International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Y. Dasthagir1 , V. Venkata

Subbamma2

1 Assistant Professor, Dept. of Civil Engineering, K.S.R.M. College of Engineering Autonomous, Affiliated to JNTUA, Kadapa, A.P, India.

2 Assistant Professor, Dept. of Civil Engineering, K.S.R.M. College of Engineering Autonomous, Affiliated to JNTUA,

Kadapa, A.P, India. ***

Abstract - The cubes are tested for two kinds of test to clarify the modulation of compressive strength, flexural strength of concrete by using basalt as aggregate as per the mix design. The tests were carried out with 60%, 30% basalt as aggregate. The study has gone through performance of durability studies and mechanical properties how they both performance in concrete. Based on results, the compare between concrete with normal aggregate and concrete with basalt aggregate was performed for durability parts Curing conditions are improved by adding recycled aggregate, use of fly ash. Basalt aggregate (BA) with a 3% water absorption, raw recycled aggregate and basalt (RRA), and improved recycled aggregate and basalt (PRA) were the main experimental variables. The drying shrinkage of PRA was similar to that of BA with an average difference of <7% as the age increased. The efficient use of recycled aggregate higher performance than that of concrete comprising BA and improved durability.

Key Words: Basalt, Recycled Aggregate, Curing, Fly ash CompressiveStrength,FlexuralStrength.

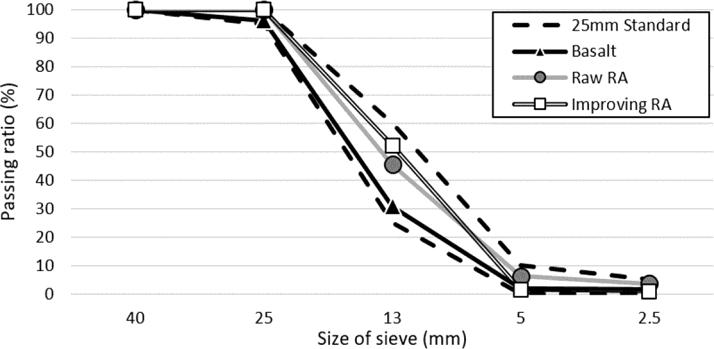

Industrialgrowthhasresultedintherapidriseofconcretebasedbuildingsattendedbyenvironmentaldegradationdue totheuseofnumerousnaturalresources,suchasaggregate. The group of natural resources led to the destruction of riversandmountains,resultinginalackofresources. The durabilityofastructureissaidtobeitsabilityto serveits intendedpurposeforanecessarilyoflongperiodoftimeorat least its service time and a durable concrete in onewhich satisfactorily performs in its exposed environ- mental conditionsduringitsservicelifespan.Aggregatesareused for very specific purposes including significant economic benefitinthefinalcostofconcrete.Theymakeabout65-75 % of the volume of the concrete mixture and they are the least expensive component of the concrete mixture. Therefore,wehavedecidedtoreplacethenormalaggregates withbasaltaggregates Thephysicalpropertiesofconcrete arenotexpressivelyaffectedifrecycledaggregatereplaces less than 30% of coarse aggregate during concrete production. Although new studies with various novelty have been conducted, they have not been applied to research or practical applications.

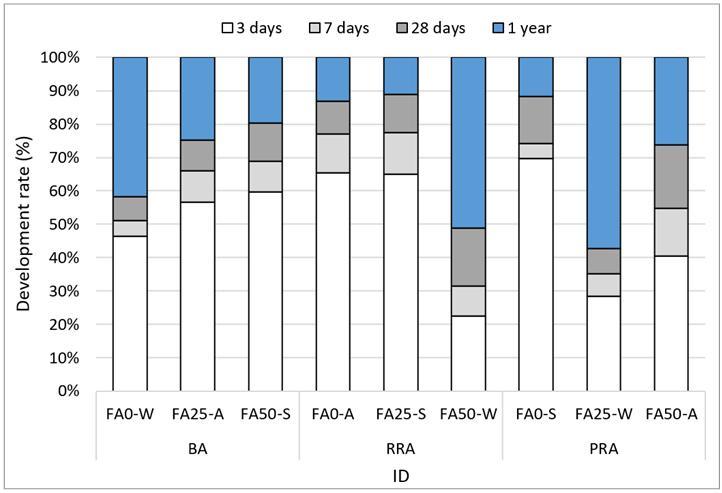

Theexperimentalvariablesincludetheaggregatetype,FA substitution rate, and curing condition. For the three variableswiththreefactors,ninemixturesweresetusing theTaguchiinvestigationaldesignmethod.

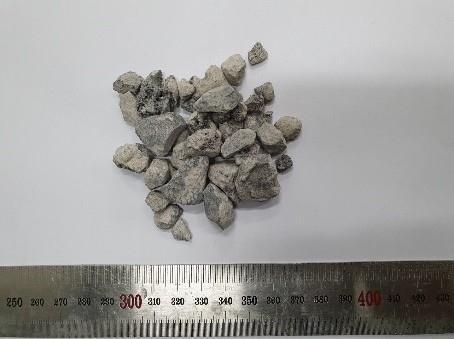

Theaggregateusedintheexperimentwaspre-wettedin waterfor24h,consideringthehighabsorptionrateofthe aggregate, and then the experiment was conducted by correcting moisture. It has a fine-grained material texture due to molten rock cooling too quickly for large material crystalstogrow.

Apartfrombasalt,thetypeofPortlandcementused inthe current experimentation as a component of con- crete is ordinaryPortlandCementofGrade43andhighquality.For theexperimentationthenominalsizesofthecoarseaggregate usedwere20mmand10mmandthe sandconformingto ZoneIIwasusedasthefineaggregate.

Intheexperiment,weusedTypeIordinaryPortlandcement from“S”companyandFAfrom“Y”thermalpowerplant.The physicalpropertiesofthematerialsarelistedinTables1and 2whiletheirchemicalpropertiesarelistedinTable3

Table -1: Physicalpropertiesofcement

Density Finenes s Setting Time in (mints) Compressive Strength (MPa) (m2/kg) Initia l Final 3 Day s

(g/cm3)

28 Day s 314 383 46 376 24 301 436

Table -2 Physicalpropertiesoffly-ash

7 Day s

Density g/cm3 Fineness m2/kg

Activity Index (%)

Flow Value Ratio (%) 28 Days 91 Days 2.15 356 108 90 96

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Table -3 Chemical composition of cement

Type Ca O (% )

Table -3 Chemical composition of cement

SiO 2 (%)

Al2O 3 (%) Fe2O 3 (%) Mg O (%)

Ig. Los s (%)

Tota l (%) Cemen t 2.4 21. 1 4.4 3.2 3.1 3.4 2.4 100 Flyash 5.8 52. 7 21.7 7.8 2 2 2.4 7.6 100

Othe r (%)

Aggregate Type Replacement Ratio of Fly Ash (wt%) Curing Condition

Basalt aggregate 0 Water curing Rawrecycled aggregateand Basalt 30 Air-drycuring Improvedrecycled aggregateand Basalt 60 Steamandair-dry curing

Table -4 Mixproportionofconcrete

Unit Weight (kg/m3)

Threetypesofmouldswereusedforcurrentexperimentation cubes, cylinder and prisms. The cubic moulds were of the dimensions 150 x 150 x 150 mm, the cylindrical moulds havingdiameteras150mmandheightas300mmandthe prismswithcrosssectionalareaof150x150mmandlength 7oomm.Tamping,withusually25blowsisdoneafterevery layerofconcreteisadded.

Thematerialscomprising oftheconcretemixwereweighed onthebalanceandtheninsertedinsidethemechanicalmixer.

Duringtheproductionofconcreteaconsiderableamountof airisentrapped.Alsoduring its transportation, there is a possibility of par-tial segregation of aggregates. If the entrappedairisnotremovedandthesegregationofcoarse aggregatenotcor-rected,theconcretemaybeporous,nonhomogenousandofpoorstrength.

Inthecurrentexperimentation,curingofcubeandcylindrical specimenstogain28daystrengthwasdoneusingthesteam curingmachineavailableattheMaterialtestingLaboratory, DepartmentofCivilEngineering.

Thecuringofprismsfor7,14and28daysstrength;cylinders for 7 and 14 day strength andcubes for 7 and 14 day strengthswasdonebypondingwithwaterinacuringtank locatedjustoutsidethelaboratory.

S.No of ID

A i r ( % )

w /b ( % )

s/ a ( % )

W at er

Binde r

F A

BA FA0 1 6 4 38 2 -

BA FA30 1 6 4 28 6 9 6

BA FA60 1 6 4 19 2 1 9 1

Coarse Aggregat e

B as al t

1 0 4 2

R R A

P R A

Fine Agg reg ate Total Ce m en t

- - 660 2242

1 0 1 6

- - 644 2203

9 9 2 - - 628 2162

RRA FA0 1 6 4 38 15 2 2

RRA FA30 6 44 41 1 6 4 28 6 9 6 5 1 0

RRA FA60 1 6 4 19 2 1 9 1

4 4 2 - 660 2163

4 3 1 - 644 2124

4 9 7

4 2 0 - 628 2085

PRA FA0 1 6 4 38 15 2 24 8 6 660 2208

PRA FA30 1 6 4 28 6 9 6 5 1 04 7 5 644 2168

PRA FA60 1 6 4 19 1 1 9 1

4 9 74 6 3 628 2129

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Forthefireresistancevalue,theresultsshowthatconcrete with50%and30%basaltasaggregateshowsmuchbetter fire-resistantvaluethannor- mal concrete,thusmaking it betterfire-resistantmaterial Forwaterpermeabilityvalue, Theresultsshowthatconcretewith50%and30%basaltas aggregateshowsmuchlesswaterpermeabilityvalue than normalconcrete.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

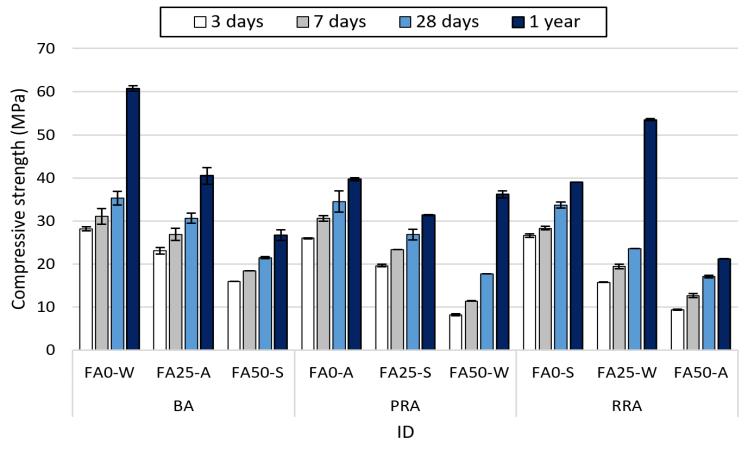

Thecompressivestrength,asignificantincreaseof 30.1%,43.6%wasseeninthemixcontainingbasalt aggregate 50%, 30% respectively. Therefore,this resultisfavorable.

Theflexuralstrength,therewasamarginalincrease of4.69%,3.4%intheflexuralstrengthinthebasalt mix50%,30%respectively.Hencefavorable

Thedurabilityofconcrete,steamcuringtended to decrease drying shrinkage, which this is because blended water was consumed and a dense matrix was constructed due to high temperature heat and humidity in early curing. Whentheimprovedrecycledaggregatewasused, the drying shrinkage decreased over time at a levelsimilartothatofbasalt.

The fire resistance, the basalt aggregate of 50%,30%replacedconcreteisfoundtobe16.49%, 9.8%morefireresistant

Thewaterpermeability,therewasanincreaseof 49.26%,32.98%inthepermeabilitypenetrationin thebasaltmixof50%,30%respectively.

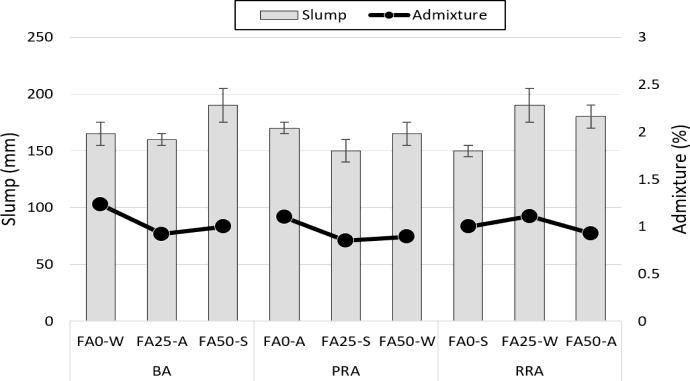

Thepropertiesoffresh concrete, there wasno decreaseintheslumpduetotheinfluenceofthe recycled aggregate, but some air content increased due to the porous old paste of the recycledaggregate.

[1] DeccanBasaltVolcanism–GeographicalSurveyIndia. 2016. Available from: http://www.portal.gsi.gov.in/ portal/page?_pageid=127,689645&_dad=portal&_ schema=PORTAL

[2] PunmiaBC,JainAK,JainAK.ReinforcedCementConcrete Design.10thed.LaxmiPublication;2015.

[3] Neville AM, Brooks JJ. Concrete Technology. 2nd ed. PearsonEducation.LongmanGroupUKLtd;1987.

[4] Swati Jha-To study the durability aspects of concrete usingbasaltaggregate,Dept-ofcivilengineering,IJSTVol 9(30), DOI: 10.17485/ijst/2016/v9i30/99203, August2016

[5] Hong-BeomchoiandJin-o-park,StudyonMechanical Properties of Concrete Using Basalt-Based Recycled Aggregate and Varying Curing Conditions, MDPIMaterials2022,15,4563. https://doi.org/10.3390/ ma15134563.