International Research Journal of Engineering and Technology (IRJET) Volume: 08 Issue: 01 | Jan 2021 www.irjet.net The mix design for geo polymer concrete using HBG metal as coarse aggregate and river sand as fine aggregate is calculated based on the minimum void approach using the powers formula and the weight proportions are listed in tab12

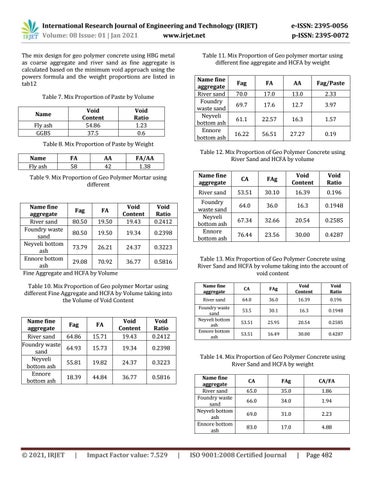

Table 11. Mix Proportion of Geo polymer mortar using different fine aggregate and HCFA by weight Name fine aggregate River sand Foundry waste sand Neyveli bottom ash Ennore bottom ash

Table 7. Mix Proportion of Paste by Volume Void Content 54.86 37.5

Name Fly ash GGBS

Void Ratio 1.23 0.6

Table 8. Mix Proportion of Paste by Weight Name Fly ash

FA 58

AA 42

Table 9. Mix Proportion of Geo Polymer Mortar using different

0.2398

Š 2021, IRJET

15.71

64.93

15.73

19.34

0.2398

55.81

19.82

24.37

0.3223

18.39

44.84

36.77

0.5816

64.86

|

Fag/Paste

70.0

17.0

13.0

2.33

69.7

17.6

12.7

3.97

61.1

22.57

16.3

1.57

16.22

56.51

27.27

0.19

CA

FAg

Void Content

Void Ratio

River sand

53.51

30.10

16.39

0.196

64.0

36.0

16.3

0.1948

67.34

32.66

20.54

0.2585

76.44

23.56

30.00

0.4287

Table 13. Mix Proportion of Geo Polymer Concrete using River Sand and HCFA by volume taking into the account of void content

0.5816

Void Ratio 0.2412

FA

AA

0.3223

Void Content 19.43

Fag

FA

Name fine aggregate Foundry waste sand Neyveli bottom ash Ennore bottom ash

Void Ratio 0.2412

Table 10. Mix Proportion of Geo polymer Mortar using different Fine Aggregate and HCFA by Volume taking into the Volume of Void Content Name fine aggregate River sand Foundry waste sand Neyveli bottom ash Ennore bottom ash

Fag

Table 12. Mix Proportion of Geo Polymer Concrete using River Sand and HCFA by volume

FA/AA 1.38

Name fine Void Fag FA aggregate Content River sand 80.50 19.50 19.43 Foundry waste 80.50 19.50 19.34 sand Neyveli bottom 73.79 26.21 24.37 ash Ennore bottom 29.08 70.92 36.77 ash Fine Aggregate and HCFA by Volume

e-ISSN: 2395-0056 p-ISSN: 2395-0072

Impact Factor value: 7.529

Name fine aggregate

CA

FAg

Void Content

Void Ratio

River sand

64.0

36.0

16.39

0.196

53.5

30.1

16.3

0.1948

53.51

25.95

20.54

0.2585

53.51

16.49

30.00

0.4287

Foundry waste sand Neyveli bottom ash Ennore bottom ash

Table 14. Mix Proportion of Geo Polymer Concrete using River Sand and HCFA by weight Name fine aggregate River sand Foundry waste sand Neyveli bottom ash Ennore bottom ash

|

CA

FAg

CA/FA

65.0

35.0

1.86

66.0

34.0

1.94

69.0

31.0

2.23

83.0

17.0

4.88

ISO 9001:2008 Certified Journal

|

Page 482