Rising to the Challenge

Learn how you can foster a culture of adaptability and flexibility to navigate uncertainties and build resilience in your business.

VOLUME 17 / ISSUE 1 • QUARTER 1, 2024 • SINGLE ISSUE $14.95 THE OFFICIAL PUBLICATION OF THE INTERNATIONAL SURFACE FABRICATORS ASSOCIATION

FOUNDED FOR FABRICATORS BY FABRICATORS TO LEARN MORE ABOUT THE BENEFITS OF MEMBERSHIP, VISIT

JOINING ISFA WILL CROSS

THE OTHER ITEMS OFF YOUR LIST.

WWW.ISFANOW.ORG. PROUDLY SERVING THE DECORATIVE SURFACE INDUSTRY SINCE SINCE 1997

CREDITS

Editor:

Sarah Peiper

Contributors:

Marissa Bankert

Tony Calvert

Tim Saddoris

Ted Sherritt

David Smith

Ed Young

Proofreader:

Marsha Jo Scott

Design:

V2 Marketing & Management

Printing and Distribution:

LSC Communications

ABOUT THIS MAGAZINE

Countertops & Architectural Surfaces (ISSN 2372-983x) is published quarterly by the International Surface Fabricators Association (ISFA), with a fifth edition, a Buyers Guide, publishing in October.

Individual copies of Countertops & Architectural Surfaces magazine are available at the nonmember newsstand price of $14.95. Countertops & Architectural Surfaces magazine is also available by annual subscription (five issues) for $30.00. ISFA members receive a complimentary annual subscription with every membership renewal. Special rates and charges apply for orders outside of the United States. To subscribe, call (888) 599-ISFA.

For change of address, please include old label with new information, including both old and new ZIP codes. Allow 3-6 weeks for address change to take effect.

Countertops & Architectural Surfaces magazine is proudly printed in the United States of America. Copyright © International Surface Fabricators Association 2024. All rights reserved. No part of this publication may be reprinted or otherwise reproduced without the publisher’s written consent.

Countertops & Architectural Surfaces magazine and the International Surface Fabricators Association assume no responsibility for unsolicited manuscripts or photographs. Materials will be returned only if accompanied by a stamped, self-addressed envelope.

Opinions expressed by contributors in this magazine are not necessarily the opinions of Countertops & Architectural Surfaces magazine or the International Surface Fabricators Association, but rather those of the individual writers.

PHOTOGRAPHY

Photos in this publication may not depict proper safety procedures for creative purposes. ISFA and Countertops & Architectural Surfaces magazine support the use of proper safety procedures in all cases and urge readers to take steps to institute such procedures.

Photography/graphics provided by:

Cambria

Caragreen

Cosentino Coverings

Durasein

ENVI Surfaces

FreePower

GEM Industries

glass2

Hyperion

Hyundai L&C USA

Infinity Surfaces

International Surface Fabricators Association

Karran USA

Lapitec

Laser Products Industries

LX Hausys

Neolith

PaperStone

Park Industries

Porcelanosa

Tower Industries

Trinseo

Vadara

Vicostone

Ed Young

POSTMASTER: Send address changes to:

LSC Communications

c/o Countertops & Architectural Surfaces magazine 3401 Heartland Drive Liberty, MO 64068

THE

4 • Vol. 17 / Issue 1 • International Surface Fabricators Association

OFFICIAL PUBLICATION OF THE INTERNATIONAL SURFACE FABRICATORS ASSOCIATION

14

A Fabricator’s Guide for Annual Planning

This month-to-month forecasting tool will help you spend more time running your business instead of it running you.

16

Stone Fabrication in the Age of the Great Retirement: Adapt or Be Left Behind

The skilled labor pool isn’t getting any deeper. Here’s why you should be looking for new opportunities and start planning for the future.

20

New Colors and Materials

From quartz to the ever-growing popularity of porcelain, here’s what’s on trend in 2024.

26

The Future of Convenience: Smart Faucets and Sinks Revolutionize Everyday Living

A look at the profound impact that smart faucets and state-of-the art sinks can have on modern home living. 32 Fabricator

A

of solid surface, Tower Industries takes pride in delivering premium products built from quality materials supported by reliable customer service.

6 • Vol. 17 / Issue 1 • International Surface Fabricators Association CONTENTS Follow us on social media! @ISFAnow.org @ISFAnow @ISFAnow @ISFA

FEATURES

Profile: Tower Industries

champion

DEPARTMENTS 8 Editor’s Note 10 Calendar of Events 12 Industry News 14 Education Connection 29 Sustainability Matters 37 Perspectives: Marissa Bankert 38 ISFA News 44 ISFA Associate Member Directory 47 Product News 49 Perspectives: Ted Sherritt

true

AVONITE Solid Surface is a recent addition to Trinseo’s material solutions portfolio resulting from the acquisition of Aristech Surfaces. Thermoformable and hygienic, due to its nonporous physical properties, AVONITE Solid Surface offers seamless assembly and the possibility to create intriguing light effects, thanks to its subtle translucency. The Riverine Collection of AVONITE is modern yet timeless, featuring the appearance of soft, free-flowing marble patterns with warm, neutral and cool palette options to enhance any décor. To learn more, visit www.aristechsurfaces.com. 16 20 14 26 32

Cover Photo

EDITOR'S NOTE

Embracing Change: A Catalyst for Innovation

The Greek philosopher Heraclitus is credited with the idea that the only constant in life is change. Only fragments of his writings are on record, one in which he says, “Life is flux.” Other philosophers have quoted him saying something along the lines of: Everything changes, and nothing remains still; you cannot step into the same stream twice. Heraclitus lived about 2500 years ago, by the way, so this is certainly not a new concept. Yet, many of us are surprised or derailed by change in a way that suggests we don’t expect it when, in fact, we should always expect it. What “it” is — well, that is just a matter of detail.

In the decorative surface industry, we are navigating an era defined by technological advancements, evolving consumer preferences and sustainability imperatives. Material manufacturers and fabricators find themselves at the crossroads of tradition and transformation. In this evershifting landscape, the key to success lies in embracing change as a catalyst for innovation.

Over the years, the countertop has gone through a remarkable evolution, transcending beyond its utilitarian roots to become a centerpiece of expression in homes and public spaces. Gone are the days when countertops were mere functional surfaces; today, they serve as focal points that seamlessly blend style with substance. As we stand on the precipice of innovation, the industry must recognize change not as a threat but as a powerful force propelling us toward new horizons. In this issue, we round up 13 material manufacturers creating impressive designs that are sure to elevate the aesthetic in any space while preserving functionality (page 20).

Meanwhile, technological advancements have emerged as a driving force behind change in countertop manufacturing. From introducing engineered materials to integrating smart technologies and sustainable processes, the industry has embraced innovation to meet the demands of a changing environment. Cutting-edge materials, such as quartz, sintered stone and porcelain, have revolutionized the industry by offering durability, versatility and a spectrum of design possibilities. Integrating smart features, like embedded

wireless charging stations (page 48) and touch-sensitive faucets (page 26), transforms countertops into interactive hubs within the modern home.

The demand for sustainable and eco-friendly options has become increasingly pronounced, prompting manufacturers to explore environmentally conscious materials and production processes. We have a host of companies looking at ways to create safer materials that reduce fabricators’ exposure to crystalline silica while using fewer natural resources in the process. Adapting to these changing preferences is not just a trend; it is necessary to stay relevant in an ever-evolving reality, especially considering the increased awareness of the dangers of respirable crystalline silica dust (pages 13 and 49).

While change brings forth innovation, it also necessitates a reassessment of traditional practices. This issue’s fabricator profile features Tower Industries, a manufacturer and fabricator in Ohio that embraced solid surface in the ’90s and continues to find terrific success with the material today (page 32). While fabricators must adapt to emerging trends and new materials, Tower’s story is a testament to the importance of fostering a culture of continuous learning and collaboration, where professionals across the supply chain share insights and ideas and come up with the next great idea. Industry associations and trade events play a crucial role in facilitating this exchange, serving as platforms for networking, knowledge-sharing and the exploration of new possibilities.

And that brings me to my desk and the changes happening all around it. Being the editor of this magazine is just part of my role at the International Surface Fabricators Association (ISFA), and 2024 brings some new faces to our leadership team, including a new executive director (page 38). Under her guidance, along with ISFA’s board of directors, the association is well-positioned to support its membership as it navigates the challenges and opportunities within this industry. I look forward to facilitating the positive changes that elevate everyone’s success. Because, in fact, the only constant is change, and when you apply a forward-thinking mindset, it’s an opportunity for growth.

8 • Vol. 17 / Issue 1 • International Surface Fabricators Association

CALENDAR OF EVENTS

California Stone Summit: Fabricator Town Hall

March 7

Pacific Shore Stones North Hollywood, Calif. www.naturalstoneinstitute.com

Xiamen Stone Fair

March 16-19

Xaimen, China www.stonefair.org.cn

ISFA Webinar: Beneath the Surface Interior Cladding with Corian Solid Surface

March 20

Virtual www.ISFAnow.org

Solid Surface Fabrication Training

March 26-27

San Antonio, Texas www.ISFAnow.org

Alabama Stone Summit: Take Your Organization to the Next Level

April 4

Triton Stone Group Birmingham, Ala. www.naturalstoneinstitute.com

ISFA Fabricator Forum

April 10-11

Charlotte www.ISFAnow.org

Woodworking Industry Conference 2024

April 9-11

St. Petersburg, Florida www.woodworking industryconference.com

Marble Izmir Fair 2024

April 17-20

Izmir, Turkey www.marble.izfas.com.tr/en

Coverings

April 22-25

Atlanta www.coverings.com

HD Expo & Conference

April 30-May 2

Las Vegas www.hdexpo.hospitalitydesign.com

New Jersey Stone Summit: Fabricator Town Hall

May 9

Architectural Surfaces Jamesburg, N.J.

www.naturalstoneinstitute.com

Porcelain Training Presented by Panoramic by Daltile

May

San Antonio, Texas www.ISFAnow.org

ISFA MemberConnect Meeting

May 16

Virtual www.ISFAnow.org

Colorado Stone Summit: Dynamic Intentionality

June 6

Architectural Surfaces

Denver www.naturalstoneinstitute.com

Solid Surface Fabrication Training

June 4-5

Boston www.ISFAnow.org

ISFA Fabricator Forum

June 12-13

San Francisco www.ISFAnow.org

AIA Conference on Architecture

June 5-8

Washington, D.C.

www.conferenceonarchitecture.com

NEOCON

June 10-12

Chicago

www.neocon.com

Wisconsin Stone Summit: Know Your Business

July 11

UGM Surfaces

Oak Creek, Wis. www.naturalstoneinstitute.com

Solid Surface Fabrication Training August 6-7

San Antonio, Texas www.ISFAnow.org

International Woodworking Fair August 6-9

Atlanta www.iwfatlanta.com

International Manufacturing Technology Show

September 9-14

Chicago www.imts.com

ISFA Fabricator Forum

September 11-12

St. Louis www.ISFAnow.org

ISFA MemberConnect Meeting

September 19

Virtual www.ISFAnow.org

Ohio Stone Summit: Dynamic Intentionality

September 19

MSI Surfaces

Columbus, Ohio www.naturalstoneinstitute.com

Cersaie

September 23-27 Bologna, Italy www.cersaie.it

Marmomac

September 24-27 Verona, Italy www.marmomac.com

Washington Stone Summit: Fabricator Town Hall

October 10

MSI Surfaces

Kent, Washington www.naturalstoneinstitute.com

Solid Surface Fabrication Training October 22-23

Chicago www.ISFAnow.org

BACA BASH by BACA Systems November 6-7

Orion Township, Michigan www.bacasystems.com

Texas Stone Summit: Know Your Business

November 7

Arizona Tile

Dallas www.naturalstoneinstitute.com

ISFA Annual Conference November 6-8

Miami www.ISFAnow.org

ISFA MemberConnect Meeting November 14 Virtual www.ISFAnow.org

10 • Vol. 17 / Issue 1 • International Surface Fabricators Association

2024

Submit your event for consideration in Calendar of Events by emailing Editor Sarah Peiper, Sarah@ISFAnow.org.

Coverings Offers Well-Rounded Programming for Surface Professionals

Coverings, the preeminent event for the ceramic tile and natural stone industry in North America, has announced a select lineup of featured educational opportunities for Coverings 2024, which will take place April 22-25, 2024, at the Georgia World Congress Center in Atlanta.

Education at Coverings 2024 will span all tile and stone industry segments, focusing on Coverings’ four learning tenets: Sustainability, Health & Wellness, Outdoor Spaces and Timeless

Luxury. Eventgoers will benefit from live demonstrations, show floor tours with prerecorded audio, interactive sessions and partner education.

Coverings 2024’s robust roster of educational offerings will concentrate on the show’s three strategic learning tracks: Installation & Fabrication, Materials & Trends and Workforce & Profits. All learning opportunities have been created to foster professional, business and revenue growth for those in the tile and stone industry.

The Installation & Fabrication track is designed to assist attendees in refreshing their knowledge of industry best practices and staying abreast of cutting-edge techniques in the installation and fabrication of tile and stone. Attendees of the Workforce & Profits sessions will gain insights regarding innovative business practices and tactics to enhance workforce growth and management. Those engaging in the Materials & Trends sessions can expect to receive updates on the most recent tile and stone trends, design inspirations and techniques.

Coverings 2024 will also feature four education stages on the show floor, providing participants with countless opportunities to explore the latest innovations, trends and insights. These stages include the return of the Installation Innovation Stage, Trends & Solutions Stage, Fabricator Stage and a new addition, the Art Tile Stage.

Attendees at Coverings 2024 can expect additional educational opportunities, offering relevant insights and information about other trending topics in the tile and stone industry. Learn how you can make the most of your Coverings experience and register at no cost at www.coverings.com.

12 • Vol. 17 / Issue 1 • International Surface Fabricators Association

IN THE INDUSTRY

Have a new product or service announcement? IFSA can help you get the word out! Send press releases to: Editor@IFSAnow.org or visit www.IFSAnow.org/advertise for more information about our marketing channels.

Growing Concerns About Silica Risk Lead to Additional Restrictions

Engineered stone has faced increased scrutiny and regulatory measures in recent months. Australia has initiated a ban on the material, which is set to go into effect on July 1, 2024. The industry has witnessed a surge in concerns over the health and safety risks associated with the production and installation of stone products.

Respirable crystalline silica dust is generated during the cutting, grinding or polishing of natural stone and engineered stone, posing severe health risks to workers. Prolonged exposure to silica dust has been linked to respiratory problems, including silicosis, a debilitating lung disease that is not reversible. In response to these health concerns, regulatory bodies and occupational safety agencies in various regions have implemented stricter guidelines and restrictions on the handling and processing of these materials.

An Emergency Temporary Standard (ETS) was unanimously approved by the California Occupational Safety and Health Standards (Cal/OSHA) board in mid-December 2023, with the ETS going into effect later that month. The new ETS requires that all fabrication of artificial materials containing more than .1% silica, or natural stone materials containing more than 10% crystalline silica by weight, be done using wet cutting methods. In addition, fabricators must wear poweredair purifying respirators, and employers are mandated to facilitate medical testing.

Representatives from the Natural Stone Institute and the International Surface Fabricators Association (ISFA) attended the December Cal/OSHA board meeting in California. “We will continue to provide updates relevant to employee safety to our members,” said Austin Maxwell, 2023 ISFA board president. “We urge you to stay informed and stay safe.” The associations have prioritized the issue, assembled additional resources and support, and they continue to collaborate with government officials on future regulations.

International Surface Fabricators Association • Vol. 17 / Issue 1 • 13 IN THE INDUSTRY

A Fabricator’s Guide for Annual Planning

By Ed Young, Fabricator’s Business Coach

As you consider what 2024 may have in store, you may have questions like:

I think I need to add an install crew. Will I have the revenue to sustain the overhead?

I want to start a marketing campaign, but can I afford it?

If I add a salesperson, when will I need to add that new templater?

I know we need more employees as we grow, but it will increase my cost. Can I afford them?

A great aid in answering these questions is to put together a month-to-month plan that not only forecasts your sales but also helps you think through what staff changes you need to make as your sales change. For this exercise, let’s assume an increase in sales in 2024. If you expect the opposite, the same logic applies but in reverse.

Step 1: Download the Annual Planning Spreadsheet at www.fabricatorscoach.com/free-helpful-tools.

Step 2: Forecast your sales for 2024. Hopefully, you are continuously talking to local economic development people, your local home builders’ association, the chamber of commerce and your customers to keep your finger on the pulse of the economy in your area. Use this data plus your experience to forecast sales levels for each month. Remember to include the impact of your normal seasonal patterns.

In the spreadsheet, you can enter the sales volume you anticipate for each month, or you can estimate the additional jobs you expect to add for each month. To use this feature, you will also need to have some data on the average sales price of your jobs. The spreadsheet will calculate the monthly impact of those added jobs.

Keep in mind that this is your best guess based on the information you have today. It won’t be perfect, but it’s a great

starting point and essential for planning out the year. As the year progresses and you have new insights, you can update your forecast accordingly.

Step 3: Take several jobs from each market segment you serve and calculate Throughput Dollars ($T) for each. Then, divide the $T by the sales price of each job to get an average percentage. Entering that percentage in the spreadsheet will calculate your Monthly $T based on your estimated sales.

Step 4: Forecast your monthly Operating Expense (OE) for the end of 2023. If you don’t anticipate making any changes between now and the end of the year, you can use your most current average OE. Enter your OE in the Base OE line for January. Note that the spreadsheet automatically copies this number for the other months.

Step 5: Determine the personnel changes you need to make to accommodate the changing sales levels. Make a list of the positions you need to add.

If you expect sales to increase this year and your current templater is already fully booked, you may need to add a templater early in the year. If your salespeople spend too much time handling paperwork and scheduling, you may need to add a dedicated scheduler or an office support person.

Knowing how loaded the people are in the various functions is critical to this part of the analysis. While you likely won’t have data to verify this, making your best assessment now is a significant first step.

A key concept here is playing to your strengths and the strengths of your people.

A classic example is having capable salespeople handle customer service calls or scheduling functions while sales are increasing. Capable, experienced salespeople are hard to find — why waste that capability on something other than sales? Hire

14 • Vol. 17 / Issue 1 • International Surface Fabricators Association

EDUCATION CONNECTION

someone else to handle those nonsales tasks.

Also, note and estimate other significant additional costs, like the marketing program in the example spreadsheet.

Step 6: Estimate when each position needs to be filled based on your sales projections. Then, estimate the monthly cost of that position: wages, taxes and benefits. List the positions in the Additions section of the spreadsheet. Enter the monthly costs in the OE Adds line. The cumulative impact will be carried through the subsequent months.

Final Step: Review the Net line to see the impact of both the sales and OE increases. Think through each month and confirm that your plan for adding those new positions correlates with the sales increases. You’ll likely want to sleep on this and review it over several days. Don’t be surprised if you make several changes. It also helps to review your thought process with other key people in your company

and get their input.

Remember that you are essentially predicting the future — and you won’t get it right — so don’t obsess too much over the details. The point is to get you thinking about what this year may look like and help you plan how to deal with the changes you expect. As you progress throughout the year, it is helpful to enter the actual OE and $T numbers as each month closes. Also, update your sales or staffing forecasts as the year unfolds.

If you continue to work with this tool, it will become an essential part of your management rhythm. Using tools like this helps you spend more time running your business instead of it running you.

If you want another set of eyes to help review the finished product, send me an email, and I’ll be happy to take a look. You deserve a business that makes you money and allows you time to enjoy it.

Ed Young is the owner of Fabricator’s Business Coach, a consulting firm designed to strengthen and elevate fabrication shops of all sizes. A former shop manager, Ed fully understands the challenges of today’s professionals. He has consulted with a range of businesses, from one-person startups to international Fortune 100 corporations, covering a broad array of products and processes. As a result, Ed knows that each business needs an appropriate structure for its unique situation. To learn more about how Fabricator’s Business Coach can take your shop to the next level, visit www.fabricatorscoach. com or reach Ed directly at Ed@fabricatorscoach.com

International Surface Fabricators Association • Vol. 17 / Issue 1 • 15 C C C A A A B B B 2 2 2 V V V

CONNECTION

EDUCATION

Stone Fabrication in the Age of the Great Retirement: Adapt or Be Left Behind

By Tim Saddoris, Grand Onyx

We’ve all seen Help Wanted signs popping up everywhere. For years now, we’ve had trouble finding enough people. Unfortunately, it’s likely to get even more challenging due to the significant number of people retiring.

Baby Boomers have hit retirement age, and they’re calling it a career in record numbers. Pre-pandemic, about 3 million Boomers retired annually. Post-pandemic? That number hit 29 million a year. By 2030, some 75 million are projected to retire from the workforce.

Forget about the Great Resignation. It’s about the Great Retirement.

The numbers are even worse when it comes to skilled trades.

Younger people aren’t seeking trades at similar rates as in the past. Everyone told these kids to go to college! Applications at technical schools are down nearly 50% from 2020. Fewer than 9% of workers under 24 years old are entering the trades. In the construction and contracting business, almost a million jobs are going unfilled. About 85% of companies looking for skilled labor have open positions, and nearly nine in 10 say they are having difficulty filling them.

Over the next decade, it’s estimated that there will be some 3.4 million open positions in manufacturing and fabrication. Yet, there will be only 1.3 million workers to fill those spots. Labor shortages will grow larger and get more expensive.

This isn’t a normal workforce transition. It’s changing the way businesses have to operate. If you’re not preparing for this next phase, you’ll be in for a shock.

Just ask bowlers.

In my area, bowling is (still) a big deal. My brother almost went pro, but now he runs most of the bowling leagues in northwest Ohio. He’s seeing this workforce shift play out

in real time. He says there are only five technicians in this area who can work on the machines that set the pins. One is retiring this year. The remaining four are in their 60s, and nobody can take their place.

It’s changing the way bowling centers will have to operate. They are considering putting a dozen lanes in the area with string pins because a high schooler can repair them. If you haven’t seen string pinsetters, let’s just say it’s a different experience. Pins suspended by strings fall differently, so there is physics involved that changes the way the game plays out. Serious bowlers aren’t happy about it, but alley operators and owners have little choice. These systems are easier to maintain and cost-effective.

These changes are happening right before our eyes across nearly every industry, even those you think aren’t depending on technology. Take lawn mowing. Pretty soon, you won’t see

16 • Vol. 17 / Issue 1 • International Surface Fabricators Association

EDUCATION CONNECTION

people riding lawnmowers anymore. Already, some landscape companies have transitioned to a fleet of Roomba-style robots. They drop them off, and two hours later, the grass is cut.

I’m in the middle of building a house. Five years ago, installing a home septic system took three guys working five days. New technology allows one person to install it in just one day. It’s more expensive to the business owner, but there’s no real cost difference to the homeowner.

What does this have to do with the stone fabrication business? A lot. Almost every shop has that one guy who does amazing work. He’s the master of his craft, and he’s been doing it for 30+ years. But he’s not going to be there forever. What are you going to do when he’s gone?

Technology is not always the answer, either. Take the example of Stanley Black & Decker as a warning. They spent nearly $90 million to build a plant in Fort Worth, Texas, to modernize their Craftsman toolmaking process to overcome the shortage of skilled labor. Despite considerable spending on technology and robotics, they simply couldn’t make it work. In 2023, they announced plans to shutter the plant.

Not every business is going to survive. You need to take stock now and act.

So, where do you get started?

Conduct a Workforce Audit

The first step is to audit your workforce, so you know where you stand. Talk to your team members about their retirement plans and understand how long they plan to stick around. Look at your key positions and think about what happens if they leave.

Do you have someone ready to step in and take over their role?

Can you train someone to fill their shoes?

18 • Vol. 17 / Issue 1 • International Surface Fabricators Association

Do you have documentation in place for steps and procedures?

You can no longer wait until they are about to leave to put out the Help Wanted sign. Many places that do that find no qualified applicants are coming along. You need to have a transition plan in place now. This may require getting commitments from employees and paying them more to train and prepare to be your next generation of talent.

One simple way to get started, especially for skilled positions, is to use your phone and record how that person does things so you can document it for later. This will come in handy when you have to train new employees or want to refer back to it to learn the tricks of the trade.

Look for New Opportunities

At the same time, this may be the time to look at new opportunities.

Other industries that require specialized labor, such as tile installation, are struggling with the same shortage of workers. Is this a market niche you can exploit? This could be ample opportunity to revolutionize the industry with slabs. Think kitchen backsplashes, bathroom floors, shower surrounds — any areas where tile is used.

Not only might this be an opportunity to expand your business and generate more revenue, but it’s a faster install. A tile guy might take a week to get the job done (and make a mess doing it). You can do it faster and skip the mess for the homeowner. This can offer a competitive advantage and turn jobs faster, putting more cash in your pocket.

EDUCATION CONNECTION

Many fabricators we work with are on the fence about products like Dekton, but there are also opportunities to realize with that material. It could replace other materials in commercial applications, for example, opening up new product lines for profit.

Find Workers With Similar Skills

This might also be an excellent time to recruit. You may be able to offer a better job or opportunity to someone who already has some of the skills you need. For example, roofers are often seasonal workers with unpredictable paychecks due to the weather. It’s also an incredibly dangerous job. Yet, roofers have some of the same skills as installers. You can offer them a steady paycheck, year-round work and steady hours.

Consider other occupations with similar skills and see whether you can provide a better career path.

It’s Time to Act

Regardless of your situation, you cannot afford to wait any longer. Assess your staffing, look for new opportunities, identify your next generation and start planning for the future. No matter how well things are going at the moment, we’re in for change. Adapting to the new normal and futureproofing your business is essential to remaining viable and building your business.

B

2

A V V V

International Surface Fabricators Association • Vol. 17 / Issue 1 • 19

A A

B B

Tim Saddoris is the president of Grand Onyx. a firm dedicated to helping stone fabricators increase their revenue by 30% to 300% using proven techniques and a World Class Blueprint System to help you build a more profitable, scalable business. They help companies refine their sales process, uncover insights about better ways to sell, and coach sales teams for greater success. Learn how Grand Onyx can help your business grow at www.grandonyx.pro. C C C 2 2

New Colors & Materials

By Sarah Peiper

From quartz to the ever-growing popularity of porcelain, here’s what’s on trend in 2024.

Vadara Quartz: New Colors Capture the Essence of Nature

XLIGHT by Porcelanosa

Vadara Quartz Surfaces is expanding its portfolio with seven new designs. Vadara searched the world over and found inspiration in the natural beauty of such places as White Sands National Park in New Mexico and the Okavango Delta in Botswana. The result is an addition that enhances and advances Vadara’s well considered and expansive existing colors and patterns.

These new colors add to Vadara’s reputation as a quartz surface leader and demonstrate the brand’s ability to manufacture patterns and colors that are as beautiful to see as they are easy to live with. Shown here is Scandi Blue, a calacatta marble-inspired quartz, featuring a bright white background with bold, dynamic blue, brown and rust veining.

All seven designs feature bold, striking visuals that are complimentary in color, ranging from blue-gray backgrounds and veins with hints of green, maroon and rust. Available in 2 cm and 3 cm thicknesses, these designs could be viable, cost-effective alternatives to natural stone slabs with the performance characteristics of quartz. See all the designs at www.vadaraquartz.com.

Functionality and beauty come together in XLIGHT by Porcelanosa. This largeformat porcelain is available in extra slim sizes. XLIGHT recreates the look of cement, marble, stone, wood and metal with extraordinary realism. The wide range of large format tiles is ideal for walls and floors with excellent quality and a visual continuity that can elevate the aesthetics of any space. This technical porcelain tile is offered in four finishes — polished, silk, textured and natural. XLIGHT is available in three sizes: 24 inches by 47 inches, 47 inches by 47 inches and 47 inches by 106 inches. Slabs come in two thicknesses: 6 mm and 9 mm. The 9 mm pieces are ideal for more highlytrafficked areas.

This large-format porcelain can be used as flooring or cladding, but also as exterior elements like facades, and is well suited for kitchens and bathrooms. XLIGHT is prized for its lightness, waterproof and stain resistance, as well as easy cleaning. Learn more at www.porcelanosa.com/en/collections/xlight/.

HanStone Quartz Launches Three New Designs

Building on the successful launch of the Opimo Collection in 2023, HanStone Quartz recently introduced its three newest colors — Antello, Riviere and Tahitian Cream, shown here.

The new colors all focus on expressing the innate beauty and unique features found in nature, creating both a bold and welcoming environment. Under the main theme of “Unveil,” HanStone continues its journey to inspire designers and architects to venture into the unprecedented realm of quartz design.

Antello, Riviere and Tahitian Cream are all available in jumbo slab sizes of 65 inches by 130 inches and thicknesses of both 2 cm and 3 cm. Meet HanStone’s new colors at www.hyundailncusa.com/colors?brand%5B%5D=hanstone-quartz.

20 • Vol. 17 / Issue 1 • International Surface Fabricators Association

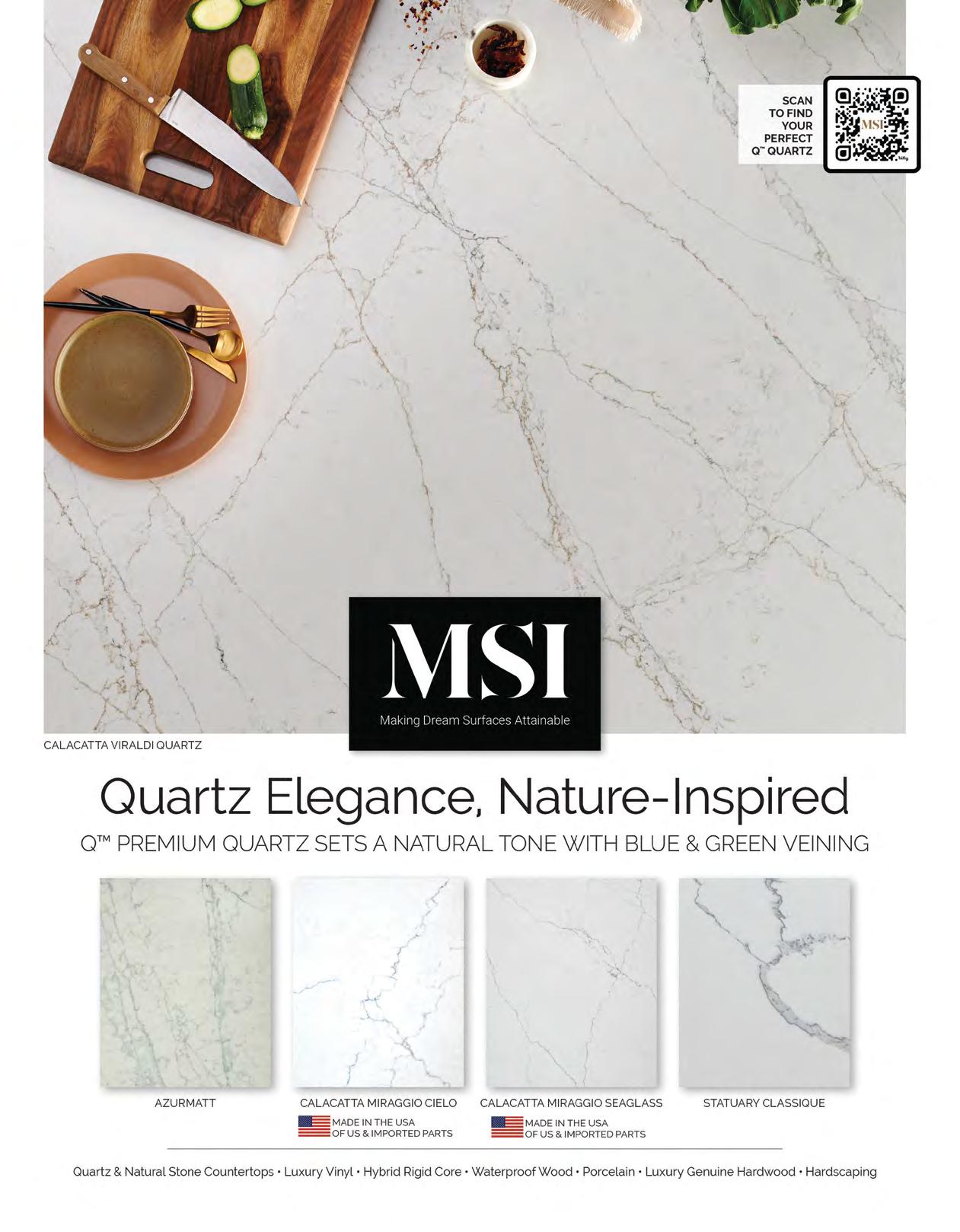

Polaris by Vicostone

Vicostone continues its trailblazing efforts in engineered stone innovation with the latest addition to its Natural Collection: Polaris. This new quartz color embodies the elegance of Carrara marble, harmonizing design-centric patterns with hues borrowed from the natural world. Polaris captivates with its tranquil lake-in-winter aesthetic and realistic marbling. Its design is characterized by an intricate network of veins, reminiscent of light dancing across a frozen landscape, adding a touch of serene beauty to any interior space. Crafted for versatility and aesthetic appeal, Polaris is offered in both 3 cm and 2 cm Jumbo slabs, with dimensions of 130 inches by 65 inches, accommodating a variety of design needs. This addition to Vicostone’s product line exemplifies sophistication, merging functionality with the artistry of nature-inspired surfaces. Discover more about Polaris at us.vicostone.com.

Durasein Presents Blanca Carrera

Dekton Launches Ukiyo

Create new experiences with Cosentino’s Dekton Ukiyo, a reinterpretation of textures into geometric patterns that unveil new vertical application possibilities. Ukiyo is available in a variety of Dekton colorways, thicknesses and fluting options to create imposing vertical universes endowed with linearity and depth. Cosentino partnered with renowned interior designer Claudia Afshar to create color-filled structured patterns that offer a sensory experience.

Ukiyo is available in six colors:

• Bromo: A dark gray shade inspired by slate featuring subtle faded graphics and a carefully crafted texture with a natural aesthetic.

• Kreta: Inspired by cement, this design is even and controlled. It can create lighter or darker spaces depending on the density of the pattern.

• Umber: This terra cotta color features a natural reddish pigment creating a warm, textured surface that adds character to any space.

• Nacre: A cream shade characterized by subtle details from fine micro-concrete to lime plastering.

• Rem: Its intricate design with brown and gray veining and hints of gold reflects the traditional and linear structure of Calacatta Lincoln. See all the new designs and learn more at www.cosentino.com/dekton.

Blanca Carrera is Durasein’s newest addition to their marble-inspired Dreamy Collection. The design boasts a crisp, clean and modern interpretation of a classic Calacatta veining pattern. Exuding a serene and composed charm, Blanca Carrera elevates any area effortlessly with its sophisticated appearance, reminiscent of traditional marble, and coupled with the practical advantages of solid surface.

From air quality to food safety, Durasein is engineered to maintain a safer environment for human health. With concerns that prolonged exposure to nanoparticles may lead to health issues, it’s also reassuring to know that Durasein solid surfaces are free from nanoparticles. With zero emissions, Durasein’s material and the cured adhesive used in installation are 100% free of formaldehyde and volatile organic compound emissions. In addition to Greenguard, Greenguard Gold Indoor Air Quality, HPD and REACH certifications, Durasein surfaces are also NSF-51 certified to ensure that they are safe for food equipment and food contact.

Durasein’s solid surfaces have also been tested to meet and/or exceed the requirements for industry standards, including ASTM, ANSI, UL and NEMA. It’s undergone strict stain and chemical resistance testing in accordance with CSA B45.5-17/IAPMO Z124-2017, and EN ISO 16000-9 testing to show that there are no traces of harmful substances in the products. Learn more at www.durasein.com.

International Surface Fabricators Association • Vol. 17 / Issue 1 • 21

Trinseo’s AVONITE Acrylic Solid

Surface: The Riverine Collection

The Riverine Collection of AVONITE Acrylic Solid Surface is a nature-inspired palette that is particularly appropriate for featured vertical spaces where a faux marble appearance enhances the aesthetic. AVONITE Solid Surface, offered in both 12- and 6-mm thicknesses, can be used in a wide range of interior and exterior applications including countertops, bath surrounds, vanities, interior walls, facades and furnishings.

“Trinseo is expanding its solid surface portfolio with a collection of three free-flowing patterns and colors that make up Riverine,” said Peter Allread, Trinseo’s sales director of engineered materials for the Americas. “The material mimics the appearance of natural cut marble and granite, with every sheet unique from one another. The Riverine Collection’s natural expansive pattern provides designers with a hygienic material solution that meets their aesthetic needs.”

The colors included in the Riverine Collection are:

• Haze 8514: Featuring a delicate natural undertone, this warm, soft hue offers inspired elegance and simplicity.

• Mist 8512: Understated and contemporary, this white-on-white colorway is subtle, refined and timeless.

• Oxbow 8510: Cool gray tones and misty white hues flow unhindered to create a tranquil visual texture.

Haze 8514

Oxbow 8510

22 • Vol. 17 / Issue 1 • International Surface Fabricators Association

Mist 8512

There is no material that allows for greater cleanliness. Both AVONITE 12 mm and WET WALL 6 mm 100% acrylic solid surface sheets do not absorb bacteria, can be cleaned using common household products, are seamlessly assembled and the material malleability makes it possible to design curved corners for more efficient cleaning.

AVONITE Acrylic Solid Surface is produced using a continuous cast, doublebelt manufacturing process with versatile production widths and lengths, specified by the customer to reduce scrap and transportation costs within their projects. A renowned brand in the interior design industry, it is a recent addition to Trinseo’s material solutions portfolio resulting from the 2021 acquisition of Aristech Surfaces, an American manufacturer of surface and design materials.

Over 50 years of rich history, customer-centric focus and a journey of innovation defined Aristech Surfaces. Now under the Trinseo umbrella, the company continues to offer a full portfolio of surfacing solutions under flagship brands AVONITE, AVONITE Flex, ACRYCLEAR, ACRYSAN, ACRYSPA, ACRYSWIM, ACRYSTEEL, and INDURO.

Whether creating a higher impact formulation to withstand environmental extremes, inventing new shipping methods to maximize space, constructing a natural stonelike texture that you would swear was from Mother Earth, or simply bringing the delicate rose petal indoors, Trinseo focuses on the success of its customers by developing effective partnerships and innovative solutions.

View the available colors at www.aristechsurfaces.com/market/wellness/avonite/colors.

International Surface Fabricators Association • Vol. 17 / Issue 1 • 23

Infinity Surfaces: Calacatta Oro

Here’s a beautiful example of a freshly renewed working space featuring Infinity Surfaces’ Calacatta Oro, a porcelain material that will stand the test of time.

A team of skilled designers meticulously selected Infinity Calacatta Oro porcelain slabs to enhance every room’s unique character. With almost seamless veining of gold, silver and light brown, Calacatta Oro blends contemporary aesthetics with timeless functionality, creating a harmonious and inviting atmosphere for patients and medical staff.

From concept to execution, the team of expert fabricators prioritized the flawless vision of elegance, comfort and style, ensuring a personalized touch in every detail. Meticulously crafted with 6 mm and 12 mm gauged porcelain panels, both in satin and polished finish, each room is a testament to the unwavering commitment to quality that the ownership required for this project. Infinity’s rigorous quality guaranteed that the end result surpassed expectations, and embodied durability and functionality. Learn how you can elevate your next project with Infinity at www.infinitysurfaces.it/products/calacatta-oro/.

Cambria Quartz: Inverness

Make a design statement with the newest additions to Cambria’s Inverness palette: Inverness Everleigh, Inverness Bristol Bay, and Inverness Swansea, shown here. These designs feature innovative technology and gently textured debossing throughout the veining — all inspired by disruptions in nature.

Use the Inverness designs to create showstopping focal points in any application, from kitchen islands, countertops and backsplashes to flooring, shower walls, bathroom vanity countertops and full walls. American-made quartz surfaces come naturally. For over 20 years, Cambria’s family-owned company has perfected the transformation of Earth’s finest raw material into luxurious designs and unparalleled realworld performance. The company’s commitment to quality and superior service is inspired by our rich heritage and propelled by our industry-leading ingenuity. Learn more at www.cambriausa.com/contact/fabricator.

Lapitec Adds Three New Designs

Lapitec, Italian manufacturer of sintered stone surfaces, recently added three brand-new designs to the Musa Collection. The new styles — Bianco Alba, Bianco Diana and Bianco Pandora — all feature the dramatic through-body veining that the Musa Collection is known for. Lapitec uses patented technology to create a surface that is not only beautiful but versatile and resilient as well. Lapitec can be used indoors or outdoors for countertops, backsplashes and flooring that make a stunning visual impact. Check out the new colors and learn more about sintered stone at www.lapitec.com.

Viatera Quartz by LX Hausys America: The Monte Collection

A testament to the majestic allure and raw splendor of mountainous landscapes, the Monte Collection is crafted with an artful blend of design and innovation while capturing the essence of various mountain ranges across the globe. Shown here is Dolomites.

Viatera quartz contains up to 93% quartz, one of the hardest minerals on earth. It is manufactured at state-of-the-art facilities in the United States and abroad, and it’s available throughout North America via LX Hausys America’s extensive distribution network. Providing exceptional durability, high resistance to staining and ease of maintenance, all Viatera colors come with multiple independent certifications verifying their environmental and health attributes. Viatera is backed by LX Hausys’ 15-year limited warranty. Learn more at www.lxhausys.com/ us/products/viatera-quartz-surface/.

24 • Vol. 17 / Issue 1 • International Surface Fabricators Association

Neolith’s Calacatta Royale

Neolith is a pioneering architectural surface with superior technical characteristics made of 100% all-natural raw materials that can provide indoor and outdoor solutions.

The inspiration for Calacatta Royale comes from marble with the gray, neutral, defined veins on a white background. It comes in ultrasoft, décor polished and silk finishes in 6 mm, 12 mm and 20 mm thickness options. With a 25-year limited warranty, it’s ultra hygienic and UV resistant.

The virtues of Neolith surfaces combine next-generation technology and high functionality which, along with Neolith’s sustainable DNA, have led it to becoming one of the most environmentally-friendly materials on the planet. Learn more about all Neolith has to offer at www.neolith.com.

ENVI Quartz and Porcelain

The ENVI

Quartz and Porcelain slab collections represent a turn-key brand solution for savvy trade professionals. Backed by the company’s concierge support team and comprehensive merchandising program, each slab brings together the world’s most on-trend looks, crafted by a hand-selected group of dedicated producers.

Expansive and always evolving, these market-defining collections now encompass 40 quartz and 40 porcelain selections. Recent porcelain additions include a dozen brand-new, ontrend colorways: Odyssey, 54, Roxy, Troubadour, Connemara, London, Monet, Moonlight, Pure, Silhouette, Timber and Treasure. Pictured here is a sleek, contemporary reception foyer showcasing the bold aesthetic of ENVI Odyssey. Visit www.envisurfaces.com to learn more.

International Surface Fabricators Association • Vol. 17 / Issue 1 • 25

The Future of Convenience: Smart Faucets and Sinks Revolutionize Everyday Living

By Tony Calvert, Karran USA

In the fast-evolving landscape of smart homes, where technological innovation continually reshapes our daily routines, smart faucets and sinks stand at the forefront of transformative change. Beyond their aesthetic appeal, these intelligent fixtures are redefining the way we engage with water in our kitchens and bathrooms. Let’s take a look at the multifaceted advantages, cutting-edge features, and the profound impact that smart faucets and sinks can have on modern home living.

The Rise of Smart Faucets

Smart faucets, equipped with advanced motion sensors, introduce a touchless revolution to the traditional kitchen or bathroom setup. The ability to control water flow with a simple wave of the hand not only enhances convenience but addresses hygiene concerns by reducing the spread of germs. This touchless operation is particularly valuable in high-traffic areas, making daily tasks cleaner and more efficient.

One of the standout features of smart faucets is their ability to provide a highly customizable experience. Users can finetune water temperature and flow rates to their preferences, ensuring a consistent and personalized encounter with every use. This level of control adds a touch of luxury to daily rituals while contributing to water conservation by avoiding unnecessary usage.

The integration of smart faucets with voice-activated assistants, such as Amazon Alexa or Google Assistant, brings an entirely new dimension to hands-free convenience. Imagine preparing a meal with messy hands and effortlessly instructing the faucet to dispense water at the perfect temperature, all through simple voice commands. This intersection of technology and utility transforms the kitchen or bathroom into a space where efficiency and innovation coalesce seamlessly.

Further, smart faucets play a pivotal role in addressing water conservation challenges. Features like automatic

26 • Vol. 17 / Issue 1 • International Surface Fabricators Association

shut-off and precise control over water usage contribute to sustainable practices. By actively monitoring and optimizing water consumption, these faucets empower users to reduce their environmental footprint without compromising functionality.

The Intelligence of Smart Sinks

Intelligent faucets often come equipped with built-in sensors, initiating water flow without physical contact. This touchless operation not only enhances hygiene but also contributes to the overall cleanliness of the sink space, reducing the likelihood of surface contamination.

In addition, many smart faucets boast integrated water filtration systems, eliminating the need for stand-alone devices and ensuring a direct supply of clean, purified water. This feature improves water quality for drinking and cooking and aligns with a broader trend toward reducing reliance on single-use plastics.

In the kitchen, where functionality is paramount, smart sinks often incorporate innovative prep solutions. These may include built-in cutting boards, roll-up drying racks, or other accessories seamlessly integrated into the sink’s design. Such features optimize space utilization and transform the sink into a multifunctional work area.

through a dedicated mobile app. This level of connectivity not only adds convenience but also contributes to energy efficiency by allowing users to manage their water usage even when they are away from home.

Beyond Convenience and the Comprehensive Benefits

The touchless operation of a smart faucet significantly reduces the potential for the spread of germs and contaminants. In a world increasingly focused on health and hygiene, this feature becomes invaluable, particularly in high-traffic areas like kitchens and bathrooms.

Smart faucets and sinks streamline daily tasks, saving valuable time and energy. Automated features, customizable settings, and connectivity options cater to the fastpaced nature of modern life, ensuring that routine activities are executed efficiently.

One of the most compelling aspects of smart faucets and sinks is their contribution to environmental sustainability. Water conservation features, coupled with efficient usage monitoring, empower users to be more conscious of their environmental impact. By actively participating in water-saving practices, homeowners can make a meaningful contribution to global efforts to conserve this precious resource.

Connectivity is a hallmark of the modern smart home, and smart faucets are no exception. Some models can be connected to a home’s Wi-Fi network, allowing users to monitor and control various functions remotely

Smart faucets and sinks are not merely fixtures; they represent a paradigm shift in how we interact with essential elements of our homes. The fusion of technology and utility creates an environment where convenience, efficiency, and sustainability coexist harmoniously. As these intelligent fixtures evolve, they promise to redefine the fabric of our living spaces, turning kitchens and bathrooms into smart, responsive, and ecoconscious zones. Embrace the future of home living, where every drop of water becomes a testament to the seamless integration of innovation and everyday functionality.

USA. Boasting a diverse career in both B2B and B2C contexts across various industries, his expertise particularly shines in crafting compelling strategies tailored to the unique needs of the brands he represents. At Karran, Tony leverages his experience with a commitment to steering the sink and faucet company toward new heights by combining innovation and strategic consumer insights to achieve excellence. Learn more about Karran USA at www.karran.com.

28 • Vol. 17 / Issue 1 • International Surface Fabricators Association C C C A A A B B B 2 2 2 V V V

Tony Calvert heads up marketing for Karran

ESG vs. EcoVadis: What’s the Difference and Why You Should Be Familiar With Both

By David Smith, Garnica North America

In today’s corporate landscape, the convergence of profitability and environmental responsibility is more than a mere trend — it’s a necessity. Concurrently, distinguishing between various frameworks has also become a crucial component of informed decision-making. Two terms in particular that are garnering more attention in recent years are ESG and EcoVadis. But what’s the difference and why are they so important?

Understanding ESG and EcoVadis

ESG is a broad concept encompassing three pillars — Environmental, Social and Governance —which together evaluate a company’s impact on society and the environment. EcoVadis on the other hand is a global platform that specializes in assessing and guiding companies on their journey toward sustainability and equality. It provides a comprehensive evaluation across four key metrics: environment, resources and human rights, sustainable procurement, and ethics. While ESG sets the overall direction, EcoVadis offers a detailed roadmap for implementation. Participating in EcoVadis enables businesses to measure, improve and communicate their sustainability performance effectively. It also allows for a standardized comparison with peers, fostering healthy competition and promoting best practices across industries.

EcoVadis: How it Works

EcoVadis is a global platform that moves beyond conventional ESG assessments offering a nuanced perspective on sustainability management. The EcoVadis score, ranging from 0 to 100, serves as a barometer for a company’s sustainability management efficacy at a given juncture. To receive an EcoVadis assessment, companies must register and then answer a series of questions accompanied by supporting documents. Once submitted, the information is analyzed, and a scorecard is awarded to the company.

EcoVadis Medals and Badges

EcoVadis Medals and Badges recognize businesses that exhibit robust sustainability management systems, emphasizing their dedication to each of the four key assessment metrics (environment, resources and human rights, sustainable procurement, and ethics).

International Surface Fabricators Association • Vol. 17 / Issue 1 • 29

SUSTAINABILITY

MATTERS

SUSTAINABILITY MATTERS

Medals are awarded based on percentile ranks:

• Platinum: Top 1% (99+ percentile).

• Gold: Top 5% (95+ percentile).

• Silver: Top 15% (85+ percentile).

• Bronze: Top 35% (65+ percentile).

A company must meet a minimum score of 30 across the four metrics to be eligible for a medal. The percentile rank, calculated across all industries, offers a standardized comparison, fostering inter-industry best practices.

Badges are designed to recognize companies making commendable strides in sustainability.

• Committed Badge: Minimum score of 45.

• Fast Mover Badge: Score between 34-44, with a minimum 6-point improvement compared to the previous assessment in an 18-month period.

It is important to note that companies working in specific industries may not be eligible for EcoVadis medals or badges. Currently, these include but are not limited to the manufacturing of tobacco products, weapons and ammunition manufacturing, coal or lignite mining, and companies with substantial revenue from coal sources and/or producing a substantial portion of coal-based power generation.

A Call to Business Leaders

For business leaders and entrepreneurs, the integration of ESG principles and engagement

with platforms like EcoVadis present multifaceted advantages:

• Enhanced Reputation: A robust ESG framework, coupled with accolades from esteemed platforms, signifies a brand’s commitment to ethical practices, fostering trust among employees, customers and stakeholders.

• Risk Mitigation: Proactive sustainability measures can preempt regulatory challenges and potential environmental liabilities, ensuring long-term viability.

• Competitive Advantage: Embracing sustainability propels innovation and encourages healthy competition as other companies adapt to keep pace, paving the way for differentiated offerings in the market.

As ESG frameworks continue to gain traction, embracing platforms like EcoVadis is not merely a strategic choice, it’s an ethical imperative. As an example, Garnica, a leader in premium sustainable plywood, epitomizes the transformative impact of embedding ESG principles into business operations. Garnering global recognition, Garnica ranks in the top 1% for sustainable procurement and the top 2% for environmental management within the forestry sector, underscoring the tangible benefits of ESG integration. For businesses poised to make a lasting impact, the journey toward sustainability begins with a single, decisive step: a commitment to holistic ESG integration and a relentless pursuit of excellence.

David Smith is the President of Garnica’s North American Division and brings over 28 years of industry expertise to his role. Prior to joining Garnica, he held senior positions at EGGER Group and Arclin USA, later founding The David Smith Group, a consulting firm focused on sustainable building materials. With a proven track record in customercentric solutions, David specializes in dynamic market leadership through sustainable innovation. Learn more about Garnica at www.garnica.com.

30 • Vol. 17 / Issue 1 • International Surface Fabricators Association C C C A A A B B B 2 2 2 V V V

Tower Industries

Founded by father-and-son team Bob and Todd Werstler in 1995, Tower Industries is known nationally as a manufacturer of solid surface shower and restroom products. Located in Massillon, Ohio, about an hour south of Cleveland, the company expanded to include a stone fabrication division, Tower Countertops — now one of Ohio’s leading custom surface fabrication and installation providers. As a familyowned and operated company, the Tower team takes pride in delivering premium surfaces built from quality materials supported by reliable customer service.

Humble Beginnings

Todd looks back at how it all started. His father, Bob, got his start in the plumbing trade, eventually owning a plumbing business and then a hardware store. Later in his career, he worked as a sales representative for a cultured marble company. Meanwhile, Todd went off to college to pursue a degree in business. It was then he discovered a passion for economics. After college, Todd worked for a transportation company, where he gained valuable cross-functional experience and a prowess for management.

But the entrepreneurial spirit was alive and well in the Werstlers. “I wanted to work for myself,” said Todd. “I wanted to create something unique — find a niche in the marketplace.”

With a deep understanding of cast polymer products, Bob’s idea was to delve into solid surface. “In the ’90s, solid surface was seeing extraordinary growth in popularity,” Todd recalled. “So we huddled together and carved out an opportunity.”

Bob brought valuable experience in the remodeling and construction trade, while Todd had developed business acumen and management experience. Even Todd’s mom, Joyce, chipped in by helping with accounting, answering the phones, and

32 • Vol. 17 / Issue 1 • International Surface Fabricators Association

FABRICATOR PROFILE

The Tower Countertops division fabricates solid surface, natural stone, quartz and sintered surfaces for all kinds of projects, primarily residential kitchens and baths.

FABRICATOR PROFILE

otherwise supporting however she could. “We scraped it together in the beginning; it took everything we had to get it off the ground,” added Todd. “But we were mindful of building something with staying power.” Together, they launched Tower Industries. Nearly 30 years after its humble beginnings, Tower remains humble. They’ve even written it into the company’s core values.

Building a Solid (Surface) Foundation

The company was founded to manufacture its brand of solid surface, which is now trademarked under the name Meridian Solid Surface. The material is a proprietary blend of resins and mineral fillers that comes in a range of colors and patterns. They manufactured sheets and fabricated countertops initially, and by 2004, they had developed a line of prefabricated products for restrooms.

“When the design world changed, and the demand for natural stone — materials like granite — surged past solid surface,” explained Todd, “people moved away from solid surface countertops in new construction, so we had to figure out how to keep the material relevant.” Meanwhile, they nudged the countertop division forward by expanding to other materials like quartz and granite. For Meridian Solid Surface, they had mastered making the material and now needed to find a new space to sell it into.

Around the same time, Todd got a call from a general contractor who had won a bid to remodel a college dormitory. “Somehow, this contractor found our website and discovered we made solid surface, and one of the applications we featured was a shower. He told me he needed 100 showers in six weeks. Of course, I told him we could do it — ‘No problem!’ — but I had no idea how we would pull it off. Where there’s a will, there’s a way.” Todd took the job, the project went well, and a light went off; if there’s one college dorm in the U.S. that needs this product, there are probably more.

“After that first dormitory, we started poking around,” he recalled. “We went looking for projects at colleges, and we found them. We worked our way in, selling however we could and marketing to that sector. Our second project was at Ohio State University, proving we had a concept.” Since then, Tower Industries has provided Meridian Solid Surface solutions to more than two hundred colleges nationwide. The company has a complete line of products — including fully customizable options — from shower bases and wall panels to accessories like seats, soap dishes, shelving niches, and more. They serve primarily the commercial market, including higher education, health care, military and multifamily facilities. The solid surface division makes up more than 75% of Tower’s total revenue. Todd says the growth with Meridian scales larger by territory — a national market, whereas the countertop business is locked geographically to central and northern Ohio.

Today, Tower Countertops — accounting for the remaining 25% of revenue — fabricates solid surface, natural stone, quartz and sintered surfaces for all kinds of projects, primarily residential kitchens and baths. On average, they fabricate about a dozen kitchens each day. “Today, we’re seeing more demand for sintered materials that we didn’t 10 years ago — including porcelain — so we’ve adapted our offerings,” explained Todd. “You have to keep up with trends to remain competitive.”

International Surface Fabricators Association • Vol. 17 / Issue 1 • 33

Todd Werstler regularly opens his doors to give tours and host industry events.

In the Meridian manufacturing area, Tower runs dual continuous casting machines and continuous casting mixers, with most of the casting performed via robotics.

FABRICATOR PROFILE

In the Shop

Tower’s two divisions operate under one roof in a sprawling 60,000-square-foot factory with about 60 staff members. Staff is divided between the two divisions, with just over a dozen staff members spanning the whole business in sales and operations.

The factory floor has evolved to meet the company’s scale. On the Meridian side, they started with hand tools, routers, straight edges and the like. As they made more countertops, it made sense to add a CNC. “Our first CNC was installed in about 1998,” recalled Todd. “Automation has definitely helped to make us grow.”

On the wet side of Tower Countertops, they run Park Industries’ Fusion sawjet, a Titan 2800 CNC, polishers, and edgers, including a Velocity and Bovone’s straight line edging machine. On the dry side, they run a Komo 3-axis CNC and an Anderson 5-axis CNC.

In the Meridian manufacturing area, they run dual continuous casting machines and continuous casting mixers, with most of the casting performed via robotics. “The majority of the operation is automated, allowing us to streamline manufacturing and maximize output with a small crew,” explained Todd. “We only have about 20 workers on this side of the shop.”

In the Marketplace

On the whole, about 75% of Tower’s projects are commercial. Tower’s residential game is a mix of new construction, remodeling and direct-to-customer. They have a showroom where they display both Meridian products as well as premium countertop solutions in stone and other materials. They partner with residential builders, remodelers, architects, developers and property owners to drive business.

Todd says selling a package is vital in certain parts of the business. “We recently completed an apartment renovation project that included shower walls, shower bases, shower accessories and a glass shower door along with demo and installation,” he explained. “The fact that we

“The majority of the Meridian operation is automated, allowing us to streamline manufacturing and maximize output with a small crew,” explained Todd. “We only have about 20 workers on this side of the shop.”

34 • Vol. 17 / Issue 1 • International Surface Fabricators Association

Meridian Solid Surface solutions is a complete line of products — including fully customizable options — from shower bases and wall panels to accessories like seats, soap dishes, shelving niches and more.

FABRICATOR PROFILE

could handle a wider scope — offer a turnkey solution for the client — won us the job. But on a more basic level, I can’t imagine selling a kitchen or bath countertop without supplying the sink. That’s where it started, but over the years, you look at ways to be more competitive and increase your value proposition.” Todd encourages other fabricators to look at ways to differentiate themselves from the competition and provide more value while minimizing customer pain points.

Managing the Dream

Todd attributes Tower’s success to their service-focused approach. “We are an excellent service organization,” he explained. “When there is an issue, we solve it quickly. The size of our team and its scope allow us to have a deep bench, providing us with prompt problem resolution.”

Todd’s management experience and business acumen are built on his belief in processes and procedures. “When we started the company, we were tiny,” he explained. “I only needed to make a one-story house — nothing huge. When the business grew, we had to add a second story, but when we put the third story on, it all got a little wobbly. That’s when I knew we needed a new foundation. He joined the Entrepreneur’s Organization, where he learned about the Entrepreneurial Operating System (EOS).

Expansion would not have been possible without structure, he notes. About five years ago, the company fully embraced EOS, a simple set of principles by which a company is run. It begins with identifying and implementing core values based not on goals but on strengths. “Our core values are at the

heart of our success,” he explained. “We are kind; we take initiative; we get it done; we make it right; we are humble; and we are enthusiastic.” It forced the team to align and embrace these core values, and the process created a road map, which included processes like structured meetings where issues are identified and solved, quarterly conversations, regular reviews and laser-focused planning that otherwise didn’t occur.

“Before EOS, I didn’t love our company culture, to be honest,” he said. “It enabled bad behavior to exist because we thought we couldn’t afford to lose people. But it wasn’t fair to those who were excelling.

“Tower’s General Manager Kerry Klodt suggested Matthew Kelly’s book The Dream Manager. ‘The book’s premise is if employers help employees realize their dreams,’ explained Kerry, ‘they will more willingly help us realize ours growth, profitability, success and service. To do that, we need productive people who want to come to work and take pride in their work and the product we create.”

International Surface Fabricators Association • Vol. 17 / Issue 1 • 35

Tower provides its staff with great benefits, growth opportunities and hosts company functions that celebrate successes, like this chili cookoff.

Last year, Tower Industries collaborated with the International Surface Fabricators Association to host a fabrication training session for porcelain materials.

Tower’s residential game is a mix of new construction, remodeling and direct-to-customer. They partner with residential builders, remodelers, architects, developers and property owners to drive business.

FABRICATOR PROFILE

“When we adopted EOS and began to emphasize the importance of our core values, it changed the dynamic. People work here because they are treated with respect and kindness, and they know that the company they work for truly cares about them.”

Tower’s General Manager Kerry Klodt suggested Matthew Kelly’s book The Dream Manager. “The book’s premise is if employers help employees realize their dreams,” explained Kerry, “they will more willingly help us realize ours — growth, profitability, success and service. To do that, we need productive people who want to come to work and take pride in their work and the product we create.” Tower provides its staff with great benefits, growth opportunities and mutual respect by celebrating successes and fostering an excellent work-life balance. From holiday parties to chili cookoffs and hosting industry events like the International Cast Polymer Association’s (ICPA) Polycon or Mineral Surface Fabrication Training with the International Surface Fabricators Association (ISFA), they always include all the staff. “We work diligently to regularly engage our entire team, so they know we care about them.”

Staying Connected

Industry involvement has been essential to Tower’s evolution since its inception. Todd has served as president of both ISFA and ICPA, and Kerry is ICPA president today. “Being involved in these organizations helped me to understand the industry better,” said Todd. “I developed Meridian Solid Surface based on what I learned from chemists and technical support advisers who worked

for raw material manufacturers within ICPA. I learned polymer chemistry by volunteering on a quality committee in 1995. I showed up to meetings, and I listened. I asked a lot of questions, and I got a lot of answers. Being involved with ISFA led to terrific insights about how to be more efficient in fabrication by implementing automation. I discovered that my problems and challenges were not exclusive to me. There were others out there who were happy to share their pitfalls and successes and gave me a much better understanding of how to find success in this business.”

In the end, Todd says there’s no magic bullet, and there’s definitely no substitute for hard work. “The success of an organization is never due to one person, and the Tower story is no different. There have been an endless number of dedicated, hardworking individuals who have come together, enabling us to persevere for nearly 30 years and make Tower Industries the company it is today.”

Having a full management team in place, Todd can leave the business for long stretches of time, and he doesn’t worry about what’s going on back in the shop. “All my key players and contributors do a great job of keeping this machine running. I love this business, but I also like to play golf,” he quipped.

What’s next for Tower? Well, by definition, to tower would suggest an aim to reach great heights. Given the trajectory thus far, there’s no doubt this fabricator will continue to find success for years to come.

Learn more about Tower Industries at www.towerindustries.com and find more information about Tower Countertops at www.towercountertops.com.

FOR YOUR BOOKSHELF

Managing people is difficult. With disengagement and turnover on the rise, many managers are scratching their heads wondering what to do. It’s not that we don’t dream of being great managers, it’s just that we haven’t found a practical and efficient way to do it. Until now …

The fictional company in this remarkable book is grappling with real problems of high turnover and low morale so the managers begin to investigate what really drives the employees. What they discover is that the key to motivation isn’t necessarily the promise of a bigger paycheck or title, but rather the fulfillment of crucial personal dreams. They also learned that people at every level need to be offered specific kinds of help and encouragement or our dreams will forever remain just dreams as we grow dissatisfied with our lives and jobs. Beginning with his important thought that a company can only become thebest-version-of-itself to the extent that its employees are becoming better-versionsof-themselves, Matthew Kelly explores the connection between the dreams we are chasing personally and the way we all engage at work. Tackling headon the growing problem of employee disengagement, Kelly explores the dynamic collaboration that is unleashed when people work together to achieve company objectives and personal dreams.

The power of The Dream Manager is that simply becoming aware of the concept will change the way you manage and relate to people instantly and forever. Get the book at www.amazon.com/Dream-ManagerMatthew-Kelly/dp/1401303706.

36 • Vol. 17 / Issue 1 • International Surface Fabricators Association

New Year, New Perspective

By Marissa Bankert, ISFA Executive Director

It seems like the only constant is change, and ISFA went through a lot of that in 2023. And even though it’s disruptive to the status quo, it’s a terrific exercise that allows us to reframe and rethink how we approach our work. As an organization, I can tell you that we’re better prepared for what lies ahead — with renewed perspective. While I get up to speed and learn more about this industry, I’m inspired and motivated to lead this organization and implement strategies that will power us forward in 2024.

Who is ISFA’s New Executive Director?

Great question! My professional background is in leadership and management, including nonprofits and educational resources within various industries, and my most recent role was as executive director for a statewide electrical trade association in Pennsylvania. In that role, I focused on apprenticeship, workforce development, networking, advocacy and partnerships for the membership. While developing the staff and board resources and growing the association overall, I also grew as a leader. Personally, I’m a mother, a sports fan, fitness lover and pursuer of … fun! I am energetic and forward-thinking, and I like to surround myself with like-minded individuals who share my enthusiasm.

What’s the Plan?

In 2024, you will see a renewed focus on ensuring that our fabricator members have opportunities to grow their businesses through educational resources and networking events. The goal of our association has always been to guide the industry while providing value to our members — actionable insights that lead to growth. We prize our relationships with our associate partners and experts in the industry. Through those relationships, we can offer quality events in many locations — all centered around helping our fabricator members with the things that keep them up at night.

In addition to events, we’ll focus on the #1 pain point of the industry today: employee safety — silica safety, to be specific.

Throughout the year, you’ll see ISFA bring our members and the industry more information through education, training and advocacy. The goal is to work alongside you, arming you with the resources you need to succeed in your business while keeping your employees safe. Meanwhile, we’ll sit at the table where governing bodies make decisions that change how we do business. The goal here is to ensure all viewpoints are represented — including yours.

All the while, we will be working diligently to grow ISFA as an association and bring more awareness to the industry, our members and our partners. As we bring more experts and thought leaders to the association, we’ll be well-positioned to solve the woes of our fabricator members and thereby further the industry. We want to be the voice of the industry, and we will work as an organization to do so in an effective and meaningful way.

So, What’s Next?

Next is the choice you have in how you leverage your membership or partner with ISFA. I hope you’ll engage — join us as we launch into a new season of growth, opportunity and change. Attend our events, take advantage of our training opportunities, and learn from great thinkers in our industry and beyond. I’m excited to work with ISFA’s board of directors, staff and members to elevate the association to new heights and provide significant value to all who partner with us. Change with us as we grow and adapt, too!