International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072

Mangesh Deshmukh1 , Arab Basha2 , Ravi Khare3

1 Senior Project Manager, Tata Technologies Ltd, Pune

2 Senior Program Manager, Tata Technologies Ltd, Pune

3 Program Manager, Tata Technologies Ltd, Lucknow

Abstract - In modern automobiles to enhance steering efficiencyandvehiclemanoeuvrabilitydirectadaptivesteering system is technological advancement in the field of steering systems. In these systems conventional steering shaft is replaced with electronic devices that relay steering signals from the steering wheel to a servo motor. Servo motor is used for managing the operation of a rack and pinion assembly, which in turn propels the wheels. After installation of DAS, it will eliminate mechanical components such as the steering shaft, adaptive steering systems which will contribute to reduce both weight andcomplexityofthesteeringapparatus, which therefore shall improve efficiency and decrease the overall cost of the steering system. Direct Adaptive Steering can also provide considerable benefits regarding handling accuracy,comfort,andtheoverallperformanceofthevehicle.

Direct Adaptive Steering (DAS) represent sophisticated technologies aimed at improving vehicle handling and enhancing driving comfort. DAS operates by converting the driver's steering actions into electronic signals, which autonomously manage both the tire angles and the steering effort. This results in a pronounced sense of propulsion and better road feedback, particularly on uneven or rough terrains, thereby lessening the necessity for the driver to maintainafirmgrip onthesteeringwheel.Byminimizingthe transferofvibrationstothedriver,DAScontributestoastable trajectory, facilitating easier navigation on irregular roads. Furthermore, on highways, the system automatically adjusts the steering, promoting a more relaxed and assured driving experience.

DirectAdaptiveSteering(DAS)representsanadvancement in automotive engineering, designed to improve vehicle control and enhance driving comfort through real-time adjustments to steering response. In contrast to conventional steering systems, DAS provide sophisticated electroniccontrolandsensortechnologieshelpstodeliver adaptive feedback to the driver, thus facilitating more accurate handling and smoother driving experience. The system operates by continuously modifying the steering characteristicstoalignwithvariousdrivingfactorsincluding speed, road conditions, and steering input. The primary objective of DAS is to provide drivers with improved manoeuvrability,lessensteeringeffort,andoverallsafety.As this technology progresses, it holds the promise of

transforming the interaction between drivers and their vehicles,deliveringamoreintuitiveandresponsivesteering experiencethatadaptstopersonaldrivingstylesandvarying roadconditions.

In Conventional steering systems the driver generally required to manually rotate the steering wheel, which is linked to the front wheel via steering shaft. This action activatesthesteeringgearbox,whichinthendrivesthefront wheelsofthevehicle.Fortheproperrotationalmovement, universaljointsareemployed,allowingthesteeringshaftto rotate while ensuring smooth functionality. The steering columnactsastheconnectionbetweenthesteeringwheel andtherestofthesystem,andasthedriverturnsthewheel, theknucklepivots,directingthewheelstotheleftorright.In contrast,adaptivesteeringsystemspresentnotablebenefits over traditional mechanisms, particularly in terms of steeringperformanceenhancement. Oftenintegratedwith power steering, these systems significantly improve both functionality and the overall driving experience for consumer.Theintroductionofelectronicsteeringsystems haspavedthewayforfullyadaptivesystems,whichprovide high efficiency and advanced safety features for future vehicles.

Adaptive steering systems function by modifying the steering ratio based on the vehicle's speed and driving conditions. At higher speeds, the system decreases the steering ratio, resulting in a more stable and controlled steeringexperience.Conversely,atlowerspeeds,thesystem increasesthesteeringratio,allowingthefrontwheelstoturn a greater distance with reduced driver effort, thereby facilitatingeasiermaneuveringandparking.Thesesystems consistofvariouscomponents,includingthesteeringwheel, gearbox,LCDinterface,andlinkages,alldesignedtoensure smoothandefficientoperation.Duringparkingmaneuvers, the friction between the vehicle's front tires and the road surface escalates, necessitating greater effort from the driver.Toalleviatethiseffort,adaptivesteeringsystemslink the wheel to a gearbox that adjusts the required effort, thereby enhancing the ease and efficiency of steering control.

Directadaptivesystemevolvedfromtraditionalmechanical steeringsystemsinwhichthemechanicalcomponentsofthe steeringsystemisreplaced bytheelectroniccomponents.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072

Thus, to understand the direct adaptive system first we understandthetraditionalsteeringsystems

1.1 How does traditional steering system works?

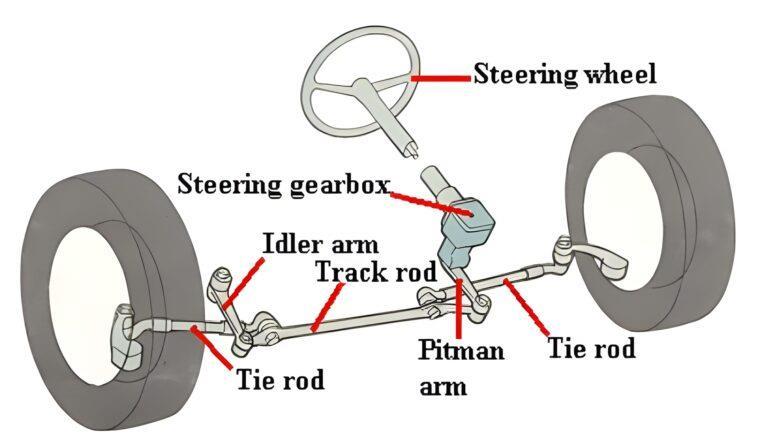

Thefront-wheelsteeringsystemisthemosttraditionaltype of steering mechanism found in automobiles, in which the vehiclecontrolitspathbymaneuveringthefrontwheels.This procedurestartswhenthedriverrotatesthesteeringwheel and the steering wheel is connected to a steering column. Thiscolumnactsasashaftthatcarriestherotationalmotion from the steering wheel to the steering mechanism. The turningofthesteeringcolumnisimportantasitconvertsthe driver's physical actions into mechanical force which then convert into translational movement that influences the wheelstoturn.

The steering gearbox, whichcanalso be referred to as the steeringrackorsteeringgearislocatedatthecenterofthe steeringsystem.Themainroleofthesteeringgearboxisto changetherotationalmovementofthesteeringwheelinto linearmovement,whichledtomovethefrontwheelstoleft or right. There are two primary varieties of steering gearboxes.Therackandpinionmechanism,commoninmost cars,featuresacirculargear(thepinion)thatinterlockswith aflatgear(therack).Whenthesteeringwheelisturned,the pinionrotates,shiftingtherackhorizontallyandsteeringthe wheels.Therecirculatingballmechanism,typicallyseenin trucksandlargervehicles,utilizesballbearingstominimize friction as the steering wheel turns a worm gear, which subsequentlyshiftsasectorgearlinkedtothepitmanarm.

Thesteeringgearboxconnectstothewheelsthroughaseries of linkages, including tie rods and control arms. These linkages guarantee that the movement produced by the steeringgearisfaithfullytransmittedtothewheels.Thetie rodsarevitalinthisconnection,linkingthesteeringgearbox withthesteeringknuckles,whichareconnectedtothefront wheels. When the steering gear shifts the tie rods, the steeringknucklesrotate,causingthewheelstomove.

Fig -1

1.2.1

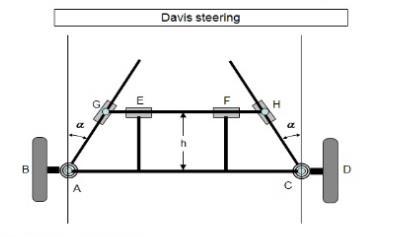

TheDavissteeringmechanismisbasedonastructurethat createsfrictionandwearbecauseitutilizesslidingpairsin placeofturningpairs.Thisleadstoasystemthatcansuffer frominaccuraciesovertime,whichisamajordisadvantage.

DetailedDescriptionoftheDavisSteeringMechanism:

1.SlidingPairs:Thismechanismfeaturesslidingpairsthat, by their nature, produce more friction than turning pairs. The resulting friction leads to wear on the components, which ultimately results in diminished steering precision overtime.

ComponentLayout:

1. Cross-Link CD: This is a sliding element that moves in paralleltoanotherelement,AB.

2. Bell Crank Levers (LAC and MBD): The cross-link CD is linkedtothestubaxlesofthefrontwheelsthroughtwobell cranklevers,LACandMBD.TheseleverspivotatpointsA andB,respectively.

3.SlidingPairsatEndsCandD:Theextremitiesofthecrosslink CD (points C and D) are designed as sliding pairs, permittingthelinktoglidewithinitsbearings.

OperationalMechanics:

1. Center Position of Steering Gear: When the automobile travelsstraight,thesteeringgearissaidtobeinacentered position.Thispositionisvitalsinceitsignifiesthesteering system'sneutralconfiguration.

2. Angle of the Cross Arm (��): The functionality and precision of the Davis steering mechanism hinge on the optimalchoiceofthecross-armanglerepresentedby��.An appropriate measurement of this angle guarantees that steeringremainsaccurateandeffectiveduringnormaluse.

Selectingtherightcrossarmangle(��)isessentialforproper steering.Thisangleinfluenceshowwellthesystemcankeep thewheelscorrectlyaligned,ensuringthatthevehiclesteers accuratelyevenaspartsweardown.Thedistancebetween the pivots of the front axle is denoted as c, while the wheelbase is represented by b. The value of �� is between 11.3°and14.1°.

While the Davis steering design is theoretically sound, it proves inefficient in real-life situations because of an increased number of sliding components, leading to additional wear and decreased accuracy. As a result, this systemisnotcommonlyused.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072

1.2.2AckermanSteeringMechanism

TheAckermansteeringsystemispopularinvehiclesbecause ofitsstraightforwardnessandeffectivenessinmaintaining properwheelpositioningduringturns.Thissteeringdesign ingeniouslyarrangesthesteeringlinkagestoenabletheinner and outer wheels to turn at suitable angles. Such arrangement allows the wheels to follow an appropriate trajectory in a turn, minimizing tire wear and enhancing maneuverability.

ComponentStructure:

1. Cross-Link CD: This component links the short arms of both front wheels, playing a vital role in preserving the properrelationshipbetweenthewheelswhensteering.

2. Short Axles AL and BM: The front wheels’ short axles connecttothecross-linkCDthroughtheshortarmsACand BD.

3.BellCrankLevers(LACandMBD):TheshortarmsACand BDfunctionasbellcrankleversLACandMBDinrelationto the cross-link CD, aiding in transmitting motion from the steeringsystemtothewheels.

4. Angles and Arrangement: When the vehicle is traveling straight,thecross-linkCDalignsparalleltolinkAB.Theshort armsACandBDformequalangles,referredtoas��,withthe horizontalplaneofthechassis.

OperationalFunctions:

1.ForwardMotion:Whenmovinginastraightline,theangles formedbetweentheshortarmsACandBDandthechassis remainequal,ensuringthewheelsareparalleltoeachother.

2.TurningMotion:Duringaturn,themechanismmodifiesthe anglesfortheinnerandouterwheels,enablingthemtorotate atdifferentangles.Thismechanismensuresthateachwheel adheres to its designated circular path, adhering to the geometryprinciplesoftheAckermansteeringdesign.

3. Core Equation for Correct Steering: To achieve precise steering, itiscrucial tocarefullyselectand proportion the lengths of the links AC and BD alongside the angle ��. This proportionalityisvitalformeetingthefundamentalequation forcorrectedsteering,ensuringthatthewheelspivotatthe correctanglesconcerningoneanother.

Now let’s explore the functioning of the direct adaptive steeringsystem:

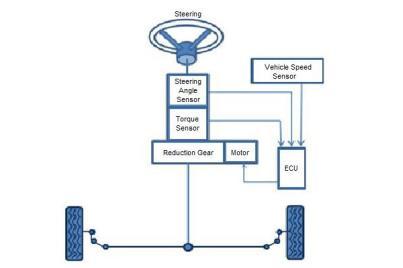

Powersteeringhasimprovedtheefficiencyofthesteering and thus made it possible to drive the vehicle without discomfortingtheupperbodyofthedriverbutthesteering ratio(Noofturnsofsteeringwheelrequiredtoturnthefront wheels) of most vehicles remained fixed. In the case of adaptive steering the system adjusts the steering ratio dependingonthedrivingconditions.Astheadvancementof thissystemthemechanicalcomponentwillreplacedbythe electrical component for transferring power from the steering to wheels. In this case, at low speeds the vehicle steers the front wheels at greater distance for the same amountofrotationofthesteeringwheel.Fortransferringthe steering signals to LCD, an electronic device is used. From LCD steering signals is transferred to a servomotor which then carries the power to final drive. Depending upon the speedthesteeringsystemreact.Itismostefficientintermsof steeringratiowhenthespeedofthevehicleislow.Sincein direct adaptive steering system there is no mechanical linkagessothereforethefunctionofmissingcolumnsmustbe doneforboththedirections.Inforwarddirectiontheangleof the steering wheel applied by the driver is measured by a steeringanglesensorandaccordinglythesuitablesteering ratio is provided to the wheels. While in case of reverse direction the steering torque sensor measure the steering torque of wheels and decrease it respectively. Modified feedbackreceivedbythedriverasacountertorqueonthe steeringwheel

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072

1.4 Technology Configuration of Direct Adaptive Steering (DAS)

The Direct Adaptive Steering (DAS) system is designed by combining a multiple type of technologies that helps to analyse the vehicle's steering behavior and to adjust it in accordancewithreal-timedrivingconditions.Theprimary elementsoftheDirectAdaptiveSteeringinclude:

Electronic Control Unit (ECU): ECU being the central part helps for processing data from an array of sensors and governs the entire steering mechanism. It executes algorithmsthatascertainthenecessarymodificationstothe steeringratiobyanalysingrealtimefactorssuchasvehicle speed, steering angle, and other driving conditions. Its purpose is to continuous monitoring and adjustment of steering performance to ensure an optimal driving experience.

ElectricMotorsandActuators:ElectricMotorsandActuators arethedeviceswhichdoestheactualphysicaladjustmentof thesteeringcolumn,therebyalteringtheconnectionbetween thedriver'sinputandthemovementofthevehicle'swheels. AstheECUrunsthealgorithmandaccordinglytheactuators and motors operate. The actuators are designed for high precision and operate in real-time, assuring that steering modificationsoccurswiftlyandeffectively.

Sensors: Speed and Vehicle Dynamics Sensors: These instruments gauge the vehicle's speed and other dynamic parameters,includingaccelerationandbraking.Theysupply essentialdatatotheECU,facilitatingtheadjustmentofthe steeringratio.

SteeringAngleSensors:Thesesensorsmonitorthesteering wheel'sangle,assistingthesystemindeterminingtheextent ofwheelrotationandprovidethisinformationtotheECUfor necessarymodifications.

TorqueSensors:Thesedevicesmeasuretheforceappliedto the steering wheel, providing feedback to the system to adjusttherequiredsteeringeffortfromthedriver.

Feedback Mechanisms: DAS systems utilize a variety of feedback mechanisms to ensure that the driver enjoys a naturalandintuitivesteeringexperience.

1.5 Technology functionality of Direct Adaptive Steering (DAS)

The Direct Adaptive Steering (DAS) system is designed to make real-time modifications to the vehicle's steering response, enhancing the overall driving experience by making it more efficient, precise, and comfortable. DAS utilizessensorstogatherreal-timedata,whichhelpsitassess the current driving environment. Key parameters such as vehicle speed, steering angle, and road conditions are continuously monitored to ascertain the most suitable steering response. In response to this data, the system dynamicallymodifiesthesteeringratio.Atlowerspeeds,such aswhenparkingornavigatingthroughnarrowspaces,the steering ratio is increased, allowing for a smaller steering wheelmovementtoresultinalargerturnofthefrontwheels, thereby enhancing maneuverability with reduced effort. Conversely,athigherspeeds,thesteeringratioisdecreased, offering the driver a more stable and controlled steering experienceakintotraditionalsystems.

The DAS incorporates force feedback mechanisms to preserveanintuitiveconnectionbetweenthedriverandthe road.Thesteeringwheelcanexhibitvariableresistanceto replicatefeedbackfromtheroadsurfaceoralterationsinthe vehicle's dynamics, thus providing a more engaging and responsive driving experience. The power steering componentofthesystemaidsinadjustingthesteeringeffort accordingtovehiclespeedandconditions.Atlowerspeeds, where greater steering effort is generally necessary, the systemamplifiesthedriver'sinputtofacilitateeasierturning.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072

Athigherspeeds,itreducesassistancetoenhanceroadfeel andcontrol.

The system continuously fine-tunes the steering based on real-time variables such as road surface quality, tire conditions,andchangesinvehicleload.Theseadjustments ensurethatthesteeringresponseremainsoptimalacrossa range of driving conditions, from smooth highways to windingorunevenroads.

Incertainadvancedconfigurations,theDASenablesdrivers to personalize their steering experience by choosing from various steering modes, such as sport or comfort, thereby cateringtoindividualpreferences.

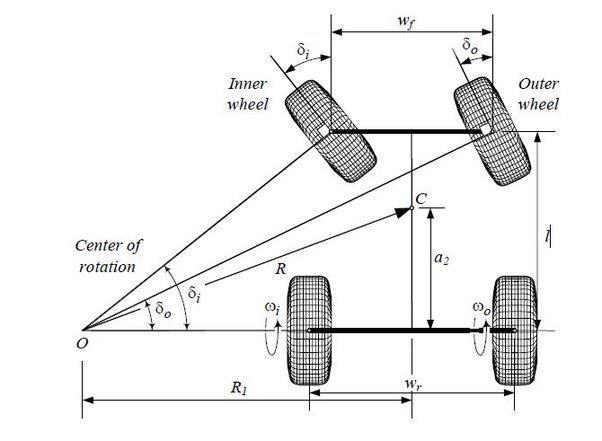

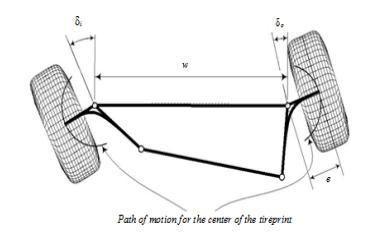

Takingintoconsiderationthatthevehicleismovingslowly. Thekinematicconditionbetweentheinnerandouterwheels allowsthewheelstoturnslip-free.Thisconditioniscalledthe Ackermanconditionandisexpressedby Where,

δiisthesteerangleoftheinnerwheel,

δoisthesteerangleoftheouterwheel

wisthefronttrack

listhewheelbaseofthevehicle

Themasscenterofasteeredvehiclewillturnonacirclewith radiusR.Tofindthevehicle’sturningradiusR,wedefinean equivalentbicycle.Then Where,

aisthelengthsofthelinksofafour-barlinkageand

δisthecot-averageoftheinnerandoutersteerangle

Thatis-

The Ackerman condition is needed when the speed of the vehicle is too small, and slip angles are zero. There is no lateralforceandnocentrifugalforcetobalanceeachother. The outer point of the front of the vehicle will run on the maximumradiusRMax,whereasapointontheinnersideof the vehicle at the location of the rear axle will run on the

minimumradiusRmin.Thefrontouterpointhasanoverhang distancegfromthefrontaxle.ThemaximumradiusRMaxis

The best advantage of DAS is that it can change the steering ratio dynamically which allows more precise control. This helps while travelling the vehicle at tight cornersortrickyroadconditions.

Direct Adaptive Steering (DAS) provides a better and smoother drivingexperience byadjusting thesteering ratioinreal-timebasedondrivingconditions.Athigher speeds,thesystembecometightforgreaterstabilityand controlwhereasatlowspeeds,suchasduringparkingor citydriving,thesystemreducessteeringeffort,makingit easiertohandlethevehicle.

Some direct adaptive steering system allow for driver preferences to be set, enabling a more personalized drivingexperience.Whetherthedriverprefersasportier feeloramorerelaxedsteeringresponse,thesystemcan adaptaccordingly.

Sinceatlowspeedthesystemreducestheeffortrequired tosteer,ithelpsreducefatigueonlongtripsorinstopand-gotraffic.Thisisespeciallyhelpfulinurbanregion

DirectAdaptiveSteeringcancontributetobettervehicle stability,especiallyathigherspeeds.Itadjuststoroad conditions and driving behavior, which can enhance overall vehicle control and reduce the likelihood of driverovercorrectioninemergencies.

4.DISADVANTAGE OF DIRECT ADAPTIVE STEERING

DASismoretechnologicallyadvancedthantraditional steering systems, incorporating electronic motors, sensors,andcontrolunits.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072

Traditionalsteeringsystemsprovidephysicalfeedback from the road, allowing drivers to "feel" the road and vehicle behavior. Some drivers may find the artificial feedbackfromDASlessengagingorlessintuitive,which couldimpacttheoverall drivingexperience,especially forthosewhovalueroadfeel.

Aswithanyadvancedelectronicsystem,theremaybe concerns about the reliability of the components over time.Ifthesystemfailsormalfunctions,itcouldleadto serious driving issues, requiring costly repairs or replacements.

Driversaccustomedtotraditionalsteeringmaytaketime to adapt to the feel of DAS. The lack of mechanical connection and the varying steering response could initiallyfeelunusualoruncomfortableforsome.

Table -1:ComparisonofDASandMechanicalSteering

Feature MechanicalSteering Directadaptive steering

Steering Mechanism Conventional mechanicallink (rackandpinionor recirculatingball)

Driving Comfort Lessstableathigh speeds,High steeringeffortat lowerspeeds

EaseofUse Requiresmore effortsatlower speed,lessadaptive

Mechanismis controlledby electronic componentsfor adjustmentsof steeringratio(ECU, Actuators,Sensors etc.)

Morestableathigh speeds,Easier steeringatlowspeeds

Easiertomaneuverin tightspaces,high comfortoverlong distances

Complexity Simpler Complex

Cost Lessexpensive Moreexpensive

Maintenance Lowermaintenance comparedto adaptivesteering Requiredspecial maintenancedueto electronic components

Responsiven ess Comparatively Slower Quick

Steeringratio constant Variable

Application Preferredforlow weightvehicles Preferredforhigh weightvehicles

Direct Adaptive Steering (DAS) shall allow drivers to enhancetheirsteeringexperiencebyadjustingsteering response with respect to roadconditions. Itshall also provide feedback to driver which shall result in more comfortabledrivingexperience.

With fewer mechanical components than traditional steering systems, DAS helps reduce vehicle weight, which may lead to improved fuel efficiency. The flexibilityofitsdesigncanalsocreatenewpossibilities forvehicleinteriorarrangements.

DAScanimprovestabilitybyautomaticallyadjustingthe steering by analysing the real time conditions thus making the vehicle safer and less volatile during emergencysituations

DASrepresentsaninnovativeleapinautomotivedesign, incorporating advanced sensors and algorithms. It serves as a precursor to future advancements in autonomous driving systems, where steering adjustmentscouldbecontrolledautomatically.

Asthetechnologycontinuestodevelop,DASislikelyto feature even more sophisticated adjustments, such as real-time modifications based on road conditions, furtherenhancingbothsafetyanddrivingperformance

Thepathshallleadfrommechanicalsteeringsystemvia hydraulic steering system and then electric power steeringtodirectadaptivesteering

DAS system can also be integrated with electric and hybridvehicleswhichshallprovidemoresmootherand intuitive control and can get easily aligns with the electricpowertrains.

Thesafetyfeatureofthevehiclecanbeenhancedbythe introductionofDASwhichrespondsbetterincriticalor emergency situations by automatically adjusting the steering.

DAScanplayapivotalroleinsoftwaredefinedvehicles asitcanmanagetodorealtimeadjustmentinsteering inputbyanalysingtheroadconditions

InfuturetheDASsystemcanbeeasilymodifiedbetween more sensitive or stiffer steering depending upon the drivercomfort,thuscanbeabletofulfiltheconsumer demand.

Withtheriseofconnectedinfrastructureandvehicle-toeverything(V2X)communication,DAScouldevolveto adapt based on real-time data from roadways, traffic

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

conditions,orothervehicles,furtherenhancingsafety anddrivingexperience.HenceDASsystemwillprovide bothsteeringcomfortaswellaswillenhancethesafety featureofthevehicle

[1] Singh, J. K. (2015). Vehicle Handling Improvement by Adaptive Steering System”. International Journal of Engineering and Innovative Technology, 5(3),48-51.

[2] Jiang,Y.,Deng,W.,Wu,J.,Zhang,S.,&Jiang,H.(2019). Adaptive steering feedback torque design and control fordriver–vehiclesystemconsideringdriverhandling properties. IEEE Transactions on Vehicular Technology, 68(6),5391-5406.

[3] PowerSteering,Wikipedia.

[4] TopTechCars2013:InfinitiQ50,LawrenceUlrich,IEEE Spectrum,Mar.29,2013.

[5] AutomobileEngineeringByKirpalSingh,Vol-1,Vol-2

[6] Shimizu,Y.,&Kawai,T.(1991).Developmentofelectric powersteering. SAE transactions,1-15.

[7] Mortazavizadeh, S. A., Ghaderi, A., Ebrahimi, M., & Hajian,M.(2020).Recentdevelopmentsinthevehicle steer-by-wire system. IEEE Transactions on Transportation Electrification, 6(3),1226-1235.

[8] Yih, P., & Gerdes, J. C. (2005). Modification of vehicle handling characteristics via steer-by-wire. IEEE transactions on control systems technology, 13(6),965976.

[9] Naranjo, J. E., González, C., García, R., de Pedro, T., & Haber,R.E.(2005).Power-steeringcontrolarchitecture for automatic driving. Ieee transactions on intelligent transportation systems, 6(4),406-415.

[10] Eckstein, L. (2016). Future trends for automotive steeringsystems. JTEKT Eng. J

[11] Miura, S. (2014, July). Direct adaptive steering–independentcontrolofsteeringforceandwheelangles to improve straight line stability. In 5th International Munich Chassis Symposium 2014: chassis. tech plus (pp. 75-89).Wiesbaden:SpringerFachmedienWiesbaden.

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072 © 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified

| Page152