Berns of Ecocentric, Louwna Joubert of Zutari and Reabetsoe Kgoedi of Growthpoint Properties. Engineering stream mentors included Alex Varughese of WSP, Mischa Tessendorf of the GBCSA, Mary Anne Fetcher of Zutari and Siziwe Mulidi of AMC Engineers.

The 2022 judges for the property category included Marc Sherratt of Marc Sherratt Sustainability Architects, Kedibone Modiselle of the City of Tshwane, Georgina

Smit of the GBCSA, Kushinga Kambarami of IFC, Adrie Fourie of Solid Green Consulting and Sally Misplon of Misplon Green Building Consulting. Judges for the engineering category included Mike Aldous of MPAMOT, Dash Coville of GBCSA, Werner van Antwerpen of Growthpoint Properties, George Muchanya of Growthpoint Properties, Conrad Sanama of IFC, Bruce Paul of Concor Construction and Songo Didiza of the Green Building Design Group.

Through Greenovate, young talent is exposed to the latest in sustainability thinking and enjoys direct access to leading sustainability and property companies, which creates a

SOUTH AFRICAN BUILDER FEBRUARY 2023 20 INDUSTRY NEWS

(Above): Tristan Fernandes of UCT receiving his award at the Growthpoint Greenovate Awards 2021.

“THROUGH GREENOVATE, YOUNG TALENT IS EXPOSED TO THE LATEST IN SUSTAINABILITY THINKING AND ENJOYS DIRECT ACCESS TO LEADING SUSTAINABILITY AND PROPERTY COMPANIES, WHICH CREATES A SPRINGBOARD TO LAUNCH THEIR FUTURE CAREERS.”

springboard to launch their future careers. These special awards are growing the green talent pool not only for Growthpoint, but also for the green building movement and the benefit of SA Inc. During this process, the students also create lasting networks and partnerships.

Next year’s Greenovate Awards promise to be even more exciting, with the planned introduction of a new prop-tech category and students from all SA universities are invited to participate. They can register at: greenovatecompetition. co.za/register.

The winners of the 2022 Greenovate Student Awards are:

PROPERTY:

First: Mbali Mahlangeni and Toneka Pasiwe – UCT: An Investigation Into the Impact of the SA Private Sector Investing in Social Infrastructure as a Vehicle to Attaining their Environmental, Social and Governance Goals.

Second: Mpidiseng Mohlaba, Manqoba Mthimkhulu and Asanda Gwala – Wits University: The Use of Artificial Photosynthesis in the Construction of Building Façades.

Third: Kingsley Martell and Kyle Motani – Wits University: The Effect of Greenness on the Financial Performance of SA Real Estate Investment Trusts (REITs).

ENGINEERING

First: Anna Pamela Reid – UCT: Mycelium Bio-Composite as a Sustainable Insulation Solution.

Second: Msawenkosi Mkhize – UCT: Internet of Things Technology in Monitoring

Greywater Quality for Non-Potable Water Use.

Third: Reinhard Ferreira, Mulisa Shavhani and Beth Watson – UP: Carbon-Neutral Building Vooling via Phase Change Materials With Ventilation.

IFC PRIZE

Winner: Mpidiseng Mohlaba, Manqoba Mthimkhulu and Asanda Gwala – Wits University: The Use of Artificial Photosynthesis in the Construction of Building Façades.

ABOUT GROWTHPOINT PROPERTIES

Growthpoint creates space to thrive with innovative and sustainable property solutions in environmentally friendly buildings, while improving the social and material well-being of individuals and communities. It is an international property company invested in real estate and communities in SA and across Africa, Australia, the UK and Eastern Europe. Growthpoint is a 50% co-owner of the V&A

Waterfront in Cape Town. SA’s largest primary JSE-listed REIT, it is an established leader in commercial green developments and owns and manages the biggest portfolio of greencertified buildings in Africa. Visit: www.growthpoint.co.za for more information and connect with Growthpoint on Facebook, Twitter, LinkedIn and YouTube.

ABOUT THE GBCSA

The GBCSA is a member-based organisation focused on green building advocacy, certification and training. We advocate that all buildings be designed, built and operated in an environmentally sustainable manner. We are one of 75 members of the World Green Building Council, inspiring a built environment where people and planet thrive. Visit our website: www.gbcsa.org.za or connect with us on LinkedIn, Instagram, Facebook or Twitter.

FEBRUARY 2023 SOUTH AFRICAN BUILDER 21 INDUSTRY NEWS

(Below): Karabo Makole of UCT receiving his award at the Growthpoint Greenovate Awards 2021.

QUALITY OF MORTAR MIX IMPORTANT

FOR SUSTAINABILITY

The quality of the mortar invariably determines the durability of any new structure, says Matthews Magwaza, lecturer at Cement

&

SA’s School of Concrete Technology.

&

SA’s School of Concrete Technology.

Concrete

“Mortar binds bricks and blocks together to give strength and stability to a wall and in developing countries, where contractors tend to produce their own mortar rather than factory-purchase it, correctly produced mortar is extremely important to ensure sustainable structures,” he says.

Magwaza says freshly mixed mortar must be soft and plastic so that it spreads easily and makes good contact without becoming too strong. Mortar that is too strong may crack and is

wasteful and expensive. “The proportion of each material in the mix should suit the type of work being done. In general terms, the classes of mortar commonly used in SA are Class I for high-strength structural units such as multi-storey load-bearing buildings or reinforced masonry and Class

SOUTH AFRICAN BUILDER FEBRUARY 2023 22 INDUSTRY NEWS

“THE PROPORTION OF EACH MATERIAL IN THE MIX SHOULD SUIT THE TYPE OF WORK BEING DONE.”

II mortar for normal load-bearing applications, as well as parapets, balustrades, retaining structures, free-standing and garden walls, as well as walls exposed to possible severe dampness.”

Magwaza says the preferred cement types for quality mortars are:

• Common cement complying with SANS 50197-1; and

• Masonry cement complying with SANS 50413-1; strength class 22,5X.

“The addition of lime in the mortar mix is optional. Lime should be used if the sand lacks fine material or is single-sized, as such sands tend to produce mortar with poor workability unless lime is included in the mix. Lime also helps the fresh mortar to retain water when it's placed against dry masonry units and helps to prevent cracking of the hardened mortar. Use only building lime complying with SANS 523 and don't use quick-

lime, lime wash or agricultural lime. Lime should also never be used with masonry cement.

“The sand in the mix mustn't contain organic material produced by animal or plant activities, nor particles retained on a sieve of nominal aperture size 5mm. When 2,5kg of cement is mixed with 12,5kg of air-dry sand, the mixture won't require more than 3 litres of water to be added to reach a consistency suitable for the laying of masonry units. When mixed with the cement in accordance with the mix proportions, the sand must have workability suitable for the laying of masonry units. Sands which require the addition of more than three litres of water to reach a consistency suitable for the laying of masonry units can, in some instances, be blended with a coarse sand for compliance. The proportion of the blended sand can be determined by trials. Some pit sands are suitable. River, dune and beach sands are often too uniform in size or too fine to give

good results without being blended with another suitable sand.

“When it comes to batching, a 65-litre builder’s wheelbarrow is a convenient measure for large batches. Steel drums of 20- or 25-litre capacity and buckets are useful for small batches.

“Mixing should be done on a clean, hard surface such as a smooth concrete floor or a steel sheet. Small batches may be mixed in a wheelbarrow, provided that the volume of the batch is no more than half the capacity of the barrow. Sand and cement – and lime, if used – should be mixed dry until the colour of the mix is uniform. Then add water in small quantities, mixing after each addition, until the mix is soft and plastic,” he explains.

Magwaza says that if mortar is left in the sun before being used, it should be covered with plastic sheeting or a wet sack. Mortar that has stiffened so much that it is impossible to restore workability without adding more water should be discarded.

“Mortar mustn't be used after it's started to set, which usually occurs about two hours after it's been mixed. Don't use too thick a layer of mortar between bricks or blocks; this is wasteful and may lead to cracking,” he cautions.

For more information, including strength requirements and mix proportions recommended by Cement & Concrete SA, download the CCSA free leaflet, Mortars, at www.cemcon-sa.org.za or tel: 011 315 0300.

FEBRUARY 2023 SOUTH AFRICAN BUILDER 23 INDUSTRY NEWS

DIGITAL SYSTEMS TAKE THE PAIN OUT OF MANAGING EMPLOYEE REMUNERATION AND INCENTIVES

By Michael Ketz, CEO: ShareForce

By Michael Ketz, CEO: ShareForce

Administrating employee incentive plans can be challenging, but the financial implications and rigorous reporting requirements for awarding these plans to selected staff can be even more of a minefield to navigate. Issuing a share incentive plan to employees not only represents the cost that the company and its shareholders are willing to spend to retain their

key employees, but also indicates the value that the participants of the plan have received.

Companies with incentive plans are responsible for determining this cost, but quantifying the value of an incentive plan is not as straightforward as looking at the most recent share price or determining the company’s equity value. Valuing the incentive largely comes down to the complexity of the

underlying terms of the plan and, like all financial instruments related to equity or shares, this calculation can be quite complicated, probably requiring the expertise of a valuation specialist.

Using mathematical pricing techniques, the valuation specialist calculates the fair value of the incentive by assessing various market factors, including historical share price movements, expected

SOUTH AFRICAN BUILDER FEBRUARY 2023 24 BUILDING BUSINESS

Integrated business tools are opening up largescale operational and administrative tools for smaller enterprises.

interest rates and dividends, as well as the likelihood of meeting share price conditions. Yes, it is as complicated as it sounds.

FINTECH BY DESIGN: TEST – ASSESS – UTILISE

Although this may seem like an issue for the accounting team, it is crucial that compensation experts have a firm grasp of this value when designing and testing an equity incentive plan. Considering the effects of rising inflation, recent share price movements or even the company’s share price performance against its peers can be of great value in creating a suitable plan for the business.

It is vital to perform these calculations whenever needed, but the reality is that most businesses do not have the internal resources or expertise to undertake such analyses inhouse, necessitating the help of an external valuation specialist or a specialist technology flexible enough to cater for a scheme’s nuances. An automated solution or technology is always preferable when testing is needed – it is more cost-effective and helps make smarter decisions by providing real-time access to dynamic valuation results.

GAMIFYING TEDIOUS COMPLEXITIES INTO STREAMLINED ACCESS

Once the optimal plan is formulated and awarded to participants, it must be expensed and accounted for according to international financial reporting standards. The terms of the share plan and the conditions that an

employee needs to fulfil for the shares to vest (referred to as vesting conditions) are just some of the factors that directly impact the accounting treatment.

Additional accounting considerations include whether awards are settled in cash or equity, the extent to which employees meet their performance targets and whether employees exit the company before achieving these.

Considering that large companies tend to grant awards regularly to a sizeable participant base and then need to track, administer and account for them, it is evident that manual spreadsheets will not suffice. Financial technology (fintech) is typically the solution to manual workplace processes by gamifying and streamlining otherwise tedious and complex tasks and freeing up the time of internal staff to focus on higher-level, more strategic responsibilities.

Compensation and finance departments require instant access to accurate and timely data on the company’s share plans in order to manage their finances effectively. A centralised digital solution which houses the necessary skills and provides bespoke access to stakeholders will go a long way towards simplifying the complexities of this very critical process.

FEBRUARY 2023 SOUTH AFRICAN BUILDER 25 BUILDING BUSINESS

“AN AUTOMATED SOLUTION OR TECHNOLOGY IS ALWAYS PREFERABLE WHEN TESTING IS NEEDED.”

(Above): Complex calculations and time-consuming trials are things of the past when assessing employee benefits and allocations.

(Above): Retaining skills poses unique challenges for small and medium enterprises, and FinTech technologies can really fortify incentives in a way previously reserved for large corporates.

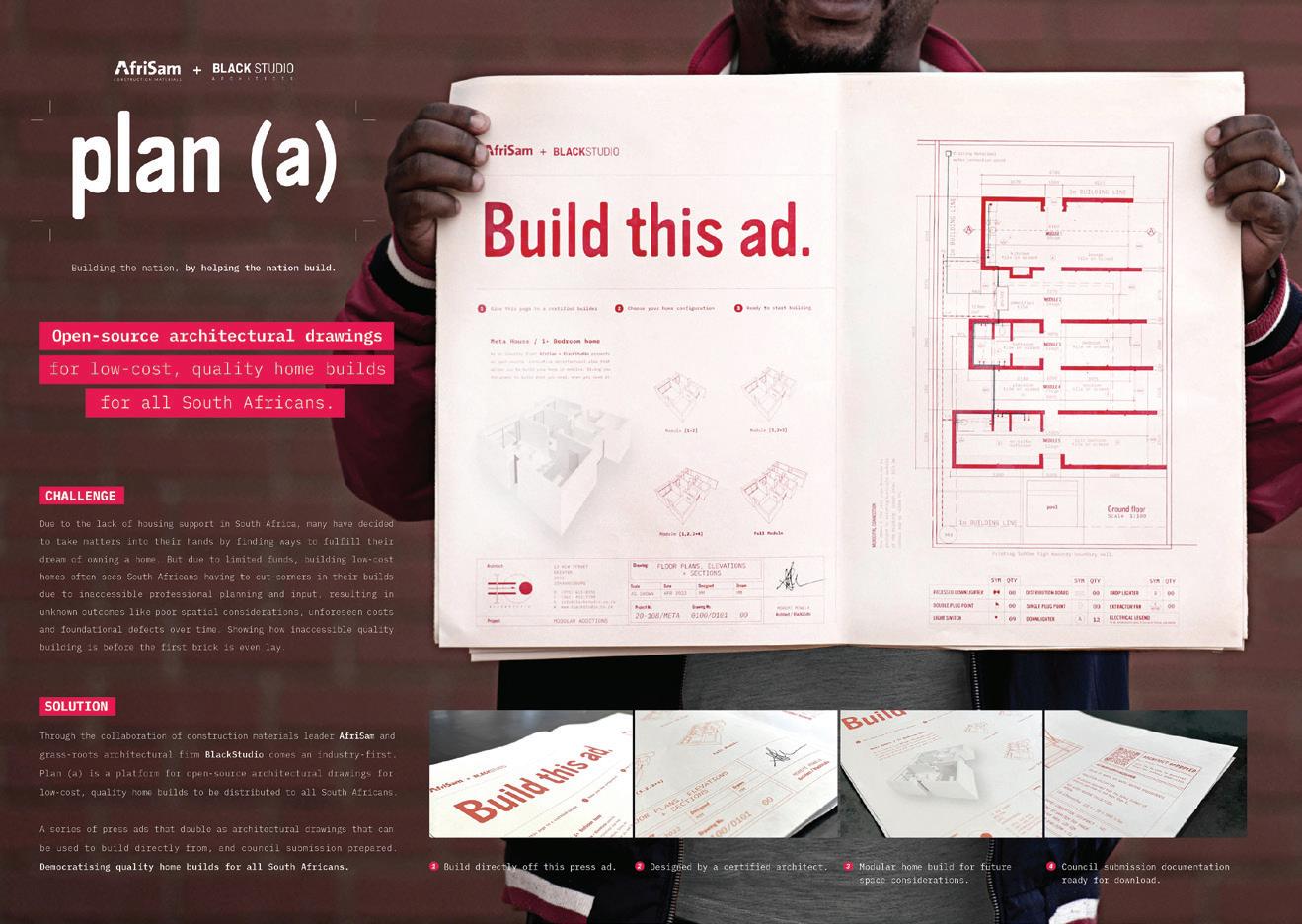

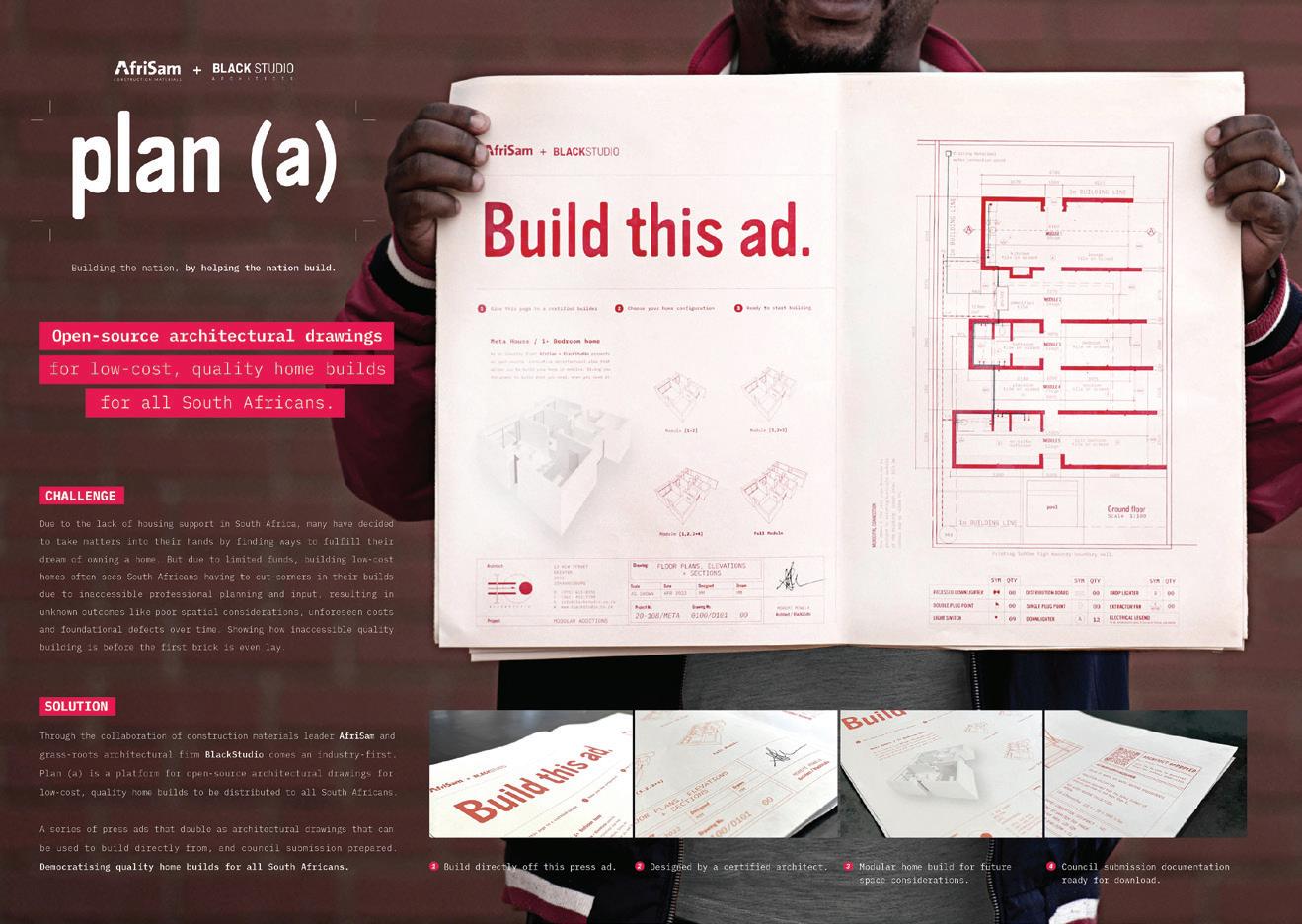

PLAN (A): POWERING DREAMS FOR MODULAR HOMES

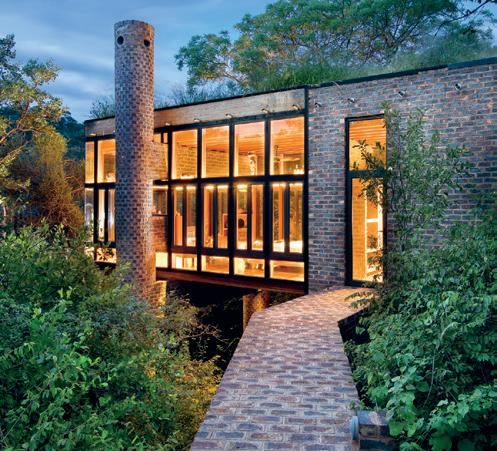

For people wanting to build their own homes over time, AfriSam has opened the door to more concrete possibilities. The company collaborated with its advertising and brand agency, Promise Group and leading architectural firm, BlackStudio, to produce its “Plan (a)” campaign, an invaluable modular house plan.

To ensure a wide reach, this has been published as a double-page spread in community papers and is also available to download online free of charge. The idea leverages AfriSam’s vision of building a positive African future, empowering and inspiring homemakers to plan ahead when constructing their dream houses.

A CONCRETE COLLABORATION

The “Plan (a)” campaign helps people build their own homes from an architect-approved plan. The modular design allows for the home to be expanded as needs change and financial resources allow. As part of its ongoing branding efforts, AfriSam has for many years provided practical guidance for customers on how best to use its cement and other construction materials. This has included top tips for working with cement and concrete, as well as handy guides in various aspects of building projects.

HELPING TOWNSHIPS THRIVE

In the latest campaign, a carefully designed, fit-for-purpose and

architect-approved plan for a modular home is being published. The social significance of improved home design and quality is hard to over-estimate, according to Moremi Mowela, co-founder and architect at black-owned architectural practice Black Studio. He points out that many township areas are regarded as transitory spaces by young people and are still “dormitory towns” serving the large cities.

“This leads to many people leaving townships as soon as they have the means, creating a drain on skills and capital,” says Mowela. “This process can be reversed if those residential spaces become aspirational, thereby playing a

SOUTH AFRICAN BUILDER FEBRUARY 2023 26 FEATURES

(Above): The architect’s plan adds value across a range of aspects, from technical issues such as foundation structures to how the spatial design over time would accommodate changing family needs.

(Right): To ensure a wide reach, the plan has been published as a double-page spread in community papers and is also available to download online free of charge.

transformational role in shaping behaviour.”

A HOME FOR THE ASPIRANT

He argues that building a professionally designed home –using AfriSam’s flexible house plan – can be a crucial step in building attractive spaces. When people aspire to live and invest in these areas for the long term, thriving communities can be fostered.

Nic Kostouros, integrated creative director at the Promise Group, ascribes the concept’s success to the way it addresses one of SA’s burning social needs, supported by AfriSam’s vision of building a positive African future.

ANCHORING COMMUNITIES

“Credible research points to the importance of decent housing as an anchor – both financial and psychological – for people’s progression as they seek a better life,” says Kostouros. “With the backlog in housing provision around the country, many people

are taking the initiative to build their own homes.”

He highlights that many working people save diligently to initiate the building process, but corners may be cut due to lack of knowledge or finances. By taking a broad view of what a first-time home-builder needs to know, AfriSam’s “Plan (a)” campaign helps to improve project outputs without adding to the upfront costs. The plan allows a home to be built in modules, starting off small and extending as families grow.

BEST PRACTICE AND QUALITY

“The architect’s plan adds value across a range of aspects, from technical issues such as foundation structures to how the spatial design over time would accommodate changing family needs,” says Kostouros. “A lot can go wrong in a home-building project, so our campaign helps readers avoid these pitfalls. The ability to build according to a

plan maximises the long-term fulfilment they can get from their hard-earned investment.”

Bauba Maila, co-founder and architect at Black Studio, notes that the company’s experience with township clients has shown that a modular design is common and stands are often similar in size and orientation to the street.

NOW WITHIN REACH

“Working from these common elements allowed us to create a house plan that would be relevant to most people’s conditions,” says Maila. “What we finally achieved was a plan that’s been designed and vetted by an architect, as well as a procedure for people to apply these ideas. This was previously out of their reach.”

Group marketing manager at AfriSam, Ebeth van den Berg, adds that the sentiment behind the campaign was very much to “pay it forward” for customers and the South African public.

“We look forward to developing the concept and creating a hub for this kind of information,” says Van den Berg. “There’s clearly a need for a highly credible platform where key segments of the housing market can be empowered with professional insights and tools.”

ADVERTISING WITH HEART

From a creative perspective, the double-page advertisement containing the plan has already been recognised by peers in the media industry, says Kostouros.

FEBRUARY 2023 SOUTH AFRICAN BUILDER 27 FEATURES

(Left): The plan helps to improve project outputs without adding to the upfront costs.

CONSTRUCTION LABOUR IN REMOTE AREAS

By Wayne Alcock, MD: Quyn International Outsourcing

It can be challenging to assemble a reliable, skilled workforce to run large-scale construction projects in rural locations. Often companies need to source and relocate skilled labour from other parts of the country or from within their own organisations to meet project-specific needs. This can result in tension with local communities, who feel as though they are missing out on employment opportunities.

For companies in the mining, engineering and construction industries, the process of identifying and onboarding skilled and unskilled labour from rural communities can be costly and excessively time-consuming. Navigating community and stakeholder engagement can be tricky and, if not handled respectfully, can lead to conflict that delays and jeopardises project progress.

By partnering with a temporary employment services (TES)

provider, companies can mitigate their labour risks, ensuring that project requirements are met and effectively balanced against community and labour considerations.

ELIMINATING DISTRACTIONS AND DELAYS

Having a TES partner puts labour-intensive projects such as infrastructure development and mining operations in rural areas in a strong position to fulfil their production targets and workforce needs. The human resources and industrial relations aspect of infrastructure and mining projects can easily distract businesses involved from their core objectives, but by partnering with a TES provider, they can outsource such time-consuming needs to a trusted partner. An accredited, trustworthy TES partner will assist in identifying and onboarding workers from

SOUTH AFRICAN BUILDER FEBRUARY 2023 28 FEATURES

(Left): It is possible, and hugely advantageous, to outsource the community and regional skilled and unskilled labour, municipal authority and available services preparatory work and engagement ahead of breaking ground on remote construction projects.

the local community, which means taking prospective hirees through an interview process, the importance of on-site safety, the correct use of personal protective equipment and much more.

BENEFITS TO BUSINESS AND COMMUNITY

Not only does the company benefit from a ready, reliable workforce, but the labour-providing community benefits greatly too. Many people in rural areas have never been formally employed, do not have bank accounts and have never had a full medical check-up to assess whether they are fit enough to work. By taking them through these procedures, TES partners are often the first to provide workers in rural areas with their first experience of formal recruitment. This gives them

invaluable knowledge that can be put to good use when seeking other job opportunities further down the line.

TIMING IS EVERYTHING

A TES provider starts with conducting interviews in the area, often months before the project is due to start, with the purpose of compiling a database of available job-seekers and skills. This can be very time-intensive and, in some cases, more than 1 000 interviews are conducted – only to discover that there is only one skilled individual to hire. This time has not been wasted, however, as it makes it possible to formulate a list of what skills need to be outsourced, as well as what training needs to be provided to unskilled workers sourced from the community to meet

project requirements. All of this can then be handled by the TES provider before the project is due to start, which means that when contracting companies arrive on site, the project can commence immediately, without any labourrelated delays.

ADVANTAGES OF OUTSOURCING

It is usually the case that the companies responsible for running the project have not previously set foot on the project location. This is where a TES partner can make a huge difference. They know exactly how to approach this kind of scenario, because it is their domain of expertise. They will be clear on how to approach and engage communities and will be knowledgeable about cultural and political formalities that need to be observed before a working relationship can be established. They will be informed

FEBRUARY 2023 SOUTH AFRICAN BUILDER 29 FEATURES

“NOT ONLY DOES THE COMPANY BENEFIT FROM A READY, RELIABLE WORKFORCE, BUT THE LABOUR-PROVIDING COMMUNITY BENEFITS GREATLY TOO.”

(Above): A labour force drawn from communities in remote locations that experiences meaningful engagement with project representatives prior to and during a contract is significantly more productive and less likely to cause downtime – and the returns on investing in a TES for this function are hard to quantify in the extent of their reach.

(Left): Wayne Alcock, MD: Quyn International Outsourcing.

FEATURES

about which traditional or political leaders need to be approached for permission to start seeking workers in the region. Language will not be a barrier for the TES provider either, as they will ensure that access to jobs is provided on an equitable basis.

ESTABLISHING STABILITY ON SITE

The TES partner will then act as a go-between, representing both the contracting companies and the project employees. Where there are multiple contracting companies involved in a project, by utilising the same TES provider, it is possible to create uniformity and stability on site. Everyone is paid a uniform rate, in line with their agreement, everyone is paid at the same time and everyone is subject to the same working conditions, with access to the same channels for airing grievances. This ensures that in-fighting between workers, and conflicts between workers and employers, do not arise.

CHOOSING THE RIGHT TES PARTNER

Instead of sourcing thousands of workers for a project, companies only need to focus on finding a single TES provider with which to partner for their labour requirements. Companies should seek a provider that has knowledge of the area from having worked there previously and built up contacts and an understanding of how everything is done in that region. This means that there is already trust built with the community and it will not be necessary to start from scratch. By outsourcing the riskiest component of any construction or development undertaking, companies can focus on their core objectives in meeting project and progress deadlines right through to completion.

SOUTH AFRICAN BUILDER FEBRUARY 2023 30

(Above): Training regional construction staff to operate heavy equipment, as well as sourcing the equipment, are two of numerous functions where appropriate outsourcing can pay massive dividends to a project’s successful delivery, within targets.

(Left): Community leaders can accelerate overall results significantly.

“WHERE THERE ARE MULTIPLE CONTRACTING COMPANIES INVOLVED IN A PROJECT, BY UTILISING THE SAME TES PROVIDER, IT IS POSSIBLE TO CREATE UNIFORMITY AND STABILITY ON SITE.”

SAICE’S INFRASTRUCTURE REPORT CARD

The South African Institution of Civil Engineering (SAICE) launched its much-anticipated 2022 Infrastructure Report Card (IRC) in November last year, reporting on the current condition of a broad range of public infrastructures. The SAICE’s fourth report rates the overall condition of SA’s infrastructure at its lowest since its first report in 2006, giving it a D rating.

Steven Kaplan, the institution’s president for 2023, explains the overall goal of the report as increasing awareness and influencing change for the better. “We also aim to stimulate debate on the condition of SA’s infrastructure and its effect on the quality of life and the economy,” he says.

The IRC team, led by convenor Sam Amod and research leader Dr Kevin Wall, analysed large volumes of detailed information and followed a rigorous process in the report’s preparation, confining its scope to a condition and performance assessment, without prescribing remedies.

Both Amod and Wall explain that in each IRC, the SAICE has progressively widened the scope of its scrutiny. “In this report we introduce fire engineering, information and communication technology, oil and gas pipelines, as well as coastal infrastructure, while reintroducing fishing harbours to the portfolio. Our comments also touch on the impact of global warming and

other environmental factors on infrastructure,” they say.

THE SCORECARD IN SUMMARY

The scorecard is based on a simple five-point scale: A (world-class), B (fit for the future), C (satisfactory for now), D (at risk of failure) and E (unfit for purpose). It also features a snapshot of the current condition and performance of 32 sub-sectors of infrastructure. These include gradings for:

Water: The quality and reliability of water supply has decreased in small towns and rural systems.

In contrast, the national water resources infrastructure system has been able to meet the demands for which it was designed.

• Bulk water resources: D-

• Major urban areas: C+

• All other areas: DSanitation (including wastewater): 16% of households still need improved sanitation.

• Major urban areas: C-

• All other areas: E

Solid waste management: A slight reduction in the provision of refuse removal services in urban areas. In rural areas, there is a significant increase in indiscriminate dumping.

• Waste collection in the major urban areas: C-

• Waste collection in other areas: D-

FEBRUARY 2023 SOUTH AFRICAN BUILDER 31 FEATURES