Volume:

BOND STRENGTH OF BETHEMCHERLA STONE WASTE CHARACTERSITICS AGGREGATE CONCRETE

K MOHAMMAD ZAKI, C. RUKMUNNISA SULTHANA, C. NAGARJUNAABSTRACT

A trial examination was led in any built up substantial development, the heap move among steel and encompassing cement happens in light of bond. The codes of training give significance on advancement length prerequisites for move of burden from steel to substantial which depends on the bond strength between them. Bond strength is the shearing pressure created at the steel substantial connection point a record of composite collaboration between the two materials, contributing towards flexibility part of underlyingwayofbehaving.Theconnectionbetweenthe steel and cement empowers the two materials to act together without slip at as far as possible state and endlesslycontrolsthebreakwidthandredirection.

Atextremecutoffexpress,thestrengthoflapsandjetties relies upon bond. The bond pressure in built up substantialindividualsemergesfromtheharborsofbars and change in bar force along its length or because of fluctuatingtwistingsecond.Activationofbondshouldbe guaranteed under an assortment of stacking circumstance like strain, pressure and flexure. Many examinations on ordinary cements (CCs) are accessible, however relatively few examinations are accounted for on the bond strength of built up concrete contain bethemcherla total in the halfway substitution of rock totalandtheutilizingofPPCement,restrictingwirefiber assupportwiththesteelbars.

The examination in this paper are pointed toward readingupthebondqualitiesforconcreteinlightofthe bethemcherla total with fractional substitution of rock total of 0%, 25%, 50%,75 and 100 percent, With the limiting wire fiber of 1% and 2%. The cover material of PPC in the traditional cement (CC). This was finished utilizingHSDbarof12mmdistanceacross.

Presentation

INTRODUCTION:

In the years after the nationwide conflict, the early pioneers came to Kansas and found the grasslands almost treeless. As they broke the grass, they found bethemcherlastone,whichtheycalledamateur.Thiswas a readymade building material. The main homes were called holes. As time won the pioneers wiped off the stone and quarried it into building materials. They utilized these to construct homes, stables, corrals, and fenceposts.Thepostwereutilizedwiththeinnovationof thorn wire, as the earliest type of fencing domesticated

animals.Thesescaleddownstonesarehighqualityfrom the equivalent be them cherlastone that was utilized in theearlyyears.

Albeit this little stone doesn't weigh a lot, its bigger siblings weigh around 300 to 500 pounds. More than 40,000milesoffencewereimplicit50years,utilizingthe stone posts. Asignificant number ofthesearestill being usedtoday.Insuchmanneranitemizednewpresentfor underneathforbethemcherlastone.

Be them cherlastone is a sedimentary stone made principally out of calcium carbonate (CaCO3)intheformofthemineralcalcite.Itmostcommonlyf ormsinclear,warm, shallowmarinewaters.Itisusuallyanorganicsedimentaryr ockthatformsfromthe aggregation of shell, coral, algal and waste garbage. It can likewise be a compound sedimentaryrockformedbytheprecipitationofcalciumcar bonatefromlakeoroceanwater.

Bethemcherlastoneiscalcareoussedimentaryrocksformed atthebottomoflakesandseas with the gathering of shells, bonesandother calciumrichproducts.It ismadeout of calcite (CaCO3). The natural matter whereupon it gets comfortablelakesoroceans,areprotectedasfossils.

Thestonewhichcontainsover95%ofcalciumcarbonate is known as hiigh calciumbethemcherlastone.Re crystallizedbethemcherlastonetakesgoodpolishand is generallyutilizedasenrichingandbuildingstone.

A piece of calcium particles assuming that being supplanted by magnesium, it is known asmagnesium bethemcherlastoneordolomitebethemcherlastone. Bethemcherlastone that will take a clean are viewed as marbles by the vast majority, yet actually, assuming there are still shells noticeable or the design isn't translucent,itisasyetabethemcherlastone.

TargetsandSCOPEOFPRESENTSTUDY

The extent of present examination is to review and assess the compressive ansd bond strength of concrete, ready with poor quality bethemcherla stone waste total. The substitutions of % of bethemcherla stone total (0, 25,50,75,and100percent)andCrimpedSteelFibers(0, 1and2%) inconcrete.For all blends blocksofstandard size 150mmx150mmx150mm were projected and tried for 28 compressive strength and bond qualities in the researchcenter.

Goals

The particular goals of the current examinations are as recordedbeneath.

International

Engineering

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

gation of creating bethemcherla stone substantial utilizing Crimped Steel Fibers

compaction factor and vee honey bee time on substitutions of bethemcherla stone total (0 100 percent)alongsidecreasedsteelstrands(0 2%)

Technology (IRJET)

e ISSN:2395 0056

p ISSN:2395 0072

Inthetabletheclassificationofblendscanbeperusedas

i) NC 0: Where NC alludes to Granite Aggregate Concrete, '0' alludes to % substitution of Natural Coarse totalbyBethemcherlastoneConcrete. ii) LC

25:WhereLCreferstoBethemcherlastoneConcreteand'25' refersto% substitution of rock total by Bethemcherla stonetotal. iii) LC

50:WhereLCreferstoBethemcherlastoneConcreteand'50' refersto% substitution of rock total by Bethemcherla stonetotal iv) .LC

75:WhereLCreferstoBethemcherlastoneConcreteand'75' refersto% substitution of rock total by Bethemcherla stonetotal v) LC

100:WhereLCreferstoBethemcherlastoneConcreteand'10 0'refersto% substitution of rock total by Bethemcherla stonetotal

(Hearafterforothertestresultsthesamenomenclatureused inthesubsequentareas)

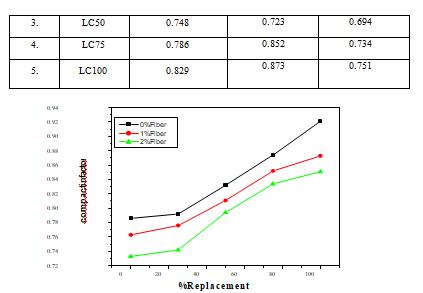

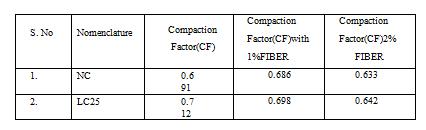

Fromthegotresults,itisseenthatthecompactionfigure increment with increment the % of bethemcherla stone total in the substantial blend. HankfiBinci et.al (2008) has been likewise revealed same kind of outcome for marbleconcrete.Theincrementoffunctionalitymightbe because of lower water ingestion and smooth surface of bethemcherlastonetotalthantherocktotal

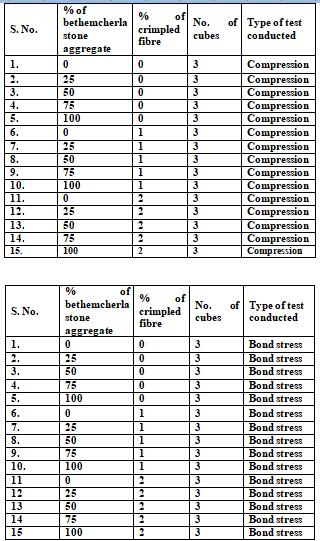

TESTPROGRAMME

To assess the strength attributes as far as Compressive strength and Bond strength, a sum of 15 blends were attempted with various rates of bethemcherla stone totals(0,25,50,75,and100percent)andvariousratesof pleatedsteelstrands(0,1and2%).Inallblendsasimilar kind of total for example squashed rock total; waterway sand and a similar extent of fine total to add up to total areutilized.Theoverallextentsofconcrete,coarsetotal, sand and water are gotten by IS Code strategy. M20 is consideredasthereferencemix.(Appendix I)

The boundaries concentrates on are:Percentage of bethemcherlastonetotal 0,25,50,75,and100percent.

• LevelofCrimpedSteelFiber 0,1&2%.

DISCUSSION OF TEST RESULTS

The usefulness of blends has been estimated by Compaction factor test. The upsides of compaction factorsresultsareintroducedinTable5.1andFigure5.1.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008

2395

Volume:

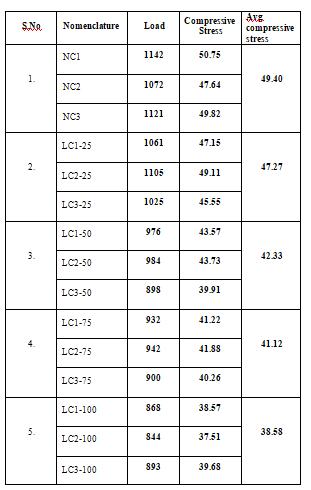

Influence of be them cherla stone aggregate on compressive strength.

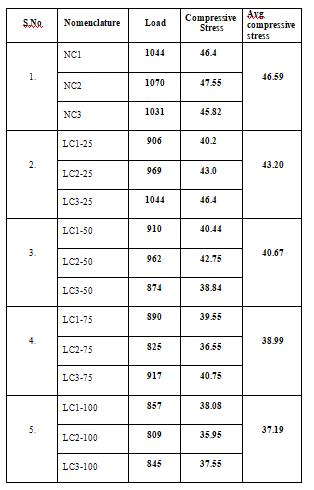

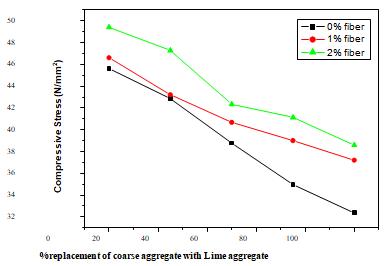

The compressive strengths for all mixes are presented in table5.2, 5.3, 5.4 and Figures 5.2. From this, it can be observed that the 28 days compressive strength decrease with the increase in the percentage of bethemcherla stone up to 100%. For 25% replacementofbethemcherla stone aggregate thereis decrease in cube compressivestrengthby6.07%over graniteaggregateconcrete.For75%replacementlevel, the compressive strength has decrease by 23.35% when compared with reference concrete. At 100% replacement of bethemcherla stone, the compressive strength has decreased by 29.26% over granite aggregate concrete. This type of observation was observed by HanfiBinici et.al (2008) for marble concrete. But Hebhoub et.al (2011) reported in different way for marble concrete. aggregates. Same pattern observedwith incorporation of crimpled fiber also. For 1% fiber at 100% replacement of bethemcherla stone, the compressive strength has decreasedby 20.17%overgraniteaggregateconcrete. For 2% fiberat 100% replacement of bethemcherla stone, the compressive strength has decreased by21.90%overgraniteaggregateconcrete.

e

p

Table Compressive Strength values in N/mm2 for 1% Fiber

Table Compressive Strength values in N/mm2 for 2% Fiber

Figure CompressiveStrengthvs.%Bethemcherlastone aggregateInfluenceofbethemcherlastoneaggregateon bondstrength.

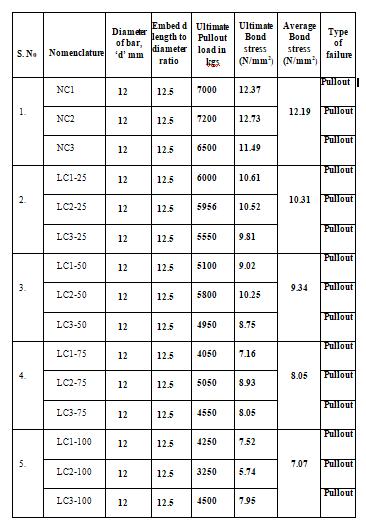

The bond strengths for all mix esare presented in table andFigures

Fromthis,itverywellmaybeseenthatthe28daysbond strengthdeclinewiththeincreaseinthelevelofbethem cherla stone up to 100 percent. For25% substitution of bethemcherla stone total there is decline in block bond strength by 15.42% more than granite aggregate concrete. For75% replacement level, the bond strength has decrease by 33.96% when contrasted and reference concrete. At 100 percent substitution of bethemcherla stone, the compressive strength has diminished by 42.00% over rock total cement. This kind of perception wasseenbyHanfiBiniciet.al(2008)formarbleconcrete. In any case, Hebhoub et.al (2011) revealed in various wayformarbleconcrete.That'swhattheyannounced,at 75%substitutionlevel thestrengthwasimprovedwhen contrasted and different substitutions and at 100 percent substitution level there was decline in compressive strength. While from present exploratory work it is seen that there is constantly decline in compressive qualities as level of bethemcherla stone total expansions in substantial blend. This might be because of various surface of totals. Same example saw withconsolidationofcrimpledfibertoo.

For1%fiberat100%replacementofbethemcherlastone,the bondstrength has diminished by 14.15% over rock total cement. For 2% fiberat 100 percent substitution of bethemcherla stone, the compressive strength has diminishedby18.14%overrocktotalcement.

Engineering

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

Table Bond Strength values in N/mm2 for 0% Fiber

Failure Mode Analysis

For everything 3D squares pressure test was directed. The 0% filaments substantial solid shapes were shown lower load when compared with cubes containing with 1 and 2%. Among the 1 and 2% fiber 3Dsquarestheblockswith2%showedhigherburden conveyinglimit.In0%fiber3Dshapesthesubstantial was strip off at edges this can be seen in the figure5.16, whereas the 3D squares containing filamentsdisplayedthereisnostripoffandaslevelof fiber expands the break with and less harm was seen duringtrialanderror.

Foreachblend threesolid shapesweretriedfor bearing strength with bearing ratio of 5,10 and 15.In

Technology (IRJET)

e ISSN:2395 0056

p ISSN:2395 0072

every one of the 3D squares it were seen to during trial and error spiral breaks. This can be seen from figure 5.4 to figure 5.12 This kind of breaks were likewise observed by S. A. Al Taan and J. A. Al Hamdony (2005) for steel fiber concrete. The layered solidnessissomething else forhigher ratesubstantial blocks when contrasted and other rate strands and furthermore the break width is diminished as the % offibercontentincrements

CONCLUTION

The accompanying ends might be drawn from thepresentexploratorywork

Theworkabilityforbethemcherlastoneaggregatei sincreaseswithcomparedwithstonetotalcement.

The bond strength were diminished with increment the be them chelas stone total in the substantialblend.

The incorporation of be themcherla stoneupto 75%isbeneficialfortheconcreteworks.

Thefailuremodesaresimilarforbothbethemcherla stoneandgraniteaggregateconcrete.

The utilization of bethemcherla stone total for substantial works is shown in bond strength and compressivequalities

This study could enligh ten the local peoples to use of be them cherla stone aggregate for substantial works(minorworksatbeginningstages).

REFERENCES

1. P.Torres,“Incorporatedthegranitecuttingsludgein industrial porcelain tile formuations”. A journal of theEuropeanceramicsociety24(2004)3117 3185.

2. Mustafa karasahin and SerdaTerzi, “Evaluation of marble dust in the mixture of asphaltic concrete”,Construction and Building Materials, Vol 21,2007,pp.616 620

3. Almeida,N.,Recycling of stone slurry in industrial activities:Applicationtoconcretemixtures.Building andEnvironmentvol 42,2007,pp.810 819.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

Volume: 09 Issue: 04 | Apr 2022 www.irjet.net

4. HanifiBinici, “Durability of concrete made with granite and marble as recycle aggregates”,Ajournal of material processing technology.vol 208, 2008,pp. 299 308.

5. HuseyinAkbulut and CahitGurer, “use of aggregate produced from marble quarry waste in asphalt pavements”,Building and Environment vol 42,2007,pp.1921 1930.

AUTHORS

1. K MOHAMMAD ZAKI M.TechScholar CIVILEngineering, SSSISE,ANANTAPUR.

2. C. RUKMUNNISA SULTHANA, AssistantProfessor, CIVILEngineering, SSSISE,ANANTAPUR.

3. C. NAGARJUNA AssistantProfessor, CIVILEngineering, SSSISE,ANANTAPUR.

(IRJET)

e ISSN:2395 0056

p ISSN:2395 0072