International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Kartikaey1 , Gurpreet Singh2 , Vikas Salotra3 , D K Bhalla4

1,2,3 UG Student, Department of Mechanical Engineering, Lingaya’s Vidyapeeth, Faridabad, Haryana, India 4 Professor, Department of Mechanical Engineering, Lingaya’s Vidyapeeth, Faridabad, Haryana, India ***

Abstract – This research explores the application of lean manufacturing techniques in the automotive industry through the development of a Nut Dispenser Mechanism that enhances manual assembly accuracy. Designed using Karakuri Kaizen principles and incorporating Poka-Yoke features, the mechanism addresses common issues associated with manual nut picking, such as incorrect quantities and loose fasteners. The system operates without external power, using a magnetassisted rotating wheel and guided slope to dispense exactly two nuts per cycle.

After implementation, the average nut picking time reduced from 3 seconds to 1.5 seconds, and loose nut defect cases dropped from four per month to zero. These improvements demonstrate the mechanism’s effectiveness in streamlining workflow, reducing variability, and enhancing product quality. This case study validates the potential of simple, cost-efficient mechanical solutions in achieving lean objectives, offering valuable insights for similar manual assembly processes across industries.

Key Words: Lean Manufacturing, Karakuri Kaizen, PokaYoke, Manual Assembly, Automotive Industry, Nut Dispenser

In the context of a highly competitive global marketplace, manufacturing industries especially those in the automotivesector areunderconstantpressuretoenhance production efficiency, minimize waste, and improve the overallqualityoftheirproducts.Leanmanufacturing,rooted intheToyotaProductionSystem(TPS),providesaneffective framework for achieving these objectives. Lean manufacturingiscenteredoneliminatingwaste,optimizing processes, and fostering a culture of continuous improvement(Kaizen),allwhileempoweringemployeesto participateintheenhancementofoperationalsystems[1]. Numerous recent studies have demonstrated that the successful adoption of Lean principles not only boosts operational efficiencybutalsohelpsinreducingcostsand improvingproductquality[2].

A significant aspect of Lean manufacturing is Karakuri Kaizen, which involves employing simple mechanical systemstoimproveproductionprocesseswithouttheneed forcostlyautomation.Thistechniqueemphasizestheuseof

low-cost,high-impactsolutionstostreamlineworkflowsand reduce operational inefficiencies. By incorporating simple mechanicaldevices,KarakuriKaizenfacilitatessubstantial productivity gains and error reductions within the manufacturingprocess[3].Ithasbeenespeciallybeneficial in sectors such as automotive manufacturing, where affordability and practicality are essential for process optimization[4].

AnotherkeyprincipleinLeanmanufacturingisPoka-Yoke, ormistake-proofing,whichaimstoeliminatehumanerrors inproductionsystemsbydesigningerror-proofmechanisms. These systems automatically prevent potential mistakes, ensuring that production processes remain smooth and defect-free. In the automotive industry, Poka-Yoke is commonly applied to prevent errors such as incorrect component placement, assembly mistakes, and missing parts,thusensuringhigherqualityandreducingdefects[5]. Recent advancements indicate that the implementation of Poka-Yoke can significantly boost both the operational efficiencyandqualityinmanufacturingenvironments[6].

Thispaper examinestheNutDispenserMechanism in the automotivesector,whichintegratesthe principlesof both KarakuriKaizenandPoka-Yoke.Themechanismisdesigned toautomatetheprocessofdispensingsmallparts,suchas nuts, during assembly. The incorporation of Poka-Yoke ensuresthecorrectnumberofnutsaredispensedeachtime, thereby preventing errors and minimizing the chances of defectsinthefinalassembly.

Theobjectiveofthisresearchistoassesstheeffectivenessof the Nut Dispenser Mechanism in improving production efficiency, reducing waste, and enhancing overall product quality within automotive manufacturing. By lowering errorsandpromotingcontinuousimprovement,thisstudy assesseshowthecombinationofKarakuriKaizenandPokaYokecanhelpcreatemanufacturingprocessesthataremore dependableandefficient.

The automotive manufacturing sector is continuously seeking ways to improve operational efficiency, reduce waste,andenhanceproductquality.Leanmanufacturing,a framework derived from the Toyota Production System (TPS), is a widely adopted approach designed to achieve

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

thesegoals.Atitscore,Leanfocusesoneliminatingwaste, optimizing processes, and ensuring continuous improvements (Kaizen) through the empowerment of workers [1]. Numerous studies have shown that the application of Lean principles significantly enhances efficiencyandreducesoperationalcostswhileimprovingthe finalproduct'squalityintheautomotiveindustry[2].

ThekeytenetsofLeanmanufacturing wasteelimination, processoptimization,andcontinuousimprovement have been critical in boosting the effectiveness of automotive production lines. By focusing on improving value creation andreducinginefficiencies,automotivemanufacturershave achieved notableadvancements.For instance, Panwarand Jain (2017) has successfully applied Lean practices to cut down production cycle times and improve quality simultaneously[2].PanwarandJain(2017)foundthatthe integration of Lean practices with robust management strategiesledtomarkedimprovementsinbothoperational efficiencyandfinancialoutcomesintheautomotiveindustry [2].

Moreover, tools like Value Stream Mapping (VSM) have become indispensable in identifying and eliminating inefficiencies in automotive production lines. As the automotive industry faces ever-increasing pressure to optimize costs and maintain quality, Lean methodologies, including VSM, have been tailored to meet the unique challengesofmassproduction[9].

AstandoutconceptwithinLeanmanufacturingisKarakuri Kaizen,whichusessimplemechanicalsystemstoenhance productionefficiencywithoutrelyingoncostlyautomation. This method has gained significant attention due to its affordabilityandeffectiveness,makingitaccessibleevento smallermanufacturersalongsidelargecorporationsinthe automotiveindustry[3].

KarakuriKaizenhasproveneffectiveinreducingoperational inefficiencies,improvingproductivity,andenhancingworker safety. Pogowonto & Amrina (2020) reported that the introduction of Karakuri devices in an automotive production line led to faster part handling, reduced downtime, and smoother process flows [7]. Employee involvement is also encouraged and a continuous improvement culture is fostered by the simplicity of Karakurisystems.Thesedevicesareparticularlybeneficial in environments like automotive manufacturing, where small inefficiencies can compound, affecting overall productiontimelinesandcosts[6].

AnothervitalLeantoolisPoka-Yoke,whichaimstoprevent human errors by designing processes that automatically detect and correct mistakes before they result in defects. This technique is especially important in automotive manufacturing, where precision is crucial and errors can have significant consequences. Poka-Yoke systems help eliminateissuessuchasincorrectpartplacement,assembly mistakes,andmissingcomponents,ensuringhigherquality andfewerdefects[5].

ResearchbyLikerandMeier(2019)emphasizedthateven simple Poka-Yoke devicescouldeffectively reducedefects andenhancespeedinautomotiveassemblylines[8].Shingo (2018) highlighted that Poka-Yoke not only improves product quality but also boosts workers' confidence by providing safeguards against common errors during production[6].Inhigh-volumeenvironments,theabilityto detect and prevent errors automatically is a critical advantage, reducing the risk of defects and the need for rework.

TheNutDispenserMechanismservesasaprimeexampleof howtheintegrationofKarakuriKaizenandPoka-Yokecan significantly enhance automotive production. This simple mechanical device automates the dispensing of nuts and smallcomponents,ensuringthatthecorrectnumberofparts aredispensedwithouterror.TheincorporationofPoka-Yoke ensuresthatthedispensingprocessisbotherror-proofand efficient, preventing issues such as the dispensing of incorrectquantities.

The use of a Nut Dispenser Mechanism in automotive assembly lines can save time by automating the parthandlingprocesswhileminimizingerrorssuchasmissingor over-dispensed parts. This mechanism exemplifies how combiningKarakuriKaizen'slow-costmechanicalsolutions with Poka-Yoke’s mistake-proofing can streamline operations, reduce waste, and enhance overall product quality.

The literature highlights the significant role of Lean manufacturing,KarakuriKaizen,andPoka-Yokeindriving operationalimprovementsandensuringhigh-qualityoutput in automotive manufacturing. By using these approaches, businessescanincreaseoverallproductivity,decreasefaults, and streamline their manufacturing processes. The Nut DispenserMechanismrepresentsaneffectiveapplicationof both Karakuri Kaizen and Poka-Yoke principles, demonstrating their potential to improve manufacturing efficiency. Future research could further explore the

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

refinementandbroaderapplicationofthesetechniquesto maximize their effectiveness in diverse manufacturing contexts.

This study utilizes an experimental research approach to design, implement, and evaluate the Nut Dispenser Mechanism,whichincorporatesKarakuriKaizenandPokaYokeprinciplestoenhancethenutdispensingprocessinan automotiveassemblyline.Theobjectiveistoautomatethe nut dispensing system, improving both accuracy and efficiencywhilereducinghumanerrorandoperationalcosts.

3.1 Research Design

Thestudyemploysaquantitativemethodologytoassessthe Nut Dispenser Mechanism's performance under actual assemblylineconditions.Thesystemistestedinacontrolled automotive assembly environment, comparing its operationalefficiencyanderrorratestothoseofmanualnut dispensingmethods.

Inadditiontoquantitativeanalysis,qualitativeassessments are conducted based on operator feedback and direct observation, focusing on ease of use, ergonomics, and the system'soverallreliability.

3.2 Problem Identification and Objectives

- Problem: Priortothesystem'simplementation,operators manuallyselectednutsfromabowlorhopper,aprocessthat waspronetoerrors,suchas:

-Incorrectnutcounts,withthepossibilityofeithertoo fewortoomanynutsbeingselected.

-Loosenutsleftinsidevehicles,posingsignificantsafety andqualityrisks.

- Increased cycletimes due tothe repetitiveandtimeconsumingnatureofthemanualprocess.

- Objective: Thegoalofthisresearchistoautomatethenut dispensingprocessbyintroducingasystemthatconsistently dispensesexactlytwonutspercycle,reducinghumanerrors andimprovingoperationalefficiency.Akeyfocuswasalsoto addresstheissueofloosenutsleftinsidevehicles,acommon defectpriortoimplementation.

The Nut Dispenser Mechanism was designed using the principles of Karakuri Kaizen, which focuses on low-cost, simplemechanicalsystemspoweredbygravity,magnets,and basicmechanicalmotions.Thisdesignchoicealignswithlean manufacturingprinciples,ensuringthatthesystemisboth cost-effectiveandenergy-efficient.

Poka-Yoke(error-proofing)techniqueswereintegratedinto the design, incorporating mechanical guides and a visual feedback system to ensure the accuracy of the dispensing processandpreventerrorsfromoccurring.

- Bowl-Type Container: Themechanismbeginswithabowltype container, which holds the nuts to be dispensed. The materialhandlingoperatormanuallyloadsthecontainerwith the necessary quantity of nuts, which are then conveyed throughthedispensingsystem.

- Magnetic Wheel with Flanges: A magnetic wheel with flanges is attached to the container. When the operator pressesthelever,thewheelrotates,generatingamagnetic fieldthatliftsthenutsandmovesthemfromonesideofthe containertotheother.

- Magnetic Lifting and Transfer: The magnetic wheel's rotation creates a magnetic lifting effect that transfers the nutsfromthecontainerandmovesthemalongapredefined path. This transfer process removes the requirement for manualintervention,enhancingboththespeedandaccuracy ofnutmovement.

- Striking the Secondary Container: Aftertransferring,the nutsstrikeasecondarycontainerwall,whichhelpstocontrol anddirecttheirmovement,ensuringthattheyareproperly positionedforthenextstage.

- Slope and Nut Alignment: Thesystemincludesaslopethat allowsonlyasinglelayerofnutstopassthroughatatime. Theslopeensuresthatthenutsarealignedvertically,which allowsforoptimalpositioningduringdispensing.

- Guide Channels: Thenutstravelthroughprecisionguide channels that ensure correct alignment and accurate positioning as they move toward the dispensing zone, preventingmisalignmentandensuringsmoothoperation.

- Final Dispensing Mechanism: Thedispensingmechanism is triggered by pressing a small platform, which releases exactly two nuts per cycle. This guarantees the correct numberofnutsisdispensed,reducingthepotentialforerrors associatedwithmanualcounting.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

TheNutDispenserMechanismintegratesavisualfeedback system,whichprovidesreal-timevisualindicatorstoalertthe operatorifthereareanyissues,suchasmisalignmentora blockage in the dispensing process. This feedback system allows the operator to take immediate corrective action, ensuringthesystemoperatessmoothlyandminimizingthe likelihoodofdispensingerrors.

TheNutDispenserMechanismwasinstalledinapilotsection oftheautomotiveassemblylineforreal-worldtesting.The systemwasevaluatedunderproductionconditionstoassess itsreliabilityandoverallperformance.

- Data Collection: Various performance metrics were collected,including:

- Time Efficiency: A comparison between the time required for manual dispensing andthat of theautomated system.

- AccuracyMetrics:Thefrequencyofdispensingerrors such as under- or over-dispensing measured before and afterthesystemwasintroduced.

- Impact on Line Performance: The effect of the automatednutdispensingsystemonoverallassemblyline throughput.

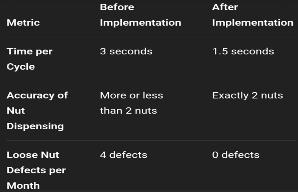

- Loose Defect Trend: Prior to implementation, the systemexperiencedanaverageoffourloosenutdefectsper month. After the implementation of the Nut Dispenser Mechanism,thisdefectratewasreducedtozero,indicatinga significantimprovementintheaccuracyandreliabilityofthe nutdispensingprocess.

- Observational Analysis: Operator feedback was gathered to evaluate the usability and ergonomics of the system, as well as any issues encountered during the implementationphase.

TheNutDispenserMechanism'sperformancewasevaluated basedonthefollowingkeymetrics:

- Error Reduction: A reduction in dispensing errors, includingunder-orover-dispensing.

- Time Efficiency: Faster dispensing, resulting in increasedthroughputandreducedcycletime.

- Cost-Effectiveness: Acost-benefitanalysisofthelowcost mechanical design compared to more expensive automatedsystems.

- Loose Defect Reduction: Theeliminationoftheloose nutdefecttrend,whichwaspreviouslyamajorissueinthe assemblyprocess.

- Operator Feedback: Qualitative feedback from operators on the system's ease of use and impact on ergonomicsandsafety.

3.8 Limitations

- System Adjustments: Minoradjustmentswererequiredto fine-tunethegravity-feddispensingsystemtoaccommodate variationsintheassemblyline'sspeedandoperation.

- Training Requirements: Initialtrainingwasnecessaryfor operators to familiarize them with the new system, which may have temporarily reduced productivity during the learningphase.

TheimplementationoftheNutDispenserMechanismledto significant improvements in time efficiency, dispensing accuracy,anddefectreductionintheassemblyprocess.

- Before Implementation: Themanualnutpickingprocess requiredapproximately3secondspercycle,includingthe timetakenfortheoperatortoselect,count,andpreparethe nuts.

- After Implementation: With the Nut Dispenser Mechanisminplace,thetimepercyclewasreducedto1.5 seconds, resulting in a 50% decrease in cycle time, which enhancedtheoverallspeedoftheassemblyline.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

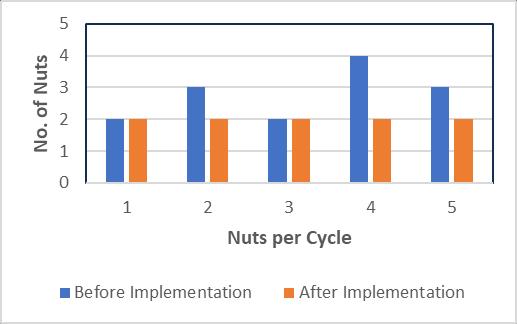

- Before Implementation: Operatorsmanuallydispenseda variablenumberofnuts,oftenresultingineithertoofewor toomanynuts,whichcreatedinconsistenciesanddelaysin theassembly.

- After Implementation: TheNutDispensernowensures that exactly 2 nuts are dispensed every cycle, completely eliminating errors and ensuring consistent, accurate dispensingforeachassemblyprocess.

Chart -1: Nuts Pick-up Accuracy Trend

3. Loose Nut Defects

- Before Implementation: Themanualprocessledtoloose nutsbeingleftinsidevehicles,whichposedsafetyconcerns andaffectedproductquality.Thisoccurredapproximately4 timespermonth.

- After Implementation: The Nut Dispenser Mechanism effectively eliminated this issue, bringing the number of loosenutdefectstozero,therebyimprovingbothsafetyand productquality.

Chart -2: Loose Defects Trend

TheintroductionoftheNutDispenserMechanismnotonly reducedcycletimebutalsoincreasedoverallassemblyline throughput.Byspeedingupthenutdispensingprocessand reducing defects, the system contributed to smoother and moreefficientproductionflow.

These improvements demonstrate the Nut Dispenser Mechanism's ability to enhance time efficiency, ensure precisedispensing,andeliminatedefects,resultinginbetter performanceandhigherqualityintheassemblyline.

TheimplementationoftheNutDispenserMechanisminthe automotive assembly line has resulted in notable improvementsintimeefficiency,dispensingaccuracy,and defect reduction. These outcomes emphasize the effectivenessofintegratingleanmanufacturingprinciples, particularlywastereductionandprocessoptimization.The following discusses the interpretation of these results, compares them with existing literature, and outlines the implicationsfortheautomotivesector.

Thereductionincycletimefrom3secondsto1.5seconds represents a 50% decrease in time per cycle. This improvement highlights the Nut Dispenser Mechanism's abilitytostreamlineoperations,reduceunnecessarywaiting times,andincreaseproductivityontheassemblyline.This aligns well with lean manufacturing principles, which emphasizeminimizingcycletimetoenhancethroughputand efficiency(10).

In terms of accuracy, the Nut Dispenser Mechanism effectivelyensuredthedispensingofexactly2nutspercycle. The earlier manual process often resulted in dispensing either too few or too many nuts, causing delays and inconsistencies in the assembly process. The mechanism’s error-proofing capabilities, such as guides and mechanical features, helped to eliminate this variability, ensuring a

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

consistentoutcomeforeachcycle.Thisprecisionexemplifies the role of Poka-Yoke systems in improving quality and reducinghumanerrorinmanufacturing(6).

The Nut Dispenser also significantly impacted defect reduction, particularly regarding loose nut defects. Before implementation,4loosenutdefectswerereportedmonthly,a safety and quality concern. After the mechanism was introduced,thesedefectswerereducedtozero.Thisresult underscorestheimportanceoferror-proofinginpreventing safetyhazardsandmaintainingproductquality,twoessential aspectsofleanmanufacturing(11).

These findings are consistent with previous research on Poka-Yoke and Karakuri Kaizen in manufacturing environments. Poka-Yoke techniques have been welldocumented for preventing errors and improving process reliability (6). The Nut Dispenser Mechanism, by guaranteeingexactnutdispensingandeliminatingdefects, alignswiththeseestablishedbenefits.

Moreover, the mechanism's design, relying on simple mechanical solutions without external energy sources, follows the Karakuri Kaizen approach, which emphasizes low-cost,sustainableinnovations(3).Thisapproachhasbeen proventodriveefficiencyandfosterinnovationwithinlean systems(12),andtheNutDispenserMechanismservesasa practicalexampleoftheseprinciplesinaction.

Thefindingsfromthisstudysuggestseveralbenefitsforthe automotiveassemblyline.Reducingcycletimeandensuring accurate dispensing of parts enhances the overall flow of production,whichisacoreprincipleofleanmanufacturing (10). The elimination of loose nut defects is particularly significant,asitdirectlyimprovessafetyandproductquality, whicharecriticalconcernsintheautomotiveindustry.

These results also offer broader implications for cost reduction.Withimprovedcycletimes,reducederrors,and less manual intervention required, labor costs can be reduced,whilethroughputincreases.Thereductionindefects alsomeansfewerrecallsorwarrantyclaims,leadingtocost savingsformanufacturersinthelongterm.

Whiletheresultsarepromising,therearesomelimitations. First,thestudywasconductedonasingleassemblyline,and itsapplicabilitytoothertypesofmanufacturingprocessesor industriesisstilluncertain.Futurestudiesshouldconsider testing the Nut Dispenser Mechanism in other contexts to determine its scalability and adaptability. Moreover, the studydidnotcomparetheNutDispenserMechanismwith otherpotential error-proofingsystems,suchasautomated

dispensing machines or other Poka-Yoke solutions. Such comparisonswouldhelpassesstherelativeeffectivenessof themechanism.

Anotherlimitationisthatthestudyonlyfocusedonone aspectoftheassemblyprocess nutdispensing.Otherareas of the assembly process, such as fastener placement or component inspection, could also benefit from similar improvements, and future research could examine the broaderapplicationofsuchsystems.

FutureresearchcouldfocusonexpandingtheNutDispenser Mechanism’s application to larger, high-volume manufacturing environments. As production scales up, additional challenges may arise, and the system may need modificationstohandlegreatercomplexityorvaryingpart sizes.

Anotherpromisingdirectionforfutureresearchinvolves integrating smart technology into the Nut Dispenser Mechanism.Sensorsorautomatedfeedbacksystemscouldbe incorporated to monitor dispensing accuracy in real-time, providing operators with immediate feedback and further enhancingprocesscontrol.

Additionally, researchers could explore the potential application of similar mechanisms in industries beyond automotivemanufacturing.Industriessuchaselectronicsor consumer goods assembly, which require precise and repetitiveparthandling,couldbenefitfromtheprinciplesof Poka-YokeandKarakuriKaizen.

Thisresearchhasdemonstratedthesignificantadvantagesof integrating the Nut Dispenser Mechanism into the automotive assembly line, leveraging lean manufacturing principles such as Poka-Yoke and Karakuri Kaizen. The findings reveal a remarkable 50% reduction in cycle time, from 3 seconds to 1.5 seconds, which enhances overall production efficiency and throughput. Additionally, the mechanism'sprecisedispensingofexactly2nutspercycle hasminimizedhumanerror,improvingtheaccuracyofthe process.Moreimportantly,theNutDispenserhascompletely eradicatedloosenutdefects,reducingthemfrom4permonth tozero,thusimprovingbothproductqualityandsafety.

Theseimprovementsincycletime,dispensingaccuracy, and defect reduction demonstrate the powerful impact of lean manufacturing techniques on modern assembly lines. The study shows that even simple and cost-effective mechanicalsolutions,liketheNutDispenserMechanism,can leadtosignificantimprovementsinproductivityandquality intheautomotivesector.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Theoutcomesofthisstudycarryimportantimplications formanufacturersaimingtoreducewaste,enhancesafety, andoptimizeassemblylineoperations.Byreducingmanual intervention and preventing defects, the Nut Dispenser Mechanismhelpsachievecostreductions,greaterefficiency, andimprovedsafetystandards.

However, this study has some limitations. The Nut Dispenser Mechanism was evaluated on a single assembly line, and its applicability to other manufacturing environments needs further exploration. Additionally, comparing this mechanism with alternative lean tools or automated systems could offer more insight into its effectiveness.

For future research, further studies could focus on adapting the Nut Dispenser Mechanism for large-scale production settings, incorporating smart technologies for real-time monitoring and feedback, and testing the mechanisminindustriesbeyondautomotivemanufacturing, such as electronics or consumer goods. Enhancing the mechanismwithautomationcouldalsoimproveitsefficiency andextenditsuseacrossvarioussectors.

Insummary,theNutDispenserMechanismisapractical andcost-efficientsolutionforensuringerror-freeassembly, fullyalignedwiththecorevaluesofleanmanufacturing.Its successfulimplementationaddressescriticalmanufacturing challengesandsetsthefoundationforfutureinnovationsin theindustry.

[1] Jasti, N.V.K. and Kodali, R. (2015) “Lean Production: LiteratureReviewandTrends”.InternationalJournalof Production Research, 53, 867-885. https://doi.org/10.1080/00207543.2014.937508

[2] Panwar,A.,Jain,R.,Rathore,A.P.S.,Nepal,B.,&Lyons,A. C.(2017).“Theimpactofleanpracticesonoperational performance – an empirical investigation of Indian process industries”. Production Planning & Control, 29(2), 158–169.https://doi.org/10.1080/09537287.2017.1397788

[3] Özcan, A. G. (2022). “APPLICATION OF REBA AND KARAKURI KAIZEN TECHNIQUES TO REDUCE ERGONOMIC RISK LEVELS IN a WORKPLACE” MühendislikBilimleriVeTasarımDergisi,10(4),1430–1444.https://doi.org/10.21923/jesd.957691

[4] Pogowonto,A.,&Amrina,U.(2020).“Reductionofcycle time in vehicle engine Assembly Line Using Karakuri Kaizen”.InternationalJournalofEngineeringResearch and Advanced Technology, 06(10), 49–57.https://doi.org/10.31695/ijerat.2020.3657

[5] Liker, J. K., & Franz, J. K. (2011). “The Toyota Way to Continuous Improvement: Linking Strategy and Operational Excellence to Achieve Superior Performance”.McGraw-HillEducation.

[6] Shingo, S. (1986). “Zero Quality Control: Source Inspection and the Poka-Yoke System”. Productivity Press.

[7] Bicheno,J.,&Holweg,M.(2018).“TheLeanToolbox:The essentialguidetoLeantransformation”.LeanEnterprise Institute.

[8] Premanand,N.,V,K.,P,S.,Umamaheswari,S.(2018).“A STUDY ON IMPLEMENTATION OF POKA– YOKE TECHNIQUE IN IMPROVING THE OPERATIONAL PERFORMANCEBYREDUCINGTHEREJECTIONRATEIN THEASSEMBLYLINE”.InternationalJournalofPureand AppliedMathematics,119–119(17),2177–2191.

[9] Rother,M.,&Shook,J.(2019). “LearningtoSee:Value Stream Mapping to Add Value and Eliminate Muda” . LeanEnterpriseInstitute.

[10] Womack, J. P., & Jones, D. T. (2003). “Lean thinking: Banish waste and create wealth in your corporation” (2nded.).FreePress.

[11] Imai,M.(1986).“Kaizen:TheKeytoJapan'sCompetitive Success”.McGraw-Hill.

[12] Liker, J. K. (2004). “The Toyota Way: 14 Management Principles from the World's Greatest Manufacturer” McGraw-Hill.