International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN:2395-0072

Vishvajit Baban Patil¹, Prof. Pravin Bhasme²

¹PG Student, School of Civil and Environmental Sciences, JSPM University, Pune

²Assistant Professor, School of Civil and Environmental Sciences, JSPM University, Pune

Abstract

This report presents a comprehensive technical assessment and evaluation of a fire-affected building located at MIDC Dhatav, Roha. The assessment focuses on determining the extent of structural and non-structural damage caused by the fireincidentandoutlinesappropriatestrengtheningtechniquesforrehabilitation.

The inspection involved a visual survey, documentation of fire-induced damages, and a preliminary evaluation of structural integrity. Key observations indicated varying levels of thermal damage to reinforced concrete elements, masonry walls, roofing systems, and essential services like electrical and plumbing. The fire primarily compromised the structural performance of load-bearing components in localized zones, necessitating detailed investigation through nondestructiveanddestructivetestingmethods.

Basedonthefindings,thereportrecommendsspecificstrengtheningtechniquesincludingfiber-reinforcedpolymer(FRP) wrapping, section enlargement, epoxy injection for crack repair, and use of fire-resistant coatings. The goal is to restore the structural performance, ensure occupant safety, and bring the building back to serviceable condition in compliance withapplicablecodesandstandards.

This assessment serves as a critical step toward informed decision-making for repair, retrofitting, or partial reconstruction,ensuringbothsafetyandcost-efficiencyinpost-firerehabilitation.

Keywords

Fire-affected building, structural assessment, non-destructive testing, concrete spalling, thermal damage, retrofitting, strengtheningtechniques,concretejacketing,epoxyinjection,structuralrehabilitation

1. Introduction

Fire incidents can significantly compromise the structural integrity and safety of buildings, especially in industrial or commercialsettingswherehighheatloadsandcombustiblematerialsareoftenpresent.Thestructuraldamageinducedby firemaynotalwaysbeimmediatelyvisiblebutcanhavecriticalimplicationsforthelong-termstabilityandusabilityofthe structure.Therefore,amethodicaltechnicalassessmentbecomesessentialtodeterminetheseverityofthedamageandto formulateappropriatestrengtheningorrehabilitationstrategies.

ThebuildingunderassessmentisanindustrialplantlocatedinMIDCDhatav,Roha,constructedin1997usingM20grade concrete, designed to withstand industrial loading requirements. The plant primarily deals with the handling and processingofrubber-basedrawmaterials,whichareknowntobehighlycombustibleunderelevatedtemperatures.

On 12th May 2024,during the morning shift,a fireincident occurred on the first floor of thetwo-storey building. The firewasreportedlycaused byan electrical short circuit,which rapidly escalatedduetothepresenceof flammable raw materialsinthevicinity.Thefirewascontainedbyfireresponseteamsbeforeitcouldspreadsignificantlytootherfloors. As a result, the ground floor and second floor remained structurally unaffected, with no visible signs of distress or thermalexposure.

A visual inspection wasconductedimmediatelyaftertheincidenttoidentifyandmapthefire-damagedzones.Thiswas followed by Non-Destructive Testing (NDT) on selected structural elements, including rebound hammer tests and ultrasonicpulsevelocity(UPV),toassesstheresidualstrengthoftheconcreteanddetectinternalflaws.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN:2395-0072

Given the industrial nature of the building and the potential operational and safety implications, a detailed structural assessment and strengthening plan were deemed essential. This report documents the findings from the inspection and testingprocessesandoutlinesastrategyforrepairingandrehabilitatingthefire-damagedsectionoftheplant.

The report outlines the methodology adopted during the visual and structural inspection, summarizes key findings, and proposes actionable strengthening techniques such as concrete jacketing, and epoxy grouting. These techniques aim to restore structural functionality, ensure safety, and support the building’s potential reuse or continued operation. The recommendations are based on standard engineering practices, guidelines for fire-damaged structures, and expert judgment,withemphasisonsafety,durability,andcost-effectiveness

The assessment procedure followed a multi-stage methodology comprising visual inspection, preliminary damage mapping, and recommendations for non-destructive testing (NDT) such as Rebound Hammer Test, Ultrasonic Pulse Velocity(UPV),andcoresamplingwherenecessary.Theevaluationwasconductedinaccordancewithrelevantstandards andguidelines,including:

IS 456:2000 –CodeofPracticeforPlainandReinforcedConcrete

IS 15988:2013 –GuidelinesforSeismicEvaluationandStrengtheningofExistingBuildings

IS 13311 (Part 1 & 2) –MethodsofNDTofConcrete(ReboundHammer&UPV)

ACI 562-21 –CodeRequirementsforAssessment,Repair,andRehabilitationofExistingConcreteStructures

Eurocode 1 & 2 –ActionsonStructures&DesignofConcreteStructures

Followingtheassessment,appropriatestrengtheningtechniqueshavebeenproposedforvariouslevelsofdamage,ranging from surface repairs to structural retrofitting. Recommended interventions include epoxy injection for crack sealing, polymer-modified mortar patching, concrete jacketing of columns and beams, and Fiber Reinforced Polymer (FRP) wrappingforcriticalload-bearingmembers.Theapproachemphasizesrestoringthefunctionalintegrityandsafetyofthe structurewhileensuringcompliancewithregulatorystandards.

Thisreportservesasatechnicalfoundationforrehabilitationplanning,riskmitigation,andre-certificationofthebuilding forfutureoccupancyoroperation.

Non-destructive testing (NDT) was carried out on the fire-affected structural components of the first floor to assess the residual strength and internal integrity of the concrete without causing any damage to the structure. These tests complemented the visual inspection findings and provided quantitative data for evaluating the actual condition of the concrete.

Structuralmembersshowingmoderatetoseverevisualdamagewereshortlistedfortesting.Theseincluded:

o Beamsandslabswithvisiblespallingorcracking

o Columnsnearfiresourcepointsorwithdiscoloredpatches

Theselectionaimedtorepresentallstructuralelementsandlevelsofobserveddamage.

Thetestareasoneachmemberwere cleaned ofdust,soot,looseparticles,andpainttoensurereliableresults.

Inthecaseof rebound hammer testing,smooth,dry,andhardconcretesurfaceswereensured.

For UPV testing,boththetransmittingandreceivingprobesurfaceswerewettedtoimproveacousticcoupling.

Step 3: Rebound Hammer Test (IS 13311 Part 2)

Purpose:

Todeterminethesurfacehardnessandestimatecompressivestrengthofconcrete.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN:2395-0072

Procedure:

A digital Schmidt hammer wasusedtotake10–12readingsatvariouspointsoneachselectedelement.

Thehammerwasheldperpendiculartothesurface(horizontal,vertical,oroverheadasperthememberorientation).

Reboundvalueswererecordedandaveraged,excludingoutliersorinconsistentreadings.

Interpretation:

Thereboundnumberswerecorrelatedwithstandardcalibrationchartstoestimatein-situconcretecompressive strength.

ResultswereclassifiedasperISguidelinesinto:

o 30–Goodconcrete

o 20–30–Fairquality

o <20–Poorquality(possibledeterioration)

Step 4: Ultrasonic Pulse Velocity (UPV) Test (IS 13311 Part 1)

Purpose:

Toevaluatetheinternalqualityandhomogeneityofconcreteanddetectcracksorvoids.

Procedure:

A UPV meter wasusedwithpiezoelectrictransducersplacedacrosstheconcreteelementineither:

o Direct transmission (oppositefaces)

o Semi-direct (adjacentfaces)

o Indirect (sameface,whereaccesswaslimited)

Acousticgelwasappliedtoensuresignaltransmission.

Pulsetraveltimewasrecorded,andthevelocity(m/s)wascalculated.

Interpretation:

Velocityreadingswerecomparedwithstandardranges:

o 4500m/s–Excellentconcrete

o 3500–4500m/s–Good

o 3000–3500m/s–Doubtful

o <3000m/s–Poor/damaged

Lowvelocitiesindicated internal cracking, voids, or material degradation duetoheatexposure.

Step 5: Correlation and Mapping

Resultsfrombothtestswerecorrelatedforeachstructuralelement.

A color-coded condition map wascreated:

o Green:Safe

o Yellow:Requiresmonitoring/repair

o Red:Needsstrengtheningorreplacement

Thesezoneswerelinkedwithvisualinspectionfindingstovalidateobserveddamageordetecthiddenflaws.

2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN:2395-0072

WhereNDTresultsshowedseveredeteriorationorunclearoutcomes:

Core sampling and lab testing wererecommendedtodetermineactualcompressivestrength.

Carbonation depth or chloride penetration tests weresuggestedifchemicaldegradationwassuspected.

Equipment Used:

ReboundHammer(DigitalType,ISCertified)

UltrasonicPulseVelocityTester

Acousticgel

Cleaningbrushesandwater

Crackmeasurementgauge

Laddersandscaffoldsforelevatedaccess

Outcome:

TheNDTtestingprovidedascientificbasisforquantifyingthe loss in concrete strength anddetecting hidden structural defects,helpingprioritizestructuralmembersforstrengthening,repair,orreconstruction.

Toverifyin-situconcretestrengthandfireimpactdepth,coretestswereperformedonselectedstructuralelements.

Core Extraction:

o Cores of75 mm diameterandminimum100mm lengthweredrilledfrom beams, slabs,andcolumnsin bothaffectedandunaffectedzonesforcomparativeanalysis.

o Extractionlocationswerechosenbasedonvisiblesurfacedamageandaccessibility.

o Drilling was performed using a water-cooled diamond-tipped core cutter to avoid inducing additional thermalormechanicalstress.

Lab Testing:

o Extractedcoreswerelabeledandsenttoanaccreditedlab.

o Compressive strength tests were conducted per IS 516 / ASTM C42 to evaluate residual concrete strength.

o Additionalvisualinspectionofcoresurfacewasnoted:

Colorgradient

Presenceofcracks,delamination,orcarbonation

Interpretation:

o Strengthvaluesfromcoresampleswerecomparedagainstdesigngradeandmatchedwithzonesofvisibledamage.

o Reduction of more than 25–30% from design strength prompted further non-destructive or structural modelingchecks.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN:2395-0072

Results

1. Rebound Hammer Test

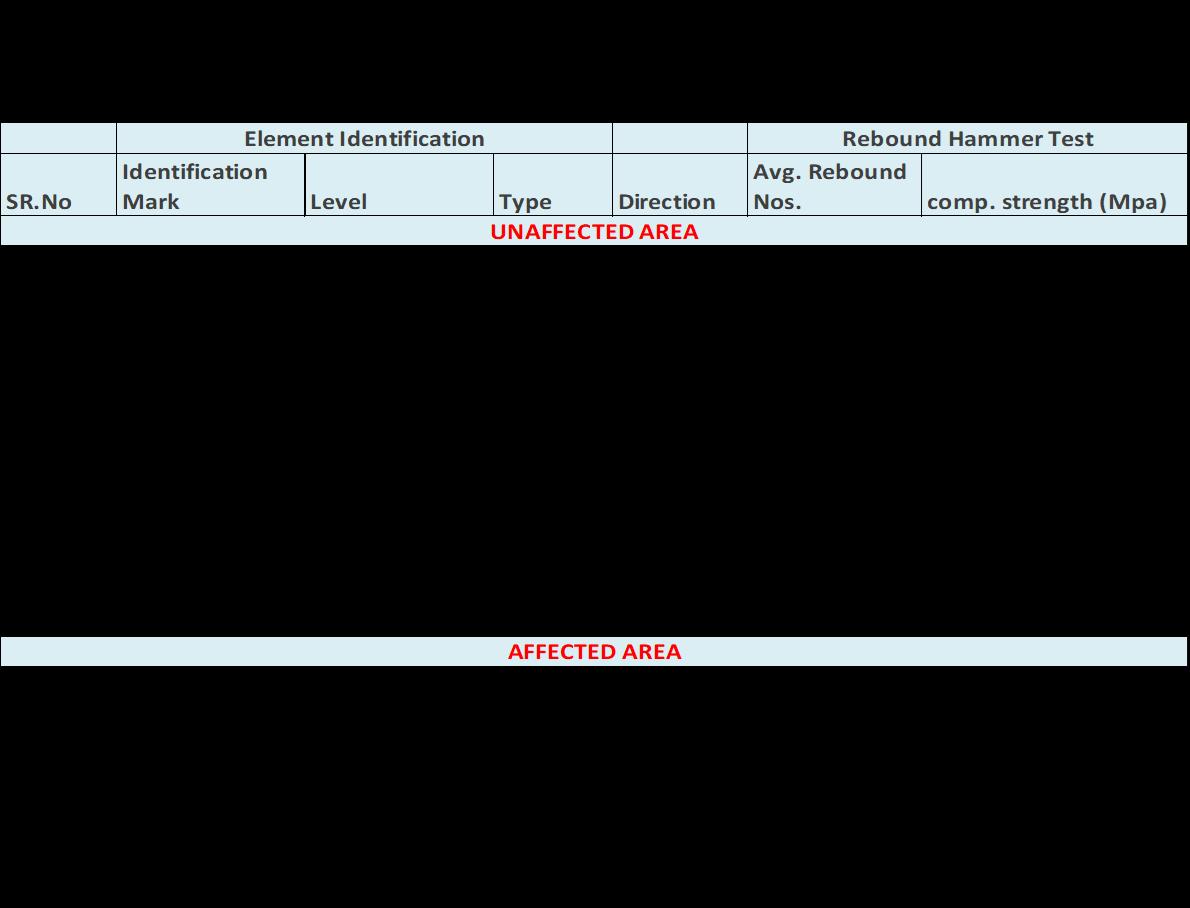

Table1:ReboundHammerResults

Rebound Hammer Test Summary

Unaffected Area (Control Zone)

Number of Samples:5structuralelementstested

Compressive Strength Range: 25.8 MPa to 32.4 MPa

Average Compressive Strength: 29.3 MPa

Indicatesconcreteisin good condition withnovisiblefire-relateddegradation.

Affected Area (Fire-Exposed Zone)

Number of Samples:8structuralelementstested

Compressive Strength Range: 16.2 MPa to 26.4 MPa

Average Compressive Strength: 21.4 MPa

Notable drop in compressive strength compared to unaffected area, indicating moderate to severe material degradation incertainelementsduetofireexposure.

Key Observations

Columns and beams in affected areas (like C5, B2, B3) show reduced rebound numbers and compressive strength

Element C5 hadthe lowest strength at 16.2 MPa,indicatingitmightneed detailed assessment or core testing forconfirmation.

Strengthdropsuggests localized thermal damage,possiblycompromisingserviceabilityandrequiring retrofitting or load reassessment

2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN:2395-0072

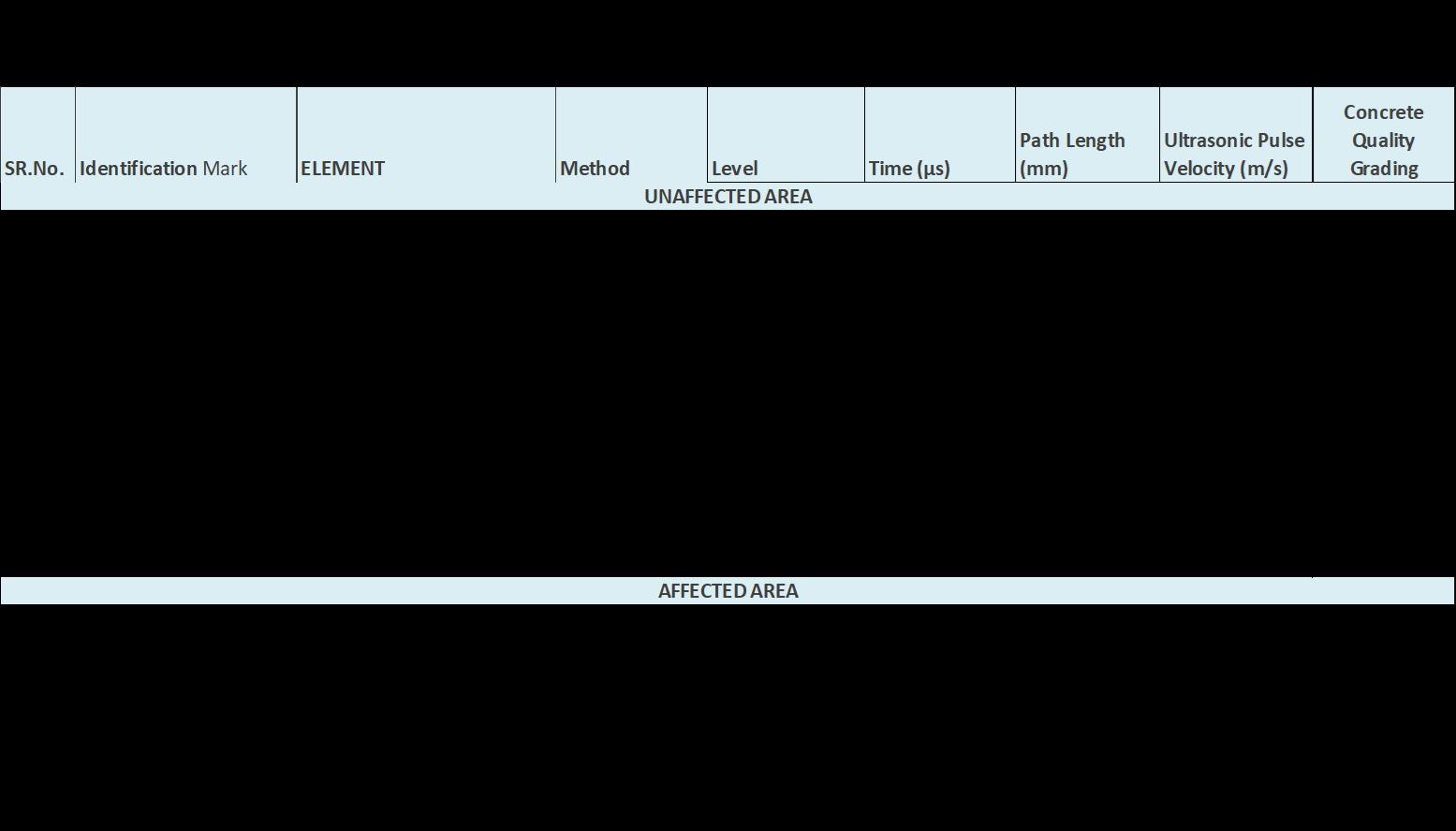

Table2:UPVResults

UltrasonicPulseVelocity(UPV)testswereconductedtoevaluatetheinternalqualityandintegrityofconcretein both unaffected and fire-affected zones. In the unaffected area, five structural elements were assessed. The measuredpulsevelocitiesrangedfrom 4.11 m/s to 4.54 m/s,allfallingwithinthe “Excellent” concrete quality grading,indicatingdense,homogeneousconcretewithnointernalflawsormicrocracking.

In the affected area, a total of seven elements were tested. The pulse velocities ranged from 3.03 m/s to 3.91 m/s,correspondingtoconcretequalitygradingsbetween “Good” and “Questionable”.Notably,elementssuchas C5 and B3 exhibitedlowervelocities(3.03m/sand3.21m/s,respectively),suggestingpotentialinternaldamage, cracking, or loss of concrete integrity due to high thermal exposure during the fire. These findings support the conclusion that thermal degradation has adversely impacted the homogeneity and soundness of the concrete in severalstructuralmemberswithinthefire-affectedzone.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net

3. Core Test

Table3:CoreTestResults

UNAFFECTEDAREA AFFECTEDAREA

The core test results reveal a distinct difference in the compressive strength between structural elements locatedinunaffectedandfire-affectedareas.Intheunaffectedarea,thecorrectedcorestrengthsrangefrom28.27 MPato30.45MPa, withcorresponding equivalentcube strengths between 31.11MPaand33.51MPa, indicating good concrete quality with minimal degradation. In contrast, the affected area shows a noticeable decline in strength, with corrected core strengths ranging from 21.36 MPa to 26.42 MPa and equivalent cube strengths between23.58MPaand29.17MPa.Thisreductionsuggestsmoderatetosignificantmaterial degradationdueto high-temperature exposure, impacting the residual strength and integrity of the structural components in the affectedzones.

4. Combined Summary

Thecomprehensiveassessmentofstructuralelements,including Rebound Hammer Tests, Ultrasonic Pulse Velocity (UPV) Tests,and Core Sampling,hasidentifiedspecificcomponentswithinthefire-affectedzonesexhibitingdiminished strength and integrity. Notably, elements such as Column C5 and Beam B3 have demonstrated significant reductions in compressivestrengthandinternalcohesion,indicativeofmaterialdegradationduetoelevatedtemperatureexposure

ItissummarizedfromvisualinspectionandNDTtestingthatreinforcedconcreteelementsinsidethebuildingwerejust affectedexternallybythefire.Comparisonofcolorandtextureshowsthattheelementswereexperiencinglessthan300degreeCelsiustemperature.

RC members were affected externally only. There is no appearance of severe damage for RC members except spalling of plaster and cover concrete at certain parts of beam and slab. No cracks found on concrete surface. The concrete to steel bondwasdeterminedtobegood.StrengthofconcretehasbeenestimatedbyNDT.Fromtheresultsofthetestitindicates thatthestrengthofconcreteisstillunaffectedbythefire

5. Result & Discussion

Visual Inspection

Azone-wisevisualinspectionwasconductedacrossthebuilding.Keysymptomsrecordedincluded:

Spallingofplasterandconcrete

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN:2395-0072

Discolorationandcracking

Exposureofreinforcementbars

Saggingordeflectioninslabsandbeams

2.2 Non-Destructive Testing (NDT)

Rebound Hammer Test (IS 13311 Part 2):

AffectedZone:21.4MPaaverage

UnaffectedZone:29.3MPaaverage

Ultrasonic Pulse Velocity (IS 13311 Part 1):

AffectedZone:3.03to3.91km/s

UnaffectedZone:4.11to4.54km/s

2.3 Core Testing

Compressivestrengthvalues:

AffectedZone:21.36–26.42MPa

ControlZone:28.27–30.45MPa

Theseresultsconfirmedsurfacedegradationwhileinternalstructuralintegrityremainedmostlyintact.

6. Proposed Strengthening Measures

6.1 Concrete Jacketing

Appliedtobeamsandcolumnswithstrengthloss;enhancesaxialandflexuralcapacity.

6.2 Epoxy Injection

SealsmicrocracksandrestoresbondingincrackedRCelements.

6.3 FRP Wrapping

Forbeams/slabsatgridB26-C28andE28-E29;increasesductilityandtensilestrength.

6.4 Micro-concrete Repair

Forslabsandlintelswherecoverconcretewaslost.Includesrustremovalandreapplicationofbondingagents.

7. Standards Compliance

Allassessmentsandproposalsareinlinewith:

IS456:2000–DesignofConcreteStructures

IS15988:2013–SeismicEvaluationandStrengthening

IS13311–NDTofConcrete

ACI562-21–EvaluationandRepairofExistingConcrete

Eurocode2–DesignofConcreteStructures

8. Conclusion

The comprehensive post-fire assessment confirmed that the fire did not critically impair the structural integrity of the building. Minor and moderate damage was observed, mostly in surface layers. Targeted strengthening and retrofitting strategies are recommended, especially due to the building's age (>50 years) and location in Seismic Zone IV. A reduced liveloadof500kg/m²isadviseduntilfurtherloadtestingvalidatescapacityrestoration.

© 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page1819

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN:2395-0072

The authors express their gratitude to Prof. Pravin Bhasme for guidance, and to JSPM University for infrastructure and support.SpecialthankstoDr.SachinPorefortechnicalmentoringthroughouttheproject.

References

1. JosephA.V.,“AdvancedStructuralAuditScheme CaseStudy,” IJETT,vol.38,no.2,pp.108–115,2016.

2. DaungwilailukT.etal.,“EvaluatingFireDamageinRCStructures,” Engineering Journal,vol.21,no.7,pp.233–249, 2017.

3. QinD.etal.,“FireDamageinRCStructures Review,” Case Studies in Construction Materials,vol.16,2022.

4. KodurV.,“ConcretePropertiesatElevatedTemperatures,” ISRN Civil Engineering,vol.2014.

5. WaniS.B.,“FireImpactonConcrete,” IJTSRD,vol.4,no.5,2020.

6. AseemA.etal.,“StructuralAssessmentUsingNDT,” Case Studies in Construction Materials,vol.11,2019.

7. IS456:2000–PlainandReinforcedConcrete–CodeofPractice

8. IS13311–NDTofConcrete

9. IS15988:2013–EvaluationandStrengtheningofExistingBuildings

10. ACI562-21–CodeRequirementsforAssessmentandRepairofExistingConcreteStructures

© 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page1820