International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

Tanaya P. Jagtap1 , Heramb S. Khandve1 , Parth J. Khedekar1 , Pranjali R. Tete2

1U.G. Student, Dept. of Mechanical Engineering, AISSMS COE, Pune, India 2 Assistant Professor, Dept. of Mechanical Engineering, AISSMS COE, Pune, India

Abstract - Even though India has seen many advancements in regards to Electric Vehicles, one of the main issues Indian EVs are facing is dealing with the temperature irregularities within the battery pack, effective cooling systems and sudden fires to batteries. Though adapting to new techniques is essential, cost cutting, compactness of the system and optimal weight of the battery should be looked after as well. A battery thermal management system with phase change material with silica, aluminum fins and perforated slots is developed which effectively improves the battery working condition. An intricate system based on multipurpose dry chemical fine powder, which would act on extreme conditions of fire and thus cease the spread of fire and protect the vehicle and the passengers has been developed. An effective battery thermal management system can significantlyreduce the chances ofan EV battery catching fire, maintain the temperature distribution within the battery pack and thus improve the life of a battery.

Key Words: Phase Change Material (PCM), Silica, Battery Pack, Effective Cooling, BatteryThermalManagement System, Electric Vehicle, Fins.

Currently in India, Government is enforcing the stringent emissionnormsfortheinternalcombustionenginesdriven vehicle.Hencethevehiclemanufacturershavetoshifttheir focustothemanufacturingoftheelectricvehicles.Oneofthe challenges is to develop an efficient battery thermal managementsystemforanelectricvehicle.Thissystemalso applies to a large number of different vehicle applications, rangingfromthecompactcartothemulti-utilityvehicleand fromthelow-levelhybridvehicletotheentirelyelectricallydrivenvehicle.Thus,itbecomesnecessarytodevelophighly efficientenergystoragedevicesforthesame.Theattraction oftheelectronicsmarkettowardslithium-ionbatteryasan energystoragedeviceisincreasingprimarilyduetoitshigh energydensity,capacity,longcyclelifeandlowself-discharge rate[1].

Li-ionbatteriesareverysensitivetothetemperature.Inside thesebatteries,duringchargeanddischargeprocesses,like anyrechargeablebatteries,heatisgeneratedthatcausesto

increase their temperatures. This increase in temperature hastwodifferenteffectsonthebatteries.Thebeneficialeffect isthat,byincreasingthetemperature,Li-ionbatterieswork moreefficientlyandtheirperformancebecomesbetter.On theotherhand,theunfavorableeffectisthat,theyarecloser tothermalrunawaythatdecreasestheirreliabilitybecauseof probableexplosion[2].

2. To study the feasibility of phase change material in lithium-ionbatteries.

3. Tousethephasechangematerialwithadditivesandpin finsheatsinksinbatteriesforbetterheatdissipation. 4. To set an experimental setup of a battery pack with PCM,pinfinsandfinepowder.

5. Toanalyzetheproposeddesignandcompareitwitha standardbatterypackofanEVbike.

Battery Thermal Management with PCM presents more effective thermal performance. The pin fins decrease bulk temperature and improve temperature uniformity. Hybrid cooling effect shows an effective rate of heat dissipation. Provisionofventhelpsprotectbatteryenclosure.

In response to safety concerns surrounding OLA S1 PRO batteries,ascaled-downanalysishasbeenundertaken,with datarepresenting1/20thofthebatterypack.Thisdeliberate reductionaimstofacilitatecontrolledtestingandevaluation, givenreportedincidentsoftheoriginalbatteriesexhibiting safetyissues,includinganotableriskofcatchingfire.

The consideration of data of 1/20TH of the OLA S1 PRO batterypackisasfollows:

ThenumberofbatterycellsconnectedinseriesNcs [-]ina string is calculated by dividing the nominal battery pack voltageUbp [V]tothevoltageofeachbatterycellUbc [V]. The numberofstringsmustbeaninteger.Therefore,theresultof thecalculationisroundedtothehigherinteger.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

Ncs=Ubp/Ubc

Ncs=3V/3.6V =0.83 =1S

If1Sinseries,thentheeffectivevoltagewouldbe3.6V. 0.195kWh/3V=65Ah

Nomenclature

k thermalconductivity(W/mk)

h heattransfercoefficient(W/m2k)

ρ density(kg/m3)

Cp specificheat(J/mol.k)

T temperature(k)

t time(s)

C CapacityofBattery

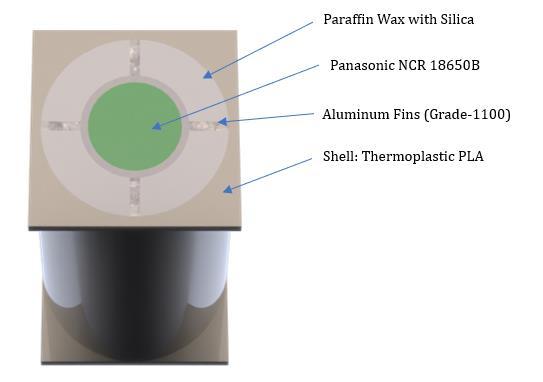

3. PROPOSED BATTERY CONFIGURATION

I. BatteryPackSpecifications:

▪ 1S–20P(20cellsintotal)

▪ Output0.395kWh

▪ 6V/3Ah

II. Singlecellspecifications:

▪ Cylindricalcells

▪ PanasonicNCR18650B

▪ Dimensions-Diameter18mm,Height65mm

III. PCMComposition:

▪ PrimaryPCM–ParaffinWax(GradeRT42)

▪ Additives–Silica(SiO2)

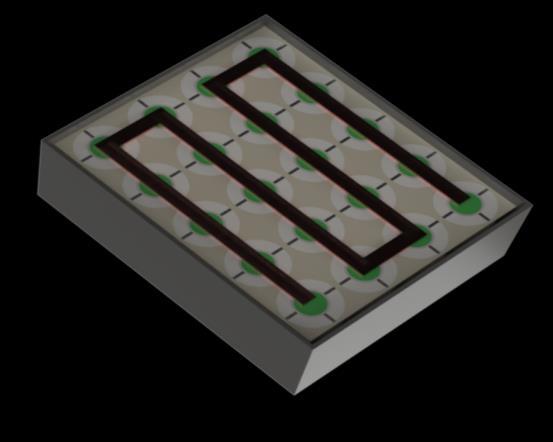

IV. FinSpecifications:

▪ Material-Aluminum(Grade-1100)

▪ Dimensions-8mmx2mmx65mm

▪ 4RectangularFinsaroundeachcell

V. ShellSpecifications:

▪ OuterCover:2mm,ThermoplasticPLA

65/3.4=19.11 =20P

Therequiredconfiguration1S-20P.

Subscripts

BTMS batterythermalmanagementsystem

BMS batterymanagementsystem

ePTFE expandedpolytetrafluoroethylene

PCM phasechangematerial

s solid

l liquid

m melting

▪ InnerCover:2mm,ThermoplasticPLA

VI. BMSContainerwithTerminals:

▪ 20mmThickness,Thermoplastic

VII. Sensors:

▪ Temperaturesensor

As shown in the figure 4.1, the developed battery thermal managementsystemintegratesaphasechangematerialwith silica, aluminum fins, and perforated slots to enhance the operationalefficiencyofthebattery.Thisintricatesystemis designedtoeffectivelyregulatetheworkingconditionsofthe battery pack The primary goal of this innovative thermal management system is to substantially reduce the risk of electricvehiclebatteryfires.Itachievesthisbymaintaining optimal temperature distribution within the battery pack, thereby enhancing the overall lifespan of the battery. The integration of phase change material, aluminum fins, and perforated slots collectively contributes to efficient heat dissipationandtemperaturecontrol

Thermalrunawayisanuncontrolledtemperatureescalation within a system, particularly concerning in batteries like lithium-ion, where heat generated from internal reactions can trigger a self-reinforcing cycle, potentially leading to

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

catastrophic failure, fires, or explosions. Effective thermal management systems are essential to mitigate the risk of thermalrunawaybyregulatinganddissipatingheatwithin the battery. The vulnerability of battery cells to thermal runaway necessitates proactive measures to mitigate its potential risks. Silica gel, served as a major shape-stability material that could prevent the leakage of melted Paraffin

wax.Thermalrunawayisachainreactionwithinabattery cellthat,onceinitiated,canbechallengingtohalt.Totackle thechallengesof electricvehiclebatterypacks,a dual-stage ventingsystemhasbeenimplemented.

Table 1

ThermophysicalpropertiesofLi-ion cell,Paraffin(RT42),Aluminum,Silica(SiO2)andThermoplastic(PLA)

kg/m^32720 820 2719 2648 1252

J/kgK 300 2000 871 680 1955

Thefirststageutilizespassiveventing,employinganePTFE membranetomanagegradualchangesintemperatureand pressure,ensuringcontrolledventingforminorvariations.In contrast, the second stage, active venting, is designed to swiftlyrespondtocriticalsituationslikethermalrunaway.In the event of thermal runaway, the vent enables rapid gas escape,preventingtheescalationofthechainreaction.This dualstageventingsystemoffersacomprehensiveandtailored approach, safeguarding the safety and integrity of electric vehiclebatterypacksinvariousscenarios.

ByemployingMultipurposeDryChemicalFinePowder,the system can respond to extreme fire conditions, swiftly curbingthespreadoffireandsafeguardingboththevehicle anditsoccupants.Intheeventofafire,theMultipurposeDry ChemicalFinePowderactsasaproactivemeasuretomitigate the potential dangers, ensuring the safety of the electric vehicleanditspassengers.Thiscomprehensiveapproachofa robustthermalmanagementsysteminpromotingboththe longevityandsafetyofelectricvehiclebatteries.

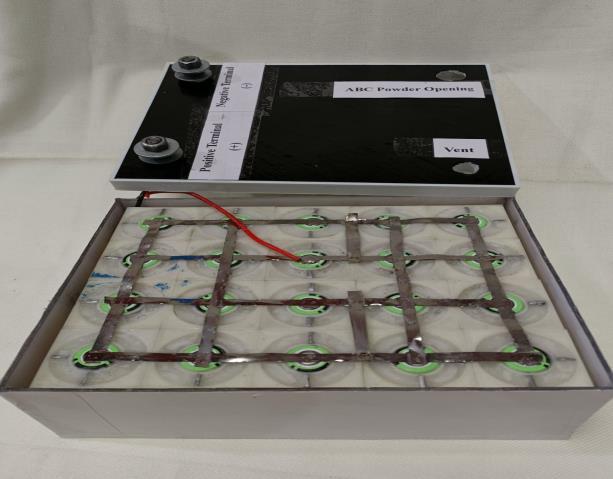

Thebatterypackismanufacturedasshowninfig5.1,using 3Dprintingtechnologyandspotweldingfortheconnection oflithium-ionbatteries.Thedesignincorporateskeyfeatures such as a temperature sensor, Paraffin RT 42, silica gel, aluminumfins,andindividualcells.

Toassessitsperformance,thebatterypackundergoestesting witha loadappliedbya coilat3.2A,complyingwitha 1C discharge rate. Additionally, each motor connected to the pack draws 0.8 A, aligning with a 0.5C discharge rate. The combined load from both the coil and motors results in a dischargerateof1.5C.Thiscomprehensivetestingapproach ensures the battery pack's efficiency and suitability for its intendedapplications.

Theexperimentwasconductedbyensuringfamiliaritywith safety guidelines for lithium cells and wearing protective equipment. The positive terminal of the lithium cell was connectedtotheload,linkingittothemultimeter.Theload was activated, and voltage and current were recorded at intervals during the predetermined test duration. The collected data, including voltage and current profiles, were analyzed. After completing the experiment, the circuit was safely disconnected, the lithium cell was responsibly disposedof,andtheequipmentwasstoredsecurely.

Table 6.1 Comparativeresultsobtainedatvarious dischargerates

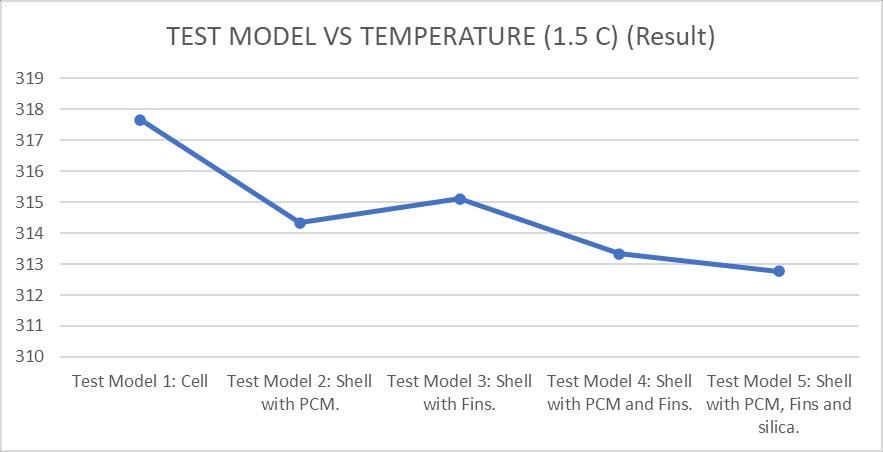

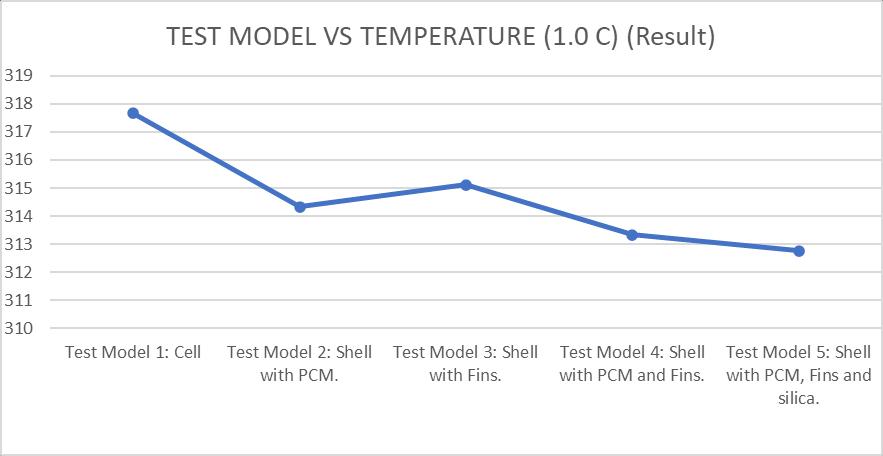

The experimental results provide a comprehensive comparisonof mean observation temperatures(in Kelvin) forvarious test modelsunderdifferent dischargerates(1C and1.5C)comparedtotheroomtemperatureof302.72K.

6.2 Representsthecomparativeanalysisbetween TestModelandTemperaturevariationat1.5C

The presence of PCM, fins, and silica in the shell demonstratesanoticeableimpactontemperaturevariations, suggesting their effectiveness in influencing thermal characteristics. Further analysis, considering factors like thermal conductivity and heat dissipation, it is recommended for a more nuanced understanding of the thermalperformanceofeachmodel.

Individual model performances at 1C and 1.5C discharge ratesvary,highlightingtheinfluenceofdesignfeatures on thermalbehavior.

Fig. 6.1 Representsthecomparativeanalysisbetween TestModelandTemperaturevariationat1C

Inconclusion,thisresearchpaperisdedicatedtoexploring thevitalroleoftemperaturereductioninextendingbattery life,withtheprimaryobjectiveofadvancingbatterythermal managementsystems.Themethodologiesemployedinclude integrating Phase Change Material (PCM) in the module, incorporatingaluminumfins,andintroducingsilicainPCM forleakageprotection.Theexperimentsrevealthataluminum finseffectivelydecreaseoverallthermalresistance,providing additional heat propagation paths. The Battery Thermal ManagementSystem(BTMS)withPCMcoolingdemonstrates enhanced performance, notably reducing the Lithium-ion battery temperature within its safe operating range, especiallyatlowercurrentratesof1Cand1.5C.

Specifically,at1C,thecelltemperatureexperiencesadropof approximately1.03%,decreasingfrom312.43Kto309.6K

when utilizing the designed battery pack, showcasing a significanttemperaturereduction.Similarly,at1.5C,thereisa percentagedropofapproximately3.38%,asthetemperature decreases from 312.77 K to 302.33 K, underlining the effectivenessoftheproposedBTMS.However,thispositive

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

outcomeisaccompaniedbyaconsideration:thecombined integration of PCM and aluminum fins contributes to an increaseintheoverallweightandareaofthebatterypack. TheinclusionofPCMwithSilicaandfins,althougheffective in controlling temperature, raises concerns about the practicalimplicationsforweight-sensitiveapplications,such as electric vehicles and portable electronics. As weight and space are critical factors in these contexts, future research should aim to optimize the balance between thermal managementeffectivenessandtheaddedweightandvolume associated with PCM and fins. Striking a balance in weight reductionwhilemaintainingoptimalthermalperformanceis a crucial aspect for the widespread adoption of these technol

ogies in real-world applications. Despite these considerations,thestudy'soutcomesprovidevaluableinsights intothepotentialimprovementsandchallengesinenhancing battery performance, emphasizing the need for a holistic approachtobatterythermalmanagementsystemdesign.

[1]V.G.Choudhari,A.S.Dhoble,SatyamPanchal-Numerical analysisofdifferentfinstructuresinphasechangematerial module for battery thermal management system and its optimization.December2020,120434

[2]ShahabeddinK.,Mohammadian,YuwenZhang-Thermal management optimization of an air-cooled Li-ion battery moduleusingpin-finheatsinksforhybridelectricvehicles. 2014.09.110