International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Veena Anilkumar Lalvani1 , Jatin R Makwana2

1U.G. Student, 2Professor, Department of Production Engineering, BVM Engineering College, Vallabh Vidyanagar, Anand, Gujarat, India

Abstract - This study explores the development of a semiautomated robotic arm designed to address inefficiencies observed in frozen food industries where manual pick-andplace tasks dominate operations. These repetitive tasks contribute to early fatigue and inconsistency in worker performance, particularly duringthe initialhours ofshifts. To tackle this issue, a simulation-centric robotic model was createdusingMATLABandSimulink, leveragingtheSimscape Multibody Toolbox to replicate the mechanical behavior of a manipulator. The simulated environment facilitated precise analysis of motion dynamics, actuator control, and trajectory optimization. Complementing the simulation, a physical prototype constructedas a non-integratedblack-box model using Arduino Nano validates the basic control mechanism through joystick inputs and servo motion. While not a fully realized Digital Twin, the system enables experimentation with its core principles, establishing the groundwork for realtime predictive modeling and performance tuning. The projectedoutcome would indicateimprovedhandlingstability and productivity, demonstrating the potential of simulationaugmentedautomationinenhancingcoldstorageoperational efficiency.

Key Words: Manipulator, simulation, Arduino nano, kinematics,coldchainautomation,prototyping,productivity, trajectorycontrol.

In frozen food processing units, maintaining consistent performanceinsub-zeroenvironmentsposeschallengesdue to worker fatigue and reduced dexterity during repetitive tasks.Theseinefficiencieslowerthroughputandincreasethe riskofhumanerror,highlightingtheneedforautomation. Thisstudy addressesthese issuesby developinga robotic armforautomatedpick-and-placeoperations.AMATLABSimulink simulation models kinematics and control logic, whileamicrocontroller-basedblack-boxprototypevalidates physical feasibility. The combined virtual and physical approaches support scalable automation in cold storage settings.

Recentadvancementsinindustrialautomationhighlightthe growingrelevanceofroboticarmsinenhancingoperational efficiency,precision,andsafety.Variousstudiesemphasize

theroleofsimulationandprototypinginoptimizingrobotic systemsforspecializedtasks.

Onebodyofresearchfocusesonsimulation-basedmodelling usingtoolssuchasMATLABandSimulink.A3-DOFrobotic manipulatorwasmodelledusingcomputedtorquecontrol (CTC)toensureaccuratetrajectorytracking,showcasingthe significanceofdynamic modelling incontrol optimization. AnotherstudyemployedtheDenavit-Hartenbergconvention forkinematicanalysis,integratingMATLABsimulationswith Arduino-drivenactuatorsforeffectivejointcoordinationand motion control. The use of inverse kinematics further validatedmotionaccuracyandsystemreliability.

Prototypingeffortshavedemonstratedpracticalfeasibility throughmicrocontroller-basedsystems.Lightweight pickand-place robotic arms utilizing servo motors, Arduino platforms, and joystick inputs were shown to deliver accurate object manipulation. Some implementations incorporated pneumatic circuits and revolute joints to handle larger payloads or reduce operational cycle time, with applications in palletizing, sorting, and automotive assembly.

In domain-specific contexts such as the food industry, robotic automation has contributed to productivity gains, improvedhygiene,andreducedmanualeffort.Technologies like SCARA robots and vision-assisted mechanisms have beendeployedinpackagingandprocessing,althoughhigh initialcostsremainachallenge.

Colour-sorting robotic systems have also been explored, where robotic arms use sensor input to classify and sort objects,indicatingstrongpotentialinlaboratoryautomation andqualitycontrolscenarios.

Collectively, these studies underscore the importance of combining simulation environments with physical prototypingtocreateefficient,adaptable,andapplicationspecificroboticsystems.

Manualpick-and-placeoperationsincoldstoragefacilities are inefficient, error-prone, and time-consuming. These operationsarehinderedbylaborcosts,lowthroughput,and the challenges of working in sub-zero temperatures. This research addresses the need for an affordable, efficient

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

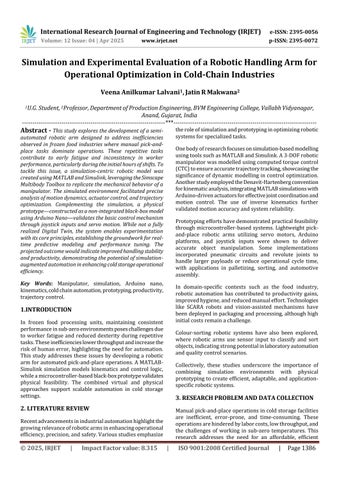

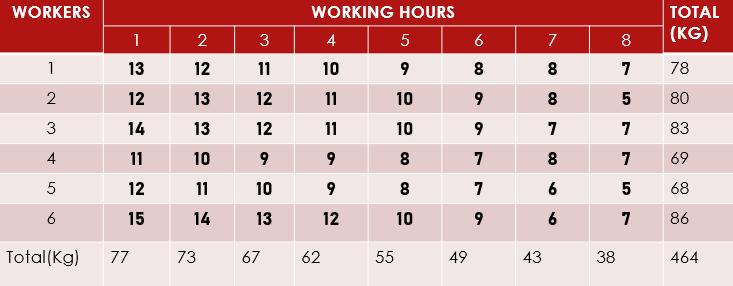

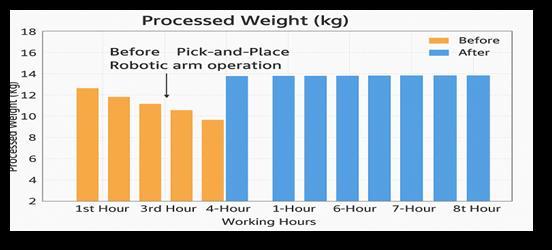

automation solution to improve operational efficiency in suchenvironments.Datawascollectedforthemanualpickand-place processes to quantify improvements. The table belowsummarizeskeyoperationalandworkforcemetrics observed:

Workstation Details:

6workerseachstation|8-hourshift

Expected Productivity: 10–13 kg/worker/hrs

Expected Daily Output: 650–750 kg

Analyzeddata:

It was observed from the data collected that workers perform best in the initial hours of their shifts, with productivity dropping over time due to fatigue. Some individuals showed sharper declines, suggesting possible ergonomic issues or skill gaps which can lead to face bottlenecksituationsanddelayinsupplyinggoods.

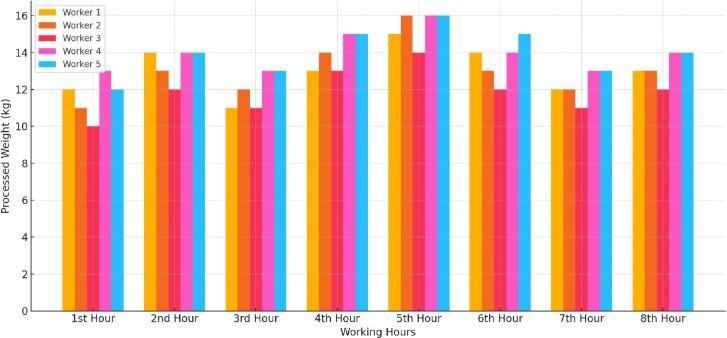

4. METHODOLOGY

5.

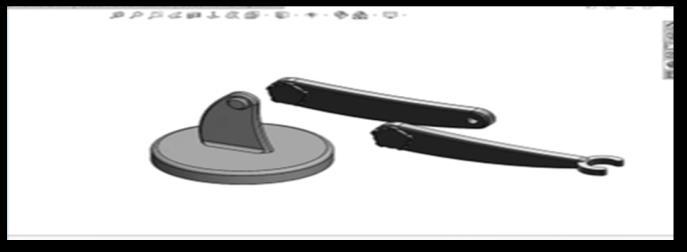

TheCADmodelwasbuiltusingonshapeapplicationbefore importingitontheMATLABforsimulation wherevarious suitabletoolboxeswereusedtomakeitworkobservethe virtualmovementsbeforebuildingitinrealtime.

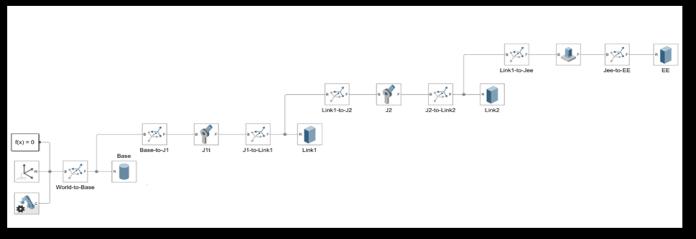

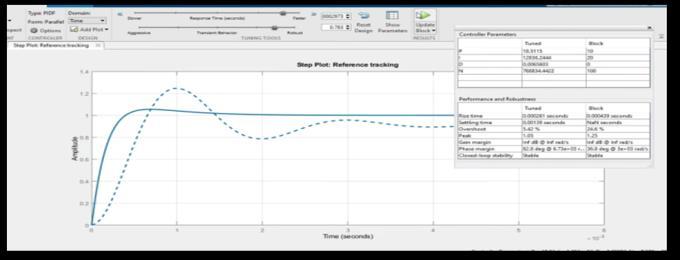

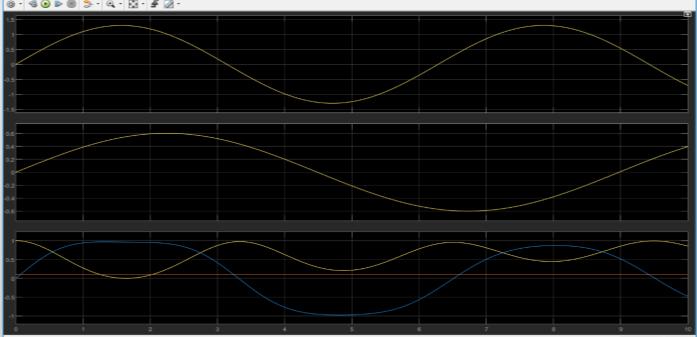

AarmwasmodeledusingCADandsimulatedinMATLABSimulink with Simscape Multibody to analyze motion dynamics and control accuracy. Key parameters such as torque, speed, and joint angles were evaluated using PID control. Though not a full Digital Twin, the approach supportscoresimulation-to-prototypeverification.

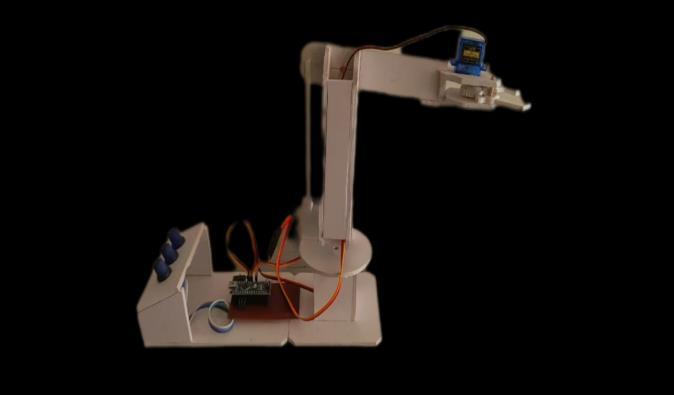

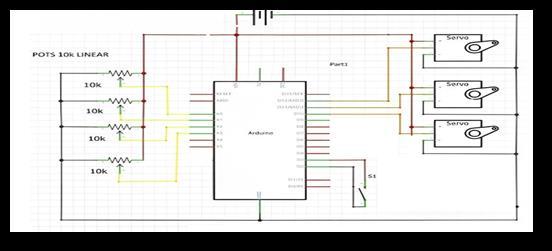

Theprototypeshowcasesafunctionalsimplifiedroboticarm controlledviaArduinonanoandservomotors.Designedasa black-box model, demonstrates the core pick and place through joysticks type components, offering a tangible

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

previewofthesimulatedsystemandvalidatingreal-world feasibility.

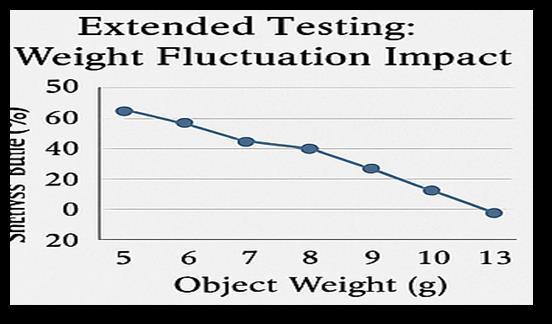

Preliminarytestingrevealsthattheroboticarmhaslimited payload capacity and exhibits reduced consistency in performance. This is primarily due to the use of PVC material,which,despitebeinglightweightandeconomical, lacksthestructuralstrengthrequiredforstableandprecise operations.

This project presents a simulation-driven robotic arm alongside a functional black-box prototype, developed to address labor-related challenges in frozen storage environments.Althoughinitialtestingindicateslimitations in payload handling, the system effectively demonstrates conceptual feasibility. The overall framework provides a solid foundation for future enhancements, including the integrationofsensorsandincreasedloadcapacity,paving the way for scalable automation solutions in cold-chain industries

[1] Rajesh P., Naveen Kumar N., Ganesh K., "Design and Analysis of Robotic Arm for Efficient Pick and Place Operations", International Journal of Creative Research Thoughts (IJCRT), Vol. 12, Issue 5, May 2024, ISSN: 23202882.

[2]Md.Saad,SajjadHussain,"SimulationandOptimizationof Computed Torque Control 3-DOF RRR Manipulator using MATLAB", Unpublished Manuscript/Technical Paper

[3]SamarthNimgaonkar,PranaliChaudhari,KomalGhadge, Surekha Kamble, Jayashri Chopade, "Design and Developmentofa3-AxisPickandPlaceRobotforIndustrial Use", International Research Journal of Engineering and

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Technology (IRJET), Vol. 10, Issue 1, Jan. 2023, ISO 9001:2008CertifiedJournal.

[4] Madiha Farman, Muneera Al-Shaibah, Zoha Aoraiath, FirasJarrar,"DesignofaThreeDegreesofFreedomRobotic Arm", International Journal of Computer Applications, Vol. 179,No.37,April2018,ISSN:0975–8887.

[5]S.Premkumar,K.SuryaVarman,R.Balamurugan,"Design and Implementation of Multi Handling Pick and Place Robotic Arm", International Journal of Engineering Trends and Technology (IJETT),Vol.33,No.3,March2016.

[6] Hasan Dawood Salman, Mohsin Noori Hamzah, Sadeq HusseinBakhy,"KinematicsAnalysisandImplementationof ThreeDegreesofFreedomRoboticArmbyUsingMATLAB", The Iraqi Journal for Mechanical and Material Engineering, Vol.2,No.2,June2021.

[7] Vo Duy Cong, Dang Anh Duy, Le Hoai Phuong, "Design and Fabrication of 3-DOF Robot Arm Using Parallelogram Mechanisms", International Journal of Emerging Trends in Engineering Research,September2021.

[8] Yudi Fernando, Anas Mathath, Mohsen Ali Murshid, "ImprovingProductivity:AReviewofRoboticApplications in Food Industry", International Journal of Robotics Applications and Technologies,Vol.4,Issue1,January–June 2016

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072 © 2025, IRJET | Impact Factor value: 8.315 |