Abstract - This paper presents an investigation on self compacting Mortar (SCM) with three cementitious contents. The work involves three types of blends namely ternary & quaternary, the first &second consisted of different percentages of fly ash (FA), Metakaolin (MK) & Silica fume (SF) as a cement replacement [0 40,0 20 & 0 15 by weight %(wt.), respectively] and the third uses different percentages of fly ash (FA), metakaolin(MK) & silica fume (SF) withatotal oftenternary mixes, two quaternary mixes were designed. for each mix designed, the mini slump andminiV funnel testsare carried out on the fresh SCM, and nine cubes and prism specimens of each are cast and cured in water for 7,14 & 28 days and hardened properties of Mortar like compressive strength & flexural strength values are determined in the laboratory. The results show that ternary SCM mix with 20% ofFA,10% MK (M1.2) and10% MK, 5%SFandquaternarymix with 20% FA, 10% MK and 7.5 % SF gives values of compressive strength and flexural strength higher than reference mix at 28 Days of water curing.

Self compacting Mortar has basic naturally available ingredients such as cement, sand, Superplasticizer, and water.Afterthewater,cementisthe2nd mostusedmaterial intheworld.Butthisrapidproductionofcementcreatestwo bigenvironmentalproblemsforwhichwemustfindoutcivil engineering solutions. The first environmental problem is theemissionofCO2 emissionisveryharmfulwhichcreates lots of environmental changes. 1 ton of carbon dioxide is estimatedtobereleasedintotheatmospherewhen1tonof ordinaryPortlandcementismanufactured.Peopleworking in the environmental field create awareness in the public abouttheenergysourceslikepetrol,dieselislimitedinearth crestandforthefuturegeneration,wehavetosaveitorwe have to find alternative energy sources. But the people working in the construction field are having the same awareness about line consumption. This is the second environmentalproblemrelatedtotheconsumptionoflime. Asthereisnoalternativebindingmaterialthatreplacesthe cementsotheutilizationofpartialreplacementofcementis wellacceptedforself compactingmortarcomposites.

1.1 Advantages and applications of SCM

2Associate Professor, Dept. of Civil Engineering, University Visvesvaraya College of Engineering, Banglore 56, Karnataka, India. ***

Mortarisconsistent,stable,andeasytohandle. Moreflowableandcanaccessintonarrowfills. Self compactedwithagoodsurfacefinish. Actasabindingagenttovariousstructuralfills Mortariscorrosion resistant.

Usedinflooringtiles,roofing,andalsoforgroutfilling Mortaractsasaprotectivelayer,usedforwaterproofing Highstrength High strength fiber reinforced SCM's are used to caste sheetpiles. Used to develop kitchen work surfaces which is aestheticallygoodatappearance. Usedindevelopingsinks,cupboards,andotherinterior andexteriordesigns. Usedinfillingcracksandjoints. SCM'scanbeusedinsprayedmortars.

Key Words: Self compacting mortar, Ternary mix, quaternary mix, Compressive strength, Flexural strength

1.INTRODUCTION

Study on Rheological & Mechanical Properties of SCM using Mineral Admixture as a Partial Replacement of Cement Hanchalappa1 , S Bhavanishankar2

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1066

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 02 | Feb 2022 www.irjet.net p ISSN: 2395 0072

1M.Tech scholar, Department of Civil Engineering, University Visvesvaraya College of Engineering, Banglore 56, Karnataka, India, Karnataka, India

Withthedevelopmentofconstructionofmegastructures,the world over, the need for self compacting concrete (SCC) applicationsareincreasing.Manysiteshaveproblemswith congestion of reinforcement in principal structural members.Thedesignissuesarecompoundedduetothehigh riskoftheearthquakezone,vulnerabilitytocyclonicstorms, andhugecapacityadditionoftheplantstoaverylargescale. SCC has become the only choice in such difficult site environments. Ideally, the development of concrete mix whereplacingandcompactionhaveminimaldependenceon theStandardofworkmanshipavailableonaparticularsite shouldimprovethetruequalityoftheconcreteinthefinal structure, and hence its durability. This was an important driving force behind the development of self compacting concrete(SCC). Self compacting concrete is considered a breakthrough in concretetechnologyduetoitsimprovedperformanceand working environment. It has wide application from thin elementstobulkrobuststructures.SCCcanbetakenasthe greatest technological advancement and most advanced developmentinconcretetechnologyovertheyears.SCCis concreteofthefuture,asitwillbesubstitutingconventional concreteduetoitsdistinctadvantages.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 02 | Feb 2022 www.irjet.net p ISSN: 2395 0072

5.4 Silica fume SilicaFumeusedwasconfirmingtoIS153882003,IS1727 1967,ASTMC1240 14&EN13263andwassuppliedby“LA GREENS”.TheSilicaFumeisusedasapartialreplacementof cement up to 15% at an interval of 5%. The properties of SilicaFumeareshowninTable1&2.

Based on literature study rheological and mechanical properties are studied in the laboratory with different admixtures. SCMmixesaredevelopedintheinthelaboratory.with industrialbyproducts Ternary&quaternaryblendedSCMmixesaredeveloped inlaboratory Freshpropertiesarestudiedusingminivfunnel&mini slumpcone. Hardenedpropertieslikecompressive&flexuralstrength arestudied.

3. AIM AND SCOPE OF THE PRESENT STUDY

5. 5.1MATERIALSOrdinaryPortland Cement

It is cost effective, as cement content can be replaced withpozzolanicashes.

Table 1: ChemicalCompositionofCementitiousMaterials CompositionChemical OPC ashFly Metakaolin SilicaFume CaO 63.87 2.23 0.02 0.29 SiO2 20.62 58.55 53.20 92.00 Al2O3 4.87 28.20 43.90 0.46 Fe2O3 3.35 3.44 0.38 1.60 MgO 1.54 0.32 0.05 0.28 K2O Nil 1.26 0.10 0.61

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1067

Fig 1:SamplesofMineraladmixtures.

Ordinary Portland Cement of Zuari brand of 43 grades confirming to IS: 8112 2013 & EN 197 1 was used in the presentstudy.ThepropertiesofcementareshowninTable 1&2 5.2 Fly ash FlyashusedwasconfirmingtoIS38121981,EN450&was suppliedby“JSWCement”.Itisusedasapartialreplacement ofcementupto40%atanintervalof10%.Thepropertiesof FlyashareshowninTable1&2. 5.3 Metakaolin Metakaolin used was confirming to ASTM C 618 and was supplied by “JSW”. The Metakaolin is used as a partial replacement of cement up to 20% at an interval 5%. The propertiesofMetakaolinareshowninTable1&2.

2. OBJECTIVES OF THE PRESENT INVESTIGATION

Severalliteraturereviewsonthereplacementofcement by mineral admixtures such as Fly ash, Silica fume, Metakaolin,etc.inSCC/SCMmixesarestudied. In this investigation, cement mortar of 1:2 ratio is considered & Percentage of different admixture is determinedreferringtovariousresearchpapers. Preliminary basic tests are conducted on material samplesandareprocuredonsatisfyingthecriteriagiven bythecodes. Marshconetestwasemployedinthelaboratorytofind theoptimumdosageofsuperplasticizer(MasterGlenium 8233). In this investigation, fresh properties are determined using mini slump and mini v funnel test & Hardened properties like compressive strength and Flexural strengtharedeterminedat7,14,28daysofwetcuring.

Theaimofthepresentstudyistoproducegreenmortarby use of industrial by products which are a threat to the environmentondisposedofbyanymode. Making use of these byproducts to produce binary, ternary & quaternary blends of SCMs to provide improvedoverallresponse. Usingindustrialwasteasapartialreplacementtocement toproduceSCMmix. The aim was to explore Rheological & Mechanical propertiesandtheircomparisonwithreferenceSCMMix

4. METHODOLOGY

SF 1 M0 100%C

7. RESULTS AND DISCUSSION

Thepresentinvestigationdealswiththestudyofdeveloping Self compactingmortarsandtheseSCM'sarereplacedwith admixtures obtained from industrial wastes to cement contentatdifferentpercentages.SCMmixesweredeveloped with keeping the overall powder content constant. The optimumdosageofSPisdeterminedusingmarshconetest &freshpropertiesareenhancedusingmini slumpcone&

MasterGleniumSKY8233isanadmixturebasedonmodified polycarboxylic ether. This product has been developed primarily for applications in high performance and highly durableconcrete.Table2.Providesthephysicalandchemical properties of the admixture. Masterglenium SKY 8233 is Chloridefree&lowhaslowalkalicontent.Itiscompatible withalltypesandgradesofcements. Table 3: PropertiesofMasterGlenium8233 Particulars Content Chemicalcontent Polycarboxylicether Specificgravity 1.08 Chloridecontent <0.2% Solidcontent 35.46% Compatibility Alltypesofcement PH 7.02 viscosity 50 150s 6. MIX PROPORTIONING Thequantityofcement,fineaggregates,water,andmineral admixtures(Flyash,Metakaolin,Silicafume)foreachbatch ofproportionispreparedasmentionedinthedesign. Table -3: Mixproportions Sl.No. Mixid Mixnotation OPC FA MK 100 2 M1 60%C+40%F 60 40 3 M2 85%C+15%S 85 15 4 M3 80%C+20%M 80 20 5 M1.1 85%C+10%F+5%M 85 10 5 6 M1.2 70%C+20%F+10%M 70 20 10 7 M1.3 55%C+30%F+15%M 55 30 15 8 M1.4 40%C+40%F+20%M 40 40 20 9 M2.1 75%C+20%F+5%S 75 20 5 10 M2.2 60%C+30%F+10%S 60 30 10 11 M2.3 45%C+40%F+15%S 45 40 15 12 M3.1 85%C+10%M+5%S 85 10 5 13 M3.2 75%C+15%M+10%S 75 15 10 14 M3.3 65%C+20%M+15%S 65 20 15 15 M4.1 10%M+7.5%S62.5%C+20%F+ 62.5 20 10 7.5 16 M4.2 20%M+15%S35%C+30%F+ 35 30 20 15

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 02 | Feb 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1068 Na2O Nil 0.58 0.17 0.51 SO3 2.50 0.07 Nil 0.19 LOI 1.50 4.17 0.50 1.00 (m2/Kg)Fineness 367 m501500 2/kg 700 900 m2/kg 15000 30000 m2/kg 5.5 Fine aggregates Locallyavailable M sandwith4.75mmmaximumsize was usedasfineaggregate,andfineaggregateconformedtoIS: 383 2016,EN12620&ASTMC33wasused.Theproperties offineaggregateareshowninTab2&3. Table 2: PhysicalPropertiesofMaterials Materials Testconducted Results IS Code (OPCCement43) Specificgravity 3.14 3.15 Fineness(%) 5% <10 Normalconsistency(%) 34 Initialsettingtime(min) 95 30 Finalsettingtime(min) 360 600 7days StrengthCompressive(MPa) 25.4 26 14days StrengthCompressive(MPa) 39.45 38 28days StrengthCompressive(MPa) 43.4 43 Flyash Specificgravity 2.1 2.1 3.0 Fineness(%) 7 <10 Metakaolin Specificgravity 2.5 Fineness(%) 8 10 Silicafume Specificgravity 2.2 Fineness(%) 8 10 (MaggregateFineSand) Specificgravity 2.5 2.75 Finenessmodulus(%) 2.74 3.2 BulkDensity(Kg/m3) 1090 1250 Table 3: SieveAnalysisofFineAggregate Sieve size Cumulative percent (IS:Specification3831970) Retained Passing Zone II 4.75mm 0.8 99.2 90 100 2.36mm 6.4 93.6 75 100 1.18mm 44.4 56.6 55 90 600μm 61.4 38.6 35 59 300μm 81.6 18.4 8 30 150μm 92.6 7.4 0 10

5.6 Superplasticizer

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1069

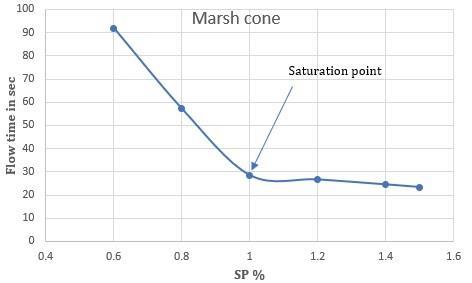

Trial no. W/C ratio SP % flow time S 1 0.35 0.6 92 2 0.35 0.8 57.2 3 0.35 1 28.51 4 0.35 1.2 26.68 5 0.35 1.4 24.53 6 0.35 1.5 23.39

7.3.1 Compressive strength

mini V funnel test, hardened properties i.e. Compressive strength,Flexuralstrengthofallthemixesaredetermined. 7.1 Marsh cone test Flowtimeofcement/mortarthroughmarshconeisindicator ofviscosity,whichdependsuponcementsuperplasticizer compatibility It is widely used to study cement superplasticizer compatibility and to determine optimum superplasticizerdosageofaspecificcement superplasticizer combination. Optimum dosage is the percentage of superplasticizer beyond which there is no significant increaseinthefluidityofthemix Table -4: Marshconetest

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 02 | Feb 2022 www.irjet.net p ISSN: 2395 0072

It is observed that SCM with FA and SF decreases the slump&increasesflowtimeontheincreaseofFAandSF content due to an increase of fineness of mineral admixtures.

Hardened properties

Results show that reference mix(M0) has mini slump flowdiameter&minivfunnelflowtimeof254mm,8Sec respectively,thatsatisfyEFNARCrequirementsforSCM withW/Bratioof0.33andsuperplasticizerof0.6%.

7.3

Chart 1:MarshconetestSP%v/stime Aliterofslurrymadewith2kgofcementpowderandw/c ratio of 0.31 to 0.35 is tested varying the percentage of superplasticizerstartingfrom0.6%.itisobservedthat1%of Superplasticizeroptimumdosagefortheabovecondition 7.2 Fresh properties. Freshpropertiesofallthedesignedmixesaredeterminedin the laboratory by adjusting dosage of SP such that mini slump flow diameter of 240 260mm & mini v funnel flow timeof7 11S.theresultsaretabulatedintable 5 Table 5: Freshproperties IdMix proportion W/P SP% InSlumpmm V Flow,funnelsec M0 1:2 0.36 0.6 255 11 M1 1:2 0.36 0.8 257 7 M2 1:2 0.37 0.7 253 11 M3 1:2 0.37 0.85 250 10 M1.1 1:2 0.38 0.75 243 11 M1.2 1:2 0.38 0.8 249 9 M1.3 1:2 0.38 0.85 257 8

ThecompressivestrengthdevelopmentofSelf compacting mortarcontainingdifferentpercentagesofFA,MK,SFat7, 14,28days ofcuring,testspecimen of70.6*70.6*70.6mm andprocedurearecarriedoutfollowingtheguidelinesofIS: 4031(part6)1988,ASTMC109

Itisobservedthattherate of waterdemandincreases with an increase in the replacement of cement by admixturecontentduetoanincreaseinthefinenessof cementitiousmaterials. Itisobservedthat SCM mix withFAandMKincreases slump&decreasesflowtimeontheincreaseofFAand MKcontent.

The hardened properties investigated are compressive & Flexural strength. The SCM mixes with/without partial replacement of cement by mineral additives are tested at 7,14&28days.TheresultsobtainedarepresentedinTable6

M1.4 1:2 0.38 0.9 263 7 M2.1 1:2 0.37 0.75 258 7 M2.2 1:2 0.37 0.8 253 8.4 M2.3 1:2 0.37 0.85 246 9 M3.1 1:2 0.38 0.8 243 7 M3.2 1:2 0.38 0.85 250 9 M3.3 1:2 0.38 0.9 257 10 M4.1 1:2 0.38 1.1 242 11 M4.2 1:2 0.38 1.1 253 7

ItisobservedthatSCMmixwithFA,MK&SFrequires more water due to increased fineness of mineral admixtures.

Flexural strength

TheternarySCMmixwithcementreplacementlevel20% FA,10% SF(M2.2) shows good flow properties & hardenedpropertiescomparedtoreferencemix(M0).

The durability of SCM's against chloride and sulphate attackscanbestudiedtoknowthepercentageofstrength reductionascomparedwiththenormalSCM's.

Mixv/sFlexuralstrength

Fromtheexperimentalresultsitisobservedthatthereis a decrease of compressive and flexural strength on increase of percentage of cement replacement level above35%.

Theternarymixwith20%FA,10%MK(M1.2)and30% FA,15% MK(M1.3) shows good flow properties and hardenedpropertiescomparedtothereferencemix(M0).

9. SCOPE FOR FUTURE STUDY

ItisobservedfromtheresultsthatternarymixwithFA and MK gives optimum results at 20% FA & 10% MK(M1.2). It is observed from the results that ternary mix(M2.1) withFAandSFgivesFlexuralstrengthof7.41MPa.and anincreaseof8.33%comparedwiththeReferencemixis observed. It is observed from the experiment that a decrease in flexuralstrengthontheincreaseofMKandSF. It is observed from the results that ternary mix(M3.1) withMKandSFgivesFlexuralstrengthof9.53MPa.and increase of 39% compared with the Reference mix is observed Quaternarymix(M4.1)with20%FA,10%MKand7.5% SFgivesFlexuralstrengthof5.483MPa,andadecreaseof 19.83%isobserved.

Chart -2:Mixv/scompressivestrength Itisobservedfromtheresultsthatthereferencemix(M0) hasacompressivestrengthof43.4MPa Resultsshowsthatbinarymix(M3)with20%Metakaolin givesstrengthmorethanreferencemix(M0).

ItisobservedthatternarySCMmix(M1.2)with20%FA &10%MKgivescompressivestrengthof41.8MPa,there isadecreaseof3.18%comparedtoreferencemix. ItisobservedthatternarySCMmix(M2.1)with20%FA &5%SFgivescompressivestrengthof39.8MPa,thereis adecreaseof8.27%comparedtoreferencemix. ItisobservedthatternarySCMmix(M3.2)with15%MK &10%SFgivescompressivestrengthof49.8MPa,there isanincreaseof14.74%comparedtoreferencemix. It is observed that quaternary mix(M4.1) with 20% FA,10%MKand7.5%SFgivescompressivestrengthof 43.25MPa. 7.3.2

8. CONCLUSIONS

ThereferenceSCMmix(M0)showsgoodflowproperties and hardened properties like compressive strength of 43.4MPa,Flexuralstrengthof6.84MPa.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1070

The flexural strength development of Self compacting mortarcontainingdifferentpercentagesofFA,MK,SFat7, 14,28daysofcuring,testspecimenof 40*40*160mmand procedure are carried out following the guidelines of IS: 4031(part6)1988,ASTMC348 Chart -2:

TheternarySCMmixwithcementreplacementlevel15% MK, 10% SF (M3.2) shows good flow properties & hardenedpropertiescomparedtoreferencemix(M0).

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 02 | Feb 2022 www.irjet.net p ISSN: 2395 0072

Itisconfirmedfromthemarshconetestthatflowrate becomesconstantafter1%ofSuperplasticizer&henceit istheoptimumdosageofsuperplasticizerforthebrand ofcementused.

TheQuaternarymix(M4.1)with20%FA,10%MK&7.5% SF shows good flow properties & hardened properties comparedtothereferencemix(M0).

TheindustrialbyproductssuchasFA,MK&SFareusedasa partial replacement of cement in self compacting mortars showed better results with good compressive strength. Further scope for extending the same work is reported below.

Itisobservedfromtheresultsthatthereferencemix(M0) hasFlexuralstrengthof6.844MPa. Resultsshowsthatbinarymix(M3)with40%Metakaolin givesflexuralstrengthmorethanreferencemix(M0).

BulletinofengineeringTomeXI(2018).

10. REFERENCES [1] Turk,Kazim.“ViscosityandHardenedPropertiesofSelf Compacting Mortars with Binary and Ternary Cementitious Blends of Fly Ash and Silica Fume.” ConstructionandBuildingMaterials,vol.37,2012,pp. 326 34. [2] Güneyisi,Erhan,etal.“StrengthandDryingShrinkage PropertiesofSelf CompactingConcretesIncorporating Multi System Blended Mineral Admixtures.” Construction and Building Materials, vol. 24, no. 10, 2010,pp.1878 87. [3] KannanVet.al. “Mechanicalandtransportpropertiesin ternary blended self compacting concrete with metakaolinandflyash”,IOSRJournalofMechanicaland CivilEngineering(IOSRJMCE)ISSN:2278 1684Volume 2,Issue4(Sep Oct.2012),PP22 31. [4] Sanjeev Kumar, Rinku Saini “Effects of Metakaolin Content on Fresh and Hardened Properties of Self Compacted Concrete” International Journal of ComputationalEngineeringResearch,VOL.5(2015).

[12] Dinakar,P., et al.“Effectof MetakaolinContentonthe Properties of High Strength Concrete.” International JournalofConcreteStructuresandMaterials,vol.7,no. 3,2013,pp.215 23.

International Journal of Innovative Technology and Exploring Engineering (IJITEE) ISSN: 2278 3075, Volume 8Issue 2SDecember,2018.

[20] M.AdamsJoeet.al.“ExperimentalInvestigationonThe Effect Of M Sand In High Performance Concrete”

[21] Schutter G and Audenaert K, editors. Report 038: durabilityofself compactingconcrete state of the art ReportofRILEMTechnicalCommittee205 DSC.RILEM Publications;2007.208p. [22] “Concretetechnology:theoryandpractice”bookbyM.S Shetty. [23] “concrete4 technology” book by A.M. Neville & J.J Brooks.2018]

Otherindustrialwasteslikeredmudandcopperslagcan beusedtodevelopSCM. The properties of SCM can be studied from the replacement of natural sand with alternate materials. SCMwithoutsuperplasticizercanbestudied. Agro basedwasteslikesawmillash,juteash,cottonstalk ash,etc.canbeusedindevelopingSCM. SCMwithdifferentcuringconditionscanbestudied. Self healingself compactingconcretecanbeproduced.

[6] Naik,T.R.,SinghS,“Influenceofflyashonsettingand hardeningcharacteristicsofconcretesystems”Materials Journal,Vol.94,Issue5,pp.355 360.

[13] ShobanaK.Set.al“PreliminarystudyofSelfCompacting Concrete by adding Silica Fume A review paper” International Journal of Engineering Research & Technology(IJERT)Vol.2Issue11,November 2013

[19] AkshayC.Sankhet.al. “RecentTrendsinReplacementof NaturalSandWithDifferentAlternatives”IOSRJournal ofMechanicalandCivilPP59 66(2014).

[11] Deveshan L. Pillay et.al. “A Review of the Engineering Properties of Metakaolin Based Concrete: Towards Combatting Chloride Attack in Coastal/ Marine Structures” Hindawi Advances in Civil Engineering Volume2020,ArticleID8880974,13pages

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 02 | Feb 2022 www.irjet.net p ISSN: 2395 0072

[15] R.Duval1andE.H.Kadri“Influenceofsilicafumeonthe workability and the compressive strength of high performanceconcretes”CementandConcreteResearch, Vol.28,No.4,533 547,1998.

[7] Mojdeh Mehrinejad Khotbehsar et.al “Durability Characteristics of Self Compacting Concrete IncorporatingPumiceandMetakaolin”2017American SocietyofCivilEngineers. [8] SelçukTürkelet.al“FreshandHardenedPropertiesof SCC Made with Different Aggregate and Mineral Admixtures” [9] L.Krishnarajet.al “InvestigationonEffectivenessofthe Top DownNanotechnologyinMechanicalActivationof High Calcium Fly Ash in Mortar” Indian Journal of ScienceandTechnology,Vol9(23),(June2016)

[5] HOUYunfen et.al “ComparisonofEffectofMetakaolin and Silica Fume on Fly Ash Concrete Performance”, BeijingUniversityofCivilEngineeringandArchitecture, Beijing(2016).

[10] VRajkumaret.al“significanceofflyashindurableeco friendlyconcretewithcorrosioninhibitor”

[16] P. Sachin Prabhu et.al “Behaviour of Self Compacting Concrete with Cement Replacement Materials”

American Journal of Engineering Research (AJER), Volume 02,Issue 12,pp 46 51(2013) XI

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1071

[14] Alsana Bashi et.al “Study of Permeability and Compressive Strength of Silica Fume Concrete” International Journal of Engineering and Advanced Technology(IJEAT)ISSN:2249 8958,Volume 3,Issue 4,April2014.

[17] Beata Łaźniewska Piekarczyk, Patrycja Miera, Janusz Szwabowski “Plasticizer and Superplasticizer CompatibilitywithCementwithSyntheticandNatural Air Entraining Admixtures”. Materials Science and Engineering 245 (2017).

[18] Salahaldein et.al. “Omran effect of superplasticizer on propertiesofmortar”,ACTATECHNICACORVINIENSIS