International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

1B. Tech Civil Engineering, Student, JCET, Palakkad, Kerala, India

2B. Tech Civil Engineering, Student, JCET, Palakkad, Kerala, India

3B. Tech Civil Engineering, Student, JCET, Palakkad, Kerala, India

4B. Tech Civil Engineering, Student, JCET, Palakkad, Kerala, India

5Professor, Dept. of Civil Engineering, JCET, Palakkad, Kerala, India

Abstract – Finding alternative sources of raw materials is essential for sustainability of construction. Engineers are increasingly striving to use wastes as a sustainable supplement for conventional building materials. Many researchershavebeenadvocatingvariousprocessestoutilize the waste materials in as a supplement to the scarce traditional sources. Nowadays decomposition of waste materials is one of the most difficult problems, which affects the environment. Sewage sludge is the residual left from sewage treatment processes. Sludge production raises proportionately to the wastewater collection at treatment facility and also increase in the amount of effluent in water. Sewage sludge contains pathogens and potentially harmful chemicals that cause risk to human health. Hence by making use of this material, it will become a remedy for this problem. Irontailings,isawastematerialfromblacksmith'sworkshop. The inclusion of iron tailings and sewage sludge offers ideas and a vision for recycling waste to enhance the qualities of construction materials and prevent the loss of natural resourceslikeclay.Throughthisstudy,differentproportionsof sludge and iron tailings are used to cast clay and cement bricks. While also increasing the usage of industrial wastes and improving sustainability of bricks as a construction material.

Key Words: Bricks, Sewage sludge, Iron tailings, Waste management, Recycling waste, Sustainable construction materials.

Clay bricks are made from clay that is usually mixed with sand and other additives to enhance its properties. The mixtureisthenformedintorectangularblocksusingmoulds, which are then left to dry in the sun or in a controlled environment. After drying, the bricks are fired in a kiln at hightemperaturestomakethemstronganddurable.

One of the advantages of clay bricks is that they are environmentally friendly, as they are made from natural materials and are recyclable. They also provide excellent thermal insulation, helping to keep buildings cool in the summer and warm in the winter. So many attempts have beenmadetoincorporatethewastesintotheproductionof

bricks to reduce the clay content in bricks and thereby protectingtheenvironment.Conventionalcementbrickisa mixture of cement and aggregate. Properties of aggregate affectthedurabilityandperformanceofbricks.Themostly usedfineaggregateisnaturalriverorpitsand.Aggregates constituteabout75%oftotalvolume.

Sewage sludge, also known as biosolids, is the semi-solid material left over after wastewater treatment processes Treated sludge, also known as biosolids, is sewage sludge thathasundergoneatreatmentprocesstoreducethelevels of pathogens and contaminants and make it safe for beneficialuse.Sludgefromwastewaterisbiodegradablebut itrequireslargeareaandtimetodisposecompletely.Useof sludgefromwastewatertreatmentplantsintheproduction ofbricksnotonlyreducetheenvironmentalharmbutalso reduce cost of production of bricks as sludge is waste material.Thesewagesludgehasplasticpropertiessimilarto thatofclayandhencetheclayisreplacedbysludge.

Iron tailings is also a waste material obtained from blacksmith’sworkshopwaste.Irontailingscanbeaddedto clay bricks as a fluxing agent to impart heat to the clay during firing and also improve the compressive strength. The addition of iron tailings in clay brick production can have several benefits, including improved strength and enhancedaesthetics.

To introduce a satisfactory means of disposal, these two wastes were combined to produce a building material. It givesaninnovativeapproachtoconvertlargelyunacceptable wastes to a beneficial and useful material. The reuse of sludgeasbrickmaterialisalong-termapproachtosludge disposal for economic and environmental sustainability. Here, bricks have to be cast for various proportions of sludge, iron filings and soil mixture. The structural and environmentalsuitabilityofthebrickhavetobeevaluated and they have been tested for various engineering properties.

Collectionofrawmaterials

Identificationofpropertiesofmaterials.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Preparationofrawmaterials.

Manufacturingofbricks.

Testingofbricks.

Analysisofresults.

Drysludgeshouldhavea lowmoisturecontenttoprevent excessiveshrinkageandcrackingduringthedryingandfiring process.Drysludgecancontainorganicmatterthatcanaffect thefiringprocessandthepropertiesofthefinalproduct.The organiccontentshouldbelowtopreventexcessivesmoke, odors, and cracking during firing. The particle size of dry sludgecanaffecttheworkabilityandhomogeneityoftheclay mixture.Itshouldbefinelygroundtoensurepropermixing and distribution within the clay mixture. The chemical compositionofdrysludgecanaffectthefiringprocessand the properties of the final product. It should be free from contaminants such as heavy metals, pathogens and other harmfulsubstances

Irontailingscanimprovethestrengthofthebricksbyacting asareinforcingmaterial.Whenthebricksarefired,theiron tailings fuse together with the clay particles, forming a strongerbond.Thiscanhelptoreduceenergyconsumption andimprovetheenergyefficiencyofbuildingsconstructed withthesebricks.

Irontailingscanhelptoreducecrackinginthefinalproduct by reducing shrinkage during the firing process. This is becauseirontailingsdonotshrinkorexpandasmuchasclay during the firing process, helping to reduce the overall shrinkageofthebrick,improvedcolor Dependingonthetype ofirontailingsused,thebrickscanhaveauniquereddishbrowncolorthatcanbeappealingincertainapplications.

The clay brick is manufactured by mixing the soil with variouspercentagesofsewagesludgeandirontailings.The siltyclaytypeofsoilisusedforthemanufacturingofbrick. The silty clay soil contains silica, alumina, iron oxide, magnesia,limeandorganicmatter.

Sewagesludgepossessasimilarnaturetothatofclay.For themanufacturingofbricks,thesewagesludgeisdriedand sieved.Thedriedsludgeofsizebelow600micronsisused. Thesludgeisaddedinvariouspercentageslike10%,15%, and 25%. Similarly iron tailings are also powdered and sieved. The tailings of size below 600 microns is used to manufacture bricks. The iron tailings is added in varying percentagesof1,2and3%inclaybricks.Thecementbricks weremadebyaddingirontailingsinvariouspercentages ThecementbricksaremadeintheproportionsofM15and M20withpartialreplacementoffineaggregate(sand)by25 and50%.theproportionsofclaybricksaregiveninthetable below.

Table-1: Proportionofclaybricks

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Thefigurebelowshowsthemanufacturedclaybricks.

Various tests are done on bricks to find the suitable proportion of bricks made with sewage sludge and iron tailings.

Thecompressivestrengthofconventionalclaybricksis11.25 N/ .Thesurfaceareaofbrickis20000mm2 .

Tableshowsthecompressivestrengthtestresultsofvarious proportionsofbricks.

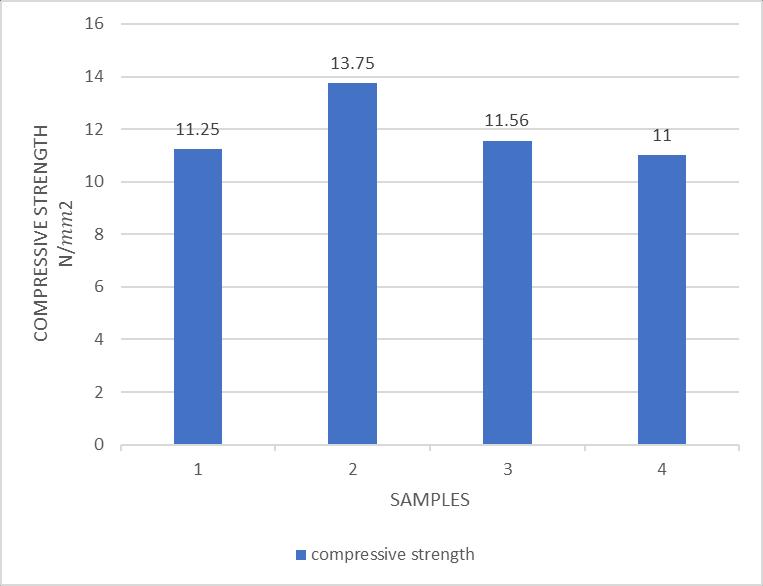

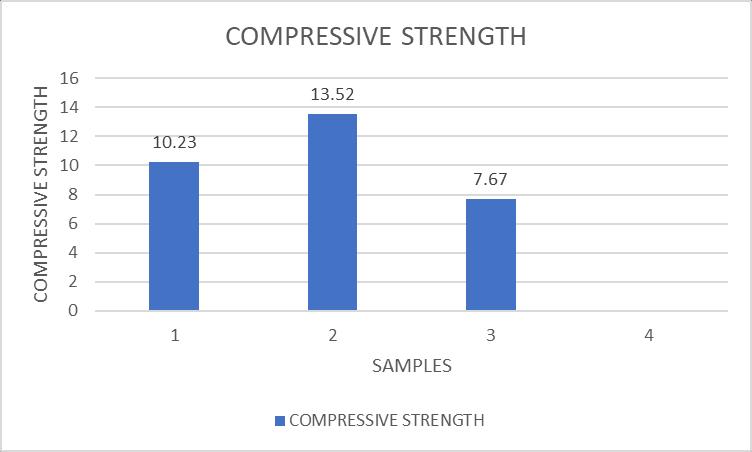

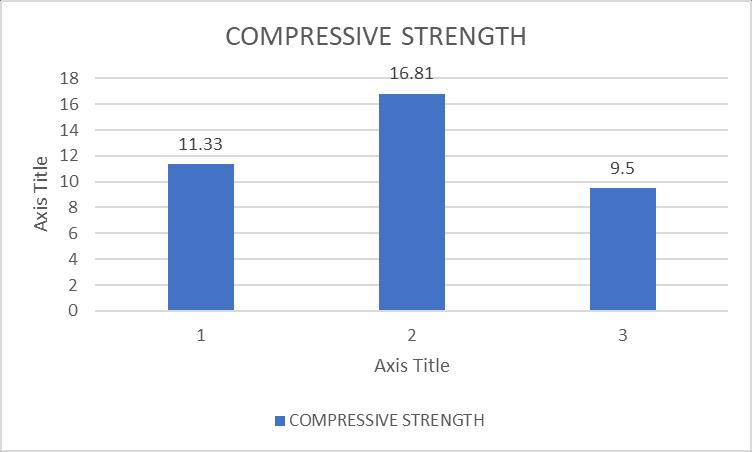

Thegraphicalrepresentationofcompressivestrengthresults isshownbelow;

Thefigureshowsthecompressivestrengthresultsofnatural claybricksandbrickswith10%sewagesludgewithvarying percentagesofirontailingsas1,2and3%.Fromthegraph wecananalyzethatthebrickswith10%sludgeand1%iron tailings gave higher compressive strength with a value of 13.75N/ .Thebrickswithproportion10%sludgeand 2%irontailingsalsogivehighercompressivestrengththan conventionalbrick.Butthebrickwith10%sludgeand3% possess a lower compressive strength than conventional brick.Astheirontailingsincreasesthebrickmaybegaining brittlenatureandhencelowerstrength.

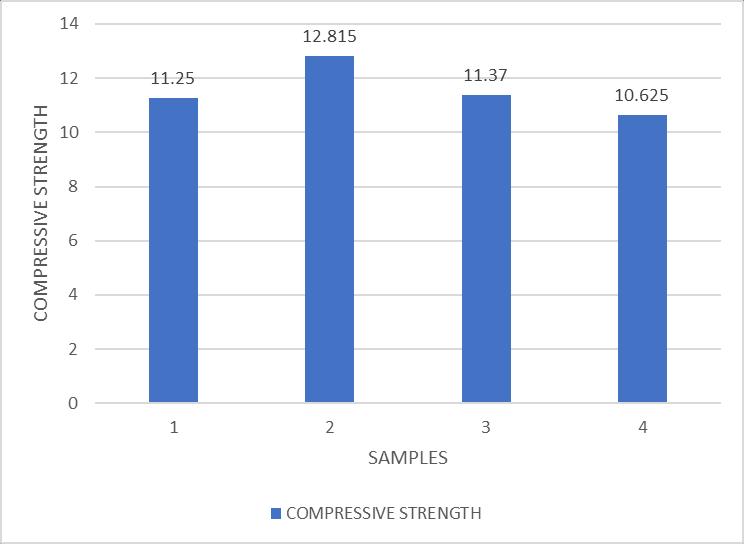

Thegraphaboveshowsthecompressivestrengthofnatural clay bricks and bricks with 15% sludge with varying percentages of iron tailings like 1, 2 and 3 %. By the comparisonofthecompressiontestresults,thebrickswith 15%sewagesludgeand1%irontailingsgivesthehigher compressive strength than conventional brick. It gives a valueof12.81N/ .Theotherproportionwith2%iron

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

tailings also gives more compressive strength than conventionalbrickswithavalueof11.37N/ .Butthe proportion of bricks with 3 % iron tailings gives lower compressivestrengththanconventionalclaybricks.

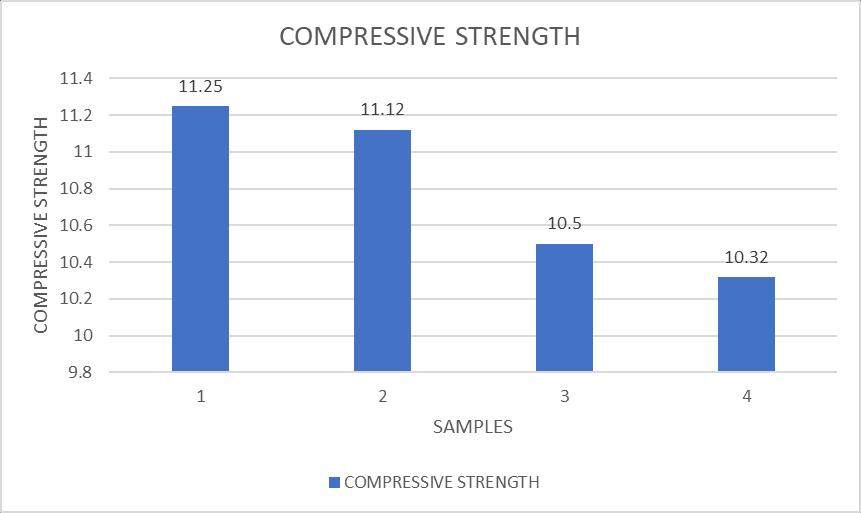

Chart-3: Compressivestrengthofbrickwith25% sludge

Theabovegraphshowsthecompressivestrengthofbricks with25%sewagesludgewithvaryingpercentagesofiron tailings.Theresultsofthetestgivethat,theypossessalower compressive strength than conventional bricks. By comparison,thecompressivestrengthofthebricksreduces whenthepercentageofaddingirontailingsisincreased

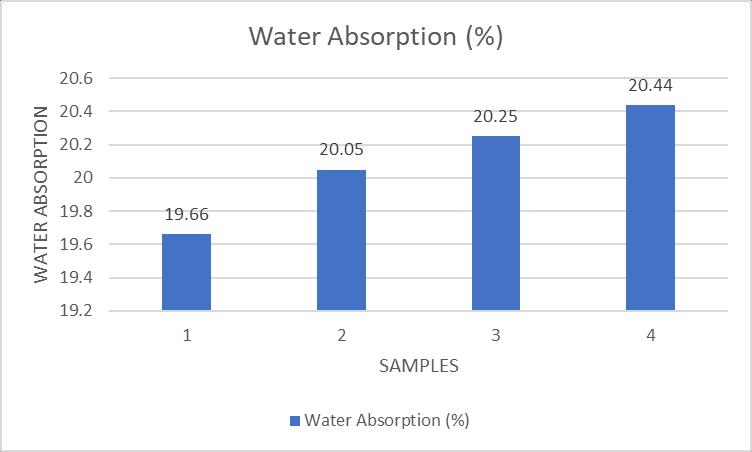

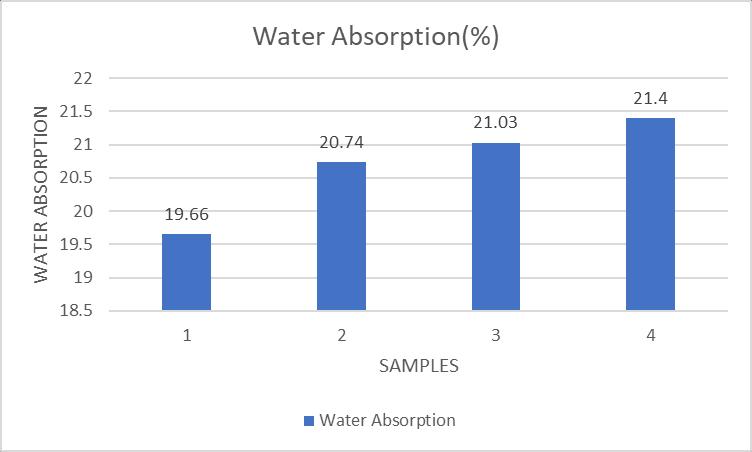

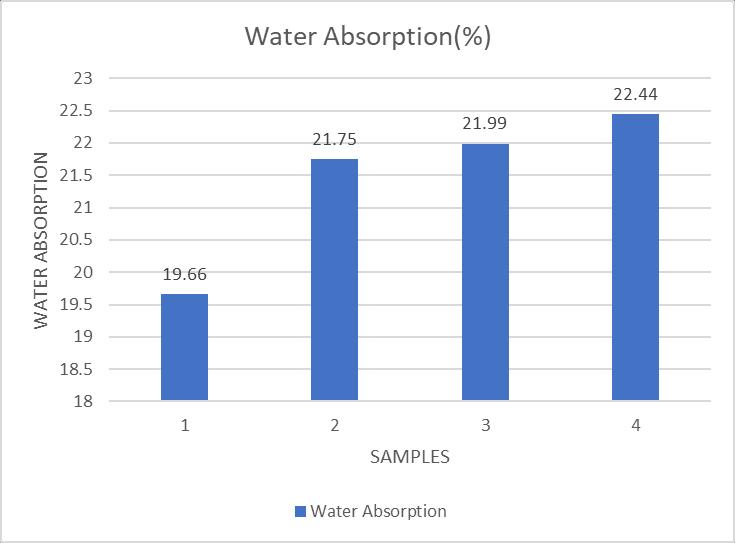

Thewaterabsorptiontestofconventionalbrickisdonefor comparison. The dry weight of the conventional brick is 2039gandthewetweightis2538g.Thewaterabsorptionof conventional brick is 19.66%. For mix with 10% sewage sludge, the minimum water absorption is shown by brick with 1% iron tailings For the mix with 15% sludge, the minimumisshownbythebrickwith1%irontailings.Forthe mix with 25% sludge, the minimum water absorption is shownbybrickwith1%irontailings.Whenthesludgecontent increasesthewaterabsorptionalsoincreases.TheMixwith 25%showsthemaximumwaterabsorption.Also,increasein theamountofirontailingsincreasethewaterabsorptionof bricks.Thus,waterabsorptionislessforbrickswith1%iron filings.Thegraphicalrepresentationofwaterabsorptionis givenbelow.

Waterabsorptionofbrickswith10%sludge

Chart-5: Waterabsorptionofbrickswith15%sludge

Chart-6: Waterabsorptionofbrickswith25%sludge

Efflorescence is an important issue in the development of alkali-activated or geopolymer binders. All bricks were examinedforefflorescence.Efflorescenceisnotoccurredin any bricks under observation From the test results, white patchesdidn’tappearonthesurfaceofbricks.So,bricksare freefromsaltcontent.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Hardnessofbrickistheresistancetoscratchingorcutting.In thistest,ascratchismadeonthebricksurfacewiththehelp of a finger nail. No impressions areleft on the bricks after scratching by finger nails.Therefore, bricks aresufficiently hard.

5.5 Soundness test

Twobricksaretaken,oneineachhand,andtheyarestruck witheachotherlightly.Themanufacturedbrickwithsewage sludge and iron tailings did not break and a clear ringing soundisproduced.

5.6 Color test

Themanufacturedbrickpossessesauniformcolorofreddish brown The uniformity in color of bricks represents uniformity in chemical composition and homogenous burningofbrick.

5.7 Shape and size test

Bricks are compared according to their length, width and height.Allbricksareseemedofsimilarsize.

6. TEST ON CEMENT BRICKS

6.1Compressive strength of cement bricks

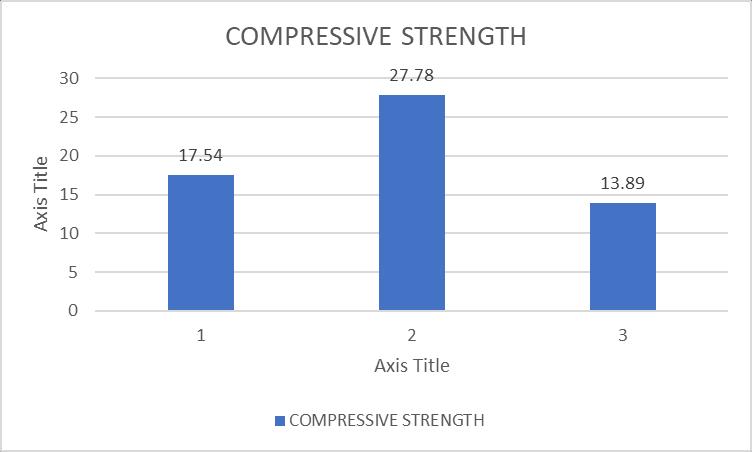

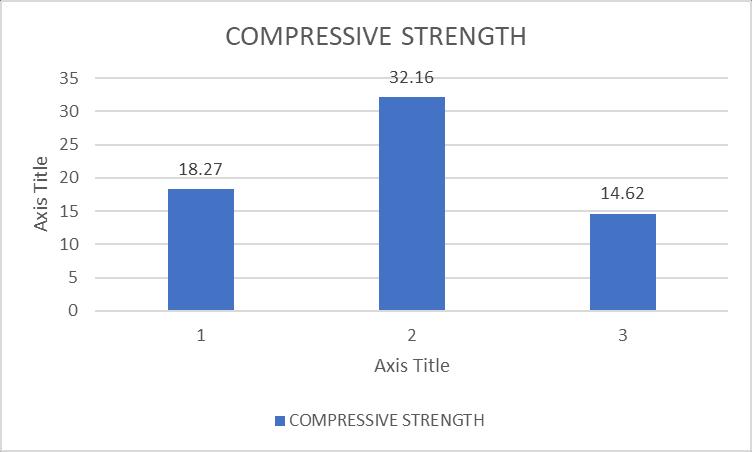

Cement bricks made with iron tailings also gives more compressivestrengththanconventionalcementbricks.The replacement of fine aggregate by 25% gave more compressivestrengththanconventionalcementbricks.The replacement of sand by 50 % iron tailings gave lower compressivestrengththanconventionalcementbricks.The curingisdonefor7daysand14daysandtheircompressive strengthsaredetermined.Thecomparisonofcompressive strengthofnormalbricks,brickswith25%replacementof fineaggregatesand50%replacementrespectivelyaregiven below.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Chart-10: compressivestrengthofmixratioM20of14 dayscuring

The comparison of results finalizes that the compressive strength of cement bricks also increases with the replacement of fine aggregate by iron tailings. But more replacement of sand by iron tailings decreases the compressivestrengthofbrick.

7.

By utilizing these waste materials, it provides an alternativewaytomakebrickinmostcosteffectiveway. Useoftailingswithclayforproducingbrickscanleadto consumptionoflargequantitiesofwastematerialsand manageitinanenvironmentfriendlyway.

Asperthetests,theclaybrickswith10%and20%sludge with 1 and 2% iron tailings gives more compressive strengththanconventionalbricks.Theotherproportions give a lower compressive strength than conventional brick.

The water absorption test of 10% sludge and 1% iron tailingsgaveminimumwaterabsorptionof20.05%.

From the result analysis, it can be concluded that the brickswith10%sludgeand1%irontailingsisasuitable proportiontomanufacturethebrickswithgoodqualities.

The replacement of sand by iron tailings by 25% in cement bricks also gives higher compressive strength thannormalbrick.But50%replacementofirontailings giveslowercompressivestrength.

Thebricksmadewithsewagesludgeandirontailingswill introduceagoodquality,ecofriendly,andfeasiblebricks in to the construction field where no additional techniquesareneededfortheproductionofbricks.

[1] Eman N Shaqour, Aimen H Abo , Aimen A Rasheed (2021), Journal of Engineering and Applied Science, Volume 68, issue 5, “Improved fired clay brick compressive strength by recycling wastes of blacksmiths’ workshops”.

[2] K Muoulato, M Ammari, L Ben Allal (2023), Global Journalof Environmental Science and Management, “performance of sewage sludge reuse in the manufacturing of fired bricks”

[3] Kumaresh Bahera, Bishnu Pada Bose, Milan Kumar (2022)InternationalJournalofWasteManagementand ResourceEfficiency,“Production of Construction Bricks Using Iron Ore Tailings and Clay”.

[4] P. Amsayazhi, K Saravana Raja Mohan (2018), InternationalJournalofEngineering&Technology,“Use of Sludge Waste as Ingredient in Making of Brick” .

[5] Ranjeet Kumar Singh, Shailendra k Singh, Nimisha Tripathi (2021) In Journal of Scientific & Industrial Research,Volume80,“UtilizationofIronOreTailingsfor BrickManufacturefromDonimalaiMinesofKarnataka, India”

[6] Tuanizat, Mariyana Bandieira, Gihad Mohamad, Robinson C D Cruz (2021), International Journal of EnvironmentalManagement,“Potentialre-useofsewage sludgeasarawmaterialintheproductionofeco-friendly bricks”.