International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

DESIGN, DEVELOP AND IMPLEMENTATION OF D PUNCH MACHINE

Mr. V.R.Sonawane1, Sneha Chaudhari2, Nupur Duse3 and Siddhesh Divate4

1Professor, Electronics and Telecommunication

MVP'S Karamveer Adv. Baburao Ganpatrao Thakare College of Engineering, Nashik 2,3,4 Student, BE Electronics and Telecommunication

MVP'S Karamveer Adv. Baburao Ganpatrao Thakare College of Engineering, Nashik

Abstract :- Drill machines have been the core of every industry. Drilling holes in parts, sheets and structures is a regular industrial work. The demand for efficient and precise manufacturing processes in various industries has led to the development of specialized machinery tailored to specific tasks. For precise and secure drilling, fixed drills are essential. However, in instances wherethereis limitedspacebetweenthe drill bit and drill bed, fixed drills may not be suitable. In such cases, hand drills are necessary, but they often encounter alignment issues during drilling. This research focuses on the design, development, and implementation of a Drill Hole Checking and Punching Machine (D Punch Machine), a special purpose machine aimed at automatingtheprocess ofverifying drill hole dimensions and accurately punching in workpieces. The primary objective of this machine is to design, manufacture, and assemble parts while verifying the proper execution of the drill hole inspection. Ifthedrillholeinspection is successful, the machine proceeds with the subsequent punching process. However, if thedrillholeinspectionfails, the part is rejected.

Key Words: Special Purpose Machine (SPM), Drill machines, Precision, Drill Hole Checking and Punching Machine,drillholeinspection.

1. INTRODUCTION

1.1 Motivation:

The use of drill hole checking and punching machine’s is essential in maintaining high quality and precision in manufacturingoperations.Thesemachinesoffernumerous benefits, including cost savings, improved efficiency, and faster results. By automating the inspection process, the needformanualinspectionisreduced,whichsavestimeand minimizes the risk of human error. Additionally, these machinesprovideahigherlevelofprecisionandconsistency in measurements, enabling early detection of errors or deviations. This helps to prevent defective products from reachingthemarket,whichultimatelyprotectsacompany's reputation and financial well-being. With the ability to rapidly inspect and measure multiple drill holes and punchedfeatures,thesemachinesareavaluableadditionto anymanufacturingfacility.Investindrillholecheckingand punchingmachinestotakeadvantageofthesebenefitsand improveyourmanufacturingprocess.

1.2 Necessity:

Theneedoftheprojectistocheckwhethertheworkpieces orjobhasaproperdrillholeornot.Asdrillholeoperation onaworkpieceisregularindustrialworkso,itisrequiredto be perfectly done. Thus, this SPM is developed to analyze whether thedrill holeoperationis properlyperformed or not.Iftheoperationisfailedthentheworkpieceisrejected which can cause various other issues such as inadequate sample identification, deviation of drill hole, more feed, Instrumentationerrors.

1.3 Objectives:

1)Tostudyanddevelopafunctionalandefficientdrillhole checking and punching machine that meets the industry’s standardsandrequirements.

2) To ensure that the machine can accurately locate and verify drill hole positions on workpieces and check and punchwithhighprecision.

3) To implement automation features to reduce manual laborandincreaseproductivity.

4)Toreduceproductioncostbyminimizingmaterialwaste, laborrequirements,etc.

2. LITERATURE REVIEW

2.1 Literature Survey:

Suchada Sitjongsataporn(IEEE), This paper features an automatic prototype drilling and sorting line using programmablelogiccontrol(PLC).

Nekrasov, S.; Zhyhylii, D.; Dovhopolov, A.; Karatas, M.A. researchesonmanufacturingofthenewinnovativejointof FRPmachineparts.

MajidRad,methodadoptedisofAutomationwhichimprove productivityandefficiencyofoperationtobeperformedand multispindle drilling for high output with challenges like Unplanned pauses in the process of drilling causes interruption inmachinery.

N.A.Ghaffar,AhmadBaharuddinAbdullah,ZahurinSamadHole precision is highly critical for precise assembly. This

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

factorisconsiderablyvitalforstructuralmaterials,suchas compositematerials.

Prof.CatalinTeodoriu(UniversityofOklahoma),Automation indrillingequipmentisthemethodbeingadoptedandthe benefitsareusedindrillingperformancethroughadvancing systemsandmethods,Companyenableddrillingsolutions, improvedfeasibilityanddifficultyfaced

O.OJoesph(NBRRIinstitute),methodadoptedisAutomation and punching for SPM and the features are to Reduced material waste ,high speed production and the main challengesoccurredafterexecutionareofMaintenance,Tool costs

Giasin, K.; Hawxwell, J.; Sinke, J.; Dhakal, H.; Köklü, U.; Brousseau,E.Thechangesofcuttingtoolcoatedonformand measurementalerrorsofmachinedholes.

MuhammadAamir,MajidTolouei-Rad, KhaledGiasin-Inthe industrythedrillingprocessisthemostchallengingamong alltheothermachineryprocessasmillionsofholesareused tomakeboltedjoints.

3. METHODOLOGY

3.1 Workflow :-

The flowchart shows the steps involved in a process that uses a pneumatic cylinder to pass air through a part. The process starts and the part is set on the machine. This is followed by passing air inside, solenoid valves are electromechanical devices that control the flow of air or process gas and are used for controlling the pneumatic cylindersintothepart(job).Theairpassingwillbedetected by air pressure switch. Air pressure switch are used in pneumaticsystemtomonitorchangesinairpressure.

Thenitentersinthecontinuousloop,iftheairpassesfrom onepointtoanotherpoint,asindicatedbythe"Yes"path, thenitwillproceedto"Pressletter"D"onpart".

Iftheairdoesnotpassfromonepointtoanotherpoint,as indicated by the "No" path, the part is then thrown into a rejectionbox.Thenextcyclestartscontinuouslyunlessthe machineisturnedoffbytheoperator.Thismeansthatthe machinewillcontinuetocyclethroughtheprocessuntilitis turnedoff.

Overall,theflowchartshowsaprocessthatusesapneumatic cylindertotestwhetheraircanpassthroughapartornot.If aircanpassthroughthepart,thepartismarkedwitha"D" and then rejected. If air cannot pass through the part, the machinecyclesthroughtheprocessagain.

3.2 Block Diagram:

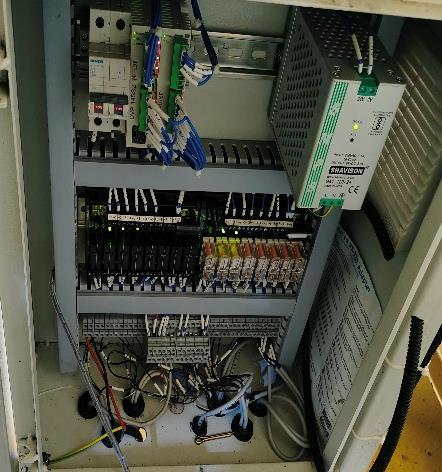

Thisblockdiagramshowsintegrationofcomponentstocrea teanefficientandautomatedsystem.Whenthemachinegets started the part will be set on the machine and then the sensors will determine the actual part and then the air pressure passed through the pneumatic cylinder from the part with the help of PLC will be determined and through PLCitwillanalysethepassorfailcondition.Hence,thehole willbecheckedinthepartandtheoutputwillbeobtained.

International

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Designingadrillholecheckingandpunchingmachineusing AutoCAD is a complex process that requires following severalsteps.However,followingthesestepswillensurea successfuloutcomethatmeetsallrequirements.Bydefining the requirements, creating a conceptual design, and using AutoCADtocreatea2Dand3Dlayout,themachinecanbe designed with precision and accuracy. Additionally, designing individual components, assembling them correctly,andcreatingdetaileddrawingsarecrucialstepsin theprocess.Byperformingvirtualtestsandsimulations,the machine can be tested to ensure it functions as intended. Oncethedesignisfinalized,themachinecanbeprototyped andtestedintherealworld.Byfollowingindustrystandards andbestpractices,AutoCADprovidesapowerfulsetoftools for designing, simulating, and documenting complex machineslikeadrillholecheckingandpunchingmachine.

5. RESULT

Improved Quality Control :This leads to a reduction in defective parts and an overall improvement in product quality as error caused due to manual intervention were minimized.

IncreasedEfficiency:Withautomateddrillingandpunching operations,numberofunitsmanufacturedearlier-200(per shift),numberofunitsmanufacturednow-800(pershift)

EnhancedAccuracyandPrecision: 99%partareinspected beforeproceedingfornextoperations.

FlexibilityandVersatility:Dependingonthecapabilitiesof the machine, it can offer flexibility in handling various materials,holesizes,andpatterns.Thisversatilityallowsfor adaptingtochangingproductionneedsandrequirements.

CostSavings:Reducedlaborcosts,decreasedmaterialwaste duetofewererrors,andincreasedproductivitycontributeto overallcostefficiency.

6. CONCLUSION

Insummary,theDrillHoleCheckingandPunchingMachine marks a significant leap forward in manufacturing

technology,providingaremedyfortheinherentchallenges encountered in drilling and punching processes within industrial environments. The implementation of this machine has yielded remarkable results, with process efficiencysoaringtoanimpressive95%.Thisimprovement notonlybolstersproductivitybutalsoleadstosubstantial costreductionsandwasteminimizationformanufacturing enterprises.

Moreover, our study underscores the pivotal role of automationandprecisionincontemporarymanufacturing practices.Byintegratingsophisticatedtechnologiessuchas automated checking and punching mechanisms, we can mitigatehumanerrors,ensureuniformityinproductquality, andstreamlineproductionworkflows.

Furthermore, the successful deployment of the Drill Hole CheckingandPunchingMachineunderscoresthepivotalrole of research and development in tackling industry-specific hurdles. This endeavor serves as a testament to the transformative potential of innovation in enhancing efficiency and competitiveness within the manufacturing domain.

Lastly, the Drill Hole Checking and Punching Machine heralds a promising era of enhanced manufacturing efficiency,providingaglimpseintothefutureofautomated production systems. Through continued innovation and refinementofsuchtechnologies,wecanchartapathtoward amoreefficient,sustainable,andcompetitivemanufacturing sector.

ACKNOWLEDGEMENT

We would like to express our sincere gratitude and appreciation to all those who have contributed to the successfulcompletionoftheDrillHoleChecking&Punching MachineProject.

Firstandforemost,weextendourheartfeltthanksto[Mr. VirajSonawaneSir&Mr.SandipGadheSir],whoseguidance, expertise, and support were invaluable throughout this project.Theirinsightfulfeedbackanddirectionhelpedshape theproject'scourseandensureditssuccessfulexecution.

Wewouldalsoliketoacknowledgethecontributionsofour team members [Siddhesh Divate], [Sneha Chaudhari], [Nupur Duse], whose dedication, hard work, and collaborationwereessentialinovercomingchallengesand achievingprojectmilestones.

Furthermore, we are grateful to [Company- Quaint Automation Pvt Ltd. Nashik] for providing us with the necessaryresources,facilities,andencouragement,without whichthisprojectwouldnothavebeenpossible.

Lastbutnotleast,weextendourthankstoalltheindividuals andorganizationswhoprovideduswithvaluableinsights, feedback,andsupportduringvariousstagesoftheproject.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

REFERENCES

[1] Suchada Sitjongsataporn (IEEE) “Development of Automatic PLC-basedColorObject SortingandDrilling LinePrototype”

[2]Nekrasov,S.;Zhyhylii,D.;Dovhopolov,A.;Karatas,M.A. Researchonthemanufactureandstrengthoftheinnovative jointofFRPmachineparts.J.Manuf.Process.2021,72,338–349.[GoogleScholar][CrossRef]

[3] Majid Tolouei-Rad (Edith Cowan University) “Drilling Technology”.

[4] N.A. Ghaffar, Ahmad Baharuddin Abdullah, Zahurin Samad- “Precision hole making on laminate composite: A tool wear analysis and comparison between drilling and punching“.

[5]Prof.CatalinTeodoriu(UniversityofOklahoma)“Drilling SystemDesignandOperations”.

[6]O.OJoesph(NBRRIinstitute)“AutomationandPunching Machine”

[7] Giasin, K.; Hawxwell, J.; Sinke, J.; Dhakal, H.; Köklü, U.; Brousseau,E.Theeffectofcuttingtoolcoatingontheform anddimensionalerrorsofmachinedholesinGLARE®fibre metal laminates. Int. J. Adv. Manuf. Technol. 2020, 107, 2817–2832.[GoogleScholar][CrossRef][GreenVersion].

[8]MuhammadAamir,MajidTolouei-Rad, KhaledGiasin–“A review: drilling performance and hole quality of aluminiumalloysforaerospaceapplication.”