International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Aryan

Lande1, Shreyash More2, Aditya Patil3, Prof. Hrishikesh Shirke4

P. E. S. Modern College of Engineering Pune, Maharashtra 411005, India

Abstract - Managing urban drainage systems is a critical task,oftenhinderedbyproblemssuchasblockages,overflows, andwatercontamination.Thispaperpresentsasolutionusing a Programmable Logic Controller (PLC)-based automatic drainage water monitoring and control system designed to addressthesechallengeswithgreaterefficiencyandreliability. The system integrates a range of sensors including pH sensors to assess chemical quality, turbidity sensors to detect water clarity, and ultrasonic sensors to monitor water levels. These components feed real-time data to the PLC, which processes the information and responds automatically by activating pumps or valves as needed. By continuously monitoringandrespondingtodrainageconditions,thesystem enhances both environmental safety and operational effectiveness. This approach supports smarter urban water management and contributes to the broader goals of sustainability and infrastructure modernization.

Key Words: Industrial Automation System, PLC, Smart drainage system.

Urban drainage systems constitute a vital aspect of contemporary infrastructure, playing a key role in the management of wastewater, the prevention of urban flooding,andtheprotectionofpublichealth.Thesesystems are tasked with efficiently conveying surface runoff and sewage to designated treatment facilities or discharge locations. However, the increasing complexity of urban environments, coupled with the growing prevalence of extreme weather events driven by climate change, has significantly intensified the challenges associated with effectivedrainagemanagement.

Conventionaldrainagesystems,whichpredominantlyrely on manual inspections and reactive maintenance approaches, are becoming increasingly insufficient in addressingtheevolvingdemandsofrapidlyexpandingcities. Manualmonitoringtechniquesareinherentlyconstrainedin termsofcoverage,timeliness,andaccuracy,oftenresulting in delayed identification of critical issues such as pipe blockages,watercontamination,andoverflowevents.These delayscancauseconsiderableenvironmentaldegradation, compromisewaterquality,accelerateinfrastructurewear, and pose serious public health threats due to exposure to untreatedwastewaterorstagnantwater.

In light of these limitations, there has been a growing emphasisonincorporatingautomationandreal-timecontrol

technologiesintourbandrainagesystems.Attheforefrontof thistransformationistheimplementationofProgrammable Logic Controllers (PLCs), which offer a robust, adaptable, andprogrammableplatformfortheautomationofdrainage systemoperations.

This study presents the development of an automated drainage water monitoring and control system based on Programmable Logic Controllers (PLCs), aimed at overcoming the limitations associated with traditional drainage management methods. The proposed system integratesarangeofenvironmentalsensors suchaswater level and gas sensors to enable continuous, real-time monitoring of water quality and flow dynamics. The collecteddataisprocessedbythePLC,whichautonomously executescontrolmeasuresincludingpumpactivation,flow redirection, and the initiation of alarms in response to abnormalorhazardousconditions.

Through automation of both monitoring and response functions, the system significantly improves operational efficiencywhileminimizingrelianceonmanualintervention andreducingthelikelihoodofhumanerror.Thiscontributes to faster, more reliable responses to potential drainage systemfailures.Furthermore,thedesignsupportsbroader globalobjectivesrelatedtotheadvancementofsustainable, resilient,andintelligenturbaninfrastructure.Itsadaptability todiverseenvironmentalconditionsandscalabilityacross different urban contexts highlights its potential as a foundational model for future drainage management technologies.

Theprincipalaimofthisprojectistodevelopandimplement afullyautomatedindustrialdrainagesystemcapableofrealtimemonitoringandresponsivecontrol,therebyeliminating theneedformanualoperation.Toachievethisobjective,all systemcomponentswereselectedwithcarefulconsideration oftheirtechnicalperformanceandadherencetoindustrial automationstandards.

At the core of the system is the Delta PLC model DVP14SS211R a compact, high-performance controller recognized for its fast-processing capabilities and flexible input/output configuration. This PLC functions as the system's central control unit, responsible for executing automation logic, interpreting data from various sensors, andmanagingtheoperationofactuatorsinrealtime.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

To ensure continuous monitoring of environmental and operationalconditions,thesystemincorporateswaterlevel sensorsandagasdetectionsensor.Thewaterlevelsensors provide real-time measurements of fluid levels within drainagechannels,enablingthePLCtoinitiateappropriate responses suchaspumpactivationoralarmsignals when specificthresholdsarereached.Concurrently,thegassensor detects the presence of hazardous gases, which pose significantsafetyrisksinindustrialsettings.

Upon detecting unsafe gas concentrations, the system automatically activates a ventilation exhaust fan, which is directly controlled by the PLC based on sensor input. This mechanismensuresthepromptdispersalofharmfulgases, therebymaintainingasafeoperationalenvironment.

Thesystem’sautomatedresponsefunctionalitysignificantly enhances its safety, efficiency, and reliability, making it particularly suitable for complex industrial drainage environmentswherecontinuoushumanoversightmaynotbe feasible.Withintheproposedsetup,twowaterlevelsensors are strategically deployed to monitor and distinguish betweenlowandhigh-waterlevelsinthedrainagechannel. Thesesensorsfunctionascriticaldiagnostictools,aidingin thedetectionandlocalizationofpotentialblockageswithin differentsegmentsofthepipeline.

When water levels drop below the threshold of the lower sensor,thesysteminterpretsthisconditionasindicativeof an upstream blockage often resulting from sediment buildup or structural obstructions that restrict flow. In response, a red warning indicator is activated, and the motorizedpumpisengagedtoinitiatewatermovementor notifymaintenancepersonneloftheissue.

Conversely, activationoftheupper-levelsensorsuggestsa downstream blockage, typically caused by accumulated debris,silt,ornon-degradablematerialsbeyondthecurrent monitoring point. Such obstructions impede water flow, leadingtoelevatedwaterlevelsthattriggerahigh-levelalert.

Unresolvedblockagesofthisnaturecanseverelycompromise drainageefficiencyandmayresultinoverfloworlocalized flooding. The system’s ability to detect these anomalies in real-timeenablestheissuanceofearlywarnings,facilitating timelyinterventionsandminimizingpotentialdamage.This proactiveapproachisessentialformaintaininguninterrupted drainageoperations.

The dual-sensor configuration not only allows for the detection of blockages but also provides insight into their likelylocationwithinthenetwork.Thisintelligentfeedback mechanismsupportsfasterfaultidentification,reducesthe time and effort needed for diagnostics, and empowers maintenance teams to shift from reactive to preventive maintenancestrategies.

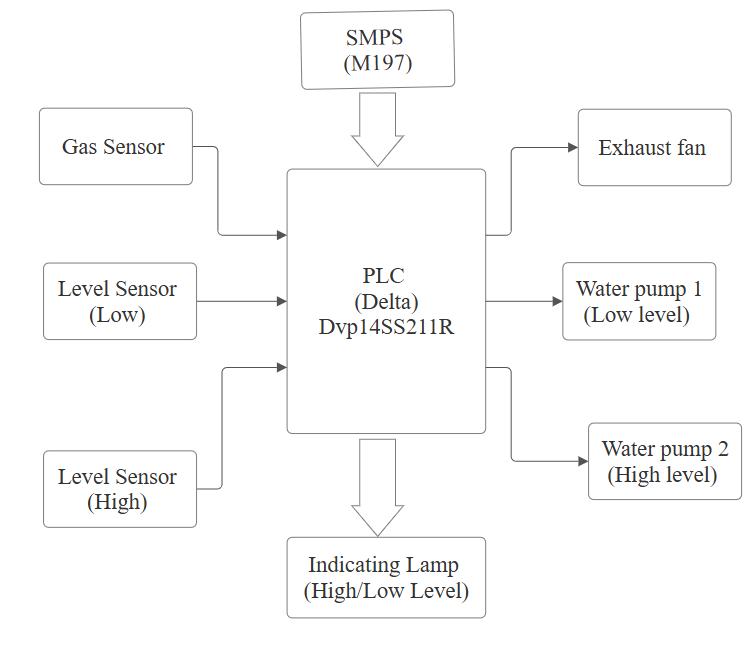

TheblockdiagramoftheproposedsystemispresentedinFig. 1.

Thesystemarchitectureisstructuredaroundacentralized ProgrammableLogicController(PLC),whichservesasthe brain of the monitoring and control operation. The input terminalsofthePLC typicallylocatedontheleftsideofthe module areinterfacedwithessentialsensors,includinga liquid level sensor and a gas sensor. These sensors continuouslymonitorenvironmentalparameterswithinthe drainage system. The PLC is powered through a stable external power supply, ensuring uninterrupted operation. Sensor data is transmitted in real time to the PLC, where predefinedlogicdeterminesappropriatecontrolresponses basedonthecurrentsystemconditions.

OntheoutputsideofthePLC,whichistypicallyconfiguredon the right side of the module, key actuators are connected. These include two water pumps and an exhaust fan, each serving a distinct purpose. One pump is dedicated to discharging excess water from the drainage tank, thereby preventingoverflowandreducingtheriskofwaterblockage inthedrainagesystem.Thesecondpumpmaintainsastable water level within the system by regulating inflow or circulation as needed. Additionally, the exhaust fan also connectedtoboththePLCandapowersupply iscontrolled directlybyreadingsfromthegassensor.Whenhazardousor elevatedgaslevelsaredetected,thePLCactivatestheexhaust fantoensureproperventilationandminimizesafetyrisks. This integrated design enables automated, efficient management of both fluid dynamics and air quality in the drainageenvironment.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Thecorefunctionalityofthesystemliesinthecontrollogic programmedintothePLCusingladderlogicorfunctionblock diagrams. This logic governs the sequence of operations based on sensor inputs, ensuring that responses are both timelyandappropriate.Forinstance,ifthegassensordetects ariseinharmfulgasconcentrationbeyondasetthreshold, theexhaustfanisautomaticallyactivatedtoexpelthegasand maintainsafeairqualitylevels.Similarly,whenwaterlevels fluctuate either dropping below or rising above critical points the corresponding pump is engaged to restore balance.Thisautonomousdecision-makingprocessnotonly reducestheneedformanualinterventionbutalsoenhances the reliability and safety of the entire drainage system. By leveragingreal-timefeedbackandintelligentautomation,the system exemplifies a practical application of smart infrastructuretechnologiesaimedatimprovingurbanutility management.

Inthisproject,arangeofelectromechanicalandelectronic componentsareintegratedtoenableautomatedmonitoring and control of drainage water and toxic gases. The key componentsincludegassensors,liquidlevel(float)sensors, an SMPS (Switched Mode Power Supply), an exhaust fan, water pumps, indicator lamps, relays, and semiconductor devices such as the 7812 voltage regulator, BJT 3904 transistor, and a thyristor. Each component is carefully selectedtofulfillaspecificfunctionwithinthesystem.The gassensorisusedtodetectthepresenceofharmfulgasesin thedrainageenvironment,whilethefloatsensorsmonitor thewaterleveltoidentifyoverfloworlow-waterconditions. TheSMPSsuppliesstableDCpowertothePLCandconnected devices.

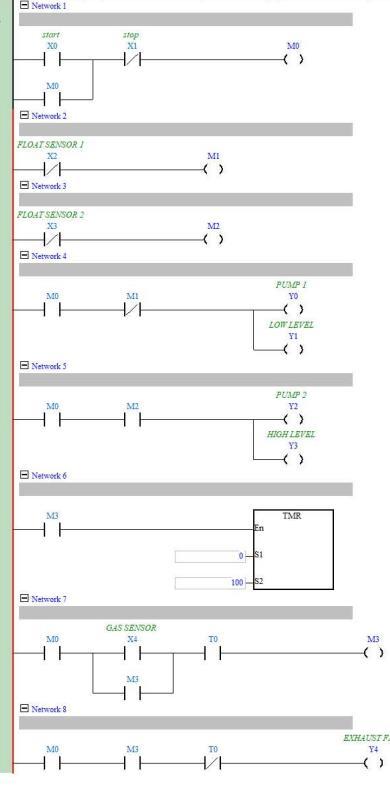

Theheartofthecontrollogicliesintheconfigurationofthe PLC,whichconsistsofbothinputand outputterminalsfor interfacing with external devices. The input pins include: COM(0Vreference), X0 (Start switch),X1(Stop switch),X2 (Float Sensor 1 – Low Level), X3 (Float Sensor 2 – High Level),and X4 (Gas Sensor).Theseinputsservetoinitiate operations,controlsystemstatus,andprovidereal-timedata tothePLCfordecision-making.Theoutputpinsarepowered via COM (24V) and include: Y0 (Water Pump 1 – for releasing excess water), Y1 (Low Water Level Indicator Lamp), Y2 (Water Pump 2 – for maintaining water level), Y3 (High Water Level Indicator Lamp),and Y4 (Exhaust Fan).ThePLCusestheseoutputstoactivatedevicesbasedon theprogrammedlogicandsensorconditions.

Thisconfigurationisdesignedtoensurethesystemoperates withminimalhumanintervention,relyingonreal-timedata fromsensorstomakeintelligentdecisions.Aswaterlevels fluctuateorgasconcentrationsincreasewithinthedrainage system,theProgrammableLogicController(PLC)interprets these inputs and activates the appropriate output devices. For example, if the water level falls below a predefined threshold,thesystemengagesthewater-levelmaintenance

pumpandilluminatesthelow-levelindicatorlamp.Similarly, whentheupperfloatsensordetectsapotentialoverflow,the secondpumpistriggeredtodischargeexcesswater,andthe high-levellampisactivatedtoalertmaintenancepersonnel. Inthepresenceoftoxicgases,thePLCenergizestheexhaust fantoimproveaircirculationandpreventhazardousbuildup.

Thesystem’scontrolcomponents includingrelays,voltage regulators,andtransistors playacrucialroleinensuring safeandstableoperations.Relaysareemployedtointerface low-powercontrolsignalswithhigh-powerdevicessuchas pumps and fans, preventing electrical overload. The 7812 voltage regulator maintains a consistent 12V supply to sensitivecomponents,enhancingthesystem'sdurabilityand electrical safety. The BJT (3904) and thyristor are used to manage switching operations and provide additional protectionfromvoltagespikesorshortcircuits.Overall,the modular integration of these components allows for scalability,easeoftroubleshooting,andreliableperformance incomplexurbandrainageenvironments.

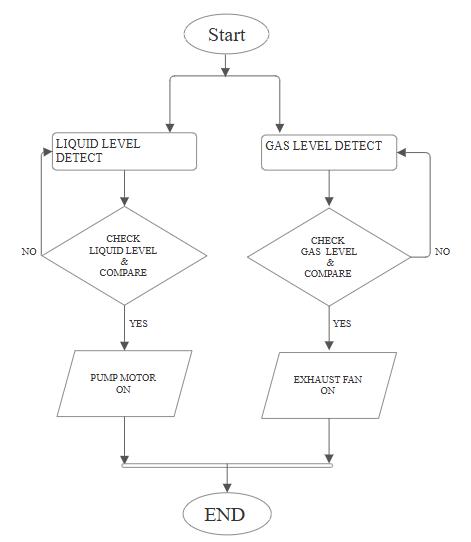

The operational logic of the proposed system is visually representedinFigure2,whichoutlinesthestep-by-stepflow of processes fromsystem initiation (START) toconclusion (END).Thefiguredelineateshowthesystemrespondstotwo primarytypesofinput liquidlevelandgasconcentration by triggering specific outputs through the PLC. Each input activatesadedicatedsensinganddecision-makingprocess, allowing the system to carry out two independent but interrelated control functions in real time. The flowchart provides a clear visualization of how input conditions are evaluated,comparedagainstpredeterminedthresholds,and howappropriatecontrolactionsareexecutedinaclosed-loop cycle.

Inthecaseof liquid level monitoring,theprocessbegins with the "Liquid Level Detect" block. Here, float sensors measurethecurrentwaterlevelinthedrainagesystem.The information is then passed to the "Check Liquid Level & Compare"block,whichevaluateswhetherthedetectedlevel matchesapredefinedsetpoint.Iftheliquidlevelexceedsthis threshold,thesystemsendsasignaltothePLCtoactivatethe associated pump motor, allowing excess water to be discharged.Oncethewaterlevelreturnstoasaferange,the system resets to its initial state. However, if the detected water level does not match the set point, the system continues to monitor until the desired level is achieved, ensuringastableandcontrolleddrainagecondition.

For toxic gas detection,theoperationbeginswiththe"Gas Levels Detect" block, where gas sensors measure the concentration of harmful gases present in the drainage atmosphere. This data is then evaluated in the "Check Gas Value & Compare" block, where the measured value is compared to a critical threshold set at 40% gas concentrationforthisproject.Ifthesensorreadingreaches or exceeds this threshold, the PLC is instructed to open a

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

solenoidvalveandactivatetheexhaustfan.Thefancontinues tooperateuntilthegasconcentrationisreducedtoasafer level, specifically down to 20%. If the detected gas concentrationisbelowthe40%threshold,thesystemloops backtore-evaluatethegaslevelscontinuously.Thisensures thatanybuild-upofhazardousgasesisaddressedpromptly and efficiently, enhancing safety within the drainage environment.

Figure2presentstheflowchartthatoutlinestheoperational logicofthePLC-basedautomaticdrainagemonitoringand controlsystem.Thechartillustratesthesequentialflowof dataandcontrolsignalswithinthesystem,beginningwith continuous monitoring from the level sensors and gas sensor. When the water level in the drainage tank drops below or rises above the predefined thresholds, the respective float sensors (low and high level) detect the changeandtransmitasignaltotheinputterminalofthePLC. The PLC, using pre-programmed logic, processes this informationandactivatestheappropriatemotor(pump).If thewaterisbelowtheminimumlevel,thepumpresponsible formaintainingthewaterlevelisswitchedon.Incontrast,if

thewaterexceedstheupperthreshold,thesecondpumpis engaged to discharge the excess water and prevent overflow.

Simultaneously,thegassensorconstantlymonitorsforthe presenceofharmfulorflammablegaseswithinthedrainage environment. When toxic gases are detected beyond the safety threshold, the sensor sends a signal to the PLC. In response, the PLC immediately triggers the exhaust fan throughitsoutputterminal.Thefanthenstartsoperatingto ventilatetheareabyextractingthetoxicgases,thusensuring saferairconditionsinandaroundthedrainagesystem.This automated response eliminates the need for manual inspection and reduces exposure risks for maintenance personnel.

Theflowchartservesasavisualrepresentationofhoweach componentinteractswithinthesystembasedonreal-time environmental feedback. It highlights the conditional decision-making process embedded within the PLC program where actions are taken only when specific sensorinputsmeetorexceeddefinedcriteria.Thislogical, step-by-stepoperationensuresthesystemremainsenergyefficient, responsive, and safe under various operating conditions. Ultimately, the flowchart simplifies the understandingofacomplexcontrolsystem,makingiteasier totroubleshoot,optimize,orscaleinfutureapplications.

Table -1: PLCpinandconnectedtothespecificelement Sr.No. PLC Pin

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

HeretableshowPLCPinconnectedtodesiredelements.

ToprogramthePLCISPSoftprogrammingsoftwareisused in this project. Ladder Diagram (LD) method is used as a programming language. The Delta PLC was enabled to be programmedusingthissoftware.InFig.4theladderdiagram forthisprojectwasdrawnusingthissoftware.

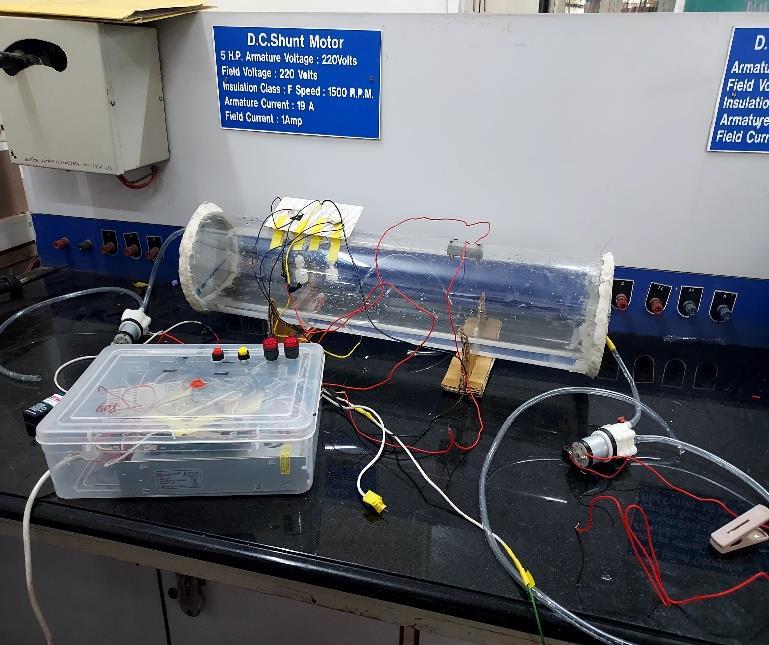

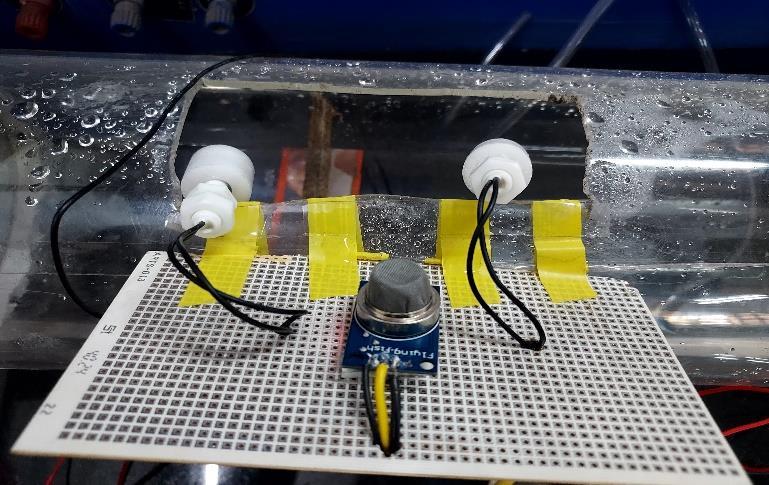

Figure4illustratestheexperimentalsetupofthePLC-based automatic drainage water monitoring and control system. The diagram showcases the integration of two primary sensingcomponents:agassensorandaliquidlevelsensor.

Thegassensorisresponsiblefordetectingtheconcentration of toxic gases within the surrounding environment. Upon identifyingthepresenceofharmfulgasesabovethepreset threshold,thesensorsendsasignaltothePLC,whichinturn activates the exhaust fan. The fan operates to extract the toxic gases and facilitate the inflow of fresh air, thereby restoring safe atmospheric conditions. This real-time response ensures rapid mitigation of hazardous gas exposure, especially in enclosed or poorly ventilated drainageenvironments.

Simultaneously, the liquid level sensor continuously monitors the volume of waste liquid in the drainage or storage tank. When the liquid level reaches or exceeds a defined limit, the sensor communicates with the PLC, prompting it to activate the pump motor. The motor then evacuatestheexcessliquidfromthetank,maintainingthe system’soperationalstabilityandpreventingoverflow.This experimentalconfigurationclearlydemonstratestheroleof the PLC as the central control unit, processing data from bothsensorsandcoordinatingthecorrespondingactuator responses.Theresultisafullyautomatedsystemcapableof managing two critical aspects of drainage safety gas ventilation and fluid level regulation without manual intervention.

Duringthesystem'sperformanceevaluation,allintegrated sensors including the gas sensor and the liquid level sensors functioned as expected, accurately detecting environmentalconditionsandtransmittingreal-timedatato the Programmable Logic Controller (PLC). The sensors exhibited high sensitivity and responsiveness, promptly identifying variations in both water levels and toxic gas concentrations.Thisreal-timedataacquisitionwascriticalin enablingtimelydecision-makingwithinthePLC,whichthen executedtheappropriatecontrolactionssuchasactivating theexhaustfanorinitiatingpumpoperations.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

ThePLCsuccessfullymanagedtheentireprocess,validating its role as the central controller of the system. It not only processed sensor input with precision but also effectively coordinated actuator responses, ensuring smooth system functionality. Additionally, the system provided visual feedback by displaying both water levels and gas concentration values, allowing for better monitoring and transparency. This confirmed that the PLC-based control mechanism is both reliable and efficient for continuous drainage system automation, aligning with smart infrastructureobjectives.

ThePLCdemonstratedrobustandconsistentperformancein managing the entire system, reinforcing its role as the centralprocessingandcontrolunit.Itaccuratelyinterpreted inputsignalsfromboththegasandliquidlevelsensorsand coordinated timely responses by activating the corresponding actuators, including the exhaust fan and water pumps. This ensured uninterrupted operation and quick adaptation to changing environmental conditions. Furthermore,thesystemfeaturedreal-timevisualfeedback, effectivelydisplayingwaterlevelsandgasconcentrations. This added layer of transparency enhances monitoring efficiency and supports rapid decision-making. The successfuloperationconfirmsthereliability,responsiveness, andsuitabilityofthePLC-basedautomationframeworkfor smart drainage system applications within modern urban infrastructure.

determine whether to activate the pump for drainage or maintainwateratadesiredlevel.

The gas sensor, positioned within the drainage area, is responsiblefordetectingthepresenceandconcentrationof hazardousgases.Itcommunicatesreal-timedatatothePLC, whichprocessestheinputand,whennecessary,triggersthe exhaust fan to ventilate the area. The inclusion of these sensorsensuresacomprehensivemonitoringmechanismfor bothwaterandairquality,makingthesystemreliableand responsiveinmanagingdrainageoperationsundervarying environmentalconditions.

Figure 6 depicts the interface components used for user interactionandsystemstatusindicationwithintheproject. The setup includes two push-button switches and two indicatorlamps,eachassignedaspecificfunctiontosupport theoperationandmonitoringofthedrainagesystem. The first switch functions as the START switch, initiating the system's operation by supplying power to the PLC and activatingthesensors.ThesecondswitchservesastheSTOP switch,allowingtheusertosafelyterminatesystemactivity whenrequired.

Figure 5 illustrates the primary sensing components employedinthePLC-baseddrainagemonitoringandcontrol system.Thesetupincludestwoliquidlevelsensorsandone gas sensor, each playing a critical role in environmental monitoring.Thetwofloat-typelevelsensorsarestrategically positionedtodetectbothlowandhighwaterlevelsinthe drainage tank. These sensors provide the PLC with continuous feedback regarding fluid status, enabling it to

Additionally, the two indicating lamps provide real-time visualfeedbackbasedonwaterlevelstatus.Thefirstlampis configuredtoilluminatewhenthewaterlevelfallsbelowthe lower threshold, indicating a low-level condition and signallingthatthepumpforwaterlevelmaintenanceshould beactivated.Thesecondlamplightsupwhenthewaterlevel exceedsthehigh-levelthreshold,alertinguserstopotential overflow and triggering the pump for excess water discharge.Together,theseswitchesandindicatorsenhance the system’s usability, safety, and monitoring clarity, ensuringoperatorsareinformedofkeyconditionswithout relyingsolelyonsensordatadisplays.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

In conclusion, the PLC-based automatic drainage water monitoringandcontrolsystemoffersareliable,intelligent, and efficient solution for managing urban drainage infrastructure.Byintegratinglevelsensorsandagassensor with a programmable logic controller, the system enables real-timedetectionofwaterlevelsandtoxicgases,ensuring timely activation of pumps and exhaust fans. This automation reduces manual intervention, enhances operationalsafety,andminimizestheriskofenvironmental contamination or overflow. The project successfully demonstrates the potential of smart control systems in transforming conventional drainage networks into responsive and sustainable infrastructure components, aligningwithmodernsmartcityobjectives.

1. Md. Atikur Rahman, Hasan al Banna, Amran Hossain, Md. Mosaraf Hossain Khan, Shafayat Hossain, “Design andImplementationofaPLCbasedAutomaticIndustrial DrainageSystem”,April2021.

2. Yousef M. K. Ali, Omar A. Zargelin, Fadel Lashhab, AbdulbasitAlaribi,“WaterLevelControlSystemusing ProgrammableLogicController(PLC)”,May2021.

3. QiFeng,Tian-leSun,ZhangZhuo,Gang-fuLv,“Designof Automatic Exhaust Control System of Central Heating SystemBasedonS7-200SMARTPLC”,Febeuary2023.

4. "WhataWaste:AnUpdatedLookintotheFutureofSolid WasteManagement",WorldBank,2020

5. S. Amir, M. Kamal, S. Khan and K. Salam, "PLC based trafficcontrolsystemwithemergencyvehicledetection and management", 2017 International Conference on Intelligent Computing, Instrumentation and Control Technologies(ICICICT),2017.

6. M. Chattal, V. Bhan, H. Madiha and S. Shaikh, "INDUSTRIALAUTOMATION&CONTROLTROUGHPLC ANDLABVIEW",20192ndInternationalConferenceon Computing,MathematicsandEngineeringTechnologies (iCoMET),2019.

7. Y.Wang,P.Zeng,J.Xiao,Q. ZhangandD.Li,"Wireless gateway for wastewater treatment," 2011 IEEE International Conference on Signal Processing, CommunicationsandComputing(ICSPCC),Xi'an,2011