Extendable additional steps for busses and trucks

Dharun T1

1UG Student, Dept. of Production Engineering, PSG College of Technology, Coimbatore. ***

Abstract - The Product Design and Development Laboratory is for the students to gainexperience indesigning and developing a product from feasibility assessment to development. As a part of this laboratory, I have generated ideas and conceptual sketches for these ideas. Using the weighted matrix, I have selected the “Extendable additional steps for busses and trucks”. The design for the product is finalizedusingPughmatrixandCADmodelsarecreatedusing SolidWorks. This report contains the ideas generated, conceptual design, product design and the CAD model for the finalized idea.

Key Words: Design,analysis,pneumatic,Steel,bussesand trucks

1.INTRODUCTION

Public transportation plays a major role in many people’slife.Withhighsteps,busridesarenotsmoothfor elderly. The low-floor busses are not completely implemented in Tamil Nadu. The low-floor busses are available only on the semi-air conditioned or fully airconditionedbussessuchasVolvoandDaimlerbutthetickets areexpensive.

While using high-floor steps in busses, elderly peoplehavetheriskofgettingkneepain.Also,whileusing high-floorstepseveryonehasthechanceofgettingkneepain by carrying heavy weight. And for children this will be a toughtask todo.Thegroundclearancebetweenthesteps andheightofallindividualstepsmakesitharder.

Forthisproblem,extendableadditionalstepscanbe used to reduce the found clearance. These steps can be extractedandretracted.Thisadditionalstepcanreducethe kneepainaspeopledonothavetostrainwhilelandingon thegroundandboardingthebusses

1.1 Problem definition

Withhighsteps,busridesarenotsmoothforelderly.The low-floorbussesarenotcompletelyimplementedinTamil Nadu.Thelow-floorbussesareavailableonlyonthesemi-air conditionedorfullyair-conditionedbussessuchasVolvoand Daimlerbuttheticketsareexpensive.Whileusinghigh-floor stepsinbusses,elderlypeoplehavetheriskofgettingknee pain. Also, while using high-floor steps everyone has the chanceofgettingkneepainbycarryingheavyweight.Andfor thechildrenthiswillbeatoughtask.Thegroundclearance

betweenthestepsandheightofallindividualstepsmakesit harder.

1.2 Aim

Forthisproblem,extendableadditionalstepscanbeused toreducethegroundclearance.Thesestepscanbeextracted andretracted. Theseadditional stepscan reducetheknee pain as people do not have to stain while landing on the groundandboardingthebusses.Thesewillberetractedsoit willnotbeadisturbanceintheside.

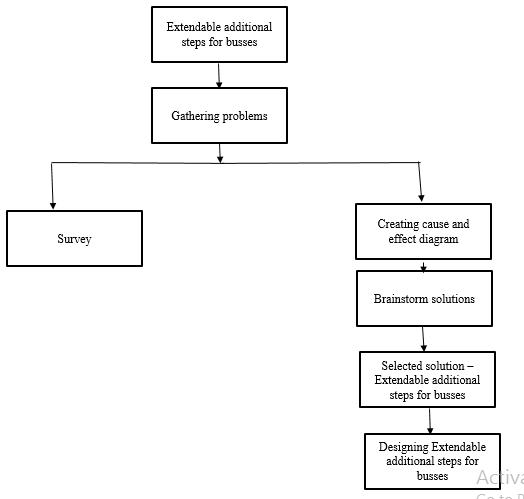

2. METHODOLOGY

Methodology is specific procedures followed to identify,select,analyzetheprocessandcompletetheproject. The following methodology is carried for completing the EXTENDABLE ADDITIONAL STEPS FOR BUSSES AND TRUCKSproject.

Basedontherequirementandconsideringvariousdesign factortheconceptualsketcheswerecreatedandfinalizedone design among the conceptual sketch. The dimensions are adapted based on Indian Anthropometric dimension data. The dimensions such as weight of the person were determinedwiththehelpoftheanthropometric data. Irjet templatesampleparagraph,Irjettemplatesampleparagraph .Irjet template sample paragraph. Irjet template sample paragraph

3.1 Factors considered for Design

3.1.1 Indian Anthropometric Data

Anthropometricdataaredataofhumanbodysizeandshape. Thecoreelementisweight.

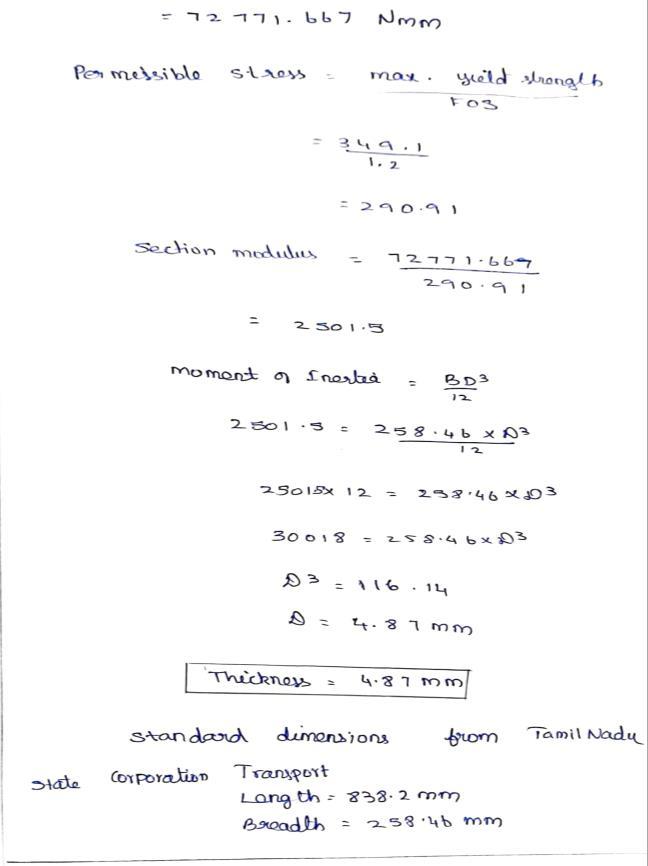

3.1.2 Design Calculation

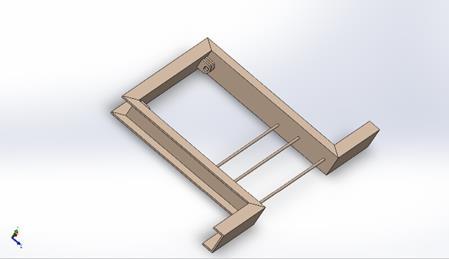

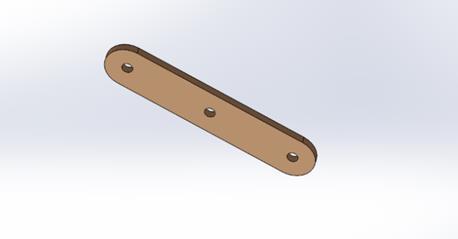

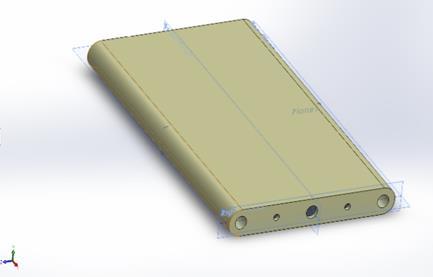

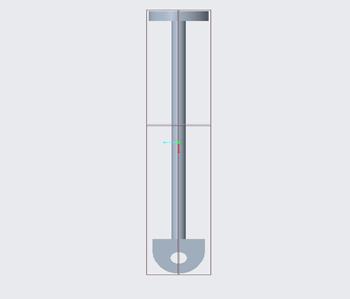

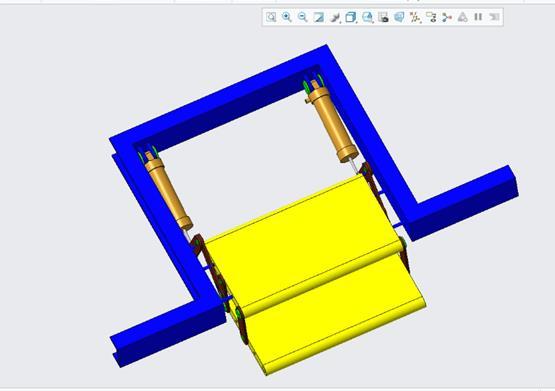

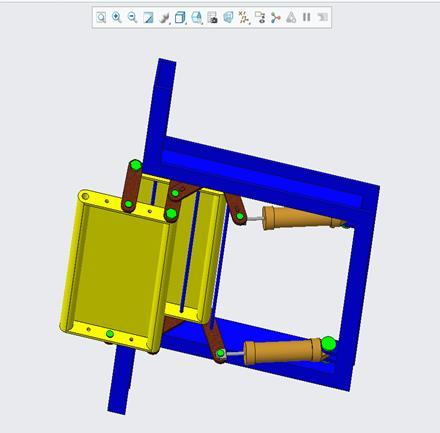

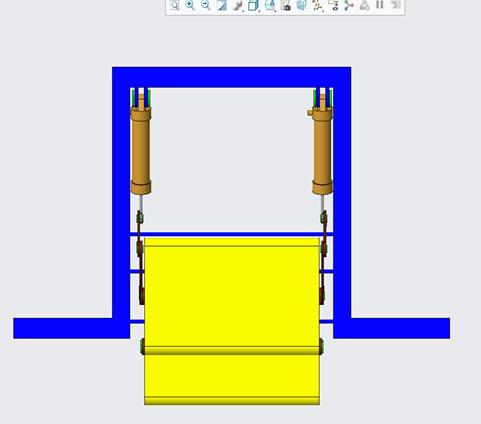

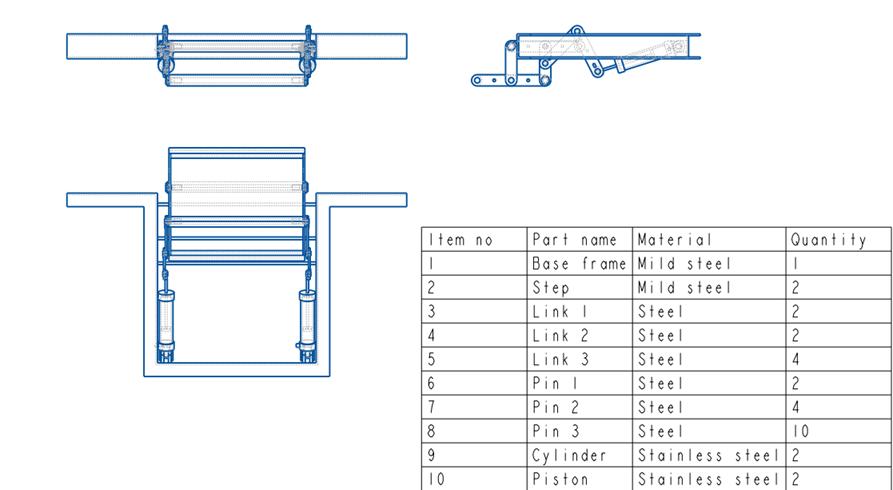

The components of the extendable steps assembly are shownin the above figures from a toj.Listing baseframe, cylinder,link1,link2,link3,step,piston,pin1,pin2,andpin 3.

3.4. Bill of Materials

Table -1: BillofMaterials

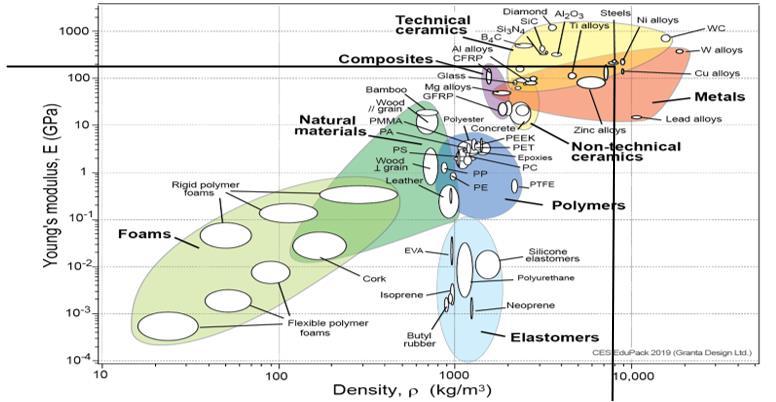

4.1 Material properties

Table

Materialproperties

3.5 Parts

Theproductshownintheassembledmodelconsists of eight major parts: base frame, link, step, piston, and cylinder

Base frame: Thebaseframesupportsallotherpartsanditis connectedtothebus.

Link: Thelinkhelpsinconnectingthestepswiththeframe.

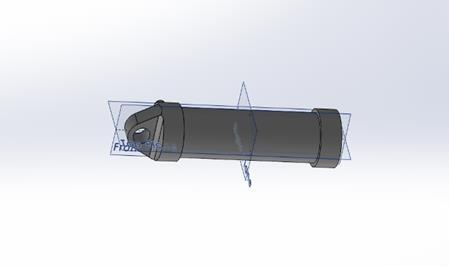

Piston: Pistonisthepartofdoubleactingcylinder.

Cylinder: Thecylinderisthedoubleactingcylinder’sbody. Step: Thestepisarectangularpartanditisthemajorpartof thisassembly

4. STATIC STRUCTURAL ANALYSIS

Astaticstructuralanalysisdeterminesthestresses, strains, displacements, and forces in structures or componentsorproductscausedbyloadsthatdonotinduce significantinertiaanddampingeffects.

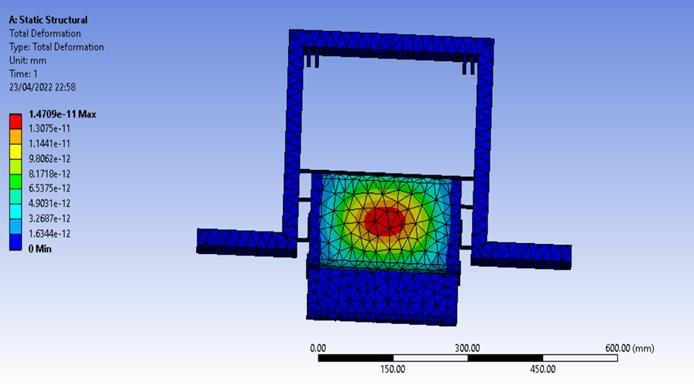

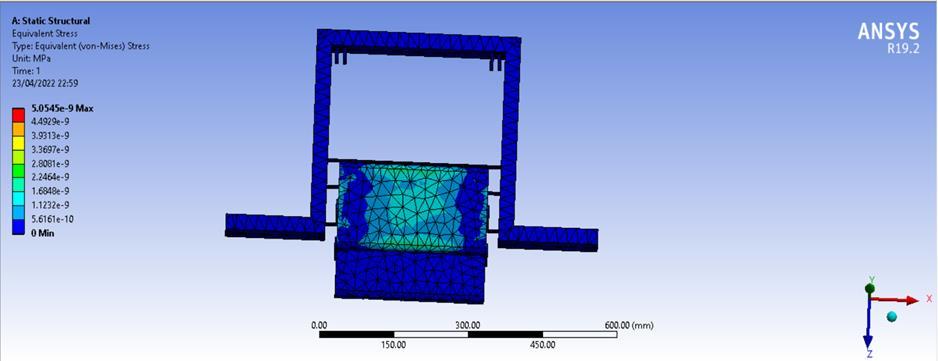

The model is imported as iges file into the Ansys software.Theabovearetheboundaryconditionsappliedto the model in Ansys software. Coarse mesh structure type with a size of 5mm is used for generating mesh for the model.Themodelissolvedandtheresultsareobtained.

4.3

4.3.2

Themaximumtotaldeformation2.0589e-12mmandthe minimumtotaldeformationwas0mm.

Themaximumequivalentstresswas5.0545e-9MPaand theminimumequivalentstresswas0MPa

Themaximumequivalentstresswas7.9284e-11MPaand theminimumequivalentstresswas0MPa

Themaximumequivalentelasticstresswas2.6075e-16 mm/mmandtheminimumequivalentelastic stresswas0 mm/mm

4.3.3 Analysis of second step

Themaximumequivalentelasticstresswas4.1105e-21 mm/mmandtheminimumequivalentelastic stresswas0 mm/mm.

The maximum total deformation 1.4709e-11 mm and the minimumtotaldeformationwas0

6. CONCLUSIONS

During analysis the project is tested on total deformation,equivalentstressandequivalentelasticstress, modellingandanalysisdonebyusingPTCCreo,andAnsys. Andtheresultswerewithinthespecificationlimitsdefined by automotive standards from Automotive industry standardscommittee.

REFERENCES

[1] JohnPucher,“UrbanpublictransportinIndia:Trends, challengesandinnovation,”ResearchGateMarch2004,

[2] RamuInala,“Staticanalysisofanisotropicrectangular plateusingfiniteelementanalysis(FEA)”,ResearchGate, 2012

[3] Imo,“TransportationPatternsandProblemsofPeople withDisabilities,”Nationallibraryofmedicine,2004

[4] Jakun Korta, “Multi-material design optimization of a busbodystructure,”ResearchGateJanuary2013.

[5] M. Jimenez, “Experimental study of double-acting pneumaticcylinders”,ResearchGate,February2020.

[6] Imo, “Impact and corrosion behavior of mild steel”, Engineering Science and Technology,an International Journal,May2020.

[7] RamuInala,“Staticanalysisofanisotropicrectangular plateusingfiniteelementanalysis(FEA)”,ResearchGate, January2012.

[8] John Pucher, Nisha Korattyswaroopam, “The Crisis of Public Transport in India: Overwhelming Needs but Limited Resources”, University of Southern Florida, 2014.

[9] Ramu Inala, “Vehicle body engineering”, Blogspot, September2015.

[10] Automotive industry standards committee, “The automotiveresearchassociationofIndia”,Automotive industrystandard,May2017.

[11] Dr.DebkumarChakarabarthi,“IndianAnthropometric Dimension for Ergonomic Design Practice, National InstituteofDesign” ,FirstPublishedApril1,1999ISBN 81-86199-15-0.

BIOGRAPHY

Motivated project management professionalpassionateinbringing ideas to life. Proficient in project management, lean methodology, supply chain management and data analytics. Enjoys finding creative solutions in improving productivity.