International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

1Final year Civil Engineering student at Government College of Engineering Jalgaon affiliated to KBCNMU,

2 Final year Civil Engineering student at Government College of Engineering Jalgaon affiliated to KBCNMU,

3 Final year Civil Engineering student at Government College of Engineering Jalgaon affiliated to KBCNMU,

4 Final year Civil Engineering student at Government College of Engineering Jalgaon affiliated to KBCNMU,

5 Final year Civil Engineering student at Government College of Engineering Jalgaon affiliated to KBCNMU,

6Example: Assistant Professor, Dept. of Civil Engineering, Government college of Engineering Jalgaon, Maharashtra, India ***

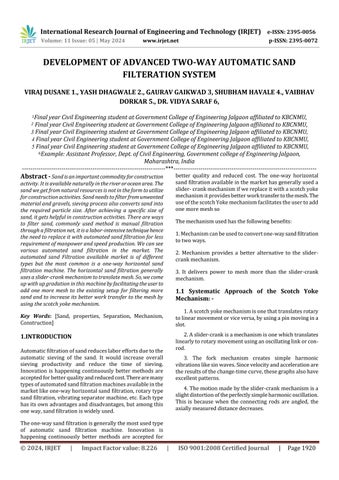

Abstract - Sand is an important commodity for construction activity. It is available naturally in the river or ocean area. The sand we get from natural resources is not in the form to utilize for construction activities. Sand needs to filter from unwanted material and gravels, sieving process also converts sand into the required particle size. After achieving a specific size of sand, it gets helpful in construction activities. There are ways to filter sand, commonly used method is manual filtration through a filtration net, it is a labor-intensive technique hence the need to replace it with automated sand filtration for less requirement of manpower and speed production. We can see various automated sand filtration in the market. The automated sand Filtration available market is of different types but the most common is a one-way horizontal sand filtration machine. The horizontal sand filtration generally uses a slider-crank mechanism to translate mesh. So, we come up with up gradation in this machine by facilitating the user to add one more mesh to the existing setup for filtering more sand and to increase its better work transfer to the mesh by using the scotch yoke mechanism.

Key Words: [Sand, properties, Separation, Mechanism, Construction]

1.INTRODUCTION

Automaticfiltrationofsandreduceslaboreffortsduetothe automatic sieving of the sand. It would increase overall sieving productivity and reduce the time of sieving. Innovation is happening continuously better methods are acceptedforbetterqualityandreducedcost.Therearemany typesofautomatedsandfiltrationmachinesavailableinthe marketlikeone-wayhorizontalsandfiltration,rotarytype sandfiltration,vibratingseparatormachine,etc.Eachtype hasitsownadvantagesanddisadvantages,butamongthis oneway,sandfiltrationiswidelyused.

Theone-waysandfiltrationisgenerallythemostusedtype of automatic sand filtration machine. Innovation is happening continuously better methods are accepted for

better quality and reduced cost. The one-way horizontal sandfiltrationavailableinthemarkethasgenerallyuseda slider-crankmechanismifwereplaceitwithascotchyoke mechanismitprovidesbetterworktransfertothemesh.The useofthescotchYokemechanismfacilitatestheusertoadd onemoremeshso

Themechanismusedhasthefollowingbenefits:

1.Mechanismcanbeusedtoconvertone-waysandfiltration totwoways.

2. Mechanism provides a better alternative to the slidercrankmechanism.

3. It delivers power to mesh more than the slider-crank mechanism.

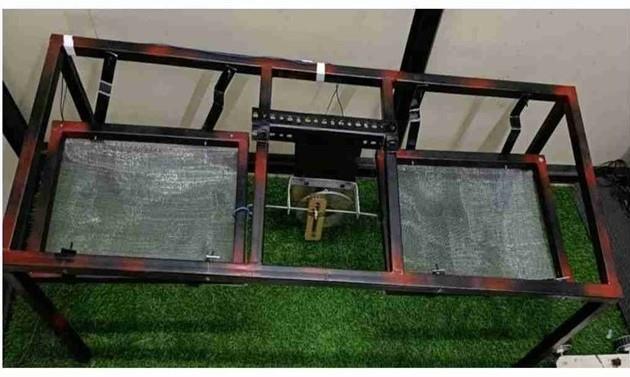

1.Ascotchyokemechanismisonethattranslatesrotary tolinearmovementorviceversa,byusingapinmovingina slot.

2.Aslider-crankisamechanismisonewhichtranslates linearlytorotarymovementusinganoscillatinglinkorconrod.

3. The fork mechanism creates simple harmonic vibrationslikesinwaves.Sincevelocityandaccelerationare theresultsofthechange-timecurve,thesegraphsalsohave excellentpatterns.

4.Themotionmadebytheslider-crankmechanismisa slightdistortionoftheperfectlysimpleharmonicoscillation. This is because when the connecting rods are angled, the axiallymeasureddistancedecreases.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

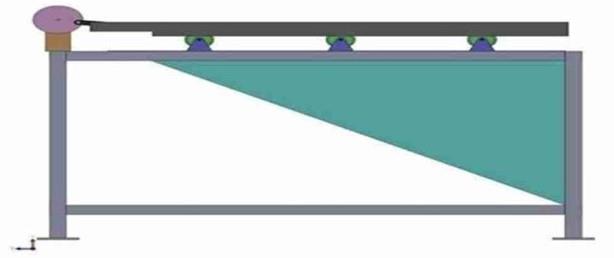

Twosandseparationmachineworksontheprincipleof the Scotch yoke mechanism. This scotch yoke mechanism coverts the rotation motion of the shaft into for means of horizontalrotational.Therearevariousbenefitsofthissand filtrationtechniques,suchasduetouseofthistechniqueit notonlysavestheeffortsbutalsoitsavesthetime,it’salso reducingthedependenciesoftheskilledlabor.

The shaft of the DC motor is connected to the disc when powerisonthemotorwillstartandtheshaftstartsrotating due to the rotation of the haft the circular dick also starts rotating,inthisdick,theslotisprovidedforthepin,thisslot is connected to two external arms called as yoke in the horizontal direction. When the disk starts rotating then meshes are alsostartedslidinginthehorizontal direction these meshes are placed on rollers which are placed on rectangularboxes.Nowthesandisplacedonbothmeshes, due to the sliding motion of meshes the sand separation startsinthemachine,thisfilteredsandcomesdownthrough themeshwhichiscollectedatbottomofslidingboxes,And thehigh-gradesandparticlewhichstillremainsonmeshes nowweremovethishighgradsandparticleandfurtherdrop newsandforfiltration.Inthisway,ourtwo-wayautomatic sandseparationmachineworksinaneffectivemannerand filteredadoubleamountofsandcomparedtotheone-way

The scotch yoke mechanism is a reciprocating machine mechanism converting the linear motion of slider into rotational or vice versa. The piston or other reciprocating part is directly coupled to a sliding yoke with a slot that engages a pin on the rotating part. The scotch yoke mechanism is considered to be a more efficient means of producingtherotationalmotionasitspendsmoretimeatthe highpointofitsrotationthanapiston&ithasfewerparts.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

TheScotchYokemechanismisasimplesttypeofmechanism whichconvertscircularmotionintoreciprocatingmotionas discussed in the construction part above. The power is suppliedtothe.ADCmotor,spindleandcrankareconnected totheshafttostartrotation.Asthecrankturns,thepinslides intotheyokeandmovestheyokeforward.Asthecrankturns clockwise,theyokewillmoveforward

Themaximumdisplacementwillbeequaltothelengthofthe crank. The yoke returns to its original position when the crankcompletesitsnextrotation.Onthenextturntheyoke movesbackwards.Theyokereturnstoitsoriginalposition whenthecrankcompletesonefullrotation.Foronecomplete revolution of the crank, the yoke moves a length equal to twicethelengthofthecrank.Thechangeinmagneticfield canbecontrolledbychangingthelengthofthecrack.

2.2Mounting Of Mechanism

Themainpartsofthescotchyokemechanisminclude

LCircularDisk

II.Fixedlink

Slidingpin

IV.Slidingyoke

V.Connectingrod

2.3 Arrangement of Mechanism in Machine: -

Thediskisthebaseofthemachineandisconnectedtothe Johnson engine using a fixed linkage. @@mm drilling was doneonthebackofthedisc.Theslidingpinisfixedtothe slidingyoke;Themovementofthepintransmitsmotionto theslidingshaft.Theslidingyokeisconnectedtoagridthat transmitsthemovement

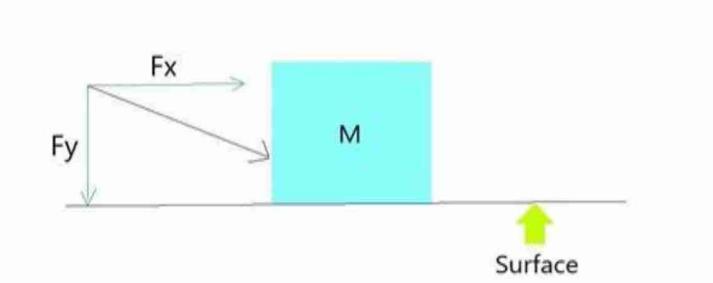

Assumeblockofmass'M'onthesurfaceappliedwithoblique pushforce'F'whichissameasforceappliedbyconnecting rodinslidercranktomesh.

After separating force F into vertical and horizontal directions, we obtain the force Fx as the horizontal component of force F and the force Fy as the vertical componentofforceF.

Advantages:-

1)Automatic sandfiltrationcanbedoneusingsandfilters andseparators.

2)Itcanfilterlargesands.

3)Easytouse

4) Compared to manual sand saw, automatic sand saw requireslessenergy.

5)Itiseasytouse.

6)Time-savingequipment.

7) Size The number of particles in the sand filter can be changedasnecessarybyadjustingthemeshtothedesired meshsize.

8)Noskilled workers, workers whoare unableto operate easily,shouldoperatethemachine.

9)Workingchangeforscanningisbetterthanusingcrank.

10)Ifitisdeterminedthatthesandcanbeimproved,itcan beimprovedifnecessary.

2.4 Model Details

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

Thecapthataccommodatesthegearhasanarccutfromits side to avoid frictional resistance forces with the bottom gearassembly:

Table:1 TollsandEquipment

1 Measuring Steel rule, measuring tape, tri-square,protractor

2 MarkingOut Scriberandpunch

3 Drilling DrillingMachineAnd Handmachine

4 Sawing and cutting Electricsaw,hacksaw, shears/snip

5 Filing Files

6 Threading Setoftapsanddies

7 Grinding GrindingMachine

8 Bending Bending Machine, hammers,andpliers

9 Welding Electric arc and gas weldingequipment 10 Machining LatheMachine 11 Cleaning Emery paper and wirebrush

12 Spraying Sprayingequipment (Spraying gun compressor) and

13 Assembly Spanners, screwdrivers, and pliers.

Holding Benchvices

TheDCmotorworksoverafairrangeofvoltage.Thehigher theinputvoltagemoreistheRPM(rotationsperminute)of

themotor.Forexample,ifthemotorworksintherangeof 612V,itwillhavetheleastRPMat6Vandmaximumat12V.

2.5 Specification

Dimensions

A) DimensionofSupportingStructure:

Dimensionsofsupportingstructuregetfixedaccording to thesizewewantfortheproject.

Hencedimensionofthesupportingstructureis:

Length(outer)=12lcm Breadth(outer)=12lcm

Height =45cm

Length(inner)112.4cm

Breadth(outer)112.4cm

B) Dimensionofmesh:

Meshshouldfitinsidethestructurehencemeshshouldbe lessthanandequaltoeachsideofthestructuredimensions.

Dimensionforkeepingmeshforeachstructureis:

Length(outer)=45cm Breadth(outer)=33cm

Length(inner)=40.4cm

Breadth(outer)=27.4cm

C) Dimensionsofmechanismandmotormounting

Length=15.3cm

Breadth=3.5cm

D) MechanismDimensions

l.Circularcrankdisc

DiameterOfdisk=14.2cm

Thicknessofdisk=0.5cm

2.SlidingYoke

Height (total yoke) = 16.8cm Length (total yoke) 3.9cm

Height =45cm

Length(inner)112.4cm

Breadth(outer)112.4cm

Dimensionofmesh:

Meshshouldfitinsidethestructurehencemeshshouldbe lessthanandequaltoeachsideofthestructuredimensions.

Dimensionforkeepingmeshforeachstructureis:

Length(outer)=45cm Breadth(outer)=33cm

Length(inner)=40.4cm

Breadth(outer)=27.4cm

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

Dimensionsofmechanismandmotormounting

Length=15.3cm

Breadth=3.5cm

MechanismDimensions

l.Circularcrankdisc

DiameterOfdisk=14.2cm

Thicknessofdisk=0.5cm

2.SlidingYoke

Height(totalyoke)=16.8cmLength(totalyoke)3.9cm

3,Connectingrod

Length 13.3cm

SpecificationofMotorRPMoftheMotor=45rpm

VoltageoftheMotor=12VDCTorqueofthemotor=196Nmmmm

Figure:8 12RT1245battery

Table: 2 TableofComponent

SrNo. Component

Material selected

Reason(s) for Selection

1 Frame Mildsteel high wear resistance, high strength, good rigidity.

2 Speedreducer Shaft Carbonsteel high strength, good machinability, heat treatment properties, high wear resistance properties.

3 SlidingYoke Acrylic Material

Highly transparent, highly impact resistant, easy to cleanandpolish,high durability, light and easy to ort, more scratchresistant.

4 Plywood Wood high strength andstability,high resistance to impact,flexibility in size, shape, thickness.

5 Clamp Mildsteel

High wear resistance,high strength, rigidity.

6 Boltsandnuts Stainlesssteel high resistance to corrosion

7 Controlswitch Plastic ow cost and light weight, good insulating property.

8 Mesh StainlesssteelHigh resistance to corrosion.

4. Future Scope:

ΠRiceThreshingcanbeautomated

Π Winnowing can be done by making automated sand filtrationmachine.

ΠCornShellingandpeanutshellingcanbedonewithhelpof thissetup.

Automated Baby cradle can be made by using same mechanismandconcept.

ΠOperatingaCircularSaw

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 05 | May 2024 www.irjet.net p-ISSN: 2395-0072

ΠWaterPumpingfromaShallowWell

ΠOperatingaWoodWorkingLathe

Πforthelargerdemandhorizontalsandseparatorismost efficient as its efficiency reduced as the amount of sand reduced and sand separators are used in small scale and mobilework,onewaysandfiltrationtechniqueavailablein market but requirement and advantages of two-way advancedsandfilterismoreinpracticallife.

5. Conclusions

A complex biogas production and utilization system was createdbydevelopingexperimentalbiogasvariants,andin suchawayboththeenergyandtheenvironmentalgoalscan be achieved together, as the applied variants can provide favorableconditionsfortheproductionandtheutilizationof biogas.Themethanecontentofbiogassatisfiestheconditions ofutilizationsothattheheatenginescanoperateproperly. Simultaneously,wastedisposal canalsoberealized.Inthe interestofanearoptimalsolution,itisnecessarytoanalyze theproductionandutilizationfunctionstogether,considering thattheprincipleofthecomplexoptimizationfocusesjuston the environmental-friendly energy utilization. Thus, if the quantityand/orqualityoftheinputmaterialnecessaryfor developingvariantscannotbeprovided,theenergyoutput candecreaseandwastedisposalcanbeovershadowedtoo.

This work was supported by Government College of EngineeringJalgaonandCivilEngineeringDepartmentand ourguideDrVidyaSaraf.

[1] Review of Multi-level Sand screening Machin and Analysis of "Vibration mechanism “Swapnil Bandgarl, DnyaneshwarChate2,VijayDongare3,DipakMirpagar Vol-4Issue-32018IJARIIE-ISSN(O)-2395-4396

[2] "Traditionalmethodofsandsieving."[Online].

Available: https://www.ekshiksha.org.in/chapter/77/images_of_S eparation_of_substancesVI/8.png.[Accessed:10-Mar2020]

[3] Design and Fabrication of Automatically Driven Sand SievingMachine.R.GajbhiyelPrashantGawalkar2Rahul Pache3 Rupesh Khode4 Vicky Chap l Vol. 7, Issue 01, 2019|ISSN(online):2321-0613

[4] DesignandFabricationofInclinedTrommelAutomatic Sand Sieve Machine Sunil Chavhan1, Dilip Bhagat2, AshwinPatil3,PallaviBisne4,Pratikshashakhare5,Prof. NehalJadhaovolume:07Issue:05May2020fabrication ofsieving".V.P.Duriraj2,J.Manikandan.

[5] BureauofIndianstandardsIS:383-1970,"Specification forcoarseandfineaggregatesfromnaturalsourcesfor concrete

[6] Design and Fabrication of Sand Sieving and Cement MixingMachineSaiKarthik

[7] Design,ConstructionandTestingofaDrySandSieving Machine, Oladeji Akanni Ogunwole Journal of Multidisciplinary Science & Technology Volume: 01 Issue:03|July-2016

[8] DesignandFabricationofHorizontalSievingMachine, Nachimuthu A.K et International Research Journal of Multidisciplinary Science & Technology Volume: 01 Issue:03|July-2016

Nemcsics,Á.:Technical Ecology(Aműszakiökológia), Természetbúvár,Hungary,Vol.1(2003)p.37

[9] Braun,R:Biogas-MethangärungorganischerAbfallstoffe, SpringerWien(1982)

© 2024, IRJET | Impact Factor value: 8.226 | ISO 9001:2008