International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

1Post graduate student Department of Civil Engineering, KJ College of Engineering & Management Research, Pune411048, Maharashtra, India

2Associate Professor Department of civil engineering, KJ College of Engineering & Management Research, Pune-411048, Maharashtra, India ***

Abstract - The progressive collapse is that the phenomenon of the worldwide failure of the structural system results from the failure of the only element of it. The good research work made for the progressive collapse ofthe buildingstructure, but the very small response has shown towards the bridge structure. For this study, we consider 4 types of25msteeltruss foot over bridge models by using Staad Pro Connect Edition V 22 software and are designed according to the Indian Standard Codes, for all load combinations. This model is to be an analysis for progressive collapse analysis as per latest GSA guideline 2016. The linear dynamic analysis is administered for a steel truss foot over bridge considering different loadings like dead, live, wind and seismic using Staad Pro Connect Edition V 22 software. After the design load is applied, the live load is increased until the bridge model collapses. Although the collapse process differs depending on liveload distribution for both steel truss bridge models collapse due to buckling of compression members. When the live load is applied incrementally by 25% on the span, bracing member starts yielding in model 1 & 3 whereas model 2 & 4 is safe. When live load increased by 50% bracing members starts failing and compression members like upper chord and column starts yielding. When Live load increase by 75% and 100% case bracing, upper chord, walkway beams and columns start failing in all four models. As utilization ratio defined by ultimate stress to allowable stress, bridge model-2 i.e. A-type with sub brace is more resistible to collapse compare to rest of models. This study clarifies the collapse process due to incremental live load and effective truss arrangement for steel truss bridge.

Words: Steel Truss bridge, Progressive Collapse, Incremental Live Load, Linear Dynamic Analysis, Staad Pro Connect Edition, IRC 6-2017.

Indiaisadevelopingcountry.Transportationfacilitiesand theirrelatedinfrastructuredevelopmentplayavitalrolein theprogressofdevelopingcountrieslikeIndia.Bridgesare oneoftheforemostimportantengineeringinfrastructures utilizedintransportation.Railwaybridgesareconstructedto connect to platform separated by railway track to carry pedestrians safely from one platform to another platform andalsotoexitstation.NowadaysSteelfootoverbridgesis widely adapted by railways. Steel bridges provide overall easeandeconomyforconstruction.Steelbridgesareeasyto

constructwithinashortperiodoftime.Itisenvironmentfriendly and commuter – friendly. Foot over bridges is provided at platform in such a place where it can carry maximumpedestriantrafficatpeakhoursandalsoatnon peak hours.Andalso,itcouldbeveryconvenienttousers frombothsidesofplatform.Steelfobscanbeusedrightfrom the time construction is over. A structure undergoes progressive collapse when a primary structural element fails,leadingtothefailureofadjoiningstructuralelements, which causes structural failure. It also defined as extent damageorcollapsethat'sdisproportionatetothemagnitude of initiating event. Progressive collapse analyses are intended to work out the capacity of a structure either to resistanabnormalloading.

Astructureundergoesprogressivecollapsewhenaprimary structuralelementfails,resultinginthefailureofadjoining structuralelements,whichcausesstructuralfailure.Italso definedasextentdamageorcollapsethatisdisproportionate to the magnitude of initiating event. Progressive collapse analysesareintendedtodeterminethecapacityofastructure eithertoresistanabnormalloading.

Inthehistoryofbridges,lotsofbridgesarecollapseddueto variousreasons.Mostlytherearetwomainreasonswhich areNaturalfactorsandHumanfactors.Naturalfactorsare Floods,Earthquakes,landslide,debrisflow,hurricane,and typhoons,scouringthesenaturalcalamitiesareunavoidable which causes plenty of damage to the structure. Human factors are Imperfect design & Construction, collision, TerroristAttack,LackofInspection&Maintenance,Heavy pedestrianTraffic.

Tostudyofprogressivecollapseanalysisofsteeltrussfoot bridge having span of 25 meter. The Dissertation work is beingcarriedouttoachievethefollowingobjectives:

1) Modelling of the steel foot over bridge in STAAD PRO CONNECT EDITION V22 software. 2) Study the structural behavior of the foot over bridge under different load conditionslikegravityloads,windload,seismicloadasper IRC.3)Studytheconceptofprogressivecollapse.4)Perform

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1059

KeyInternational Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

theprogressivecollapseanalysisofthesteelfootoverbridge using STAAD PRO CONNECT EDITION V22 software by IncrementalLiveLoad.

To study the structural behavior of the foot bridge under differentloadingconditionslikegravity,seismic,windand progressivecollapsebehaviorofthesteeltrussfootbridge underincrementalliveload.Thefollowingdetailsareused.

Table -1: DetailsofSteelTrussBridge

Thespanofthebridge 25m

Typeofsuperstructure Steelfootbridge

No.ofsupports 2

Widthofeachspan 3.5m

Heightofwalkwayaboveground 6m

Bridgelocation Pune

Seismiczone III

Zonefactor 0.16 Importancefactor 1.2 Responsereductionfactor 3 %Damping 2% Windspeed 39m/s

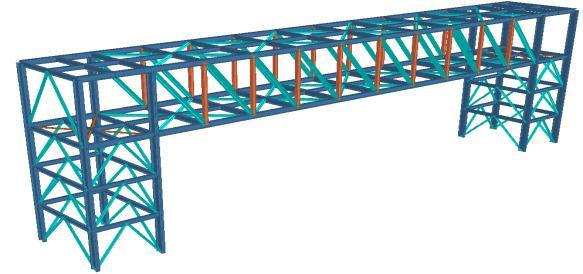

Fig -1:A-TypeTrussBridge

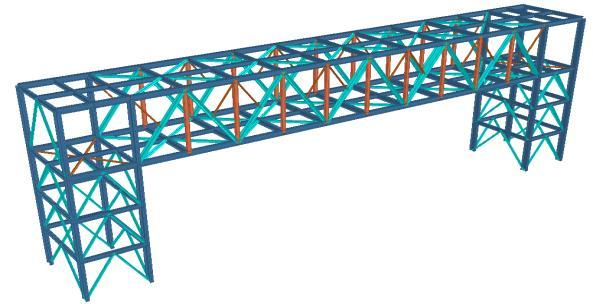

Fig -2:A-withSubBraceTrussBridge

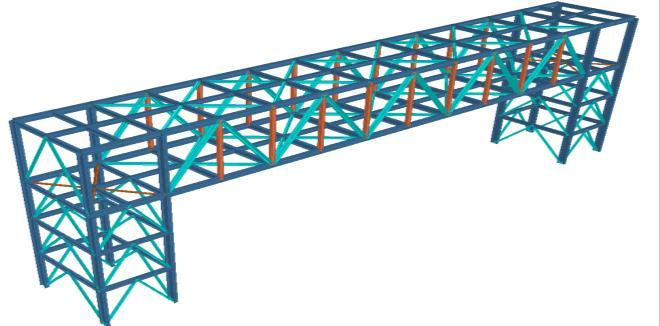

Fig -3:N-TypeTrussBridge

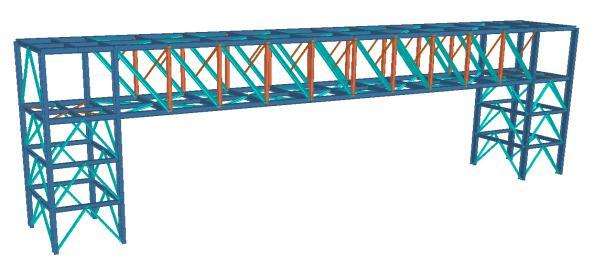

Fig -4:N-withSubBraceTrussBridge

ThepartanalysisworkhasbeencarriedoutinSTAADPRO CONNECTEDITIONV22Softwaretochecktheprogressive collapse of the steel truss bridge at actual dead load and incremental live load according to the acceptance criteria suggested by GSA (2016) Revision 1. All other load combinations & loads like dead load, live load, wind load, seismicloadconsideredasperIRC6(2017).

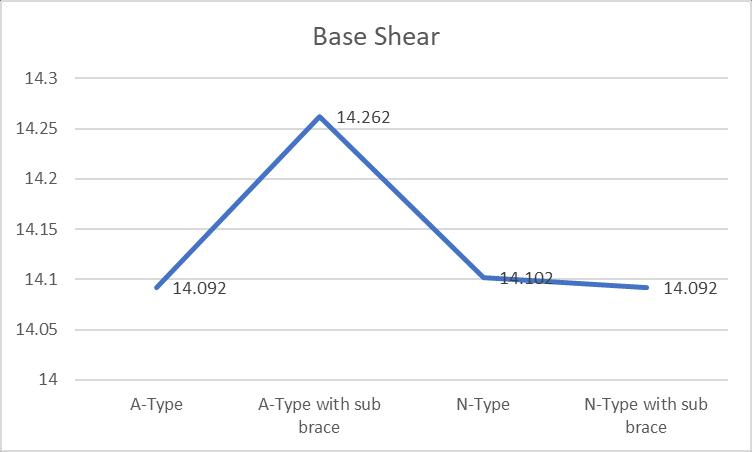

4.1 Base Shear Results

Chart -1:BaseShearComparison

Base Shear (KN)

A-Type A-Type with sub brace N-Type N-Type with sub brace 14.092 14.262 14.102 14.092

Table -2: BaseShearResultComparison

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

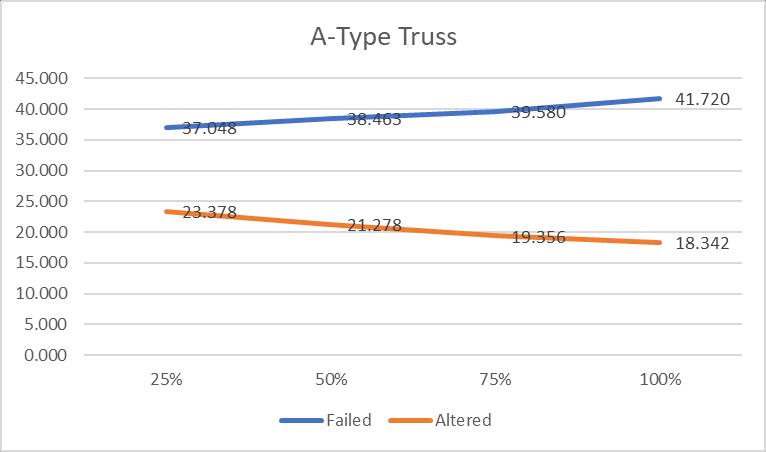

Chart -2:VerticalDisplacementForA-TypeModel

Vertical Joint Displacement (mm)

Actual Model 23.680 25 % Increment model 37.048 23.378 50 % Increment model 38.463 21.278 75 % Increment model 39.580 19.356 100 % Increment model 41.720 18.342

Table -3: VerticalDisplacementForA-TypeModel

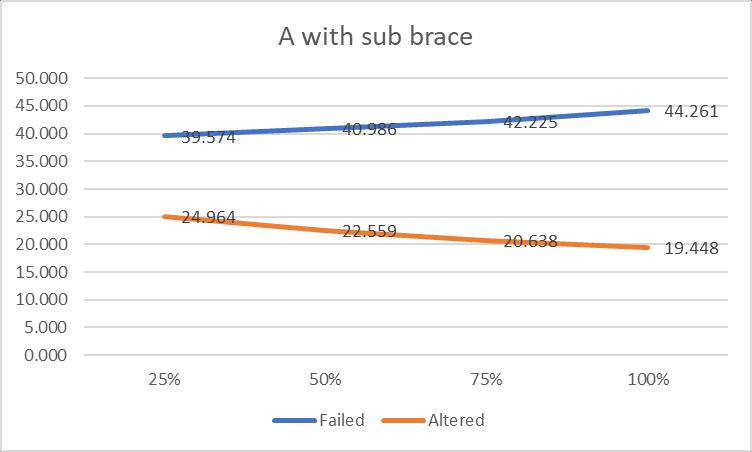

75 % Increment model 42.225 20.638

100 % Increment model 44.261 19.448

Table -4: VerticalDisplacementForA-withSubBraceModel

Chart -3:VerticalDisplacementForA-withSubBrace Model

Vertical Joint Displacement (mm)

Actual Model 24.964 25 % Increment model 39.574 24.964 50 % Increment model 40.986 22.559

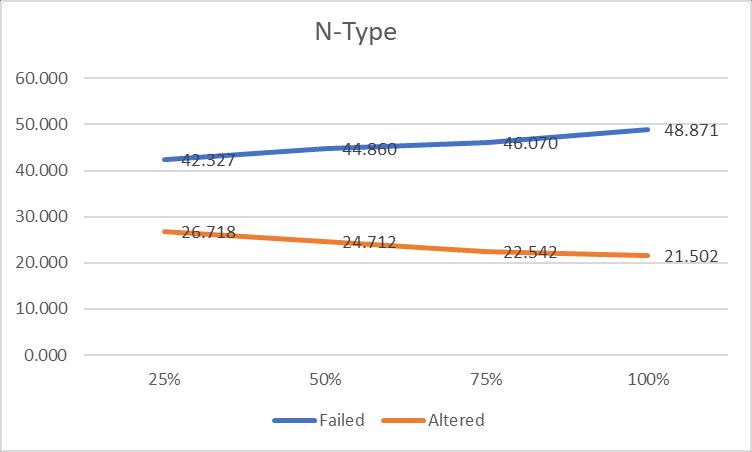

Chart -4:VerticalDisplacementForN-TypeModel

Vertical Joint Displacement (mm)

Actual Model 26.875 25 % Increment model 42.327 26.718 50 % Increment model 44.860 24.712 75 % Increment model 46.070 22.542 100 % Increment model 48.871 21.502

Table -5: VerticalDisplacementForN-TypeModel

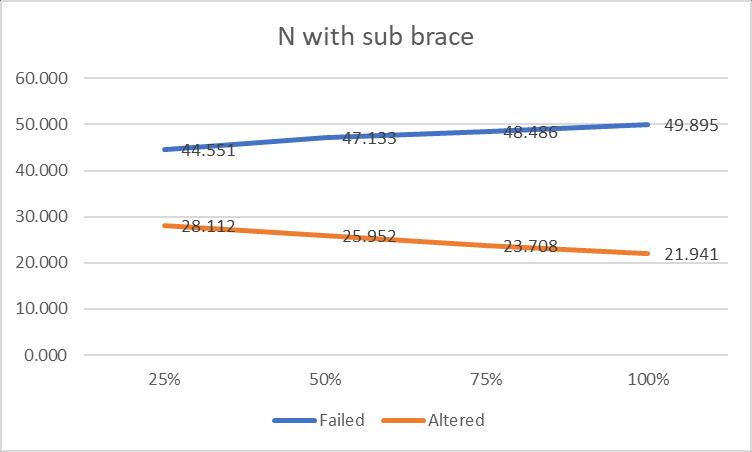

Chart -5:VerticalDisplacementForN-withSubBrace Model

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072

Vertical Joint Displacement (mm)

Actual Model 28.112 25 % Increment model 44.551 28.112 50 % Increment model 47.133 25.952 75 % Increment model 48.486 23.708 100 % Increment model 49.895 21.941

Table -6: VerticalDisplacementForN-withSubBrace Model

Inthisstudy,progressivecollapseanalysisforacontinuous steeltrussbridgewithtotalspanoflength25mwascarried outforfourdifferenttypesoftrussarrangementandwith fourdifferentliveloaddistribution.Thecollapseprocessis different depending on increase in live load at each stage. Liveloadisincreaseby25%(1.25timesofactualliveload) ineachstage.

Inmodel-1andmodel-2whereliveloadisfullyappliedon thespan,Bridgemodel1and2collapseduetothebuckling ofupperchordatthecenterspan.Thecollapseprocessand theultimatestrengthofbridgemodel1and2arealmostthe sameand the sideandcenterspanratiodoes nothave an effect. The number of yield members are more than 60 at buckling and the applied load seems to be redistributed effectivelyafteralteringthemembers.

Inmodel-3andmodel-4whereliveloadisfullyappliedon thespan,Bridgemodel3and4collapseduetothebuckling ofupperchordatthecenterspan.Thecollapseprocessand theultimatestrengthofbridgemodel3and4arealmostthe sameand the sideandcenterspanratiodoes nothave an effect. The number of yield members are more than 73 at buckling and the applied load seems to be redistributed effectivelyafteralteringthemembers.

Theultimatestrainofatensilestressofmemberislessthan 10%inallthecases.Itisthereforeconcludedthatthebridge model does not collapse due to breakage of the tensile memberbutbucklingofthecompressivemembers.

Summarizingtheaboveresults,bridgemodelscollapsedue to buckling of the compressive member in all the cases. When the live load is fully applied in the center span, the span ratio does not affect the ultimate strength which is sufficientlyhigh.

Itisfoundthatmodel 2isbetterto resisttocollapsethan model4andhashigherredistributionofloads.

The authors acknowledge Dr. Atul B. Pujari, Associate Professor Department of civil engineering, KJ College of Engineering&ManagementResearch,PuneMaharashtrafor providing the necessary facilities for the completion of researchwork.

1. Akihiro MANDA*1 and Shunichi NAKAMURA*2 “ProgressiveCollapseAnalysisofSteel TrussBridges” “Received on Sep. 27, 2010 and accepted on Nov. 17, 2010”

2. Kazuhiro Miyachi a, Shunichi Nakamura b, ⁎, Akihiro Manda a “Progressive collapse analysis of steel truss bridges and evaluation of ductility” “Received 31 January2012Accepted29June2012Availableonline3 August2012”

3. Dr.PrashantD.Hiwase,2SVenkatShubham,3AshleshS Reddy,4ArshadAAli“ComparisonofFoot-OverBridge with Different Configuration of Members” “Received: 06th November 2019, Accepted: 10th February 2020, Published:29thFebruary2020”

4. ArturasKilikeviˇcius¯1,DariusBaˇcinskas2,Jaroslaw Selech3,JonasMatijošius1,*,KristinaKilikeviˇciene˙4, DariusVainorius1,DariuszUlbrich3andDawidRomek 3 “The Influence of Different Loads on the Footbridge Dynamic Parameters” “Received: 27 March 2020; Accepted:10April2020;Published:22April2020”

5. Tzu-Ying Lee⁎ , Wen-Hsiao Hung, Kun-Jun Chung “Seismic-induced collapse simulation of bridges using simpleimplicitdynamicanalysis”

6. HoangTrongKhuyena,EijiIwasakib,“Anapproximate method of dynamic amplification factor for alternate loadpathinredundancyandprogressivecollapselinear static analysis for steel truss bridges” “Received 22 March 2016 Received in revised form 30 May 2016 Accepted6June2016Availableonline7June2016”

7. Uwe Starossek “Typology of progressive collapse” “Structural Analysis and Steel Structures Institute, HamburgUniversityofTechnology(TUHH)Denickestr. 17,21073Hamburg,Germany”

8. Liqiang Jianga,⁎ , Jihong Yeb , Hong Zhengc “Collapse mechanismanalysisoftheFIUpedestrianbridgebased ontheimprovedstructuralvulnerabilitytheory(ISVT)”

9. KaimingBia,Wei-XinRenb,⇑,Pi-FuChengc,HongHao “Domino-typeprogressivecollapseanalysisofamultispansimply-supportedbridge:Acasestudy”“Received

Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

22August2013Revised19February2015Accepted19 February2015Availableonline7March2015”

10. ElsaCAETANO,ÁlvaroCUNHA“Studyofthepotentialof collapse of a footbridge under vandal loads” “IABSE SYMPOSIUM LISBON 2005, Structures and Extreme Events,Lisbon,14-16September2005”

11.IRC-6-2017StandardSpecificationsandCodeofPractice

For Road Bridges Section: II Loads and Load Combinations

12.GeneralServiceAdministrationAlternatePathAnalysis &DesignGuidelinesforProgressiveCollapseResistance Revision-1January28,2016

Sagar Jagdish Dhakne Post graduate student Department of Civil Engineering, KJ College of Engineering & Management Research,Pune-411048

Dr Atul B Pujari, Associate Professor Department of civil engineering, KJ College of Engineering & Management Research,Pune-411048

Volume: 09 Issue: 09 | Sep 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |