International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

1

2

1M.Tech student, Department of Civil Engineering, Lucknow Institute of Technology, Lucknow,UP

2Head of Department , Department of Civil Engineering, Lucknow Institute of Technology, Lucknow ***

ABSTRACT: The concrete When used to build structures and then given time to cure, concrete a mixture of cement, water, sand, pebbles, or crushed rocks (the aggregate or fillers) hardens into stone. The three essential components are water, aggregate, and cement. In comparison to steel, plastic and polymer are the least expensive and most widely available materials .The cement industry is one of the three primary producers of carbon dioxide, a significant greenhouse gas. As of 2011, it contributed 7% to global human CO2 emissions, mostly as a result of the sintering of clay and limestone at a temperature of 15000 C. Concrete construction and repair projects are using Styrene Butadiene Rubber (SBR) latex emulsions more frequently because of its advantages in terms of flexure strength, compressive strength, adhesion, and impermeability. SBR emulsion can boost the compressive and flexural strength of concrete members when applied in a certain proportion between old and new concrete layers. The ceramics industries are under pressure to come up with a solution for the disposal of the growing volume of ceramic waste. In order to protect the environment, several industrial sectors, especially the building industry, should use ceramic waste powder. As a result, more eco-friendly concrete is being used. By partially substituting leftover ceramic tile powder for cement, concrete can be produced more environmentally friendly. With SBR latex and waste ceramic tile powder, the study's objective is to create an inexpensive and environmentally friendly concrete replacement.

Key Words: Styrene Butadiene rubber latex, Waste ceramic tile powder , eco-friendly concrete, compressive strength, flexural strength.

Concreteisacompositematerialmadeofcoarsegranularmaterial(theaggregateorfiller)thatisencasedinastiffmatrixof material(thecementorbinder)thatfillsthegapsandholdstheaggregateparticlestogether.Concretecanalternativelybe thought of as a composite material made mostly of a binding medium with embedded aggregate particles or fragments. Concretecanbesimplestrepresentedasfollows:

Coarse aggregate + fine aggregate + cement + water+ admixture→

Themostcommonbuildingmaterialworldwideisconcrete.Itisutilisedinawidevarietyofstructures,includingbridges, dams,paving,andbuildingframes.Additionally,comparedtoothermaterials,itisutilisedthemostwidelyintheworld.In termsoftonnageandvolume,itsglobalproductionoutpacesthatofsteelbyaratioof10andmorethan30respectively.Atthe presenttime,concreteisconsumedatarateofabout10billiontonnesannually,ormorethan1.7tonnesperperson.Byweight, itconsumesmorethantentimesasmuchsteeldoes.Whyisconcretesopopularifitisneitherastoughnorasstrongassteel? Economical: The cheapest and most widely-available material is concrete. Comparing concrete to other engineered constructionmaterials,thecostofmanufactureisinexpensive.Water,aggregate,andcementarethethreemainingredients. Plasticandpolymeraretheleastpricedmaterialsascomparedtosteelandarewidelyaccessible.Thismakesitpossiblefor concretetobemanufacturedlocallywhereveritisneeded,savingonthetransportationexpensesassociatedwithmostother materials.

Styrene-butadienerubber,anall-purposesyntheticrubber,ismadefromacopolymerofstyreneandbutadiene(SBR).SBR consistsprimarilyofbutadiene(CH2=CH-CH=CH2)andstyrene(CH2=CHC6H5),around75%and25%,respectively.Thesetwo compoundsaretypicallycopolymerized(theirshort,single-unitmoleculesarejoinedtoformlong, multi-unit molecules) duringtheemulsionprocess.DuetoalackofnaturalrubberduringWorldWarsIandII,research onsyntheticrubberwas conductedinEuropeandtheUS,leadingtothedevelopmentofSBR.Germanchemistsstartedproducingsyntheticelastomers in 1929 by copolymerizing two substances with a catalyst. After butadiene, one of the copolymers, and sodium, the polymerizationcatalyst,thisserieswasgiventhenameBuna.Asaresultofbeingdeprivedofitsnaturalrubbersourcesfrom

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page387

Shubham

, Rajneesh Kumar

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

EastAsiaduringWorldWarII,theUnitedStatescreatedanumberofsyntheticmaterials,includingacopolymerofbutadiene andstyrene.

Theceramicsindustriesareunderpressuretocomeupwithasolutionforthedisposalofthegrowingvolumeofceramicwaste Inordertoprotecttheenvironment,severalindustrialsectors,especiallythebuilding industry,shoulduseceramicwaste powder.Asaresult,moreeco-friendlyconcreteisbeingused.Ceramicwasteisclassifiedasnon-hazardoussolidwastesinceit exhibitsPozzolanicproperties.Asaresult,recycledmaterialscanbeappliedoncemoreinmanydifferentbuildingconstruction processes.Industrialwastesthatarecoarserthancementparticlesgenerallymakeupupto35%oftheaggregateinconcrete mixtures.

1. ToinvestigatetheeffectsofStyreneButadieneRubber(SBR)latexonthecompressivestrength,flexuralstrength,and workabilityofconcrete.

2. Toestablishthebestratioofstyrenebutadienerubberlatextopowdereddiscardedceramictileforthebestconcrete mix.

3. Tolookintonewmaterialsaspossiblealternativesforcurrentonesinordertomakeconcretethatismorereasonably pricedandenvironmentallyfriendly.

1. Severalliteraturereviewswereundertakentobetterunderstandthesubjectbeforetheprojectwasstarted.

2. Specifictestsonthematerialsutilisedinthedissertationworkwereconductedtodeterminetheirspecifications andquality.

3. UsingIS10262-2009,themixdesignforM25gradeconcretewascompleted.

4. ThepreparedandmixedM25gradeconcrete'scompressiveandflexuralstrengthswereevaluatedafter28days.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Flexuralstrengthtestconcrete. 5.4 TESTS ON WASTE CERAMIC TILE POWDER

Table -1: ForFlexuralStrengthatvariouspercentageofSBRLatexand0%ceramicpowder

Variation of Flexural Strength For Various Percentage of SBR Latex

4.2

SBR latex percentage Flexural strength at 28 days (N/mm2) 0 3.65 1.5 3.68 3.0 3.83 4.5 3.97 6.0 4.13 7.5 4.37 9.0 4.18 10.5 4.05 3.65 3.68 3.83 3.97 4.13

4

3.8

3.6

3.4

4.4 0 1.5 3 4.5 6 7.5 9 10.5 Flexural Strength at 28 das ()N/mm 2) Percentage of SBR Latex

4.37 4.18 4.05 3.2

Variation of Flexural Strength For Various Percentage of SBR Latex Graph -1:GraphForFlexuralStrengthatVarious%ofSBRLatex

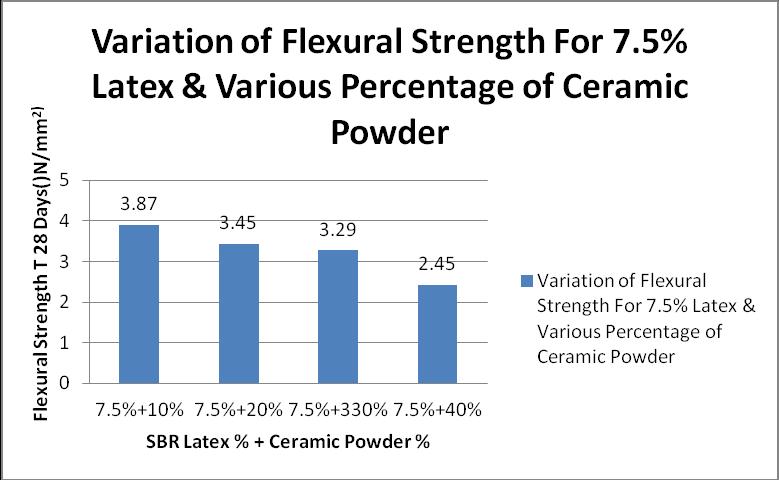

Table-2: ForFlexuralStrengthat7.5%SBRLatexandvariousPercentageofCeramicPowder 75%SBRLatex&CeramicPowder Percentage FlexuralStrengthat28Days(N/mm2) 10 3.87 20 3.45 30 329 40 245

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Graph-2: FlexuralStrengthat7.5%SBRLatex&various%ofceramicpowder

Onthebasisofvarioustestfindingsfromlaboratoryexperiments,thepresentstudyhasestimatedthemechanicalpropertiesof threetypesofconcrete:plainconcrete,latexmodifiedconcrete,andlatexmodifiedceramictilepowderreinforcedconcrete.

The following conclusions are reached based on these findings and the observations obtained during this experimental researchstudy:-

1. At0%SBRlatexand0%ceramictheflexuralstrengthisseentobe3.67N/mm2 after28days.

2. At7.5%SBRlatexand0%ceramictheflexuralstrengthisseentobe4.37N/mm2maximumfromalltheresults.

3. ItisseenthatasweincreasethepercentageofSBRat0%ceramictheflexuralstrengthoftheconcretefirststartsto increasethenitstartsdecreasing.

4. At7.5%SBRlatexandvariouspercentageofceramicpowdertheflexuralstrengthiscalculated.

5. At7.5%SBRlatexand10%ceramicpowderflexuralstrengthisseentobemaximum.

6. Asweincreasethepercentageofceramicpowdertheflexuralstrengthofconcretedecreasesthusspecificpercentage ofceramicpowderisused.

1. T.Subramani,B.Suresh,ExperimentalInvestigationOfUsingCeramicWasteAsACoarseAggregateMakingALightWeight Concrete,InternationalJournalofApplicationorInnovationinEngineering&Management,2015.

2. AbdullahAnwar,SabihAhmad,SyedMohd.AshrafHusainandSyedAqeelAhmad,ReplacementOfCementByMarbleDust AndCeramic WasteInConcreteForSustainableDevelopment,International Journal ofInnovativeScience,Engineering& Technology,2015.

3. GarimaArora,andM.ParvezAlam,UtilizationofPozzolonicMaterialfortheEnhancementoftheConcreteStrength: A ComprehensiveReviewPaper,JournalofCivilEngineeringandEnvironmentalTechnology,2015.

4. AmirJaved,SalmanSiddique,RamPrasadVS,Investigationonceramicwasteandstonedustasaggregatereplacementin concrete,InternationalJournalofEngineeringTechnology,ManagementandAppliedSciences,2015.

5. ArunaD,RajendraPrabhu,SubhashCYaragal,KattaVenkataramana,studiesonusagepotentialofbrokentilesaspartial replacementtocoarseaggregatesinconcretes,InternationalJournalofResearchinEngineeringandTechnology,2015.

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page390

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

IhavecompletedmyB.techincivilengineeringfromG.LBajajinstituteoftechnologyintheyear2017Gr.Noida.NowIam pursuingM.techincivilengineeringfromLucknowInstituteoftechnology.

Mr.RajneeshKumarisworkingasHeadofDepartmentinLucknowinstituteoftechnologyincivildepartmentandhave workingexperienceof10years.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page391