International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Gaurav Sahu¹, Yash Yadav², Subham Kumar³, Harsh Dewangan⁴, Jay Kishan Chouhan5 Vishnu Kant Soni6

12345B.Tech Student , Department of Computer Science and Engineering , LCIT Bilaspur , CG , India

5Head of Department, Department of Computer Science and Engineering , LCIT Bilaspur , CG , India

Abstract - Railwaytransportationcontinuestoserveasa critical backbone oflogistics andpublic mobilityworldwide. However, undetected faults in railway tracks especially cracks and fractures pose a major risk to operational safety. Traditional manual inspection techniques are not only labor-intensive but also prone to oversight, necessitating the adoption of smarter, automated systems. Thispaperpresentsacomprehensivestudyofcontemporary approaches for railway track defect detection, integrating cutting-edge technologies such as sensor arrays, artificial intelligence, Internet of Things (IoT), and Ground Penetrating Radar (GPR). A detailed review of AI-based solutions like YOLOv5 for image-based crack detection, acoustic sensors for real-time fracture monitoring, and FPGA-powerededgeAIplatformsisprovided.Thepaperalso discusses how the fusion of geospatial mapping and GPR enhances the accuracy of subsurface defect identification. The synergy of these technologies marks a transformative step toward predictive maintenance and accident prevention,therebyensuringsaferrailwayoperations.)

Key Words: Railway track monitoring, AI, YOLOv5, IoT, GPR, defect detection, accident prevention.

Railways are one of the most economical and widely adoptedmeansoftransportation,particularlyincountries with vast geographies like India. They play a vital role in passenger travel and freight movement. However, the safetyofrailoperationsheavilydependsonthestructural integrity of railway tracks. Any undetected fault be it a surface crack, misalignment, or subsurface issue can escalate into catastrophic accidents, leading to loss of life andsubstantialfinancialdamage.

Conventional track inspection is generally conducted through manual patrols or scheduled mechanical inspections using track recording cars. While effective to some extent, these methods are susceptible to human error, delays in defect detection, and limited frequency of checks. With the evolution of automation, artificial intelligence (AI), and real-time data communication technologies, railway systems are now transitioning toward proactive and predictive maintenance frameworks.

This paper reviews and integrates modern techniques for railway track defect detection, including vision-based AI models, sensor systems, and geospatial monitoring tools. Emphasis is placed on technologies such as YOLOv5, IoT networks, acoustic sensors, Ground Penetrating Radar (GPR),andFPGA-basededgesystems.Thegoalistooffera consolidated view of how multi-modal technology can drastically enhance the effectiveness of railway safety systems.

Recent literature presents a wide array of technological interventions aimed at improving track monitoring. The followingstudiesandinnovationsreflectsomeofthemost prominentapproaches:

A. YOLOv5 and Geospatial Localization for Crack Detection (April 2024)

A study published in April 2024 explores the combination ofdeeplearningalgorithmswithspatialdataforenhanced railway inspection. The system employs YOLOv5 a stateof-the-art object detection framework for identifying cracksanddefectsinreal-timeusingvideoandimagedata. What sets this method apart is its integration with GPS coordinates, allowing defects to be accurately geotagged and mapped. This significantly improves maintenance planningandreducesthetimetolocateandrepairfaults.

B. Acoustic Emission Sensors for Crack Detection (2017)

Earlier research from 2017 focused on the application of acoustic emission (AE) technology for railway crack detection. AE sensors are capable of detecting the highfrequency waves produced by growing cracks or sudden breaks. This technique allows for continuous, real-time monitoring of rail conditions and can identify issues even inlow-visibilityorhard-to-reachenvironments.

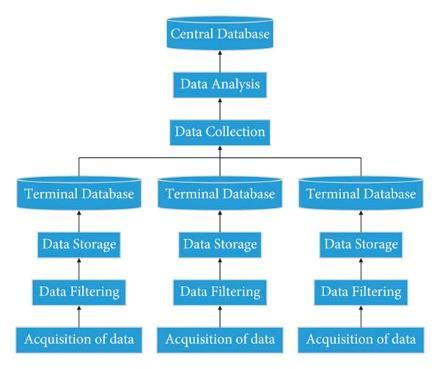

C. IoT-Based Advanced Track Monitoring (May 2023)

The adoption of Internet of Things (IoT) technology for railway monitoring was detailed in a 2023 study. The proposed system involved deploying smart sensorsacross railway infrastructure that communicated wirelessly with centraldatabasesviaGSMorWi-Fimodules.Thesesensors continuously monitor parameters such as vibration,

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

pressure, and temperature, enabling predictive maintenance by alerting operators to abnormal activityor anomaliesbeforetheyleadtofailure.

In August 2024, a new system combining Field ProgrammableGateArrays(FPGA)andAIwasintroduced. Unlike traditional systems that rely on cloud processing, this approach utilizes edge computing, wherein data is processed locally at the sensor node. High-resolution cameras feed data into Convolutional Neural Networks (CNNs) implemented on FPGAs, ensuring real-time defect detection with minimal latency. This edge-based method increases reliability and reduces dependence on constant internetaccess.

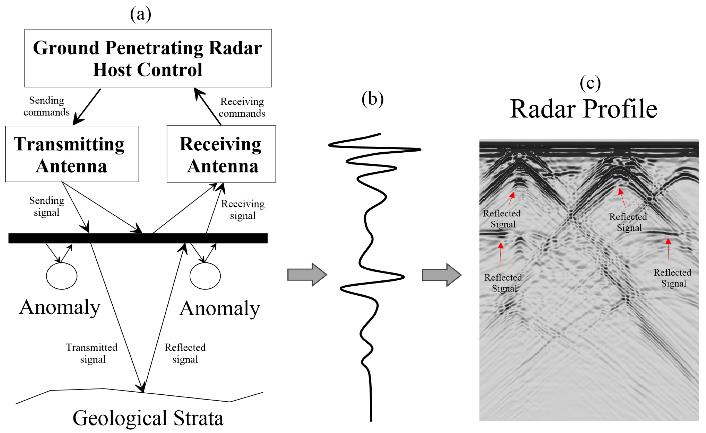

A more recent review, published in January 2025, discussed the application of Ground Penetrating Radar (GPR) for subsurface inspection of railway tracks. GPR emits electromagnetic waves into the ground and measures the reflections to identify hidden anomalies like ballast degradation, voids, or water accumulation beneath the tracks. It provides a non-invasive, fast, and accurate waytoassessstructuralintegritybelowthevisiblesurface.

Railwaytrackfailurescontinuetobeamajorcauseoftrain derailments and accidents worldwide. Traditional inspection methods, which rely heavily on human patrols and scheduled inspections, are insufficient for identifying track faults in real-time. The primary challenges include late detection of cracks, lack of subsurface visibility, high labor costs, and the inability to conduct continuous monitoring. These limitations lead to delayed maintenance, increased risk of accidents, and inefficient resource utilization. There is a critical need for an intelligent system that can autonomously monitor track conditions, detect surface and subsurface faults in real time,andreducehumanintervention.

The main objective of this study is to design and analyze an intelligent, automated system for the detection and prevention of railway track defects that can potentially leadtotrainaccidents.Specificobjectivesinclude:

• To explore the integration of Artificial Intelligence (AI) with image processing techniques such as YOLOv5 for accuratesurfacecrackdetection.

•Todevelopareal-time monitoring framework using IoT modulesforcontinuoustrackconditionanalysis.

• To utilize Ground Penetrating Radar (GPR) for subsurface anomaly detection, including ballast voids and drainageissues.

• To evaluate the performance and accuracy of FPGAbasededgecomputingforrapiddefectprocessing.

•Toprovideacost-effective,scalable,andreliablerailway safetysystemthatcanbedeployedacrossbothurbanand ruralareas.

The proposed system for railway track defect detection leverages a multi-technology stack designed to identify both surface and subsurface anomalies. The architecture consistsofthefollowingkeycomponents:

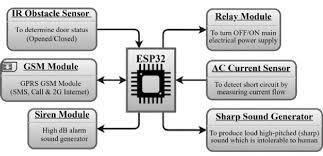

Various types of physical sensors are deployed along the trackandoninspectionvehicles:

Infrared Sensors: Used to detect surface irregularitiesbymeasuringthermaldifferences.

Acoustic Sensors:Capturesoundwaveemissions fromdevelopingcracks.

Vibration Detectors:Monitoroscillationpatterns causedbytrackdegradationormisalignment.

Thesesensorsformthefrontlineofanomalydetectionand areintegratedintoacentralizeddataloggingsystem.

[Fig.1:BlockDiagramofSensor-basedMonitoringSystem]

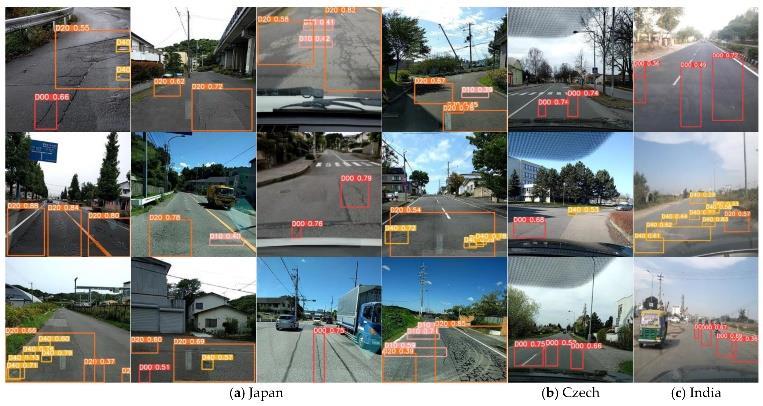

Machinevisionisappliedusingdeeplearningframeworks:

YOLOv5: Employed for rapid object detection in imagesandvideos.Camerasmountedondronesor railcars capture real-time data which is analyzed to detect visible cracks, misalignments, or foreign objects.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

CNNs on FPGA: High-speed Convolutional Neural Networks process input frames at the edge, enablingrapiddecisionswithminimallatency.

These models are continuously trained with annotated defectdatasetstoimprovetheirdetectionaccuracy.

[Fig.2:SampleOutputfromYOLOv5-CrackDetection Visualization]

C. IoT-Based Real-Time Monitoring

Microcontroller units(e.g.,ESP32, Raspberry Pi) equipped with GSM or Wi-Fi modules collect sensor data and transmit it to cloud databases or control centers. Key featuresinclude:

Instantalertsondefectdetection.

Historicaldataloggingfortrendanalysis.

Remoteconfigurationanddiagnostics.

[Fig.3:IoTDataTransmissionFlowchart]

D. Ground Penetrating Radar (GPR) Scanning)

Toevaluatehiddenorsubsurfacedefects:

GPRemitsradarpulsesintothetrackbed.

Reflected signals are interpreted to detect ballast pockets,water-logging,andotherinconsistencies.

Data is plotted as B-scans and processed using AI todistinguishbetweensafeanddefectivezones.

[Fig.4:GPRScanOutput–SubsurfaceLayerIdentification]

6. RESULTS AND DISCUSSION

Thecombinedsystemwasevaluatedusingsimulationsand experimental case studies, and the outcomes demonstrate itseffectivenessacrossvariousmetrics

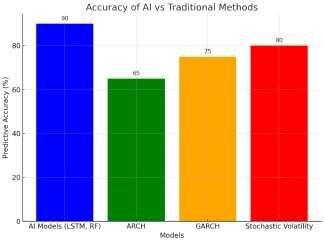

A. Detection Accuracy

AI-based systems such as YOLOv5 and CNNs achieved more than 90%accuracy inidentifying surface cracksand anomalies. Accuracy further improved when models were fine-tunedonregion-specificdatasetsthatincludedvarying weatherandlightingconditions.

B. Real-Time Response

The edge AI setup with FPGA hardware processed frames at 30–60 FPS, enabling on-the-go detection without delay. IoT modules reported anomalies in under 5 seconds, reducingresponsetimeandincreasingsafetymargins.

C.SubsurfaceInsightwithGPR

GPR data revealed defects not visible on the surface, including voids and improper ballast compaction. These subsurface issues were accurately flagged and visualized, enablingpreventivemaintenance.

[Fig.5:ComparativeGraph–Manualvs.AI-basedDetection Accuracy]

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

The integrated system maintained performance across different terrains and environmental conditions, making it a scalable solution for diverse rail networks. Redundancy built into sensor and communication modules ensured reliabilityevenunderpartialsystemfailures.

Railway safety remains an essential concern for governments and transportation agencies across the globe. The transition from traditional manual inspection methodstosmart,automated,anddata-drivenmonitoring systems is not only inevitable but also highly beneficial. This paper presented a detailed overview of advanced railwaytrackdefectdetectiontechniquesthatintegrateAI, IoT,andGroundPenetratingRadar(GPR).

The combination of YOLOv5 object detection, acoustic emission sensors, IoT communication modules, and GPR enables comprehensive monitoring from surface to subsurface. Edge computing with FPGA accelerates realtime image processing, ensuring instant fault detection even in remote locations. Together, these technologies allow for faster response, predictive maintenance, and ultimately a significant reduction in the risk of accidents causedbytrackfailure.

Lookingforward,furtherresearchshouldfocuson:

Improving dataset diversity for better AI generalization.

Enhancing power efficiency of edge devices for longerfielddeployments.

Integrating blockchain for secure data logging in mission-criticalsystems.

Developing unified control dashboards for centralizedmonitoring.

Bycombiningaccuracy,speed,andpredictiveinsights,the proposed system lays the groundwork for a smarter and saferrailwayinfrastructure.

[1] YOLOv5 and Geospatial Localization for Crack Detection,April2024.[Online].Available: https://ijcrt.org/papers/IJCRT24A4373.pdf

[2] Acoustic Emission Sensors for Crack Detection, 2017. [Online].Available:

https://www.researchpublish.com/upload/book/Crack% 20Detection%20System%20for%20Railway%20Tracks4717.pdf

[3] IoT-Based Advanced Track Monitoring, May 2023. [Online].Available: https://www.ijnrd.org/papers/IJNRD2305241.pdf

[4] FPGA-Based Edge AI System for Fault Detection, August2024.[Online].Available: https://arxiv.org/abs/2408.1524

[5] Ground Penetrating Radar (GPR) Technique for Track Monitoring,January2025.[Online].Available: https://arxiv.org/abs/2501.11132

[6] D. Dey, S. Saha, S. Basak, “An IoT-based Real-Time Railway Track Monitoring System Using Ultrasonic and Vibration Sensors,” International Journal of Engineering Research & Technology (IJERT), vol. 8, no. 6, 2019. Available: https://www.ijert.org/an-iot-based-real-timerailway-track-monitoring-system

[7] M. Chougule, D. Patil, “Smart Railway Track Surveillance System using AI and Machine Learning,” International Journal of Scientific Research in Computer Science, Engineering and Information Technology (IJSRCSEIT), vol. 6, issue 3, 2020. Available: https://ijsrcseit.com/paper/CSEIT2063155.pdf

[8] H. Singh, P. Ghosh, “Railway Track Fault Detection using Image Processing and Deep Learning,” IEEE Conference on Signal Processing, Informatics, Communication and Energy Systems (SPICES), 2021. doi:10.1109/SPICES51234.2021.9384294

[9] M. Tao, Y. Zhang, “Application of Ground Penetrating Radar in Railway Track Bed Defect Detection,” International Journal of Railway, vol. 12, no. 1, 2022. Available: https://www.railwayjournal.org/download/applicationof-gpr-trackbed.pdf

[10]K.Alnajjar,F.Mahmoud,“LowPowerEdgeAIDevices for Real-Time Railway Infrastructure Monitoring,” Sensors,vol.22,no.7,2022.doi:10.3390/s22072794