International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

1M.Tech, Production and Industrial Engineering, Integral University, Lucknow, India.

2Associate Professor, Department of Mechanical Engineering, Integral University, Lucknow, India. ***

Abstract - This paper studied the performance of the CNC machine for cutting thedifferentmetalsheets.Thesummaryof the all research paper is given in detail in the literaturereview section. Due to its favourable qualities, alumina is one of the most extensively utilised technical ceramics for a number of applications rangingfrommicroelectronicstoprosthetics.Due to the extreme hardness and brittleness of the ceramic material, traditional machining processes frequently result in fracture, tool failure, low surface integrity, high energy consumption, low material removal rate, and high tool wear during machining. For the quick processingofbrittleandhard engineered ceramics, laser machining is an option. However, due to heat degradation, the material qualities, particularly the high thermal expansion coefficient and limited thermal conductivity, may induce ceramic fracture. Another flaw in laser cutting is the creation of striations. These disadvantages restrict the use of sophisticated ceramics in engineering. Various lasers and machining processes are studied in this study to see if high quality laser machining of different thicknesses of alumina is possible. The followingarethemajor contributions: I Fibre laser crack free thick section alumina cutting (up to 6 mm thickness). To investigate the effects of process parameters on temperature, thermal stress distribution, fracture initiation, and propagation in laser cutting, a three dimensional numerical model was built. For crack free cutting of thick sectionceramics,aquickparameter optimisation approach was presented. (ii) Surface finish and integrity wereprovenforlow powerCWCO2laserunderwater machining of closed cavities (up to 2 mm depth) in alumina. To examine the physical processes during CO2 laser underwater machining, a three dimensional thermal stress model and a two dimensional fluid smooth particle hydrodynamic model (SPH) were constructed.

Key Words: CNC machine, CO2 laser machine, Metal Sheet, Aluminum Sheet, Pin Profile.

CNCmachiningisacyclewhereassemblingmachinesand instruments are moved as per pre modified PC programming.Accordingly,makerscancreatepartsquicker than expected, lessening waste and disposing of human blunders This creation strategy is utilized to work an assortmentofperplexingmachines,whichwillbecanvassed laterinthisarticle.Fundamentally,CNCmachiningmakesit conceivabletoperformthree layeredcutsbyadheringtoa

solitaryarrangementofguidelines.Thisisthefigureofthe CNCmachine:

Figure 1: CNC Machine.

The CNC machine is classified into eight types, which are givenbelow:

1. CNCMilling Machine. 2. CNC Router. 3. CNC PlasmaCuttingMachine. 4. CNC LatheMachines. 5. CNC LaserCuttingMachine. 6. CNC WaterjetCuttingMachine. 7. CNC ElectricalDischargeMachine. 8. CNC Grinder

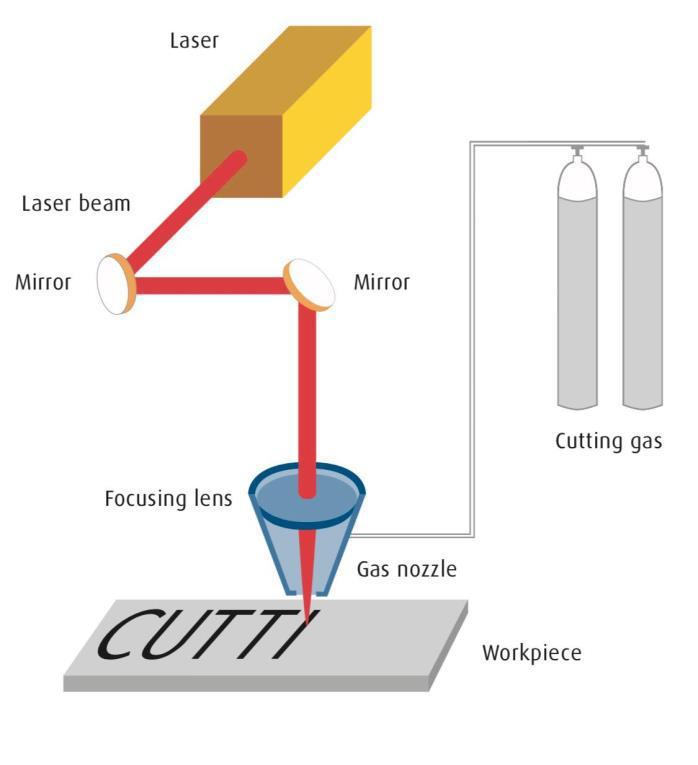

Thiskindoflaserisregularlyusedfordiminishing,dull,and etchingreasons.Theco2lasersareusedinweightyventures for diminishing fabric like slight steel, aluminum, plastic, puresteel,titanium,wooden,andtextures.Amixofcarbon dioxide,helium,andnitrogenareflownoutatextremespeed throughablower.Thelasergeneratorandmindfulnessfocal point require cooling. For the most part coolant or air is utilized for cooling. Water is for the most part utilized for coolantandiscircledthroughachillerorwarmnessswitch framework.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

aCO2lasercutpartifitisworkedinCWmodeandwitha similar laser cutting boundaries, with a 1087 effect more prominentthana0.5mmexpansioninbasemetalthickness ofsheetwithoutsurfacecovering.Theaftereffectsoflaser cuttingonworkpieceshavehorriblemathematicalattributes contrasted and CW laser activity (like sharp internal and external corners,openings, andspaces.all around)can be enormously improved with the utilization of the laser's mathematicalhyper throb,thoughwithapenanceofcutting rate.

Thiskerfcompletelyentersthematerialclosetothefavored decreasedshape.Thisstrategyisahithandiestifthemellow areainfiltratestheworkpiece.Lasermetallicdecreasingis therefore regularly restricted to thin portions. While decreasing has been accounted for through 100 mm segmentsofsteel,thetechniqueismoreprominentforthe mostpartutilizedonmetallicsheets6mm.orontheother handsubstantiallylessinthickness.

Zelený et al [2014]: Actuator check computations are performedforalltomahawksofmovementofthemachineto decide whether they fall inside the plan rules. Because of testingthemostextremespeedoftheX pivotleadscrew,we foundthatbecauseofitslength,theneededtodecreaseits movement speed to 7.6 m × min1. Development of the Y what'smore,Ztomahawksoughttobeconceivablewiththe firstrecommendedspeed,forexample,10mxmin1.Fromthe unbending nature, elements, and power perspective, the actuators offered to meet the necessities. Furthermore, it won't be hard to interface little moving items to the tomahawks. Furthermore, the not set in stone by the task (0.01 mm) should be noticed. In any case, the genuine assemblingprecisionthenotsetinstonefromhereonout. Thegadgetisrightnowinthetestingstage.Thestructureis outfittedwithenergychainswithlinksembedded.Atrialof the laser association with the control framework is in progress.Preliminarycutswerelikewisemade.Weintendto preparethewithonemorekindofcapacitivesensorshaper. Thismakesitconceivabletocutformedsurfacesandavoid thematerialbeingcut.Itwillbeinthefieldoftrainingand examination.

The section outline of the archive concentrated on the functioningsystemofCNClasermachines,plan,andactivity ofCNCmachines.

Gerck, Lima [1997]: Fromanaturallyvisibleperspective, the fundamental determination is that for a 1.5 mm thick gentlesteelplate,thepresenceofa20mmthicklayerofzinc oraluminumcanchangethequality.lastamount.normalfor

Gadallah, Abdu [2015]: Kerf tighten and mean surface harshnessisatthesametimeupgradedduringbeatNd:YAG laser cutting of tempered steel (316L). closes as follows: Taguchi advancement results show that the best draining qualityis150Wlow levelpower,0.5MPagaspressure, 125 Hzsignificantlevelheartbeatrecurrence,and0cmcutting velocity./minute.Ata similarsurfaceunpleasantness,the normalis150Wlow endpower,0.5MPagaspressure,25 Hzlow endbeatrecurrence,and20cm/mincuttingvelocity. PowerandSupportgaspressuresessentiallyinfluencethe nature of the kerf over the working scope of cycle boundaries.Taisessentiallyimpactedbythepower,oxygen voltageappropriation,beatrecurrence,cut offrate,andthe cooperation impact of the tension division and oxygen recurrence.Thenagain,Raisessentiallyimpactedbypower, oxygen pressure, beat recurrence, cutting velocity, the cooperation impact of oxygen tension, and cutting pace. Approval of the RSM models demonstrated that the mean percent deviations in kerf tighten and surface unpleasantnessbecauseofS/Nproportionvalueswere21.1 % also, 2.86%, individually. From the plot of the reaction surface,itisseenthatthebeatrecurrencealso,thecut off ratehavelesseffectonTathandifferentboundaries.Bethat asitmay,lowerupsidesofRacanbegottenatlowerlevelsof

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

cycleboundariesasidefromcuttingvelocityinthecurrent review.

Ranjan et al [2015]: For low end utilizations of CNC innovationdoesn'tneedtoohighaccuracy,minimalexpense computerization can be given by utilizing this program. These developments are intended to be less difficult and have great exactness. Numerous other comparable items, (forexample,drills,processors,punchers,andsoforth)can becreatedatamuchlowerimprovementcost,makingthem reachableforlittleandmediumenterprises.

Jamaleswara et al [2018]: According to modern practicality, the expense of laser cutting and etching machineshasbeenenhancedwithaforceof500mW,anda frequencyof05nm.Givenarecordsurveyandworkprocess steps, the laser cutting and etching machine have been improved. You needtoknowhow tofabricate a displayed laseretchingandcuttingmachineinthelab.Theoutcomeis thebestcuttingandetchingquality.

Habsi, Rameshkumar [2016]: Due to the developing interest for 3axix scaled down CNC machines with high accuracypartsindifferentventures,theretailcostof3pivot little CNC machines has expanded essentially. For the assembling area, little parts should be presented in an adaptableandeffectivewayinanassemblingapproachand decrease all out costs that are reasonable for people and private ventures. Because of effective body part determination and exact adjustment, testing, and get together, CNC machines have accomplished the ideal accuracy and precision. In this work, a small 3 hub CNC machine is planned and produced for modest 150 Omani Rials.Duringtheunderlyingmodelstage,numerousfamous CNCstructureswerefoundandtried.Themostreasonable construction is the support type structure chosen and planned by a French in England. Basic parts, for example, liners,stepperengines,microcontrollers,andmodulesare unequivocallychosenfromcountlessvariouschoicestomeet prerequisites. The best expense parts are chosen to give exactnessandstraightforwardnessaswellasfinancialplan requirements. The gathering of a mechanical part and its appearanceinanelectronicpartisimpeccablyanticipated. TheCNCmachinemodeliscollectedin houseutilizingandin the research facility to satisfy pre gathered testing of machine parts. The means to construct a wooden design were continued exhaustively from a CNC structure organization that was followed to meet accuracy while joiningitintoelectronicandmechanicalpartstogether.The setupandalignmentstepsaredemonstratedwitheveryone ofthesubtleties.Thewholecapacityofthemachineistried utilizing different tests from programming testing to mechanical tests, the underlying imperfections have been explainedanddistinguishedtoguaranteethedependability ofthemachine.machine.

Ji et al. [2017]: presentacrackleslasercuttingtechniquefor Al2O3earthenwareproductionbyaone timeelapseprocess.

Theycanmakestraightandbentprofiles.Itisfoundthatto getabreak freecut,theinteractionboundariesoughttobe as per the following: the cutting velocity ought to be somewhere in the range of 0.23 and 0.2 mm/s when the laserheadmovesataspeedof3mm/s.s,boringtimeought tobe0.1 0.5seconds,penetratingadvanceoughttobe0.03 0.05mm. Power should top at 3500W and the obligation cycle ought to be under 30%. It is reasoned that these outcomesshowthatthebreak freelasercuttingstrategyisa promisingtechniqueforgettingperplexingdesignsinclay materials. CO2 laser cutting for thick ceramic tiles with thicknessesfrom8.5mmto9.2mmhasbeenconcentrated on by Black and Chua [76]. They utilized a mix of various slicing velocities to slice the tiles to decide the cutting boundaries required for various tile calculations. They likewise took a gander at the effect of lessening the utilizationofvariousprotectinggases.Multi linecuttingand submergedslicingwereperformedtotesttheirimpacton heatloadduringhandling.Themainelementbecauseofthe utilization of CO2 laser to cut fired tiles has been demonstratedtobebreakharm,whichisbroughtaboutby the high temperature slope in the substrate surface. It is presumed that the decrease of cycle actuated break development is significant for the business utilization of lasersinceramictilecutting.Inanotherreport,financially accessibleearthenwaretileswerecututilizingaCO2laser shaper,fullyintentonmakingalaserpillarmachining(LBM) datasetcontainingtheboundarydataexpectedforgetting donewithhandling.work.ThiswasfinishedbyBlacketal. [77].Theyconcentratedonvariouslasercuttingboundaries thatcancreatecutsonearthenwaretiles,however,require negligiblepost handling.Theylikewiseconsidertheimpacts of various safeguarding gases, different cutting, and submerged cutting. The impacts of these boundaries have been portrayed previously. Research by Hong et al. [78]. Theyfosteredamodeltoconcentrateontheimpactofthe stateoftheartontheretentionofthelaserpillar.Itwould seema"breakfree"cut,withthelengthofthelittlebreaks restrictedtothegrainsize,canbeaccomplishedutilizinga rapidmulti linecuttinginteraction.Theimpactofinteraction boundariesonthequalitygotbylasercuttingofaluminawas introducedbyWeeetal.[79].Theimpactsofcollaboration time,radiation,andhelpgastensiononqualityresultfactors, for example, periphery point, periphery frequency, and distinctperipherydistancewereexplored.Itwasseenthat the tendency of the periphery was most impacted by the connectiontime,withthesupportinggaspressuremakinga sidedifferenceandradiationassumingaminorpart.Also,it hasbeenaccountedforthatperipheryfrequencyandupper and lower periphery lengths are generally impacted by communicationtimeandradiation,thetwoofwhichcause longer frequencies. Grabowski et al. [80] researched the laser cutting of the AlSi alloy/SiCp composite by demonstrating the calculation of the kerf. They utilized a mathematicalmodeldepictingtheheterogeneousopticaland thermophysicalpropertiesoftheAlSialloy/SiCpcomposite. Foundspeedingupthelasershaftexpandstheslantofthe

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2755

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

bleedingedge.HongandLi[81]concentratedonthelaser cutting strategy for SiN pottery. Their objective was to accomplishbreak freecutsonthisdesigningclaywithhigh throughpututilizingabeatCO2laserQswitchedmechanical shaperwithimprovedprocessboundaries.Itisfoundthat thebeatlengthoughttobeshorttolessenundesirablewarm impactsduringlasercutting.Likewise,theyreportthatthese unwantedwarmimpactscanbeadditionallydecreasedby utilizinghighshearratesandnumerouspasses.Boutinguiza et al. [82] concentrated on shale cutting with a CO2 laser. Theyexaminedtheimpactofspecificinteractionboundaries (normal power and help gas pressure) on the shape and natureofthecut.TheCO2laserhasbeendemonstratedtobe a suitableinstrument for effectivecutting ofshale.Also, it has been affirmed that the component of the CO2 laser slicingrecordislikethatofmetal.Itwasaccountedforthat the utilization of oxygen as the help gas brought about a marginallyspedup.Atlast,itwasfoundthattilesupto13 mmthickcanbecutwithanOKcuttingpaceat1200Wlaser power. Jiao and Wang [83] proposed a double laser pillar technique for slicing glass substrates to work on the cut quality.TheyutilizedanengagedCO2laserbartodefinea straight boundary on the substrate surface, then, at that point,anunfocusedCO2lasershaftwasutilizedtoilluminate thedefinedboundarytomakepliablepressureandseparate thevarioussegments.ofthesubstrate.TheyutilizedANSYS limitedcomponenttechnique(FEM)programmingtowork out the temperature appropriation and the subsequent warm pressure field. It has been reasoned that the glass substrate can be parted along the chosen way with this doublelaserpillarframeworkandthattheslicingqualityis worked on contrasted with cutting utilizing just a solitary unfocusedlaserbar.Anexaminationoftestresultsutilizing CO2andhighpowerdiodelasersundergenerallyidentical exploratorycircumstanceshasbeenintroducedbyCrouseet al. [8]. It has been found that the multifocal diode laser deliversahigherinfiltrationratethantheCO2laserunder practicallyidenticaltrialconditions.

Pushkal Badoniya [2018]: Broadexplorationworkisbeing doneinlasercuttingforworkingonthe natureof thecut. Thesurveyshowsthatthenatureofthecutreliesonmany control variables or boundaries, for example, laser shaft boundaries (laser power, beat width, beat recurrence, methods of activity, beat energy, frequency, and central position); material boundaries (type, optical and warm properties, and thickness); help gas boundaries (type and strain) and handling boundaries (cutting rate). Numerous specialists have explored the impact of these cycle boundaries on various quality attributes, for example, materialexpulsionrate(MRR),kerfqualityattributes(kerf width,kerfdeviation,andkerftighten),surfacequality(cut edge surface unpleasantness, surface morphology), metallurgicalqualityattributes(recastlayer,heatimpacted zone,oxidelayeranddrossconsiderations)andmechanical properties(hardness,strength).

N. Yusoff et al. [2019] concentratedontheCO2lasercutting strategyonlighthardwoodinMalaysia.Theyendeavoredto lay out the connection between handling boundaries and woodspecieswithvariousproperties,decidingidealcutting circumstances.Likewise,theypresentguidelinesforcutting an assortment of Malaysian woods. Dampness has been accounted for to lessen cutting proficiency since water promptly assimilates CO2 laser radiation. It has likewise been demonstrated the way that utilizing an idle gas, for example, nitrogen can be gainful and produce a greater finished result. In any case, they guide out that this suppositionneedstobedemonstratedthattherelatedcosts arenotentirelysetinstonebeforethemethodologycanbe legitimate. Hattri [66] attempted to think about various lasersincarpentry.HeconcludedthattheCO2laserwasthe most logical since it was easier to achieve a larger energy thicknesswiththeCO2laserthanwiththeYAGlaserwhile workingwithwood.Theparametersimpactingthelaser's abilitytocutwood,accordingtoBarnekovetal.[67],maybe divided into three categories: laser pillar qualities, gadget andcyclefactors,andworkpiecefeatures.Theydiscovered thatmostwood cuttinglasershadpowersrangingfrom200 to800W.Theyclaimthatthebestcombinationofcutting velocity and laser power depends on the workpiece thickness,thickness,andoptimalkerfwidthformaximum precision. Furthermore, they discovered that cutting wet woodrequiresmorepowerthancuttingdrywood,providing thecuttingvelocityremains constant.Barnekov etal.[68] conducted yet another review on laser cutting of wood composites.Usinglaserpowerrangingfrom00to500Wand a cutting velocity of 20 in/min, they discovered that the optimal centre point is at the surface. They also used compressedairwitha0.05 inchspoutwidth.Finally,they stated that these preliminary findings suggest that laser slicingofwoodshouldbeinvestigatedfurther.BothKhanet al.[69]andMukherjeeetal.[70]conductedlasercuttingof developing wood experiments. Both studies looked at the importance of focusing on LBC limitations such as laser power,cuttingrate,spoutlayout,andvariationinprotecting gas speed, as well as their influence on the type of the safeguard. Lum et al. [71] discovered optimum CO2 laser cuttingconditionsforMDF.Theydiscoveredthatwhenthe cuttingspeedincreased,theusualkerfwidthshrank.Ithas been demonstrated that the arrangement of MDF, which includesextracomponentssuchascovers,folios,tar,andso on,isalsocapableofcreatingvariationinthecuttingrate. Furthermore, they said that no significant reduction in cutting breadth was seen when the kind or tension of the protectinggaswaschanged.Theyalsosaidthatincreasing thegaspressuredidnotresultinanincreaseintheRavalue. TheRavalue,ontheotherhand,risesasthecuttingvelocity rises.Finally,theydemonstratethatthemostsevereshear rate for any thickness is independent of tension or gas expansion. As a result, using compressed air rather than nitrogentolasercutwouldbemoreefficient.MDF.Ngetal. [72] carried out their investigation to see how power dispersion varied with different cutting speeds, material

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2756

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

thicknesses, and heartbeat proportions. They were successfulindevelopingatestdevicetodeterminecritical powermisfortuneswhilelasercuttingMDF inCWor beat mode.LetellierandRamos[73]discoveredthatcuttingMDF sheetswiththicknessesmorethan8mmwhilemaintaining thecentrallocationstableatthesurfaceresultsinkerfswith bent sides. As the MDF board grows thicker, the sidelong form increases. Similarly, they changed the shaft's centre position and speed to focus on the influence on the horizontalstream'scondition.Foreachboardthicknessand interactionboundarymixes,theyproposeacentralscenario. They also had the option of combining a histogram of the centresituationwiththethicknessoftheboardfortheleast edgekerfwithachartofthecuttingvelocityvsthethickness oftheboardtodetermineoptimalcuttingconditions.witha reasonablelaserpower

Jayaprasad et al [2020]: By utilizing the CNC regulator, item quality, as well as high adaptability, have expanded fundamentally. It increments efficiency and diminishes execution time. This equipment coordinated effort with Gcode and Mode brings about improved efficiency and decreasedresponsibility.GcodeandModemakeitsimpleto findthepositiondataofallmovingstepperengines,asthe conditionofourmovingengineisshownstraightforwardly onthePC.Buildingalittlemachineextendsadaptabilitywith regardstodoingtheemploymentopportunityandlessens prototyping costs, making it usable for cutting paper, polystyrene, and flimsy sheets. This piece is planned and produced for a minimal price. Taking everything into account,theaccuracyplanandproductionoftheCNC based lasercheckingmachinebodygettogethereffectivelymetthe exactnessandrepeatabilityobjectivesofthistask.

Mehendiratta et al [2020]: Inthisexplorationpaper, we utilize the idea of a minimal expense CNC laser etching machine that is handily controlled through a PC. Our undertaking isa minimal expense project contrasted with other significant expense machines. The machine has a genuinelybasicconstructionandcanbeconveyedanyplace absentalotofexertion.Numerousdifferentspecialistshave utilized various sorts of streamlining methods like GLA strategies,ANOVAexamination,andsoon.Ourmachinesare reasonable,simpletowork,anddon'tneedgiftedfaculty.

Oktatian et al [2021]: Inthisreview,wedirectedareview todecidetheidealsettingofcycleboundariesduringacrylic cutting with a CO2 CNC laser shaper. The trial was performed utilizing the Taguchi multi reaction strategy including four responses, to be specific, treatment time, layered exactness, surface harshness, and fossil fuel byproducts. Taguchi's strategy was utilized to decide the SNR for every reaction. The GRA strategy was utilized to decide the ideal setting of the interaction boundaries for everycomponentofthetrialatthesametime.Thereaction surface technique (RSM) was applied to decide the numerical model given the consequences of the trial to empower multi objective improvement and to decide the

specificworthoftheidealcycleboundaries.simultaneously compromise the input. In light of the consequences of the trial,theidealcycleboundariesare65%laserpower,mm/s cuttingpace,andmmspoutseparating.Whileasindicatedby the consequences of the RSM technique, the ideal cycle boundariesare75%laserpower,5.9mm/scuttingpace,and 3mmspoutdispersing.

Afterstudyingthealltheresearchpapersintheliterature review section the following conclusion found which are givenbelow:

The finishing quality on the surface of the metal sheet is dependinguponthegaspressurewhichejectsfromthepin profileoftheCNCmachine.Whenthepressureofthegasis lowandvaryingthenthesurfaceofthemetalsheetisrough.

Fromthesestudiesthatthesurfaceroughnesschangeswith cuttingspeedandlaserpower.1.2KWto2.6KWofLaser power by cutting with a CO2 laser cutting machine. The potential for laser cutting can be greatly enhanced by automation and adaptive control to achieve high process efficiencyandhighcutquality.Torealizeadaptivecontrolof the laser cutting process three major developments are required: firstly, the development of in process quality analysissystems;secondly,thedesignanddevelopmentof electronically controlled parameter adjustment of the process parameters and finally the development of the processcontrolhardwareandsoftware.

1. Gabzdyl J. T., “Effects of gases on laser cutting of stainless steels”, In Laser Materials Processing: Proceedings of the International Congress on ApplicationsofLasers&Electro OpticsICALEO'96 heldinDetroit,Michigan,USA;14 17October1996, pp.C39 C44

2. RajaramN.,Sheik AhmadJ.,andCheraghiS.H.,“CO2 laser cut quality of 4130 steel”, International JournalofMachineTools&ManufactureVolume43 (2003)pp.351 358

3. Anon., “Stainless Steel Overview: Applications”, http://www.ssina.com/overview/app_intro.html, referenced10/01/2006

4. Anon., “Stainless Steel”, http://www.nisshin steel.co.jp/nisshin steel/english/profile/stain.htm, referenced10/01/2006

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2757

5. Anon., “Types of Stainless Steel: Austenitic” http://www.assda.asn.au/asp/index.asp?pgid=180 41&cid=34330&id=56984,referenced10/01/2006.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

6. Balbi M., Silva G., “Stainless steel plate cutting: thermal and mechanical cutting. Laser cutting someobservations”,AvestaStainlessBulletin,Oct. Nov. Dec.1982,Volume6,Number4,pp.3 11

7. Crafer R. C. and Oakley P. J., “Laser Processing in manufacturing”, Chapman & Hall, ISBN 0 412 41520 8,pp.1,13 15

8. Golnabi H. and Mahdieh M. H., “Trend of laser research developments at global level”, Optics & LaserTechnology,Volume38,Issue2,March2006, pp.122 131

9. DirkPetring,“LaserCutting”,LIAHandbookofLaser Materials Processing, I st edition, 2001, Laser InstituteofAmerica,ISBN0 912035 15 3,pp.425 433

10. ThomasR.Kugler,“Nd:YAGLasers”,LIAHandbook of Laser Materials Processing, 1 st edition, 2001, LaserInstituteofAmerica,ISBN0 912035 15 3,pp. 37 44

11. Rajendran Natarajan, Ph.D. Dissertation: “An experimentalandtheoreticalstudyofheattransfer effects during a laser cuttingprocess”,IowaState University, 1990, U.M.I Dissertation Information Service,OrderNumber9100495,pp.1,10 12,69

12. Hügel H., “New solid state lasers and their application potentials”, Optics and Lasers in Engineering,Volume34(2000),pp.213 229

13. AdolfGiesen,“ThinDiskLasers Powerscalability and Beam quality”, http://www.pro physik.de/Phy/pdfs/NEWS_PDF_GER_6737.pdfand http://www.wiley vch.de/berlin/journals/ltj/05 02/LTJ02_42_45.pdf,referenced20/10/2005

14. ThomyC.,SeefeldT.andVollertsenF.,“High Power FiberLasers ApplicationPotentialsforWeldingof Steel and Aluminium Sheet Material”, Advanced Materials Research,Volumes6 8,(2005)pp.171 178,availableonlineathttp://www.scientific.net/

15. EuropeanCommitteeforStandardization,“Thermal cutting Classificationofthermalcuts,Geometrical product specification and quality tolerances”, EN ISO9013:2002(ISO9013:2002)

16. Anon., “High Powered Disk Laser” from http://www.trumpf laser.com/208.img cust/Disk_Laser.pdf; “The Disk Laser” from http://www.trumpf laser.com/208.img cust/Scheibenlaser_engl.pdf;“TheHLDCWLasers”

from http://www.trumpf laser.com/208.img cust/HLD_Laser_engl.pdf, and “Disk lasers Technical data” from http://www.trumpf laser.com/208.index.html,referenced29/09/2005

17. Anon., “DS series (disc): principle”, http://www.rofin.com/index e.htm, referenced 24/09/2005

18. ZapataL.E.,BeachR.A.,MitchellS.,andPayneS.A., “Yb Thin Disk Laser results”, http://www.llnl.gov/tid/lof/documents/pdf/24617 7.pdf,referenced24/09/2005

19. John Vetrovec, Rashmi Shah, Tom Endo, Andrea Koumvakalis, Kevin Masters, William Wooster, KennethWiden,andStevenLassovsky,“Progressin the development of solid state disk laser”, http://www.kigre.com/yb16.pdf, referenced 20/05/2005

20. Reinhart Poprawe and Wolfgang Schulz, “Developmentandapplicationofnewhigh power laser beam sources”, Fraunhofer Institut Lasertechnik ILT, Germany, http://www.ilt.fraunhofer.de/ilt/pdf/ger/50_003.p df,referenced24/09/2005

21. Anon., “The Thin Disk Laser Technology”, http://www.fgsw.de/homepage/leistungen/produk te/scheibenlaser/ThinDiskTechnology_LOT_2005.p df,referenced29/09/2005

22. Anon., “Laser Focus World May 1999” http://lfw.pennnet.com/Articles/Article_Display.cf m?Section=Archives&Subsection=Display&ARTICLE _ID=31572,referenced20/09/2005

23. ChristianSchmitz,“TRUMPFDiskLaser Statusand Prospect”, Trumpf Technology Day Disk Laser, Schramberg,27 th January2004

24. WolframRath,“Disclasersandtheirapplications”, ROFIN SINARLaserGmbH,OpenHouseRofinSinar 2004,20 th April2004

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2758