SINCE 1958

SINCE 1958

Established in 1958, Vacuum Barrier has grown to become the leading manufacturer of liquid nitrogen handling systems with an experienced team that has an in-depth knowledge on various cryogenic processes.

Working with a variety of industries, Vacuum Barrier provides the most advanced dosing systems designed to deliver liquid nitrogen with extreme consistency at speeds up to 2000 containers per minute. Combined with Vacuum Barrier’s liquid nitrogen piping, plant manufacturers can limit LN2 loses and achieve greater efficiency.

It is Vacuum Barrier Corporation’s policy to understand and fully meet our customer’s requirements at all stages of work. Our goal is to design, manufacture and deliver safe and defect-free products while achieving the highest level of customer satisfaction. It is our commitment to continuously improve our quality management system which provides the framework to monitor quality and promote involvement from all employees.

Providing custom and standard solutions for all LN2 handling applications, Vacuum Barrier prides itself on being your one source for a complete LN2 system. Our highly skilled team of engineers, sales consultants and field service technicians collaborate with plant engineers to address their specific LN2 needs efficiently and economically.

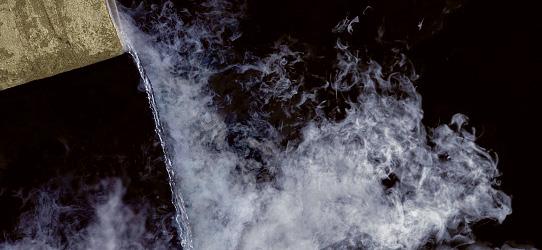

Liquid nitrogen is used to pressurize non-carbonated beverages in PET packages and aluminum cans providing the manufacturer with the rigidity/stability necessary – allowing for use of lightweight material and significant cost savings.

BENEFITS

Limits damage of packages during transportation

Enhanced labeling

Improved palletizing in warehouse

Compensation for atmospheric pressure

Vending machine compatibility

Preservation of package shape on shelf

PRESSURIZING EXAMPLES

Bottled water

Energy drinks

Juices

Teas

Coffee

Beer

Aseptic applications

Liquid nitrogen is used to inert delicate products that should have minimal contact with oxygen to eliminate paneling and improve shelf-life by preserving the product taste, color and freshness.

BENEFITS

Eliminate paneling

Improve shelf life

Preserve taste, color and freshness

INERTING EXAMPLES

Vegetable oils

Dairy products

Wine

Fruit juices

Energy drinks

Snacks

Vegetables

Sauces

Powders and solids

Vitamins

Health drinks

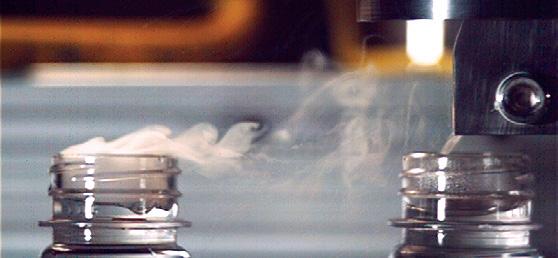

Using liquid nitrogen dosing technology, a craft brewer can precisely dose non-widget cans to achieve similar results as with a widget. The agitation necessary to create the creamy head can be caused by a rigorous pouring, or to a lesser degree, by using glassware that has been laser-etched.

NITRO-INFUSED

Gaining momentum from the success of nitro-beer, nitro-infused drinks re-imagine familiar drinks such as coffee, tea, chocolate milk, energy drinks and cocktails to create rich, creamy, visually intriguing drinks. Dosing just a drop of liquid nitrogen creates an enhanced mouthfeel and enrichment to the flavor.

Vacuum Barrier provides a complete line of liquid nitrogen injection equipment designed to discrete dose low pressure liquid nitrogen at line speeds of 200 to 2000+ containers per minute with the greatest reliability, accuracy and consistency.

COMMON SYSTEM FEATURES

Allen Bradley or Siemens PLC

Allen Bradley or Siemens 6” touchscreen HMI

Real-time Graphical User Interface

Five on-board languages

Continuously self-monitored with alarm outputs and beacon

Electronic dosing valve

Clean hygienic design

MINIDOSE

Named for its size, operating speed and cost the MiniDose is designed to discrete dose up to 200 containers per minute with accuracy +/- 5% dose weight. This unit is ideal for lab testing.

Simplified liquid nitrogen dosing designed to discrete dose up to 450 containers per minute with accuracy +/- 3% dose weight. This system is equipped with user-friendly language symbols and simplified control panel.

Simple to install and operate the EasyDose G2 is designed to discrete dose up to 450 containers per minute with accuracy of +/- 3% and converts to continuous stream thereafter.

Simple to install and operate the EasyDose G2 Plus is designed to discrete dose up to 2000 containers per minute with accuracy of +/- 3% and converts to continuous stream thereafter.

Advance liquid nitrogen dosing with discrete dosing speeds up to 450 containers per minute with accuracy of +/- 3% and converts to continuous stream thereafter.

Advanced liquid nitrogen dosing performance with powerful control systems to discrete dose up to 2000 containers per minute and converts to continuous stream thereafter. Designed with improved durability.

The highest level of control in liquid nitrogen dosing with discrete dosing up to 2000+ containers per minute with accuracy of +/- 1% and converts adjustable stream thereafter. This system is virtually maintenance free.

Low cost liquid nitrogen dosing system with discrete dosing up to 500 containers per minute with accuracy of +/- 3%. This system is designed to reduce oxygen levels in large volume containers.

Precisely delivers sterile, low pressure liquid nitrogen for all aseptic filling lines up to 750 containers per minute with accuracy of +/- 3% and converts to continuous stream thereafter. This system is constructed of non-corrosive 316L stainless steel free from crevices.

When access to the filling line proves difficult, we offer alternative layouts to the standard dimensions – positioning the dosing head in the ideal location. For easy installation adjustable supports are available in various designs

MULTI-HEADS

For filling lines that require simultaneous dosing into multiple packages Vacuum Barrier’s multi-head dosers are the perfect solution. Dosing heads are installed side by side and each package is dosed simultaneously and with the greatest consistency.

ASEPTIC SYSTEMS

Vacuum Barrier dosers adapt to operate in clean room environments and integrated into ultra clean bottling lines. Various units and solutions are available depending on the design of the filling line.

Precise discrete dosing of liquid nitrogen using direction dose dispersion eliminates splashing to improve accuracy. This advancement can be used for lightweight PET packages or hotfill beverages in PET or lightweight aluminum cans.

Vacuum Barrier’s automatic nozzle protection prevents moisture from entering the dosing head to eliminate potential freeze ups. Withstands high pressure wash down or aggressive chemical cleanup and provides immediate nozzle closure after dosing stops.

Provides Vacuum Barrier certified technicians with the ability to remotely access control panels to troubleshoot and assist with any setting modifications. This option is available on most Nitrodose touchscreen systems.

Vacuum Barrier offers dynamic or vacuum-sealed SEMIFLEX® piping in either OHFC copper or stainless steel, both providing the lowest cool down and steady state heat loss of any liquid nitrogen piping system.

Dynamic systems include a vacuum pump that continuously maintains and improves the vacuum insulation. Sealed systems do not include a vacuum pump, since the vacuum is created during manufacturing and is permanently sealed with each component.

SEMIFLEX® systems deliver liquid nitrogen at bulk tank pressure in two-phase condition. This basic system is used in applications that simply require transfer of liquid nitrogen.

SEMIFLEX® systems with a vapor vent employ a mechanical float operated device that minimizes two-phase flow – maintaining the liquid nitrogen in SEMIFLEX® at storage pressure. This system is used in applications where the piping system is required to be cold and ready for immediate use.

SEMIFLEX®/Triax/Liquid Vapor Phase Separator systems deliver liquid nitrogen in pure liquid form at atmospheric pressure. The addition of the Triax pipe and Liquid Vapor separator eliminates twophase flow delivering sub-cooled liquid nitrogen by gravity to each use point. By separating the vapor and venting it prior to liquid delivery, no gaseous nitrogen passes through your equipment. This system is used in applications where singlephase liquid is critical to the production process.

COBRAFLEX® sealed vacuum liquid nitrogen hoses are available in stainless steel with a highly flexible outer wrap. Combined with SEMIFLEX®, efficient plant piping, connections are easily made to use points.

4 Barten Lane, Woburn, MA 01801

T 781-933-3570

F 781-932-9428

sales@vacuumbarrier.com

vacuumbarrier.com