PRECAST

IF YOU CAN DREAM IT, WE CAN MAKE IT

IN THIS ISSUE:

Twinstar's custommade perfection

The rise and rise of managed precincts

Fire-resistance: Concrete makes the grade

IN THIS ISSUE:

The rise and rise of managed precincts

Fire-resistance: Concrete makes the grade

Our range of high quality locally-produced cement is designed for specialised applications where high early strength, improved durability and superior concrete is needed. Backed by our dedicated and highly skilled expertise our range of superior quality products are the ideal choice when there is no room for compromise, and no time to waste. Together, we make it possible. Ask for AfriSam.

WITH YOUR HIGH STANDARDS, UNCOMPROMISING QUALITY IS NOT NEGOTIABLE.

The current peak in South Africa’s most pressing problems – namely our unstable power supply, which is severely impacting industries, businesses and citizens, as well as seemingly endless musical chairs in government, mounting pressure on consumers because of rising food and fuel prices and, with them, rising criminality – is a critical time.

However, like all crises, this is a period which has as much potential to create as to destroy. The concrete and construction industries, which are bedrocks in any stable society, have shown themselves to be not only resilient, but highly resourceful and informed. We at Precast continue to draw inspiration from the sector and the endless forbearance and ingenuity of those in it. We also remain deeply proud of our association with the sector and of acting as a voice for it.

In this issue, we highlight innovative projects and products attesting to those qualities, as well as developments which reflect the needs of a fluid and expanding population. Our feature on managed precincts, which provide residents with both the security of a community and the amenities needed for comfortable living, indicates that this will likely be the way forward in urban centres. Environmentalism, too, has now become an intractable element of any construction project, with manufacturers and suppliers to the industry ensuring that their offerings are sustainable and compliant with green requirements.

There is an old African adage which goes: “When two elephants fight, it is the grass that gets trampled first.” While government parties slug it out in the media and election campaigns, the construction industry, in maintaining its commitment to its own growth, innovativeness and foresight, has shown that it is not grass, but as solid and dependable as precast. We salute it!

4 Dreamed by you – made by Twinstar

6 Cement leader unveils two new classrooms at KZN secondary school

Twinstar Precast is truly a one-of-a kind company. Quality, bespoke precast concrete pieces, elements and parts have all taken on a life of their own, through development, planning, creation, delivery and assembly.

PRECAST is independently published by Isikhova Media (Pty) Ltd 10th Floor, Metal Box, 25 Owl Street, Milpark, South Africa Tel: +27 (11) 883 4627 www.isikhova.co.za

Director: Jenny Justus

E-mail: jenny@isikhova.co.za

Operations director: Thuli Majola

E-mail: thuli@isikhova.co.za

Creative director: Joanne Brook

E-mail: joanne@isikhova.co.za

Managing director: Imraan Mahomed

E-mail: imraan@isikhova.co.za

Copy editor: Anne Phillips

Media sales: Tel: +27 (11) 883 4627 / 083 450 6052

The views and statements expressed in this publication are not necessarily those of the editor or the publishers and neither the publishers nor the editor accept responsibility for them. No person connected with the publication of this journal will be liable for any loss or damage sustained as a result of action following any statements or opinions expressed herein. The same applies to all advertising. Precast© 2023. All rights reserved. No part of this magazine may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording, or any information storage retrieval system, without prior written permission from the publishers.

“In line with its policy of supporting the South African industry, Twinstar uses small local suppliers, rather than large corporate ones, as well as SMMEs for transporting its products.”

Twinstar has long been a trusted and respected leader in the production and supply of precast concrete offerings such as slabs and plinths (ranging from 2kg to 6 tons), moulds and mining solutions, as well as a wide range of other products, including stormwater, water reticulation and polymer manhole covers and grids. In addition, it offers a wide range of electrical reticulation and installations for generators and solar (an area which is top of mind, given South Africa’s energy crisis). All these standard products and installations comply with Eskom, City Power and council specifications.

The overall value of all Twinstar products makes them an excellent choice for a wide range of civil construction and electrical applications. They are also environmentally friendly, designed for a long lifespan and low maintenance.

Designed with expert precision, and delivered timeously and reliably, its electrical products include standard minisub and kiosk plinths, trench covers for cable protection, cable markers, electrical joint boxes, distribution boxes and kiosk boxes used by municipalities to protect pre-paid meter boxes from vandalism and theft – a prime consideration at present.

Renowned, respected –and relied upon

These extensive standard offerings make Twinstar the go-to resource for the construction and precast industry. Its 26 years of experience give it unrivalled credibility in the industry and have resulted in many long-standing relationships with mainstream precast concrete companies who, in turn, refer their own clients to it.

In line with its policy of supporting the

South African industry, Twinstar uses small local suppliers, rather than large corporate ones, as well as SMMEs for transporting its products.

Going beyond the standard Twinstar takes its already proud reputation for excellence in the construction industry up a notch with its expertise in custommaking any of its extensive products to suit specific project requirements or design – something not usually offered by large mainstream companies, for whom such a service would be unprofitable.

Whether it is a once-off item, a cherished vision of a client or a project requiring unusual modifications, Twinstar’s experts will deliver a product – on time and

safely – which is perfectly aligned to those specifications. The company upholds its motto: “If you can dream it, we can make it.” Clients can relax in the peace of mind that their needs are being efficiently and expertly met.

Twinstar also offers expert design assistance and fabrication for its standard and custom-made products.

All its products are known throughout the industry for their durability, versatility, cost-effectiveness and aesthetic appeal. Designed to withstand extreme weather conditions, they undergo stringent quality checks before being made available to clients. The products are supplied with meticulous manufacturer’s guidelines for installation which ensure correct positioning, proper alignment and stability.

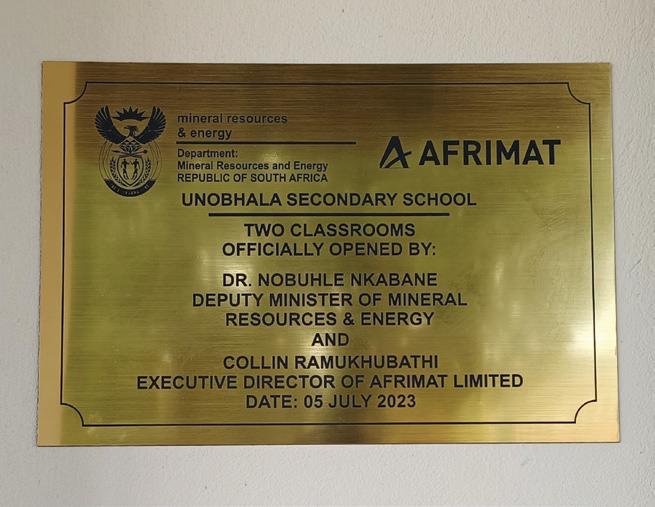

Afrimat’s Pietermaritzburg Quarry recently unveiled two additional, newly-built classrooms at UNobhala Secondary School. In partnership with the Department of Education and the Department of Mineral Resources and Energy, it has expanded the school’s infrastructure to 12 classrooms with offices.

UNobhala Secondary is in rural KwaZulu-Natal’s uMkhambathini Municipality, in the Nkanyezini area, under the leadership of the KwaNyavu Tribal Authority. It is a Section 20 institution, meaning it is a non-fee-paying rural school whose finances are centrally managed by the provincial education department.

The school is well-known for achieving excellent matric results under difficult teaching and learning conditions, such as overcrowded classrooms, a lack of resources and an imbalanced pupil-teacher ratio. The school currently has 750 pupils enrolled and a staff complement of 20. Prior to the additional two classrooms, the number of children per classroom averaged an unmanageable 75.

Great result from Social and Labour Plan

This project, costing just over R700 000,00, was undertaken as part of Afrimat Pietermaritzburg Quarry’s Social and Labour Plan commitment for the 20192023 cycle. The two additional classrooms have been allocated to Grade 12 pupils,

enabling teachers to achieve a more manageable learning environment. Jaco Daniel Construction led the project as contractor, with Meshack Wencwadi Investment Company providing services

as the sub-contractor.

This project follows other local economic development projects and initiatives undertaken by Afrimat Pietermaritzburg Quarry, including:

• 2014-2018 cycle: Pandora Environment Conservation and Education (PEACE) in the Msunduzi/Mkhambathini Municipalities. The project focused on the removal of alien plants in those areas.

• 2009-2013 cycle: Construction of an ablution block at Ashburton Primary School.

Stakeholders who attended the event included Deputy Minister Dr Nobuhle Pamela Nkabane, UNobhala High School principal Thulisani Ndlovu, executive director of Afrimat Collin Ramukhubathi, chief operating officer of Afrimat’s Construction Materials division Davin Giles, Afrimat regional manager for social development Themba Duze, Umkhambathini district director Siqhamo Mabinza (of the KZN Department of Education), Chief Mdluli (of the KwaNyavu Tribal Authority) and chairperson of the school governing body ZF Mbambo. Afrimat remains committed to partnering with different stakeholders to continue creating value in the communities in which it operates.

Cement & Concrete SA’s extensive Online Directory of Services of members is playing an important role in connecting potential customers and businesses, says Hanlie Turner, business development manager of CCSA.

She says website statistics show that the directory has become a high-traffic facility, clearly addressing a market need to find contact details for service providers on all matters pertaining to cement and concrete matters. “As CCSA’s extensive membership portfolio includes specifiers, consultants, contractors, material suppliers, service providers and academics, the scope of the online directory is enormous,” she explains.

“It’s varied and includes products and services ranging from specialised concrete performance enhancers to cementitious

requirements for reservoirs, road construction, waterproofing and temporary works, among others. This service provides potential commercial exposure for CCSA members and streamlines the search for appropriate contact information for the whole industry, from major corporate clients to individual end-users. The online directory makes trade with industry professionals much easier.”

Turner says all Cement & Concrete SA members can have their names and contact details listed in the directory, which is arranged under service categories. The offer adheres to the POPI Act (No 4 of 2013) for data protection and privacy and only members who consent are listed.

“The CCSA Online Directory is updated in real time: as soon as the CCSA’s advised of a member’s new contact details, they’re changed immediately, making this service more current than any published directory,” she says.

For further details about the directory, visit: https://cemcon-sa. org.za/online-directory.

For 131 years we’ve cemented our legacy as a reliable and supportive Pan-African industry partner, with a range of hard working, 100% LOCAL, 100% PREMIUM QUALITY PRODUCTS.

Today, our products remain as proudly South African and unshakeable, as the people who invest in them. Provider of Premium Quality Building Materials.

By Chris Campbell, CEO: Consulting Engineers SA (CESA)

By Chris Campbell, CEO: Consulting Engineers SA (CESA)

Public Works and Infrastructure Minister

Zihle Zikalala

Zihle Zikalala

recently announced the establishment of a call centre for reporting disruptions by the construction mafia at construction sites. CESA has reservations about the effectiveness of a call centre as a solution.

While we appreciate government’s efforts to address these disruptions, historically, government-operated call centre facilities have faced challenges in delivering timely and efficient services, so there are concerns about the viability of this approach. Prime among these is the absence of an efficient and reliable police response service.

Secondly, we need to ask important questions about the safety and anonymity of individuals reporting these disturbances at construction sites. It is crucial to ensure that those who come forward with information are protected and that their concerns are addressed promptly. We seek clarity on the measures in place to safeguard anonymous callers who may face threats or reprisals for reporting such incidents.

Our industry has faced persistent

disruptions since 2018. We acknowledge the efforts of law enforcement officers in this regard, but progress has been too slow in holding perpetrators accountable. It is our belief that addressing the root causes of these disruptions is essential and we echo the sentiment that without addressing such issues, challenges will persist.

We understand that public announcements and initiatives often align with political cycles, especially in the run-up to an election year. However, it is imperative that we prioritise the development of our infrastructure to foster economic growth and national development. The construction industry plays a vital role in this process and we must focus on strengthening our capacity for crime intelligence, rather than hastily recruiting individuals without the necessary qualifications or expertise to handle an issue as delicate and dangerous as the construction mafia.

CESA recognises the significance of the construction industry for our country’s development. We remain committed to constructive dialogue and collaboration with all stakeholders to address disruptions and create a conducive environment for infrastructure development. We encourage a comprehensive approach that considers the concerns and safety of all parties involved.

MAPEI offers a complete range of high-quality adhesives for ceramic, porcelain and stone materials. MAPEI stays up to date with growing trends and technology within the market, making it the ideal application solution.

The range includes:

• Polymer modified cementitious adhesives

• Deformable cementitious adhesives

• Fast-setting levelling compounds

• Reactive resin polyurethane and epoxy adhesives

• Water repellent cementitious grouts

• Water based epoxy grouts

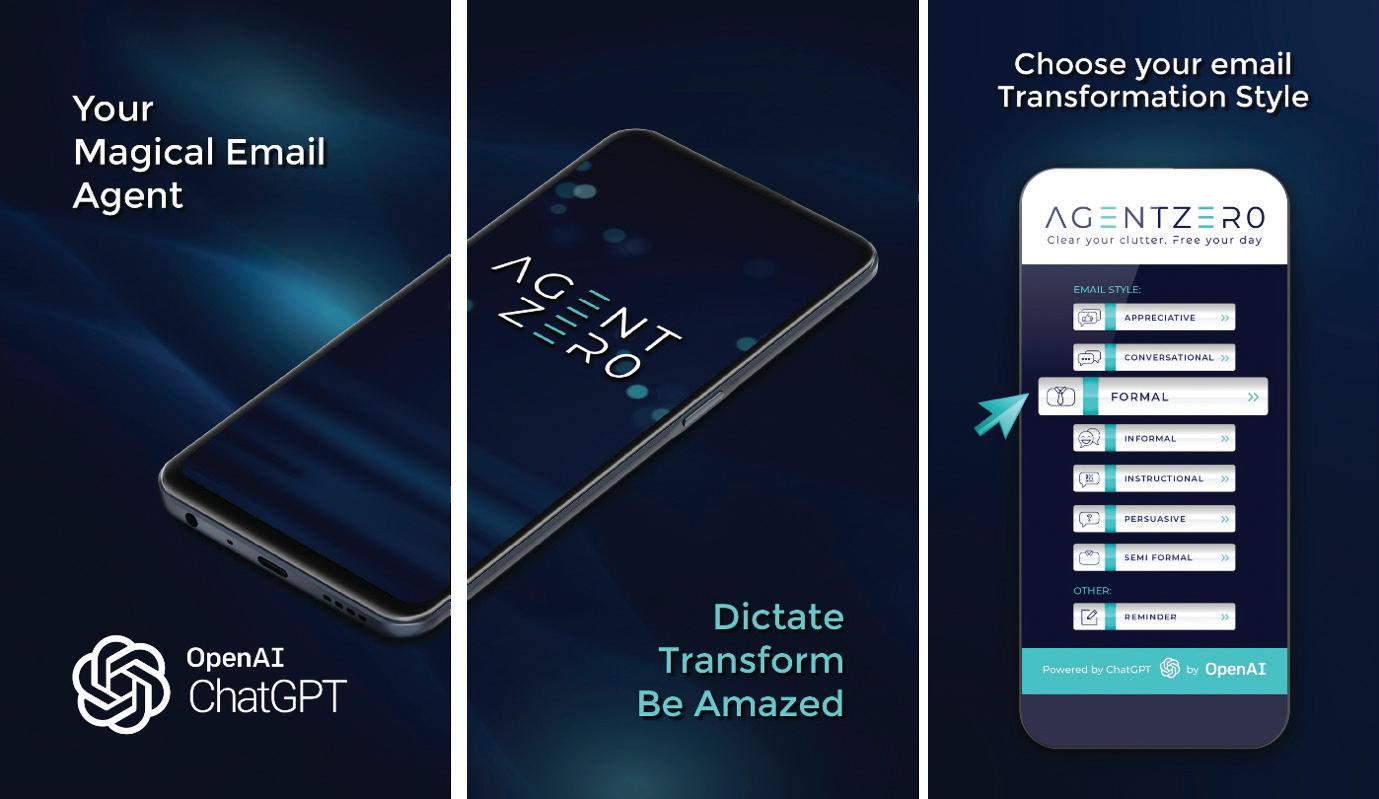

In an age when convenience and time management have never been more crucial to industry, artificial intelligence (AI) is increasingly assuming tasks that have traditionally cost companies time, money and productivity. Which is why two Boomers, Pieter Geldenhuys and Johan Pretorius, are proving that it is never too late to innovate. Drawing on their life experiences, the duo has launched an AI business that promises to revolutionise e-mail communication. Enter AgentZero.

Saving hours of work and streamlining processes, the app uses voice dictation in tandem with advanced AI algorithms to transmute raw ideas into polished, professional e-mails.

While the idea behind the concept is familiar to many from Chatbot, which – for all its controversy – is fast becoming ubiquitous, an app developed specifically for e-mails (which are shorter, more concise and more specific than lengthy, discursive articles) is a significant and welcome refinement.

Geldenhuys’s and Pretorius’s journey to developing AgentZero was not conventional. Without the foundational coding knowledge of many younger techpreneurs, they turned to AI to bridge their knowledge gap. From coding the app to sculpting its brand personality, they leaned into the power of advanced technology.

Geldenhuys says that even the name of the offering was AI-influenced.

“AgentZero, a name suggestive of a new beginning and the streamlined nature of the application, was born from algorithms that analysed market trends, linguistic appeal and brand compatibility. It was like having a branding guru at our fingertips. It makes every user feels as if they’ve just witnessed a spell being cast when their scattered thoughts are woven into coherent, eloquent messages,” he enthuses.

Users can choose the tone of the e-mail they need to send: formal, semi-formal, informal, appreciative, conversational, instructional, persuasive or a reminder.

While Pretorius says the two realised that their strength did not necessarily lie in coding or the nittygritty of app development, they did understand the value of effective communication. “We entrusted AI to help bridge our concept with the technological aspects. Instead of typing away on a tiny phone keyboard or labouring over phrasing, users can effortlessly speak their thoughts and let the app do the rest,” says Pretorius.

He believes that the success of AgentZero not only highlights the universal applicability of AI, but also underlines the power of diverse perspectives in the tech industry.

AgentZero can be downloaded from Apple Store or Google Play.

(Above): Pieter Geldenhuys, co-developer of AgentZero.

(Above): Pieter Geldenhuys, co-developer of AgentZero.

The role that Cement & Concrete SA (CCSA) plays in the promotion of concrete and the assistance it provides to users of the world’s oldest building material – even at layman’s level – should not be overlooked, says John Roxburgh, technical specialist at CCSA’s School of Concrete Technology.

Roxburgh says the official and main mission of CCSA – the voice of the South African cement and concrete industry – is to create shared value and industry growth through driving collaboration, skills development, innovation and the highest standards in sustainable cement and concrete materials and products.

“However, a less conspicuous role that CCSA plays is the extensive service it provides to the general public. This contact can be through telephonic or e-mail enquiries, visits to the CCSA website or personally calling at the CCSA offices in Midrand. CCSA’s vast experience provides a great sounding board for ideas with suggestions that could save innovators hours in development and application,” he says.

Roxburgh adds that he has personally helped many enthusiasts produce innovative concrete pots, furniture or concrete jewellery, DIY enthusiasts build their own concrete countertops, farmers build reservoirs and concrete strip roads, and diverse entrepreneurs start their own flooring businesses or precast yards.

“However, the most exciting people I’ve dealt with are the innovators. These ‘concrete inventors’ constantly show the huge innovative scope of cement and concrete. Some come up with crazy ideas, but others have amazing, exciting concepts and infectious enthusiasm. A striking example is Carl Supra.”

The two met about 10 years ago at a trade show when Supra approached

Roxburgh to discuss technical aspects of an innovative, low-density concrete building system using light plastic shutter that he was working on. “Carl’s passion and speciality is plastic moulding, which ideally complements his substantial industrial design knowledge. He’s designed and developed many products, including a revolutionary one-piece pool-cleaner. Having spent many hours as a youngster pottering around a concrete testing laboratory managed by his uncle, Carl wasn’t new to concrete and had long seen the potential of combining his plastic moulding knowledge with concrete. He’s ingeniously used the technical advice CCSA has given him and two excellent new products, developed for his company, Polycrete Eco-Panels, have resulted from his association with us.

“Firstly, he became aware of the need for locally produced plastic cube moulds, so he promptly designed and produced one. That resulted in the only South Africanproduced plastic 100mm and 150mm cube moulds which are now manufactured locally by Polycrete Eco-Panels. Over

10 000 are already in use in SA.

“More recently, CCSA introduced Carl to textile concrete and again, he quickly developed an extremely versatile textile concrete wall panelling system, based on an ingenious internal thinly-filmed plastic shuttering system which works well with roll-formed, light steel-framed building sections. The panels are both structurally sound and lightweight, with a unique concrete mix design that accepts nails as if it were wood. The simplicity of the panel construction – along with almost no capital outlay – could become a relatively easy new business for anyone wanting to produce these panels,” says Roxburgh.

He feels Supra’s concrete achievements should be an inspiration to all other innovators to work with CCSA to expand and apply their concrete inventions. “It clearly shows that all potential entrepreneurs – not only big-budget corporates and major industry – should make full use of the technical potential of concrete. Budding entrepreneurs shouldn’t hesitate to talk to CCSA to help develop the small businesses SA needs right now,” he adds.

“However, the most exciting people I’ve dealt with are the innovators. These ‘concrete inventors’ constantly show the huge innovative scope of cement and concrete.”

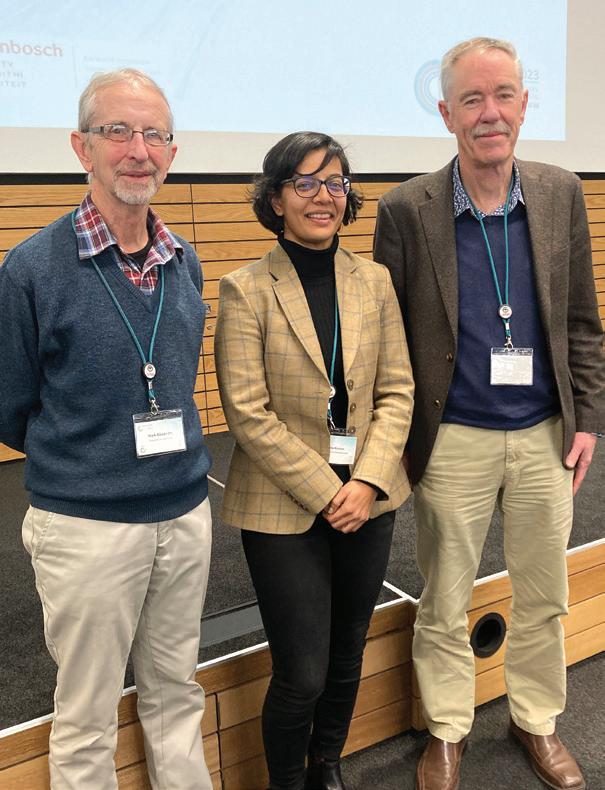

Cement & Concrete SA (CCSA) has presented its Young Concrete Researcher Award for 2023 to Janina Kanjee, who is currently completing her PhD studies in civil engineering at the University of the Witwatersrand. The 34-year-old was singled out for her “significant contribution to the advancement of cement and concrete through research excellence in the South African environment”.

Kanjee holds MSc (Eng) and BSc Civil Engineering degrees from the University of Cape Town. Currently a lecturer at the Wits School of Civil and Environmental Engineering, she has extensively researched subjects such as concrete durability, testing and assessment, as well as rehabilitation and maintenance.

Criteria for the prestigious biennial CCSA award, introduced at YCRETS 2021, include published papers in accredited journals, presentations at peer-reviewed conferences, postgraduate supervision, dissertation and paper reviewer experience, as well as participation in industry-related activities in SA.

In addition to Kanjee’s impressive academic research record, she is a board member of the erstwhile Concrete Society of SA and was the conference chairperson for the CCSA YCRETS 2021 organising committee. Furthermore, she was actively involved in establishing the Wits SA Institution of Civil Engineering (SAICE) Student Chapter in 2017 and the Wits Institution of Civil Engineering (ICE) Student Chapter in 2019 – the latter a first student chapter in SA for the internationally renowned UK institution.

Other candidates in contention for the CCSA Young Concrete Researcher Award 2023 were:

• Dr Alice Bakera of the University of Dar-es-Salaam, Tanzania.

• Nikhiel Budhai of building materials supplier Upat SA.

• Dr Jacques Kruger of the University of Stellenbosch.

• Dr Sanjeev Kumar of the University of Virginia, USA.

The award adjudicators were Bryan Perrie (CCSA CEO), Prof Mark Alexander (UCT Emeritus professor and CCSA board member) and Hanlie Turner (CCSA business development manager) and their choice of Kanjee was unanimous.

Reacting to receiving the award, Kanjee said: “I’m deeply honoured. My heartfelt thanks go to the organisers, the judging panel and everyone involved in this journey for their unwavering support, encouragement and belief in the potential of young researchers.

“This award motivates me to push the boundaries of cement and concrete research further to advance our understanding of concrete materials, explore innovative construction techniques, and promote sustainable practices to benefit both society and the environment.”

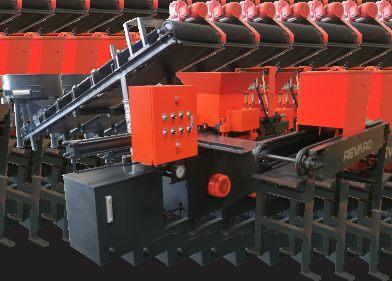

(Above): The CCSA Young Concrete Researcher for 2023, Janina Kanjee, with Bryan Perrie (CEO: CCSA) (right) and Prof Mark Alexander (UCT Emeritus professor and CCSA board member).In the realm of concrete and construction, innovation is a driving force for progress. Revaro, a renowned supplier of precast manufacturing equipment and machinery, has been at the forefront of this revolution, simplifying processes and transforming the concrete industry.

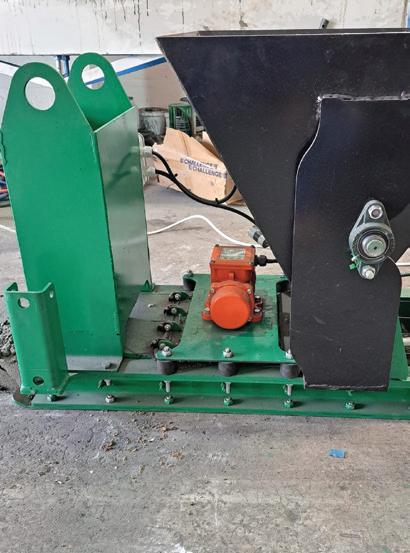

One of the key ways in which it does this is through its state-of-the-art concrete batching plants, ranging from two to five bin batches with hoppers of 2-20m³ respectively. These plants are designed with precision in mind, ensuring the accurate mixing of various materials to create high-quality concrete products with a productivity capacity of up to 192m³/h. By automating the batching process, Revaro eliminates the guesswork, reducing human errors and delivering consistent results.

Revaro batching plants are the perfect addition to complement and optimise the wide range of concrete mixers available, from drum mixers, 350500L pan mixers and 500-1 500L twinshaft mixers to 500-3 250L planetary mixers, as well as manual and fully automated PLC-controlled mixers.

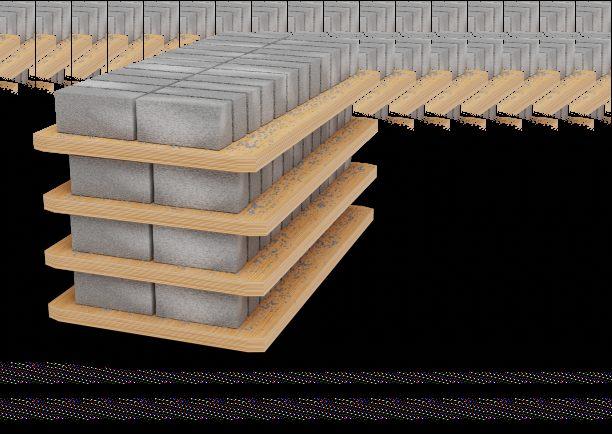

Another vital aspect of Revaro’s range of precast equipment is its concrete brick-, block- and paver-making machines. These machines, from the REL range of egglayers to the medium RS static and large RE fully automated machines/plants, come with interchangeable moulds. This means you can easily switch between various profiles, from stock bricks to hollow blocks, pavers and everything in between. By centralising multiple production capabilities into a single machine, Revaro helps manufacturers optimise their space and resources, resulting in a more efficient and simplified operation. To further increase automation, single-, doubleand triple-pallet stackers that work in conjunction with forklifts are also available from Revaro.

Below are just some of the additional key points that make Revaro the trusted one-stop-shop for the concrete and construction industries:

– Our lintel extruder machines cut down 75% of the labour in lintel production. This value for money is only available from Revaro.

– Revaro has the most affordable roof tile plant available in Africa.

– Revaro is the only company in SA to supply an automatic single-head kerb press, which is also the most affordable. We also supply three-head kerb plants.

Revaro precast manufacturing machines

have a 33-50% lower cost for the same output machine available in the market today, delivering the highest return on investment on the continent. We have customers in more than 20 countries who vouch for this!

Our range of precast manufacturing equipment and machinery plays a vital role in simplifying the concrete and construction industry. From automated batching plants to versatile brick-, blockand paver-making machines, Revaro empowers manufacturers with tools to streamline their operations and meet the ever-evolving demands of the market. As the industry continues to embrace innovation, Revaro remains a trusted partner, driving simplicity and efficiency for a brighter future in construction.

“Revaro precast manufacturing machines have a 33-50% lower cost for the same output machine available in the market today.”

Kirby Group Engineering has officially opened its new office in Cape Town, the company’s first base outside Europe. The management welcomed Tánaiste and Minister for Foreign Affairs of Ireland, Micheál Martin TD, to the office within the iconic Newlands Cricket Ground to mark the occasion.

The Limerick-headquartered firm was established by brothers Tom and Michael Kirby in Thomondgate in 1964 and has since grown into a leading provider of mechanical and electrical engineering contracting services. Kirby now employs over 1 400 staff across nine European countries and recorded a turnover of more than R9 billion in 2022.

Thirty people are expected to be working at the Cape Town office by the end of this year and the firm is expecting to grow that number further in 2024.

“Establishing a presence in SA offers many benefits to a company such as Kirby and I’d like to wish you every success as you build further on a great Irish business story,” said Martin. “Ireland’s business and trade links with SA are strong and growing, and Kirby is very much at the forefront of that growth.”

Kirby’s management team selected SA for the new base for several reasons, including the talented workforce, which has already seen many South Africans join the Kirby team across Europe, the high standard of education within the graduate community, the lack of a language barrier and the fact that SA has a similar time zone to that of Ireland.

The company’s Cape Town team will comprise engineers, quantity surveyors, talent acquisition specialists and others who can all contribute to projects on an off-site basis.

“Expansion outside the EU and into SA Africa represents a great opportunity to access local talent here and is a statement of confidence in the future of this company. This move has been 12 months in the planning and execution and I look forward to building on Kirby’s relationships here long into the future,” said Kirby executive chairperson Jimmy Kirby.

“Wesgro welcomes Kirby to Cape Town and the Western Cape. With our world-class infrastructure, top universities, young talented workforce, excellent governance record and a commitment to making it easy to do business, the Western Cape supports thriving manufacturing and construction businesses,” responded Wesgro CEO Wrenelle Stander.

Recruitment for the Cape Town office began in recent months and current vacancies are listed on careers.kirbygroup.com.

An exciting upgrade of the refinery interchange on Cape Town’s busy N7 motorway will soon ease the flow of traffic and enhance safety. Construction material specialist AfriSam is working with wellestablished Cape contractor Haw & Inglis Construction to ensure a smooth project roll-out to the highest quality standards.

Since July 2021, Haw & Inglis Construction has been proceeding apace on the upgrade of Cape Town’s refinery interchange, supported by construction materials from AfriSam.

The project is due for completion in early 2024, delivering two new higher and wider bridges over the busy N7 highway – a new road-over-rail bridge alongside the existing bridge which receives rehabilitation works and the upgraded access ramps, among the key achievements.

Leiton Chan, construction manager at Haw & Inglis Construction, says that due to capacity and height limitations of the existing bridge, the new bridges double the capacity and provide an additional 1,7m

clearance from the existing bridge for vehicles travelling on the N7. To accommodate existing traffic, the west-bound carriageway was constructed alongside the existing eastbound one. Once completed, the traffic was diverted onto the new carriageway to complete the east-bound carriageway. The existing bridge was demolished in December 2022 to make space for the new bridge, which is currently under construction.

“Each bridge deck over the N7 was cast in two, consisting of a dual-spine, posttensioned structure,” explains Chan. “The project’s currently on schedule, with the completion of the east-bound carriageway bridge over the N7 in August this year.”

Materials matched for demanding design

AfriSam is providing around 6 300m3 of ready-mix concrete, as well as material for layer works, according to Bradley Thomas, territory sales manager at the company, which is also supplying some 15 000t of aggregate for the road work to the project’s asphalt supplier, Much Asphalt.

“An important application of our ready-mix was for the piling under the bridges, which required almost 1 500m 3 of high-strength 40MPa concrete for this purpose,” says Thomas. “A priority here was avoiding any jointing in the piles, so it was essential that each pour – about 3,5m3 per pile – was continuous.”

He notes that the decks on the two main bridges over the N7 also require continuous pours, amounting to substantial volumes of 500m3 of W50MPa concrete per deck. Placement is carried out using a high-

capacity 36m boom placer. The ready-mix is supplied from AfriSam’s Contermanskloof plant in Durbanville, located 8km from the site, with support from the company’s other nearby plants at Woodstock and Bellville.

The spreading of supply sources allows

for further mitigation of project risk related to ready-mix deliveries, says Thomas. For instance, large continuous pours leave little room for error, while unforeseen events such as traffic congestion have to be factored into the resource planning.

From ready-mix pours to precast kerbs

“On the smaller-scale aspects of the project’s ready-mix requirements, our flexibility also allows us to effectively supply the smaller sub-contractors on the project,” he adds. “We’ve therefore also been able to play a role in enterprise development, supplying the kerb mix to SMME contractors installing the precast kerbs.”

According to Chan, Haw & Inglis Construction has been able to incorporate a considerable amount of recycled material in the road fill. He points out that the westbound carriageway fill was made up of in-situ G7 sand material excavated from the bridge and mixed with recycled asphalt product (RAP). The RAP is milled material from the various road contracts conducted by the Western Cape government.

In addition to carefully facilitating the traffic flow through the interchange during construction, the project has had to navigate underground and overhead services from high-voltage power lines and diesel pipes to sewer networks and optical fibre lines, he says. A further environmental priority was not disturbing two small wetlands within the road reserve.

“Large continuous pours leave little room for error, while unforeseen events such as traffic congestion have to be factored into the resource planning.”(Below): The ready-mix is supplied from AfriSam’s Contermanskloof plant, with back-up plants nearby in Woodstock and Bellville. (Above): The critical path is the two bridges, joined by a 1 000mm stitch to resemble a single structure.

frustration among citizens, creating an urgent need for alternative solutions.

According to the World Bank collection of development indicators, the urban population in SA accounted for 67,85% of the total population in 2021. This indicates a significant proportion of the country’s population residing in urban areas, adding more pressure for urban planning to meet their needs.

Managed precincts have emerged as a promising answer to these challenges, providing well-planned developments that integrate residential, commercial and recreational spaces within a cohesive, safe and well-maintained environment.

In the dynamic landscape of urban development, South Africa is witnessing a remarkable shift towards managed precincts. These thoughtfully designed and carefully curated spaces are redefining the way we inhabit and experience our cities. Managed precincts are revolutionising the concept of a harmonious and fulfilling lifestyle.

SA faces significant challenges in terms of infrastructure and essential service delivery, including power outages, water shortages, inadequate waste management and poorly maintained public spaces. These shortcomings have led to mounting

SA boasts a collection of successful managed precincts that have transformed urban landscapes and set new standards for community living. The Umhlanga Urban Improvement Precinct (UIP), established in 2015, has played a crucial role in transforming Umhlanga into a thriving and well-maintained urban hub. Focusing on safety, cleanliness and aesthetics, the UIP has significantly enhanced the quality of life for residents and visitors. Through dedicated security patrols, efficient waste management systems, landscaping initiatives and urban maintenance projects, the precinct has successfully reduced crime rates, improved street cleanliness and created a more welcoming environment. Its collaborative

approach, involving local stakeholders, residents and businesses, has fostered a strong sense of community pride and ownership.

Waterfall City – a large-scale, mixed-use development located between Johannesburg and Pretoria – redefines urban living with its seamless integration of residential, commercial and retail components. Offering a holistic and sustainable lifestyle, it provides a diverse range of residential options, convenient access to amenities, well-designed infrastructure, efficient transportation networks and ample green spaces. Its appeal extends to businesses as well, attracting numerous corporate offices and commercial spaces, both locally and internationally.

Other prominent examples include Melrose Arch in Johannesburg, the V&A Waterfront and Century City in Cape Town, Menlyn Maine in Pretoria and Steyn City on the outskirts of Johannesburg. What all these developments have in common is that they are beacons of progress, demonstrating the potential for welldesigned precincts to enhance quality of life, attract investment and foster economic growth.

Riverfields: Managed precinct 2.0

It is therefore no surprise that Riverfields, as the newest kid on SA’s precinct block, has opted to follow and try to improve the managed precinct model. In a country where service delivery challenges faced by municipalities are experienced daily, Riverfields has instituted meticulous planning and efficient management of the precinct to make it an ideal place to live and work. A key factor contributing to the increased demand and rising success of this up-and-coming precinct is the emphasis on integrated urban planning. Thanks to the ongoing public and private partnership developed for the precinct, it boasts

diligently maintained infrastructure, including road networks, utilities and public recreational spaces, all meeting the needs of residents and businesses.

These strategic partnerships with local authorities and service providers ensure the efficient delivery of essential services to the area. The Riverfields Management Association prioritises safety and security, implementing robust measures to create a secure environment for residents. Active community engagement fosters a sense of belonging and pride among residents, further enhancing the overall living experience.

Unlocking a brighter future Riverfields showcases the transformative potential of a managed precinct, creating a harmonious and sustainable community where residents can thrive. We have seen time and again that successful precincts can have a significant positive impact on the local economy. They attract businesses, tourism and investment, which leads to job creation and increased economic activity. The presence of commercial spaces and retail outlets also generates revenue for local government through taxes and fees.

There is no denying that managed precincts represent a transformative solution to SA’s infrastructure and essential service challenges. With their focus on sustainability, security and superior living environments, these precincts offer a glimpse of a brighter future and are already featuring in the decision-making process as attractive criteria for businesses and individuals seeking a home.

It is crucial for stakeholders to embrace managed precincts as catalysts for change, encouraging increased private-sector involvement and government support. By working together, we can forge a path towards a more sustainable and desirable SA.

“These precincts offer a glimpse of a brighter future and are already featuring in the decisionmaking process as attractive criteria for businesses and individuals seeking a home.”

As a leader in your organisation, it is crucial to embrace the task of continuously fostering growth and development within your teams. This approach holds the key not only to enhancing existing leadership skills, but to identifying untapped potential among individuals. The precast business is equally task-driven by capable operational management. By cultivating their capabilities, you pave the way for strong leadership and a pipeline of leaders for the future.

Jacqueline van Rooijen, business strategist and transformation coach, shares 10 transformational leadership growth hacks that will elevate your team’s leadership capabilities:

1. Foster a culture of trust: Trust is the cornerstone of high-performance teams. Nurture it by demonstrating transparency, promoting open communication and following through on commitments. A culture of trust fosters collaboration and empowers a team to take risks and innovate.

2. Embrace authenticity: Emphasise the value of authenticity in leadership. Encourage leaders to be genuine, show vulnerability and lead with integrity. Authentic leaders inspire trust and create an environment where team members feel safe to express themselves.

3. Develop emotional intelligence: Emotional intelligence is a key driver of effective leadership. Help leaders to cultivate self-awareness, empathy and emotional regulation. Leaders who understand and manage emotions foster stronger relationships with their teams.

4. Encourage a growth mindset: Promote a growth mindset among leaders and teams alike. Emphasise the importance of continuous learning, embracing challenges and viewing failures as opportunities for growth. A growth-orientated culture breeds resilience and fosters innovation.

5. Prioritise effective communication: Communication is the lifeblood of successful leadership. Train leaders to communicate with clarity, active listening and empathy. Clear communication aligns teams, reduces misunderstandings and enhances overall performance.

6. Empower through delegation: Equip leaders with effective delegation skills. Teach them to distribute tasks according to team members’ strengths, providing the necessary support and trust. Empowered team members become more engaged and take ownership of their work.

7. Create a compelling vision: Inspire leaders to craft a compelling vision that aligns with the organisation’s mission. A clear vision energises and motivates team members to work towards shared goals, fostering a sense of purpose and direction.

8. Embrace diversity and inclusion: Encourage leaders to embrace diversity and inclusivity. Highlight the value of diverse perspectives in problem-solving and decision-making. Inclusive environments promote creativity and lead to stronger team dynamics.

9. Cultivate coaching skills: Develop leaders as coaches to nurture their teams’ potential. Coaching encourages selfdiscovery, boosts performance and fosters a culture of continuous improvement.

10. Lead through change: Equip leaders to navigate change effectively. Provide tools to address uncertainties, communicate the vision for change and inspire resilience among team members.

By focusing on these 10 transformational leadership growth hacks, leaders can make a positive impact on their teams and foster an environment that thrives on trust, authenticity and continuous improvement. The result is a workforce that is empowered, motivated and ready to embrace challenges with resilience.

“Leadership growth is an ongoing journey,” says Van Rooijen, “and as we explore and implement these insights, we set the stage for transformation, unlocking the full leadership potential within teams.” As each growth hack is adopted, your teams inch closer to becoming catalysts for positive change, enabling your organisation to achieve exceptional results.

“Clear communication aligns teams, reduces misunderstandings and enhances overall performance.”(Above and below): It is the age of blue-sky thinking across the concrete industry: new ways of sourcing new materials; precast components that catalyse engineering solutions... Leadership with a view on creating a sustainable future will lead precast into its full potential as a champion of construction's transformation.

Even in an industry as competitive as construction, the pressure to improve environmental performance is growing. Developers are targeting “green buildings” and want their contractors to be fully on board. An important way of reducing the carbon footprint of projects is by carefully sourcing one’s construction materials, argues AfriSam.

With the trend towards green buildings, contractors are expected to support their customers in reaching sustainability goals. AfriSam’s product range has been evolving with this in mind.

Decades of innovation in terms of environmental responsibility and carbon reduction have put the company out front, according to cementitious executive Hannes Meyer. It was one of the first to develop its own sustainability roadmap and this is now paying off for customers.

“The sustainability drive in the construction sector is gathering momentum,” says Meyer. “The carbon footprint of construction materials is where contractors can make immediate gains when seeking to align a project with more stringent environmental standards.”

He points out that the company has made continuous progress in fields such as energy-efficiency, cement extenders, water conservation and biodiversity. This allows customers to procure products in the knowledge that the environmental and carbon impact is minimised.

“We give our customers the opportunity to support a more sustainable future for the sector by choosing construction materials that embody this commitment,” explains Meyer. “We don’t just set theoretical targets for environmental performance; we’re practical about what we can achieve, because we’ve been innovating on this front for so long.”

This is in clear contrast to a significant level of “green-washing” in this sector, where

many companies advertise a sustainable approach, but without credible evidence of how their targets are to be achieved. Since 1990, AfriSam has been able to reduce the volume of carbon dioxide emissions per ton of cementitious material by 33%.

In a carbon-intensive industry like cement manufacturing, it is difficult to reduce the carbon impact without a depth of expertise and constant investment in innovation, says AfriSam process engineer Marieta Buckle. It is also important to consider the cost implications of any changes, given South Africa’s need for a just transition to a sustainable future.

“In our position as a developing country, our future will demand the construction of millions of houses – structures that require considerable quantities of cement,” she says. “The way we pursue our just transition must take into account the affordability of these homes for the vast majority of citizens.”

For these reasons, AfriSam has been cautious in the way it sets and publicises its sustainability targets, while continually prioritising research and development into how to achieve lower carbon products. Having considered a wide variety of options, it has implemented strategies which have the least cost impact on customers and the market.

“We don’t just set theoretical targets for environmental performance; we’re practical about what we can achieve, because we’ve been innovating on this front for so long.”

As the demand for new power generation grows, so does the demand for qualified and skilled talent in the country’s renewable energy sector – and, like its international counterparts, it needs a rising pool of qualified candidates to draw from. South Africa’s shortfall has been exacerbated by the sector’s seven-year hiatus and subsequent failed procurement rounds, resulting in the industry losing hundreds of skilled people, including a large cohort of engineers, wind turbine technicians and general service personnel, who sought employment in the global market.

The industry is now working hard to attract talent back in order to rebuild the dwindling talent pool, warns Nordex Energy SA, citing the direct effects on the manufacturing and services sector.

“We currently have a shortfall of trained and experienced wind technicians in the country, having lost much of our skilled capacity to advanced international markets. This is a direct result of the interrupted procurement that’s plagued the sector since 2014. We stress that consistency, policy and market certainty are the bedrocks of unlocking the renewable energy sector’s enormous employment and investment potential,” says Zelrese Brair, head of People & Culture at the company.

If the sector is to shift from its current survival mode, policy certainty and a robust skills base geared towards services and renewable energy manufacturing are necessary.

The draft sector masterplan (SAREM) has identified nine key working areas

a workforce fit for the industry,” says Brair.

that need support to create an enabling environment for the renewable energy value chain, specifically identifying skills.

The foundation of a clean energy workforce is rooted in STEM education, so it is necessary to look at government stakeholders to drive school and tertiary education, across all grade levels.

“The development and enhancement of STEM education and the addition of more training facilities will unlock greater job potential for our country in the renewable sector, in the same way that it will provide

The wind industry needs a broad talent pool that focuses on engineering (electrical, mechanical, industrial, civil); natural sciences and maths (physics, chemistry, maths, statistics and environmental sciences); administration and management (accounting, business administration, finance, procurement, human resource management), and social sciences/humanities (economics, gender, international relations, communication, population studies, law), in addition to other skills such as computer science, management information systems and software engineering.

“If the sector is to shift from its current survival mode, policy certainty and a robust skills base geared towards services and renewable energy manufacturing are necessary.”(Above): Zelrese Blair, head of People & Culture: Nordex Energy SA.

Amphibious Toyo VH pumps, available from IPR – the official southern African distributor of this range – are designed to operate effectively in challenging environments. They can function both above the water (dry) and underwater (submerged), making them an ideal solution for diverse applications across the mining, oil and gas, construction and agricultural sectors.

In the mining industry, these pumps play a crucial role in dewatering (ie, the removal of water infiltrating open-pit and underground mines). They are also capable of handling heavy and abrasive slurries in the construction sector, particularly in dewatering building sites and during tunnel construction. They can operate either partially or completely submerged. A compact version with an inline outlet discharge is highly beneficial in tunnelling works where space is limited.

Ruaan Venter, business development manager at IPR, says the usefulness of Toyo VH amphibious pumps extends to environmental clean-up and remediation efforts, where they efficiently pump out contaminated groundwater or surface water, even when the water is laden with solids or sediment.

“In wastewater treatment facilities,

Toyo VH pumps handle sludge and other dense materials, while in the agricultural industry, these amphibious pumps are key in irrigation and drainage systems, especially in flood-prone areas. Their ability to function both submerged and above water is crucial in maintaining optimal growing conditions by controlling water levels in fields,” says Venter.

The industrial sector also relies heavily on the pumps’ versatility. They are used in processing plants for food processing, chemicals and petroleum, where they handle slurries . Thanks to their robust construction, they are able to manage corrosive and abrasive fluids by solidifying them.

Their design incorporates a semi-open impeller, ample passageways for solids, heavy-duty shaft and bearing configuration and double mechanical seals operating in an oil bath. They can function as priming or booster pumps and are installed on a frame with a strainer or with a fixing cone, with or without an agitator. Models from the Toyo VH15 and larger ones come with an adjustable wear plate to optimise hydraulic efficiency.

These pumps can manage slurries with densities of at least 1,25kg/dm³ and solid contents up to 55% by weight. They can handle solid particles up to 80mm in

diameter and liquid temperatures up to 60°C, with pH levels of 4-14.

Venter explains that one of the most important advantages of the Toyo VH range features a unique agitator design which lifts sediment into suspension, enabling the continuous pumping of media with high solid concentrations.

Capable of operating at maximum depths of 30m, these pumps are suitable for surface applications or those requiring partial or total submersion. Special versions of Toyo VH pumps can handle solid content of up to 60% by weight and liquid temperatures up to 80°C. Variations in materials of construction, including stainless steel and specialised alloys, are available for applications with these extremely high temperatures.

“Capable of operating at maximum depths of 30m, these pumps are suitable for surface applications or those requiring partial or total submersion.”(Above): The Toyo VH range of amphibious pumps can manage slurries with densities of at least 1,25kg/dm³ and solid contents up to 55% by weight. (Left): The Toyo VH range features a unique agitator design that lifts sediment into suspension, enabling the continuous pumping of media with high solid concentrations.

In the design and construction of buildings and structures, the preservation of life and prevention of injury due to fire are the most critical considerations – apart from minimising damage to the structure itself, says John Roxburgh, technical specialist at Cement & Concrete SA’s School of Concrete Technology.

Roxburgh says approaches taken to mitigate fires in buildings are multi-faceted and include active measures such as smoke detectors, fire alarms, sprinkler systems, smoke extraction and evacuation protocols. Passive measures include fire containment through fire-resistant walls, roofs, floors and the installation of fire doors, along with clear signage to show accessible fire escape routes.

“An important component of fire engineering is preventing the spread of fire within a building. By containing

the fire, further damage to the building is prevented, while minimising the heat build-up and deadly smoke emissions. Concrete is an excellent building material to use for the containment of fire,” he explains.

He says concrete:

• Is non-combustible and will therefore not add to the fire load.

• Does not produce toxic smoke or drip hot molten material.

• Retains its structural strength under most fire conditions.

Highest-grade fire-resistance

“Concrete also doesn’t need any fireprotective coating and can slow down the transfer of heat in a building. For all these reasons, it’s classified as an A1 building

material which represents the highest grade of fireresistance under the stringent European standards.

“Concrete’s fire-resistance is based on its unique composition and physical properties. It’s made from a mixture of cement, water and aggregates. These components combine to make a material with low thermal conductivity, which allows the concrete to shield other parts of the building from the heat. Even after prolonged exposure to fire, the internal concrete temperatures can remain low to both prevent the spreading of fire and protect the steel reinforcement embedded in the concrete,” says Roxburgh.

He says that at temperatures above 300°C, concrete starts to lose its strength. However, even then, high temperatures are typically localised at the surface of the concrete, with the core concrete retaining its structural integrity. “This is important to prevent sudden and catastrophic collapse. At very high temperatures, the surface of the concrete can spall and at times this can be explosive, depending on the rate of heat build-up. Spalling is caused by the residual water in the concrete turning to expansive steam. To control this in areas where spalling may occur – such as traffic tunnels – polypropylene fibres can be included in the concrete mix. The fibres melt under high temperatures to provide space into which the steam can expand.

“Most concrete buildings aren’t completely destroyed by fire and, in many cases, there’s no adverse effect on the structure’s load-bearing capacity. Since one doesn’t have to demolish and replace the building, it’s possible for repairs and reoccupation to take place quickly. This gives obvious economic benefits to the property-owner, including reduced insurance premiums.”

Understanding more about concrete Roxburgh says it is not surprising that concrete is regarded as the ideal building material for factories, warehouses and power plants, particularly those with flammable materials or machines operating at high temperatures.

“Concrete can be manufactured to an extensive range of specifications to suit a wide variety of requirements and applications by using different mix designs or adding different materials in the concrete mix.

“Concrete offers both aesthetic appeal and economy. Its strength, durability and natural thermal mass produce structures that require low maintenance, while providing high durability. It’s by far the most economical building solution based on initial cost, long-term durability, energy-efficiency, low maintenance and operational costs, as well as opportunities for future modification and re-use, should the occupancy of the building change,” adds Roxburgh.

“Even after prolonged exposure to fire, the internal concrete temperatures can remain low to both prevent the spreading of fire and protect the steel reinforcement embedded in the concrete.”

Four phases of service stands at Twatwa, near Benoni on the East Rand, will have all infrastructural elements completed by the end of October 2023. Technicrete, part of the Infrastructure Specialists Group (ISG), supplied Zig-Zag (JZZ) pavers and mountable and garden kerbing for the 2 560 stands.

“Technicrete quality needs no explanation. The pavers and kerbs supplied were all manufactured to SA National Accreditation System [SANAS] requirements at Technicrete’s Olifantsfontein plant. Additionally, having worked with Technicrete before, we know that its stock-on-hand, delivery, pricing and availability are what give it the edge in the marketplace,” says Hendrik Reyneke, site manager for Road-Tech, the infrastructure contractor for the project.

The Twatwa project required 2 000m² of Technicrete’s precast 60mm and

6 000m² of its 80mm grey JZZ interlocking pavers. The JZZs form a durable, hard-wearing surface overlay, while still remaining a cost-effective paving solution. Offering superior longevity, they are designed to withstand a high level of foot and vehicle traffic. These are the product elements for which Technicrete is renowned and the ones best suited to the large application for the pavers and kerbs required on the project.

The kerbs are precast concrete kerbs. The JZZ 80mm pavers were used in conjunction with the mountable kerbs. The garden kerb, with a light- to mediumduty bull-nosed edge restraint, supported the 6 000m2 pavers used for the project’s pathways. It is used specifically to service areas where there is a possibility that vehicles will access the pathways and need to be guided to remain on them. It is also applied around islands in parking areas with light traffic conditions.

“Technicrete always brings product reliability to site with SANAS certification via CMA Certification Services. Addi -

tionally, our technical teams’ ability to ensure the correct solution is supplied to match customer requirements is an invaluable service that ISG offers as a whole,” says Thabani Mtolo, Technicrete’s sales consultant.

Accidents happen in a heartbeat – and often, even lightning-fast reflexes are not enough to repel looming danger. How to safeguard the seconds before conscious thought kicks in has posed a problem for construction workers for centuries, particularly when it comes to chainsaws, which are among the most lethal of tools when things go wrong.

These are the moments when personal protective equipment (PPE) is an unwavering necessity. While many conscientious chainsaw users employ helmets and gloves, a vital component often remains overlooked – protective pants. Astonishingly, studies reveal a stark reality: just under half of all chainsaw-related injuries target the legs.

For this reason, Husqvarna – a global leader in outdoor power products – has introduced an essential addition to its PPE arsenal: chainsaw pants.

Crafted with meticulous care in South Africa, the pants represent Husqvarna’s unwavering dedication to exceptional craftsmanship, unrivalled innovation and – above all – safety.

for him and that local manufacturers were deliberately chosen. “South Africans are talented, resourceful, innovative and our chainsaw pants epitomise our faith in the synergy between innovation and local ingenuity,” he says.

Husqvarna chainsaw pants are designed for protection. Certified Class 1 – 20M/S, they courageously face chainsaw speeds of up to 20m per second. Meeting the ISO 11393-2 international standard, they are an unmatched safeguard, catering to both home-owners and professionals in construction, forestry, arboriculture, farming and the realms of green space management. Tailored sizing, ranging from waist sizes 77-132, weaves a tapestry of custom fit, fusing flexibility and comfort into a seamless union.

The pants are also constructed from flame-retardant and acidrepellent materials, providing comprehensive protection against both chainsaw-related hazards and environmental risks. Additionally, their water-resistant properties enhance

Pieter Smuts, Husqvarna SA’s MD, says the chainsaw pants were a passion project (Right): Husqvarna chainsaw pants.

their versatility, making them indispensable for professionals working in demanding conditions.

“This isn’t just another product release – it’s a commitment to innovation, safety and those who rely on chainsaws to shape the world around us,” says Smuts.

Husqvarna chainsaw pants are available through certified Husqvarna dealers or can be purchased directly from the official Husqvarna eCommerce site: https://zapromo.husqvarna.com/.

A Lintec CSD2500B containerised asphalt batching plant has completed its first job on an important municipal highway contract in Aswan, Egypt. The plant belongs to Rsquared Construction, one of Egypt’s leading privately owned construction and infrastructure companies. It played a crucial role in building the approximately 3km-long Semad Highway connecting Aswan’s industrial estates to the CairoCape Town highway.

Installed in January 2023, the Lintec CSD2500B began production in February and mixed over 300 000 tons of asphalt for the project, with an average output of 500 tons per day. The plant has capacity to deliver a maximum of 140-160tph.

It will now be moved to another project, supporting Rsquared’s ambitious business expansion plans. “We bought this plant with the aim of expanding our operations and opening a new branch in Upper Egypt,” explains Mohamed Abdel Raouf Hussein, the company’s CEO and founder.

A key reason for Rsquared’s purchasing decision was the ease with which Lintec CSD models can be dismantled before travelling to the next project. The modular design, built entirely within 100% ISO-certified sea containers, lends itself

(Below): The CSD2500B produced 500 tons

even during Aswan’s harshest tropical desert temperatures.

to efficient, economical transportation and makes the plants ideal for short- and long-term projects. Their flat, rigid design also speeds up installation by eliminating the need for concrete foundations.

Lintec facilitates smooth set-up by pre-assembling each plant at the manufacturing stage, before subjecting them to rigorous testing to ensure the highest reliability.

In addition, the containerised design provides the internal components with a high level of protection against the elements, while reducing noise and dust emissions. On the Aswan project, one of Rsquared’s challenges was coping with the tropical desert climate, with its harsh, sandy conditions that can easily damage unprotected equipment. However, thanks to the intelligent design of the Lintec CSD2500B, there were no such concerns for the contractor, with the mixing plant maintaining the highest-quality production in temperatures that often pass 30˚C.

Easy access to all levels via walkways and staircases helped to reduce downtime when maintenance was required, while limiting access to one central, lockable security entrance was also important, given the tight space available. “The congestion made it harder for us to work, but we’ve been involved in the roads and bridges sector since 1981, so it wasn’t a first for us,” says Hussein.

The fuel-savings provided by the double-screen drum technology were another attraction for Rsquared. The combination of heating and screening of minerals in a single process unit eliminated the need for a hot elevator and vibrating screen, thereby significantly reducing energy costs and maintenance requirements.

“This was an essential project for the Aswan Governorate and part of the presidential initiative to provide a higher living standard for the people of Upper Egypt,” adds Tony Chakra, the company’s regional sales manager: Middle East & Africa.

ABB Ability™ Expert Optimizer has improved operations and reduced thermal energy consumption in the kiln by 3% at the Tokuyama Nanyo cement plant, one of the largest single factories in Japan.

The advanced process control-based system controls, stabilises and optimises industrial processes across the calciner, kiln and cooler.

ABB’s technology enables automation of kiln operations, reducing the number of operator manual operations by about 70%.

Tokuyama manufactures high-quality cement at the Nanyo plant, which has a clinker production capacity of 4,54 million tons per year and supplies customers in Asia and Oceania, as well as Japan. The company has invested in an efficient and sustainable factory that manufactures cement, incorporating by-products in the Nanyo plant, as well as raw material waste and fuel substitutes, mainly from neighbouring areas. All materials are treated in the cement kiln to ensure that they are harmless ahead of cement manufacturing.

ABB Ability™ Expert Optimizer further stabilises production at the Nanyo plant by properly controlling equipment such as induced draft fans, burners and grade speeds, etc in each process. It is an industrial software-based advanced process control solution that enables and automates the best operational decisions accurately

and consistently at all times, drawing on linear and non-linear model predictive control, fuzzy logic and neural networks. By co-ordinating the setpoints of the different stages of the process and immediately detecting deviations among the various operation procedures, ABB Ability™ Expert Optimizer helps plant managers reach set profitability and sustainability goals within significant payback time and typically provides a return on investment of less than six months.

“We selected ABB’s Expert Optimizer to equalise the quality of the operation and improve the operational efficiency,” says Ryota Kakimoto of Tokuyama’s cement manufacturing department. “As expected, we’ve significantly reduced the number of the operator manual operations normally spent on manual tasks. Through increased automated operations, we can use the time saved for other tasks. We believe that this solution will also help our young operators learn the know-how of the operation efficiently.”

“Expert Optimizer emulates an operator and provides sharp control with fewer deviations. It’s already bringing efficiency and sustainability benefits to production at the Nanyo plant,” adds

Hiromichi Yoda, local division manager for Japan, Process Industries at ABB. “Although the system was introduced during Covid-19, we worked remotely between Japan and Switzerland to complete the commissioning, which was successful, thanks to the support of our customer. As part of the ABB Ability™ portfolio of digital applications, Expert Optimizer supports digital transformation and sustainability at the customer’s plant.”

ABB provides tailored automation and industrial software solutions that use realtime data enabling constant monitoring and analysis of process and assets. The ABB Ability portfolio delivers additional value with integrated digital applications for unmatched operation and maintenance, as well as process and production optimisation in the cement industry.

ABB’s Process Automation business automates, electrifies and digitalises industrial operations that address a wide range of essential needs, from supplying energy, water and materials to producing goods and transporting them to market. With about 20 000 employees, leading technology and service expertise, ABB Process Automation helps customers in processing, hybrid and maritime industries improve both their performance and the safety of their operations, enabling a more sustainable and resource-efficient future.

• Precast concrete plasticising admixtures

• Ready-mixed concrete plasticising admixtures

• Extended workability polymers

• Set retarding admixtures

• Hardening accelerators

• Viscosity modifying admixtures

• Form release agents

• Synthetic fibres

• Pozzolan-activity mineral additions

• Permeability-reducing admixtures

• Water-repelling admixtures

• Anti-washout admixtures

• Expanding agents

• Drying shrinkage-reducing admixtures

• Clay mitigating admixtures

• Pumping aides

• Air entraining and foaming agents

• Concrete rescue packs

• Evaporation-retarding admixtures Learn

www.afrisam.co.za debbie.harvey@za.afrisam.com 011 670 5941

822 2320

CONCRETE MOULDS

www.concretemoulds.co.za nigelbrown@mweb.co.za 082 774 4657

CORROSION INSTITUTE OF SOUTHERN AFRICA www.corrosioninstitute.org.za admin@corrisa.org.za 0861 267 772

info@masterbuilders.org.za

CALL

SEPHAKU CEMENT

www.sephakucement.co.za

MMlotshwa@sepcem.co.za 012 684 6300

JESSOP & ASSOCIATES

www.jessop.co.za info@protile.co.za 016 421 2521

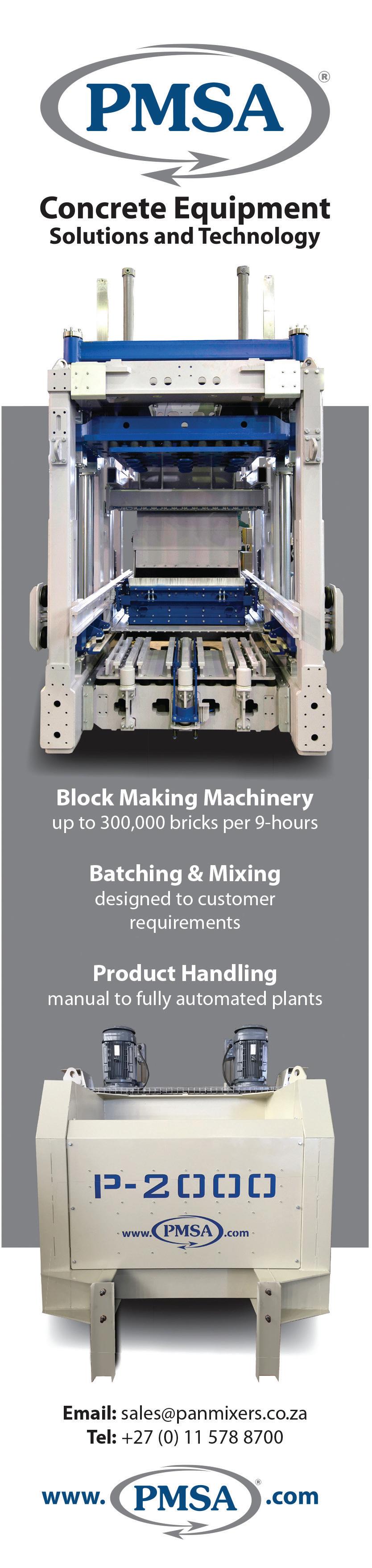

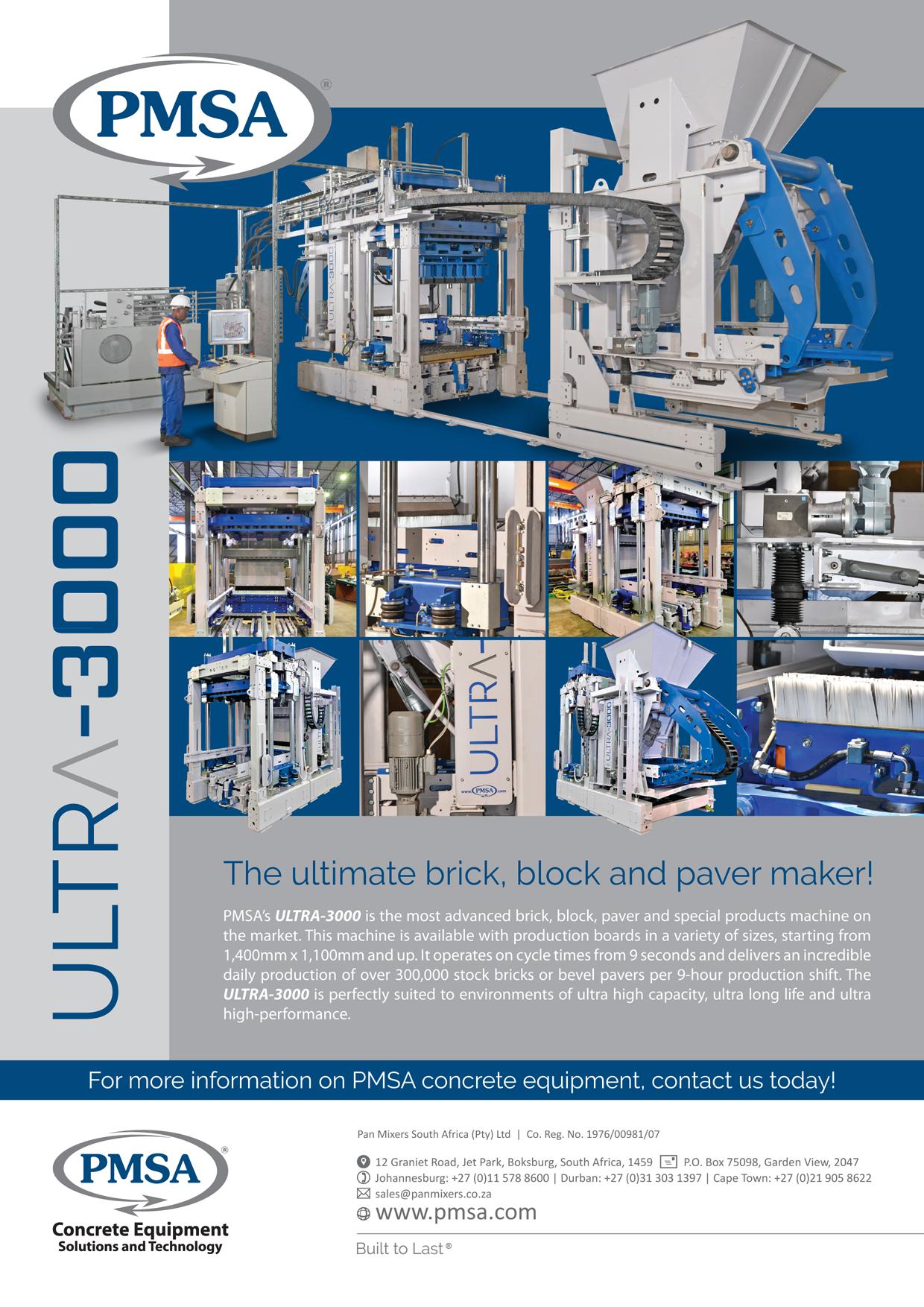

PAN MIXERS SA www.panmixers.co.za quintin@panmixers.co.za 011 578 8600

SIYENZA EVENTS

0861 32 42 52

www.siyenza.za.com info@siyenza.za.com 011 463 9184

TWINSTAR www.twinstar.co.za

Annemerie@Twinstar.co.za 012 670 9083

Strong and steady sets the pace for constructive progress on the road ahead as we build the future from the ground up. Lay steadfast foundations with leading quality cement produced on Africa’s beautiful playground.